#automated inspection

Text

Smart Solutions for a Sustainable Future: Harnessing the Power of Visual Intelligence in Energy Management

As climate change continues to threaten the stability of our power grids, weather-related power outages are on the rise. The outdated infrastructure, built for past weather conditions, is struggling to keep up. But fear not! The digital revolution is transforming the utility industry, offering cutting-edge technologies for a safer, more resilient future.

Enter visual intelligence - a game-changer for the energy sector. Smart utilities are using cutting-edge technologies like Lidar, drones, thermal imagery, and satellite technology to monitor their operations from remote areas. By harnessing the power of visual data, utilities can stay ahead of the curve and ensure public safety.

Hitachi is leading the charge in this sustainable transformation. With their Lumada Inspection Insights solution, utilities can automate the inspection process and analyze images from anywhere in the world. This advanced technology not only detects asset health but also helps companies make informed decisions and optimize operations.

From image-based inspections to vegetation management and mapping solutions, Lumada Inspection Insights is making a difference. By helping utilities remotely monitor electrical substations and transmission lines, AI-based image processing is revolutionizing the industry. The solution also helps energy companies manage vegetation trimming with satellite imagery, increasing grid reliability while reducing truck rolls and carbon emissions.

Hitachi is helping the world move towards sustainability by developing smart solutions that tackle current problems while empowering companies to face future challenges. In a rapidly changing climate, visual intelligence is key to thriving in a carbon-neutral era.

Explore how Hitachi is unlocking value for society with their Social Innovation in Energy :

https://social-innovation.hitachi/en-us/think-ahead/energy/

#digital technology#critical infrastructure protection#infrastructure asset management#visual inspection#visual intelligence#aging infrastructure#asset inspection#critical asset monitoring#asset performance management#asset risk management#automated inspection#climate-proofing infrastructure#climate-resilient infrastructure#image analysis#infrastructure monitoring tools#vegetation management solutions#visual analytics#visual data analysis#utilities#sustainability#digital#technology AI#artificial intelligence#artificial intelligence in utility industry#ai based image processing#decarbonization

0 notes

Text

Putting Customers First in the Custom Automation Equipment Development Process

As a leading custom automation equipment solution provider in the semiconductor metrology and inspection, medical devices, and emerging technologies, we have witnessed how the relentless pursuit of technical excellence—prioritizing streamlined processes and criteria fit—can inadvertently overshadow the deeper needs customers.

That is why this article focuses on the importance of understanding customer needs from the beginning. By embracing a holistic approach and redirecting the focus towards customer needs, stronger relationships are developed, exceptional experiences are delivered, and mutual success is achieved.

Exploring Strategic Objectives: The Foundation of Understanding

Steering teams towards a more strategic understanding of our customers, instead of superficial interactions, is an important duty as company leaders. It’s important to inspire teams to learn what customers really need and what is important to them instead of over-focusing on technical specifications. This can be accomplished by, "What do you want to achieve?" or "What would a successful outcome look like?" These answers will reveal a deeper understanding of customer needs, beyond what lies upon the surface.

Typical goals include:

Commercialization of a product concept

Accelerated time-to-market

Scaling manufacturing

Strategic objectives can be broader and include corporate, user or environmental goals. The more all high-level objectives are known, the stronger the potential partnership.

Empathy Is Key

Nurturing an atmosphere of empathy within our institutions is crucial to be effective leaders. We must prioritize customer concerns and fears with sincerity and understanding. Doing so will lead to a comprehensive knowledge of their expectations, build trust, and open the door for tailored solutions.

Asking "What are your biggest concerns or fears regarding this project?" or "What obstacles do you anticipate?" lead to deeper conversations, trust, and pave the way for a more successful outcome.

Customization as a Competitive Advantage

It’s important to remember that the true value lies in tailoring solutions to meet the unique needs of customers, more so than achieving technical excellence. Encourage teams to consider more than just technical specs, including scheduling, budgeting and more is crucial. This sets the stage for proposing solutions that better align with customer specific needs and can lead to a competitive advantage for them.

For example, during one discussion, a client expressed concerns about project timelines and potential delays that they experienced with vendors in the past. Commitments were made to the customer’s customers, so on-time delivery was critical. After engaging in an open and honest dialogue and listening closely to their worries and discussing options and tradeoffs, led to a better understanding so the project could move forward with both parties having more confidence in it.

