#advanced microcontroller

Explore tagged Tumblr posts

Text

Active Electronic Components Market Will Grow at Highest Pace Owing to Growing Usage in Consumer Electronics Industry

The active electronic components market comprises of products such as integrated circuits (ICs), transistors, and diodes. These components are building blocks in electronic devices and their demand is driven by rising usage in consumer electronics, smartphones, computers, automotive vehicles, and industrial equipment. Active components offer advantages like low power consumption, miniaturization, high efficiency, and longevity. With technology advancement, these components have become essential building blocks in a wide range of electronic devices. The Global active electronic components market is estimated to be valued at US$ 661.18 Bn in 2024 and is expected to exhibit a CAGR of 8.9% over the forecast period 2024 to 2031. Key Takeaways Key players operating in the Active Electronic Components Market Growth are Infineon Technologies AG, Advanced Micro Devices, Inc., STMicroelectronics N.V., Microchip Technology, Inc., Analog Devices, Inc., Broadcom Inc., NXP Semiconductors N.V., Intel Corporation, Monolithic Power Systems, Inc., Texas Instruments Incorporated, Qualcomm Inc., Renesas Electronics Corporation, Semiconductor Components Industries, LLC, and Toshiba Corporation. These players are focusing on developing new and innovative products to gain a competitive advantage. The growing usage of electronic devices across various industries along with rising demand for energy efficient and compact components is driving the market. Consumer electronics is the largest application segment for active electronic components. Smartphones, laptops, tablets, and other handheld devices require large number of integrated circuits, transistors, and diodes. Ongoing technological advancements are leading to development of new generation active components like FinFET transistors, gallium nitride transistors, and embedded passive devices. These new components offer higher efficiency, speed and integration than previous versions. Their adoption is increasing in applications like 5G infrastructure, electric vehicles, renewable energy equipment and AI/ML systems. Market Trends - Miniaturization of active electronic components: Ongoing research in nanotechnology and 3D fabrication techniques is leading to development of miniature integrated circuits, transistors and other active components. Their small size enables developing compact smartphones, wearables and other electronics.

Get More Insights On This Topic: Active Electronic Components Market

#Active Electronic Components Market#Semiconductor Devices#Integrated Circuits#Microcontrollers#Electronic Manufacturing#Consumer Electronics#Industrial Automation#Market Trends#Technological Advancements

0 notes

Text

Finally ready to start showing off the project we've been working on for a few weeks.

TRAIN PUZZLE (dot exe) (title pending)

me and @msasterisk are working on a switching puzzle game set on slimegirl astronaut Eaurp Guz's homeworld. You operate an Advanced Steam switcher to move cars around. The prototype implements a single level, a model railroad Inglenook layout, but there will be other original levels as well.

MsAsterisk has done all of the programming and game engine work, I've done the game design and art assets.

more screenshots and development photos below the cut:

Until the last couple of days, the game has used plain colored boxes for its cars. The first playable version, shown here, was just a pixel art train toy, with no actual game mechanics, but with an external list randomizer you could still run the inglenook game.

The physics was apparently a monumental undertaking to get working, but now it works great!

i don't remember what this was about. Truncated the vertices to the unit cube or something.

@thefallencomet's playtesting of the first prototype revealed a severe bug with couplers where switching cars coupled at a distance between three tracks at once would completely break physics. MsAsterisk fixed it by simply breaking couplers when they're too far apart.

car concept art

u.i. concept art. The tracks are bonafide pixel art here, but they've since been replaced with all 3D assets. The loco here is a pixelated render done in blender of the advanced steam tank engine model that i made about a month ago.

control stand model, WIP. We're not sure if we're going to go for this kind of detailed control stand. Why does a steam engine use a control stand that would look more at home on an EMD diesel? It's the magic of Advanced Steam Technology! The actual engine is controlled with actuators and microcontrollers, they're merely operated from the safety of the control cabin. The gauges are for brake cylinder, boiler pressure, steam chest, and speedometer--but no promises about whether these will be functional.

and finally, portraits of the engine crew

More to come as the game continues development.

#Train Puzzle#train#advanced steam#mellanoid slime worldbuilding#shunting#switching#switching puzzle#shunting puzzle#puzzle game#indie game#game dev#video game#train game#steam train#boxcar

119 notes

·

View notes

Text

Snippet - Off the Hook - Forward but Never Forget/XOXO

Soul-bonds aren't all they're cracked up to be...

tw: body horror, mentions of convalescence

Forward but Never Forget/XOXO

Snippet:

It wasn't something she could confide in anyone. Not to Singed, who was there every evening, with his icky potions and ickier smiles. To him, she was J17: a collection of warm, pliable parts with a fascinating gooey center. His eyes, always looking for a place to cut the incision and dig in.

And not even Silco's implacable hand, clamping his bony shoulder, could pry Singed's hungry stare off her.

She was a science-fair, waiting to happen.

It wasn't something she could confide in Viktor, either. Even though he was there nearly as often as Singed. Always looking at her too. But so sweet, so solicitous, and so, so scared because of what they'd done—what he'd done—that Jinx couldn't stand it.

They'd had so much fun working together—two gears in a perfectly synchronized machine. But after the Change, the synchronicity was soul-deep. Infusion, exfusion; blood, bone; bile, brains. He felt everything Jinx felt. Hurt everywhere Jinx hurt. He knew her insides better than anyone in Zaun.

And he couldn't stand it.

Not because of Jinx's big-eyed, freckle-faced youth—though Jinx knew it was a huge factor—but because Viktor couldn't stand himself. His shame was a sub rosa scent, and it soured even the smallest joys, like Jinx showing off her gnarly stitches or sticking little paper hats on her finger stubs or doing a wickedly accurate impression of Singed when he brandished the catheter—"Tsk, tsk, it only hurts a teeny bit."

Viktor had a thing for guilt, the way Jinx had a thing for guns. And though the Change had knitted them closer—fused them into the same spiritual superstructure—the truth was they had a better dynamic apart.

He had his machines and his monomania to take him away from it all. Jinx had her monstrosity, and the madness of knowing what it meant.

And though he'd sit for hours and hold her mangled hand—even kiss it, if she pouted extra pitifully—he was too careful, like she was made of cracked porcelain. His guilt insulated their connection. And though he was attuned to her pain, it was a reminder of those parts of himself he'd rather leave behind.

The Change had altered him too. Made him a different man from the Viktor of yesteryear.

He sought the very perfection Jinx dreaded.

A final destination; a final breath.

A be-all and end-all.

