#all types of roller manufacturer

Note

Hello! It’s been hot minute since you’ve done a fic rec …. sooo pretty pretty please bless us with one ?

Hi lovely anon! I'd love to do another rec list - I'm sorry it's taken me so long to get to answering this, but I hope you enjoy the selection. As always all these fics are andreil-centric unless stated otherwise, be mindful of tags and warnings and show all these writers some support!

Fluff

The One Where They Adopt The Cats by athousandstoriesleftuntold

Hold my hands tight by Faithpollen

You're Worth Losing a Bet by jaydreamz

Holy Ground by freshtaylorswiftduck

King of My Heart by marie_pothos

Lay All Your Love On Me by somebodytoundress

yeah i'll pay 7 dollars for that by archiveofourfoxes

Neil Josten, Sugar Daddy by tomat0head

When Neil Stole Andrew's Cats by LeosBrainrotvvv

Angst

You are in love by freshtaylorswiftduck (misunderstandings)

White Noise by Esmay_Writes (panic/anxiety)

Let's Go To the Beach by greencherrybomb (attempted assault)

the ticking of a heart by kariospy (depression, dissociation, panic attacks)

Broken Compass by JostenlovesMinyard (twinyard-centric, referenced abuse and assault)

So It Goes... by marie_pothos (light angst, mutual pining angst, mild sexual content)

Smut

Better than Sex by sillyunicorn6154

Floating with you by boredgojo (Bottom Andrew)

One Squeeze For Yes by bri_ghtly (aftercare)

Manufactured Urgency by andrewiel

No Kissing Challenge by zoellendraws

But I Can Try (If You Like It) by sambutwithbooks (fem andreil)

When I'm awake with you by TheseSmallDelights

you the type i wanna marry and keep you merry by miehczyslaw (fem andreil, omegaverse)

you are a masterpiece by coritkyo (bottom Andrew)

Longer

Little by Little by klarfire (incomplete, Neil and Nathaniel are twins, read tags for warnings)

Of Keyboards and Streams by PastelKnights (incomplete, streamer au)

100 days by doodlingstuff (incomplete, blind Andrew)

Who's your roommate? by neil_jos10 (Neil and Aaron are roommates, references to past abuse)

The Art of Being Human by kanekicure (merfolk au, part of the 'way down we go' series you should read itttt)

Growing pains of becoming a Real Person series by nightwalker4769 (Neil has a fear of needles)

A Tragic Beauty by rayla2tobe (incomplete, Sleeping Beauty au)

Absolute Favorites

roller rink kids (steady on your feet) by Major_816 (Mac is a god read all their works)

Thicker Than Water by Fortheloveofexy (vampire Andrew)

For The Dancing & The Dreaming by Tidalst (sorcerer Neil)

How to Write a Love Story by tomat0head (fake dating)

#jinger answers#jinger's recs#aftg#aftg fic rec#tfc#tfc fic rec#all for the game#all for the game fic rec#the foxhole court#andreil#andreil fic rec#andriel#andriel fic rec

430 notes

·

View notes

Text

Restoring a 1930s Typewriter + Some Scattered Thoughts

There’s something so magical about holding something this old in one’s hands. Who used it before? What feelings had it translated into words? How many families did it watch grow and scatter? How many houses has it survived?

A couple of months ago I set out to fulfill a lifelong dream of mine to have a vintage typewriter. One evening, I found a listing for this gorgeous piece for relatively cheap. I didn’t know much about the world of manual typewriters but I was eager to learn. And just like that, I was knee deep in a new hobby.

As soon as I got the machine, I went to work. I used cheap toothbrushes and Waschbenzin to clean the slugs. As it is really quite old, some gunk in between the characters were not lifting. I had to improvise and use a sewing needle to scrape the caked ink. I then removed the tattered old ribbon and replaced it with a new one.

I still have the task of cleaning and doing some small repairs on its leather case. And while the platen itself is still in really good condition the feed rollers have flat spots making it a bit temperamental when advancing the paper. I will have to find a specialty store that can replace them in the future. There are areas of chipped paint which should be quick enough to address with some black nail polish. And then for a final touch, it needs to be polished with car wax. But these tasks are secondary. The typewriter is fully working despite its age. It was incredible seeing it come to life the first time I used it. It felt like a fantasy, like time travel.

Throughout the whole process of cleaning and repairing my typewriter, I was constantly reminded that this machine is 87 years old. The curved cover, the font on the decal and the simplicity encapsulates the art deco style from that era. WWII was just starting when this was manufactured. My grandfather wasn’t even born yet. Working with this typewriter was a meditative experience but it also brought on a lot of melancholy thoughts on existence, technology, consumerism.

You can just tell how much thought and care was put into building this typewriter. It’s innovation with purpose, not solely for profit. This machine’s ribbons feed from right to left. Once it is completely wound to one side, there is a button that reverses the gears and the ribbon will then feed from left to right, ensuring that the ink in the ribbon is used up without any waste. There is a button that allows you to type beyond your set margins in case it’s necessary. There is a lever that centers the platen and disengages the margin bell in order to prevent it from jiggling around and breaking while in transport. There is a self-starter key which is practically a tab button. The case comes with clamps that keep the typewriter from moving around. It also allows you to type with the case attached.

The manufacturers and innovators of that time thought about everything. Technology is meant to last. It is meant to address as many problems as possible, and meant to stand alone without needing more attachments. Back in the day, when you purchase something, it’s meant to last your lifetime, if not beyond. Just the fact that it still works after all this time is a testament to the integrity of its creation.

87 years from now, what will our era have left for the future? What will be left of our time when iPhones self destruct every two years to force purchase of the newest model? What will the future generation seek out to repair and refurbish from our time that isn’t made of plastic? What would be “vintage” to them when everything is made to break?

19 notes

·

View notes

Text

What am I even doing I don't know how to write articles...

The name Seto Kaiba may not be familiar to most of our readers. I admit, when I received this assignment, I had to google his name. What I found seemed like a fictional story.

Orphaned at a young age, Seto Kaiba found himself adopted by the founder of Kaiba Corporation after beating him at a game of chess. At the time, the company manufactured weapons. However, Kaiba made headlines at the age of 16 when he took control of Kaiba Corporation and turned it into a gaming company. Many believed that by dismantling a successful company, Kaiba was guaranteeing bankruptcy, but he proved them wrong, and today, Kaiba Corp is a household name in Japan.

With his cutting edge technology, Kaiba plans to make his company a household name worldwide. Currently, he plans to expand his reach to the United States with Kaiba Land, an amusement park dedicated to showing off his games and technology.

At first, I was convinced his park would be a rip off of Disneyland. However, I was able to visit prior to the official opening and experience the park for myself. I can say with confidence that Kaiba Land is in a league of its own.

In Kaiba Land, children can live out their wildest fantasies. Seto Kaiba, a visionary when it comes to technology, has equipped his park with the best his company has to offer. The virtual reality simulators allow you to visit anywhere in the world at any point in history that you desire. I was able to visit ancient Egypt and see the pyramids in all their glory.

If you want to visit somewhere fictional, you can do that too. I was able to experience flying on a dragon in a medieval-type setting.