By understanding how they felt, we developed a detailed project plan that met their timeline and accounted for potential challenges and risks. This level of proactive engagement addressed their concerns while solidifying our status as a trusted advisor that is invested in their success, which is a higher level relationship than a partnership.

Developing a Customer-Centric Culture

Cultivating a customer-centric culture within our company is critically important as leaders. By encouraging our teams to actively listen, develop a deep understanding of customer needs with empathy, we will be in a much stronger position to serve customers in the way they need and elevate our position to that of an advisor that can be trusted.

6 notes

·

View notes

Text

🦾 A001 - MaterialHandling & Vision Inspection Kawasaki duAro DualArm

SCARA Robot KawasakiRobot @KawasakiRobot Robotics ... collaborative robots

Flexible Printed Circuits FPC

▸ TAEVision Engineering on Pinterest

Data A001 - Jul 12, 2023

#automation#robot#robotics#MaterialHandling#Vision Inspection#Kawasaki#KawasakiRobot#duAro#DualArm#collaborative robots#Flexible Printed Circuits#FlexiblePrintedCircuits#FPC

2 notes

·

View notes

Text

The smart manufacturing market is projected to reach $733.4 billion by 2031, growing at a CAGR of 24.6% from 2024 to 2031, according to Meticulous Research®. This growth is fueled by the demand for reduced operational costs through predictive maintenance, the integration of AI and ML technologies, and the increased use of 3D printing. However, challenges such as high capital expenses, a shortage of skilled personnel, and privacy concerns may hinder progress. The introduction of 5G connectivity and the rising adoption of smart manufacturing in developing countries are expected to create significant opportunities, while advanced human-robot collaboration emerges as a key technological trend.

#Smart Manufacturing Market#Industrial Internet of Things#Cloud Computing & Storage#Robotics & Automation#Industrial Cybersecurity#Augmented Reality (AR)/Virtual Reality (VR)#Digital Twin#Surveillance & Safety#Inventory & Warehouse Management#Machine Inspection & Maintenance#Production Planning#Resource Optimization

0 notes

Text

Vision Based Assembly Machine

Visimaster, another name for Varad Automation and Robotics, is a well-known brand in the Indian market for Vision Based Assembly Machine. This company produces well-known robotics and vision-based assembly machines in the market.

#Vision-Based Assembly Machine Pune#Robotics Assembly India#Horizontal Visigauge manufacturer#Vertical Visigauge Manufacturer in Pune#Machine Vision System#Certificates#Washer Inspection Machine#Robotics Automation Company Bhosari

0 notes

Text

360° No-dead-angle And No-bubble Labeling Solution

The core of the visual labeling machine lies in its highly integrated visual recognition system and advanced laminating technology. At present, many factories are manually laminating and manually positioning the auxiliary materials, but there are still bubbles and large laminating accuracy errors. In order to solve this industry pain point, the bubble-free laminating technology ensures the seamless connection between the label and the product surface, improving the overall aesthetics and market competitiveness of the product. The laminating accuracy is as high as ±0.05mm to ±0.15mm, which provides higher efficiency for labeling operations. Gosunm has developed a high-precision visual positioning auxiliary material laminating machine.

Featureds

360° no-dead-angle lamination

gosunm visual labeling machine can handle products of various complex shapes, and can achieve precise lamination no matter which part of the product needs to be labeled.

Bubble-free lamination

By precisely controlling the labeling process, ensure that the label is tightly attached to the product surface without bubbles or wrinkles, thus ensuring the labeling quality

Non-standard customization

In response to the special needs of different customers, gosunm visual labeling machine provides non-standard customization services to meet various specific production needs,

High-precision lamination

The lamination accuracy is as high as ±0.05mm to ±0.15mm, ensuring the high precision of labeling operations and meeting the industry standards with strict requirements on product quality.

Multiple advantages of visual labeling machine

◆Perfect combination of efficiency and precision

The Hardson visual labeling machine greatly improves production efficiency through automated processes. At the same time, its high-precision visual system ensures the accuracy of labeling position, meeting the dual needs of modern production for speed and quality.

◆Strong adaptability and high flexibility

Whether it is regular or irregular product shape, the Hardson visual labeling machine can quickly adapt to different labeling needs through software adjustment, greatly improving the flexibility and adaptability of production.