It was something else Jinx couldn't mention. So she let him off the hook in simpler ways. Most evenings, she'd let him make himself useful.

It was a cinch. Viktor had a thing for atonement too. He'd bend over backwards to remedy what he'd ruined. He made so many small improvements to Jinx's room. A bedside monitor, a gooseneck reading lamp, an ergonomic pillow, a massaging mattress topper, a heating pad, a white-noise machine, an aromatherapy diffuser, an extra-foamy skin lotion, an extra-frothy bidet.

(That's a thingamajig that washes your nethers, for the yobs.)

He also designed a pair of cybernetic prosthetics for her missing fingers. They were aces: composed of ultra-durable alloy that was 99.9% waterproof and 99.99% airtight, with an extra layer of ultra-fine nanomesh for maximum flexibility. It even had an integrated shock absorber for extra comfort.

Each digit had an advanced microcontroller. At a touch, they processed pressure, temperature, and humidity, so she could adjust the grip strength of her prosthetics on the fly. And to top it off, he added a nifty laser targeting system similar to his own robotic arm. The laser was controlled through an intuitive haptic interface, allowing Jinx to literally shoot finger-guns at her enemies.

A one-of-a-kind masterpiece. The perfect booby-trap for the ultimate prankster.

He even painted them her favorite colors. Pink and blue, in candy-cane stripes.

The prosthetics looked amazing. They also felt... weird. Viktor had added an extra layer of neural networking to the digits. They never spazzed, or shortcircuited or stopped mid-task. But the fusion between metal and meat wasn't a straight line. It was a spiral staircase, going down, down, down.

It gave Jinx vertigo. It gave her the chills.

Perfect symbiosis wasn't the same as the real deal. Flesh that was warm. Nails that cracked. Skin that bled. Her brain liked those fingers. They were grubby, grimy, grabby. But they were part of the whole.

Part of Jinx.

She couldn't tell Viktor that, either. For a Tinman, Viktor was unbearably sensitive. And Jinx, in her new state of hyperempathy, sensed how the act of soothing her physical ills soothed Viktor's psychic ones.

So she'd lay in bed and languish in agony—"They hurt they hurt they HURT!"—and let him fidget and fixate and fuss. His own augmented joints moved faster than ever, zipping everywhere with unsettling smoothness. He'd teach her how to flex the digits using his own Hex-claw: a show of stealthy shadow-puppetry and high-swooping panache. Whenever Jinx got it right, he'd crack his one and only smile: a reflexive curl of lips that never quite crossed into mirth, but was unrecognizable as anything else. He'd work out the rest of her too, if she asked: moving her, turning her, positioning her. If she needed her legs massaged, her neck cricked, her spine realigned, he did so with alacrity. Ditto if she needed her nails trimmed, her skin exfoliated, her eyebrows tweezed.

He'd even brushed her teeth once, which had been weird but also weirdly... erotic? He was so methodical. He worked the brush in a repetitive, almost hypnotic rhythm: back and forth, up and down. Twenty-five even strokes on the upper and lower teeth, fifteen strokes on the inside, and another ten to get all that gunk between her gums.

The sensation made Jinx's lips tingle and her tongue buzz. Her giggles throughout the operation were pure helium for his ego. He had no idea that by letting him help her, she was helping him help himself.

He had a lot of pain, too. And a lifetime's practice at denying it.

But Viktor could not deny her.

After the Change, he'd left off his stilted silences and terse civility. He'd stopped being curt. Stopped talking to her, too, like she was an unhinged brat with too many explosives and too little common sense.

Slowly, inexorably, he let slip the natural reserve that kept the world out—and kept his real self locked in.

His best self.

He showed it to Jinx in slices. He had a lovely reading voice. Jinx was a rotten reader—she had too many thoughts to follow any plot. But she could listen, if she concentrated really, really hard. Viktor was good at keeping her engaged. He had a soft, deep voice that was easy on the earholes. Its rhythm reminded Jinx of the sanding wheel in Silco's steelmill: slow, steady, precise. The Drekkengate accent had a lovely, lulling quality that put her right to sleep the way Mommy's lullabies used to.

And he could be funny. He had a wit that would've been dry as desert sand, except it was so painfully sincere you'd think he'd bled himself out to harvest every ounce. He'd tell her stories from his past. About the Academy. About Heimerdinger. About Talis.

They weren't always happy stories. But there was an honesty to them that Jinx—the trickster—couldn't help but covet as her own.

He told her about Sky.

Jinx listened, though the Change made his pain her pain. Made his guilt her guilt. Made her want to crawl out of her skin and set the rest of herself on fire.

Because she'd given him her pain, too. Like a present wrapped in pink foil, the edges of her psyche peeled off for his perusal. And he, Vik the Voracious, had eaten it raw. Everything—her childhood hurts, Mylo, Claggor and Vi, the Cannery, Vander in the burning alley, and most agonizing of all: Silco—Viktor had swallowed, and never spat out.

He kept the hurt. He held it for her. Same way Jinx held his own. They were a perfect circle: a circle of suffering. The snake eating its tail.

And the only way they'd ever find completion was to cut the circle in two.

Jinx couldn’t say that, either. So, on the nights when the circle closed too tight, a feedback loop of ow-ow-OW, Jinx would fake cataleptic fatigue, and send Viktor packing. It hurt her. It hurt him too. But the short nights apart, away from her spooks and his shadows, kept the circle from strangling them both.

Gave them each space to breathe.

Anyway, Viktor was Zaun's premier Machinist. He always had somewhere to be. A higher plane to ascend. One foot in the workshop; the other, in eternity.

Jinx knew he was busy with the post-disaster salvage effort. He was rebuilding the collapsed mining rig in the Deadlands; rebuilding the jellified bodies of the victims.

Rebuilding Zaun, one screw at a time.

And he was rebuilding himself along the way: reworking every foible; excising every flaw.

He'd finish it, too. Even if it killed him.

He was already a third gone: one arm, half a leg, a lung, three vertebrae's worth of spine. The augmentations were subtle; only someone as savvy as Jinx could spot the difference. But every replacement cost a pound of flesh. His body wasn't metamorphosing. It was nosediving, and Viktor had his hands all over the mothership's controls. Pulling levers. Pushing buttons. Steering the ship towards its final destination.

Not perfection.

Death.

Whereas Jinx was everywhere and nowhere at once. Trapped, as only perfection can trap.

