#Automatic Bottle Capping Machine

Explore tagged Tumblr posts

Text

Reliable Semi-Auto Crimping Machine | NPM Machinery

Looking for a high-performance Crimping Machine? NPM Machinery offers a reliable Semi-Auto Crimper for precise cap sealing. Ideal for pharma & cosmetics.

Explore now at NPM Machinery.

#Crimping Machine#Semi Auto Crimper#Cap Sealing Machine#Pharma Packaging Machine#Cosmetic Packaging Equipment#NPM Machinery#Bottle Capping Machine#Packaging Automation#Industrial Crimping Equipment#Semi Automatic Capping Machine#Pharmaceutical Machinery#Cosmetic Machinery#Sealing Solutions#Crimping Solutions#Reliable Crimping Machine

0 notes

Text

Pour, Pack, Preserve: Nichrome’s Packaging Powerhouse Arrives at ProPak East Africa

Packaging is experiencing a significant shift in Africa. Manufacturers in the Africa region are seeking smart, scalable solutions due to rising consumer interest, growing agro and dairy industry. ProPak East Africa 2025, the region's most significant and influential processing and packaging exhibition, is at the heart of this evolution. And, Nichrome is once again at the forefront.

With a rich legacy of experience, Nichrome has transformed the way brands package milk, grains, pulses, powders and liquids in India. Our focus at ProPak East Africa is not solely on machines, but also on facilitating new possibilities. Our show floor will showcase a powerful combination of state-of-the-art technology, application-specific engineering, and deep understanding of African market dynamics.

We're offering end-to-end packaging solutions for your business at an advanced level, so take a look at what Nichrome is exhibiting at ProPak East Africa 2025.

Liquid Packaging Solutions: Edible Oils, Detergents & Beyond

Handling liquids and ensuring their seals are free of any contamination. Filpack Servo 6K, FilPack Servo 12K and Filpack CMS 5L are Nichrome's VFFS and High Fidelity Flavors (HFFS) liquid packaging machines that can process edible oil sack or detergent pod fillings.

Edible Oils

Edible Oil Packaging Machine solutions come in the form of multi-layer, nitrogen-flushed pouches that retain freshness.

With servo-driven accuracy, our Bottle Filling Capping Machine lines, including the Filpack Universal bottle filler, can safely fill up to 6,000 bottles/hr.

Detergents & Powders

Our detergent packaging machine integrates an auger filler for powders and a volumetric cup filler for granules, ideal for washing powder and detergent sachets.

Washing Powder Packaging Machine setups feature quick‑change feed screws to switch between coarse and fine powders in minutes.

Mini Dairy Plant & Milk Packaging:

Hygiene and consistency are essential aspects of any dairy production. Our mini dairy plant puts pasteurization, homogenization, and pouch‑packing under one roof—ideal for small to medium cooperatives and private dairies.

We pioneered India’s first milk pouch packing machine in 1977, and today our milk filling machine range includes:Filpack Universal, Excel 400 and Filling lines.

Why settle for generic when you can get application‑specific? Our automatic powder packaging machine and bottle filling capping machine keep your line flexible, moving from edible oil pouches to detergent sachets with ease. We guarantee our products will never break.

Powder & Granular Packaging: Speed, Accuracy & Versatility

From sugar to spices, our powder and granule systems are built to scale. At ProPak East Africa, we’ll demo:

Powder sachet packaging machine for milk powder, RTE mixes, and spices

Volumetric cup filler units for rice, pulses, maize, and wheat

Auger filler packing machine modules for fine powders like flour and detergent

Key machines on display:

Excel 400 with Servo Auger Filler: Packs up to 400 sachets/min with ±1 % precision.

Sprint 250: Compact, high‑speed VFFS for small‑batch runs of spices and coffee.

Flexible 450: Multi‑lane powder sachet packaging machine—perfect for RTE coffee mixes.

Our solutions are suitable for center, threeside, gusseted, and zipper pouches, which can be used with rice packaging machines, maize packaging machinery, or wheat packaging equipment. Changeovers are now simple, meaning you can easily switch from sugar to coffee packaging machine formats.

Agrochemical & Seed Packaging: Precision Under Pressure

Agribusinesses require machines that handle corrosive chemicals and bulk seeds with extreme care. Enter our seed packaging machine and Pulses Packaging machine lines:

Anti-corrosive contact parts and dust-tight enclosure design are hallmarks of our seed packaging machine units.

Various pulses packaging machines are equipped with nitrogen flushing to prevent rancidity.

Our automatic powder packaging machine can control the dosage of powdered pesticides and fertilizer, while our powder packaging machines with multitrack heads achieve rates up to 1,200 packs/min. The ability to customize powder sachet packaging machine configurations for 5 g–50 ml is essential for small dose agrochemicals.

Our agro line is built with safety in mind: emergency‑stop interlocks, ATEX‑rated motors, and full CE certification. When you need a seed packaging machine that won’t quit halfway through planting season, you know who to call.

Tea, Coffee & Snack Packaging: Freshness You Can Taste

The scent of freshly ground coffee or crunch of your favourite snack is omnipresent almost everywhere, making it imperative that your packaging machine maintains that aroma and taste.

Coffee & Tea

Our Coffee packaging machines are equipped with features such as nitrogen flushing, vacuum sealing, and tamper‑evident sachets for singleserve and bulk configurations. Our cup filling sealing machine can divide leaf tea into individual cups with the lid applied automatically for tea delivery.

Snacks & Yogurt

The cup filling lines deliver up to 240 cups/min for pudding, yogurt, and RTE noodles. Coupled with our cup filling sealing machine, you get leak‑proof seals—crucial for chilled snacks. And yes, our Yogurt Packaging Machine ensures creamy consistency every time.

Whether you’re in the chai business or snack aisle, Nichrome has you covered: from Sugar Packaging machine sachets for traditional tea to multi‑serve coffee canisters.

Why Nichrome is Africa‑Ready

To cope with the exceptional conditions in Africa, machines must be robust enough to handle humidity levels, voltage fluctuations, and dust. We've invested in:

Local service hubs in Kenya, Uganda, Tanzania, Rwanda, and Nigeria

Tech‑savvy field engineers who speak Swahili, English, and French

Customized voltage stabilizers & heat‑resistant components

Our ROI calculators show payback in 12–18 months for mid‑range lines—thanks to reduced labour, lower scrap rates, and 24/7 reliability. We calibrate each rice packaging machine, maize packaging machine, and milk filling machine for local SKUs, ensuring your line doesn’t hiccup when you switch from 500 ml milk pouches to 50 g coffee sachets.

We’re not just here to be at booth C5, we’re to be your long‑term partner. From training your team on the mini dairy plant to stocking spares for your Detergent Packaging machine, we stand behind every solution with genuine, end‑to‑end support.

