#aerospace electronics

Explore tagged Tumblr posts

Text

Revolutionizing Aerospace Manufacturing: The Power of Advanced Technologies in Combustion Liner Production

In the dynamic and challenging landscape of aerospace manufacturing, the production of combustion liners stands as a critical component that demands utmost precision and reliability. A visionary team of engineers set out on a transformational journey to revolutionize the industry's approach to manufacturing aerospace combustion liners. By addressing complex challenges head-on, they not only resolved existing issues, but also propelled the company towards unparalleled success. This blog unveils their strategic triumphs and the remarkable impact created while providing actionable insights to optimize aerospace combustion liner production.

Unraveling Opportunities and Ingenious Solutions:

A Thorough Foundation: The journey began with a meticulous analysis of the initial input study for combustion liners, complemented by a comprehensive gap analysis. By identifying potential failure points and aligning processes with precise engineering requirements, the team laid a solid foundation for their subsequent endeavors.

Streamlined Process Design: Armed with invaluable insights, the team crafted an ingenious process design that maximized efficiency and accuracy in manufacturing combustion liners. An intuitive process flow diagram provided a holistic view of the production process, allowing the team to pinpoint optimization opportunities and enhance combustion liner quality.

Stage-Wise Manufacturing Mastery: A groundbreaking stage-wise manufacturing process emerged, comprising individual components of combustion liners, precise sub-assembly, and the final assembly of the combustion liner. Empowered by process-controlled tools featuring a foolproof poke-yoke mechanism, errors were minimized, and productivity soared.

Elevating Quality with CTQ Inspection Gauges: To surpass customer expectations and stringent aerospace standards, the team introduced stage-wise inspection gauges for Critical to Quality (CTQ) aspects in combustion liners. These precision tools became guardians of uncompromising quality, ensuring the final combustion liners met rigorous performance requirements. A Symphony of Control: A meticulously crafted control plan was orchestrated, harmoniously linking each manufacturing step of combustion liners to key inspections. This symphony of control guaranteed a flawless production process, eliminating rework and costly delays. Mastering Welding Challenges: Recognizing welding's significance in combustion liners, the team established a state-of-the-art welding cell. Welding operators underwent rigorous training and qualification, ensuring precision and consistency in every weld to enhance the combustion liner's structural integrity. The Crucible of Brazing and Heat Treating: Critical brazing and heat treatment processes found perfection under the watchful eye of a reliable and qualified source. These pivotal steps culminated in aerospace combustion liners of uncompromising durability and performance, ensuring optimal operation under demanding conditions.

Unleashing the Impact:

Time-Defying Triumph: The transformational project delivered combustion liners with exceptional efficiency, setting a new benchmark for aerospace manufacturing timelines.

Scaling Heights: With streamlined processes and enhanced capabilities, the team achieved awe-inspiring success by producing a considerable number of combustion liners. The optimized workflow exhibited its scalability and adaptability, driving productivity to soaring heights.

NADCAP-Certified Excellence: The pinnacle of achievements was the coveted NADCAP certification earned for the manufacturing of aerospace combustion liners. This prestigious recognition solidified the company's reputation as a trailblazer in combustion liner production.

Conclusion:

The journey of revolutionizing aerospace combustion liners showcased the potential and bold implementation. By harnessing the power of streamlined processes, meticulous quality control, and a dedicated team, the company realized exponential growth and customer satisfaction in aerospace combustion liner manufacturing.

To embark on your own path of transformation, embrace a holistic approach to process optimization, leverage NPI technologies, and invest in nurturing a skilled and committed workforce. In the ever-evolving aerospace industry, adaptation and continuous improvement are the wings that will propel you towards unrivaled success in aerospace combustion liner production. Now is the time to soar to new heights and unlock the true potential of your combustion liner endeavors.

#electronics#electronic manufacturer#quality#innovation#ems industry#manufacturing#ems company#industry#ems india#electronic contract manufacturing#Aerospace#aerospace components#aerospace combustion linear#component manufacturer#aerospace electronics#trendy#news#new post#avalontec#avalon#electronic manufacturing services#electronic manufacturing industry#electronic manufacturing company#usa#news of the day#blog

1 note

·

View note

Text

Electrifying the Future: The Evolution of Aerospace Electronics

The realm of aerospace electronics stands as the cornerstone of modern aviation and space exploration. This intricate field encapsulates a broad spectrum of electronic systems and technologies that power aircraft, satellites, rockets, and other spacecraft, enabling them to navigate, communicate, and function in the extreme conditions of the skies and beyond.