#arcane#arcane league of legends#arcane silco#forward but never forget/xoxo#silco#forward (never forget)/xoxo#arcane jinx#jinx#arcane viktor#viktor#arcane singed#singed#jinx and viktor#vinx science bros#jinxtor

80 notes

·

View notes

Text

Avoiding Back EMF Feedback Need for BLDC Motor Controller

I had a eureka moment recently that I wanted to share. So basically I was thinking that I may not need to read back emf from a BLDC motor in my custom motor controller. Instead, I can have it just mindlessly advance the motor at a fairly low power mode by default and a default speed of advancement of the rotating electromagnetic field. Without feedback, it may overshoot, rotating faster than the output shaft and thereby skipping some turns. That is the reason why people want to read the back emf to avoid that issue and instead only advance the electromagnetic field forward at just the right moment - the zero point crossing moment. But I was thinking about it and realized that is not really necessary. For this application, if skips start happening, it doesn't really matter. To the degree that skips are happening, the motor will stop advancing the load with its winch system and this will show up when readings are taken by the potentiometer measuring the final joint angle. If alot of skips were taking place, the advancement of the potentiometer would not match the angle it thought it would be at were no skips involved and this would tell the motor controller that it has been having skips and give it an idea of how many skips as well based on the divergence of projected joint angle by now and actual joint angle by now. So then it would turn down the speed a bit or turn up the amount of on time of its pwm and thereby put more force into the rotating magnetic field to give a bit more oomph to the motor. It would then track progress by way of the potentiometer again and see if that solved it. If it still is skipping a fair amount that could indicate the load is more than expected or there is a jam in the system or it just needs more power and it could turn up the power more and slow the speed down more on its rotating magnetic field overall speed and try again. Rinse and repeat until it finds the sweet spot or finds out it simply cannot lift the load because its too heavy or there's a jam in the pulleys or w/e. So in a way then this would give it collision detection as well as the ability to have an idea of how heavy loads are based on how much it had to slow down and add forces to get the joint to move. I then see no real need to implement ANY back emf reading NOR any need for hall effect sensors etc to monitor rotation progress. The potentiometer on the final joint the motor is actuating is enough clues to tweak the rotating magnetic field to our satisfaction. By eliminating the back emf circuitry we greatly simplify the schematic of the motor controller, suffer negligible performance hit, and eliminate a lot of processing for the microcontroller chip handling the logic of many bldc motors simultaneously which means it can handle more bldc motors by itself. It doesn't get bogged down so much by having to read in all the zero point crossings as part of its routine. This saves on processing demands and processing speed demands. Getting this all to work in real time and perfecting it will require a fair bit of trial and error but this is how I'm seeing it working out and my proposed solution for simplifying things. I think it should work great! I'm excited to have much more dumbed down circuitry like this and to get to working on this soon. Just have to finish making my pulleys and then this electronics development can get underway again. That's why I've been thinking ahead about it a fair bit since it seems I'm likely nearing the end of solving the pulleys situation soon.

13 notes

·

View notes

Text

For future reference (my own and others), if your TI SilverLink USB cable stops working and starts showing up as "TUSB3410 Boot Device" or similar under device manager (AKA this issue on TI's help page), this is how you can fix it:

Download the TUSB3x10 EEPROM Burner. This is a Windows-only program, but to my knowledge will work on basically any windows machine from XP on -- so long as it's got USB ports. No clue if it'll work in a VM. (You might want to consult this user's manual.)

Download the SilverLink firmware. I got it from here, and compiled it from their de-compilation. It's just a standard 'make' to build. The output file you're looking for is called "ti_graph_link_silver.eep".

Rename "ti_graph_link_silver.eep" to "ti_graph_link_silver.bin".

Open the TUSB3x10 EEPROM Burner, click on the options dropdown and click "Show the 'Program Full Binary Image' button". (page 7 of the manual).

Select the entry under "Computer" labeled "TUSB3410 EEPROM Burner Instance (1.00)".

Set EEPROM size to "64Kb".

Set "File Path" to point to "ti_graph_link_silver.bin". (The renamed .eep, not the original .bin)

I don't know if the VID, PID, Manufacturer string, Product string and Serial # need to be set manually or not with a 'Full Binary Image' burn. Just to be safe, I set VID to 0451, PID to e001, Manufacturer to "Texas Instruments", Product to "TI-GRAPH LINK USB", and checked "Not Serialized"*.

Click the "Program Full Binary Image" button (yellow triangle with the exclamation point), and proceed with the write.

Unplug and re-plug your cable, and it should show up as a SilverLink again!

Additional notes:

The reason that this happens is because the SilverLink cable (revision b, at least) is based on the TUSB3410 microcontroller. That microcontroller's boot process involves checking for an I2C EEPROM containing program code. If it finds that EEPROM and its contents are properly formatted, it'll copy that code into internal RAM and start executing it. If it can't find the EEPROM, or its contents aren't properly formatted, it'll fall back to looking for boot code over USB. Thus: "TUSB3410 Boot Device". Your cable has, in essence, forgotten who it is and and is begging for you to give it a purpose.

The default page-write buffer size (32 bytes) and I2C bus speed (400 KHz) in the burner app are already correct, so no need to change them.

*I don't remember exactly what the Manufacturer string, Product string, or serial number fields were set to pre-corruption. Likewise, no idea about the advanced descriptor options. If someone wants to send the output of lsusb -v -s [whatever their silverlink's bus/id numbers are], I'd really appreciate it!

You might be able to skip the header rigamarole by taking the ti_graph_link_silver.bin file directly ("directly coming from the compiler") -- but I again I don't know exactly what information is in the .eep file and what isn't. Are the PID and VID encoded somewhere in there? I peeked with a hex editor but have no clue. If someone has hardware lying around they're willing to experiment with/potentially brick, I'd love to hear your results!

If you mess up and accidentally forget to do a "Full Binary Image" write, or otherwise brick the firmware, you can force the TUSB3410 to fall back to USB boot mode by opening the plastic shell around the PCB (one Torx screw under the sticker, then just normal plastic tabs) and shorting the right-bottom (Vss) and right-top (SDA), or right-bottom (Vss) and center right-top (SCL) pins of the EEPROM (the chip labeled "24LC64") as you plug it into the USB port. You may need multiple attempts. This works because it temporarily convinces the TUSB3410 that the EEPROM is missing/corrupt, and thus it decides to fall back into USB boot mode -- until you reset it. It might be better to do this with a ~1k resistor instead of a jumper wire, but IDK I'm not an electrical engineer. All I know is that shorting Vss and SDA worked for me. Again, would love feedback.

No clue what causes the corruption in the first place, or how long this fix will last. It might be because the EEPROM's write protect pin is set to "write enable"? It could also just be degrading hardware, for all I know, so no idea how long the fix will last. All I do know is that everything seems nominal right now (immediately after performing this procedure).

