#absolute rotary encoder

Explore tagged Tumblr posts

Text

Explosion proof Absolute Rotary Encoder with RS232 Modbus RTU Communication

Key features

Power-Off Memory: Maintains precise position data even during power outages, eliminating recalibration needs and ensuring consistent performance.

Absolute Multi-Turn Capability: Delivers accurate position data across numerous turns, making it suitable for intricate rotational tasks.

Mechanical Gear Counting: Uses sturdy mechanical gears for turn counting, eliminating the dependency on internal batteries and boosting reliability.

High Resolution: Offers up to 17-bit resolution with 0.07° accuracy for meticulous angle measurements.

Compact and Rugged Design: Features a minimal outer diameter of just 39mm and EX protection, making it resilient in harsh environments.

Data Interfaces: Equipped with RS232 connections and supports Modbus RTU, enabling seamless data integration and communication.

Visit https://briterencoder.com/product/explosionproof-absolute-rotary-encoder-with-rs232-modbus-rtu-communication/ for more.

0 notes

Text

Pepperl+Fuchs FVM58 ABSOLUTE ROTARY ENCODER

Manufacturer: Pepperl+Fuchs Product no. : FVM58N-011AEA3GN-0813 Product type : Multiturn absolute encoder Data format : F = Fast parallel Shaft version : V = Solid shaft Principle of operation : M = Multiturn Housing material : N = Aluminium, powder coated Shaft dimension/flange version : 011 = Shaft ÿ10 mm x 20 mm with clamping flange Connection type : AE = Plug connector type 9426,…

View On WordPress

#Absolute Rotary Encoder;#P+F बैरियर#P+F ปัญหาและอุปสรรค#P+F halangan#P+F hambatan#P+F rào cản#P+F الحواجز#Pepperl+Fuchs Absolute Rotary Encoder;#Pepperl+Fuchs Barriers#pepperl+fuchs encoder#pepperl+fuchs sensor

0 notes

Text

Re-designing my Waldo

I found out they make rotary hall effect sensors (why did no one tell me). These little guys are miracles; they have the exact same effect on the voltage as a traditional potentiometer but with all the advantages of hall-effects. Straight upgrade. And unlike optical encoders, the positioning is absolute, so no calibration needed. The sensors are a slightly different form factor though, and because my first prototype prioritized fewer parts over upgradeability, a tiny little change requires a complete re-design. As you can see, I'm trying to avoid that in the future. This version has far more parts that bolt together rather than weld, particularly where sensors get installed. This was also an opportunity to make some long overdue ergonomic adjustments (the thumb position was atrocious) and add a couple extra sensors for my fingers. If I've done everything right (and I almost never do) this will be easier to repair, lighter, and more expressive.

9 notes

·

View notes

Text

response types:

every example of this issue. ovens. fridges. microwaves. dish washers. light-switches. phones. washing machines. cars. ticket-buying machines. etc.

people who seem to think I'm not serious about this issue (I promise you I am serious about this issue)

people saying it's an accessibility issue. it is absolutely an accessibility issue yes (ux designer person sees us)

people who wanna go retro. I wish for you old-timey radios and a car that still works after 20 years and functional appliances that don't run on software and light-switches that make little clicky noises. I wish for all of us these things

everyone working in a job with various dials and knobs and levers. shout out to pilots and lab technicians and engineering types and musicians who play with live sound-mixing and looping etc, and people in various kinds of factories and medical spaces, use those dials and knobs and levers for all of us!

everyone who has Solutions to the issue! big fan of Solutions, there are Solutions out there (not currently for me, a humble renter, but for anyone out there who can apply themselves to a Solution). something about a rotary encoder and modular synthesizers. things to look into with sexy names

people calling me david tennant

if you want to microdose on a lever, I recommend the humble button-maker. bit pricey on the first buy (about seventy-five pounds) but after that making buttons is so easy you'll cry

we need more dials and knobs and levers again. this world is lacking in dials and knobs and levers. it's one of our biggest issues.

59K notes

·

View notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Explosion proof Absolute Rotary Encoder with Biss Communication

Key features

Power-Off Memory: Retains accurate position data even after power loss, eliminating the need for recalibration and ensuring reliable performance.

Absolute Multi-Turn Capability: Provides precise position information across multiple turns, making it ideal for complex rotational tasks.

