#automatic tubing cutter

Text

Auto Cutter USA

USA manufacturer of industrial cutting machines. We deliver affordable and precision equipment to cut to length wire, tubing and cable.

#automatic cable cutter machine#automatic tubing cutter#automatic wire cutting machine#heat shrink tubing cutter machine.

0 notes

Video

youtube

H shape metal tube laser cutter cutting machine for pipes cutting

More details or free tutorials ,please contact on whatsapp :008618053182392/ [email protected], Our website : jxautocnc.com

0 notes

Photo

finally my GIRLS

i actually made older designs for them back in January i just did a slight do over from the first designs here

lets be real Whisper would look sick with a trench coat and Tangle would need braces for joints because of her old lady body failing her

There kid Smith was the result of an anniversary gift that both of them separately asked Tails to make for a surprise for one another so now they have a kid, something happened in the tube so his arm is disfigured, he can still function, it makes a great rest for Pink

Yes I purposely made him look like him its for the lore and Whisper was the one that named him that

He mainly inherited Whisper’s introverted tendences with Tangle’s enthusiasm for things, and prefers to keep to himself with Pink while trying to make things but if someone comes and asks about something he light up like a lightbulb, he’s decently skilled at his age for creating simple gadgets and putting things together. Smith was created by Tails as a surprise as the request of Tangle and Whisper, this was his first time making life so he kinda studied Starline and Robotnik’s notes on this stuff to get an understanding, Smith came fairly a success and live happily with his mothers. When they first saw him Tangle automatically when “Awwww” then 😬 when the realization hit, when she looked at Whisper she just hugged him and decided to name him Smith out of tribute.

When he got older he started expanding his skills and kind of became a blacksmith and made tools, casing, and stuff. He’s the main guy to go when you need something made and he can make it pretty nice

-Pink just got attracted to him

-he can use his tail as an arm like tangle but his grip is iffy

-pretty neutral on everything

-he is curious about the old Diamond Cutters but Whisper is iffy on telling him the story, mainly due to him being very similar to Smithy and he’s a child, Tangle’s keen on it but to respect Whisper she doesn't

-his creation process eventually lead to Mint existing and people getting concerned about Tails

37 notes

·

View notes

Text

dräede

I.

age:// at times he speaks about the days of the old galactic empire and the nights after the fall of the old republic

species:// unknown

height:// 7'+

build:// automatous; an armory; an altar

known features:// a bleakness; a blackness; a dryness; like charcoal; like gestalt; like ashes

II.

force adeptness://

⬛️⬛️⬛️◻️◻️◻️◻️◻️◻️◻️

force tactics://

force-bond {to the knights of ren}

force-walk {it is only said}

time-stream sight

III.

visible armor://

a scuffed and bullet-ridden phrik armet with headrest plate/neck flap {off-world}

a grand helm; broken respirator tubes; the face within thought long gone to rot {at 'home'}

weapons://

blast tubes

class d-detonators

disruptor rifle

fusion cutter

IV.

absorption point://

found ren kylo through time river before ren kylo found him

purpose://

a conductor; the knights united through him; carries their messages; haunts them

V.

2 notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

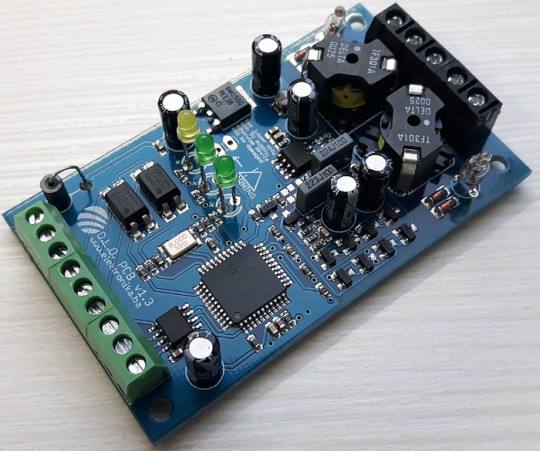

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

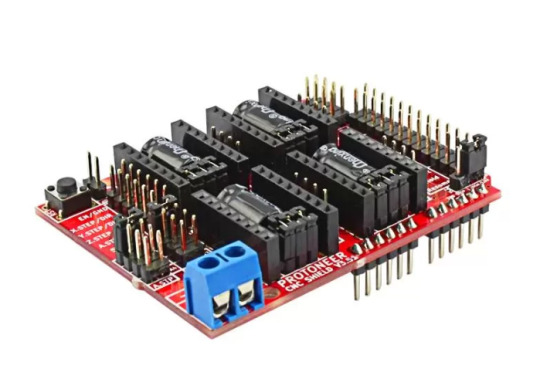

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

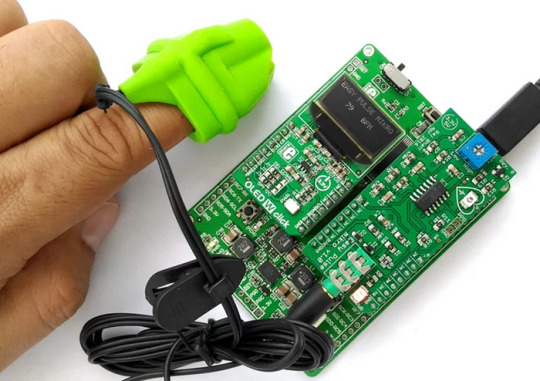

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

Plasma Metal Cutting Machines

Plasma Metal Cutting Machines

The plasma metal cutting machines provided by our company include metal flat plasma cutting machine, metal plate and tube integrated plasma cutting machine,metal square tube plasma cutting machine, portable metal plasma cutting machine, round tube plasma cutting machine, gantry plasma cutting machine.