10 notes

·

View notes

Text

Daneel would totally be able to self-heal minor damage automatically, just like biological entities.

Wrote a bit about heating to heal in No Unnecessary Distinctions!

The team’s “muscle” — or actuator, the part of a robot that converts energy into physical movement — has three layers. The bottom one — the damage detection layer — is a soft electronic skin composed of liquid metal microdroplets embedded in a silicone elastomer. That skin is adhered to the middle layer, the self-healing component, which is a stiff thermoplastic elastomer. On top is the actuation layer, which kick-starts the muscle’s motion when pressurized with water.

To begin the process, the team induces five monitoring currents across the bottom “skin” of the muscle, which is connected to a microcontroller and sensing circuit. Puncture or pressure damage to that layer triggers formation of an electrical network between the traces. The system recognizes this electrical footprint as evidence of damage and subsequently increases the current running through the newly formed electrical network.

This enables that network to function as a local Joule heater, converting the energy of the electric current into heat around the areas of damage. After a few minutes, this heat melts and reprocesses the middle thermoplastic layer, which seals the damage — effectively self-healing the wound.

6 notes

·

View notes

Text

Smart Switches: Integrated microcontrollers for diagnostics (e.g., contact wear, cycle count) via IO-Link.

Enhanced Materials: Graphene coatings for lower contact resistance, self-lubricating polymers.

Haptic Feedback: Simulating different "click" feels electronically.

Sustainable Design: Recycled thermoplastics, lead-free plating, extended lifespan focus.

Miniaturization with High Power: Advanced contact materials enabling smaller 20A+ switches.

Custom Illumination: Full RGB LEDs with programmable patterns via embedded drivers.

2 notes

·

View notes

Text

Why Python Will Thrive: Future Trends and Applications

Python has already made a significant impact in the tech world, and its trajectory for the future is even more promising. From its simplicity and versatility to its widespread use in cutting-edge technologies, Python is expected to continue thriving in the coming years. Considering the kind support of Python Course in Chennai Whatever your level of experience or reason for switching from another programming language, learning Python gets much more fun.

Let's explore why Python will remain at the forefront of software development and what trends and applications will contribute to its ongoing dominance.

1. Artificial Intelligence and Machine Learning

Python is already the go-to language for AI and machine learning, and its role in these fields is set to expand further. With powerful libraries such as TensorFlow, PyTorch, and Scikit-learn, Python simplifies the development of machine learning models and artificial intelligence applications. As more industries integrate AI for automation, personalization, and predictive analytics, Python will remain a core language for developing intelligent systems.

2. Data Science and Big Data

Data science is one of the most significant areas where Python has excelled. Libraries like Pandas, NumPy, and Matplotlib make data manipulation and visualization simple and efficient. As companies and organizations continue to generate and analyze vast amounts of data, Python’s ability to process, clean, and visualize big data will only become more critical. Additionally, Python’s compatibility with big data platforms like Hadoop and Apache Spark ensures that it will remain a major player in data-driven decision-making.

3. Web Development

Python’s role in web development is growing thanks to frameworks like Django and Flask, which provide robust, scalable, and secure solutions for building web applications. With the increasing demand for interactive websites and APIs, Python is well-positioned to continue serving as a top language for backend development. Its integration with cloud computing platforms will also fuel its growth in building modern web applications that scale efficiently.

4. Automation and Scripting

Automation is another area where Python excels. Developers use Python to automate tasks ranging from system administration to testing and deployment. With the rise of DevOps practices and the growing demand for workflow automation, Python’s role in streamlining repetitive processes will continue to grow. Businesses across industries will rely on Python to boost productivity, reduce errors, and optimize performance. With the aid of Best Online Training & Placement Programs, which offer comprehensive training and job placement support to anyone looking to develop their talents, it’s easier to learn this tool and advance your career.

5. Cybersecurity and Ethical Hacking

With cyber threats becoming increasingly sophisticated, cybersecurity is a critical concern for businesses worldwide. Python is widely used for penetration testing, vulnerability scanning, and threat detection due to its simplicity and effectiveness. Libraries like Scapy and PyCrypto make Python an excellent choice for ethical hacking and security professionals. As the need for robust cybersecurity measures increases, Python’s role in safeguarding digital assets will continue to thrive.

6. Internet of Things (IoT)

Python’s compatibility with microcontrollers and embedded systems makes it a strong contender in the growing field of IoT. Frameworks like MicroPython and CircuitPython enable developers to build IoT applications efficiently, whether for home automation, smart cities, or industrial systems. As the number of connected devices continues to rise, Python will remain a dominant language for creating scalable and reliable IoT solutions.

7. Cloud Computing and Serverless Architectures

The rise of cloud computing and serverless architectures has created new opportunities for Python. Cloud platforms like AWS, Google Cloud, and Microsoft Azure all support Python, allowing developers to build scalable and cost-efficient applications. With its flexibility and integration capabilities, Python is perfectly suited for developing cloud-based applications, serverless functions, and microservices.

8. Gaming and Virtual Reality

Python has long been used in game development, with libraries such as Pygame offering simple tools to create 2D games. However, as gaming and virtual reality (VR) technologies evolve, Python’s role in developing immersive experiences will grow. The language’s ease of use and integration with game engines will make it a popular choice for building gaming platforms, VR applications, and simulations.

9. Expanding Job Market

As Python’s applications continue to grow, so does the demand for Python developers. From startups to tech giants like Google, Facebook, and Amazon, companies across industries are seeking professionals who are proficient in Python. The increasing adoption of Python in various fields, including data science, AI, cybersecurity, and cloud computing, ensures a thriving job market for Python developers in the future.

10. Constant Evolution and Community Support

Python’s open-source nature means that it’s constantly evolving with new libraries, frameworks, and features. Its vibrant community of developers contributes to its growth and ensures that Python stays relevant to emerging trends and technologies. Whether it’s a new tool for AI or a breakthrough in web development, Python’s community is always working to improve the language and make it more efficient for developers.

Conclusion

Python’s future is bright, with its presence continuing to grow in AI, data science, automation, web development, and beyond. As industries become increasingly data-driven, automated, and connected, Python’s simplicity, versatility, and strong community support make it an ideal choice for developers. Whether you are a beginner looking to start your coding journey or a seasoned professional exploring new career opportunities, learning Python offers long-term benefits in a rapidly evolving tech landscape.

