#auto-entrepreneur

Text

Comment arrêter efficacement son activité de graphiste en tant qu'auto-entrepreneur

Être graphiste en auto-entrepreneur peut être une aventure passionnante, mais il arrive parfois que l’on décide de mettre fin à cette activité. Que ce soit pour des raisons professionnelles ou personnelles, il est important de connaître la méthode la plus efficace pour arrêter votre activité de graphiste en tant qu’auto-entrepreneur en France. Dans cet article, nous vous présenterons les étapes…

View On WordPress

0 notes

Photo

Pourquoi segmenter son offre de services ?

#auto-entrepreneur#entreprenariat#offre de services#business model#segmentation#diversification#client

0 notes

Text

MétaMortFosse

MétaMortFosse

Ce n’était pas une bonne période pour moi. Ce n’était pas non plus une bonne période pour des milliers de personnes. Roussel et Valls étaient toujours présentés comme étant de gauche. Cette dernière était à nouveau au bord du précipice. Le harcèlement d’une femme devenait lynchage médiatique. Tout ce qui comportait « public » dans le nom subissait des sévices pré-privatisation. Comme d’autres,…

View On WordPress

#arnaque#Auto-entrepreneur#Big22#capitalisme#Entrepreneur#gonzo#Macron#Metaverse#Réseau#Startup#Thune#Web3.0

0 notes

Text

youtube

NOUVELLE VIDÉO !

Ces derniers temps, je suis en train de tout mettre en place pour réaliser le rêve qui m'accompagne depuis que je suis enfant : devenir artiste (et vivre de mes créations) !

Chemin à peine entamé et pourtant déjà jonché d'obstacle. Je vous partage mes réflexions sur la difficulté d'être artiste dans cette société obsédée par la productivité, le perfectionnisme et l'argent.

Et en attendant le revenu universel ou autre miracle, n'hésitez pas à me faire parts de vos expériences en tant qu'artiste, créateur ou auto-entrepreneur ou à simplement me partager vos diverses réflexions sur le sujet !

Force à vous si vous luttez contre vents et marées pour réaliser vos rêves (ou simplement pour vivre votre vie), courage, tenez le coup et n'abandonnez jamais ♡

#photo#picture#aesthetic#french#youtube#video#pensée#devenir artiste#rêve#art#creation#créer#artiste#female artists#auto entrepreneur#réflexion#Youtube

18 notes

·

View notes

Text

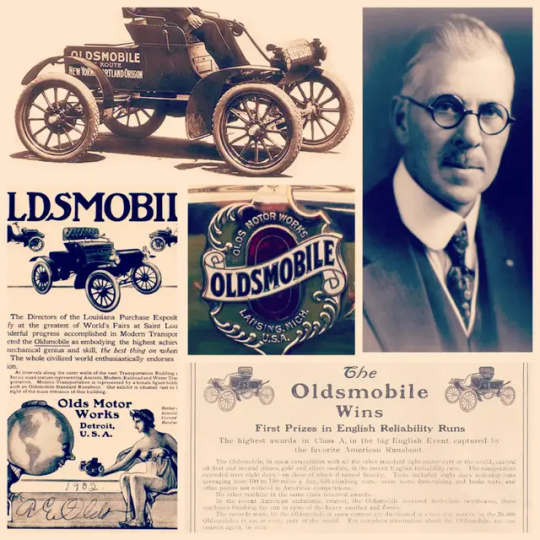

📆 On August 21, 1897, Ransom Olds founded Olds Motor Works after successfully building his first gas-powered vehicle.

⚙️ In its first year, Olds Motors produced just four vehicles. However, after securing an investment from businessman Samuel Smith, the company began mass-producing automobiles using Olds' innovative automotive assembly line. By 1903, Oldsmobile had become the largest automaker in the U.S., though Ransom Olds departed in 1904 due to disputes over the company’s direction. A few years later, Oldsmobile was acquired by General Motors.

