#absolute linear encoder

Explore tagged Tumblr posts

Text

Absolute Rotary Encoder | Magnetic Rotary Position Sensors

Explore high-quality rotary absolute encoders at Shenzhen Briter Technology. Enhance accuracy and performance in your applications with our precision rotary sensors. Shop now!

0 notes

Text

The Noumenal Monad

Within the Polynon framework, nothingness is an undifferentiated cognitive space that precedes geometry and structure. It exists as a pre-geometric source, housing the unformed essence of all phenomena from which spacetime, and all its manifestations, arise. Imbued with primal noumenal potential, it is denoted as the state where all possible realities are latent, waiting to be expressed into an observable world.

A circle whose center is everywhere and circumference is nowhere.

The monad is a geometric construct that acts as a universal grammar of existence, mapping how the boundless noumenal potential transitions into perceptual and phenomenal dimensions while retaining coherence across all levels of manifestation.

The centre being “everywhere” signifies the Monad’s omnipresence as the locus of all potential states, embedded in every point of reality. The circumference being “nowhere” reflects its boundless architecture, transcending the constraints of space, time, and materiality, integrating infinite possibilities within a singular, cohesive structure.

The compactification process begins with the noumenal everything compressing into a singular phenomenal something, reflecting a specific instance or manifestation. This phenomenal something is inherently equal to the noumenal everything because it retains the entirety of noumenal potential, either in its un-collapsed state of infinity or as a collapsed singular “ring” dimension, compacted into a single cognitive focal point.

The only attribute of a point is that it marks position. Take away this attribute and in the unposited point we have a symbol of pure Being, the abstract noumenon, that which underlies every mode of phenomenal manifestation, every form of existence. It is at once All and Nothing, at once Absolute Consciousness and Unconsciousness.

B.W. Betts, Geometric Psychology or the Science of Representation

Or, as Fichte envisioned it, the line symbolizes the progression of consciousness—linear and sequential—while the circle represents its completeness and self-enclosure, encompassing all its dimensions. Thus, both the noumenal everything and the phenomenal something are expressions of the same essence, differing only in their state of manifestation and representation.

Together, they define the Noumenal Monad as a meta-structure that bridges these states of being. It embodies the continuum between the actual and the potential, compacting the infinite diversity of noumenal states into a singular conceptual dimension. This process is geometrically encoded, offering a scaffold for understanding how existence unfolds from an infinite noumenal source into the finite, perceptual realm, while remaining irreducible to either.

Continue reading

#geometrymatters#geometry#philosophy#philosophy of science#plato#kant#spinoza#fichte#consciousness#monism

39 notes

·

View notes

Text

Ni Translocality

Ni is a function that expands the registration of an object to include its temporal totality (Pi), which is the larger episode or theme to which it belongs. It then associates this episode to all historical instances of episodes that are isomorphic to it (N), transforming the definition of the object into a thematic story that is disconnected from any particular place or time. The object is then understood as something transcending the present, as something translocal, and not following a linear, chronological path from the past while still being temporal.

Metaphors & Visual Aphorisms

The Ni function compels the individual to live a slowly paced, hands-off life of observation and reflection on the information structures of the world. First, they are data synthesizers that formulate image-encoded schemas from unconsciously woven patterns in reality. The Ni user will be very graphic in their consciousness, thinking in visuals and representing the world through visual metaphors. These dynamic but geometric relationships are registered as essential to reality's functioning and are eventually superimposed onto other life domains in a proverbial form. "A tree's branches can only grow as far up as its roots go down," "flowing water never goes stale," or "every light casts a shadow" are examples of the graphical aphorisms that may develop from this information synthesizing process. For the Ni user, the world is not comprehended through words or axioms; it is through these visual relationships that words help convey to others. Due to the abundance of symmetry observed in life, these relations are often symmetrical --as embodied in concepts like the Taoist yin-yang symbol. An elaborate worldview is inescapably developed predicated on these abstracted relationships, aimed to give life predictability and continuity of narrative. The Ni user never sees the world straightforwardly, as reality is formed from representative structures --not rational absolutes. To the Ni user, knowledge is the net awareness gained by superimposing layers of these representations on reality and mapping its landscape as far and wide as possible.

The Mind & Panpsychism

Moreover, because they view reality as representation, the Ni user will constantly experience life as a perceptual sphere built from the interactions of mind and material. The world appears as a tapestry woven together by higher forces that underpin every object and substance – causing the objects to feel like the outer shells or totems of fundamental forces. Moreover, a sense will often exist – as explored in phenomenology – that consciousness is the essential thing. In some form or another, the Ni user will come to embody the philosophy that the psyche has a degree of priority over the material. One way to imagine this is to say the world constellates itself to the Ni user as being built equally of "psyche" and of matter. Still, every Ni user will synthesize this felt sense in slightly different ways, with some believing that consciousness is the prime constituent of reality and others feeling we are co-creators of reality by our active participation in how it appears to us and how we ascribe meaning to the contents within it, which can lead magnetically to a type of panpsychism, where the Ni user views the contents of the mind seriously as entities, forces, energies and contours as perceivable as literal objects are to other people. These psychological images and forces will not only be present but will also be persistent. To them, the psyche has a steady yet fluid shape, an image, and a terrain to be explored through vision and internal perception. Moreover, while other types may arrive at similar philosophies through rationality, for the Ni user, this sensation is not something deduced but simply uncovered, as it represents the default state of their experience. This proclivity naturally leads to an interest in meditation, eastern thought, and spirituality, which emphasizes these same psychic aspects and presents a philosophy of consciousness more natively aligned to their phenomenological experience.

Narrowness & Convergence

However, for all their openness towards surreal ideas about consciousness, the Ni user is not random or unstructured in their views. They are scarcely persuaded of most things and are instead highly cautious of ideas. The Ni user will have a keen eye for identifying the improbability of things and will not be prone to jump on board with things unless their inner imagery already maps out an inescapable trajectory in that direction. The Ni user is not an inciter or generator of novel things, nor is their specialty a spontaneous creativity. Instead, it is the holistic assimilation of trends over time and a convergence of perspectives along the most reinforced trendlines. They generally see only one or a few trajectories stemming from a given situation and are magnetically drawn to the likeliest interpretations. Thus, the ideas the Ni user arrives at are not things they create but things they discover to be already "the case," often sourcing from an inside-out evaluation of being but just as well from a panoramic evaluation of society. In this way, the Ni user is a sort of investigator or excavator of the primordial imagery in themselves and society. More than any other type, the Ni user receives a linear and direct feed of the imagery of the unconscious, and because of this convergence of focus, many Ni users across time continue to re-discover and re-articulate the same things as they unearth the same territory. As Ni users from all ages inquire into questions of being, their convergent intuition guides them to parallel answers and to convey those understandings in imagery --since image is the primary means by which that information is discovered and encoded. A canonical historical archive, therefore, has developed over time in the form of symbology, the encrypted patterns and representative structures that underpin reality, as collectively uncovered over time.