Do you have a thought to DIY or buy an affordable CNC Plasma Cutter? We’ll provide you with the competitive CNC Plasma Table with expert customer service to satisfied your requirements.

CNC Metal plasma table

CNC plasma tables by iGOLDEN provide a broad range of cutting solutions. Designed for top-notch cut quality, a iGOLDENCNC plasma table is durable enough to run full production for years, yet nimble enough to cut intricate shapes with ease. iGOLDEN is here to help you select the best CNC plasma cutting table to meet your specific needs.

The table cuts a 4×4 4×8 5×10 area and works well with 4×8 and 4×10 sheets. In fact, the software allows you to automatically layout and cut 4×8 or larger (up to 20 ft long) shapes.

Industrial CNC cutting table system offers all the features to get started on cutting carbon steel, stainless steel and non-ferrous metal in any 2D graphics. The included Digital Torch Height Controller maintains distance between the plasma torch and your work – producing smooth edges, sharp details and high precision.

Gantry type metal plasma cutting machine

Heavy Frame Metal Plasma Cutting Machine Sheet Tube Metal Cutting CNC Plasma Cutter Gantry Plasma Flame Cutting Machine

1. Heavy-duty gantry cutting machine adopts heavy-duty frame, heavy-duty guide rail, good stability, large span, the gauge has a width of 4 meters, 5 meters, and 6 meters, and the length can be from 8 meters to tens of meters.

2. It can realize double flame or double plasma cutting at the same time, forming 2 workpieces at a time, increasing double efficiency, saving half of the time, half of labor and one piece of equipment.

3. Equipped with high-power plasma power supply, such as 200A 300A 400A, to achieve plasma thick plate cutting. The plasma cutting speed is 3-5 times that of flame cutting, which improves production efficiency.

4. Multi-head plasma or flame straight cutting can be added, multiple workpieces at the same time, saving time.

5. The heavy-duty gantry cutting machine has beautiful appearance and high-end atmosphere, demonstrating the strength of the enterprise and improving its competitiveness among competitors.

Portable metal Plasma cutting Machine

A new portable design man carried construction is applied to the mini CNC plasma cutter machine here. Although it is small in volume, it can still cut 5ft x 10ft metal sheets as the stroke for X & Y axis is 1500x3000mm. The portable design enables us to put the plasma cnc in any location as the production needs. Let us give an example to interpret this point here. Suppose we want to cut a 12-meter-long steel plate, and such a large steel plate is not easy to move. So how do we put it on the machine to cut it? Taking the portable cnc plasma cutter here, we put it on the metal plate, and then we start the equipment to cut. Therefore, it is the right solution for the giant metal materials cut. Except for the plasma torch, it has a flame cutting torch also. 5ft x 10ft Portable cnc flame plasma cutting machine for sale with unmatched service now!

Portable metal Flame/Plasma Cutting Machine

Mini portable design, Man-carried construction; Two options available on stroke: 1500x3000mm (5ft x 10ft) and 1500x2500mm (5ft x 8ft). Mini cnc plasma cutter with portable design

The default configuration coming with two torches, one plasma cut torch, and one Oxy-fuel flame cutting torch. plasma torch of mini cnc plasma cutter

The portable cnc plasma cutter is equipped with an automatic torque height controller (THC controller). auto torch height control of mini cnc plasma cutter

Professional plasma cutting controller dedicated for portable plasma cnc – STARFIRE control system with LED display in English. mini cnc plasma cutter control system

A cut drawing library with rich resources is built into the cnc system. Production cuts can be executed by simply setting the size parameters. drawing library in the mini plasma cutter system

Plug and Play design. mini cnc plasma cutter with plug and play design ● X & Y axis is adopting rack and pinion transmission. rack on mini cnc plasma cutter.

What is Plasma Cutting?

Plasma cutting is a process that involves cutting through electrically conductive materials using an accelerated jet of hot plasma. The technology harnesses the power of ionized gas to melt and expel material from the cut, resulting in clean and precise cuts.

How Does a Plasma Cutter Work?

A plasma cutter works by sending an electric arc through a gas that is passing through a constricted opening. The gas can be oxygen, nitrogen, argon, or even shop air. This elevates the temperature of the gas to the point that it enters a plasma state. The plasma is then directed at the workpiece, melting the metal and blowing it away.

Components of a Plasma Metal Cutting Machine

Power Supply

The power supply is the heart of the plasma cutter. It provides the energy required to maintain the plasma arc. Modern power supplies are designed to deliver consistent power, ensuring smooth and efficient cutting.

Plasma Torch

The plasma torch is the tool that directs the plasma arc onto the workpiece. It consists of several components, including the electrode, nozzle, and swirl ring, each playing a crucial role in the cutting process.

Control Console

The control console allows the operator to adjust the cutting parameters, such as speed, amperage, and gas flow. Advanced consoles come with digital displays and programmable settings for enhanced precision.