◆Reduce labor costs and improve safety

Automated visual labeling machines reduce the physical and mental requirements of operators, which not only reduces long-term labor costs, but also reduces errors and safety hazards that may be caused by manual operation.

Application fields and industry impact

Visual labeling machines are widely used in many fields, including but not limited to:

Consumer electronicsMainly used for labeling of structural shell accessories such as mobile phones, laptops, and tablets

Electronic componentsSuitable for laminating operations of electronic components such as cooling fans and foot pads

Emerging fieldsSuch as FPC wireless charging laminating operations, Hardson visual labeling machines meet the strict requirements of emerging technologies for labeling operations with their high precision and high efficiency

As a key component of intelligent manufacturing, the visual labeling machine has promoted the process of industrial automation. It not only significantly improves production efficiency, but also ensures the consistency and accuracy of product labeling, becoming an indispensable "precision eye" in modern manufacturing. With the continuous advancement of technology, we have every reason to believe that CCD visual labeling machines will play a more important role in intelligent production.

#visual labeling machine#gosunm#CCD visual labeling machines#visual positioning auxiliary material laminating machine#Automated visual labeling machine#visual inspection

0 notes

Text

A manufacturing line that includes a variety of equipment for cleaning, filling, capping, and labeling syrup bottles is known as a pharmaceutical syrup filling line. It’s interesting that it also has an automated syrup production facility. We are a well-known manufacturer of syrup filling lines with uses in the culinary, pharmaceutical, nutraceutical, and herbal industries. Our syrup suspension filling line, which has an elegant appearance, is furnished with state-of-the-art components for production, cleaning, filling, capping, and labeling tasks. The entire suspension fill line functions as a single, integrated system, streamlining the production process.

As one of the top exporters of oral suspension filling lines from India, Adinath has developed both fully automatic and semi-automated oral liquid filling lines. The manufacturing capacity of our filling lines ranges from 500 to 50,000 liters per day.

Let’s have a look on some of the key equipments of our syrup filling line:

Syrup Manufacturing Plant

The pharmaceutical business uses oral liquid manufacturing plants as the best instruments for producing oral liquids. It is specifically made to address two important issues that have a direct impact on the liquids’ quality. Minimal liquid handling by hand and efficient cleanliness throughout production.

youtube

Automatic Bottle Washing Machine

Our bottle washing machine, sometimes called a linear bottle washer, is widely utilized in the pharmaceutical business. It has an all-automatic setup that guarantees hassle-free vial loading on the stainless steel wire mesh conveyor. You can also push them manually from the feed table if you’re comfortable doing things that way. Use this automated machine to save a lot of labor, and you can even opt to have an automatic emptying mechanism when needed. The latter is not required.

youtube

Automatic Bottle Filling Machine

The pharmaceutical business frequently uses bottle filling machines, also referred to as bottle fillers, to pack various liquids into various bottle types. This adaptable device can be used to fill bottles, jars, and containers made of glass, plastic, aluminum, steel, copper, and PET, among other materials. It can also fill aqueous solutions, foamy liquid, and semi-viscous solutions. The machine’s essential components include feeding needles, a piston pump, a quality stainless steel slat conveyor belt, and a robust foundation structure.

youtube

Automatic Bottle Capping Machine

We provide bottle stoppers that are used to cap bottles in a variety of industries, including the manufacturing of chemicals, pharmaceuticals, food and beverage products, pesticides, and alcoholic beverages. Our bottle capping machine is constructed with an M.S. frame and stainless steel enclosures or cladding. An orientation-style cap feeder is included with our ROPP bottle cap sealing machine to ensure smooth cap feeding.

youtube

Bottle Visual Inspection Machine

Adinath International produces and exports a cGMP certified bottle inspection machine with a three track conveyor and hooded lighting configuration. Aside from an inspection table with an SS construction, there is a background that alternates between black and white for a perfect visual inspection. A slat chain made of stainless steel is also a part of it. This machine will last for many years because of its sturdy adjustable bolt support and stainless steel square pipes.

youtube

Automatic Bottle Sticker Labeling Machine

This machine is widely used for labeling PET, aluminum, glass, plastic, and copper bottles, cans, jars, and other containers. With the most advanced microprocessor control label dispensing mechanism available, this linear design machine can detect labels and items with maximum efficiency. Additionally, it features a specially created mechanical and electronic technology that is useful for quickly applying transparent labels on bottles. For the labeling of different bottle types, there are no sections that need to be changed.