You can even fly to space to explore the moon if that’s something that interests you.

Besides being able to live out your wildest fantasies, Kaiba Land also has an entire arcade section dedicated to gaming. Classic games are lined up side-by-side with Kaiba Corp. games.

Kaiba Land also has a few rides available. They have a dragon-themed roller coaster and a ferris wheel.

Regarding Kaiba Land, Seto Kaiba had this to say:

“I want Kaiba Land to be a place where any child can come and visit no matter how rich or poor their parents are. We’re committed to providing free access to anyone in the foster system as well as children without parents.”

If Kaiba Land is any indication of what Seto Kaiba has to offer, he should become a household name worldwide in no time. Our readers can purchase discounted early access tickets via our website.

#dragonsilk#please feedback please#I have never done any sort of nonfiction writing in my life#I don't know what I'm doing

12 notes

·

View notes

Text

a little bunny lore for you all:

the coaster i’m about to go on is my favourite coaster in the world. i rode her for the first time 10 years ago and she started my love of rollercoasters. she was shut last year for refurbishment and they’ve completely rethemed the whole area based on the lore of the roller coaster (which they also updated). it’s her 30 year anniversary and she is beautiful!!!!

she’s a b&m inverted coaster (the first one outside of the US) which is probably my favourite type of coaster. i have a lot of respect for b&m as coaster manufacturers and designers; a lot of the features they implement in their rides are specific to b&m and i just think that’s so cool!!!!!!

19 notes

·

View notes

Text

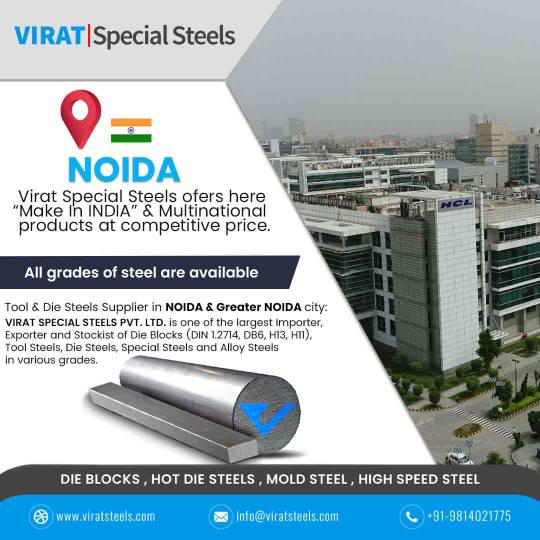

Exciting News for Noida & Greater Noida Industries! 🔥

VIRAT SPECIAL STEELS PVT. LIMITED , INDIA is thrilled to announce that we are now supplying SPECIAL STEELS directly to Noida and Greater Noida! 🌟

🏭 Whether you're a large car manufacturer, an engineering unit, or even a micro-industry, our high-quality special steels are crucial for your production needs. From heavy vehicle components to precision engineering, our steels are designed to meet your toughest requirements.

🔧As one of India's top suppliers of Tool Steel, Die Steel, and Mould Steel, we also offer a comprehensive range of special steel grades to cater to your specific needs.

Product List:

DIE STEEL ( HH 370 - 410 BHN ) (DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

🚗🔩 Our product range is perfect for:

Heavy vehicle, tractors, and automobile transmission parts

General engineering applications

Ball and roller bearings, gears of all types

Camshafts, universal joints, driving pinions

Link components, axles, arbours

Gear shafts and spinning tools

📍 Located near Noida in Gurgaon, our headquarters are at the heart of India's industrial hub, ensuring quick and reliable service.

🤝 Let Virat Special Steels be your trusted partner in driving industrial growth in the Noida and Greater Noida region.

For more information visit:

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-noida/

Contact us today to discuss your special steel needs and how we can help propel your projects forward!

📞+91-98140 21775 🌐www.viratsteels.com 📩 [email protected]

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#noida#GreaterNoida#SpecialSteels#ColdWorkSteels#HighSpeedSteels#SteelTrades

2 notes

·

View notes

Text

JWZ-BM05D/12D/20D Double Station Blow Molding Machine

Performance and advantages

1. Suitable for producing 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc.

2. Optional multi-layer co-extrusion.

3. Optional view strip line system.

4. According to the product size,select different cavity of die head.

5. According to the different material,optional JW-DB single station hydraulic screen-exchanger system.

6. According to customer's requirement,optional auto-deflashing on line,scrap conveying on line,finished product conveying on line.

Technical Parameters

Model

Unit

BM05D

BM12D

BM20D

Max product volume

L

5

12

20

Dry cycle

Pc/h

700*2

600*2

600*2

Die head structure

Continuous type

Main screw diameter

mm

75

90

90

Max plasticizing capacity (PE)

kg/h

90

160

160

Driving motor

Kw

30

45

45

Oil pump motor power

Kw

11

15

15

Clamping force

KN

70

120

160

Space between platen

mm

150-510

240-640

280-680

Platen size W*H

mm

350*400

450*500

500*520

Max.mould size

mm

360*400

500*520

560*520

Platen moving stroke

mm

450/520

600/650

650

Heating power of die head

Kw

7.5

10

12.5

Machine dimension L*W*H

m

3.7*3.1*2.7

4.2*3.2*3.0

4.3*3.2*3.1

Machine weight

T

8.5

12

14

Total power

Kw

60

90

93

Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements.

Product image display

JWELL Co., Ltd. was founded in 1978, the Chinese biggest plastic extrusion machinery manufacturers with over 24 years in extrusion industry .Now we have 6 production base , more than 3000 employees, having a strong technical & after sales service team for serving more than 150 countries.

Core components: screw and barrel, mold, roller, all processed by us. jwell group has 16 professional branches, each of which produces different products, You can get all the plastic extrusion equipments you need in jwell company and provide you with one-stop service.

Our processing equipment is all CNC imported from Japan and Europe.

The steel used in our machine is superior to our peers. For the same equipment, the lifetime of jwell company's equipment is generally two or three times longer than our peers.

The electrical components used in our equipment are imported brands or Chinese famous brands, and they are specially optimized and designed according to the requirements of jwell company, which can well match our equipment. Other companies do not have such strength and influence.

There is an old saying in China:You get what you pay for!

Read the full article

2 notes

·

View notes

Text

Roller Skates - Tricks and Tips To Choose For Beginners

If you’re new to roller skating, it can be difficult to know what kind of roller skates online Australia you need. There are so many different types of roller skates available—from classic quads to modern inline skates—that it can be overwhelming trying to figure out which one is right for you. To help you out, here are five tricks and tips to choose the perfect roller skates for beginners.

-

Determine Your Skill Level -

One of the most important things to consider when buying your first pair of roller skates Australia is your level of skill. Are you a beginner or an experienced rider? Different skate types are designed for different levels of riders; if you buy a pair that is too advanced, you’ll have difficulty controlling them and may even injure yourself. On the other hand, if you buy a pair that is too basic, then they won’t provide enough support or challenge as your skills improve. Consider where your skills currently lie and pick a skate type accordingly.

