#Web Guiding System for Fabric Inspection Batching Machine

Explore tagged Tumblr posts

Text

🏭 How Udhhyog Ensures Quality in Every Puddle Flange We Manufacture

When it comes to underground drainage, water tanks, STPs, and waterproof RCC structures, the reliability of a puddle flange is non-negotiable. A minor defect or inconsistency can lead to major water seepage, corrosion, and structural failure over time. That’s why at Udhhyog, we don’t just manufacture puddle flanges—we engineer them for 100% performance, precision, and durability.

In this article, we break down how Udhhyog ensures quality control across every stage of the puddle flange manufacturing process, making us one of India’s most trusted flange suppliers.

🔩 1. Material Selection: IS & ASTM-Compliant Raw Inputs

The foundation of a reliable puddle flange lies in the material itself. At Udhhyog, we source only certified mild steel (MS), galvanized iron (GI), and stainless steel (SS304, SS316) from verified vendors. Every batch is accompanied by mill test certificates to confirm composition, mechanical strength, and corrosion resistance.

✅ Standards Followed:

We match material type based on your project environment—whether that’s sewage, stormwater, marine, or chemical handling.

🧪 2. Precision Manufacturing with CNC Accuracy

Our production floor is equipped with CNC plasma cutting machines, MIG welding setups, and hydraulic presses, ensuring each puddle flange is cut and fabricated to the exact millimeter.

Every flange’s outer diameter (OD), inner diameter (ID), thickness, and web width are double-checked during production using calibrated tools.

💡 Udhhyog manufactures puddle flanges ranging from 50 mm to 1000 mm+, with thickness from 4 mm to 20 mm.

🔬 3. Multi-Stage Quality Inspection

We implement a 4-stage quality inspection system, which includes:

Raw Material Verification

In-Process Dimensional Checks

Weld Integrity Testing

Final Visual and Functional Inspection

Each unit is marked with a batch code, enabling full traceability.

🌧️ 4. Anti-Corrosion Coating & Surface Finish

Depending on the material and application, Udhhyog applies:

✅ Hot-dip galvanization (as per IS 4759) for MS puddle flanges

✅ Mirror or matte finish for SS304/SS316 flanges

✅ Custom epoxy coating for chemical resistance (on request)

These finishes protect the flange from moisture, soil chemicals, and oxidation, ensuring decades of service life.

🛠️ 5. Custom Engineering for Project-Specific Demands

Every civil project is different. That’s why Udhhyog offers fully customizable puddle flange designs, manufactured to meet:

Pipe type & OD

Concrete wall thickness

Fluid pressure rating

Environmental exposure (marine, chemical, soil, etc.)

Our in-house engineers create technical drawings for approval before mass production. You receive exactly what your site demands—no compromises.

📦 6. Packaging, Marking & Documentation

Each puddle flange is:

Carefully packed with rust protection and impact padding

Tagged with size, material, and batch number

Supplied with mill test reports, coating certificates, and installation guides

For government and industrial projects, we also provide compliance declarations and delivery inspection formats.

💬 Frequently Asked Questions (FAQs)

Q1: How does Udhhyog ensure uniform quality in large orders? A: We use CNC fabrication and quality batches with traceability, ensuring every flange—whether 5 or 500—meets the same exacting standards.

Q2: Are your flanges suitable for coastal or marine areas? A: Yes. Our SS316 puddle flanges are designed for high-salinity, high-corrosion environments like ports, desalination plants, and coastal foundations.

Q3: Can I request third-party inspection? A: Yes. We support third-party inspections from organizations like SGS, TUV, or your own QA teams before dispatch.

Q4: Do you offer installation support? A: Absolutely. We provide detailed technical sheets and guidance, and our team is available for virtual site consultations.

0 notes

Link

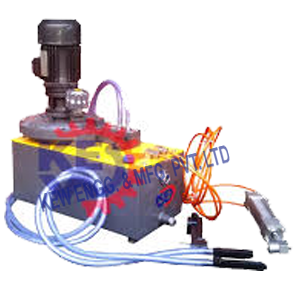

We are leading Manufacturer of Web Guiding System for Plastic Processing Machine. Web Guiding System for Plastic Processing Machine are used to automatically guide all type of plastic material, flexible or lamination material of any width, under any load, at any seed. Web Guiding Systems available with Edge Guiding, aligner, Tracking Roller Assembly etc. For more information:

Website: krishnaengineeringworks.com

Contact us: [email protected]

Sales Team No. +91-7940085305

#Web Guiding System for Plastic Processing Machine#Web Guiding System Manufacturer#Fabric Inspection Batching Machine#Automatic Web Guiding System#Edge Guiding System#Web Guiding System for Fabric Inspection Batching Machine#Web Aligner#Hydro Technology Web Guiding System#Hydraulic Power Pack#Automatic Guiding System#Hydro Pneumatic Web Aligner#Mild Steel Web Aligner System

1 note

·

View note

Link

High Performance Web Guiding System for Fabric Inspection Batching Machine Manufacturer, Find Here best quality Line Guiding System, Web Aligner, Web Guiding Unit. Web Guiding System for Fabric Inspection Coding Machine are used to automatically guide all type of flexible material of any width, under any load, at any seed. Web Guiding Systems which serves various application for all type of flexible printing, packaging & converting machineries. Web Guiding Systems available with Edge Guiding, aligner, Tracking Roller Assembly etc.

#Web Guiding System for Fabric Inspection Batching Machine#Web Guiding System#Web Guiding System Manufacturer#Web Guiding Systems#Web Guiding#Fabric Inspection Batching Machine#Fabric Inspection Batching Machines#Fabric Inspection#Fabric Inspection Coding#Web Aligner#Web Aligner System#Web Aligner Unit#Web Aligners#Web Guiding Unit

0 notes

Link

Slitting Rewinding Machine for Batch Printing Coding, Slitting Machines, Slitter Rewinder Machine for Industry specific Batch Printing, Batch Printing, Slitter Rewinder Machine, Doctoring Rewinding Machine, Batch Coding Machine, Packaging Machine, Printing Machine, Fabric Folding Machine, Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. It is great substitute to online coding / batching operation

http://www.windingrewindingmachine.com/slitting-rewinding-machine-for-batch-printing-coding.php

#batch coding machine#batch printing machine#slitter machine manufacturer#winder Rewinder machine#Winding Rewinding Machine Manufacturer#slitter Rewinder#slitting rewinding machine#motor winding machine price#date printing machine#manual batch coding machine#Bopp tape slitting machine#batch printing machine price#rewinding machine price#paper winding machine#digital batch coding machine

1 note

·

View note

Link

We are manufacturer of Web Guiding System Manufacturer for Fabric Inspection Batching Machine. Web Guiding System for Fabric Inspection Batching Machine, Web Guiding Systems are used to automatically guide all type of all type of flexible material of any width, under any load, at any seed. Web Guiding Systems which serves various application for all type of flexible printing, packaging & converting machineries. More information visit website: krishnaengineeringworks.com.

#Fabric Inspection Batching Machine#Fabric Batching Machine#Manual Fabric Inspection Machine#Fabric Inspection Machine Manual#Batching Machine in Textile#Web Guiding System#Types of Fabric Inspection Machine#Automatic Fabric Inspection Machine#Web Guiding System Manufacturer

6 notes

·

View notes