Ready to Package Smarter? Join Us at ProPak East Africa 2025

At Nichrome, we don’t just sell machines—we build packaging ecosystems designed to grow with you. Every solution we showcased at ProPak East Africa 2025—from the versatile Filpack CMD Alpha and compact mini dairy plant, to our advanced powder sachet packaging machines and bottle filling capping lines—is engineered with purpose. Whether it’s a milk pouch or a detergent sachet, a spice pack or an agrochemical dose, we customize and deliver with precision, speed, and scalability. Join us at:

Date: May 20–22, 2025

Venue: Sarit Expo Centre, Nairobi

Stall No.: Booth C5

Swing by to see live demos of our Filpack CMD Alpha, Excel 400, Sprint 250, and integrated mini dairy plant in action. Chat one‑on‑one with our experts, get tailored proposals, and pick up show‑only deals. We can’t wait to help you scale up, streamline, and dominate your category.

FAQs

1. Can Nichrome customize packaging machines for my specific product or pouch format? Ans: Absolutely! Whether you need a powder sachet packaging machine, rice packaging machine, bottle filling capping machine, or a cup filling sealing machine, Nichrome offers modular configurations with flexible fillers (auger, cup, weighers) and pouch styles (3-side seal, gusseted, zipper). We even help with product trials and format changeover support for smooth commissioning.

2. How do Nichrome machines handle sensitive products like dairy, detergent, or seeds? Ans: Our machines are engineered with product-specific technologies—like nitrogen flushing for milk and seeds, anti-corrosive components for chemicals, and hygiene-first designs for dairy. For example, the Yogurt Packaging Machine ensures cold-chain integrity, and the Automatic Powder Packaging Machine features dust-free enclosures for fine detergents or agrochemicals.

3. Does Nichrome provide after-sales support in East Africa? Ans: Yes! Nichrome has established service hubs across Kenya, Uganda, Tanzania, Nigeria, and Rwanda, with multilingual engineers and ready access to critical spares. We offer training, remote diagnostics, AMC packages, and performance optimization to ensure that every sugar packaging machine, seed packaging machine, or pulses packaging machine runs at peak efficiency.

4. What’s the ROI on investing in Nichrome’s packaging automation? Ans: Our packaging systems deliver ROI within 12 to 18 months, thanks to higher OEE, reduced wastage, and lower labor dependency. For instance, our mini dairy plant can reduce manual operations by 30% while increasing output with consistent quality. We also provide ROI calculators tailored to your product and throughput goals.

5. Why should I visit Nichrome at Propak East Africa 2025?

Visiting Nichrome at Propak East Africa 2025 means experiencing packaging innovation firsthand. You'll get to know more about our innovations across sectors like dairy, edible oils, detergents, seeds, and coffee. It’s your chance to meet our experts, explore tailor-made packaging systems, and get business-specific consultations that can future-proof your packaging line.

#Edible Oil Packaging Machine#liquid packaging machines#Bottle Filling Capping Machine#detergent packaging machine#Washing Powder Packaging Machine#mini dairy plant#milk filling machine#automatic powder packaging machine#Powder sachet packaging machine#rice packaging machines#maize packaging machinery#wheat packaging equipment#seed packaging machine#Pulses Packaging machine#Coffee packaging machines#cup filling lines#Yogurt Packaging Machine#Sugar Packaging machine#bottle filling capping lines

0 notes

Text

From Fill to Finish: Mastering Packaging with Nichrome’s Integrated Systems

In a rapidly evolving manufacturing sector where every minute of downtime is a deal-breaker and manual processes are considered a thing of the past, integrated packaging solutions are the new superstars of the modern production line. Whether it is bottling honey, pharma-grade filling in jars or cartoning pouches for FMCG, efficiency is not just an option anymore, it is a…

#advanced bottle filling line solution#Automatic Bottle Filling Machine#Automatic Carton Box Packing Machines#automatic filling machines#automatic packaging machines#automatic filling and sealing system#•#bottle filling line solution#filling lines#High-speed labeling systems#Horizontal Flow Wrap Machines#integrated packaging solution#integrated packaging solutions#jar filling linessecondary packaging solutions#jar packaging systems#oil filling machine#packaging solutions#Pouch stacking and bundling systems#rotary capping machines#secondary packaging innovations#secondary packaging solutions#smart packaging ecosystems#tool-less changeover

0 notes

Text

The Lodha Pharma bottle screw capping machine is a sophisticated and effective piece of machinery used in the cosmetic, pharmaceutical, and other sectors to seal bottles with screw caps. The high-speed functioning of this machine guarantees a prompt and dependable sealing process, which is crucial for preserving the safety and integrity of the product. Check the site at https://www.lodhapharma.com/semi-automatic-bottle-capping-machine.php for additional information

0 notes

Text

WAE’s Glass Bottle Filling Station aims to eradicate Plastic Bottles

WAE is a complete drinking water solution-providing company, committed to this indispensable resource called “water” on this planet, Earth. An Original Equipment Manufacturer (OEM) with a firm foundation in scientific research and innovative technologies, its focus and collegial approach enables it to develop complete sustainable drinking water solutions that sync with the principles of circular economy and help it to become an active participant in the resource revolution.

The firm is reckoned for providing efficient and complete drinking water solutions as well asother vendingmachines and has come up with one of its latest launches, the glass bottling plant, which is all set to transform the hospitality sector by introducing sustainable and reusable small glass water bottles, eradicating the use of plastic bottles or jars for good. In fact, the above is also the main motto of the company for launching this hi-tech glass bottle filling plant which will certainly help in minimizing plastic waste.

The Unique Concept: WAE’s glass bottling plant for hotels is all set to revolutionize the hospitality sector by its innovatively designed and technologically advanced glass bottling machine to mechanically rinse, clean, fill and cap the recyclable glass bottles with pure drinking water, ready to use. Only the bottles have to be manually placed on the machine in an inverted position for cleaning and rinsing purposes with hot water or detergents, and this process is also customizable. Then these cleaned and inverted glass water bottles pass through a conveyor belt to get dried up by air. It is after the execution of all these processes that the refillable glass bottles pass through the LED chamber for further cleaning and sterilization.

The glass bottles then pass through the filling stage where they are filled with clean and hygienic water for drinking purposes. Later, the bottles are inspected manually in the next stage. Then these small glass water bottles are finally capped and screwed tightly to avoid any leakage. The last stage is the labelling or putting stickers on the bottles. Therefore, this technologically advanced glass bottling plant is undoubtedly the best choice for the hospitality sector and can be ideally used in all luxury hotels, restaurants and resorts. Moreover, WAE, with a vast experience and expertise of more than 15 years in providing complete, sustainable drinking water solutions can be ideally referred to as the one of the best glass bottling plant manufacturer of India!

#- Glass bottling plant#glass bottling plant for hotels#glass bottling water plant#glass bottle filling station#automatic bottle filling plant#rinsing#filling and capping machine

0 notes

Text

How Nichrome’s End of Line Machines benefits businesses with efficiency

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

WAE’s Glass Bottling Plant – A Boon to the Hotel Industry!