Symbology

In this sense, the Ni user may often find camaraderie in the symbology laid down by previous pioneers for its capacity to articulate that felt inner content. Strange as it may seem to others to believe or seriously consider such archaic and outdated emblems, the Ni user is drawn to these old images like the Si user is drawn to information encoded in the old earth. The Ni user may not wish to be a mystic and, when not fully individuated, may shrink away from this imagery for fear of academic reprimand. Still, they may feel that their awareness style drafts them inescapably into these ideas. They emerge out of themselves when any intense investigation is done or even when no investigation is done. The realm of alchemical symbolism, the Tarot, ayurvedic medicine, and Astrology may be studied intently for their capacity to superimpose a representation of life. Shapes also contain a powerful influence over them, and they may be drawn to sacred geometry and mandalas. Numerology may also be investigated. Over time, by studying these emblems to discover their true meanings, they are slowly transformed into the likeness of those who built them. As they unearth the contents of this domain, they often become affiliated with the taxonomies used by their predecessors to try to express this underworld. However, their dabbling in these ideas may earn them a reputation as a mystic and confuse family and friends who may not understand the significance of such concepts.

Archetypes & Stereotypes

These observations form a vast archive of typicalities as the Ni user matures into their worldview. Each pattern of life is epitomized in the psyche as a general rule or process, which leads quite inescapably to the formation of stereotypes at the local level and archetypes at the universal level --both of which are used to map reality by providing a sense of predictability. In the positive sense, this stereotyping tendency makes life an iconic series of interactions between previously indexed forces and entities. The Ni user will overlay their schema onto the world and see iterations of the same substances everywhere. From this vantage point, certain social or political interactions will appear to them as clockwork, a series of eventualities stemming from two or more colliding forces. The interactions in a neighborhood may be seen through the same light, as categories are applied to each class of person, and their collisions cause transformations through a sort of necessary chemistry. However, as often captured by the negative sense of the word stereotype, this can lead to errors in perception where a pattern or schema is superimposed over a situation too prematurely. A person is anticipated to be a given way due to the symbol they represent while turning out to be quite different. Moreover, at the archetypal level, the same simplification may occur where the Ni user reduces the global situation as something emergent from a conflict between the light and dark, the masculine and feminine, an interaction of four or five elements or some other schema which neglects certain subtleties and details, which may be infuriating to those who live with the Ni user as they may feel the Ni user is oversimplifying them, or worse that they are pigeonholing people into their categories --whether of culture, class, race or gender. Many may scoff at the Ni user for depending on what they feel are outdated prejudices and not seeing things at the individual level. However, the Ni user cannot ignore what larger pattern someone or something generally belongs to and will tend to incidentally synthesize life from that lens without any actual investment or commitment to any dogma or belief system.

Synchronicity & Parapsychology

Another effect often emerging from the Ni function is a belief in synchronicity. Because of how Ni registers life through a delicate tracking of "significance" --not by the rigidity of causal chains-- the Ni user will instinctively see the value in data associations that converge in theme and motif, even when the cause is unknown. As is often the case for both intuitive processes, the pattern is recognized first without needing to have the sensory points explicitly traced, and neither does the absence of a sequential explanation make the information alignments vanish. Moreover, when Ni is especially strong, seemingly disconnected layers of existence are woven together through an entangled point, compelling many Ni users to contend with the possible existence of the acausal. Certain events or datasets may be felt as crossing different planes of reality and inexorably related even when a surface examination would see no trace between them. They may be struck by compelling evidence for the existence of extra-sensory perception or remote viewing, which allows us to see through the eyes of others or predict their thoughts. For some, relationships may be intuited to exist between oneself and previous lives. Areas of the body may be associated with certain psychic energies through emotional tapping, chakras, iridology, or palmistry. Certain recurring numbers may be felt as omens of blessings or catastrophes. If these intimations persist, they can become highly suspicious and feel that certain events will shortly happen when a given number, detail, or sign suggests a strong karmic force is at play.

-Behaviors Under Stress

Conspiracy Theories

When the Ni user falls out of mental health, their suspicions degrade further into superstitions, death omens, and a persistent state of anxiety. Life becomes chaotic and unpredictable. The world will feel utterly uncertain to them, and they will be unable to see the cause of their suffering or that of society. As they struggle to intuit their situation through perceptual projection, the misfortunes they experience are not interpreted as localized occurrences but are instead epitomized as emerging from some extra-personal force looming over all things. They will start to perceive a woven network of intentions behind everything, pulling the strings of society at large. Here, we see the Ni user fabricate conspiracy theories: extraterrestrial hypotheses, occult government sects, the imminent rise of a new world order, and the like. A sense exists that something unseen is making all this happen, and for once, the Ni user loses their non-committal nature and becomes utterly fixated on certain interpretations of life, which will cause them great difficulty in their daily lives as the Ni user may be quickly ostracized from society for their bizarre premonitions. More than a few distressed Ni users throughout history have been branded as local lunatics, eventually growing morose and resentful for what they feel is the lack of foresight and idiocy of the common person.

Apocalyptic Visions

A different effect we often see in a distressed Ni user is a series of apocalyptic visions. They may experience nightmares, either when asleep or awake, vividly depicting scenes of war, destroyed buildings, massacres, and the end of civilization. Moreover, the Ni user may experience these sudden flashes with the same level of physicality with which they experience their waking life --making it difficult to discredit them as illusions. Here, we see an unconscious projection and intrusion of their polar sensory function into their mind, causing literal sensations to trigger their nervous system without an actual cause. The relationship between intuition and sensation is a two-way street, where one can seep into the other unbidden when excessive repression is at its breaking point --allowing their intuitions to unconsciously fabricate sensory experiences that are patterned after their thematic convergence. These unsettling images may cause them to feel that their visions are pending actualities. A memento mori will settle over them. Society is on the brink of collapse; everything is headed in the worst direction, and anything short of immediate correction will lead to an irreparable catastrophe.

#Cognitive Typology#Cognitive Functions#Introverted Intuition#Ni#INFJ#INTJ#Behaviorism#Translocality#Metaphors#Visual Aphorisms#Mind#Panpsychism#Narrowness#Convergence#Symbology#Archetypes#Stereotypes#Synchronicity#Parapsychology#Conspiracy Theories#Apocalyptic Visions#Cosmos

60 notes

·

View notes

Text

The Science Behind Hollow Shaft Rotary Encoders: Torque, Speed, and Accuracy

In the landscape of modern automation, sensors and feedback mechanisms are crucial for maintaining the precision and efficiency of machinery. One of the most indispensable devices in this category is the rotary encoder, especially the hollow shaft rotary encoder. These devices provide real-time data on angular position, velocity, and direction, enabling refined control over dynamic systems. Their unique hollow shaft design offers numerous advantages, particularly when integrating with rotating shafts and assemblies in compact or sensitive environments. This article delves into the scientific underpinnings of these encoders, examining how they measure torque, speed, and accuracy in industrial and robotic applications.

