#aluminium casting suppliers

Text

Top Aluminium Die Casting Manufacturer & Supplier in India | BQMP

BQMP is a top aluminum die casting manufacturer and supplier in India, offering high-quality die cast components and custom solutions for diverse industries. Explore our premium Aluminum casting services to meet your specific needs.

0 notes

Text

Leading Plastic Molding Manufacturer for Custom Solutions

Partner with a trusted Plastic Molding Manufacturer for high-quality, custom plastic parts. Our advanced molding technologies and experienced team ensure precision and consistency in every project. Serving various industries, we provide tailored solutions that meet your exact specifications, from concept to production. Rely on us for durable, efficient, and cost-effective plastic molding services.

#plastic injection molding supplier#electronics manufacturing services#automotive mold manufacturers#aluminium die casting

0 notes

Text

Sunrise Brass Industries are Manufacturer, Exporter, Supplier of customized Components in Brass, Stainless Steel, Copper, Bronze, Gun Metal and special alloys at Jamnagar.

https://www.sunriseind.co.in/index.html

#Sunrise Brass Industries are Manufacturer#Exporter#Supplier of customized Components in Brass#Stainless Steel#Copper#Bronze#Gun Metal and special alloys at Jamnagar.#https://www.sunriseind.co.in/index.html#brassproduct#steel#copper#aluminium#zinc#nickel#polishing#stainlesssteel#specialalloys#electric#casting#forging#stamping#machining#surfacefinishing#testing#packaging#brassjamnagar#electrical#electronicsapplications#pipefittings#conduitfittings

1 note

·

View note

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

#die-cast-manufacturer#custom-die-casting#die-casting-services#aluminium-casting-companies#die-casting-supplier

0 notes

Text

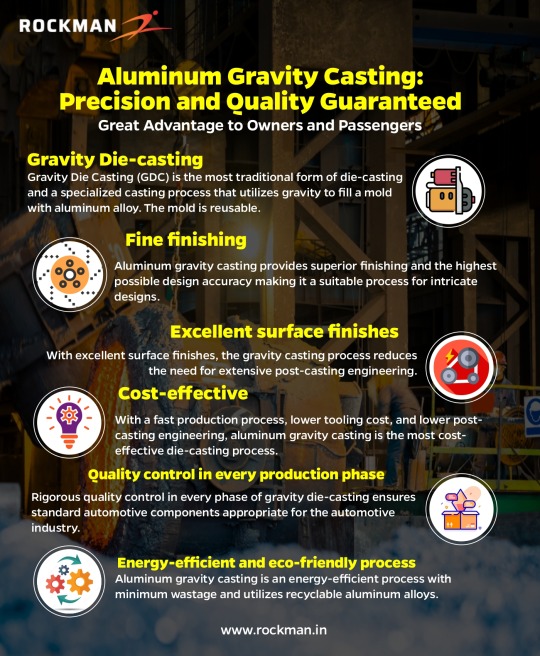

Aluminum Gravity Casting: Precision and Quality Guaranteed

Gravity Die-casting

Gravity Die Casting (GDC) is the most traditional form of die-casting and a specialized casting process that utilizes gravity to fill a mold with aluminum alloy. The mold is reusable.

Advantages of aluminum gravity casting

Fine finishing

Aluminum gravity casting provides superior finishing and the highest possible design accuracy making it a suitable process for intricate designs.

Excellent surface finishes

With excellent surface finishes, the gravity casting process reduces the need for extensive post-casting engineering.

Cost-effective

With a fast production process, lower tooling cost, and lower post-casting engineering, aluminum gravity casting is the most cost-effective die-casting process.

Quality control in every production phase

Rigorous quality control in every phase of gravity die-casting ensures standard automotive components appropriate for the automotive industry.

Energy-efficient and eco-friendly process

Aluminum gravity casting is an energy-efficient process with minimum wastage and utilizes recyclable aluminum alloys.

For more information on gravity casting and aluminum die-casting visit: https://www.rockman.in/

#Aluminum gravity casting#Alloy wheels for passenger cars#Aluminium die casting#die casting parts#High Pressure Die Casting suppliers in india#Aluminium casting#Aluminium Die cast#Aluminium die casting parts suppliers in india

0 notes

Text

youtube

We manufacture cylinder liners and cylinder sleeves for all prominent marine and industrial diesel engine makes and models, including Daihatsu, Yanmar, Bergen, Niigata, Mirrlees, Alco, ABC, Crepelle, Nohab, and Allen. We follow OEM specifications while manufacturing cylinder sleeves and liners. The design or sample is used to create and produce cylinder liners.

Small quantities are also appropriate. Please email us at [email protected], or visit this link for additional information about cylinder liner manufacturers:

https://turbineshaft.in/cylinder-liners-cylinder-sleeves.html

#cylinder liners#cylinder liners exporter#cylinder liner manufacturer#Cylinder Liner Installation#Diesel Engine Cylinder Liner Supplier#Cast Iron Engine Cylinder Liner#Main Engine Cylinder Liner#Aluminium Cylinder Liner Manufacturer#Compressor Cylinder Liner Producer#Cylinder Head Liner#Cylinder Liner Sleeve Manufacturer#Cylinder Liner And Sleeves#Youtube

1 note

·

View note

Text

Aluminum casting and forging

Aluminum casting and forging have a rich history that dates back centuries, showcasing the evolution of these manufacturing processes and their pivotal role in various industries. They form the backbone of various manufacturing operations, enabling the production of intricate components and structures that uphold the integrity and functionality of various products.