WAE is a complete drinking water solution-providing company, committed to this indispensable resource called “water” on this planet, Earth. An Original Equipment Manufacturer (OEM) with a firm foundation in scientific research and innovative technologies, its focus and collegial approach enables it to develop complete sustainable drinking water solutions that sync with the principles of circular economy and help it to become an active participant in the resource revolution.

The company is reckoned for providing efficient and complete drinking water solutions as well as other vending solutions like tea, coffee and breakfast, and has come up with one of its latest launches, the glass bottling plant, which is all set to transform the hospitality sector by introducing sustainable and reusable small glass water bottles, eradicating the use plastic bottles or jars for good. In fact, the above is also the main motto of the company for launching this hi-tech glass bottle filling plant which will certainly help in minimizing plastic waste.

The Unique Concept: WAE’s glass bottling plant for hotels has certainly revolutionized the hospitality sector by its innovative, technologically advanced glass bottling machine to mechanically rinse, clean, fill and cap the recyclable glass bottles with pure drinking water, ready to use. Only the bottles have to be manually placed on the machine in an inverted position for cleaning and rinsing purposes with hot water or detergents, and this process is also customizable. Then these cleaned & inverted glass water bottles pass through a conveyor belt to get dried up by air. It is after the execution of all these steps that the refillable glass bottles pass through the LED chamber for further cleaning and sterilization.

Then the bottles pass through the filling stage where they are filled with clean and hygienic water for drinking purposes. The bottles are then inspected manually in the next stage. Then these small glass water bottles are finally capped and screwed tightly to avoid any leakage. The last stage is labelling or putting stickers on the bottles. Therefore, this technologically advanced glass bottling plant is undoubtedly the best choice for the hospitality sector and can be ideally used in all luxury hotels, restaurants and resorts. Moreover, WAE, with a vast experience and expertise of more than 15 years in providing complete, sustainable drinking water solutions can be ideally referred to as the one of the best glass bottling plant manufacturer of India!

#glass bottle filling station#glass bottling plant for hotels#automatic bottle filling plant#sustainable drinking water solutions#wae#rinsing#filling and capping machine#washing filling and capping machines

0 notes

Text

Revolutionizing Liquid Packaging: The Role of Superfil Engineers Pvt Ltd in Unveiling Innovative Solution

Introduction:

In the realm of liquid packaging, the interplay of technology and innovation has paved the way for efficiency and excellence. In recent times, the industry has witnessed a paradigm shift owing to the emergence of cutting-edge solutions that have redefined the standards of packaging. Superfil Engineers Pvt Ltd, a pioneering name in the packaging sector, has been at the forefront of revolutionizing the landscape with its exceptional offerings. Let’s delve into the groundbreaking liquid packaging innovations and the transformative role played by Superfil Engineers Pvt Ltd.

Liquid Packaging Innovations Redefining the Industry:

Bottle Filling Machines:

Superfil Engineers Pvt Ltd has set a new benchmark with its state-of-the-art bottle filling machines. These machines are designed with precision to ensure seamless and efficient filling processes. The incorporation of advanced technologies has enabled these machines to handle a diverse range of liquids with varying viscosities, streamlining the production process for various industries such as beverages, pharmaceuticals, and more.

Shrink Wrapping Machines:

The introduction of shrink wrapping machines by Superfil Engineers Pvt Ltd has redefined the concept of product packaging. These machines offer a streamlined approach to packaging, providing a secure and appealing wrap around various products. With customizable options and user-friendly interfaces, these machines have significantly enhanced the efficiency of packaging operations, catering to the evolving demands of the market.

Mineral Water Plants:

Superfil Engineers Pvt Ltd’s innovative mineral water plants have revolutionized the production and packaging of purified water. These plants integrate cutting-edge purification technologies with advanced packaging solutions, ensuring the delivery of safe and high-quality mineral water to consumers. The company’s commitment to sustainability is reflected in the energy-efficient and eco-friendly features of these plants, making them an ideal choice for environmentally conscious businesses.

Fully Automatic Jar Filling and Capping Machines:

The fully automatic jar filling and capping machines developed by Superfil Engineers Pvt Ltd have streamlined the packaging of various liquid products, including jams, sauces, and more. These machines offer a comprehensive solution, from filling to capping, ensuring airtight packaging and preserving the freshness and quality of the contents. With their high-speed operation and minimal manual intervention, these machines have significantly increased production efficiency and reduced operational costs for businesses.

Automatic Bottle Rinsing Machines:

Superfil Engineers Pvt Ltd’s automatic bottle rinsing machines have transformed the cleaning process, ensuring impeccable hygiene standards in the packaging industry. These machines are equipped with advanced rinsing mechanisms that efficiently remove impurities and contaminants from bottles, guaranteeing a clean and sanitized packaging environment. With customizable settings and user-friendly controls, these machines have become an indispensable asset for businesses striving for impeccable product quality and consumer safety.

The Impact of Superfil Engineers Pvt Ltd:

With a relentless focus on innovation and customer-centric solutions, Superfil Engineers Pvt Ltd has emerged as a trailblazer in the liquid packaging industry. The company’s commitment to excellence, coupled with its dedication to incorporating the latest technologies, has empowered businesses to optimize their production processes and achieve unprecedented levels of efficiency and quality.

Superfil Engineers Pvt Ltd’s commitment to sustainability is evident in its eco-friendly packaging solutions and energy-efficient machinery, aligning with the growing global demand for environmentally responsible practices. By offering comprehensive support and after-sales services, the company has fostered enduring relationships with its clientele, earning trust and recognition as a reliable partner in the liquid packaging domain.

Looking Ahead:

As the liquid packaging industry continues to evolve, Superfil Engineers Pvt Ltd remains steadfast in its pursuit of innovation and excellence. With a focus on anticipating market trends and customer needs, the company is poised to introduce groundbreaking solutions that will shape the future of liquid packaging. By staying true to its core values of quality, innovation, and sustainability, Superfil Engineers Pvt Ltd is set to solidify its position as a global leader in the liquid packaging sector.

Conclusion:

In the ever-evolving landscape of liquid packaging, Superfil Engineers Pvt Ltd stands as a beacon of innovation and excellence, driving the industry forward with its groundbreaking solutions. Through its cutting-edge technologies and unwavering commitment to customer satisfaction, the company has redefined the standards of efficiency, quality, and sustainability in liquid packaging. As the journey continues, Superfil Engineers Pvt Ltd remains dedicated to pioneering transformative solutions that will shape the future of liquid packaging for generations to come.

bottle filling machine

carbonated soft drink plant

carbonator machine

fully automatic jar filling and capping machine

mineral water plant

shrink wrapper machine

shrink wrapping machine

superfil

superfil engineers pvt ltd

#bottle filling machine#carbonated soft drink plant#carbonator machine#fully automatic jar filling and capping machine#mineral water plant#shrink wrapper machine#shrink wrapping machine#superfil#superfil engineers pvt ltd#superfil engineers#carbonated beverage mixing machine#automatic bottle rinsing machine#packaged drinking water plant

0 notes

Text

Someone New 4

No tag lists. Do not send asks or DMs about updates. Review my pinned post for guidelines, masterlist, etc.