FAQ

What materials can a plasma cutter cut?

Plasma cutters can cut a variety of electrically conductive materials, including steel, aluminum, brass, and copper.

How thick can a plasma cutter cut?

The cutting thickness depends on the power of the plasma cutter. Some machines can cut materials up to several inches thick.

Is plasma cutting safe?

Yes, plasma cutting is safe when proper safety measures are followed, including wearing PPE and ensuring adequate ventilation.

Can plasma cutters be used for precision cutting?

Yes, plasma cutters are known for their precision and can produce clean, accurate cuts suitable for various applications.

What is the lifespan of a plasma cutter?

The lifespan of a plasma cutter depends on its usage and maintenance. Regular maintenance can extend the life of the machine significantly.

0 notes

Text

A small paper tube cutting machine is a specialized piece of equipment designed to cut paper tubes or cores into precise lengths. This machine is essential in various industries, including textile, paper, printing, packaging, and more.

Here's a brief overview of its functionality:

Material Loading: The process begins by loading the paper tube or core into the machine. This can be done manually or automatically, depending on the machine model.

Setting the Length: The operator sets the desired length for the cut. Most machines have a digital control panel where you can input the exact measurements, ensuring high precision in every cut.

Cutting Process: The machine uses a sharp, durable blade to cut the paper tube. The cutting can be done either by a rotating blade, a guillotine-style blade, or a saw blade, depending on the machine model and the thickness of the paper tube.

Collection: After the tubes are cut, they are collected in a bin or on a conveyor belt. Some machines also have an automatic sorting feature that separates the tubes based on their sizes.

Quality Control: Many machines come with built-in quality control features that check for any irregularities or defects in the cut tubes.

The Paper Tube Cutting Machine is known for its efficiency, accuracy, and speed, capable of producing large quantities of cut tubes in a short time. It's a valuable asset for businesses looking to streamline their production process and improve productivity. The paper tube machine's robust construction also ensures long-term durability, making it a worthwhile investment.

Adaptable Designs and Customization Options of Paper Tube Cutting Machine

Paper Tube Cutting Machines are not only efficient and precise but also highly adaptable and customizable. They are designed to cater to a wide range of industries and applications, making them a versatile choice for businesses of all sizes. Here’s a look at the adaptable designs and customization options of these machines:

Size and Capacity: Paper Tube Cutting Machines come in various sizes and capacities to accommodate different production needs. Whether you need to cut small paper cores for thermal rolls or large paper tubes for industrial packaging, there’s a machine designed to meet your specific requirements.

Cutting Mechanism: Depending on the thickness and material of the paper tube, you can choose from different cutting mechanisms. These include rotating blades, guillotine-style blades, or saw blades. Some machines even offer interchangeable blades for added flexibility.

Control System: Most paper core machine feature a digital control system that allows you to set the exact length for the cut. Some advanced models may also offer programmable controls, where you can save your settings for future use.

Automation Level: From semi-automatic to fully automatic models, you can choose the level of automation that suits your production process. Fully automatic machines can load, cut, and sort the tubes with minimal human intervention, saving time and labor costs.

Custom Features: Many manufacturers offer custom features to meet unique business needs. These may include special safety features, dust extraction systems, automatic sorting mechanisms, and more.

With these adaptable designs and customization options, Paper Tube Cutting Machines can be tailored to fit your business needs perfectly. They offer a practical and efficient solution to cut paper tubes or cores accurately and quickly, enhancing your production efficiency and profitability.

Advanced Cutting Mechanisms in Our Paper Tube Cutting Machine

Our Paper Tube Cutting Machine stands as a pinnacle of precision and efficiency with its advanced cutting mechanisms. Specifically engineered for cutting paper tubes or cores into exact lengths, this specialized equipment plays a pivotal role across diverse industries. From textiles to paper, printing, and packaging, its versatility meets the demands of varied applications. The machine incorporates cutting-edge technology, ensuring accuracy and reliability in every operation. Whether crafting customized tubes for packaging or contributing to the seamless production processes in printing, our Paper Tube Cutting Machine signifies a commitment to excellence, streamlining workflows and enhancing overall productivity across multiple sectors.

0 notes

Text

ZCUT-9 Automatic tape Dispenser Cutting Machine Intelligent 6-60mm Adhesive Tape Double Sided Cutter Packing Machine 110V 220V

Power requirements: 100V, 120V, 220-240V

Power: 25W

Size 116mm X140mm (H) X213mm (L)

Weight: 1.6 kilograms

Body material: Anti static ABS

Tape length: 5mm-999mm

Tape width: 6mm-60mm

Maximum external diameter of tape: 300 mm

High quality and exquisite body design

ABS imported material, resistant to falling and scratching, with a baking paint texture

LED Nixie tube display

Visible length…

View On WordPress

0 notes

Text

Configuration and working nature of organic fertilizer chain plate turning machine

The performance characteristics of the chain compost turning machine of fertilizer equipment

1, Optional trough material distributor, automatic discharge device, solar fermentation room and ventilation and aeration system. With the shifting machine to change the slot, it can realize the multi-slot operation of one flipping machine, saving investment.

2. When flipping, the material stays on the pallet for a long time, is scattered at a high level, is in full contact with the air, and is easy to reduce water.