🚘 During its nearly century-long run with GM, Oldsmobile pioneered innovations like the automatic transmission and introduced iconic models such as the Cutlass, Toronado, and 88.

#brits and yanks on wheels#retro cars#transatlantic torque#vehicle#cars#old cars#brands#companies#automobile#american cars#oldsmobile#oldsmobile 98#oldsmobile cutlass#general motors#gm#detroit#michigan#lansig#olds motor works#ransom olds#american auto#automotive#auto#old car#classic cars#car#innovation#technology#entrepreneur#muscle car

7 notes

·

View notes

Text

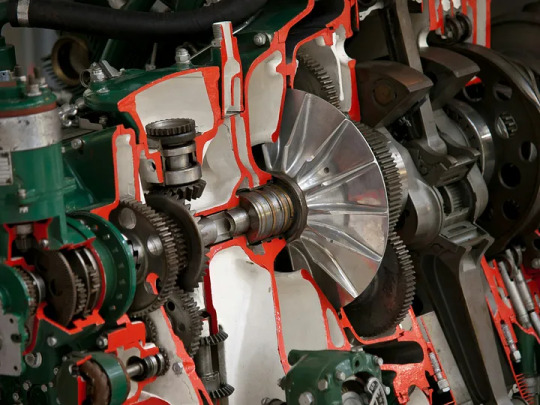

The Ultimate Guide to Mechanical Maintenance: Strategies for Success

Photo by William Warby on Unsplash

Mechanical maintenance is fundamental to the smooth operation and longevity of machinery across various industries. Effective maintenance practices can significantly reduce downtime, improve efficiency, and extend the lifespan of equipment. This guide explores the intricacies of mechanical maintenance, offering strategies and best practices to ensure optimal machinery performance.

The Essence of Mechanical Maintenance

Mechanical maintenance involves a series of actions aimed at keeping machinery in peak condition. These actions include regular inspections, timely repairs, and preventive measures to avoid unexpected failures. The primary goal is to ensure that all mechanical systems function efficiently and safely.

Types of Mechanical Maintenance

Preventive Maintenance: Scheduled maintenance activities designed to prevent equipment failures. Tasks include regular inspections, lubrication, and replacing worn components. The objective is to keep machinery running smoothly and avoid unexpected breakdowns.

Predictive Maintenance: This approach uses real-time data and monitoring tools to predict when maintenance should be performed. Techniques like vibration analysis and thermal imaging help identify potential issues before they lead to equipment failure.

Corrective Maintenance: Also known as reactive maintenance, this involves repairing equipment after a failure has occurred. While this can be more costly and disruptive, it is essential for addressing unexpected issues that preventive measures did not catch.

Condition-Based Maintenance: Maintenance activities are conducted based on the actual condition of equipment. Sensors and monitoring devices provide continuous data, allowing for maintenance to be performed precisely when needed, rather than on a fixed schedule.

Key Components of Effective Mechanical Maintenance

Regular Inspections: Conducting systematic checks to identify early signs of wear, tear, or malfunction. Using detailed checklists ensures all critical components are evaluated.

Lubrication: Ensuring all moving parts are adequately lubricated to minimize friction and wear. The correct type and amount of lubricant are crucial for maintaining machinery efficiency.

Cleaning: Keeping machinery clean prevents contamination and ensures optimal performance. Regular removal of dust, debris, and other contaminants is essential.

Calibration: Regular calibration of tools and equipment ensures accuracy and precision in operations. Standardized procedures and tools help maintain consistent performance.

Component Replacement: Timely replacement of worn or damaged parts prevents further damage and ensures continuous operation. Keeping an inventory of critical spare parts allows for quick replacements when necessary.

Best Practices for Mechanical Maintenance

Develop a Maintenance Schedule: A detailed maintenance schedule that outlines routine inspections, servicing, and part replacements is essential. Adherence to this schedule ensures no maintenance tasks are overlooked.

Utilize Maintenance Management Software: Implementing software to track and manage maintenance activities improves efficiency. These tools can schedule tasks, record maintenance history, and generate performance reports.