Warnings: this fic will include angst, pining, romcom tropes, and some darker elements later in the series. Some triggers may not be specifically tagged. My warnings are not exhaustive, enter at your own risk.

This fic will contain explicit content. 18+ only. Your media consumption is your own responsibility. Warnings have been given. DO NOT PROCEED if these matters upset you.

Summary: You’ve had a crush on your best friend for years, but you’re slapped in the face with reality when he takes things to the next level with his girlfriend.

Characters: Steve Rogers, Thor

Note: I got like insanely sick suddenly and I still feel off.

As per usual, I humbly request your thoughts! Reblogs are always appreciated and welcomed, not only do I see them easier but it lets other people see my work. I will do my best to answer all I can. I’m trying to get better at keeping up so thanks everyone for staying with me.

Your feedback will help in this and future works (and WiPs, I haven’t forgotten those!) Please do not just put ‘more’. I will block you.

I love you all immensely. Take care. 💖

“Sam, that paradise punch was a bad idea,” you groan as you struggle to get your bag out of the trunk of the taxi.

“Whatever,” Sam slurs as he comes around, “I tipped the driver extra. Bud, you think you can get this out for the lady?”

The driver is all to helpful as he comes around you take the handle from you and swiftly plants the bag on its wheels. It’s everything you have that isn’t bundled up into storage or sacrificed to the dumpster. You thank the man and swallow a belch.

“Have a safe trip, miss,” the driver nods and turns to slap Sam’s arm, “and you, sir.”

Sam salutes the man and pushes away from the cab, your carry-on slung from his shoulder. The two of you clumsily lift the bag over the curb. You look up at the airport as the roar of jet engines cuts through the dusky air.

“I feel like I’m drunker,” Sam snickers.

“Uh huh, me too,” you murmur. Two hours on his couch was barely enough. If anything, it’s just set your vision askew. “They’re not gonna let me board if – hiccup—I'm blasted.”

“Don’t worry, we can get water,” he blathers and yanks your bag onto its wheels, “off to the land of vikings! Skol!”

“Skol?” You follow him in a clamour.

“It’s what they say, isn’t it?” He chuckles, “I saw it on a show or whatever.”

“I... yeah, usually while they drink, not stumbling drunk,” you rebuff.

“Sound pretty sober to me with all that whining,” he rebukes.

“Whatever,” you roll your eyes and follow him through the automatic doors.

He veers off and you follow him in confusion, glancing back at the check-in counter. He stops before a bright vending machine and feels around in his pocket. He taps his card and focuses intently on pressing the button.

“Waterrrrr,” he drones and leans on the machine to reach through the slot.

He hands it over and you unscrew the cap. You chug half the bottle and let out an obnoxious belch. You cover your mouth in embarrassment and offer him the rest. He finishes it off and you linger by the machine as you let the cool flow settle in.

“Feel any better?” He asks.

“A little. I’ll have a coffee on the plane.”

“Nah, you should sleep.”

“Maybe,” you take out your phone and tap the side button. Nothing.

“Anything from Mr. Carter?” Sam asks.

“No,” you black the screen and shrug. “Come on, I gotta check my bag.”

“You should check that boy,” he blathers as he stands straight and once more yanks the bag after you, “tell him what’s what.”

“Sam, he’s busy--”

“He’s your best friend! At least, he likes to say so then do nothing.”

“Quit,” you beg him, “this is hard enough.”

“This is what you need--”

“I know!” You throw your hands up and face him as you come up before the counter. “I know. Okay. I’m stupid and---” you shake your head and let the truth sink back into the depths of your soul. You face the clerk and sigh, “I’m sorry, I’m here to check my bag.”

You pull out your wallet and slide your passport across the counter. You show your boarding pass and pay for the extra weight. Your bid a safe journey and carry on with only the smaller bag still on Sam’s shoulder.

Wordlessly, you sit in a row of seats. You look up at the clock. You’ll have to go to the boarding area sooner than later. He won’t be able to come with you.

“Sam, I’m sorry. I just... is it that obvious?” You croak.

He puts his hand on your back and rubs it gently. It’s soothing. The tension trickles down your sides and seeps out. It feels good to admit it aloud yet mortifying just the same.

“No, I just sense these things. I know Steve, I know you, and I know he doesn’t deserve you. Even as just friends.”

“Ugh,” you put your head in your hands, “I am so stupid.”

“No, you’re not. You’re human. It stinks. Our brains, our hearts, they aren’t logical, as much as we like to pretend,” he huffs, “trust me. We’ve all been there and if we haven’t, we’ll get our turn.”

“Yeah, I guess,” you sit up as your eyes glisten, “I just... he said he’d be here. I thought I’d at least get that--”

Your name echoes through the airy space and you wince. Right on cue, just before you can collapse completely. You turn as Steve rushes toward you. He wears jeans and grey sweatshirt. He remembered!

You stand as Sam sighs. You smile, only halfway before you see the figure trailing behind him. Peggy looks less than excited to be there. Her sleepy lashes flutter as her wave hair is pinned back in a messy chignon, still elegant despite the carelessness. She wears a dark green trench over a silver satin nightie. She must’ve rushed out with him.

“Hey,” Steve nears, “sorry I couldn’t make it for drinks, but I couldn’t miss take-off.”

“Mmm, they don’t have any afternoon flights,” Peggy mutters.

“They do but landing doesn’t line up with the train,” you shrug and glance at her briefly. Her glare darts back at you. You wonder if that work dinner was so impromptu after all.

“Are you excited?” Steve drops into the seat next to you.

“Uh, yeah, nervous,” you smile as the weight lightens from your chest. He came. Maybe Sam is wrong. Maybe friends isn’t that bad.

“It’s going to be great. You have to send me updates, oh, and I’ll be sure to send you all the wedding news!” He grins, “I still can’t believe you’re going to be so far away.”

“It’s a good opportunity,” Peggy intones as she sits on his other side, resting her hand on his forearm, “in her line of work, I’m sure they don’t come often.”

You press your lips tight and look down, “yeah, not really.”

“She can get out. Make new friends. Some girl friends, maybe,” Peggy remarks.

“I’m sure she’ll make all the friends,” Sam interjects, “I hear there isn’t much sunlight over there, she’ll be a breath of fresh air for those grumpy vikings.”

“Mm, yes,” Peggy grumbles as she trails her hand down to Steve’s. “Too bad you won’t make the engagement party.”

“Or the wedding,” Steve adds.