3, the flip plate is equipped with flexible tensioning and elastic shock absorption system to protect the efficient operation of organic fertilizer production line. It is equipped with removable wear-resistant curved tooth cutter, which has strong crushing ability and good oxygenation effect.

4. The lifting of the working parts is controlled by hydraulic system, flexible work, safe and fast. It can remotely control the operation of the machine, such as forward, transverse, flip and fast backward, and improve the operating environment.

5. High ground clearance and large carrying capacity of the front and back bridge with side reduction.

6, through the horizontal and vertical displacement can achieve any position in the slot flipping operation, flexible.

7, the use of chain drive, rolling support plate structure, flipping resistance is small, energy saving, suitable for deep slot operation.

Although the performance of organic fertilizer equipment is good, it is also necessary to do maintenance work, check the oil amount once a week, when the oil level is found to drop, check whether there is oil leakage to find out the cause, add gear oil on the lowest oil surface. When the oil needs to be changed, remove the above tubing air from the tank, unscrew the oil plug, collect the oil, and then tighten the oil plug. Add lubricating oil to the bearing part regularly. Regularly clean the rope head or wire and other debris on the chain board.

0 notes

Text

Motorized Notch Machine

Motorized Notch Machine is a selfcontained floor-mounted unit, specially designed for cutting ‘V’ and ‘U’ notches in standard 10mm square, sub-size and 0.45″ diameter specimens. Our V/U Notch Broaching Machines are suitable for ferrous & non-ferrous material for sample preparation of ‘V’ or ‘U’ notches for Impact Testing Machines. Motorized notch machine is a specialized tool or equipment used in metalworking and other industries to create notches or grooves in various materials, such as metal plates, tubes, and bars. Notches are commonly used to facilitate bending, joining, or assembly of materials.

Key Features

Motorized Operation: The machine is powered by an electric motor, which drives the cutting tool to create notches automatically.

Cutting Mechanism: The machine usually employs a rotating cutting tool, such as a saw blade or a milling cutter, to remove material and create the notches.

Adjustable Parameters: The machine may have adjustable settings for controlling the depth, width, and angle of the notches, allowing for customization based on the specific requirements of the project.

Safety Features: To ensure operator safety, a motorized notch machine might include safety guards, emergency stop buttons, and other safety mechanisms.

Workholding Devices: The machine may feature clamps or fixtures to hold the workpiece securely in place during the notching process.

Versatility: Motorized notch machines can be designed for various industries, such as metal fabrication, woodworking, construction, and engineering.

Applications of a motorized notch machine include:

Metal Fabrication: Creating notches in metal sheets or bars for welding and joining purposes, as well as for making structural components.

Woodworking: Cutting notches in wooden beams, boards, or panels for joinery, allowing for stronger connections in furniture, cabinetry, or construction.

Plastic Processing: Forming notches in plastic components for assembly or fitting purposes.

Electronics: Making notches in PCBs (Printed Circuit Boards) for component insertion or PCB assembly.

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#cutting machine#notch machine#notch cutting machine#motorized notch machine#motorized notch cutting machine#uv notch machine#uv notch broaching machine#uv notch cutting machine#motorized notch broaching machine#best price motorized notch machine#motorized notch machine in best price#motorized notch machine supplier#motorized notch machine manufacturer#motorized notch machine dealer#motorized notch machine exporter

1 note

·

View note

Text

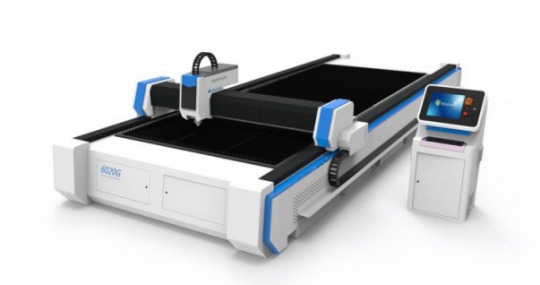

Remcor technology is a global supplier for the turnkey fiber laser cutting lines, which have around 18 years experiences, 5000 sets installations globally. No matter what type what size and how thickness your sheet material is, we can provide you the suitable equipment. Pipe Fiber laser cutting machine mainly been applied in metal pipes and tubes fabrications, with the character of fast speed, high precision or accuracy, environmental friendly, low power consumption, low table cost, and low maintenance cost. which is widely applied in fast cutting metal pipes of steel, stainless steel, carbon steel, aluminum, copper, galvanized steel, titanium alloy, gold, silver and other material. OEM ODM services are available.

Heavy Duty bed, apply the fully plate welding bed, with higher rigidity and durable use.

Compared with two chuck clamping or traditional metal pipes cutter. Three chucks equipment can realize the real zero tailing .processing details as the following descriptio.

More flexible for pipe cutting processing especially for extra heavy duty pipes or tubes, less swing or shake.Perfect accuracy and precision.

Heavy duty type load longer tailing material avaliable.