Basics of Rotary Encoders

Rotary encoders translate rotational motion into digital signals. They are broadly categorized into absolute and incremental types. Absolute encoders deliver a unique position value, whereas incremental encoders provide relative motion data. Hollow shaft rotary encoders, a sub-type of these devices, allow the shaft of the motor or machinery to pass through the encoder. This design minimizes axial load, reduces mechanical complexity, and facilitates easier installation. The hollow shaft construction is particularly beneficial in applications where space is limited or where quick replacement and alignment are essential. These encoders are primarily used in robotics, CNC machinery, elevators, and energy sector equipment.

Working Principle of Hollow Shaft Rotary Encoders

Hollow shaft rotary encoders typically use optical, magnetic, or capacitive sensing methods. Optical encoders employ a light source and photodetector array to read patterns on a rotating disk. Magnetic encoders detect changes in magnetic fields using Hall-effect sensors or magnetoresistive elements. Capacitive encoders utilize variations in capacitance caused by changes in geometry as the shaft rotates. Each method has its advantages in terms of resolution, durability, and environmental robustness. The hollow shaft design does not alter the fundamental sensing mechanism but allows the encoder to be mounted directly over a rotating shaft without additional couplings. This direct interface helps reduce backlash and enhances accuracy.

Measuring Torque with Hollow Shaft Rotary Encoders

Torque is the rotational analog of linear force. Although rotary encoders are not traditionally used as torque sensors, they play a significant role in torque estimation. By precisely measuring angular displacement and speed, and knowing the system's moment of inertia, torque can be inferred. In applications where torque sensors are either too bulky or expensive, high-resolution encoders serve as a cost-effective alternative. The key lies in correlating the angular velocity and acceleration data provided by the encoder with the mechanical characteristics of the system. For dynamic torque measurement, especially in systems with varying load conditions, encoders offer real-time feedback that can be analyzed via control algorithms to maintain performance consistency.

Speed Detection in Dynamic Systems

Speed detection is a primary function of rotary encoders. Incremental hollow shaft rotary encoders are particularly adept at delivering high-fidelity speed data. They generate pulses for every increment of rotation, which are counted over time to calculate speed. Higher pulse counts per revolution (PPR) mean greater resolution and more accurate speed readings. In applications like conveyor systems, turbines, or robotic joints, this level of speed precision ensures smoother operation and reduces wear and tear. Encoders are also favored for their minimal latency, allowing near-instantaneous speed adjustments. Furthermore, their digital output can be seamlessly integrated into programmable logic controllers (PLCs) or microcontrollers for real-time processing and control.

Ensuring Accuracy and Resolution

Accuracy in rotary encoders refers to the degree to which the measured position matches the actual position. Resolution, on the other hand, is the smallest change in position that the encoder can detect. High-resolution encoders are essential for systems requiring fine control, such as semiconductor manufacturing or surgical robotics. Hollow shaft rotary encoders often offer both high resolution and excellent accuracy due to their ability to directly interface with the rotating element. This reduces mechanical errors associated with couplings or misalignment. Optical encoders typically offer the highest resolution, while magnetic and capacitive types provide better resilience in harsh environments. Calibration and alignment during installation also play critical roles in maintaining accuracy.

The Importance of Zero Backlash

Backlash is the slight movement that occurs when direction is reversed in a mechanical system. This can cause significant errors in position sensing. Hollow shaft encoders help minimize backlash by allowing direct mounting onto the shaft, thereby eliminating intermediate couplings or gears that can introduce slack. Zero backlash is particularly critical in high-precision applications like robotics and CNC machining, where even minor errors can lead to defective outcomes. By integrating the encoder directly onto the shaft, manufacturers can achieve tighter control loops, reduced error margins, and more reliable performance. This direct integration also facilitates better synchronization between motor movement and feedback, enhancing overall system stability.

Environmental and Structural Considerations

Industrial environments often expose equipment to dust, moisture, temperature fluctuations, and vibrations. Hollow shaft rotary encoders are designed to withstand these conditions through robust housing, sealed bearings, and non-contact sensing technologies. Magnetic and capacitive encoders are particularly well-suited for such environments due to their resistance to contaminants and mechanical wear. Structural considerations also include the material of the encoder’s housing and shaft, which must align with the application’s requirements for durability and weight. The hollow shaft itself can be designed to accommodate different shaft diameters, increasing its adaptability across multiple systems. Proper installation and maintenance further ensure the encoder's longevity and consistent performance.

Integration into Closed-Loop Systems

Hollow shaft rotary encoders play a pivotal role in closed-loop control systems, where feedback is used to adjust and correct motion in real time. These systems require high-resolution and low-latency feedback to maintain accuracy and efficiency. The encoder sends position and speed data to a controller, which then adjusts the motor’s operation accordingly. This continuous feedback loop allows for precise control even in variable load conditions. Integration into such systems requires compatibility with control hardware, appropriate signal output formats, and real-time data processing capabilities. Encoders that support multiple output protocols, such as quadrature, SSI, or BiSS, offer greater flexibility in system design.

Case Study: Hollow Shaft Encoders in Robotic Arms

Robotic arms require exceptional precision and agility, often functioning in environments that demand both speed and safety. Hollow shaft rotary encoders enable these capabilities by offering accurate position and velocity feedback without adding bulk to the joints. Their compact design fits seamlessly into tight spaces, while their direct shaft interface ensures minimal mechanical error. For example, in medical robotics, where minute movements can have significant consequences, the encoder's resolution and accuracy become critical. Additionally, their ability to function reliably in varying environmental conditions makes them suitable for both cleanrooms and industrial settings. This case study illustrates how the theoretical benefits of hollow shaft encoders translate into practical performance gains.

Comparing Hollow Shaft and Solid Shaft Encoders

Solid shaft encoders require couplings or adapters for installation, which can introduce alignment issues and mechanical play. Hollow shaft encoders bypass these challenges by mounting directly onto the shaft, thereby reducing complexity and improving measurement fidelity. While solid shaft designs may offer slightly more mechanical robustness, they often necessitate more space and careful alignment. Hollow shaft encoders, by contrast, are easier to install and replace, which is beneficial in systems where downtime must be minimized. The choice between the two often comes down to the specific application requirements, including available space, desired precision, and environmental factors. Ultimately, hollow shaft models offer a compelling mix of convenience and performance.

Market Trends and Future Outlook

The market for rotary encoders is evolving rapidly, driven by advancements in automation, robotics, and smart manufacturing. Hollow shaft rotary encoders are gaining traction due to their compact design and enhanced integration capabilities. Innovations such as wireless data transmission, miniaturization, and improved environmental resistance are expanding their application scope. Additionally, the incorporation of edge computing and AI into encoder systems is enabling predictive maintenance and smarter feedback mechanisms. As industries continue to push for higher efficiency and precision, the demand for reliable and versatile encoders will only increase. In this context, the hollow shaft encoder emerges as a key component in future-ready systems.