-

Choose Quality Skates –

Quality is key when it comes to choosing the perfect pair of roller skates. Cheaply-made skates often break quickly or become uncomfortable after only a few uses due to poor design or materials that wear down easily. Investing in quality skates will ensure that they last longer and are more comfortable while also providing better control and stability on the rink floor.

-

Consider Comfort –

When selecting your first pair of roller skates, don’t forget about comfort! You’ll want a pair that fits properly without being too tight or too loose; if they fit badly, then they won’t provide adequate support while skating and may cause discomfort or even injury over time. It’s also important to make sure that your feet don’t slip around inside the skate; if they do, then you won’t be able to control your movements effectively while skating at higher speeds or performing tricks in the park.

-

Think About Style –

Beyond just functionality, style should also play into which pair of roller skates you choose for yourself; after all, what good are nice-looking but uncomfortable shoes? No matter what type of skate you go with (quad/inline/etc), make sure that its design appeals to your personal taste so that it looks great but still provides enough support for proper skating performance as well!

-

Try Before You Buy –

Whenever possible, try on any potential pairs of roller skates Australia before making a purchase decision—this way, you can get an idea of how well they fit without having to commit right away! Whenever possible (when shopping online) look at sizing charts provided by each manufacturer so that you can get an idea ahead of time as well as narrow down which size might work best based on measurements taken from both feet (as sizes may vary).

Conclusion:

Choosing the perfect pair of roller skates requires careful consideration—you want something stylish yet supportive; comfortable yet functional; affordable yet durable—so take some time when selecting yours! With these five tricks and tips in mind, we hope it will be easier for beginner roller-skaters like yourself to find exactly what they need! Good luck!

If you want to know more about it, you can visit our website at https://socalskates.com.au/

Read the full article

2 notes

·

View notes

Text

Comprehensive Guide to Bending Machines and Presses for Industrial Applications

Introduction

In the world of metalworking, precision, power, and reliability are key. Whether it’s bending profiles, shaping pipes, or pressing metal sheets, having the right tools can make all the difference. Bending machines and hydraulic presses are integral to industries like construction, automotive, aerospace, and electrical manufacturing. These machines allow for seamless and accurate manipulation of metal components, ensuring that complex designs and specifications are met efficiently. Let’s dive into the different types of bending machines and presses and explore how they’re used in various industrial applications.

Profile Bending Machines

A Profile Bending Machine is designed to bend metal profiles, such as angles, T-profiles, U-profiles, and more, into curved shapes. These machines are crucial for industries that require specific curved metal components, such as construction and automotive manufacturing. They can handle various sizes and thicknesses of metal profiles, ensuring precision in every bend.

Hydraulic Profile Bending Machine

A Hydraulic Profile Bending Machine utilizes the power of hydraulics to bend metal profiles. The hydraulic system provides more force and allows for smoother, more controlled bending compared to purely mechanical systems. This makes hydraulic bending machines ideal for heavier profiles or materials that require more precision and force during the bending process.

Pipe Bender

A Pipe Bender is an essential tool for industries such as plumbing, HVAC, and automotive, where precise bends in metal pipes are required. Pipe benders are used to create bends without the need for welding, maintaining the integrity of the pipe. They can be manual, electric, or hydraulic, depending on the scale and precision required for the task.

Pipe Bending Machine

Unlike manual pipe benders, a Pipe Bending Machine automates the bending process, ensuring uniformity and precision in each bend. These machines are widely used in industries where high volumes of bent pipes are needed, such as in the production of exhaust systems or frames for heavy machinery.

Fly Press Machines

Fly Presses are manually operated machines used to press or shape materials, typically metals. They are known for their simplicity, reliability, and precision. There are several types of fly presses, each designed for different applications:

Double Body Fly Press

The Double Body Fly Press is a robust machine designed for heavier operations. It provides more stability and power, making it ideal for tasks that require more force, such as stamping or punching thicker metal sheets.

Single Body Fly Press

The Single Body Fly Press is more compact and lightweight compared to its double-body counterpart. It's ideal for light metalworking tasks that don’t require as much force, such as small stamping or light embossing jobs.

Steel Body Fly Press

A Steel Body Fly Press is built entirely from steel, offering superior durability and strength. It’s favored in industries that require prolonged use and consistent performance under demanding conditions.

Mechanical Profile Bending Machine

A Mechanical Profile Bending Machine operates using mechanical systems to bend metal profiles. These machines are typically manual but can be automated in some models. They are suitable for simpler bending tasks where less force is required compared to hydraulic models.

Pyramid Type Bending Roller

A Pyramid Type Bending Roller is a specific type of bending machine where the metal is passed through three rollers arranged in a pyramid formation. This setup allows for gradual bending, ideal for creating smooth curves in metal sheets or profiles.

Hydro-Mechanical Plate Bending Machines

Combining both hydraulic and mechanical systems, Hydro-Mechanical Plate Bending Machines are used for bending thick metal plates. The hydraulic system provides the power, while the mechanical system ensures precision. These machines are commonly used in industries that deal with large, heavy metal sheets.

3 Roll Plate Bending Hydro-Mechanical Double Pre-Pinch

The 3 Roll Plate Bending Hydro-Mechanical Double Pre-Pinch machine offers the advantage of pre-pinch bending, meaning the material is pre-bent at the edges before the final bend is made. This feature allows for more precise control over the shape and prevents unwanted deformation.

Plate Bending Machines

A Plate Bending Machine is designed specifically for bending metal plates. Whether it's rolling, forming, or curving, plate bending machines are critical in shipbuilding, automotive, and heavy machinery manufacturing. These machines ensure uniform bending, reducing the risk of cracks or splits.

3 Roll Pyramid Type Hydro-Mechanical Plate Bending

This machine uses a three-roll pyramid configuration to bend metal plates. The addition of hydraulic systems allows for more precise bending of larger, thicker plates, making it ideal for heavy-duty applications.

Mechanical Plate Bending Machine

The Mechanical Plate Bending Machine is driven entirely by mechanical systems, making it ideal for smaller, less complex bending tasks. It’s typically used for lighter materials where high precision is still required.

Bus Bar Bending-Cutting-Punching Machine

A Bus Bar Bending-Cutting-Punching Machine is a versatile machine that allows for the bending, cutting, and punching of bus bars, which are used in electrical applications to distribute power. This multifunctionality makes it a time-saving solution in electrical fabrication.

Bus Bar in Electrical Applications

Bus Bars are conductive strips used in electrical distribution systems to manage and distribute power. They are essential in industries that require large-scale power distribution, such as manufacturing plants and power stations.

Metal Sheet Bending Machine

A Metal Sheet Bending Machine is used to bend or shape flat metal sheets into various forms. These machines are vital in producing metal housings, frames, and other components used in countless industrial and commercial products.

Folding Machines and Trunk Folding Machines

Folding Machines are specialized tools for folding metal sheets along a straight line. Trunk Folding Machines are a subset of these machines designed for more complex folding tasks, such as creating seams or intricate bends in metal sheets used in vehicle trunks or containers.