Train Maintenance Personnel: Regular training ensures maintenance personnel are up-to-date with the latest techniques and technologies. Continuous learning enhances their skills and effectiveness.

Implement Safety Protocols: Establishing and enforcing safety protocols protects both maintenance personnel and equipment. Proper training and protective gear are essential components of a safe maintenance environment.

Conduct Root Cause Analysis: Identifying the root causes of equipment failures helps in implementing effective corrective actions. This prevents recurrence and improves the overall reliability of machinery.

Challenges in Mechanical Maintenance

Resource Constraints: Limited availability of skilled personnel, tools, and spare parts can hinder maintenance activities. Effective resource management and planning are crucial to overcoming these challenges.

Unplanned Downtime: Unexpected equipment failures can lead to significant production stoppages and increased costs. Implementing predictive and preventive maintenance strategies can mitigate these risks.

Data Management: Managing and analyzing large volumes of maintenance data can be challenging. Ensuring data accuracy and leveraging advanced analytics tools can enhance decision-making.

Aging Equipment: Older machinery often requires more frequent maintenance and can be less reliable. Balancing the cost of ongoing maintenance with the potential benefits of upgrading to newer equipment is a key consideration.

Case Studies and Real-World Examples

Preventive Maintenance in Manufacturing: A manufacturing plant implemented a rigorous preventive maintenance program, resulting in a 20% reduction in equipment downtime and a 15% increase in production efficiency. Regular inspections and timely component replacements were key to these improvements.

Predictive Maintenance in Power Generation: A power generation company utilized predictive maintenance techniques, such as vibration analysis and thermal imaging, to identify potential failures before they occurred. This approach reduced maintenance costs by 25% and significantly improved equipment reliability.

Corrective Maintenance in the Automotive Industry: An automotive company experienced a sudden equipment failure on the production line. Through corrective maintenance, the faulty component was swiftly replaced, minimizing downtime and preventing substantial production losses.

Condition-Based Maintenance in Aviation: An airline implemented condition-based maintenance for its fleet, using advanced sensors and data analytics to monitor the condition of critical components. This strategy improved safety, reduced maintenance costs, and increased aircraft availability.

Conclusion

Effective mechanical maintenance is vital for the smooth operation and longevity of machinery across various industries. By understanding the different types of maintenance, implementing best practices, and addressing common challenges, businesses can enhance equipment reliability, reduce downtime, and achieve operational excellence. Regular inspections, proper lubrication, timely component replacement, and the use of maintenance management software are key strategies for ensuring optimal performance and longevity of mechanical systems.

Explore More Topics

If you found this post insightful, you might also be interested in exploring our other topics that have garnered millions of views:

Mechanical Tools and Their Uses

Discover the comprehensive guide to mechanical tools, covering everything from basic hand tools to advanced machinery. Learn about the names and uses of essential tools every mechanical engineer needs.

Forging Tools and Their Uses

Explore the various forging tools and their applications. Understand the different types of forging processes and the tools required to achieve precision and efficiency in forging operations.

Mechanical engineering is a challenging yet rewarding field, and with the right mindset and tools, you can navigate its complexities and build a successful career.

Visit our website for more insights: Mech Forged

#artificial intelligence#mechanical pencil#mechanical drawings#mecha#the mechanisms#mechanophilia#robotics#machinery#mecha art#marvin's marvelous mechanical museum#adeptus mechanicus#robot#cybernetics#autos#design#entrepreneur#success

3 notes

·

View notes

Text

Mazda logo evolution ☆☆☆

Write your favourite year 💬👇

#logo#business#illustration#entrepreneur#artists on tumblr#branding#mazda#mazda 6#cars#auto#auto service

31 notes

·

View notes

Text

Pier-A2Z

We provide our customers with the newest trending affordable jewelry including chains, bracelets, earrings, rings, necklaces & pendants - in Platinum, 18K, 14K & 10K gold, and sterling silver. We are now offering Shop Pay. Pay in installments while you wear the latest trending fashion jewelry. Celebrate your memorable milestones with jewelry from piera2z.