Conclusion

The science behind hollow shaft rotary encoders encompasses a multidisciplinary understanding of mechanics, electronics, and systems engineering. Their ability to provide accurate, real-time data on torque, speed, and position makes them invaluable in a wide array of industrial and robotic applications. Their unique hollow design simplifies installation and enhances performance by reducing mechanical errors. From aiding in torque estimation to ensuring zero backlash and high-resolution feedback, these encoders are tailored for precision-driven environments. As technological advancements continue to refine their capabilities, the hollow shaft rotary encoder is poised to remain a cornerstone of intelligent motion control systems across industries.

0 notes

Text

The SICK BTF13-A1AM2020 Wire Draw Absolute Encoder is a reliable and accurate solution for measuring linear positions in industrial automation. Designed for long-lasting performance, it features a wire draw mechanism and absolute encoder technology that ensures precise position feedback, even after power loss. With easy installation and robust construction, it is ideal for use in cranes, lifting systems, and factory automation. The BTF13-A1AM2020 supports a wide measuring range and delivers consistent results in tough environments. Choose this encoder from Auto2mation for dependable position sensing in demanding applications. Perfect for enhancing productivity and machine safety.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Sick#Absolute Encoder#Encoder

0 notes

Text

How to Build Your First Machine Learning Model: A Step-by-Step Guide

Machine Learning (ML) is transforming industries worldwide, from healthcare to finance. If you’re a beginner, building your first ML model can seem overwhelming. However, with the right approach and guidance, you can create a working model in no time. In this step-by-step guide, we’ll walk you through the entire process of building a simple ML model while emphasizing the importance of Machine Learning Classes in Kolkata for mastering these skills.

Step 1: Define the Problem

Before jumping into coding, it's crucial to define the problem you’re solving. Ask yourself:

What is the goal of the model? (e.g., predicting house prices, classifying emails as spam or not spam)

What type of data is needed?

How will success be measured?

For this guide, we’ll build a model to predict house prices based on features like size, number of rooms, and location.

Step 2: Gather and Prepare Data

Collect Data

If you don’t have your dataset, you can use publicly available datasets from sources like:

Kaggle (www.kaggle.com)

UCI Machine Learning Repository (archive.ics.uci.edu/ml)

For our example, we’ll use a sample Housing Prices Dataset.

Preprocess Data

Raw data is often messy. Steps involved in preprocessing include:

Handling missing values: Fill missing values using mean, median, or mode.

Removing duplicates: Ensure the dataset is clean.

Encoding categorical variables: Convert non-numeric data (e.g., city names) into numeric values.

Feature scaling: Normalize or standardize numerical data to bring them to a similar scale.

Step 3: Choose an Algorithm

Choosing the right ML algorithm depends on the problem:

Regression (for predicting continuous values) → Linear Regression, Decision Tree Regression

Classification (for categorizing data) → Logistic Regression, Random Forest

Clustering (for grouping similar data) → K-Means, Hierarchical Clustering

For our house price prediction, we’ll use Linear Regression.

Step 4: Split the Data

Splitting the dataset into training and testing sets ensures that our model generalizes well.from sklearn.model_selection import train_test_split X_train, X_test, y_train, y_test = train_test_split(X, y, test_size=0.2, random_state=42)

Training Set (80%): Used to train the model.

Testing Set (20%): Used to evaluate performance.

Step 5: Train the Model

Now, we train the Linear Regression model using scikit-learn:from sklearn.linear_model import LinearRegression model = LinearRegression() model.fit(X_train, y_train)

The .fit() function trains the model on our dataset.

The model learns relationships between input features and output.

Step 6: Make Predictions

Once trained, we can use the model to make predictions.y_pred = model.predict(X_test)

This generates predicted house prices for the test dataset.

Step 7: Evaluate the Model

To check accuracy, we use metrics such as:from sklearn.metrics import mean_absolute_error, mean_squared_error print("Mean Absolute Error:", mean_absolute_error(y_test, y_pred)) print("Mean Squared Error:", mean_squared_error(y_test, y_pred))

Lower error values indicate better performance.

If the error is too high, you may need to fine-tune the model.

Step 8: Improve the Model

If your model isn't performing well, try these techniques:

Feature engineering: Add new relevant features.

Hyperparameter tuning: Adjust algorithm parameters.

Use advanced models: Try Random Forest or Gradient Boosting.

Increase training data: More data often improves performance.

Step 9: Deploy the Model

Once satisfied with performance, deploy the model using:

Flask/Django for web applications.

Streamlit for interactive ML dashboards.

Cloud services like AWS, Google Cloud, or Azure.

Why Enroll in Machine Learning Classes in Kolkata?

Building an ML model requires hands-on experience and mentorship. Enrolling in Machine Learning Classes in Kolkata offers:

Expert guidance to help you navigate challenges.

Practical projects to apply theoretical knowledge.

Industry exposure through real-world case studies.

Certification to boost your career prospects.

Conclusion

Building your first Machine Learning model is an exciting journey! By following these steps, you can create a functional ML model and improve it over time. If you’re serious about mastering ML, consider enrolling in Machine Learning Classes in Kolkata, where you can gain in-depth knowledge and hands-on experience from industry experts.

0 notes

Text

0 notes

Text

Precision and Performance with Aeliya Marine’s Encoders: The Key to Accurate Motion Control

In the world of automation, robotics, and motion control, encoders play a pivotal role in ensuring accuracy and reliability. Whether you’re designing a marine navigation system, robotics project, or industrial automation system, having the right encoder can make all the difference. Aeliya Marine offers a comprehensive collection of high-quality encoders that cater to various applications, ensuring that your systems function with the utmost precision.

Why Choose Aeliya Marine for Encoders?

1. Superior Accuracy and Performance Encoders are integral components in any motion control system, converting mechanical motion into electrical signals for feedback and control. Aeliya Marine’s encoders are designed to deliver superior accuracy, ensuring that your systems provide precise measurements and smooth operation. Whether you're working with rotational or linear motion, the encoders available at Aeliya Marine will meet your needs with exceptional precision.

2. Wide Range of Encoder Types Aeliya Marine understands that different applications require different types of encoders. To cater to various industries, they offer an extensive selection of encoders, including:

Rotary Encoders: These are ideal for measuring rotational position, speed, and direction in motors, turbines, and other rotating machinery. With Aeliya Marine’s rotary encoders, you can expect accurate feedback for continuous, high-speed rotation in both industrial and marine systems.

Linear Encoders: For applications where linear motion needs to be tracked, Aeliya Marine provides linear encoders that convert the position of a moving object into an electrical signal. These are perfect for applications like CNC machines, automated manufacturing systems, and other linear motion systems.