Mechanical Gear Counting: Utilizes durable mechanical gears for counting turns, removing the need for internal batteries and enhancing reliability.

High Resolution: Achieves up to 17-bit resolution with 0.07° accuracy for precise angle measurement.

Compact and Rugged Design: With a minimal outer diameter of just 39mm and explosionproof features, this encoder withstands harsh environments.

Visit https://briterencoder.com/product/explosionproof-absolute-rotary-encoder-with-biss-communication/ for more.

0 notes

Text

The Science Behind Hollow Shaft Rotary Encoders: Torque, Speed, and Accuracy

In the landscape of modern automation, sensors and feedback mechanisms are crucial for maintaining the precision and efficiency of machinery. One of the most indispensable devices in this category is the rotary encoder, especially the hollow shaft rotary encoder. These devices provide real-time data on angular position, velocity, and direction, enabling refined control over dynamic systems. Their unique hollow shaft design offers numerous advantages, particularly when integrating with rotating shafts and assemblies in compact or sensitive environments. This article delves into the scientific underpinnings of these encoders, examining how they measure torque, speed, and accuracy in industrial and robotic applications.

Basics of Rotary Encoders

Rotary encoders translate rotational motion into digital signals. They are broadly categorized into absolute and incremental types. Absolute encoders deliver a unique position value, whereas incremental encoders provide relative motion data. Hollow shaft rotary encoders, a sub-type of these devices, allow the shaft of the motor or machinery to pass through the encoder. This design minimizes axial load, reduces mechanical complexity, and facilitates easier installation. The hollow shaft construction is particularly beneficial in applications where space is limited or where quick replacement and alignment are essential. These encoders are primarily used in robotics, CNC machinery, elevators, and energy sector equipment.

Working Principle of Hollow Shaft Rotary Encoders

Hollow shaft rotary encoders typically use optical, magnetic, or capacitive sensing methods. Optical encoders employ a light source and photodetector array to read patterns on a rotating disk. Magnetic encoders detect changes in magnetic fields using Hall-effect sensors or magnetoresistive elements. Capacitive encoders utilize variations in capacitance caused by changes in geometry as the shaft rotates. Each method has its advantages in terms of resolution, durability, and environmental robustness. The hollow shaft design does not alter the fundamental sensing mechanism but allows the encoder to be mounted directly over a rotating shaft without additional couplings. This direct interface helps reduce backlash and enhances accuracy.

Measuring Torque with Hollow Shaft Rotary Encoders

Torque is the rotational analog of linear force. Although rotary encoders are not traditionally used as torque sensors, they play a significant role in torque estimation. By precisely measuring angular displacement and speed, and knowing the system's moment of inertia, torque can be inferred. In applications where torque sensors are either too bulky or expensive, high-resolution encoders serve as a cost-effective alternative. The key lies in correlating the angular velocity and acceleration data provided by the encoder with the mechanical characteristics of the system. For dynamic torque measurement, especially in systems with varying load conditions, encoders offer real-time feedback that can be analyzed via control algorithms to maintain performance consistency.

Speed Detection in Dynamic Systems

Speed detection is a primary function of rotary encoders. Incremental hollow shaft rotary encoders are particularly adept at delivering high-fidelity speed data. They generate pulses for every increment of rotation, which are counted over time to calculate speed. Higher pulse counts per revolution (PPR) mean greater resolution and more accurate speed readings. In applications like conveyor systems, turbines, or robotic joints, this level of speed precision ensures smoother operation and reduces wear and tear. Encoders are also favored for their minimal latency, allowing near-instantaneous speed adjustments. Furthermore, their digital output can be seamlessly integrated into programmable logic controllers (PLCs) or microcontrollers for real-time processing and control.

Ensuring Accuracy and Resolution

Accuracy in rotary encoders refers to the degree to which the measured position matches the actual position. Resolution, on the other hand, is the smallest change in position that the encoder can detect. High-resolution encoders are essential for systems requiring fine control, such as semiconductor manufacturing or surgical robotics. Hollow shaft rotary encoders often offer both high resolution and excellent accuracy due to their ability to directly interface with the rotating element. This reduces mechanical errors associated with couplings or misalignment. Optical encoders typically offer the highest resolution, while magnetic and capacitive types provide better resilience in harsh environments. Calibration and alignment during installation also play critical roles in maintaining accuracy.