youtube

#syrup suspension filling line#oral suspension filling lines#semi-automated oral liquid filling lines#oral liquid manufacturing plants#Automatic Bottle Washing Machine#Automatic Bottle Filling Machine#Automatic Bottle Capping Machine#Bottle Visual Inspection Machine#Automatic Bottle Sticker Labeling Machine#Youtube

0 notes

Text

#Automated Optical Inspection Market#Automated Optical Inspection Size#Automated Optical Inspection Growth#Automated Optical Inspection Trend#Automated Optical Inspection segment#Automated Optical Inspection Opportunity#Automated Optical Inspection Analysis 2024#Automated Optical Inspection Forecast

0 notes

Text

Intsoft Tech machine vision inspection application-lamellar defect detection

#technology in quality control#automation integrator#design automated mechanical machines#automated assembly system#surface inspection

1 note

·

View note

Text

Ensuring Workplace Safety and Efficiency with Health And Safety Audits and Work Completion Reports

In today's fast-paced and ever-evolving work environment, maintaining a safe and efficient workplace is paramount. Health and safety audits and work completion reports play a crucial role in achieving this goal. They not only ensure compliance with safety regulations but also enhance operational efficiency. In this article, we will delve into the significance of these two essential practices and explore how NestForms can streamline the process for businesses of all sizes.

The Importance of Health and Safety Audits

Health and safety audits are systematic examinations of workplace safety protocols and practices. These audits help identify potential hazards, ensure compliance with safety regulations, and foster a culture of safety within the organization. Here are some key benefits of conducting regular health and safety audits:

Identifying Hazards: Regular audits help in identifying potential hazards that may not be apparent during daily operations. This proactive approach allows organizations to mitigate risks before they result in accidents or injuries.

Regulatory Compliance: Adhering to safety regulations is not just a legal requirement but also a moral obligation. Health and safety audits ensure that the organization complies with local, state, and federal regulations, thereby avoiding costly fines and legal issues.

Enhancing Safety Culture: Conducting regular audits fosters a culture of safety within the organization. Employees become more aware of safety protocols and are encouraged to prioritize safety in their daily tasks.

Improving Efficiency: By identifying and addressing potential safety hazards, organizations can prevent accidents and downtime, leading to improved overall efficiency and productivity.

The Role of Work Completion Reports

Work completion reports are detailed documents that provide a comprehensive overview of a project's status upon completion. These reports are essential for maintaining transparency, accountability, and efficiency in project management. Here’s why work completion reports are vital:

Transparency and Accountability: Work completion reports ensure that all project stakeholders are informed about the project's status, any issues encountered, and how they were resolved. This transparency fosters accountability and trust among team members and clients.

Performance Evaluation: These reports serve as a valuable tool for evaluating the performance of both the team and the project. By analyzing the report, organizations can identify areas for improvement and implement necessary changes for future projects.

Client Satisfaction: Detailed work completion reports provide clients with a clear understanding of the work performed, ensuring their satisfaction and building long-term relationships.

Documentation for Future Reference: Maintaining detailed records of completed projects is crucial for future reference. These reports can be used as a benchmark for similar projects, helping to streamline processes and improve efficiency.

Streamlining Health and Safety Audits with NestForms

NestForms, a versatile mobile form app, offers a comprehensive solution for conducting health and safety audits. Here’s how NestForms can enhance the auditing process:

Customizable Templates: NestForms allows users to create customized audit templates tailored to their specific needs. This flexibility ensures that all relevant safety aspects are covered during the audit.

Offline Capabilities: With NestForms, audits can be conducted even in areas with no internet connectivity. The app’s offline surveys feature ensures that data is collected and stored securely, ready to be synced once the connection is restored.

Mobile Data Collection: The app’s mobile form functionality enables auditors to collect data on the go, using their smartphones or tablets. This feature enhances the efficiency of the audit process, allowing for real-time data entry and analysis.

Automated Reports: NestForms generates automated inspection reports based on the collected data. These reports provide a comprehensive overview of the audit findings, making it easier for organizations to identify and address potential safety hazards.

Enhancing Work Completion Reports with NestForms

NestForms also offers robust features to streamline the creation and management of work completion reports:

Template-Based Reporting: Users can create templates for work completion reports, ensuring consistency and accuracy in reporting. This feature saves time and reduces the chances of errors.