#python course#python training#python#technology#tech#python programming#python online training#python online course#python online classes#python certification

2 notes

·

View notes

Text

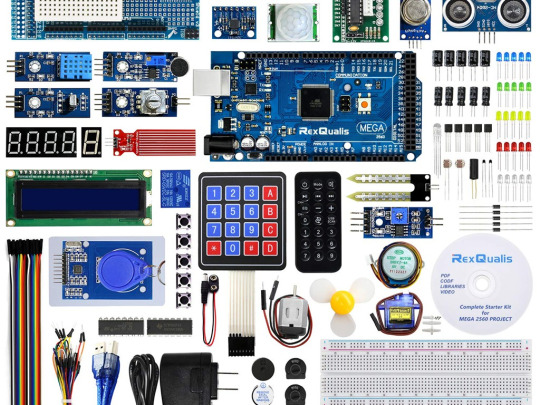

Arduino Mega 2560 Starter Learning Kit

The AINOW Arduino Mega 2560 Starter Learning Kit is an ideal choice for those interested in microcontrollers and electronic components. It includes instructional videos and a guidebook to make learning easy. The tutorials cover basic coding using Arduino software and operating electronic devices. Previous experience is not necessary as the kit teaches coding and working with electronics from the ground up. And, there’s no need for soldering skills – simply plug and play for a fun learning experience.

The main idea is that repetition should be avoided when rephrasing the following paragraph with the same tone.

A fantastic set suitable for all levels, from novice to advanced.

These components have versatile applications and are built for durability.

The kit contains a diverse range of materials to create a multitude of Endless Projects.

An excellent method to gain knowledge on sensors of both analog and digital varieties.

The characteristic is a prominent aspect that sets it apart and makes it stand out.

This kit is ideal for both novices and seasoned professionals in this particular area.

Our selection includes both Analog and Digital Sensors, perfect for those looking to make their own DIY projects.

Discovering the world of microcontrollers is a breeze with Arduino Mega 2560.

Our resources include a User Guide, Codes/Sample Programs & Reference books/Video Tutorials, and other valuable materials.

3 notes

·

View notes

Text

Understanding FPGA Architecture: Key Insights

Introduction to FPGA Architecture

Imagine having a circuit board that you could rewire and reconfigure as many times as you want. This adaptability is exactly what FPGAs offer. The world of electronics often seems complex and intimidating, but understanding FPGA architecture is simpler than you think. Let’s break it down step by step, making it easy for anyone to grasp the key concepts.

What Is an FPGA?

An FPGA, or Field Programmable Gate Array, is a type of integrated circuit that allows users to configure its hardware after manufacturing. Unlike traditional microcontrollers or processors that have fixed functionalities, FPGAs are highly flexible. You can think of them as a blank canvas for electrical circuits, ready to be customized according to your specific needs.

How FPGAs Are Different from CPUs and GPUs

You might wonder how FPGAs compare to CPUs or GPUs, which are more common in everyday devices like computers and gaming consoles. While CPUs are designed to handle general-purpose tasks and GPUs excel at parallel processing, FPGAs stand out because of their configurability. They don’t run pre-defined instructions like CPUs; instead, you configure the hardware directly to perform tasks efficiently.

Basic Building Blocks of an FPGA

To understand how an FPGA works, it’s important to know its basic components. FPGAs are made up of:

Programmable Logic Blocks (PLBs): These are the “brains” of the FPGA, where the logic functions are implemented.

Interconnects: These are the wires that connect the logic blocks.

Input/Output (I/O) blocks: These allow the FPGA to communicate with external devices.

These elements work together to create a flexible platform that can be customized for various applications.

Understanding Programmable Logic Blocks (PLBs)

The heart of an FPGA lies in its programmable logic blocks. These blocks contain the resources needed to implement logic functions, which are essentially the basic operations of any electronic circuit. In an FPGA, PLBs are programmed using hardware description languages (HDLs) like VHDL or Verilog, enabling users to specify how the FPGA should behave for their particular application.

What are Look-Up Tables (LUTs)?

Look-Up Tables (LUTs) are a critical component of the PLBs. Think of them as small memory units that can store predefined outputs for different input combinations. LUTs enable FPGAs to quickly execute logic operations by “looking up” the result of a computation rather than calculating it in real-time. This speeds up performance, making FPGAs efficient at performing complex tasks.

The Role of Flip-Flops in FPGA Architecture

Flip-flops are another essential building block within FPGAs. They are used for storing individual bits of data, which is crucial in sequential logic circuits. By storing and holding values, flip-flops help the FPGA maintain states and execute tasks in a particular order.

Routing and Interconnects: The Backbone of FPGAs

Routing and interconnects within an FPGA are akin to the nervous system in a human body, transmitting signals between different logic blocks. Without this network of connections, the logic blocks would be isolated and unable to communicate, making the FPGA useless. Routing ensures that signals flow correctly from one part of the FPGA to another, enabling the chip to perform coordinated functions.

Why are FPGAs So Versatile?

One of the standout features of FPGAs is their versatility. Whether you're building a 5G communication system, an advanced AI model, or a simple motor controller, an FPGA can be tailored to meet the exact requirements of your application. This versatility stems from the fact that FPGAs can be reprogrammed even after they are deployed, unlike traditional chips that are designed for one specific task.

FPGA Configuration: How Does It Work?

FPGAs are configured through a process called “programming” or “configuration.” This is typically done using a hardware description language like Verilog or VHDL, which allows engineers to specify the desired behavior of the FPGA. Once programmed, the FPGA configures its internal circuitry to match the logic defined in the code, essentially creating a custom-built processor for that particular application.

Real-World Applications of FPGAs

FPGAs are used in a wide range of industries, including:

Telecommunications: FPGAs play a crucial role in 5G networks, enabling fast data processing and efficient signal transmission.

Automotive: In modern vehicles, FPGAs are used for advanced driver assistance systems (ADAS), real-time image processing, and autonomous driving technologies.

Consumer Electronics: From smart TVs to gaming consoles, FPGAs are used to optimize performance in various devices.

Healthcare: Medical devices, such as MRI machines, use FPGAs for real-time image processing and data analysis.

FPGAs vs. ASICs: What’s the Difference?

FPGAs and ASICs (Application-Specific Integrated Circuits) are often compared because they both offer customizable hardware solutions. The key difference is that ASICs are custom-built for a specific task and cannot be reprogrammed after they are manufactured. FPGAs, on the other hand, offer the flexibility of being reconfigurable, making them a more versatile option for many applications.

Benefits of Using FPGAs

There are several benefits to using FPGAs, including:

Flexibility: FPGAs can be reprogrammed even after deployment, making them ideal for applications that may evolve over time.