The Importance of Zero Backlash

Backlash is the slight movement that occurs when direction is reversed in a mechanical system. This can cause significant errors in position sensing. Hollow shaft encoders help minimize backlash by allowing direct mounting onto the shaft, thereby eliminating intermediate couplings or gears that can introduce slack. Zero backlash is particularly critical in high-precision applications like robotics and CNC machining, where even minor errors can lead to defective outcomes. By integrating the encoder directly onto the shaft, manufacturers can achieve tighter control loops, reduced error margins, and more reliable performance. This direct integration also facilitates better synchronization between motor movement and feedback, enhancing overall system stability.

Environmental and Structural Considerations

Industrial environments often expose equipment to dust, moisture, temperature fluctuations, and vibrations. Hollow shaft rotary encoders are designed to withstand these conditions through robust housing, sealed bearings, and non-contact sensing technologies. Magnetic and capacitive encoders are particularly well-suited for such environments due to their resistance to contaminants and mechanical wear. Structural considerations also include the material of the encoder’s housing and shaft, which must align with the application’s requirements for durability and weight. The hollow shaft itself can be designed to accommodate different shaft diameters, increasing its adaptability across multiple systems. Proper installation and maintenance further ensure the encoder's longevity and consistent performance.

Integration into Closed-Loop Systems

Hollow shaft rotary encoders play a pivotal role in closed-loop control systems, where feedback is used to adjust and correct motion in real time. These systems require high-resolution and low-latency feedback to maintain accuracy and efficiency. The encoder sends position and speed data to a controller, which then adjusts the motor’s operation accordingly. This continuous feedback loop allows for precise control even in variable load conditions. Integration into such systems requires compatibility with control hardware, appropriate signal output formats, and real-time data processing capabilities. Encoders that support multiple output protocols, such as quadrature, SSI, or BiSS, offer greater flexibility in system design.

Case Study: Hollow Shaft Encoders in Robotic Arms

Robotic arms require exceptional precision and agility, often functioning in environments that demand both speed and safety. Hollow shaft rotary encoders enable these capabilities by offering accurate position and velocity feedback without adding bulk to the joints. Their compact design fits seamlessly into tight spaces, while their direct shaft interface ensures minimal mechanical error. For example, in medical robotics, where minute movements can have significant consequences, the encoder's resolution and accuracy become critical. Additionally, their ability to function reliably in varying environmental conditions makes them suitable for both cleanrooms and industrial settings. This case study illustrates how the theoretical benefits of hollow shaft encoders translate into practical performance gains.

Comparing Hollow Shaft and Solid Shaft Encoders

Solid shaft encoders require couplings or adapters for installation, which can introduce alignment issues and mechanical play. Hollow shaft encoders bypass these challenges by mounting directly onto the shaft, thereby reducing complexity and improving measurement fidelity. While solid shaft designs may offer slightly more mechanical robustness, they often necessitate more space and careful alignment. Hollow shaft encoders, by contrast, are easier to install and replace, which is beneficial in systems where downtime must be minimized. The choice between the two often comes down to the specific application requirements, including available space, desired precision, and environmental factors. Ultimately, hollow shaft models offer a compelling mix of convenience and performance.

Market Trends and Future Outlook

The market for rotary encoders is evolving rapidly, driven by advancements in automation, robotics, and smart manufacturing. Hollow shaft rotary encoders are gaining traction due to their compact design and enhanced integration capabilities. Innovations such as wireless data transmission, miniaturization, and improved environmental resistance are expanding their application scope. Additionally, the incorporation of edge computing and AI into encoder systems is enabling predictive maintenance and smarter feedback mechanisms. As industries continue to push for higher efficiency and precision, the demand for reliable and versatile encoders will only increase. In this context, the hollow shaft encoder emerges as a key component in future-ready systems.

Conclusion

The science behind hollow shaft rotary encoders encompasses a multidisciplinary understanding of mechanics, electronics, and systems engineering. Their ability to provide accurate, real-time data on torque, speed, and position makes them invaluable in a wide array of industrial and robotic applications. Their unique hollow design simplifies installation and enhances performance by reducing mechanical errors. From aiding in torque estimation to ensuring zero backlash and high-resolution feedback, these encoders are tailored for precision-driven environments. As technological advancements continue to refine their capabilities, the hollow shaft rotary encoder is poised to remain a cornerstone of intelligent motion control systems across industries.