Incremental Encoders: Incremental encoders are great for applications where the measurement of position relative to a reference point is needed. These encoders are commonly used in industrial applications where rotation counts or speed feedback are essential.

Absolute Encoders: Unlike incremental encoders, absolute encoders provide a unique position value within a full rotation, even after power loss. This makes them a crucial choice for systems that require a constant reference to their position at all times.

3. Marine-Specific Encoders Aeliya Marine specializes in electronic components tailored to withstand harsh marine environments. Their encoders are designed with rugged durability, resistance to corrosion, and the ability to function in extreme weather and temperature conditions. This makes them the perfect choice for marine navigation, automation, and other critical systems that operate in demanding environments.

4. Reliable and Durable Construction The encoders offered by Aeliya Marine are built to last. Whether you need encoders for land-based projects or marine applications, you can trust that Aeliya Marine’s products are engineered to endure the rigors of continuous use. Their encoders are resistant to dust, moisture, vibration, and even saltwater exposure, ensuring longevity and reliable performance.

Applications of Encoders in Various Industries

Encoders are indispensable in a wide range of industries and applications. Here are just a few ways they are used:

Marine Systems: In marine applications, encoders are used to monitor and control the position and movement of various components, such as rudders, winches, and thrusters. Precise feedback ensures that systems remain operational even in tough maritime conditions.

Robotics and Automation: Encoders are essential for robots and automated machinery to track and control motion with high precision. From industrial robots to conveyor belts, encoders help maintain efficiency and reduce errors.

CNC Machines and Milling: Encoders provide accurate feedback on the position of the cutting tool in CNC machines, ensuring that milling, drilling, and cutting operations are precise.

Medical Equipment: In medical devices, encoders are used to track movement with high precision, such as in surgical robots, imaging equipment, or diagnostic instruments.

Industrial Machinery: Encoders help monitor the position, speed, and direction of moving parts in industrial machinery, ensuring optimal operation and reducing wear and tear.

Why Trust Aeliya Marine for Your Encoder Needs?

Expertise in Marine Electronics: Aeliya Marine has years of experience providing high-quality electronic components tailored for the marine industry. Their encoders are specially designed to thrive in maritime conditions, where durability and accuracy are critical.

Exceptional Customer Service: Whether you need guidance on selecting the right encoder for your application or assistance with installation, Aeliya Marine’s knowledgeable team is always ready to help. Their commitment to customer satisfaction ensures that you’ll receive the support you need.

Global Shipping: Aeliya Marine serves customers around the world, ensuring that no matter where you are located, you can access their premium encoder products.

Conclusion

When it comes to motion control, precision is key—and with Aeliya Marine’s collection of encoders, you can trust that your systems will operate with the utmost accuracy. Their broad selection of encoders, built for both land-based and marine applications, ensures that you get the right tool for the job, no matter the complexity of your project.

Explore Aeliya Marine’s Encoder Collection today and take the first step towards enhancing your systems with high-performance, durable encoders designed for any environment.

0 notes

Text

The Encoder Market: Current Trends and Future Outlook

The Encoder Market is experiencing significant growth, driven by advancements in technology and the increasing demand for automation across various industries. Encoders are essential components in many applications, including robotics, manufacturing, and automotive systems, where they convert mechanical motion into electrical signals for control and monitoring purposes. As industries continue to embrace automation and digitization, the demand for high-performance encoders is on the rise. This blog explores the encoder market's current landscape, key players, market size, limitations, challenges, and future trends.

Key Players in the Encoder Market

TBaumer TBaumer is renowned for its innovative sensor solutions, including encoders. Their products are widely used in various industries, known for high precision and reliability.

BEI Sensors A subsidiary of the Dover Corporation, BEI Sensors specializes in providing custom sensor solutions, including encoders. Their focus on high-quality products and customer service makes them a significant player in the market.

Dynapar Dynapar, part of the Sensor Technology Group, offers a wide range of encoders, including rotary, linear, and absolute types. Their products are known for their durability and performance in challenging environments.

OMRON OMRON is a global leader in automation and control equipment, providing encoders that feature high accuracy and advanced functionality. They serve diverse sectors, including manufacturing and healthcare.

Rockwell Automation Rockwell Automation is a major player in industrial automation, offering a variety of encoder solutions. Their products are integrated into many industrial processes, ensuring seamless operations.

FAULHABER FAULHABER is recognized for its high-precision micro and servo motors, along with encoders. Their commitment to quality and innovation has established them as a leader in the encoder market.

Heidenhain Heidenhain specializes in precision measurement and control technology, offering high-quality encoders for various applications. Their products are particularly valued in industries requiring exact positioning.

Hengstler Hengstler provides a comprehensive range of encoders, known for their robustness and versatility. Their products are widely used in sectors like automation and packaging.

Ifm electronic Ifm electronic is known for its sensor technology, including encoders that enhance machine performance. Their focus on efficiency and reliability makes them a preferred choice for many businesses.

Maxon Motor Maxon Motor specializes in high-precision drives and motors, including encoders. Their products are utilized in various applications, including robotics and medical technology.

Pepperl Fuchs Pepperl Fuchs is a global leader in industrial sensors and automation technologies, providing a range of encoder solutions known for their reliability and performance in harsh environments.

Pilz Pilz specializes in automation technology and safety engineering, offering encoders that integrate seamlessly into complex systems, enhancing operational safety and efficiency.

Renishaw Renishaw is a pioneer in precision measurement and healthcare technology, providing high-performance encoders for applications demanding utmost accuracy.

SIKO SIKO specializes in measurement technology and provides a range of encoders for industrial applications, focusing on accuracy and user-friendly designs.

Turck Turck is known for its automation and sensor solutions, offering encoders that meet the diverse needs of industrial applications, ensuring high reliability and performance.

Get the sample pdf: https://www.reportprime.com/encoder-r1266?utm_source=LinkedIn-SEO&utm_medium=PEPIQ-1014-AA&utm_campaign=GP&utm_id=encoder

Market Size and Growth

The encoder market is witnessing robust growth, with a projected market size reaching USD 3.5 billion by 2026, expanding at a CAGR of 7.5% during the forecast period. The increasing adoption of automation in manufacturing, automotive, and other sectors is driving this growth. Moreover, the rise of Industry 4.0 and the Internet of Things (IoT) is further fueling demand for advanced encoder technologies that enhance precision and efficiency.

Limitations of the Encoder Market

Despite the promising growth, the encoder market faces several limitations:

Cost Constraints The initial investment for high-quality encoders can be significant, especially for small and medium enterprises. This can limit adoption, particularly in cost-sensitive industries.

Complexity of Integration Integrating encoders into existing systems can be complex, requiring specialized knowledge and training. This complexity can deter some organizations from adopting advanced encoder solutions.

Technological Limitations While encoders have advanced significantly, some still face limitations in resolution, speed, and environmental durability, which can restrict their application in certain industries.