Apollo AK Two-chuck Tube Laser Cutting Machine 1000w-6000w Parameter Details

APOLLO BK SERIES-3 Chucks

Type

6020-BK

7025-BK

9025-BK

9034-BK

Power Range

1500-6000W

Chuck Structure

3 chucks

Tube Size

Round Type: 15-200mm Square

Round Type:15- 245mm

Round Type:15- 245mm Square

Round Type:15- 330mm Square

Type:15- 140mm

Square Type:15- 175mm

Type:15- 175mm

Type:15- 230mm

Positioning accuracy of X& Y

土0.05mm/m

Max Positioning speed X&Y

100m/min

80m/min

Max cutting length

6000mm

7000mm

9000mm

9000mm

Tail length

2 0mm

Max weight single tube

135KG

260KG

260KG

500KG

Max loading length

6000mm

7000mm

9000mm

9000mm

Fully Annealed Table

The bed body adapts the segmented rectangular tube welding bed with fully annealed treatment at over 600⁰. After tempering, the strength, rigidity and stability are guaranteed, the precision would be tested and debugged which can make sure the precision can be maintained for a long time. The table is equipped with automatic lubrication device, which ensure the moving parts operate in good condition and improve the service life of guide rails, gears and rack.

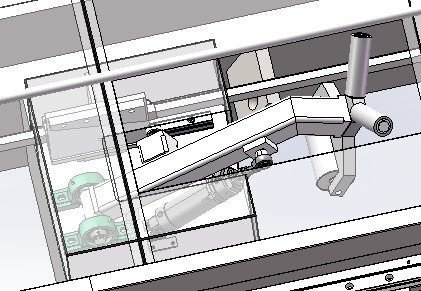

Follower Support

The follower support device will be optional. The follower support is mainly to assist in controlling the excessive deformation of cutting longer pipes (pipes with smaller diameter), and the servo motor drives the up and down movement of the pallet assembly. When the chuck moves to the corresponding position, the auxiliary support automatically drops for avoidance.

Smart Auto Focus Laser Head

Standard auto focus function, no need focus adjustment while changing sheet; Automatic tracking and accurately adjusting the focus according to the material thickness to ensure the best cutting effect of the whole board. Shorter perforation time, better perforation quality, high-speed cutting, saving time.

Intelligent CNC Operating System

It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks on big IPAD Screen. Realize the intelligent diagnosis, multi-threading operation, three-level perforation, laser energy control, adaptive edge-finding, automatic corner acceleration and deceleration, flight cutting, switching worktables, mechanical accuracy compensation etc.

Pneumatic Clamp Chucks

Pneumatic clamp design on both sides. The dual-chucks help reduce tube vibration to a minimum, guaranteeing high accuracy in even complex tube configurations at high cutting speed. Suitable for cutting a range of tube diameters from Ø20 mm to Ø220 mm and various wall thicknesses.

Front chuck

tube laser cutting machine front chuck

Back chuck

tube laser cutting machine back chuck

Fractional Automatic Support Technology

Applies the intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Equipped with two sets of variable-diameter support structures, which are automatically lifted by the cylinder to avoid the rear chuck in processing. When processing profiles with different diameters, manually turn the variable-diameter wheels to achieve fit and support for different-sized profiles. The variable-diameter wheels It can be supported every two degrees of rotation to reduce the diameter of the circumscribed circular tube by 2mm

0 notes

Text

EQUIPMENTS USED IN STEEL FABRICATION OF BEN AND GAWS

Steel fabrication is a complex process that involves a wide range of equipment and techniques to transform raw materials into finished steel structures. Ben and Gaws is a company known for their expertise in structural steel fabrication, and they use a variety of state-of-the-art equipment and techniques to create high-quality steel structures for a range of projects. In this blog, we'll explore some of the equipment used in steel fabrication at Ben and Gaws.

Welding Equipment

Welding is a crucial part of steel fabrication, as it involves joining steel pieces together to create the desired structure. Ben & Gaws uses advanced techniques like MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, which are known for their precision and high-quality welds. They also use automated welding machines for large and complex projects.

Welding Machines: Welding machines are the backbone of any welding process. These machines generate the necessary heat and electricity to create a strong and durable bond between metal components. They come in various types, including stick welders, MIG welders, TIG welders, and plasma cutters, each suited for different welding applications.

Welding Helmets: Safety is paramount in welding, and a welding helmet is a crucial piece of protective equipment. These helmets shield the welder's face and eyes from intense heat, harmful UV radiation, sparks, and debris generated during the welding process. Modern welding helmets often feature auto-darkening filters, allowing for easy visibility adjustment without needing to flip the visor up and down.

Welding Gloves: Welding involves working with high temperatures and molten metal, making welding gloves an essential safety accessory. These gloves are made from heat-resistant materials such as leather or Kevlar and provide protection against burns, sparks, and electrical shock. They offer dexterity and grip, allowing welders to handle welding tools and materials safely.

Plasma Cutting Machines

Plasma cutting machines are used to cut steel and other metals using a plasma torch. These machines are highly accurate and efficient, allowing Ben & Gaws to create intricate designs and shapes for their steel structures. They use computer-aided design (CAD) software to create the designs, which are then translated into instructions for the plasma cutting machine.

Plasma Cutting Machines: Plasma cutting machines are specialized equipment designed specifically for the plasma cutting process. They consist of a power source that generates an electric arc and a plasma torch that directs the plasma jet onto the metal workpiece. Plasma cutting machines come in various sizes and power capacities to accommodate different cutting requirements.