Hydraulic Presses

A Hydraulic Press uses hydraulic pressure to exert force on a material, making it ideal for tasks that require a lot of power, such as stamping, pressing, or forging metal components. They are more versatile than mechanical presses and can handle a wider range of tasks.

H Type Power Operated Hydraulic Press

The H Type Power Operated Hydraulic Press is a heavy-duty press designed for industrial applications that require significant force. Its H-frame construction ensures stability and precision during operation.

H Type and C Type Hydraulic Presses

Both H Type and C Type Hydraulic Presses are commonly used in metalworking. The main difference is in their construction: H Type presses offer more support and are better suited for larger tasks, while C Type presses are more compact, making them ideal for smaller tasks.

Iron Workers and Hydraulic Iron Workers

Iron Workers are machines used for cutting, punching, bending, and shaping metal. Hydraulic Iron Workers use hydraulic power for these tasks, offering more force and precision, which is essential for thicker or tougher materials.

Nibbling Machines

A Nibbling Machine is used to make small cuts in metal sheets, creating intricate shapes or patterns. These machines are particularly useful for tasks that require precision and detail, such as cutting out complex designs in metal plates.

Conclusion

Choosing the right bending machine or press depends on the specific requirements of your project. Whether you're working with large metal plates, delicate bus bars, or intricate profiles, there is a machine tailored to meet your needs. Understanding the various types of bending and pressing machines available can significantly improve efficiency, precision, and the quality of your final product.

youtube

0 notes

Text

Get the High Performance 3-Phase Linear/Roller-Type Servo Regulator at a Competitive Price!

Experience the optimal performance of a three phase linear voltage stabilizer from Shakti Electronics, the leading manufacturer in Jaipur, India. These linear types stabilizer are designed for efficient and stable performance for all electronic applications. For orders, visit our website and get a free quote!

Contact Us: +91-9829059997

Visit Our Website: https://www.shaktiecorp.com/linear-types-stabilizer.php

1 note

·

View note

Text

From Idea to Product: The Journey of a Sanitary Pad Making Machine

The journey from an initial idea to a fully functional sanitary pad-making machine is a complex and fascinating process. It involves meticulous planning, cutting-edge technology, and a deep understanding of both engineering and sanitary product requirements. This blog will walk you through the stages of developing a sanitary pad-making machine, from conception to production, highlighting the challenges and innovations along the way.

1. Conceptualization and Design

Identifying the Need

The journey begins with identifying the need for a sanitary pad-making machine. This need could arise from various sources, such as a growing demand for affordable menstrual hygiene products, a desire to introduce advanced technology, or the push for eco-friendly solutions.

Initial Research

Once the need is established, thorough research is conducted. This involves understanding:

Market Requirements: Identifying the features required by manufacturers and end-users, such as production capacity, pad types (e.g., regular, overnight, pantyliners), and customization options.

Material Specifications: Determining the types of materials the machine needs to handle, including organic cotton, bamboo fibers, or conventional materials.

Technological Innovations: Exploring advancements in automation, quality control, and environmental sustainability.

Design and Prototyping

The design phase involves creating detailed blueprints and schematics of the machine. Engineers and designers work together to:

Develop a Functional Layout: Designing the machine’s components, such as the feeding system, cutting and sealing mechanisms, and packing units.

Prototype Development: Building a prototype to test the design and make necessary adjustments. This prototype helps in validating the concept and functionality of the machine.

2. Engineering and Manufacturing

Engineering the Machine

With the prototype validated, the machine moves into the engineering phase. Key aspects include:

Mechanical Design: Ensuring the machine’s mechanical components are robust and reliable. This includes designing the frame, rollers, and cutting mechanisms.

Automation Integration: Incorporating automation technologies to enhance efficiency and precision. This involves integrating sensors, PLCs (Programmable Logic Controllers), and robotics.

Material Handling Systems: Designing systems for feeding, transporting, and processing raw materials, ensuring smooth operation throughout the production process.

Manufacturing

The manufacturing process involves:

Component Fabrication: Producing individual components, such as metal parts, electronic systems, and specialized tools.

Assembly: Assembling the machine parts into a complete unit. This step requires precision to ensure all components fit and function correctly.

Quality Control: Implementing rigorous quality checks to ensure the machine meets design specifications and safety standards. This includes testing for performance, durability, and safety.

3. Testing and Optimization

Functional Testing

Once assembled, the machine undergoes extensive testing to ensure it performs as expected. This includes:

Operational Testing: Running the machine through its paces to test its performance in real-world conditions. This involves checking for consistency in pad production, accuracy in cutting and sealing, and overall efficiency.

Material Compatibility: Testing the machine with various raw materials to ensure it handles different types of inputs effectively.

Optimization

Based on the test results, engineers make adjustments to improve the machine’s performance. This can involve:

Fine-Tuning Components: Adjusting settings and components to enhance accuracy and efficiency.

Software Upgrades: Updating software to improve automation and control systems.

4. Implementation and Training

Installation

Once the machine is finalized, it is installed at the manufacturer’s facility. This includes:

Site Preparation: Ensuring the installation site meets the machine’s requirements, such as space, power supply, and ventilation.

Machine Setup: Installing and calibrating the machine to ensure it operates correctly in its new environment.

Training

Training is crucial to ensure that operators can effectively use the machine. This involves:

Operator Training: Providing training sessions on machine operation, maintenance, and troubleshooting.

Technical Support: Offering ongoing support to address any issues that arise during the initial production runs.

5. Production and Feedback

Starting Production

With the machine installed and operators trained, production begins. The focus shifts to:

Monitoring Performance: Continuously monitoring the machine’s performance to ensure it meets production targets and quality standards.

Quality Assurance: Implementing quality control measures to ensure that the sanitary pads produced are consistent and meet safety standards.

Collecting Feedback

Feedback from operators and end-users is invaluable for continuous improvement. This involves:

Performance Reviews: Regularly assessing the machine’s performance and addressing any issues that arise.

User Feedback: Gathering feedback from operators and manufacturers to identify areas for enhancement and innovation.

Conclusion

The journey of a sanitary pad-making machine from idea to product is a testament to the intersection of innovation, engineering, and manufacturing. From initial concept and design to testing, implementation, and production, each stage plays a crucial role in creating a machine that meets the needs of modern sanitary pad production. As technology continues to advance, future machines will likely incorporate even more sophisticated features, further enhancing efficiency, sustainability, and product quality. Understanding this journey not only highlights the complexity of the manufacturing process but also emphasizes the importance of ongoing innovation in meeting global needs for menstrual hygiene.

0 notes

Text

How to Paint a Warehouse Floor: A Step-by-Step Guide

Painting a warehouse floor is a task that requires careful planning, the right tools, and proper execution to ensure a durable, safe, and professional finish. Whether you're looking to improve the aesthetic appeal, enhance safety, or protect the floor from wear and tear, a well-painted warehouse floor can make a big difference.

This guide will walk you through the process of painting a warehouse floor, covering preparation, tools, application, and post-paint care.

1. Why Paint a Warehouse Floor?

Painting your warehouse floor offers several benefits:

Protection: A high-quality epoxy or concrete paint creates a protective layer, preventing wear from foot traffic, forklifts, and other equipment.