0 notes

Text

Apple Automation And Sensor

Autonics India

Apple Automation and Sensor is an authorized dealer, supplier, and distributor of Autonics products in India. We offer competitive prices and keep most models in stock, ready for quick delivery. Our locations include major cities like Mumbai, Delhi, Ahmedabad, Chennai, Kolkata, Pune, Nashik, Aurangabad, Nagpur, Vapi, Silvassa, Surat, Vadodara, Rajkot, Gandhidham, Morbi, Indore, Bhopal, Faridabad, Ghaziabad, Noida, Gurgaon, Coimbatore, Bangalore, Hyderabad, Kanpur, Goa, Vishakhapatnam, Cochin, Ernakulam, Ludhiana, Chandigarh, Baddi, and Dehradun.

Autonics Absolute Encoder

Autonics Area Sensor

Autonics Buzzer

Autonics Cable Connector

Autonics Capacitive Sensor

Autonics Color Mark Sensor

Autonics Connection Box

Autonics Connector Cable

Autonics Control Switches

Autonics Controller Sensor

Autonics Counter

Autonics Door Sensor

Autonics Encoder

Autonics Fiber Optic Cable

Autonics Fiber Optic Sensor

Autonics Handle Type Rotary Encoder

Autonics Hollow Shaft Encoder

Autonics Humidity Sensor

Autonics Laser Displacement Sensor

Autonics Panel Meter

Autonics Photoelectric Sensor

Autonics Pluse Meter

Autonics Power Supply

Autonics Pressure Sensor

Autonics Proximity Sensor

Autonics Reflector

Autonics Scaling Meter

Autonics Solid State Relays

Autonics Stepper Motor

Autonics Stepper Motor Drive

Autonics Temperature Controller

Autonics Terminal Blocks

Autonics Thyristor Power Controller

Autonics Timer

Autonics Wheel Type Rotary Encoder

0 notes

Text

Apple Automation And Sensor

Autonics India

Apple Automation and Sensor is an authorized dealer, supplier, and distributor of Autonics products in India. We offer competitive prices and keep most models in stock, ready for quick delivery. Our locations include major cities like Mumbai, Delhi, Ahmedabad, Chennai, Kolkata, Pune, Nashik, Aurangabad, Nagpur, Vapi, Silvassa, Surat, Vadodara, Rajkot, Gandhidham, Morbi, Indore, Bhopal, Faridabad, Ghaziabad, Noida, Gurgaon, Coimbatore, Bangalore, Hyderabad, Kanpur, Goa, Vishakhapatnam, Cochin, Ernakulam, Ludhiana, Chandigarh, Baddi, and Dehradun.

Autonics Absolute Encoder

Autonics Area Sensor

Autonics Buzzer

Autonics Cable Connector

Autonics Capacitive Sensor

Autonics Color Mark Sensor

Autonics Connection Box

Autonics Connector Cable

Autonics Control Switches

Autonics Controller Sensor

Autonics Counter

Autonics Door Sensor

Autonics Encoder

Autonics Fiber Optic Cable

Autonics Fiber Optic Sensor

Autonics Handle Type Rotary Encoder

Autonics Hollow Shaft Encoder

Autonics Humidity Sensor

Autonics Laser Displacement Sensor

Autonics Panel Meter

Autonics Photoelectric Sensor

Autonics Pluse Meter

Autonics Power Supply

Autonics Pressure Sensor

Autonics Proximity Sensor

Autonics Reflector

Autonics Scaling Meter

Autonics Solid State Relays

Autonics Stepper Motor

Autonics Stepper Motor Drive

Autonics Temperature Controller

Autonics Terminal Blocks

Autonics Thyristor Power Controller

Autonics Timer

Autonics Wheel Type Rotary Encoder

0 notes

Photo

Absolute Vs. Incremental Rotary Encoders – Choosing The Best Option For Your System https://www.droidmen.com/absolute-vs-incremental-rotary-encoders-choosing-the-best-option/