“Well, we’ve a full wedding party as it is,” she shrugs. “There’ll be lots of pictures.”

“Right, yeah, I’m sorry to miss it all,” you frown. “I...” you sit back and nearly choke, “I’m gonna hit the bathroom.”

You stand as Sam puffs out heavily and to your surprise, Peggy swiftly gets to her feet, suddenly very awake. Your soberness is setting in along with a pulsing headache. You really don’t want to deal with her. If you knew he’d bring her, you’d have told Steve to stay home.

“I’ll come with you. I’m splitting at the seams,” she trills.

“Alright,” you agree with a tint of uncertainty.

She twirls and you walk parallel to her towards the bathroom signs. You chalk it up to the feminine habit. It isn’t unusual to visit the toilets in pairs, even without much kinship between you. It does however spoil your attempt at respite. You less so want to empty your bladder than clear your mind.

You don’t say a word as you enter the bathroom. You go into a stall and she does the same. Your mind clogs your biology and you have to sit and focus before you can get a flow going. By the time you’re trickling into the bowl, she’s done. A toilet flushes and you hear her unlatch the door and approach the sinks.

She’s in heels, even at this hour. The sink sprays out water and you listen to her hum as she washes her hands. You finish up and flush, coming out meekly to use the sink next to her. You focus on the simple task as she watches you in the mirror.

Sensing her gaze, you look up and pull your hands out from under the censor-activated faucet. You meet her eyes and nearly wince at the steely intensity. You stand straight and move past her to retrieve some paper towel.

“This is a wise decision,” she says, “well-needed.”

You look at her again as you dry your hands, “thanks.”

“Oh, I’m not congratulating you. About time you got some sense,” she sneers.

You wince and crumple up the towel. You drop it in the bin and cross your arms, “okay, well...”

“It’s better you’re not here for any of it. He doesn’t need the distraction.”

You chew the inside of your lip as venom drips from her voice. You’re still slightly tipsy and too tired to process this. You have no response.

“The distance will help you get over it. Finally,” she snips, “you know, I thought it was almost endearing at first then it just became pathetic.”

You swallow. You’re humiliated that even she could see right through you. You can hardly blame her for her spite. After all, she’s his fiancée, not you.

“He thinks it’s silly. He laughs.”

You flinch then. Hard. Your chest rents and your stomach boils.

“He knows. It’s obvious. I mean, it’s convenient, isn’t it? You’ll do anything for him and really it was rather helpful. Took a lot off my plate and his but it’s time for all of us to grow up. I will be his wife and he doesn’t need some girl to measure out his laundry detergent or remind him to eat.”

You blink and look away. You cross your arms and push your shoulders up, “got it.”

“So why don’t you go ahead and just put him on mute now?”

“Peggy,” you whisper.

“We’re getting married. You know you can’t stop it, that’s why you’re running away. So end it.”

“You don’t have to be cruel,” you mutter.

“I could be horrid. I could have been for all these years. I believe I’ve had remarkable restraint with you,” she points a manicured nail at you, “you should be thanking me for having the grace to do this in private.”

Your lip trembles and your cheeks tug painfully. You nod and turn away, “don’t worry, Peg, you won’t hear from me. He won’t either.” You make your way to the door, “I wish you both the best.”

“Mm, I pray you find some clarity and perhaps some maturity along the way,” she retorts as she follows you, heels clicking loudly across the tile, “perhaps you might find someone too. Someone you deserve.”

Her last words sting. The derision is pungent enough to make your nose crinkle. Someone you deserve... because you could never ever be good enough for Steve Rogers.

💟

You don’t look back as you go through the gate. You can’t. It’s too painful. The tears have receded but the pain is only deeper. Peggy’s words reverberate in your head, nipping at your ears as your nape burns hotter and hotter.

She’s right. Sam too. This is overdue. It’s exactly what you need to do. You know it. It’s the reason you chose this. That moment when you were faced with being the eternal wobbly third wheel, you made up your mind. It’s over. That part of your life is behind you, but you don’t know that you’ll ever stop feeling this way.

It’s hard to settle in your seat, even knowing you have ten hours of flying ahead of you. Disembarking alone will be another hour at least, then finding the train station, another few hours... It’s a lot of time to think and you just can’t stop.

You don’t take the book out of your bag or touch the screen in front of you. Instead, you sit, slumped down in your seat, eyes drifting back and forth, as you wallow in your self-pity. You stay like that through the flight. You decline the mid-flight meal and the snack cart. You don’t even get up to use the bathroom.

You close your eyes and float away into memory. You can feel the scene around you. You can smell the stale air freshener forgotten on the shelf above the desk and hear the muffled thrum of music through the walls. You sit on the bed, your textbook open in your lap and your laptop open by your leg. Steve’s on the other end, phone in hand, texting as his golden hair flops forward over his head.

He’s younger. That rosiness still kisses his cheeks as subtle freckles speckle his pale skin. Yet he’s just a well-built as ever. Broad shoulders, chiseled jaw, long legs. He’s the very picture that should appear next to ‘hunk’ in the dictionary. Every girl’s dream. Your dream.

“Huh,” he chuckles and drops his phone, “this girl in my history class wants to meet up.”

Your heart plucks and you force a smile, “a girl? Meet up?”

“Oh, yeah, she lets me copy off her pop quiz every lecture. Guess I kinda owe her.”

“Wow,” you utter, the only noise you can eke out. Owes her? Funny, you did his laundry last week and helped him print out his term paper... what do you get?

“Yeah, so uh, do you think you could send me a copy of your notes?” He pushes himself to the edge of the bed. “I probably won’t be back tonight.”

“Right,” you nod and hide your embarrassment at the insinuation.

“You can crash here if you wanna. Long way across campus at night,” he shrugs casually as he grabs his varsity jacket.

“No, I’ll... I’ll just go now,” you get off the bed and close up your books.

“Probably a good idea. Just in case she wants to come back here,” he chuckles, “see ya in poli sci?”

“Sure,” you keep your chin down. “See ya.”

Your eyelids lift as you come out of the dazed memory.

New York is gone. Steve is gone. You’re all alone. You’ve left it all behind but that home was never a home. It was all a farce you built on a childish hope. You’re done lying to yourself. It was never going to be. You didn’t miss any chance at all. You just wasted your own time.

You just languish there in the airplane seat. It’s still hard to believe it’s all real. It isn’t until the wheels bounce and hit the tarmac that it fully sinks in.

You’re not doing that again. You’re better off alone. You have to be, right? You don’t really know. You don’t even know yourself. You just know the girl who only wanted to be what he needed.

But what do you need? What do you want? Can you figure it out? Is there anything in this land for you that you couldn’t find in New York?

At least you’ll have lots of time to figure that out. Intimate hours with yourself to dwell and cringe and regret. Time to think, time to move on, time to cut him out.