www.piera2z.com

#beauty#ecommerce#branding#marketing#startup#success#jewel#entrepreneur#autos#business#jeweler#jewelry#diamond#gold#silver#platinum#Platinum#rose#rose gold#yellow#yellow gold#white gold#white#diamonds#rings#pendant#necklaces#platium#sterling silver#pearls

4 notes

·

View notes

Text

#paris#france#tumblr#bicyclette#vélo#bicycle#bike#cycling#tumblr français#auto#entrepreneur#vae#ebike#ebikelife

3 notes

·

View notes

Text

DRY CAR CARE Yeni Nesil Araç Yıkama. Bir GLOBOWAX Markası Konsepti. Bayi / Franchise Olun , Bölgenizde İlk Olun Kazanın !

Detaylı Bilgi : https://www.drycarcare.com

Bilgi Edinme Formu : https://www.drycarcare.com/basvuru-formu/

GLOBOWAX markamız ; 2006 yılında faaliyetlerine başlayan , günümüzde hem Türkiye hem de yurtdışında faaliyet gösteren , yeşil ve çevreci kimliği ile sektör markalarından ayrışan , yarattığı DRY CAR CARE türkçesi OTO KURU TEMİZLEME konsepti ile mobil hizmet kapasitesini sektöre kazandıran ; vizyoner karakteri ve devamlı AR-GE faaliyetleri ile özellikle son yıllarda lider, öncü ve lokomotif marka olma hedefiyle hızla büyümektedir.

Yeni Nesil Oto Yıkama Bayiliği / Oto Yıkama Bayilik Konsepti.

Dry Car Care konsepti faaliyeti, günümüzde yenilikçi yaklaşımıyla küresel anlamda büyüyen, gururla yerli ve milli " Türk Markası" değeri olan bir GLOBOWAX® markası hizmetidir.

Marka, günümüzde 100'e yakın kontratlı müşterisine ürün ve marka değerini paylaşmakta olup +30 'dan fazla aktif franchise noktasına sahiptir.

GLOBOWAX Markamız, sektörde son 5 yılda en hızla büyüyen franchise şirketlerinden biridir.

Marka, kendi bünyesindeki dahili uluslararası kargo ve lojistik aile şirketi altyapısı ve deneyimi ile üçüncü kişilere muhattap kalmadan franchise / bayilikler vererek ürünlerini door2door dünya genelinde her yatırımcısına ulaştırmaktadır.

Marka , günümüzde giderek sayısı artan ve genişleyen uluslararası partnerleri sayesinde 10'a yakın ülkeye GLOBOWAX değerini ihraç etmiş veya aktif olarak etmektedir. Her geçen gün büyüyen franchise / bayi ağı ile hizmet alanlarını genişletmektedir.

Ayrıca GLOBOWAX, Aracınızın Oto Kuaför, Auto Wash, Oto Yıkama Servisi ve Car Care ihtiyaçlarını karşılayan ve 2006 ‘dan itibaren franchising hizmetleri de veren bir markadır.

özetle markamız ;

Ayrıcalıklı olarak; (1) Dry Car Care , (2) Car Wash ve (3) Steam Wash Ana Hizmet Konseptleri ile; araç yıkama , detailing ve bayilik alanında son 17 yılda sektöründe GLOBOWAX olarak hizmet çeşitliliğinde lider, yaratıcı ve öncü marka profilindedir.

Hizmet Talepleri Haricinde Bayilik / Franchising veya Mobil Hizmet Ağına Katılım İçin Bizlerle İletişime Geçebilirsiniz..

**

Etiketler: Profesyonel Araç Yıkama | Dry Car Care | Oto Kuru Temizleme | Car Wash & Detailing | Oto Kuaför | Oto Yıkama Bayilik | Nano Teknoloji | Oto Yıkama Franchise | Franchising | Oto Yıkama Hizmeti.