Real-Time Updates: The app allows for real-time updates, ensuring that all stakeholders have access to the most current information. This transparency enhances communication and collaboration among team members.

Multimedia Integration: NestForms supports the integration of photos, videos, and other multimedia elements into the reports. This feature provides a visual representation of the project’s status, making the reports more comprehensive and informative.

Secure Data Storage: All data collected and reports generated are stored securely within the app. This ensures that sensitive information is protected and easily accessible when needed.

Case Study: Improving Safety and Efficiency with NestForms

Consider a construction company that recently adopted NestForms to streamline its health and safety audits and work completion reports. Before using NestForms, the company relied on manual processes, which were time-consuming and prone to errors.

By implementing NestForms, the company created customized audit templates, allowing their safety officers to conduct thorough inspections efficiently. The offline capabilities ensured that audits could be conducted even in remote areas, and the mobile data collection feature enabled real-time data entry. As a result, the company saw a significant reduction in safety incidents and an improvement in overall efficiency.

For work completion reports, the company used NestForms to create detailed templates that included photos and videos of completed work. The real-time updates and secure data storage ensured that all stakeholders had access to accurate and up-to-date information. This transparency improved client satisfaction and helped the company build stronger relationships with its clients.

Conclusion

Health and safety audits and work completion reports are essential practices for ensuring workplace safety and operational efficiency. By leveraging the features of NestForms, organizations can streamline these processes, enhancing both safety and productivity. With customizable templates, offline capabilities, mobile data collection, and automated reports, NestForms provides a comprehensive solution for businesses looking to improve their health and safety audits and work completion reports. Embrace the power of NestForms to create a safer and more efficient workplace.

#Health And Safety Audits#Mobile Data Collection App#Automated inspection reports#Punch List Form#Work Completion Report#Project Completion Report

0 notes

Text

Automated Optical Inspection System Market News 2024-2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Automated Optical Inspection System Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Automated Optical Inspection System Market Growth share, size, trends, and forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Automated Optical Inspection System Market?

The global automated optical inspection system market size reached US$ 956.7 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 4,275.9 million in 2032, exhibiting a growth rate (CAGR) of 18.1% during 2024-2032.

What are Automated Optical Inspection System?

An Automated Optical Inspection (AOI) System is a technology employed in manufacturing to examine printed circuit boards (PCBs) and other electronic elements for defects or quality problems. This system utilizes cameras and lighting to capture detailed images of the PCB, which are subsequently analyzed by specialized software to identify issues like missing components, misaligned parts, or soldering defects. By swiftly detecting and addressing these problems, AOI systems enhance production efficiency and ensure the quality of electronic devices.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2039

What are the growth prospects and trends in the Automated Optical Inspection System industry?

The automated optical inspection (AOI) market growth is driven by various factors. The automated optical inspection (AOI) systems market is on the rise, driven by increasing requirements for top-notch electronic components across industries like electronics manufacturing and automotive. These systems are pivotal in guaranteeing the quality and dependability of printed circuit boards (PCBs) by spotting defects such as soldering problems, absent components, and misalignments. Market expansion is also steered by technological progress in AOI systems, resulting in enhanced inspection precision and effectiveness. Furthermore, stringent quality criteria and regulations in diverse industries are boosting the uptake of AOI systems for quality assurance needs. Hence, all these factors contribute to automated optical inspection (AOI) market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type

2D AOI Systems

3D AOI Systems

By Component

Software

System

By Technology

Inline AOI

Offline AOI

By Application

Fabrication Phase

Assembly Phase

By End User

Automotive

Aerospace Defense

Others

By Region

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Koh Young Technology

Omron

Viscom

Saki Corporation

Nordson

Kla

Camtek

Cyberoptics

Goepel Electronic

Irtec

Marantz Electronics

Machine Vision Products

Mycronic Ab (Vi Technology)

Dcb Automation

Pemtron

View Full Report: https://www.reportsandinsights.com/report/Automated Optical Inspection System-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Automated Optical Inspection System Market share#Automated Optical Inspection System Market size#Automated Optical Inspection System Market trends

0 notes

Text

The Future of Auto Safety: Automated Car Inspections Explained:

Discover how automated car inspections are transforming vehicle safety. Learn about the benefits, technology, and impact of this innovation on traditional car inspection stations and mobile services. Stay ahead with the latest in vehicle maintenance technology.