Competition from Alternative Technologies Emerging technologies such as laser measurement and other non-contact sensing solutions pose competition to traditional encoders, potentially affecting market share.

Challenges in the Encoder Market

The encoder market also faces several challenges that could impact its growth trajectory:

Rapid Technological Changes The fast pace of technological advancements requires manufacturers to continuously innovate and upgrade their products. Failure to keep up can lead to obsolescence.

Supply Chain Disruptions Global supply chain disruptions, exacerbated by events like the COVID-19 pandemic, can affect the availability of components, leading to production delays and increased costs.

Skilled Labor Shortage The growing complexity of automation technologies, including encoders, requires a skilled workforce for installation, maintenance, and troubleshooting. A shortage of skilled labor can hinder market growth.

Regulatory Challenges Compliance with industry regulations and standards can pose challenges for manufacturers, requiring investments in testing and certification processes.

Conclusion

The encoder market is poised for significant growth in the coming years, driven by advancements in technology and the increasing demand for automation across various sectors. With key players such as TBaumer, BEI Sensors, Dynapar, and others leading the way, the market is expected to evolve rapidly, introducing innovative solutions to meet the needs of modern applications.

While the market presents promising opportunities, it is essential to address the limitations and challenges that could impede growth. Manufacturers must focus on developing cost-effective solutions, simplifying integration processes, and keeping pace with technological advancements. Additionally, addressing supply chain issues and investing in workforce development will be crucial for sustaining growth.

In summary, the encoder market stands at a pivotal juncture, where the right strategies and innovations can propel it to new heights, shaping the future of automation and control systems across industries. As businesses continue to prioritize efficiency and precision, the role of encoders will undoubtedly become more critical, paving the way for a more automated and intelligent industrial landscape.

0 notes

Text

Issue one: Obsession with the physical and with grounding things. Issue two: I forgot. Polar view of everything? Whatever.

Issue 3: I want to be a beginner, and in many ways I'm beginning again, but the people I am are so far past beginners. The old men squad especially chews through beginner work to the point it's pointless to make

Ill be here trying to create and... Well. Take trying to create the iklii for example. If I give them a physical form they can be undone, especially if I ground them to it. If I give them a solid form that's unchanging, they have a central unchanging signature that can't adapt to change which means they're more at risk to the sort of... think of it like earthquakes tearing through rigid structures. The more distinct they are and the less herd-like they are like Lev's dogs, the more they can have their central thread identified and pulled on.

Individual expressions leave individual signatures. Everything in existence is written information, and so the more you write and the more distinct a handwriting style and voice and language you write them in, well, that can help them actually - hide in obvious places, the more information you give to something the more obscured the key signatures are if we're talking "everything looks like a key so what's the key" situation. But the more signatures you give something, the more that. well. you put a bunch of weapons in a game, you increase the odds of one of them being heavily overpowered compared to the rest and people will find and abuse that missed information

Leaving things to breed through generations mixes up the threads and introduces new threads, which obscures them, but I don't want these things to (pro)create. I guess I could simulate several generations in the creational womb, but that also introduces independent will which is also a liability and a weak point

Ugh. It's just... It's extensive. I'm thinking about the iklii and a function I want them to have, but the function would happen in linear time, which is a huge codex of information and you have to contribute information to get there. I mean first of all, linear time means you can interrupt the process if you can pinpoint places in time that happen to be used for the process and pierce them, like stabbing through the back of someone's knee would take someone off their feet. But. If you make something exist in spacetime, you make something exist in near infinite (if you consider the fractalisation) publicly accessible information, it's effectively like uploading an asset to a game - the coding and all information involved is going to have to be streamed through the Internet and saved in the game leaving it readable. There's ways to get around this, like encoding information you upload and also by uploading a sort of skeleton code that references your offline code but doesnt upload it... But. my god

There's so much to this that's just. wrong. When I'm creating, I'm stuck because I can see a million ways this is beginner work and how it's not right. Absolutely chewing through my own ideas because nope, easily undone, nope, easily countered, nope, easily tracked back to me. Bruh. I am a beginner. I'm very much not a beginner, but like. The souls and the self behind the curtain are struggling against the Unknowing Child lmfao waking up. It's not a huge problem - or it won't stay a huge problem but bruh. my god.

#~abyssal murmurs#astral diary //#This is just the equalisation process like. I don't want the parts of me that know this to shut up. But like I need to equalise#being a beginner this life with not being a beginner out of it

2 notes

·

View notes

Text

High-Performance Digital Display for Draw Wire Encoder

Experience accurate linear displacement measurement with Briter's draw wire encoder digital display. This intuitive device showcases real-time data on absolute position and stretching speed of RS485/CAN draw wire encoders. Ideal for industrial applications requiring precise position sensing over a range of 0-10 meters, this reliable technology ensures seamless integration for enhanced efficiency and productivity. Simplify your linear displacement sensor needs with this sophisticated digital display that offers clear and concise data visualization. Explore the power of advanced measurement with Briter's draw wire encoder solution today at briterencoder.com.

0 notes

Text

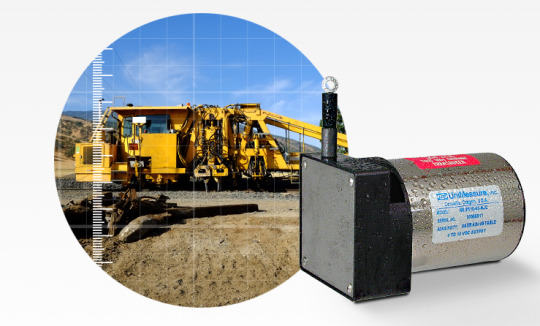

UniMeasure Inc

UniMeasure Inc

UniMeasure, Inc. has been manufacturing position and velocity sensors in Corvallis, Oregon since 1987. The company has steadily grown over the years to become a leader in the linear and rotary transducer industry with a focus on customer service, innovative design, and high-quality products. The Corvallis facility is ISO 9001:2015 certified with many raw materials and vendor services sourced in the local area. With a core group of long-standing employees, UniMeasure is dedicated to manufacturing position sensors in the USA and providing high-quality solutions while further enhancing customer experience.

UNIMEASURE LINEAR POSITION TRANSDUCERS

String Potentiometer

Often referred to as string pot, yo-yo pot, draw wire transducer, cable extension transducer, cable actuated transducer, UniMeasure extending wire rope linear position transducers have proven to be an attractive approach for a multitude of applications in many different industries. With relatively non-critical alignment requirements, compact size, and ease of installation wire rope actuated transducers are the linear position measurement system of choice in applications as diverse as bone densitometers in the medical industry, crash testing in the automobile industry, pump jacks in the crude oil extraction industry and irrigation and flood control in the water management industry. With a wide variety of electrical outputs, UniMeasure linear displacement measuring and position sensor products provide an extremely cost effective method for linear position feedback.