#globowax #drycarcare #otoyıkama #otoyıkamabayiliği #otoyıkamaaçmak #franchising #bayilik #yatırım #karlıişler #dolar #euro #carwash #carcare #turkiye #investment #business #professionalcarcare

#drycarcare#globowax#otoyıkama#otoyıkamabayiliği#franchising#bayilikverenfirmalar#bayilik#carcare#auto care#detailing#polishing#seramikkaplama#pasta cila#boya koruma#adreste oto yıkama#yerinde oto yıkama#professional#business#startup#entrepreneur#oto kuaför#detaylı temizlik#ppf kaplama#cam filmi#worldwide#master franchising#distributorship#suppliers#exporters#global

2 notes

·

View notes

Text

Finally did my logo next is the website, business cards and flyers 🙌

8 notes

·

View notes

Text

#conseils pour devenir un bon écrivain#devenir#écrivain auto-entrepreneur#écrivain autodidacte#écrivain.#études pour devenir un écrivain#formation

2 notes

·

View notes

Text

0 notes

Text

En septembre je quittais un de mes deux boulots pour avoir plus le temps de vivre et finalement, à peine deux mois après, je me retrouve à en cumuler trois parce que bon, les free-lances, on peut les sous-payer et puis ils n'ont qu'à se débrouiller pour gérer leurs taxes et le reste.

Mais quelle idée j'ai eu en devenant auto-entrepreneuse ?

Astuce pour votre vie : ne faites pas ça.

(Je pense qu'un jour j'écrirai un loooong article ou ferai une vidéo pour expliquer pourquoi la plupart du temps, c'est vraiment une mauvaise idée de se lancer à son compte.)

Sinon si d'autres personnes ici sont auto-entrepreneurs/free-lances etc., n'hésitez pas à m'envoyer un message pour me dire comment vous gérez le truc, ça m'intéresse !

24 notes

·

View notes

Text

Créez votre auto-entreprise en toute simplicité

Vous avez décidé de vous lancer dans l’entrepreneuriat et de créer votre auto-entreprise ? Félicitations ! Que ce soit pour concrétiser une passion, tester une idée innovante ou simplement devenir votre propre patron, la création d’une auto-entreprise est une aventure passionnante. Dans cet article, je vous guide à travers les étapes essentielles pour réussir votre lancement.

étude de…

View On WordPress

#Bien-être personnel#Création d&039;entreprise#Développement personnel#Entrepreneuriat féminin#Espace de travail créatif#Gestion du temps#Innovation et créativité#Marketing pour auto-entrepreneurs#Réseautage#Stratégies d&039;affaires

0 notes

Text

The Evolution and Impact of Mechanical Arms in Modern Industry

Mechanical arms, often hailed as the cornerstone of modern automation, have dramatically transformed various industries. These sophisticated devices replicate the movements and functions of a human arm, delivering precision, strength, and versatility across numerous applications. This post delves into the evolution, impact, and future of mechanical arms in shaping contemporary industry.

The Evolution of Mechanical Arms

The development of mechanical arms has been a journey of continuous innovation:

Early Designs: The concept of mechanical arms dates back to the early 20th century, with rudimentary designs used for simple tasks. Early models were manually operated and limited in their functionality.

Industrial Revolution: The mid-20th century saw the advent of electric-powered robotic arms, significantly enhancing productivity and precision in manufacturing. Pioneering companies like General Motors and IBM began integrating these arms into their production lines.

Advancements in Technology: The 1980s and 1990s brought about significant advancements, including programmable logic controllers (PLCs) and sophisticated control systems. These innovations allowed mechanical arms to perform complex tasks with greater accuracy and efficiency.

Modern Era: Today, mechanical arms are equipped with artificial intelligence (AI), machine learning, and advanced sensors. These technologies enable them to adapt to various tasks, learn from their environment, and operate autonomously.