Parallel Processing: FPGAs excel at performing multiple tasks simultaneously, making them faster for certain operations than CPUs or GPUs.

Customization: FPGAs allow for highly customized solutions, tailored to the specific needs of a project.

Challenges in FPGA Design

While FPGAs offer many advantages, they also come with some challenges:

Complexity: Designing an FPGA requires specialized knowledge of hardware description languages and digital logic.

Cost: FPGAs can be more expensive than traditional microprocessors, especially for small-scale applications.

Power Consumption: FPGAs can consume more power compared to ASICs, especially in high-performance applications.

Conclusion

Understanding FPGA architecture is crucial for anyone interested in modern electronics. These devices provide unmatched flexibility and performance in a variety of industries, from telecommunications to healthcare. Whether you're a tech enthusiast or someone looking to learn more about cutting-edge technology, FPGAs offer a fascinating glimpse into the future of computing.

2 notes

·

View notes

Text

Robotics Project Ideas for All Skill Levels: From Beginner to Advanced

Beginner Projects

Line Following Robot

Description: A robot that follows a pre-defined path marked by a line on the floor. The line can be of any color, but black on a white background is commonly used.

Components: Microcontroller (like Arduino), IR sensors, DC motors, motor driver, chassis, wheels.

Learning Outcomes: Basic electronics, sensor integration, and motor control.

Obstacle Avoidance Robot

Description: A robot designed to navigate its environment and avoid obstacles. It uses sensors to detect objects in its path and changes direction to avoid collisions.

Components: Ultrasonic sensors, microcontroller, motors, motor driver, chassis, wheels.

Learning Outcomes: Understanding of sensor data processing, basic programming, and control systems.

Bluetooth-Controlled Robot

Description: A robot that can be controlled via a smartphone or other Bluetooth-enabled devices. Commands are sent wirelessly to move the robot in different directions.

Components: Bluetooth module, microcontroller, motors, motor driver, chassis, wheels.

Learning Outcomes: Wireless communication, mobile app development, microcontroller programming.

Voice-Controlled Robot

Description: A robot that responds to voice commands, allowing you to control its movements through spoken instructions.

Components: Microphone, speech recognition module, microcontroller, motors, motor driver, chassis, wheels.

Learning Outcomes: Introduction to speech recognition, interfacing sensors, and control mechanisms.

Light Following Robot

Description: A robot that follows a light source. It can be used to follow a flashlight or navigate toward a lighted area.

Components: Light sensors, microcontroller, motors, motor driver, chassis, wheels.

Learning Outcomes: Sensor integration, basic electronics, programming.

Before next read this Robotic Revolution

Intermediate Projects

Self-Balancing Robot

Description: A robot that maintains its balance on two wheels, similar to a Segway. It uses sensors to detect its tilt and adjusts the motors to stay upright.

Components: Gyroscope, accelerometer, microcontroller, motors, motor driver, wheels.

Learning Outcomes: Understanding of feedback control systems, sensor fusion, and motor control.

Robotic Arm

Description: A robotic arm capable of performing simple tasks like picking and placing objects. It can be controlled manually or programmed to follow a sequence of movements.

Components: Servo motors, microcontroller, various sensors (like pressure or touch), structural components.

Learning Outcomes: Kinematics, servo control, programming for sequential tasks.

Maze-Solving Robot

Description: A robot that can navigate through a maze and find the exit. It uses algorithms to decide the best path and avoid dead ends.

Components: IR or ultrasonic sensors, microcontroller, motors, motor driver, chassis, wheels.

Learning Outcomes: Algorithm implementation, sensor data interpretation, navigation strategies.

Remote-Controlled Spy Robot

Description: A small robot equipped with a camera that can be controlled remotely to explore and send live video feed.

Components: Wireless camera, microcontroller, motors, motor driver, chassis, wheels, remote control.

Learning Outcomes: Wireless video transmission, remote control systems, motor and sensor integration.

Line Following Robot with Obstacle Detection

Description: A robot that not only follows a line but also detects and avoids obstacles on its path. It combines line following and obstacle avoidance features.

Components: IR sensors, ultrasonic sensors, microcontroller, motors, motor driver, chassis, wheels.

Learning Outcomes: Integration of multiple sensor data, complex programming logic, advanced control systems.

Advanced Projects

Humanoid Robot

Description: A robot designed to resemble a human body. It can perform tasks like walking, speaking, and interacting with its environment.

Components: Servo motors, microcontroller, sensors (accelerometer, gyroscope), structural components.

Learning Outcomes: Advanced kinematics, complex control algorithms, humanoid robotics.

Autonomous Delivery Robot

Description: A robot that can autonomously navigate to deliver packages within a designated area. It uses GPS and other sensors to determine its location and avoid obstacles.

Components: GPS module, ultrasonic sensors, camera, microcontroller, motors, motor driver, chassis, wheels.

Learning Outcomes: Autonomous navigation, path planning, integration of multiple sensors.

Robotic Exoskeleton

Description: A wearable robotic suit that can assist with movement, enhancing the strength and endurance of the user.

Components: Servo motors, sensors (like pressure, motion), microcontroller, structural components.

Learning Outcomes: Biomechanics, actuator control, wearable robotics.

Quadruped Robot

Description: A four-legged robot capable of walking, running, and navigating various terrains. It mimics the movement of animals like dogs or cats.

Components: Servo motors, microcontroller, sensors (accelerometer, gyroscope), structural components.

Learning Outcomes: Gait analysis, dynamic stability, complex movement programming.

Swarm Robotics

Description: A group of small robots that work together to complete tasks. They communicate and coordinate to achieve goals like collective exploration or object transport.

Components: Multiple small robots, communication modules, microcontroller, various sensors.

Learning Outcomes: Distributed systems, communication protocols, cooperative robotics.

2 notes

·

View notes

Text

Arduino Due vs. Mega: A Comprehensive Comparison

What is Arduino Due and Mega?

The Arduino platform has revolutionized the world of DIY electronics, providing hobbyists and professionals alike with versatile and powerful microcontroller boards. Among the myriad of options, the Arduino Due and Arduino Mega stand out for their advanced features and robust performance. The Arduino Due, introduced in 2012, is the first Arduino board based on a 32-bit ARM core microcontroller, the Atmel SAM3X8E. In contrast, the Arduino Mega, built around the 8-bit ATmega2560 microcontroller, is known for its abundant I/O pins and memory. Understanding the differences between these two boards can help in selecting the right one for specific projects, enhancing both functionality and efficiency.