0 notes

Text

Honeywell Announces Intent to Separate Automation and Aerospace, Enabling the Creation of Three Industry-leading Companies

Honeywell Automation will be a pure play automation leader with global scale and a vast installed base Honeywell Aerospace will be a premier technology and systems provider enabling the future of aviation globally Advanced Materials, previously announced to be spun, will be a leading provider of sustainability-focused specialty chemicals and materials Separation of Automation and Aerospace to…

91 notes

·

View notes

Text

Trump confirms American F-35 contest with Russian Su-57 for India 5th Gen combat jet deal

By N. C. Bipindra New Delhi: It is official now. US President Donald Trump has effectively set up a contest between American F-35 and Russian Su-57 for India‘s big-ticket need for a fifth-generation fighter aircraft to catch up with arch-rival China on high-end combat jets. Trump, after meeting Indian Prime Minister Narendra Modi in Washington, D.C., announced that the US is offering India the…

#ADA#Advance Medium Combat Aircraft#AeroIndia#Aeronautical Development Agency#Aerospace#Air Force#aircraft carrier#AMCA#Andurill Industries#Anti-Tank Guided Missile#Army#Asia#Autonomous Systems#Autonomous Systems Industry Alliance#BEL#Bharat Electronics#Boeing Co.#CCS#China#Combat Jet#Defence#Defence Research and Development Organisation#Defense#Donald Trump#DRDO#Emmanuel Macron#F-16#F-21#F-35#Fifth Generation Fighter Aircraft

2 notes

·

View notes

Text

Elevating Excellence: The Significance of Embraer Parts in Aviation

Introduction:

In the realm of aviation, precision engineering and reliability are non-negotiable, and one company that has consistently embodied these principles is Embraer. Renowned for producing innovative and high-performance aircraft, Embraer parts are at the forefront of aviation technology. In this article, we delve into the world of Embraer parts, exploring their significance and the impact they have on the aviation industry.

Embraer parts refer to the components specifically designed and manufactured by Embraer for use in their aircraft models. These parts are meticulously crafted to meet stringent quality standards and are integral to the overall performance, safety, and efficiency of Embraer aircraft.

Importance of Embraer Parts:

Embraer parts play a pivotal role in the performance and safety of Embraer aircraft. Designed with precision and tailored to fit seamlessly within the aircraft's systems, these parts contribute to the overall reliability and longevity of Embraer models. Whether it's engines, avionics, or structural components, each Embraer part undergoes rigorous testing to ensure it meets the company's exacting standards.

The use of genuine Embraer parts is essential for maintaining airworthiness and complying with aviation regulations. Airlines, maintenance facilities, and operators worldwide rely on the quality and reliability of these parts to keep their Embraer aircraft in optimal condition. Choosing Embraer parts ensures compatibility, performance, and adherence to the manufacturer's specifications.

In conclusion, the significance of Embraer parts cannot be overstated in the aviation industry. These parts contribute not only to the individual performance of Embraer aircraft but also to the reputation of the company as a whole. The commitment to excellence and innovation exhibited by Embraer is reflected in the quality of their parts, making them a trusted choice for aviation professionals worldwide.

Conclusion:

Within the intricate web of aviation logistics and supply chain management, the concept of an Integrated NSN adds another layer of efficiency. This system streamlines the identification and procurement of Embraer parts, ensuring a standardized approach to inventory management and supply chain operations. An Integrated NSN simplifies the process of sourcing and acquiring Embraer parts, promoting a seamless flow of components throughout the aviation industry.

#aircraft parts suppliers#aerospace parts distributor#electronic parts supply#IT hardware accessories

2 notes

·

View notes

Text

u‑blox NEO-F9P RTK samples arrived 📍🌎 🗺

#adafruit#electronics#ublox#gnss#gps#tiny#iot#location#nav#connecteddevices#aerospace#automotive#marine#smol

2 notes

·

View notes

Text

Newcastle Industries specializes in high-performance Aerospace Electronics Connectors, supplying thousands of MIL-spec connectors, backshells, accessories, and tools tailored for precision and durability in mission-critical aerospace and defense systems . Trust their 30+ years of expertise to provide reliable, certified solutions for your connectivity needs—visit https://newcastleindustries.com/ to explore their full range.