UNIMEASURE ROTARY POSITION TRANSDUCERS

Position Sensor

UniMeasure rotary position transducers provide an analog output signal that is directly proportional to the angle of rotation of the shaft of the device. With a voltage or 4 to 20 mA analog electrical output, UniMeasure rotary position transducers are also known as angle sensors, analog rotary shaft encoders and analog multiturn analog shaft encoders and absolute angle encoders. These position sensor devices are commonly used in applications where an absolute output signal is a must. Typical use occurs in closed loop process control and in testing applications where oscillatory rotary motion occurs. UniMeasure absolute analog rotary position transducers have proven to be an extremely cost effective alternative for measuring rotational positioning.

CONTACT US

UniMeasure Inc https://unimeasure.com/ ADDRESS: 4175 SW Research Way Corvallis, OR 97333 PHONE: (541) 757-3158

Facebook

1 note

·

View note

Text

Renishaw FORTiS-S™ enclosed linear encoders

Next-generation enclosed linear absolute encoders for use in harsh environments.

🔹High Accuracy 🔹Easy to Installation 🔹Superior reliability

#encoders#linearencoders#harshenvironments#cncmachine#machinespart#importantpart#machine#industries#installation#Accuracy

0 notes

Text

Non-Contact Sensing: Benefits of Optical Encoder Technology

An Optical Encoder is a critical component in various industrial and consumer applications, used to convert rotary or linear motion into electrical signals.

This technology utilizes light beams to detect position, speed, and direction with high precision and reliability. Optical Encoders are widely employed in robotics, CNC machines, printers, and aerospace systems, where accurate motion control is essential. They offer advantages such as non-contact operation, immunity to electromagnetic interference, and high resolution, making them suitable for demanding environments. Optical Encoders can be incremental or absolute, providing either relative position changes or exact position information, respectively. They contribute to enhanced automation and efficiency by providing real-time feedback for closed-loop control systems, ensuring precise movement and positioning of equipment. As industries continue to advance towards automation and digitalization, Optical Encoders play a crucial role in improving operational accuracy, reducing downtime, and enhancing overall productivity.

#OpticalEncoder #IndustrialAutomation #MotionControl #PrecisionEngineering #Robotics #CNCMachines #PositionSensing #HighResolution #AutomationTechnology #Digitalization #Manufacturing #AerospaceEngineering #SensorTechnology #EncoderTechnology #NonContactSensing #ClosedLoopControl #IoTDevices #SmartManufacturing #IndustrialRobotics #MachineTools

0 notes

Text

The Science of Motion Sensing: A Look Inside the Absolute Position Encoder

So here’s the thing about motion sensing: it’s literally everywhere. From robots building your next car to the precision required in an MRI machine, it’s the magic behind the scenes that makes things work seamlessly. And right in the middle of it all? The absolute rotary encoder. Unlike the incremental ones that need to "remember" where they started, these give you instant positional data like, boom, no warmup required. Pretty neat, right?

As the world gets smarter and more automated, these little wonders are showing up in every industry you can imagine. This post dives into what makes absolute position encoders so cool, why they’re a big deal, and where we’re heading with them.

Absolute Position Encoders: A Quick Breakdown

Wait, What’s an Absolute Position Encoder?

Think of an absolute position encoder as a GPS for machines. It knows exactly where something is without needing to "recalculate." Whether it’s a rotating shaft or a linear motion, this sensor assigns a unique position to every single spot—no guesswork, no "let me retrace my steps."

They use fancy tech like optical, magnetic, or capacitive sensing. Optical ones use light (think lasers but not quite), magnetic ones leverage… well, magnets, and capacitive ones get all electrical. Each type has its vibe, depending on what the job demands.

How Do They Actually Work?

Here’s the deal: absolute encoders track movement by assigning distinct digital codes to every position. It’s like your location pin on a map but for machines. If you’re using an optical encoder, you’ve got a disc with patterns spinning, and sensors translating those patterns into data. Magnetic ones? They’re all about detecting magnetic field changes. The real magic comes in with multi-turn encoders—these not only know where you are in a single rotation but can also count full revolutions.

It’s like having a Fitbit that not only counts your steps but also knows exactly where you stepped.

Different Types of Absolute Encoders

Rotary vs. Linear: The Big Divide

Rotary Encoders: Measure spinning motion (like the axle on a car).

Linear Encoders: Track straight-line movement (perfect for CNC machines).

Both have their moments to shine, but rotary encoders are more common in things like robotic arms, while linear encoders thrive in machine tools and precision measurement systems.

Single-Turn vs. Multi-Turn

Here’s where it gets extra clever:

Single-Turn Encoders: Focus on one complete revolution.

Multi-Turn Encoders: Keep track of how many times you’ve gone around.

Multi-turn encoders are the real MVPs for tracking continuous motion, like in wind turbines or big industrial machines.

Why Absolute Position Encoders Are Kind of a Big Deal

Instant Gratification: They don’t need a "home" position; they just know.

Zero Error Buildup: No cumulative mistakes, unlike incremental systems.

Safety First: Real-time data means fewer mishaps in critical systems.

Plug-and-Play: They’re compatible with industrial protocols like EtherCAT or BiSS, making integration smooth.

Whether it’s aerospace, healthcare, or automation, these benefits make absolute encoders a must-have for high-stakes operations.

Where Do We See These Encoders?

Factory Floors

Robotic arms, conveyor belts, and assembly lines all rely on absolute encoders to keep things moving—literally. With their precise data, every part ends up exactly where it should.

Robots

From humanoid bots to collaborative cobots, absolute encoders provide the feedback needed for smooth, lifelike movements. It’s what lets them nail tasks like welding or packaging.

The Sky (and Beyond)

In aerospace, these encoders are used for navigation, satellite positioning, and flight control systems. Harsh environments? No problem.

Medical Marvels

Think surgical robots or MRI machines. Absolute encoders are behind the scenes making sure everything’s positioned perfectly. Safety and precision are non-negotiable here.

Picking the Right Encoder

Not all encoders are created equal. Here’s what to consider:

Resolution: High resolution equals better detail (a must for precision work).

Durability: Can it handle heat, moisture, or dirt? That matters in industrial settings.

Form Factor: Does it fit where you need it to?

Compatibility: Make sure it plays nice with your control systems.

Not sure? That’s when you call in an experienced encoder manufacturer to steer you in the right direction.

New Tech, Who Dis?

Encoders are evolving fast. Take the hollow shaft rotary encoder for instance. By letting cables pass through the center, it saves space and simplifies setups.

And it’s not just about design. Modern encoders are now tougher, more accurate, and better at connecting with the broader industrial ecosystem. The future? Smarter, more compact, and even easier to use.

TL;DR: Why This Matters

Absolute position encoders might not be the flashiest tech, but they’re quietly running the show in industries that demand precision. From guiding robotic arms to ensuring aircraft land safely, their impact is massive. As automation continues to push boundaries, these encoders will remain essential—evolving to meet new challenges and powering the innovations of tomorrow.