Safety: Using non-slip paint can improve traction and reduce the risk of accidents.

Aesthetics: A fresh coat of paint gives the warehouse a cleaner, more professional appearance.

Ease of Maintenance: Painted floors are easier to clean and maintain, reducing dust and debris build-up.

2. Tools and Materials You'll Need

Before you start, gather all the necessary tools and materials:

Epoxy or Polyurethane Paint: Designed for concrete or industrial floors, it offers durability and resistance to chemicals and abrasion.

Concrete Cleaner: To remove grease, oil, and other stains before painting.

Pressure Washer: To thoroughly clean the floor.

Concrete Patch: For filling cracks and holes in the floor.

Painter’s Tape: To mark off edges and areas you don’t want to paint.

Primer: Helps the paint adhere better to the concrete.

Paint Roller: Preferably one with an extension handle to cover large areas.

Paint Trays: To hold the paint during application.

Safety Equipment: Gloves, goggles, and a respirator to protect yourself from fumes and dust.

3. Preparing the Warehouse Floor

Preparation is critical for ensuring that the paint adheres properly and lasts a long time. Follow these steps:

Step 1: Clear the Area

Remove all equipment, shelving, and debris from the area you’ll be painting. Ensure the floor is completely clear.

Step 2: Clean the Floor

Use a concrete cleaner to remove all dirt, grease, and oil. A pressure washer is ideal for cleaning large areas quickly and effectively. Allow the floor to dry completely before proceeding.

Step 3: Repair Any Damage

Inspect the floor for any cracks, holes, or damage. Use a concrete patching compound to fill any imperfections. This step ensures a smooth, even surface for painting.

Step 4: Etch the Concrete (If Necessary)

Some floors may require etching to open up the surface of the concrete and improve paint adhesion. This can be done with a concrete etching solution or a mechanical grinder. Follow the manufacturer's instructions carefully.

Step 5: Apply Primer

Once the floor is clean and dry, apply a concrete primer. This will help the paint bond to the floor more effectively and provide a longer-lasting finish. Allow the primer to dry fully before moving on to the next step.

4. Painting the Warehouse Floor

With the floor fully prepped, it’s time to start painting.

Step 1: Choose the Right Paint

For a warehouse floor, epoxy or polyurethane-based paint is ideal. Epoxy is highly durable, chemical-resistant, and ideal for industrial environments.

Step 2: Mix the Paint

Follow the manufacturer's instructions for mixing the paint. Some paints may require adding a hardener or other components before use.

Step 3: Apply the First Coat

Using a roller, apply the first coat of paint in long, even strokes. Start at the far end of the warehouse and work your way toward the exit, so you don’t paint yourself into a corner.

Be sure to cover the entire surface evenly. For edges and corners, use a smaller brush or roller to ensure precise coverage.

Step 4: Allow the Paint to Dry

Let the first coat dry according to the paint manufacturer's instructions. This may take anywhere from 24 to 48 hours, depending on the type of paint and the warehouse environment.

Step 5: Apply a Second Coat

For added durability and a more even finish, apply a second coat of paint. Follow the same process as the first coat and allow it to dry thoroughly.

5. Post-Painting Care

Once the painting is complete, it’s essential to follow these steps to ensure the longevity of the paint job:

Step 1: Curing Time

Give the floor sufficient time to fully cure. Even though the paint may feel dry to the touch, it could take several days for it to harden completely. During this time, avoid placing heavy equipment or machinery on the floor.

Step 2: Regular Maintenance

To keep your painted warehouse floor in top condition, regular cleaning is essential. Sweep and mop the floor to remove dust, dirt, and debris. For tougher stains, use a mild detergent and water, avoiding harsh chemicals that could damage the paint.

Step 3: Inspect for Damage

Periodically inspect the floor for signs of wear or damage. Touch up any worn or scratched areas to prevent further damage and keep the floor looking fresh.

Conclusion

Painting a warehouse floor is a manageable DIY project, provided you take the time to prepare the surface and use the right materials. By following this step-by-step guide, you can transform your warehouse floor, making it more durable, safer, and visually appealing. Whether you're protecting the concrete from wear or simply improving the space’s look, a well-painted floor is a long-term investment in the functionality and safety of your warehouse.

Key Takeaways:

Proper preparation, including cleaning, repairing, and priming the floor, is critical for success.

Choose the right paint, such as epoxy or polyurethane, for durability.

Apply multiple coats, allowing ample drying and curing time for the best results.

Maintain the painted floor through regular cleaning and inspections.

0 notes

Text

What is a compactor and how to choose the right one?

Did you know that the total amount of municipal solid waste in 2017 was 267.8 million tons? Are you looking to reduce the waste generated by your company?

In this article, you will learn what a compactor is. You will also learn how to choose the right one. Keep reading to learn why owning one is so important for your business and how it can be so beneficial.

What is a compactor?

A commercial, construction or industrial compactor is a machine that collects waste into a container. The operator first places the waste from a loading dock into a chute on the machine on the ground. The waste accumulates inside the container until the operator performs a compaction cycle.

The compaction cycle is the process where a platen connected to a hydraulic ram pushes the waste into one end of the container. This waste is then crushed and reduced in size.

You can also choose from road compactors, soil compactors, and earthwork compactors. Soil compactors are popular in industrial construction areas.

Soil Compactors

Soil has four components: granular rock, minerals, air, and water. Soil compactors increase density and remove air pockets by kneading, vibrating, or compressing the soil. It is vital to use soil compactors correctly because they can cause serious or fatal injuries. Always make sure you use the correct operating instructions and receive practical training for the soil compactor you use.

Before using a soil compactor, make sure you follow the manufacturer's maintenance schedule and inspect the equipment. Always use guards on pinch points and moving parts. Have a backup alarm so pedestrians know the roller is moving.

If you don't use soil compactors, you may experience pipe leaks, ruptures, slab cracks, and foundation erosion. If you use a soil compactor for a long time, you are more likely to suffer from vibration syndrome. This can cause damage to the nerves and circulation in the fingers.

Symptoms of this condition include whitening, pain, and numbness. Read the instructions for vibration level ratings and maximum usage. Always keep your back straight and your posture correct when using a soil compactor.

Road Roller

Road roller, also known as road roller, is used to compact asphalt, concrete, gravel or soil. It is used in the construction of foundations and roads.

Pneumatic Roller

Pneumatic rollers have rubber tires. They are used to compact coarse-grained soils, such as in roadbed pavement projects. The roller uses the weight of the vehicle to compress the surface. The flexibility of the pneumatic straps allows the roller to work on uneven ground.

Vibratory Plate Compactor

It is used to compact different types of gravel and soil. They use a thick steel plate at the bottom, similar to a lawn mower.

Plate Compactor

Plate compactors are best used to create level slopes. Jump jack compactors have smaller feet. Jack compactors are mainly used to compact backfill soil inside gas supply pipes or water supply ditches.

Determine What is a Compactor

Are you ready to start your next construction project and want to make sure you have all the necessary equipment? Check out our products today to meet your construction needs.