#Aerospace Connector Solutions#Aerospace Electronics Connectors#Electronic Connectors Distributor#Connector Solutions for Aerospace

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

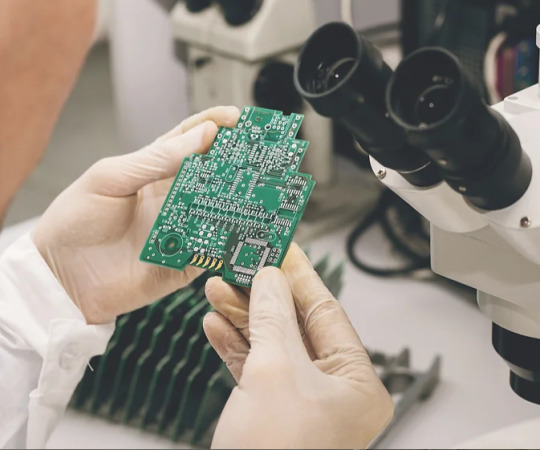

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions.

If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions. If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions.

If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

UAV Motor Components

Learn about the UAV motor components of an electric motor for a UAV and how it contributes to energy efficiency and overall performance.

#UAV Motor Components#drone propulsion system#brushless motor parts#electric UAV motors#drone motor design#UAV engineering#ePropelled UAV systems#What are UAV Electric Motors#Key Components of UAV Electric Motors#UAV electric motors#UAV motor systems#UAV Electric Motor Components#UAV motor#UAV#Drone Motors#Electric Propulsion#UAV Technology#Drone Engineering#ePropelled#UAV Components#Aerospace Innovation#electronic speed controller#ESC#unmanned aerial vehicles#epropelled solutions

0 notes

Text

#high-performance polymers used in aerospace applications#Medical device manufacturers using high performance polymers#Automotive industry demand for high temperature polymers#high-performance polymers for electrical and electronics#HPP materials for oil and gas industry components.

1 note

·

View note

Text

Variable Reluctance Market Size, Share, Trends, Opportunities, Key Drivers and Growth Prospectus

#market analysis#market report#market trends#Global Variable Reluctance Market - Size#Share#Demand#Industry Trends and Opportunities#Global Variable Reluctance Market#By Type (Single Stack Variable Reluctance Motor#Multi Stack Variable Reluctance Motor)#Applications (Telecommunication Equipment#Office Equipment#Medical Equipment#Industrial Automation#Consumer Electronics#Others) – Industry Trends.#Access Full 350 Pages PDF Report @#https://www.databridgemarketresearch.com/reports/global-variable-reluctance-market#**Segments**#- By Type: The variable reluctance market can be segmented by type into rotor and stator. The rotor segment is expected to witness signific#driving their adoption for diverse applications.#- By End-User: In terms of end-user#the variable reluctance market is divided into automotive#aerospace#industrial#electronics#and others. The automotive sector is anticipated to dominate the market share#attributed to the rising implementation of advanced technologies in modern vehicles. The aerospace industry is also expected to contribute#- By Region: Geographically#the market is segmented into North America

0 notes

Text

Shape Memory Alloy Market Set to Hit $45.4 Billion by 2035

The global Shape Memory Alloy (SMA) market is poised for remarkable growth, with industry revenue projected to increase from $14.3 billion in 2023 to $45.4 billion by 2035. This reflects a compound annual growth rate (CAGR) of 10.1% from 2023 to 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/shape-memory-alloy-market-research-report

Shape Memory Alloys are critical materials with the unique ability to return to a predetermined shape when exposed to heat. These materials are used across multiple industries, including biomedical, automotive, aerospace, and consumer electronics. The increasing demand for advanced, high-performance materials in healthcare, automotive, and aerospace applications is a key driver of market expansion.

Competitive Landscape and Market Leadership

The Shape Memory Alloy market is highly competitive, with several leading players at the forefront of innovation and market share growth. Notable companies in the market include:

Nitinol Devices & Components

Fort Wayne Metals

Confluent Medical Technologies

SAES Getters

ATI Metals

Carpenter Technology

Memry Corporation

Avient Corporation

Johnson Matthey

Daido Steel

Furukawa Electric

Nippon Steel

These companies are investing in cutting-edge technologies, expanding their manufacturing capabilities, and focusing on the development of high-performance alloys to cater to the growing demand across industries. With advancements in adaptive manufacturing and an increasing focus on sustainability, these market leaders are positioning themselves for long-term success.