As you join the line to have your Visa stamped, you pull out your phone and turn off airplane mode. You swipe through to Steve’s last message. It was weeks ago. That makes it easier to hit that button; ‘mute’. It’s a start. Maybe in a few weeks, you’ll be ready to hit ‘block’.

#steve rogers#series#au#fic#grayish fic#angst fic#someone new#mcu#marvel#avengers#captain america#steve rogers x reader#thor x reader#thor

370 notes

·

View notes

Text

Automatic Bottle Cap Sealing Machines

Automatic Rotary Bottle Capping Machine is suitable for the capping of round or other shape of Glass, Plastic, PET, LDPE, HDPE Bottles. Adinath offers various models of Capping Machine range from 60 bottles per minute to 180 bottles per minute. Our Six Head Bottle Screw Capping Machine is suitable for production up to 180 bottles per minute, our Four Head Bottle Screw Capping Machine is suitable for production up to 120 bottles per minute and our Single Head Bottle Screw Capping Machine is suitable for production up to 60 bottles per minute. Automatic Bottle Capping Machine is widely uses in Pharmaceutical, Food, Pesticide, Cosmetic & allied industries.

#Automatic Rotary Bottle Capping Machine#Capping Machine#Four Head Bottle Screw Capping Machine#Automatic Bottle Capping Machine

0 notes

Note

love love LOVE your blog!! do you have any dad! jason hcs 🤕

I have a few in mind. I’ve had an awful day so this will be short, I’ll keep these stuck on infancy hcs 🥰 now I’m gonna escape to c.ai 🏃🏽♀️

—

Jason loves kids. He holds this automatic tendency to treat them a whole lot better than how he was treated at such a young, vulnerable age.

Babies though? He thinks babies are ugly. Not ugly as in snot nosed little freaky crybabies (which he does think,) but he finds it funny how newborns look angry all the time. Like they’re judging the world before they can even understand it.

Telling him he’s going to be a father is a complete stun on his mind. Him? A dad? Are you serious?

It takes him a good second to register this, and a second longer to realize that you’re not joking. That their isn’t a hidden button to change the plus sign to negative.

He’s forced to acknowledge the fears he realizes he didn’t acknowledge before about being a father. He knew all of what not to do, but very little about how to do it right.

How is he going to raise a child if the way he was raised was completely different?

He will overprepare. Books, supplies, all the good stuff. A part of him believes it was gonna be a girl, somehow fooling himself into thinking that would be easier, but to his surprise, it’s a boy. The line of testosterone continues on, it seems.

Once his baby is placed into his arms, two things become incredibly clear.

His baby isn’t ugly.

His baby… is gorgeous.

His son has incredible; a six and a half pound child fitting perfectly into his own two hands. Sleek black hair wildly nestled underneath his little blue newborn cap. His pudgy cheeks flushed with color, with bright red quivering lips preparing to bellow out a series of cries.

He’s never heard a more incredible sound. How did something so innocent and blissfully unaware of this damaged, inhumane world come from someone like him? Damaged, inhumane..

His chest flutters with butterflies and bees dancing in the prison of his rib cage for days, his eyes attached to his son nearly every second of every day in that hospital room.

Whether you bottle fed or breast fed, Jason would keep nestled beside you with a tilted head and small smile, admiring how those little fingers mindlessly clenched on nothing.

“His fingers are so fat,” Jason’s smile grows with his words. He extends one of his own fingers onto his son’s tiny palm, marveling at said fat little fingers merely managing to wrap around the tip of his index.

“He’s got your nose,” you’d whisper, watching Jason’s eyes form hearts. “And your hair. I wouldn’t be surprised if he ends up with your eyes, too.”

“Yeah,” Jason whispers before proceeding to nod. “Yeah. Course he’s not ugly, takes after his dad after all.”

He wouldn’t want the others to come see you or the baby just yet, even after getting discharged from the hospital. He wants time to adjust, time to settle into this new routine, this new reality. He wants the love of his life to recover comfortably at home, merely thanking you every morning and every night for gifting him such a precious, innocent little boy.

It amazes Jason to see just how easily his son calms down in the presence of his father. You’d get jealous, as sometimes it took you a little longer to calm him down, but Jason was a master of reassurance.

“Relax, he’s always gonna be a momma’s boy. Can see it already.”

It runs in the family, but he’s not gonna say that,

You’ll never know that Jason wakes up in the middle of the night before his son’s first few cries. You’ll never hear how he trudges over towards the kitchen with his newborn in hand, lightly rocking his baby on his shoulder as a bottle warms up inside a small machine.

The opportunity will be incredibly rare for you to wake up and catch sight of Jason sitting back in his recliner, cradling his sleeping son against his chest. Such a small, tiny head resting over his heart, over the crosscut of his silvery scar.

He hums to his son, his lightly rumbling chest keeping the baby in a four hour slumber. Jason doesn’t want him to grow up, doesn’t want him to learn his first steps and learn to talk, but does wish that more than anything at the same time.

The more his son grows to learn these life skills, the more successful Jason will feel. He will reach achievements his parents never did, putting in the effort his parents failed to accomplish. You believe with each success, big or small, will help Jason believe he isn’t the monster he thinks he is.

He already knows it. His son is living proof of it, one he’ll protect with his life if he has to.

#jason todd#jason todd x reader#jason todd x you#jason todd x fem!reader#dc jason todd#jason todd x y/n#jason todd x female!reader#this was cute to write

101 notes

·

View notes

Text

The Good, the bad, and the Ugly

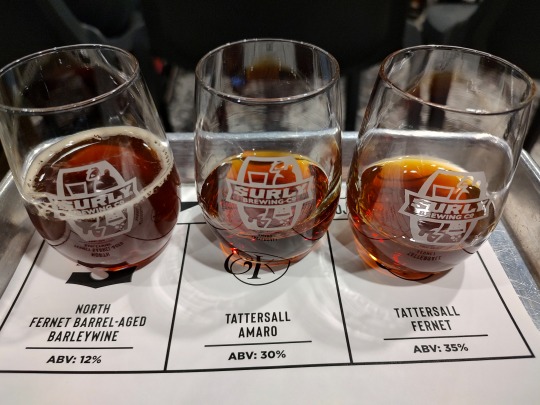

The Good - For Christmas Sheila signed me up for Surly Brewing's Bottle Project. Four times a year I get a limited edition beer. I love limited edition beers.

This week I went to the large brewery and restaurant to pick up the first bottle. There was also a metal water bottle for me. A lot of people there for the same reason. Surly also had a small tasting event for us.

We got to try a sample of what's in that bottle: North, a barleywine ale aged in fernet barrels. Very good.

Then we sampled Tattersall distillery's amaro and fernet, two bitter, aromatic spirits. I liked each, but probably not enough to buy a 750ml bottle of either.

The Bad - Last night I opened the dishwasher to put in a final glass. I peered inside to admire my handiwork before pressing the start button. Nothing caps off the end of my day like starting the dishwasher, then going to bed while it works, and I sleep.