Cutting Capabilities: Plasma cutting machines offer exceptional cutting capabilities, allowing for the precise and rapid cutting of various metals, including steel, stainless steel, aluminum, copper, and brass. They can handle different thicknesses of metal, ranging from thin sheets to thick plates, making them suitable for a wide range of applications in industries such as fabrication, automotive, construction, and metalworking.

Advanced Technology and Features: Modern plasma cutting machines incorporate advanced technology and features to enhance performance and user experience. These may include CNC (Computer Numerical Control) compatibility, which enables automated and highly accurate cutting based on programmed designs. Some machines also feature integrated cooling systems, automatic gas control, and digital displays for precise settings and monitoring.

Pipe Bending Machines

Pipe bending machines are used to bend steel pipes and tubes to the desired shape and angle. Ben and Gaws legal uses advanced pipe bending machines that are capable of bending steel pipes of various sizes and thicknesses. They use computer programs to create precise bending instructions, which are fed into the machine.

Pipe Bending Machines: Pipe bending machines come in various types, including manual, hydraulic, and electric models. These machines utilize different mechanisms and techniques to bend pipes of various materials, such as steel, stainless steel, copper, aluminum, and PVC. They are equipped with specific tooling, such as bending dies or mandrels, to achieve consistent and precise bends.

Bending Capabilities: Pipe bending machines offer a wide range of bending capabilities, allowing for the creation of various bend angles, radii, and configurations. They can handle different pipe diameters and thicknesses, making them suitable for small-scale projects as well as large-scale industrial applications. Pipe bending machines can create bends ranging from simple curves to complex shapes, accommodating the specific requirements of different industries and projects.

Efficiency and Accuracy: Pipe bending machines are designed to streamline the pipe bending process, improving efficiency and accuracy. With proper setup and calibration, these machines can achieve consistent and repeatable bends, minimizing errors and reducing material waste. The use of advanced features, such as digital controls and automatic bending sequences, further enhances precision and productivity.

Plate Rolling Machines

Plate rolling machines are used to bend and shape steel plates into curved or spherical shapes. Ben and Gaws legal uses plate rolling machines that are capable of handling steel plates of various thicknesses and sizes. They also use advanced computer software to create precise rolling instructions, which are fed into the machine.

Plate Rolling Machines: Plate rolling machines come in different types and sizes to accommodate various plate thicknesses, lengths, and materials. They consist of three rollers—two side rollers and a top roller—that work together to apply pressure and gradually roll the plate into the desired curvature. These machines are typically hydraulic or mechanical, offering different levels of automation and precision.

Bending Capabilities: Plate rolling machines offer a wide range of bending capabilities, allowing for the production of cylindrical shapes, cones, and other curved forms. They can handle different plate materials, such as steel, stainless steel, aluminum, and various alloys. The machines can accommodate varying plate thicknesses and widths, making them suitable for diverse applications in industries like construction, manufacturing, and shipbuilding.

Versatility and Adaptability: Plate rolling machines offer versatility in terms of the range of plate sizes and materials they can handle. They can accommodate plates of varying widths, lengths, and thicknesses, making them suitable for both small-scale and large-scale projects. Additionally, plate rolling machines can be equipped with different tooling options, such as interchangeable rolls and supports, to achieve various bending radii and profiles.

Drilling and Punching Equipment

Drills and punches are used to create holes and other openings in steel structures. Ben & Gaws legal uses advanced machinery like CNC (Computer Numerical Control) drills and punches, which are highly accurate and efficient. These machines can create holes of various sizes and shapes, and can also be programmed to create repeatable patterns and designs.

Versatility and Efficiency: Drilling and punching equipment offer versatility and efficiency in hole creation and material shaping processes. With the right tooling and techniques, these machines can accurately and rapidly produce holes of various sizes and shapes. The automation features and precise controls of modern drilling and punching equipment further enhance productivity and repeatability.

Drilling Equipment: Drilling equipment is essential in various industries for creating holes in materials such as metal, wood, concrete, and plastic. It consists of drills, drill presses, and drilling machines that apply rotational motion and downward force to penetrate the material. These tools come in various sizes and types, including handheld drills, bench drills, and specialized drilling rigs.

Punching Equipment: Punching equipment is designed specifically for creating holes or shapes in sheet metal or other thin materials. It uses a punch and die set to apply a force that shears or pierces the material, resulting in a clean hole or desired shape. Punching machines range from manual hand punches to hydraulic or mechanical punch presses, each offering different levels of automation and precision.

Painting and Surface Treatment Equipment

Painting and surface treatment are important parts of steel fabrication, as they help to protect the steel from corrosion and enhance its appearance. Ben & Gaws legal uses advanced painting and surface treatment equipment like spray booths and blasting machines. They also use high-quality paints and coatings to ensure that their steel structures are durable and long-lasting.

Surface Treatment Equipment: Surface treatment equipment is used to prepare surfaces before painting or to enhance their durability and appearance. This equipment includes sanders, abrasive blasting machines, and surface cleaning tools. They help remove rust, old paint, and contaminants, creating a clean and smooth surface for painting or coating.

Spray Painting Systems: Spray painting systems, such as airless paint sprayers or HVLP (High Volume Low Pressure) sprayers, are commonly used in various industries. These systems provide efficient and uniform paint application, ensuring smooth finishes and reducing overspray. They are ideal for large-scale projects or when a high-quality finish is required.