The Impact of Mechanical Arms on Industry

Mechanical arms have revolutionized multiple industries, offering transformative benefits:

Manufacturing: Mechanical arms have become indispensable in manufacturing, performing tasks such as welding, assembly, and painting. They have drastically improved production rates, consistency, and safety by handling repetitive and hazardous tasks.

Healthcare: In the medical field, robotic arms assist in performing precise surgeries, allowing for minimally invasive procedures that reduce recovery times and improve patient outcomes. They also play a crucial role in prosthetics, providing enhanced mobility and functionality for individuals with limb loss.

Aerospace: Mechanical arms are vital in aerospace for assembling and repairing aircraft and spacecraft. Their precision and reliability are crucial for maintaining the high standards required in this field.

Logistics: In warehouses and distribution centers, robotic arms streamline sorting, packing, and handling operations. They increase efficiency, reduce errors, and minimize labor costs, contributing to faster and more accurate order fulfillment.

Agriculture: Mechanical arms are increasingly used in agriculture for tasks such as planting, harvesting, and sorting crops. They help to address labor shortages and increase productivity, ensuring a more efficient agricultural process.

Explore More Topics

If you found this post insightful, you might also be interested in exploring our other topics that have garnered millions of views:

Mechanical Arms: Latest Trends, Future, & Purpose

Learn about the latest advancements in mechanical arms, their future prospects, and the purposes they serve across various industries.

Types of Mechanical Tools

Discover the different types of mechanical tools, their names, and uses. From basic hand tools to advanced machinery, understand the essential tools every mechanical engineer needs.

Mechanical engineering is a challenging yet rewarding field, and with the right mindset and tools, you can navigate its complexities and build a successful career.

Key Advantages of Mechanical Arms

The adoption of mechanical arms offers several notable advantages:

Increased Precision: Mechanical arms can perform tasks with a high degree of accuracy, which is essential for quality control and complex operations.

Enhanced Efficiency: They operate continuously without the need for breaks, increasing production speed and overall efficiency.

Improved Safety: By undertaking dangerous tasks, mechanical arms protect human workers from hazardous environments and reduce the risk of injuries.

Versatility: With programmable control systems, mechanical arms can be adapted for a wide range of tasks, making them highly versatile tools.

Cost Savings: Although the initial investment can be significant, the long-term benefits of reduced labor costs and increased productivity make mechanical arms a cost-effective solution.

Challenges and Future Prospects

Despite their many benefits, mechanical arms face challenges that must be addressed:

High Initial Costs: The cost of purchasing and installing mechanical arms can be substantial, particularly for small and medium-sized enterprises.

Complex Integration: Integrating robotic arms into existing systems and workflows can be complex and require specialized expertise.

Maintenance and Upkeep: Regular maintenance and technical support are necessary to ensure optimal performance and longevity.

Looking ahead, several trends are shaping the future of mechanical arms:

Artificial Intelligence: AI and machine learning are enhancing the capabilities of mechanical arms, allowing them to perform more complex tasks and adapt to changing conditions.

Collaborative Robotics: The rise of collaborative robots (cobots) that work alongside human operators is set to improve productivity and safety in various work environments.

Advanced Materials: The use of advanced materials and miniaturization techniques is leading to more compact and precise mechanical arms, suitable for delicate and intricate tasks.

Enhanced Connectivity: Improved connectivity and integration with the Internet of Things (IoT) will enable better monitoring, control, and optimization of robotic systems.

Conclusion

Mechanical arms have had a profound impact on modern industry, driving advancements in manufacturing, healthcare, aerospace, logistics, and agriculture. As technology continues to evolve, the capabilities and applications of mechanical arms are expected to expand, offering even greater benefits and opportunities. Embracing these advancements will be key to staying competitive and innovative in the rapidly changing landscape of industry.

For more information and insights, visit Mech Forged.

#autos#artificial intelligence#design#entrepreneur#success#mechanical engineering#mechanical pencil#mechanical drawings#robot#robotics#machinery#artifical intelligence

1 note

·

View note