Processing Power and Performance

The processing capabilities of the Arduino Due and Mega are distinctly different, primarily due to their core microcontrollers. The Arduino Due, with its 32-bit ARM Cortex-M3 processor running at 84 MHz, offers significantly higher processing power compared to the Arduino Mega's 8-bit ATmega2560, which operates at 16 MHz. This difference in architecture and clock speed means that the Due can handle more complex calculations and tasks faster and more efficiently than the Mega. For projects requiring high computational power, such as real-time data processing or handling multiple sensors simultaneously, the Due is the superior choice. However, for simpler tasks, the Mega's processing power may suffice.

Memory and Storage Capabilities

Memory is another critical aspect where the Arduino Due and Mega diverge. The Arduino Due is equipped with 512 KB of flash memory for code storage and 96 KB of SRAM for data. On the other hand, the Arduino Mega has 256 KB of flash memory and 8 KB of SRAM. Additionally, the Due features a Direct Memory Access (DMA) controller, which allows for efficient memory operations, freeing up the CPU to handle other tasks. These memory enhancements make the Due more suitable for applications requiring large codebases and significant data handling, such as advanced robotics or sophisticated control systems. The Mega, with its more modest memory, is ideal for less demanding applications.

Input/Output Capabilities and Expansion

Both the Arduino Due and Mega are renowned for their extensive input/output (I/O) capabilities, yet they cater to different needs. The Mega boasts a whopping 54 digital I/O pins, 16 analog inputs, and 4 UARTs, making it ideal for projects that require multiple sensors, actuators, or communication interfaces. The Due, while offering fewer digital I/O pins at 54, includes 12 analog inputs and 4 UARTs, along with additional features like two DAC outputs for analog signal generation and enhanced PWM capabilities. These features provide the Due with superior analog output capabilities, making it suitable for applications like audio processing or advanced signal generation.

Power Consumption and Compatibility

Power consumption and compatibility are practical considerations when choosing between the Arduino Due and Mega. The Due operates at 3.3V logic levels, which makes it more power-efficient than the Mega, which uses 5V logic levels. This lower voltage operation is beneficial for battery-powered projects where energy efficiency is crucial. However, the 3.3V logic also means that the Due is not directly compatible with 5V components without level shifters. The Mega, with its 5V logic, offers broader compatibility with existing Arduino shields and components, making it a versatile choice for a wide range of projects. Understanding these power and compatibility nuances can help in making an informed decision based on the project's specific requirements.

2 notes

·

View notes

Text

Image 1: a typical modern electric slime tram, with adorable "streamlining" and an Advanced Steam commuter train.

The steam engine is an Advanced steam engine with the gas generator boiler fired automatically using microcontrollers, with compound cylinders, steam super heaters, etc. The driver controls the locomotive electronically from a cab at either end of the train. Advanced steam engines were developed due to skyrocketing oil prices which drove up the price of electricity and made diesel hydraulics much less cost effective to operate. Old style steam locomotives would not have been considered up to snuff and the maintenance facilities for them had dwindled, but Advanced Steam sought to solve the maintenance and servicing problems. Most advanced steam was utilized for very large scale applications like freight hauls and migration trains, but the concepts could also be employed on smaller scales.

Image 2: Locomotives of the Slaibgloth Coal Mine. These comprise about 30 2-8-0+0-8-2 Garrats, 5 Shays, and 5 "easy" (non-articulated) locomotives utilizing spare engine sets from the Garrats and spare boilers from the Shays.

The Garrats were built in 2346 A.D. and retired in 2379 A.D. (two years ago) for service bringing coal carriages from the coal pits up to the interchange at the Glooiw & North Eastern. It is unusual for a coal burning steam engine to remain in revenue service--the majority that remained in use after the development of Diesel-Hydraulics were decommissioned with railway electrification and the ones that remained were mostly converted to oil burning. The Slaibsgloth steam engines meanwhile persisted right up until the closure of the coal mine. Glooiw & North Eastern has acquired the 40 locomotives. Their fates are uncertain but railway preservation groups remain optimistic.

#Mellanoid Slime Worldbuilding#Train#Steam train#steam engine#tram#trolley#railway#railroad#steam locomotive#steam train#Mellanoid slime worm#Slime Trains

12 notes

·

View notes

Text

Understanding the Functionality of Samsung Refrigerator PCB Main Assembly

Samsung refrigerators have become essential appliances in modern households, offering innovative features and advanced technologies to ensure food preservation and convenience. The (Printed Circuit Board) PCB Main Assembly serves as the brain of the refrigerator, coordinating various functions and ensuring optimal performance.

Components of the Refrigerator PCB Main Assembly

The Refrigerator PCB Main Assembly consists of several essential components, each playing a crucial role in the refrigerator's operation.

Microcontroller: It is the central processing unit (CPU) and the computer performs programmed instructions to coordinate communication between the components.

Sensors: The ambient parameters (temperature, humidity, door status) supply critical information for regulation.

Relays: You control the flow of electricity to the compressor, fan motors, and defrost heater.

Capacitors: It will help you store the electrical energy and help to regulate voltage, and guarantee that the PCB is operating reliably.

Resistors: Protect sensitive components from harm by limiting the flow of electricity across certain circuits.

Diodes: Allow current to flow exclusively in one direction to avoid reverse polarity and safeguard components from damage.

Connectors: Facilitate electrical connections between the PCB and other refrigerator components to ensure seamless integration.

Working Principle PCB Main Assembly

The PCB Main Assembly operates on a set of programmed instructions that determine its behavior depending on sensor input and user command. The micro controller continuously monitors sensor input such as the reading of the temperature from the refrigerator compartment, and freezer. The microcontroller controls the transition of the compressor on, or off or the speed of the fan and also the defrost cycles based on the sensor data as to how to keep the temperature and humidity at the optimal level. In addition to the other refrigerator components, for example, display panel and user interface, the PCB Main Assembly provides feedback and enables users’’ interaction. The PCB Main Assembly incorporates safety features of overload protection and temperature sensors to protect the refrigerator from damage and to protect the user.

Communication Protocols

Data can be communicated to other components through microcontrollers by communication protocols like UART (Universal Asynchronous Receiver Transmitter), SPI (Serial Peripheral Interface), and I2C (Inter Integrated Circuit).

UART is used to transfer real-time data from a microcontroller to external devices like display panels and temperature sensors.

There is a power of communication SPI and I2C for the communication of integrated circuits associated with the PCB Main Assembly for efficient data transfer and synchronization between components.