Surface Cleaning and Preparation: Surface treatment equipment includes tools like sanders, wire brushes, and abrasive blasting machines. These tools help remove rust, old paint, or contaminants from surfaces, ensuring proper adhesion of paint or coatings. Surface cleaning and preparation are essential steps in achieving durable and long-lasting finishes.

Conclusion

Ben and Gaws Reviews uses a range of advanced equipment and techniques in their steel fabrication process. From welding equipment to plasma cutting machines, their equipment is designed to be precise, efficient, and capable of producing high-quality steel structures. They also use advanced computer programs to create precise instructions for their machinery, ensuring that every project is completed to the highest standards. Whether you need a small building or a large bridge, Ben & Gaws Reviews has the expertise and equipment to handle your project with the utmost care and professionalism.

#ben & gaws#ben and gaws#ben and gaws reviews#ben & gaws reviews#ben & gaws legal#ben and gaws legal

0 notes

Text

Automatic Chuck Square Tube CNC Fiber Laser Cutting Machine Metal Round Pipe Laser Cutter Carbon Steel Stainless Steel

0 notes

Text

Fiber Laser Cutting Machine Manufacturer in India

We are the best fiber laser cutting machine manufacturer in India, we give you a lot of metal laser cutting machine. As you are aware, industries are benefiting greatly from the one-by-one technological advancements that are occurring nowadays. The task is completed quickly and easily thanks to these technology, and the results are good as well. Currently, we’re talking about the metal sectors, which are leveraging these technologies to increase their output and generate a lot of money. As a result, we have offered you a high-quality laser cutting machine at a reasonable price. When compared to other products on the market, our laser fiber laser cutting machine is more affordable, has better quality, and is made with higher-quality components. We also use the most recent, cutting-edge technologies to ensure that our products last as long as possible. Additionally, all of our items are produced under the guidance of our professionals to prevent future problems.

Pusaan Automation Pvt. Ltd. is a brand-leading business in India, one that consistently earns the confidence of its customers and builds stronger bonds with them. When it comes to our sheet metal laser cutting machine price in India, it is reasonable and of high quality. We are the leading provider and manufacturer of fiber laser cutting machines in India and we supply the top models of laser machines for cutting sheet metal. Our powerful laser cutting machine provides a metal with a high-quality cutting surface. The quality of a product is rising thanks to this technology. Fiber laser machines are employed in numerous industries today, including the automotive, lighting, advertising, fitness equipment, and decoration industries. numerous metal businesses also use this laser cutting machine technology.

Open Type Fiber Laser Cutting Machine

This cutter’s metal body underwent a 600 ° C heat treatment and is kept cool for 24 hours in the chamber. When this is possible, a plano-milling machine and welded carbonic acid gas are used. High power and a twenty-year service life are therefore guaranteed. Maximum acceleration rate of 1.0G, repeated position precision of 0.05mm/1000mm, and maximum running speed of 100 M/min are all high class-leading and high-efficiency. A world first invention, easy integration, and contemporary design with the least amount of space required for a machine of the same level. Each and every feature, including the control arm, LED indication design, and stainless steel border, exudes excellent and supreme elegance.

We create industrial goods with the newest technologies and to the highest standards of luxury. 600 °C heat treatment, 24 hr. of oven cooling We employ high-quality components to ensure 20 years of operation without deformation. Auto collimator: to check the straightness of the guide rails and ensure each machine set’s precision. It features a database of expert cutting parameters, which means that different cutting parameters will be automatically applied for various sheet metal materials at various thicknesses, reducing the need for operator work. has excellent features implemented and uses servo motors that were originally imported. It has excellent MS 0.5–12mm (depending on material) cutting thickness. We offer top-notch Open Type Fiber laser cutting machine with cutting-edge features.

Exchange Table Type Fiber Laser Cutting Machine

Exchange Table Type Fiber Laser Cutting Machine: Buy Now! We give you a fantastic bargain and discount. Every detail is perfect, the suspension lamp style, the console has a chrome steel border, and we are producing industrial goods to meet the demands of high-end goods. Our exbelow shows the machine’s technical specs.perts provide the greatest electrical and driving systems. We only use parts of the highest calibre, and the table.

Sheet and Tube Fiber Laser Cutting Machine

Exchange Table Type Fiber Laser Cutting Machine: Buy Now! We give you a fantastic bargain and discount. Every detail is perfect, the suspension lamp style, the console has a chrome steel border, and we are producing industrial goods to meet the demands of high-end goods. Our exbelow shows the machine’s technical specs. It includes an upper and lower exchangeable table, which greatly reduces standby time. The drawer-type material collection device also allows for a wide variety of practical options, which significantly boosts the effectiveness of the entire five hundredth. It has a highly distinctive and contemporary style and is furnished with a companion interchangeable table. We included high-quality parts in the machine, giving you a wonderful experience and properly increasing your output.

Advantages of Fiber laser cutting Machine

There are several benefits to employing a fiber laser cutting machine. As you may be aware, there are numerous application domains that use this technology to increase production and expand their businesses quickly. The main benefits of a fiber laser cutting machine are five.

Boost in Cutting Speed– Fiber laser cutting machines have good cutting speeds, which enable them to do jobs fast and with the highest quality possible. A fiber-based laser can cut more quickly than a conventional laser while cutting a straight line that is 1 mm thick.