#car inspection stations#car vehicle inspection#vehicle inspection stations#automobile inspection stations#vehicle inspection report#mobile car inspection#vehicle inspection check#full vehicle inspection#vehicle condition report#automated car inspection#car inspection app

1 note

·

View note

Text

Understanding Market Segmentation in Automated Optical Inspection: Market Insights and Trends

The automated optical inspection (AOI) market is witnessing rapid growth driven by advancements in technology and the increasing demand for high-quality inspection solutions across various industries. This market is segmented based on type, technology, industry, application, and elements, each playing a crucial role in shaping the landscape of AOI solutions.

Type

AOI systems can be categorized into different types based on their functionality and application:

2D AOI: These systems use cameras and image processing algorithms to inspect components and printed circuit boards (PCBs) for defects such as missing components, misalignment, and soldering issues.

3D AOI: Utilizing advanced imaging techniques such as structured light or laser triangulation, 3D AOI systems offer more detailed inspection capabilities, allowing for the detection of defects on complex surfaces and components with greater accuracy.

Inline AOI: Integrated directly into the production line, inline AOI systems provide real-time inspection of PCBs and components during the manufacturing process, enabling immediate feedback and correction of defects.

Offline AOI: These standalone systems are used for post-production inspection, providing comprehensive analysis and reporting of defects identified during the manufacturing process.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=179056156

Technology

AOI systems leverage various technologies to capture and analyze images for defect detection:

Machine Vision: Utilizes cameras, lenses, and image processing algorithms to capture and analyze images of components and PCBs, enabling rapid and accurate defect detection.

Artificial Intelligence (AI) and Deep Learning: AI-powered AOI systems can learn from large datasets of images to improve defect detection accuracy and adapt to changing inspection requirements over time.

Advanced Imaging Techniques: 3D AOI systems use techniques such as structured light, laser triangulation, and phase-shift profilometry to capture detailed surface profiles and detect defects with high precision.

Industry

AOI solutions find applications across various industries, including:

Electronics and Semiconductor: AOI systems are widely used in electronics manufacturing for inspecting PCBs, components, and semiconductor devices for defects such as soldering defects, component misalignment, and foreign object debris (FOD).

Automotive: In the automotive industry, AOI systems are used for inspecting critical components such as engine parts, electronic control units (ECUs), and safety systems to ensure quality and reliability.

Medical Devices: AOI solutions play a crucial role in the manufacturing of medical devices, ensuring compliance with regulatory standards and detecting defects in components and assemblies.

Aerospace and Defense: AOI systems are utilized in the aerospace and defense industry for inspecting complex components, assemblies, and electronic systems to meet stringent quality and safety requirements.

Application

AOI systems are deployed for various inspection applications, including:

Component Inspection: Detecting defects such as missing components, misalignment, and soldering issues on PCBs and electronic components.

Surface Inspection: Analyzing surface defects such as scratches, dents, and contamination on materials and components.

Assembly Inspection: Verifying the correct assembly of components and detecting assembly errors or inconsistencies.

Quality Control: Ensuring compliance with quality standards and regulatory requirements through comprehensive inspection and defect analysis.

Elements

AOI systems consist of several key elements, including:

Cameras and Optics: Capture high-resolution images of components and surfaces for analysis.

Image Processing Software: Analyzes captured images to detect and classify defects based on predefined criteria.

Lighting Systems: Provide uniform illumination of inspection areas to enhance image quality and defect detection accuracy.

Conveyors and Handling Systems: Transport components and assemblies through the inspection process efficiently and reliably.

Control and Interface Systems: Manage AOI system operation, data acquisition, and integration with production line equipment.

0 notes

Photo

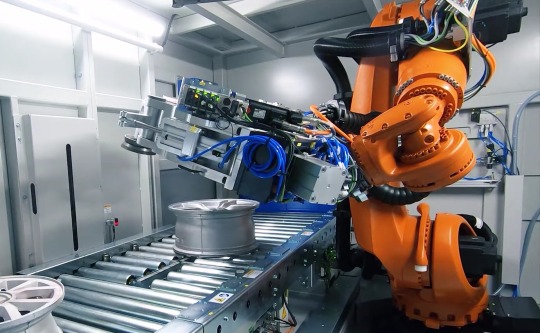

🦾 A006R - Robotic X-ray Inspection of Cast Aluminium Automotive Wheels

Robot Arm 6-axis with special gripper - BarCode inline recognition

ISAR image evaluation software - XEye detector X-ray inspection...