Troubleshooting and Maintenance

Common issues with the Samsung Refrigerator PCB Main Assembly include sensor failures, relay malfunctions, and power supply issues, which can affect the refrigerator's performance.

To solve PCB Main Assembly problems, we can use diagnostic methods, like running self-tests and checking the error code.

The assembly can stay longer depending on the main, such as cleaning dust and debris from the PCB and securing appropriate ventilation.

The PCB Main Assembly is an important component of the Samsung refrigerator systems since it organizes several functions to contribute to the overall efficiency of the refrigerator and food preservation. Fore-knowledge of the PCB Main Assembly and the way it is constructed can assist users in likely managing problems in their fridges.

2 notes

·

View notes

Text

Become an Embedded Systems Expert with Top-Rated Training at Technoscripts

The Embedded Training Program at Technoscripts is a comprehensive and immersive course designed to equip individuals with the essential skills and knowledge required to excel in the field of embedded systems. The program is 100% job-oriented, focusing on practical learning and real-world applications. It is available in both online and offline batches, making it accessible to students from all over the world.

The program is taught by industry experts with extensive experience in the field of embedded systems. They are passionate about sharing their knowledge with the next generation of embedded engineers and are committed to providing students with the best possible learning experience. The program covers a wide range of topics, including microcontrollers, digital signal processing, operating systems, and more.

One of the key features of the Embedded Training Program at Technoscripts is its emphasis on interview preparation. As part of the program, students will undergo intensive interview preparation sessions aimed at helping them land jobs in the embedded systems industry upon completion of the program. These sessions will include mock interviews, resume building workshops, and tips on how to effectively communicate technical concepts during interviews.

Throughout the program, students will participate in live projects, allowing them to apply their knowledge and gain valuable experience. These projects will expose students to real-world scenarios and enable them to demonstrate their problem-solving abilities. The program also includes regular assessments and feedback sessions, ensuring that students stay on track and make progress throughout the course.

In summary, the Embedded Training Program at Technoscripts is an exceptional opportunity for anyone looking to advance their career in the embedded systems industry. With a focus on practical learning and real-world applications, this program will provide students with the skills and knowledge needed to succeed in the rapidly evolving embedded systems industry. Its emphasis on interview preparation ensures that students are well-equipped to secure a job in the field upon completion of the program. So if you're ready to take your career to the next level, enroll in the Embedded Training Program at Technoscripts today!

#marketing#automotiveembeddedtestingcourse#automotiveembeddedsystemscourse#automotiveembeddedinstitute#automotiveembeddedcourse#python#machine learning#accounting#automotiveembeddedclasses#linux

2 notes

·

View notes

Text

Ignite Minds: The Power of STEM Robotics in Education

In today's technology-driven world, STEM robotics has emerged as a dynamic and engaging educational tool. Integrating STEM in robotics classrooms encourages creativity, critical thinking, and real-world problem-solving. At Technobotics, STEM robotics classes and robotics courses bring these benefits to life, making STEM education more exciting, relevant, and accessible for learners of all ages.

Why STEM Robotics Matters

The term STEM robotics combines science, technology, engineering, and mathematics with the hands-on construction of robots. This blend helps students:

Apply theoretical knowledge to tangible projects

Develop essential skills like coding, electronics, and mechanical design

Foster creativity and collaboration through team challenges

Prepare for future careers in engineering, AI, and automation

By integrating STEM in robotics, educators create an interactive learning experience that directly aligns with real-world industries. This is why STEM robotics classes are gaining popularity—and why parents and educators are more interested in robotics STEM education than ever before.

Robotics Courses by Technobotics

Technobotics specializes in equipping learners with the tools and knowledge to thrive in the world of STEM in robotics. Their structured robotics courses include:

Introductory Programs: Basic electronics, programming, and mechanical builds

Intermediate Tracks: Sensor integration, logic control, and robotics challenges

Advanced Workshops: AI-based programming, IoT-enabled robots, and competition training

This progressive approach ensures that whether a student is new to STEM robotics or ready for advanced robotics STEM education, they find the right course.

Benefits Students Gain

1. Strong STEM Foundations

By actively participating in STEM robotics, students solidify their understanding of scientific and technical concepts. They move from passive learning to active innovation.

2. Technological Literacy

Working with microcontrollers, sensors, and coding software builds confidence in modern technology—a skill increasingly required in today's job market.

3. Critical Soft Skills

Teamwork, patience, and communication are all naturally reinforced during robotics group projects, preparing students for future academic and professional environments.

4. Early Career Inspiration

Engaging with robotics in a STEM setting can spark a passion for careers in engineering, software development, or research in robotics. These courses can even lead learners toward career paths in tech.

5. Academic & Competitive Success

Students often perform better in science and math through robotics—plus, they gain confidence to participate in robotics competitions, which further enhance learning and motivation.

Choosing the Right Path: Factors to Consider

When exploring robotics STEM education, consider these points:

Curriculum Structure: Programs should offer progressive levels, from beginner to advanced, based on students' development.

Expert Instruction: Quality educators can tailor learning to individual needs and inspire curiosity.

Hands-on Experience: Look for courses that emphasize actual robot building and practical coding.

Technobotics fits these benchmarks, offering structured robotics courses that guide learners from basic understanding to innovative project execution.

Preparing for a Future in Robotics

With technology advancing rapidly, robotics courses give students a competitive edge. Skills learned in STEM robotics—problem-solving, coding, design thinking—are relevant in industries like manufacturing, healthcare, and even entertainment. By starting early, young learners gain a head start in a future filled with technological possibilities.

Your Next Step Toward Innovation

Take action today to bring STEM robotics into your learning environment:

For Parents: Enroll your child in a local robotics STEM course or club.

For Educators: Integrate robotics kits and modules into your curriculum or after-school offerings.

For Students: Start with beginner robotics and progress toward advanced robotics in STEM education programs.

By embracing robotics, you're not just teaching children—it's inspiring tomorrow's thinkers, creators, and problem-solvers.

Conclusion

STEM in robotics education isn't just a trend—it's a significant shift toward more interactive and relevant learning. Through Technobotics' thoughtfully designed robotics courses, learners gain confidence, foundational knowledge, and passion for innovation. As STEM and robotics continue to shape our future, equipping students today ensures a smarter, more capable generation ready for tomorrow's challenges.

Let's empower the next generation through STEM robotics—where science meets imagination and learning truly comes alive.

#STEMRobotics#RoboticsEducation#STEMLearning#FutureEngineers#RoboticsForKids#TechEducation#LearnToCode#RoboticsCourses#Technobotics

0 notes