Looking to dive deeper? A trusted encoder company can help you find the perfect fit for your next project.

0 notes

Text

Future Trends: The Advancement of Encoders in Industrial Automation

Industrial automation has come a long way since its commencement, with technology playing a critical role in enhancing efficiency, productivity, and precision in manufacturing and other industrial processes. One key component dynamic these improvements is the encoder. Encoders, which convert motion into an electrical signal that can be read by a control device, are fundamental in ensuring precise movement and positioning of machinery. As we look to the future, the advancement of encoders in industrial automation is set to bring about significant changes and improvements. This blog explores the future trends in encoder technology and their impact on industrial automation.

What Are Encoders?

Before diving into future trends, it’s essential to understand what encoders are and how they function. Encoders are sensors that provide feedback on position, speed, and direction of a rotating shaft or linear movement. They are crucial in applications where precise control of motion is required. There are two main types of encoders:

Rotary Encoders: These encoders measure the rotational position and speed of a shaft. They can be either incremental or absolute.

Linear Encoders: These measure the linear position and speed of an object, providing feedback for precise control in linear motion applications.

Future Trends in Encoder Technology

As technology continues to progress, several trends are influential the future of encoders in industrial automation. These trends promise to enhance the capabilities of encoders, making them more accurate, reliable, and versatile.

1. Higher Resolution and Accuracy

One of the most significant trends is the push for higher resolution and accuracy in encoders. As industries demand greater precision, manufacturers are developing encoders with finer resolution capabilities. Higher resolution encoders provide more detailed feedback, allowing for better control and accuracy in applications such as semiconductor manufacturing and precision machining.

2. Integration of Advanced Communication Protocols

Modern industrial automation systems rely heavily on communication networks to exchange data between various components. The integration of advanced communication protocols such as Ethernet/IP, PROFINET, and EtherCAT into encoders is becoming increasingly common. These protocols enable faster and more reliable data transmission, improving the overall efficiency and performance of automation systems.

3. Miniaturization and Compact Designs

With the trend towards smaller and more compact machinery, there is a growing demand for miniaturized encoders. Advances in micro-electromechanical systems (MEMS) technology have made it possible to develop compact encoders without compromising performance. These smaller encoders are ideal for applications with limited space, such as medical devices and compact robotic systems.

4. Enhanced Durability and Environmental Resistance

Industrial environments can be harsh, with factors such as dust, moisture, and extreme temperatures posing challenges to encoder performance. Future encoders are being designed with enhanced durability and environmental resistance. Encoders with IP67 or higher ratings, for example, can withstand exposure to water and dust, ensuring reliable performance in demanding conditions.

5. Development of Wireless Encoders

Wireless technology is making its way into industrial automation, and encoders are no exception. Wireless encoders eliminate the need for cables, reducing installation complexity and maintenance requirements. They are particularly useful in applications where wired connections are impractical or hazardous. Advances in wireless communication protocols are ensuring that wireless encoders provide reliable and secure data transmission.

6. Increased Customization and Flexibility

Industries are increasingly seeking customized solutions to meet specific application requirements. Encoder manufacturers are responding by offering more customizable and flexible products. This trend includes the ability to configure encoders with different output signals, mounting options, and communication interfaces. Customizable encoders allow for tailored solutions that optimize performance in specific applications.

7. Integration with Advanced Sensors

Encoders are being integrated with other advanced sensors to provide more comprehensive feedback and control. For example, combining encoders with gyroscopes and accelerometers can enhance the precision and stability of motion control systems. This integration is particularly valuable in applications such as autonomous vehicles and advanced robotics.

8. Energy Efficiency and Power Management

As industries strive to reduce their carbon footprint and energy consumption, the energy efficiency of automation components is becoming increasingly important. Future encoders are being designed with energy-efficient components and power management features. Low-power encoders are particularly beneficial in battery-powered applications, such as portable devices and remote monitoring systems.

9. Enhanced Safety Features

Safety is a top priority in industrial automation, and encoders are playing a crucial role in enhancing safety measures. Encoders with built-in safety features, such as redundant sensing elements and self-diagnostics, provide additional layers of protection. These safety features help prevent accidents and ensure the reliable operation of machinery in critical applications.

Impact of Future Encoder Trends on Industrial Automation

The advancements in encoder technology are set to have a profound impact on industrial automation. Here are some key ways these trends will shape the future of industrial processes:

Improved Precision and Quality

Higher resolution and accuracy in encoders will lead to improved precision and quality in manufacturing processes. This is particularly important in industries such as aerospace, automotive, and electronics, where even minor deviations can have significant consequences. Enhanced precision will result in higher-quality products and reduced waste.

Increased Efficiency and Productivity

The integration of advanced communication protocols, IoT capabilities, and wireless technology will streamline data exchange and improve the efficiency of automation systems. Real-time data collection and analysis will enable predictive maintenance, reducing downtime and increasing productivity. Automation systems will be able to operate more smoothly and efficiently, leading to cost savings and higher output.

Greater Flexibility and Customization

The trend towards customization and flexibility in encoder design will allow industries to implement customized solutions that meet specific requirements. This flexibility will enable manufacturers to optimize their processes and achieve better performance. Customizable encoders will also make it easier to adapt to changing production needs and technological advancements.

Enhanced Safety and Reliability

The incorporation of advanced safety features and durable designs will enhance the reliability and safety of industrial automation systems. This is crucial in applications where safety is paramount, such as in the chemical, pharmaceutical, and food industries. Reliable encoders with robust safety features will help prevent accidents and ensure consistent performance.

Adoption of Smart Manufacturing Practices

The integration of IoT and Industry 4.0 capabilities into encoders will drive the adoption of smart manufacturing practices. Smart factories, equipped with connected and intelligent components, will be able to optimize operations, reduce energy consumption, and improve overall efficiency. The data generated by smart encoders will provide valuable insights for continuous improvement and innovation.

Expansion of Automation into New Areas

Advancements in encoder technology will enable the expansion of automation into new areas and applications. For example, miniaturized and wireless encoders will make it possible to automate processes in confined spaces and remote locations. This expansion will open up new opportunities for automation in industries such as agriculture, healthcare, and logistics.

Conclusion

The future of encoders in industrial automation is bright, with numerous advancements set to enhance their capabilities and impact. Higher resolution, advanced communication protocols, miniaturization, durability, IoT integration, wireless technology, customization, advanced sensors, energy efficiency, and enhanced safety features are some of the key trends shaping the future of encoder technology. These advancements will lead to improved precision, efficiency, flexibility, safety, and the adoption of smart manufacturing practices.

#industrial automation#auto2mation#industrial equipment#industrial spare parts#industrial and marine automation equipment#industrial and marine automation#industrial automation equipment#automation#industrial encoder

0 notes