via HeiDetect HEITEC PTS and MetrologyNews

▸ TAEVision Engineering on Pinterest

Data A006R - Apr 12, 2023

#automation#robot#robotics#X-ray Inspection#cast aluminium automotive wheels#robot arm 6-axis#special gripper#BarCode inline recognition#ISAR image evaluation software#XEye detector#HeiDetect#HEITEC PTS#MetrologyNews

2 notes

·

View notes

Text

Smart Manufacturing Market: Key Drivers and Trends Projected to Fuel $733.4 Billion by 2031

The global smart manufacturing market is set to undergo substantial growth, expected to reach $733.4 billion by 2031, expanding at an impressive compound annual growth rate (CAGR) of 24.6% from 2024 to 2031, according to a recent report from Meticulous Research®. The market's rapid growth is primarily fueled by several key factors, including the rising demand to reduce operational costs through predictive maintenance, the integration of AI and machine learning (ML) technologies, and the increased utilization of 3D printing for additive manufacturing. However, while the market presents significant opportunities, it also faces challenges such as high capital and operational costs, alongside a shortage of skilled personnel and concerns over privacy and data protection. Despite these hurdles, advancements in 5G connectivity and growing smart manufacturing adoption in developing countries are anticipated to open up new growth avenues for industry players.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5265?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=23-09-2024

Driving Forces of Growth in Smart Manufacturing

The global push toward operational efficiency and cost reduction stands at the forefront of smart manufacturing’s growth. Predictive maintenance, which helps minimize equipment downtime and repair costs, is a significant contributor to this trend. Additionally, the integration of AI and ML into manufacturing processes allows for enhanced decision-making and operational flexibility, enabling manufacturers to optimize resource allocation and productivity.

Another pivotal factor propelling this market is the expanded use of 3D printing, or additive manufacturing, which has revolutionized the production process. By allowing for the precise creation of complex components and reducing material waste, additive manufacturing offers significant cost-saving potential, especially in industries such as aerospace, automotive, and healthcare.

However, the market does not come without its challenges. The high initial capital investment required to deploy smart manufacturing solutions, coupled with significant ongoing operational expenses, has been a barrier to entry for some companies. Moreover, the shortage of skilled labor to operate and manage these advanced systems presents a continuous obstacle. In addition, privacy concerns and the need to protect sensitive manufacturing data from cyber threats have raised further concerns among industry leaders.

Emerging Opportunities

Amid these challenges, the introduction of 5G technology is expected to unlock significant growth opportunities. 5G's high-speed, low-latency capabilities are poised to enhance communication between machines, sensors, and cloud systems, thereby enabling real-time monitoring and decision-making. The ability to remotely control and automate production processes with unprecedented precision will likely accelerate the adoption of smart manufacturing technologies.

Moreover, developing nations are increasingly adopting smart manufacturing technologies as they seek to modernize their industrial capabilities. Countries such as India, Brazil, and Vietnam have made significant strides in integrating advanced technologies into their manufacturing processes, contributing to the overall growth of the global market.

Key Technological Segments in the Smart Manufacturing Market

The smart manufacturing market can be segmented by technology into various categories, including the Industrial Internet of Things (IIoT), cloud computing and storage, robotics and automation, industrial cybersecurity, additive manufacturing, augmented reality (AR) and virtual reality (VR), digital twin, artificial intelligence (AI), and blockchain technology.

Among these, IIoT is expected to dominate the market in 2024, accounting for over 33.4% of the total market share. The increasing deployment of IIoT in manufacturing enables businesses to achieve end-to-end operational visibility, streamline processes, and reduce manual input, thus minimizing the risks associated with human error. With growing investments in smart manufacturing technologies, many companies are working to improve logistics operations and productivity through the enhanced use of IIoT.

An example of this development is the partnership between Nexans S.A. (France) and Schneider Electric SE (France), established in February 2021. The collaboration focuses on digital transformation, aiming to enhance factory digitalization, improve production line efficiency, enable predictive maintenance, and reduce carbon emissions.