Some people don't care how they load a dishwasher. But I do. I like to imagine things get more clean when the plates are aligned, pieces of silverware all face the same direction, and cups and mugs are thoughtfully placed at an angle where they don't accumulate water if the bottoms are concave.

Feng shui matters in appliances too.

My wife, standing behind me, watched. Earlier, she had turned one plate around. Two plates now faced each other. A good host doesn't seat a left-handed person to the right of a right-handed person. Their elbows will bump. Always something to think about. And plates shouldn't face each other in the dishwasher because... well, just because.

She laughed as I corrected the placement. Then I started the machine and retired to the guest room for the night.

The Ugly - Friends of ours parked a vehicle in our driveway while they were in Mexico for a few weeks. We live not far from the airport and don't mind dropping off people so they don't have to pay for parking. Last night I picked up the couple in their own vehicle.

It's a 29-year-old Jeep Grand Cherokee. At one time this was a very nice, expensive SUV with leather seats, automatic climate control, and other luxury features. The paint had been white, I think.

Today it's their winter beater.

Before I could drive to MSP I had to jump start the Jeep for the second time. I had run it the day before, to make sure it would start, after jump starting it the first time.

To unlock the hood I pulled on Vice Grip pliers that were permanently affixed to a cable under the dashboard.

Once the Jeep was running, it was loud. The exhaust system apparently was vacationing in Mexico too, leaving me with a deep rumbling, rusty Jeep.

Driving along I-494 made me think the road was covered in ice. It was just the Jeep. The right side tires were not in agreement with the left side ones, or the front with the back either. Like four kids fighting in the back seat, except I couldn't hear them over the sound of the exhaust. The power steering didn't work either. Driving in a straight line required two hands at all times and much concentration. What an ingenious way to keep a person from texting while driving.

At the cell phone lot I waited briefly while our friends collected luggage and went through customs. There was no way I was going to shut off the Jeep, for fear it wouldn't start again. So I sat next to two unfortunate drivers who surely could hear and feel the Jeep's exhaust. While stationary, I began to smell that exhaust too. Only my sense of sight was spared from it. Had I seen the toxic gas inside the Jeep I probably would have simply abandoned the vehicle where it was parked.

Finally I picked up the couple in the arrivals section. Traffic was pretty bad. After they were belted in, I tried to leave but was blocked all around. An officer directing traffic must have been tired of the sound, smell, and sight of that Jeep.

He--and I'm not exaggerating--stopped two lanes of traffic, made another car move forward, and directed me to get the Jeep into the far left lane so I could leave. I waved to him in thanks. H probably rolled his eyes.

On the way to my house I good-naturedly remarked about the condition of the Jeep. The wife of the couple laughed, then asked: "You're not writing about this on your blog, are you?"

Of course not.

40 notes

·

View notes

Text

Pump Capping Machines vs. Manual Capping: Why Automation Makes Sense

In any industry where liquid products are bottled and sealed be it cosmetics, pharmaceuticals, or food and beverage—capping is a critical step. The cap not only secures the contents but also serves as a barrier against contamination and tampering. For products using pump caps, the importance of proper capping is amplified due to the functional nature of the closure. At the heart of this process lies a key decision: Should you opt for manual capping or invest in a pump capping machine? While both methods achieve the same basic goal, automation offers several compelling advantages that can significantly improve productivity, consistency, and long-term cost-efficiency.

Manual capping involves human labor to place and tighten each pump cap onto a bottle. At small production scales or in early startup phases, this approach may seem adequate. It requires low upfront investment, offers flexibility in small batch runs, and can be effective where volume is limited. However, manual capping quickly becomes a bottleneck as production demands grow. Fatigue, inconsistency in torque application, and the risk of repetitive strain injuries begin to compromise not just efficiency but also quality and safety. Each operator may tighten caps slightly differently, which can result in loose seals or over-tightened closures that damage the pump mechanism. These inconsistencies translate into potential leakage, compromised shelf stability, and even product recalls in the worst cases.

Pump capping machines, on the other hand, are engineered to bring uniformity and speed to the process. Automation ensures that every cap is tightened to the same specification, dramatically reducing variability. This is especially vital for pump-style closures, which must function smoothly and maintain pressure integrity to dispense the product properly. A machine can deliver thousands of consistently capped bottles per hour, far surpassing what any human team can achieve in the same time frame. This increase in throughput supports higher production targets without a corresponding increase in labor costs.

In addition to consistency and speed, pump capping machines enhance workplace safety and ergonomics. Operators are no longer required to exert repetitive force, reducing the likelihood of musculoskeletal injuries. The machines are also designed with easy-change tooling and programmable settings, which make them suitable for different cap sizes and bottle types. Modern capping machines come equipped with smart features such as torque control, error detection, and automatic adjustments. These features contribute to overall product integrity and reduce the need for post-capping quality checks or rework.

Cost is often the main factor that leads businesses to initially choose manual capping. While the upfront investment for an automated pump capping system is undoubtedly higher, it’s important to view this cost in the context of long-term operational efficiency. The reduction in labor, waste, downtime, and product defects often offsets the initial investment within a short period. Furthermore, scaling up becomes much easier when the capping process is no longer a limiting factor.

In today’s competitive manufacturing environment, consistency, speed, and quality are non-negotiable. Manual capping might serve its purpose for low-volume, highly customized products, but it becomes a liability at scale. Automation is not just about replacing human labor; it’s about optimizing processes for reliability, traceability, and growth. Investing in a pump capping machine allows manufacturers to meet customer expectations, comply with regulatory standards, and ultimately gain an edge in the market.

As industries evolve, so do production demands. The transition from manual to automated capping is not merely a technological upgrade it’s a strategic move toward smarter, safer, and more sustainable manufacturing. Source: https://autopackmachinespvtltd.wordpress.com/2025/06/21/pump-capping-machines-vs-manual-capping-why-automation-makes-sense/

0 notes

Text

How to Choose the Right Water Bottle Filling Machine for Your Business

The selection of an ideal water bottle filling machine is the most critical decision to be made by any business involved in beverage manufacturing, especially mineral water and bottled water. It truly depends on the ideal equipment one selects for production, efficiency, quality, and even profitability.

This comprehensive guide will take you through understanding how to choose the water bottle filling machine that suits your business, including the major factors and the sophisticated solutions that Aim Technologies provide.

Understanding the Importance of a Water Bottle Filling Machine

The water bottle filling machine is a very crucial apparatus in the water bottling plant. It fills bottles with water, automating the process with utmost hygiene, speed, and accuracy. Any small mineral water filling plant or large water bottling plant preferring to see its production line streamlined and to look into good standards would probably prefer having the right water filling machine.

Also, to know more about water filling machine specifications, read our blog on: Cost vs ROI: Is a Water Bottle Filling Machine Worth the Investment?.