0 notes

Text

The Secret Behind Perfect Cylinders: How Plate Rolling Machines Work

Creating a flawless cylinder from a flat sheet of metal might seem like magic to some, but the secret lies in the workings of a plate rolling machine. These machines are the unsung heroes in metal fabrication, used by industries worldwide, including Himalaya Machinery, a leader in heavy engineering in India. But how do they work, and why are they crucial to metal manufacturers? If you're curious to find out, you're in the right place.

In this article, we’ll dive deep into how plate rolling machines function, their maintenance, safety precautions, and everything in between. Whether you're an industry expert or someone new to the metal world, you’ll walk away with a solid understanding of the process behind creating those perfect metal cylinders.

Introduction to Plate Rolling Machines

When you look at those perfect, cylindrical metal structures like pipelines, tanks, or even certain vehicle parts, have you ever wondered how they get their shape? It all boils down to a piece of equipment called a plate rolling machine. This machine takes flat sheets of metal and, through a controlled process, rolls them into precise cylindrical shapes.

Just like a baker rolls out dough to create the perfect pastry, a plate rolling machine rolls out metal sheets to produce a flawless cylinder. While the concept sounds simple, the machinery involved is incredibly complex. Let’s dive deeper and understand what makes these machines so special.

What Is a Plate Rolling Machine?

A plate rolling machine is a powerful tool used in the metal manufacturing industry to shape flat metal sheets into curved, cylindrical, or round shapes. Imagine a rolling pin pressing into a piece of dough—only instead of dough, we’re talking about thick metal sheets.

These machines are widely used in industries like shipbuilding, construction, and heavy machinery manufacturing. Their ability to transform flat sheets into curved products makes them indispensable for many metal fabricators, especially when producing components that need to withstand high pressure, like boilers and pipelines.

Types of Plate Rolling Machines

There are several types of plate rolling machines, each designed to handle specific tasks. Here's a quick breakdown:

3-Roll Machines: These machines have three rollers positioned in a triangular formation. They are simple but effective for basic tasks.

4-Roll Machines: Adding an extra roll makes these machines more versatile. They offer better control and are often used for more complex projects.

CNC Rolling Machines: These are the future of rolling machines. Controlled by computers, they offer unmatched precision and efficiency.

CNC Rolling Machines: The Modern Solution

If you’re looking for perfection, look no further than the CNC rolling machine. Controlled by computer numerical control (CNC), these machines take the guesswork out of metal rolling. With the push of a button, CNC rolling machines can produce perfectly shaped cylinders with incredible accuracy.

Not only do they save time, but they also reduce human error, which is critical in high-stakes industries like aerospace and energy. In fact, companies like Himalaya Machinery rely on advanced CNC technology to meet the growing demand for precision in metal rolling.

The Metal Rolling Process Explained

So, how does the metal rolling process work? It all starts with a flat metal sheet. The machine uses a set of rollers to gradually bend the sheet into a cylindrical shape. The key to getting a perfect curve is in how the rollers are adjusted. Too much pressure, and you risk cracking the metal. Too little, and the sheet won't bend enough.

Think of it like shaping a piece of clay: you need the right balance of pressure and control to create the desired form. The operator, or the CNC program in the case of automated machines, carefully controls the rollers to ensure the sheet bends smoothly and evenly.

How to Achieve Perfect Cylinders

Achieving a flawless cylinder is a bit of an art form. The secret lies in calibrating the machine correctly. You have to account for factors like the thickness of the metal, its material composition, and even the temperature in the workshop. One small miscalculation, and you could end up with a lopsided cylinder.

Companies like Himalaya Machinery are masters at this process. Their machines are engineered with precision, and they’ve perfected the art of metal rolling to deliver consistently high-quality results.

Plate Rolling Machine Applications

The applications for plate rolling machines are vast. Some of the most common uses include:

Pipeline Construction: Rolled metal cylinders form the basis of pipelines used to transport water, gas, and oil.

Shipbuilding: The curved hulls of ships are made using plate rolling machines to ensure they can withstand harsh marine conditions.

Tanks and Boilers: Pressure vessels like tanks and boilers are created through the metal rolling process, as they require strong, cylindrical forms.

Aerospace and Energy Sectors: Even industries like aerospace and energy rely on metal rolling for manufacturing certain critical components.

Safety Precautions for Operating Rolling Machines

Operating a plate rolling machine can be risky if proper rolling machine safety precautions aren’t followed. These machines exert enormous force, and a small mistake can lead to serious injury. Here are some key safety tips:

Wear Proper Gear: Always wear protective gloves, goggles, and steel-toe boots when operating the machine.

Check the Machine Regularly: Before use, ensure all parts are functioning correctly.

Use a Lockout/Tagout System: This ensures the machine is powered off and won’t accidentally start during maintenance.

Stay Focused: Distractions can be dangerous, so always keep your focus on the task at hand.

Maintenance Checklist for Rolling Machines

A well-maintained machine is a safe and efficient one. Here’s a basic machine maintenance checklist to keep your rolling machine in top condition:

Lubricate the Rollers: Regular lubrication reduces wear and tear on the machine’s rollers.

Inspect for Wear and Tear: Check the machine’s moving parts for any signs of damage or wear.

Check Alignment: Misaligned rollers can lead to defective products and damage to the machine.

Test the Electrical System: Ensure all wiring and controls are functioning properly.

Following a routine maintenance schedule can extend the life of your machine and prevent costly breakdowns.

The Importance of Proper Calibration

Proper calibration is crucial for producing high-quality cylindrical products. Even the smallest error can throw off the entire process. Calibration involves adjusting the rollers, checking the pressure, and ensuring the material is fed into the machine correctly.

An analogy? Think of it like tuning a musical instrument—if even one string is off, the whole performance suffers. Similarly, miscalibrated rollers lead to imperfect cylinders.

Common Issues and Troubleshooting

Like any machine, plate rolling machines can experience problems from time to time. Here are some common issues and how to troubleshoot them:

Uneven Bending: This is often due to incorrect roller settings. Check the calibration and adjust accordingly.

Cracking: If the metal cracks during rolling, it might be due to excessive pressure or an unsuitable material.

Misalignment: Misalignment of the rollers can result in a lopsided cylinder. Double-check the settings before starting the rolling process.

Why Choose Himalaya Machinery for Your Needs?

When it comes to plate rolling machines in India, Himalaya Machinery, a heavy engineering company stands out. They’ve been in the heavy engineering business for decades, and their machines are known for reliability, precision, and durability. Their CNC rolling machines are particularly sought after for their ability to handle even the toughest projects with ease.

How Automation is Shaping the Future of Rolling

Automation is taking the metal manufacturing industry by storm, and plate rolling is no exception. CNC rolling machines, in particular, are revolutionizing the industry by reducing the need for manual intervention and ensuring greater precision. As more industries move towards automation, companies like Himalaya Machinery are at the forefront of this transformation, offering advanced machines that meet the demands of modern manufacturing.

Conclusion: The Art of Metal Rolling

In the world of metal manufacturing, plate rolling machines are indispensable. Whether it’s creating pipelines, ship hulls, or pressure vessels, these machines are the backbone of many industries. With advancements like CNC rolling machines, the process has become more efficient, accurate, and safer than ever before. The perfect cylinder might seem like a simple shape, but achieving that perfection requires a combination of advanced technology, skilled operators, and precise calibration.