Application-Based Market Segmentation

By application, the market is further segmented into areas such as surveillance and safety, quality management, resource optimization, inventory and warehouse management, machine inspection and maintenance, production planning, energy management, and more. In 2024, the surveillance and safety segment is expected to lead, commanding over 21.1% of the market share. This growth can be attributed to rising investments in 5G networks and the integration of smart cameras that monitor worker behavior, ensure machinery compliance, and detect safety anomalies.

Manufacturers are increasingly leveraging advanced technologies such as motion detection, facial recognition, geofencing violation detection, and fire recognition to boost workplace safety and productivity. These technologies also enhance employees' awareness of their surroundings, further reducing the risk of accidents.

Smart Manufacturing Across End-Use Industries

Smart manufacturing technologies are being adopted across a broad range of industries, including automotive, aerospace and defense, electronics, healthcare, and pharmaceuticals, among others. In 2024, the automotive sector is expected to capture the largest market share, representing over 14.3% of the smart manufacturing market. This growth is driven by the increasing adoption of automation, AI, and IoT solutions in automotive production facilities, which help reduce costs, improve decision-making processes, and minimize downtime.

In January 2022, ABB Ltd (Switzerland) partnered with HASCO Hasenclever GmbH + Co KG (Germany) to accelerate smart manufacturing in China’s automotive industry. The partnership aims to enhance automation and sustainability in auto parts production, showcasing the potential for further innovation in this sector.

Regional Analysis: Asia-Pacific to Lead the Market

From a geographical perspective, Asia-Pacific is expected to dominate the smart manufacturing market in 2024, with a market share exceeding 37.3%. This region's significant market share is attributed to the increasing adoption of cloud-based smart manufacturing solutions across industries such as automotive, healthcare, and pharmaceuticals. Moreover, the expansion of manufacturing hubs in countries such as China, South Korea, and Japan further supports the growth of the market in this region.

For instance, in October 2021, Japan’s Robot Revolution & Industrial IoT Initiative (RRI) partnered with the U.S.-based Clean Energy Smart Manufacturing Innovation Institute (CESMII) to promote the development of smart manufacturing and robotics in Japan. This collaboration focuses on developing pre-competitive concepts, recommendations, and practical use cases for the industry, further driving growth in the region.

Competitive Landscape

The smart manufacturing market is highly competitive, with numerous prominent players striving to expand their market presence through strategic partnerships, innovations, and acquisitions. Key players in the global smart manufacturing market include International Business Machines Corporation (U.S.), Siemens AG (Germany), Microsoft Corporation (U.S.), SAP SE (Germany), Capgemini SE (France), ABB Ltd (Switzerland), Deutsche Telekom AG (Germany), Telefónica, S.A. (Spain), Accenture plc (Ireland), TE Connectivity Ltd. (Switzerland), NXP Semiconductors N.V. (Netherlands), Telefonaktiebolaget LM Ericsson (Sweden), Intel Corporation (U.S.), Tata Consultancy Services Limited (India), Cisco Systems, Inc. (U.S.), Honeywell International, Inc. (U.S.), Mitsubishi Electric Corporation (Japan), Robert Bosch GmbH (Germany), Rockwell Automation, Inc (U.S.), and Schneider Electric SE (France).

As companies continue to focus on improving efficiency, reducing costs, and embracing digital transformation, the global smart manufacturing market is poised for tremendous growth over the coming years. With rapid advancements in technology, emerging economies adopting smart manufacturing solutions, and increasing investments in research and development, the market is set to revolutionize the future of manufacturing on a global scale.

Read Full Report :- https://www.meticulousresearch.com/product/smart-manufacturing-market-5265?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=23-09-2024

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Smart Manufacturing Market#Industrial Internet of Things#Cloud Computing & Storage#Robotics & Automation#Industrial Cybersecurity#Augmented Reality (AR)/Virtual Reality (VR)#Digital Twin#Surveillance & Safety#Inventory & Warehouse Management#Machine Inspection & Maintenance#Production Planning#Resource Optimization

0 notes

Text

Horizontal Visigauge Manufacturer in pune | India

The brand most closely linked with horizontal vision production in all of India is Visimaster (also known as Horizontal Visigauge Manufacturer). Their specialty is the manufacture of instruments for visual examination. To assist in the development of more precise vision inspection devices, each department has specialized teams.

#Horizontal Visigauge manufacturer#Vertical Visigauge Manufacturer in Pune#Machine Vision System#Certificates#Washer Inspection Machine#Robotics Automation Company Bhosari#vision inspection machines#automatic sorting machines

0 notes