Key Factors to Consider When Choosing a Water Bottle Filling Machine

1. Type of Bottles and Production Capacity

The first step is to evaluate the types of bottles you plan to fill-plastic, glass, or PET and their sizes. Different machines are designed to handle specific bottle materials and sizes. Additionally, consider your production capacity requirements. Machines vary from semi-automatic to fully automatic systems, capable of filling anywhere from a few hundred to several thousand bottles per hour.

2. Production Speed & Bottle Size

Machines are differentiated in speed::

40 BPM Water Filling Machine: ideal for the small setups; 200-2,000 ml bottles.

60 BPM Water Bottle Filling Machine: suited for the mid-sized plants, with demo videos testifying to its performance.

120 BPM & 200 BPM Filling Machines: built for high-volume, fully automatic plants.

It all depends on your anticipated demand and bottle formats.

3. Automation Level

Automating processes work towards fostering consistency and reducing labor costs. Aim Technologies offers various options ranging from semi-automatic to fully automatic Water Filling Machines that entail:

Mono-block rotary systems

Non-contact sensors

In-feed/out-feed conveyors

Cap feeders with 3,000-4,500 cap capacity

The systems assure "no bottle, no rinse, no fill, no cap," thereby enhancing safety and efficiency.

4. Hygienic Design & Material

For beverage safety, stainless steel contact parts are preferable (SS316L/SS304). Aim's machines have rotary filling valves, rinsing nozzles, and capping heads made from those materials essential in Water Bottling Plant operations.

5. Ancillary Systems & Turnkey Setup

A Water Bottling Plant includes:

RO plant & Mineral Water Plant for purification

Bottle rinsing, filling & capping unit

Labeling and shrink-wrapping systems

Bottle blowing machine (for PET bottles)

Aim Technologies supports full turnkey installations.

6. Budget & ROI Considerations

High-speed models (120/200 BPM) could cost more up front but promise faster returns from increased throughput. On the other hand, a Mineral Water Filling Machine at 40-60 BPM might just be in the realm of possibilities for a startup. Our turnkey and modular options provide flexibility by production stage and budget.

Get in touch with us today to find the right Water Filling Machine solution for your business.

7. Future Growth & Scalability

Select systems capable of upscaling: Aim's modular plants, together with their Water Bottling Plant equipment range, would allow you to quickly increase capacity from entry-level to industrial scale.

Why Choose Aim Technologies?

Aim Technologies deals with Water Bottle Filling Machine, Mineral Water Filling Machine, Water Bottling Plant, and Water Filling Machine systems. Since 2011, they have supplied dependable machines made of stainless steel with full-service support. Their range of products include:

40 BPM, 60 BPM automated fillers

120 BPM, 200 BPM high-speed rotary systems

Purification plants (RO/Mineral Water Plant)

Ancillary equipment: labeling, shrink-wrapping, pet blowing

Final Thoughts: Invest Wisely for Long-Term Bottling Success

A Water Bottle Filling Machine is not generally chosen by subjective whims or present needs in the sense that it breeds growth, efficiency, and profitability for the business. Aim Technologies offers a broad selection of filling machines in conjunction with complete purification systems tapping turnkey solutions, enabling the user to start with small capacity and expand easily.

Being a partner who guarantees through expert support, high-quality machinery, and commitment to its Customer Success, it is the right option of choice in the bottling industry. Be it a Mineral Water Filling Machine, a Water Bottling Plant, or an advanced Water Filling Machine; we have just exactly what you are looking for to better place you to realize your goals. Choosing a partner that grows with your business is just the smart choice to make today.

#Water Bottle Filling Machine#Mineral Water Filling Machine#Water Filling Machine#Water Bottling Plant

0 notes

Text

In today’s fast-paced industrial environment, efficiency is key to staying ahead of the competition. Businesses are constantly on the lookout for innovative solutions that can streamline their operations, reduce costs, and enhance productivity. As a leading name in packaging solutions, we offer a range of end of line machines designed to meet these needs. Let's explore how our end of line machines can benefit your business with unparalleled efficiency.

#tin filling machine#Jar filling machine manufacturers#auto case erector#bulk bag filling machine#case packer manufacturers india#tin can filling and sealing machine#automatic case erector#ghee jar filling machine#tin packing machine#oil tin filling machine#powder jar filling machine#automatic carton box packing machine#carton packing machine#carton box packing machine#Bottle Filling Line#horizontal flow wrap machine#powder filling machine#box packing machine#automatic bottle filling machine#cartoning machine#flow wrap machine#secondary packaging#bottle filling machine#powder bottle filling machine#shrink wrapping machine manufacturer#bottle capping machine#shrink wrapping machine for bottles#can seamer machine

0 notes

Text

WAE’s Glass Bottling Plant transforms the Hospitality Sector

WAE is a complete drinking water solution-providing company, committed to this indispensable resource called “water” on this planet, Earth. An Original Equipment Manufacturer (OEM) with a firm foundation in scientific research and innovative technologies, its focus and collegial approach enables it to develop complete sustainable drinking water solutions that sync with the principles of circular economy and help it to become an active participant in the resource revolution.

The firm is reckoned for providing efficient and complete drinking water solutions as well as other vending machines and has come up with one of its latest launches, the glass bottling plant, which is all set to transform the hospitality sector by introducing sustainable and reusable small glass water bottles, eradicating the use of plastic bottles or jars for good. In fact, the above is also the main motto of the company for launching this hi-tech glass bottle filling plant which will certainly help in minimizing plastic waste.

The Unique Concept: WAE’s glass bottling plant for hotels is all set to revolutionize the hospitality sector by its innovatively designed and technologically advanced glass bottling machine to mechanically rinse, clean, fill and cap the recyclable glass bottles with pure drinking water, ready to use. Only the bottles have to be manually placed on the machine in an inverted position for cleaning and rinsing purposes with hot water or detergents, and this process is also customizable. Then these cleaned and inverted glass water bottles pass through a conveyor belt to get dried up by air. It is after the execution of all these processes that the refillable glass bottles pass through the LED chamber for further cleaning and sterilization.

The glass bottles then pass through the filling stage where they are filled with clean and hygienic water for drinking purposes. Later, the bottles are inspected manually in the next stage. Then these small glass water bottles are finally capped and screwed tightly to avoid any leakage. The last stage is labelling or putting stickers on the bottles. Therefore, this technologically advanced glass bottling plant is undoubtedly the best choice for the hospitality sector and can be ideally used in all luxury hotels, restaurants and resorts. Moreover, WAE, with a vast experience and expertise of more than 15 years in providing complete, sustainable drinking water solutions can be ideally referred to as the one of the best glass bottling plant manufacturers of India!

#sustainable drinking water solutions#wae#glass bottling plant for hotels#automatic bottle filling plant#glass bottle filling station#rinsing#filling and capping machine#minimizing plastic waste#glass bottling plant manufacturer

0 notes