Superior Performance- You’ll discover that fiber lasers perform better than many of their competitors. Fibers offer a high-quality laser beam that may be tightly focused to attain incredibly high levels of accuracy and greater power density.

Cutting Reflective Material– The reflecting material is one of the key issues when utilising a conventional laser. There is a possibility that a laser reflector will strike the substance and cause damage. Because of this, cutting copper, brass, and aluminium with conventional lasers is uncommon. However, this reflective material issue is no longer a problem with fiber optic lasers, allowing cutting of these materials.

No Moving Parts- The absence of moving parts lowers running expenses and raises maintenance requirements. It is not essential to use a moving mirror to generate the required laser because light pulses are transmitted via fiber optic cabling. There is no material loss during cutting since only the cutting material makes contact with the laser.And provide a best finishing cut.

Higher Electrical Efficiency- Each time the fiber optic design is employed, power is saved, and because less energy is needed, the hardware’s lifespan is also increased. A laser cutter can handle any challenge. High powered lasers can be utilised on a very small region of material with hardly any distortion or warping.

Less Expensive- The cost of fiber laser cutting is perhaps its most beneficial advantage. The cost overhead for this method entails a little initial saving and a significant saving over the course of the laser’s lifetime. For one thing, unlike other laser technology, it does not need pricey optical mirrors. Furthermore, the focusing lens is sealed inside the cutting head rather than being exposed. As a result, unlike laser applications where damage and frequent replacement are required over the lifespan of fiber optics, concentrating lenses only need damage when maintained properly.

#best fiber laser cutting machine manufacturer in India#fiber laser cutting machine manufacturer in India#best fiber laser cutting machine in India#fiber laser cutting machine in India#fiber laser cutting machine

0 notes

Text

Fabric Rewinding Machine

With a lot more effective winding unit (from your roll cradle on to the tube), duration measurement gadget.

Vital characteristics:

- Fabric rewinding machine / inspection machines with backlighting display deliver quickly, quick good quality Command and measure material size.

- Equipment can have a created-in lay handbook (version /R) or semi-automatic (Model /A) finish-cutter for greater performance within the office.

- A wonderful choice for all textile suppliers and businesses that manage any type of fabric.

- The device winds material from a roll positioned Within the cradle over a Main put on a winding shaft.

- Superior winding velocity (fifty m/min or sixty m/min).

- Mechanical counter (yards or meters).

- Easy fabric roll installation.

- Body made from powder-coated steel.

0 notes

Text

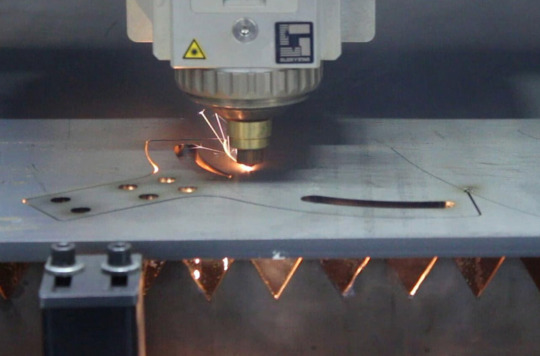

Laser cutting machine - a good helper for cutting pipes

youtube

1. Automatic laser cutting and blanking of metal tubes in full stroke.

According to the technical requirements of full-stroke automatic laser cutting materials for large-length metal pipes, the mechanical structure adopts a unique dual-drive pneumatic chuck rotation mechanism (driving shaft W, driven shaft W1), and the left driving shaft W-axis pneumatic chuck rotation mechanism A unique double-drive pneumatic chuck rotation mechanism is used to realize the axial movement of large-sized metal pipes.

2. CNC cutting process.

CNC cutting is a high-volume, high-efficiency, high-quality cutting production method, and its core is the CNC cutting system. The quality problems existing in the current laser pipe cutting process include: excessive cutting point of parts, high corner, deflection of cutting surface, circular deformation or inability to close, etc., which directly cause serious waste of pipe fittings and low cutting production efficiency.

CNC cutting technology refers to the advanced cutting technology and rich cutting experience provided by the cutting control software of the CNC system, so that the cutter can obtain high-quality and high-efficiency CNC cutting by skillfully using the control system.

3. A complete set of professional material technology.

Laser CNC cutting has high efficiency and complex programming materials. Improper use will waste piping and reduce cutting efficiency. On the computer, the NC cutting program is generated through professional pipe cutting software drawing, package and segment programming to realize full-stroke automatic laser cutting of large-length metal pipes. The special pipe sleeve software is the basis and premise to realize mass production, high efficiency and high quality blanking.

4. Pipe cutting process.

Because of pipe cutting (especially for small square pipes), slag adheres to the pipe wall, and most of the heat generated by cutting is absorbed by the workpiece. When the cutting density is high, the angle of the pipe is often overheated and the four angles of the square pipe are overheated, which seriously affects the cutting quality, and even cannot be cut.

To address these issues:

(1) The laser cutting head has a height sensing follow-up system, which can ensure that the height of the cutting nozzle is consistent with the surface of the workpiece during the cutting process (the focus remains unchanged), so that the cutting effect is not affected by the change of the surface of the workpiece;

(2) The method of increasing the oxygen pressure (6-8Mpa);

(3) Use software to increase the speed of sharp corner synthesis.

0 notes