0 notes

Text

What is the Process of Aluminum Foundry and its advantages?

The process of aluminum foundry, also known as aluminum casting, is a manufacturing method used to produce a wide range of aluminum parts and products. It involves melting aluminum and pouring it into molds to create the desired shapes. Here's an overview of the process and its advantages:

Process of Aluminum Foundry:

Pattern Creation: The process starts with the creation of a pattern or mold that represents the final product. Patterns can be made from various materials, such as wood, metal, or plastic, and they are typically shaped to match the desired part.

Mold Making: A mold is created by packing sand or other refractory materials around the pattern. This mold is made in two halves, the cope (top) and the drag (bottom). The molds must be designed to allow the molten aluminum to flow into them.

Melting Aluminum: Aluminum is melted in a furnace at temperatures exceeding 1,000 degrees Celsius (1,832 degrees Fahrenheit). Various alloys can be used depending on the desired properties of the final product.

Pouring: Once the aluminum is molten, it is poured into the mold. The mold is typically placed in a flask to maintain its shape during the pouring process.

Cooling and Solidification: As the molten aluminum cools and solidifies in the mold, it takes on the shape of the pattern. This process can be aided by cooling water or other methods to control the cooling rate and prevent defects.

Shakeout: After the aluminum has cooled and solidified, the mold is broken, and the cast part is removed. Excess material, called the casting flash, is typically trimmed or removed in this step.

Finishing: The casting may undergo additional processing steps such as machining, sandblasting, heat treatment, or surface finishing to meet specific requirements and tolerances.

Advantages of Aluminum Foundry:

Lightweight: Aluminum is a lightweight material, making it ideal for its uses where weight is a significant factor. It's commonly used in the aerospace, automotive, and transportation industries.

High Strength-to-Weight Ratio: Aluminum alloys offer excellent strength-to-weight ratios, providing structural integrity while keeping weight low.

Corrosion Resistance: Aluminum has natural corrosion resistance, which can be enhanced through various surface treatments and coatings.

Complex Geometries: Aluminum foundry allows for the production of complex and intricate parts with precise detailing.

Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. Recycling aluminum consumes significantly less energy compared to primary production.

Thermal Conductivity: Aluminum has good thermal conductivity, making it suitable for heat exchange applications.

Cost-Effective: Aluminum foundry processes can be cost-effective for high-volume production runs due to efficient production and relatively low material costs.

Design Flexibility: Aluminum casting allows for the creation of intricate and customized designs, offering flexibility in product development.

Ductility and Malleability: Aluminum is ductile and malleable, allowing for easy forming and shaping of parts.

Excellent Electrical Conductivity: Aluminum has good electrical conductivity, making it useful in electrical and electronic applications.

It's important to note that the specific foundry process, such as sand casting, die casting, or investment casting, can affect the final product's properties and cost. The choice of process depends on the desired part, production volume, and other requirements.

0 notes

Photo

Patel Heaters & Control Pvt Ltd deliver wide range of Aluminium Casted Heater, which can solve a variety of complex heating problems. The cast heaters can be designed in the exact shape and size needed. For more information, contact us!

#Aluminium Casted Heater#Aluminium Casted Heater Manufacturers#Aluminium Casted Heater Suppliers#Aluminium Casted Heater Exporters

0 notes

Text

Top Aluminium Die Casting Manufacturer & Supplier in India | BQMP

BQMP is a top aluminum die casting manufacturer and supplier in India, offering high-quality die cast components and custom solutions for diverse industries. Specializing in aluminum product design and manufacturing, we provide comprehensive services from concept to production, ensuring innovative and high-performance products tailored to your specific needs.

#marketing#business#Aluminium Die Casting Manufacturer#Aluminium Die Casting#Die Casting Manufacturer & Supplier in India

0 notes

Text

Automotive Injection Molding - Precision Manufacturing for High-Quality Auto Parts

Automotive Injection Molding by Keiteq offers advanced solutions for producing precise and durable automotive components. This process ensures high efficiency and consistency, making it ideal for creating complex parts like dashboards, bumpers, and interior panels.

#electronics manufacturing services#automotive mold manufacturers#electronic manufacturing services#aluminium die casting#automotive molding#plastic injection molding supplier#plastic injection molding company

0 notes

Text

Sunrise Brass Industries are Manufacturer, Exporter, Supplier of customized Components in Brass, Stainless Steel, Copper, Bronze, Gun Metal and special alloys at Jamnagar.

https://www.sunriseind.co.in/index.html

#brassjamnagar#entrepreneur#commercial#Sunrise Brass Industries are Manufacturer#Exporter#Supplier of customized Components in Brass#Stainless Steel#Copper#Bronze#Gun Metal and special alloys at Jamnagar.#https://www.sunriseind.co.in/index.html#brassproduct#steel#copper#aluminium#zinc#nickel#polishing#stainlesssteel#specialalloys#electric#casting#forging#stamping#machining#surfacefinishing#testing#packaging#electrical#electronicsapplications

1 note

·

View note

Text

Forge Ahead with Virat’s H13!