Companies like Himalaya Machinery continue to push the boundaries, delivering high-quality machines that meet the demands of today’s fast-paced metal manufacturing world. As automation continues to grow, the role of machines in creating flawless metal products will only become more crucial.

0 notes

Text

Discover the Best Garage Door Repair Company in Pittsburgh, PA: A1 Garage Door

In the heart of Pittsburgh, PA, a reliable and efficient garage door repair service is crucial for homeowners looking to maintain the safety and functionality of their property. If you’re seeking the best garage door repair company in Pittsburgh, PA, look no further than A1 Garage Door. Renowned for its top-notch service, experienced technicians, and commitment to excellence, A1 Garage Door stands out as the leading choice for all your garage door repair needs. Here’s why A1 Garage Door is your premier option and what sets them apart from the competition.

Why A1 Garage Door is the Best Garage Door Repair Company in Pittsburgh, PA

1. Extensive Expertise and Experience

A1 Garage Door is distinguished by its team of highly skilled and experienced technicians. With years of industry experience, their professionals are adept at diagnosing and fixing a wide range of garage door issues. From minor repairs to complex problems, their extensive knowledge ensures that every repair is handled with precision and care. Their expertise covers various types of garage doors and mechanisms, making A1 Garage Door the go-to garage door repair company in Pittsburgh, PA.

2. Comprehensive Repair Services

A1 Garage Door offers a full spectrum of repair services designed to address any garage door issue you might encounter. Their comprehensive services include:

Spring Repair and Replacement: Garage door springs bear the brunt of daily use and can wear out or break over time. A1 Garage Door provides expert spring repair and replacement to restore your door’s functionality and ensure safe operation.

Opener Repair and Replacement: If your garage door opener is malfunctioning, A1 Garage Door’s technicians can diagnose and repair the problem. They also offer replacement services for outdated or faulty openers, ensuring smooth and reliable operation.

Track and Roller Repairs: Misaligned or damaged tracks and rollers can cause your garage door to operate unevenly or get stuck. A1 Garage Door’s repair services address these issues effectively, restoring the door’s smooth and reliable performance.

Panel Replacement: Damaged or unsightly garage door panels can affect your home’s curb appeal and functionality. A1 Garage Door offers panel replacement services to match the existing design and enhance the appearance and performance of your garage door.

Cable Repair and Replacement: Garage door cables are essential for lifting and lowering the door. A1 Garage Door provides cable repair and replacement services to ensure safe and efficient door operation.

3. High-Quality Parts and Materials

Quality is a hallmark of A1 Garage Door’s repair services. They use high-quality parts and materials from reputable manufacturers to ensure that repairs are durable and long-lasting. By utilizing top-notch components, A1 Garage Door guarantees that your garage door will continue to perform optimally after the repair. Their commitment to using quality parts means you receive a reliable repair that enhances the longevity and functionality of your garage door.

4. Personalized Service

A1 Garage Door is dedicated to providing personalized service tailored to each client’s needs. Their technicians take the time to understand your specific garage door issues and offer solutions that address your concerns effectively. From the initial assessment to the completion of the repair, A1 Garage Door ensures that every aspect of the service is customized to meet your expectations. Their personalized approach guarantees a repair service that is perfectly aligned with your unique situation.

5. Transparent and Competitive Pricing

Transparency and fair pricing are integral to A1 Garage Door’s service philosophy. They provide clear, upfront estimates for all repair services, ensuring that you know exactly what to expect before any work begins. There are no hidden fees or unexpected charges—just honest pricing that reflects the quality of their service. This transparency allows you to make informed decisions and ensures that you receive excellent value for your repair investment.

6. Prompt and Reliable Service

A1 Garage Door understands the urgency of garage door repairs and is known for its prompt and reliable service. Their team prioritizes quick response times and efficient repair processes to minimize any disruption to your daily routine. Whether you have an emergency repair or a scheduled service, A1 Garage Door’s commitment to reliability means that you can count on them to address your garage door issues swiftly and effectively.

How to Get Started with A1 Garage Door

If you’re experiencing problems with your garage door and need professional repair services, A1 Garage Door is here to help. To schedule a repair or get more information about their services, contact them at (412) 404-6833. Their office is conveniently located at Pittsburgh, PA 15217, making it easy for residents throughout the Pittsburgh area to access their expert repair services.

Customer Testimonials

The positive feedback from A1 Garage Door’s clients underscores their dedication to excellence and customer satisfaction. Here’s what some of their satisfied customers have to say:

"A1 Garage Door provided exceptional service when our garage door spring broke. They were quick to respond, provided a clear estimate, and completed the repair efficiently. The technician was professional and knowledgeable, and the quality of the work exceeded our expectations. We highly recommend A1 Garage Door as the best garage door repair company in Pittsburgh, PA." — Karen L., Pittsburgh, PA

"We had a fantastic experience with A1 Garage Door. Their team was prompt, courteous, and resolved our garage door issue without any hassle. The repair was done with high-quality parts, and the pricing was very reasonable. We are extremely satisfied with their service and will definitely use them again in the future." — David M., Pittsburgh, PA

Conclusion

For the best garage door repair company in Pittsburgh PA, A1 Garage Door is the top choice. Their combination of extensive expertise, comprehensive repair services, high-quality parts, personalized attention, and transparent pricing sets them apart as the leading provider in the area. Whether you need minor adjustments or major repairs, A1 Garage Door has the skills and knowledge to deliver exceptional results. Contact them today at (412) 404-6833 or visit their office at Pittsburgh, PA 15217 to experience their premier garage door repair services.

#garage door service#garage door repair#garage door installation#garage door#garage door replacement

0 notes

Text

Understanding the wheat flour manufacturer in india Process

Introduction

Flour is the basic ingredient for cooking in every kitchen in the world. It is used to prepare a lot of recipes and culinary delicacies. This article will go deep into how flour is made through stages that turn raw grains into a powdery substance that is crucial for baking and cooking.

The wheat flour manufacturer in India process starts with the selection of the right type of grain. The most common grain used to make flour is wheat, though corn, rye, barley, and oak are also milled. The kind of flour one wants to produce and its use determines the choice of grain. Good quality grains are necessary when making top-notch flour since they influence the texture, taste, and nutritional value of the end product.

Cleaning & Conditioning

Once selected, these grains are taken through a thorough cleaning process so as to get rid of impurities such as dirt and stones among other foreign matters. This step ensures that only pure safe flour remains behind. Moisture is added on cleaned grains during conditioning where in this case, we have the outer bran layer toughened while the inner endosperm is softened, which helps it separate easily during milling.

Milling

wheat flour manufacturer in India starts with the milling process, which is considered its heart in an overall sense. Conditioned grains pass through a series of grinding and sifting operations. After initial cracking using roller mills that remove bran layers from the germ part, the endosperm would be pulverized in several stages during the whole meal milling stage.