0 notes

Text

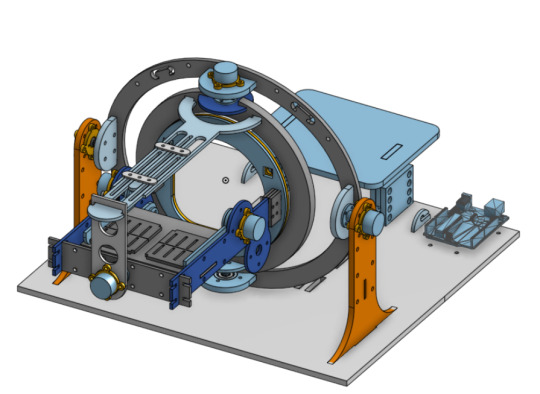

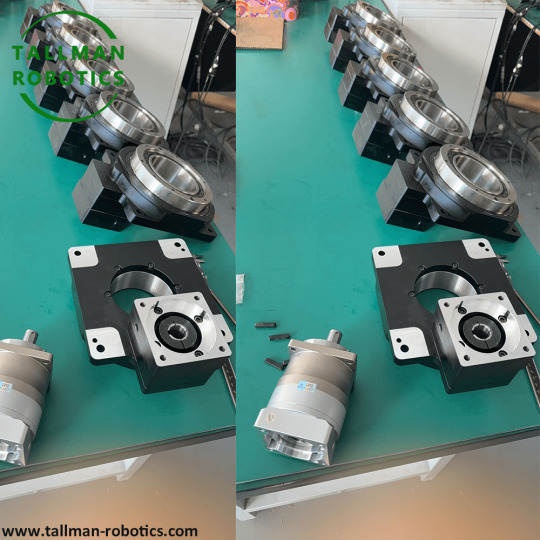

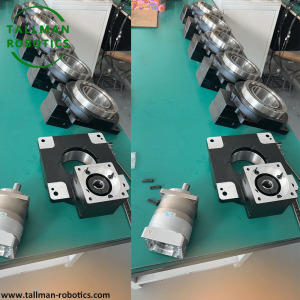

Precise Positioning Hollow Rotary Tables Will Be Delivered to Pakistan

Precise Positioning Hollow Rotary Tables are specialized rotational devices featuring a central hollow shaft, designed for high-accuracy angular positioning. The hollow core allows cables, pneumatic lines, or shafts to pass through, eliminating cable tangling and reducing system complexity.

https://youtu.be/ZP31od3m6Xc?si=KSzfpuXjjSW-2xnV Key Components and Features 1. Drive Mechanisms: Harmonic Drives: Preferred for near-zero backlash and high torque density. Direct Drive Motors: Offer smooth operation and precise control without mechanical reduction. Alternative systems like worm gears may be used but are less common in ultra-high-precision settings. 2. Bearings: Crossed Roller Bearings: Provide high rigidity and accuracy, handling both radial and axial loads efficiently. 3. Feedback Systems: High-resolution absolute encoders ensure accurate position tracking, even after power interruptions. 4. Materials and Construction: Made from rigid materials like aluminum or steel alloys to minimize deflection under load. Standardized mounting interfaces (e.g., ISO/SAE flanges) for easy integration with machinery. Applications of Large hollow shaft rotary tables CNC Machining: Enables multi-axis machining by rotating workpieces precisely. Semiconductor Manufacturing: Used in wafer handling and inspection systems. Optics and Medical Devices: Positions lenses or surgical tools with high accuracy. Robotics: Facilitates precise joint movements in automation and articulated robots. Advantages Over Standard Rotary Tables Hollow Design: Central pass-through avoids cable management issues, enhancing reliability. High Precision: Sub-arc-minute accuracy achievable with advanced feedback and drive systems. Versatility: Suitable for diverse industries due to customizable sizes and load capacities. Conclusion Precise Positioning Hollow Rotary Tables/Large hollow shaft rotary tables are critical in applications demanding exact angular positioning with central component pass-through. Their design combines mechanical precision with intelligent feedback systems, making them indispensable in advanced manufacturing and automation. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#CNCHollowRotaryActuator#HeavyDutyHollowRotaryTables#HighPrecisionHollowRotaryTablesforCNCMachines#High-precisionrotarytable#HollowAxes#HollowRotaryPlatform#HollowRotaryTableRightAngleManufacturer#LargeApertureHollowRotaryTables#Largehollowshaftrotarytables#PlanetaryGearboxes#PrecisePositioningHollowRotaryTables#PrecisionHollowRotaryTable#PrecisionRightAngleRotaryTables#RotaryActuators

0 notes