Virat Special Steels takes pride in offering high-quality Aluminium Extrusion Die Steel H13 – a true pinnacle of durability and performance in every extrusion process.

Application Areas:

Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Moulds: H13 is used in injection molding with high polishability.

Quality Assurance:

Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory:

With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#h13diesteel#aluminium extrusion#Die Steel H13#h13steelbarexporter#h13steel#h13#din 2344#din2344

2 notes

·

View notes

Text

Gate Valve supplier in Oman

Middleeast valve is one of the best Gate valve supplier in Oman . We supply to cities like Ibri, Sur, Muscat, and Mutrah.

A gate valve is a type of valve used to control the flow of fluids (liquids or gases) by using a gate or wedge-like disc that moves perpendicular to the flow path to either block or allow the passage of the fluid.

The main function of a gate valve is to provide a tight shutoff, effectively stopping the flow of fluid through the pipeline when the valve is fully closed, and allowing unrestricted flow when the valve is fully open. Gate valves are commonly used in applications where the fluid flow needs to be completely shut off, such as in water supply systems, oil and gas pipelines, industrial processes, and more.

Gate valves consist of several main components, including the body, gate (wedge), stem, actuator, and seats. Here's how they work:

Open Position:

In the open position, the gate (wedge) is fully retracted into the valve body, allowing the fluid to flow through the valve with minimal obstruction. The gate moves perpendicular to the direction of the fluid flow. The valve is opened by turning the valve stem (either manually using a handwheel or with an actuator) which is connected to the gate.

Closing Position:

To close the valve, the stem is turned in the opposite direction, causing the gate to move down into the flow path of the fluid. As the gate descends, it gradually restricts the flow until the valve is completely closed. The gate makes contact with the valve seats located at the bottom of the valve body, forming a tight seal that prevents any further flow.

Middleeast valve is the greatest Gate valve supplier in Oman and are known for their ability to provide a tight seal and low pressure drop when fully open. However, they might require more turns to fully open or close compared to other valve types like ball valves. It's important to use gate valves in appropriate applications and avoid using them for flow regulation where frequent adjustments are necessary.

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded

Standards: API607, DIN, BS, ANSI, AWWA, ASME, API6D

Gate valve types:

Rising Stem Gate Valve

Non Rising Stem Gate Valve

Bellow Seal Gate Valve

Pressure Seal Gate Valve

Cryogenic Gate Valve

Forged Gate Valve

Gate valve advantages :

They have low fluid resistance.

They have superior sealing capability.

They come with a wide application range.

They have dual flow directions.

Gate valve Industries:

Textiles.

Power generation.

Refineries.

Petrochemical plants.

Shipbuilding

Chemical industry.

Paper factories.

Gate valve parts:

Hand wheel.

Stuffing Box.

Bonnet

Gasket

Stem

Flange

Disk

Body seats

Packing

Body

Visit our website: https://www.middleeastvalve.com/product-category/gate-valve/

2 notes

·

View notes

Text

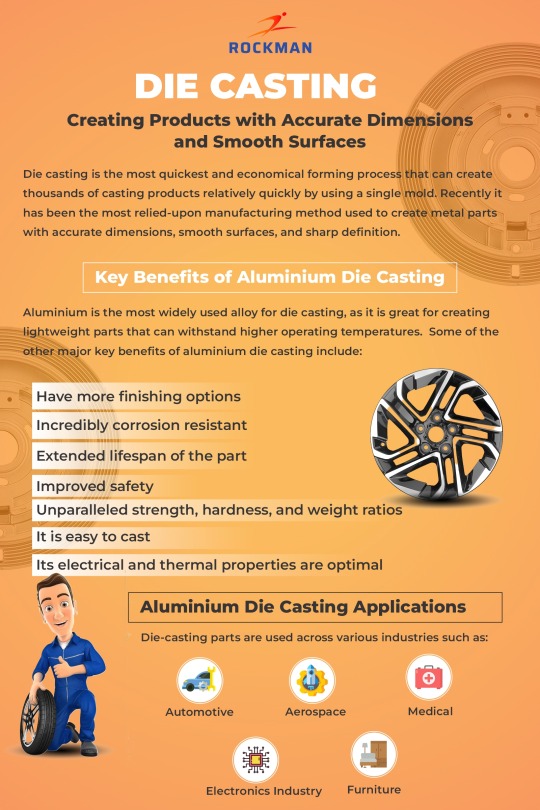

Die casting is the most quickest and economical forming process that can create thousands of casting products relatively quickly by using a single mold. Recently it has been the most relied-upon manufacturing method used to create metal parts with accurate dimensions, smooth surfaces, and sharp definition.

https://www.rockman.in/

1 note

·

View note