The desired fineness can only be achieved after sifting and sorting the mill particles throughout processing. Different types of flours are produced including whole wheat flour containing all parts of seed until refined white one having only endosperms. Ranging from whole wheat containing all parts of seed to refined white consisting solely of endosperms; each type has some unique features hence best suited for different needs in relation to cooking or baking.

Blending & Enrichment

After being milled, the flour may be subjected to blending and enrichment processes. Blending is mixing different batches of flour so that they have uniform quality and performance. On the other side, enrichment means adding nutrients such as vitamins and minerals to improve the nutritional profile of the flour. This is very common when it comes to white flour in which some of its natural nutrients are lost during the milling process.

Quality Control

Flour production must observe quality control measures effectively. Throughout the whole process, samples from every batch are frequently checked for consistency levels, purity standards or even nutritional content. In short, modern flour mills utilize advanced technology and equipment for quality monitoring purposes so as to maintain high standards. Any deviations that do not meet the specifications required will be promptly rectified thus ensuring that the end product meets expectations of consumers as well as industrial standards.

Conclusion

Understanding this flour manufacturing process shows the precise steps necessary to produce superior flour. Right from selecting what grain to use down to carrying out strict quality checks, each stage ensures that what we get satisfies both customer needs and preferences while still being useful in various food industries. By appreciating how complex this process is, people can start seeing the worth of all their daily consumed flour products.

For over 20 years, Bagaria Food has been in the business of flour manufacturing and boasts of baking flour that makes life more beautiful. See what our experts make for you this time in your kitchen. Visit Bagaria Food now, to find out more about it.

0 notes

Text

How to Maintain Your Cypress Post and Rail Fence for Longevity

Due to their durability and natural beauty, Cypress post and rail fence is an excellent choice for homeowners and farmers alike.

This type of fencing provides a robust boundary and enhances the aesthetic value of any property.

However, like any outdoor structure, cypress posts and rail fences require regular maintenance to ensure they last for many years.

Here’s an in-depth guide on effectively maintaining your rail fence.

Understanding Cypress Wood

Cypress wood is highly valued for its resistance to decay and insect damage. This is due to its natural oils and preservatives that make it less susceptible to environmental wear and tear.

Despite its resilience, cypress wood still benefits from proper care to maximise its longevity.

Understanding the characteristics of cypress wood helps tailor the maintenance approach to preserve its inherent qualities.

Regular Cleaning

Why Cleaning is Important: Dirt, mould, and mildew can accumulate on your fence over time, leading to discolouration and potential damage.

Regular cleaning is essential to prevent these issues and keep your fence looking its best.

How to Clean Your Fence:

Preparation: Begin by removing loose debris, such as leaves and branches, from the fence. This will make the cleaning process more effective.

Cleaning Solution: Prepare a mixture of mild detergent and water. Avoid harsh chemicals or bleach, which can damage the wood’s natural oils.

Scrubbing: Gently scrub the fence with a soft-bristled brush or a sponge. Focus on areas where dirt and mildew are most prevalent. Be careful not to use too much pressure, which can damage the wood.

Rinsing: Rinse the fence thoroughly with a garden hose or a low-pressure power washer after scrubbing. Make sure all detergent residue is removed to prevent buildup.

Drying: Allow the fence to air dry completely before applying protective treatments. This step is crucial to ensure that the wood does not trap moisture, which can lead to mould growth.

Inspecting for Damage

Regular inspections are vital for identifying and addressing issues before they become significant problems. Here’s what to look for during your inspections:

Cracks and Splinters: Check the wood for cracks or splinters. These can weaken the structure and make it more susceptible to further damage.

Small cracks can often be repaired with wood filler, while more significant issues may require replacing fence sections.

Loose Rails and Posts: Ensure that all rails and posts are secure. Loose components can compromise the stability of the entire fence. Tighten any loose screws or nails and replace any damaged fasteners.

Signs of Decay: Look for signs of rot or decay, especially near the base of the posts, where moisture is likely to collect.

If you notice any areas of soft or spongy wood, it may be time to replace the affected sections.

Insect Damage: Check for signs of insect activity, such as holes or tunnels in the wood.

While cypress wood is naturally resistant to insects, monitoring for any potential pest problems is still essential.

Applying Protective Finish

Applying a protective finish to your cypress post and rail fence helps to shield it from environmental damage and prolong its lifespan. Here’s how to do it:

Choose the Right Product: For cypress or similar woods, select a high-quality wood sealant or outdoor wood preservative. Look for products that offer UV protection and water resistance.

Preparation: Ensure the fence is clean and completely dry before applying any finish. This helps the product adhere properly and provides better protection.

Application: Follow the manufacturer’s instructions for applying the finish. Typically, this involves using a brush or roller to apply a thin, even coat.

Make sure to cover all surfaces, including the top and bottom of the rails and posts.

Drying Time: Allow the finish to dry completely before exposing the fence to moisture or heavy use.

This ensures that the protective layer is fully set and will provide optimal protection.

Reapplication: Depending on the product and environmental conditions, you may need to reapply the finish every 1-3 years.

Regular reapplication helps maintain the fence’s protective barrier.

Seasonal Maintenance Tips

Maintaining your rail fence throughout the year ensures it remains in top condition. Here are some seasonal tips:

Spring:

Inspect for Winter Damage: Look for any damage caused by winter weather, such as cracks or shifts in the fence alignment.

Reapply Finish: Spring is a good time to reapply a protective finish, as the weather is typically mild and dry.

Summer:

Monitor for Insects: Warm weather can increase insect activity. Check for signs of pests and apply insect repellent if necessary.

Trim Vegetation: Ensure that plants or vines are not growing onto or around the fence, which can trap moisture and cause damage.

Fall:

Clear Debris: Remove fallen leaves and other debris from the fence to prevent moisture buildup and potential mould growth.

Prepare for Winter: Ensure the fence is in good condition before winter onset. Make any necessary repairs to prevent damage from snow and ice.

Winter:

Prevent Snow Accumulation: Do not let snow pile up against the fence, as the weight can cause damage. Gently remove snow if it accumulates.

Check for Ice Damage: Look for any ice damage or freezing issues, particularly around the base of the posts.

Enhancing Longevity with Proper Installation

Proper installation is critical for the long-term success of your rail fence. Here’s what to keep in mind:

Post Installation: Ensure that posts are set securely in the ground, ideally with concrete footings. This helps prevent shifting and instability.

Rail Installation: Ensure that the rails are properly fastened to the posts and that all connections are secure. Loose or poorly installed rails can lead to structural problems.

Professional Help: Consider hiring a professional for complex installations or repairs. Proper installation from the start can prevent many maintenance issues down the line.

Conclusion

Maintaining your cypress post and rail fence is essential to ensuring its durability and beauty over time.

Regular cleaning, inspections, protective treatments, and seasonal care all contribute to the fence’s longevity.

By following these guidelines, you can keep your cypress post-and-rail fence looking great and performing well for many years to come.

Enjoy the charm and functionality of your fence, knowing that it will continue to enhance your property with the right maintenance.

Source: https://thewoodprojectaus.blogspot.com/2024/09/how-to-maintain-your-cypress-post-and.html

0 notes