Key Growth Drivers and Emerging Opportunities

Several factors are fueling the growth of the Shape Memory Alloy market:

Healthcare Demand: The increasing use of SMA in medical devices such as stents, implants, and surgical tools is driving significant demand in the biomedical sector.

Automotive Innovation: The automotive industry’s growing interest in lightweight, high-performance materials for fuel efficiency and safety is boosting the demand for SMAs, especially in smart actuators and components.

Aerospace Advancements: Aerospace applications, including actuators for flight control systems and adaptable components, are contributing to the market’s expansion.

Wearable Electronics: The rise of wearable electronics is creating new opportunities for SMAs, which can be used in flexible and adaptive devices.

Automotive Autonomy: As the automotive sector moves towards more autonomous vehicles, the demand for SMAs in systems like self-adjusting components and smart sensors is set to increase.

Regional Dynamics and Supply Chain Evolution

North America and Asia-Pacific are the two most prominent regions in the Shape Memory Alloy market, owing to strong manufacturing bases and substantial demand across key industries like automotive and healthcare.

However, emerging markets in India, Brazil, and Vietnam are expected to become increasingly important for market expansion, as they experience rapid industrialization and technological adoption. Companies are likely to make strategic investments in these regions to diversify revenue streams and capture growth opportunities.

Despite challenges related to cost constraints and technical limitations, the SMA market's supply chain—from raw material suppliers to end-user industries—is evolving. Industry players are focusing on improving efficiency and expanding their global reach, making advancements in both mature and emerging markets.

About DataString Consulting

DataString Consulting is a trusted provider of market research and business intelligence solutions, offering a full spectrum of services for both B2C and B2B markets. With over 30 years of combined industry experience, DataString specializes in delivering actionable insights that support strategic decision-making.

The firm’s expertise spans across multiple industries, and it provides tailored research services in strategy consulting, opportunity assessment, competitive intelligence, and market forecasting. DataString Consulting helps businesses navigate complex markets and capitalize on emerging trends to achieve sustained success.

#Shape Memory Alloy#SMA Market Growth#Shape Memory Alloy Market#Biomedical Applications#Automotive Innovation#Aerospace Applications#Consumer Electronics#High-performance Materials#Market Expansion#SMA Companies#Smart Materials#SMA Technology#Automotive Industry#Healthcare Devices#Wearable Electronics#Automotive Autonomy#Aerospace Advancements#Global Market Trends#Industry Leadership#Emerging Markets#Strategic Investments#Supply Chain Evolution#Market Research#DataString Consulting#Sustainability in Manufacturing#Global Business Intelligence

0 notes

Text

Top Contract Electronic Manufacturing Services

Discover top-tier contract electronic manufacturing services with East West Manufacturing Enterprises. Specializing in PCB assembly and complete product builds, we combine precision, quality, and efficiency to meet your manufacturing needs. Count on us for reliable solutions that ensure your products are built to the highest standards, helping you bring innovative ideas to market with confidence. Explore how our expertise can streamline your manufacturing process today!

#east west manufacturing austin#electronics manufacturers#electronics contract manufacturing#electronics manufacturing services#aerospace and defense manufacturing#defense electronics manufacturing#aftermarket services#east west electronics#integration system#system integration testing#Military Electronics Manufacturers#Electronic Contract Manufacturing Services#Contract Electronic Manufacturing Services#Cable and Wire Harness Assembly Services#Contract Electronic Manufacturing#Functional Testing Austin#Printed Circuit Board Assembly

0 notes

Text

Top 10 Applications of PTFE Plastics: From Aerospace to Medical Devices

Polytetrafluoroethylene (PTFE), also known as the “King of Plastics”, is an excellent engineering plastic known for its excellent chemical resistance, low friction coefficient, high temperature resistance and electrical insulation properties. These properties make it an ideal material for many industries, from aerospace to medical devices. This article will take you to explore the top 10…

#aerospace#automotive industry#chemical industry#chemical resistance#construction industry#Electrical Insulation#electronics and electrical#food processing#high temperature resistance#low friction coefficient#mechanical industry#medical equipment#PTFE plastics#textile industry

0 notes