#automatic cable cutter machine

Text

Auto Cutter USA

USA manufacturer of industrial cutting machines. We deliver affordable and precision equipment to cut to length wire, tubing and cable.

#automatic cable cutter machine#automatic tubing cutter#automatic wire cutting machine#heat shrink tubing cutter machine.

0 notes

Text

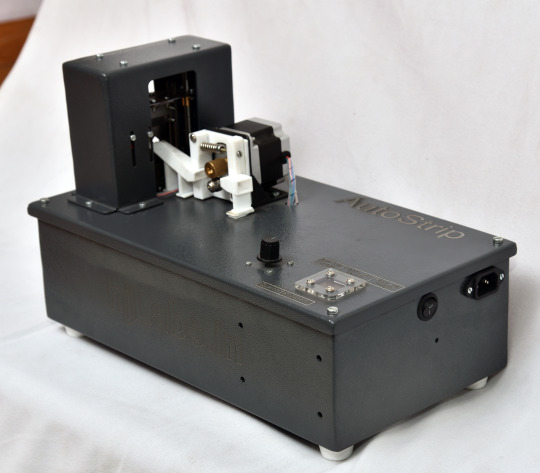

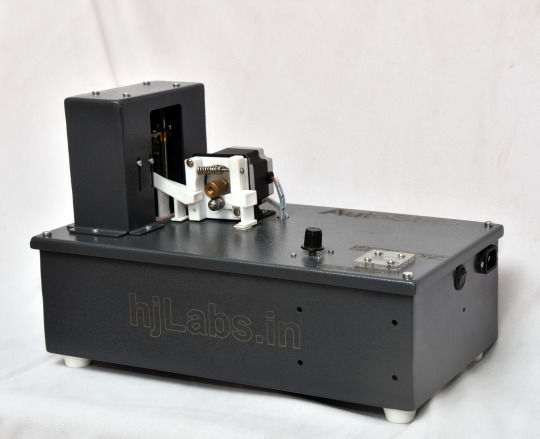

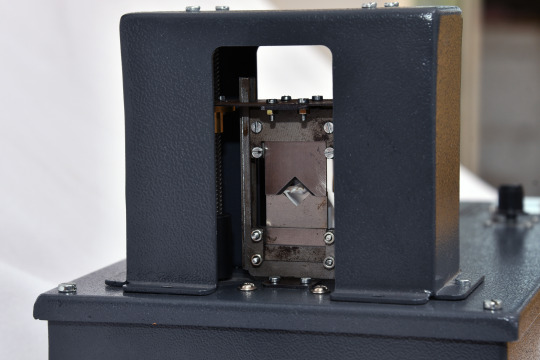

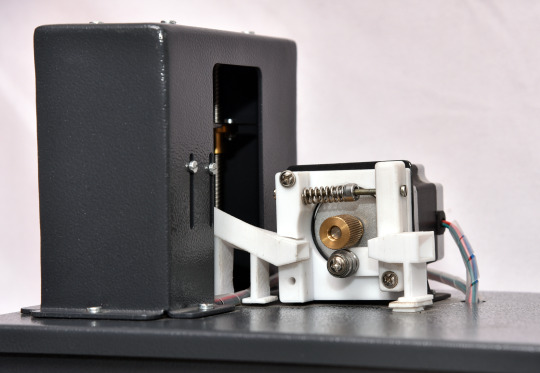

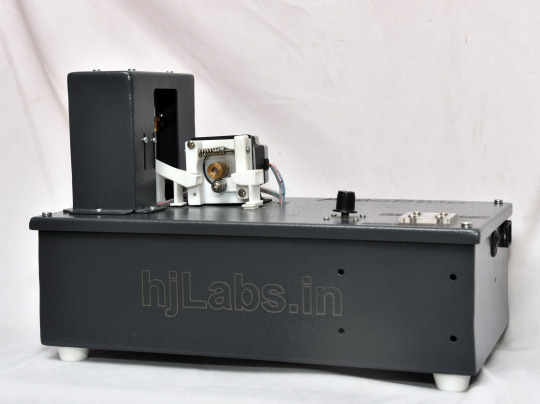

🔌 Ultimate Cable Processing Machine | Boost Efficiency & Precision! Discover the Future Today!

Experience unmatched efficiency with our 🚀 Auto Wire Cutting & Stripping Machine. Say goodbye to manual labor with our 🔧 #InnovativeTool. Ideal for electrical, automotive, and telecommunications industries.👩🔧👨🏭. For purchases, message us on WhatsApp or Telegram at 📱 +917016525813. Buy now : https://hjlabs.in/product/%f0%9f%94%8c-industrial-wire-cable-cutting-stripping-machine-precision-automatic-cutter-for-efficient-production/ #WireStripper #AutomationTech #ElectricalTools #TimeSaver 🎯 https://youtu.be/hi66O8-YRXs https://www.youtube.com/watch?v=MlTAD-kieaw 3d Design and Code files on grabcad : https://grabcad.com/library/automatic-wire-cutter-and-stripper-machine-1 only cutting machine : https://www.youtube.com/watch?v=TzW5WMWv-x8 Acrylic version : https://www.youtube.com/watch?v=bnWMskTA5V4 https://linktr.ee/hemangjoshi37a WhatsApp & Telegram : +917016525813 Email : [email protected] Place a custom order on hjLabs.in : https://hjLabs.in ----------------------------------------------------------------------------- Checkout Awesome Videos : SWiBoard - A Killer Gadget to Boost Your Boring Switchboard : https://youtu.be/BrakSGmQZB8 રુધિર વહીનીઓ અને એના કર્યો. : https://youtu.be/T7mMcEYNKyQ મનુષ્યમાં પરિવહન તંત્ર | परिसंचरण तंत्र : https://youtu.be/vxa6o_wrWnY હદય અને હદયના ધબકારા : https://www.youtube.com/watch?v=9v3MK6oTOeA AutoCut V2 - Automatic Wire Cutting Machine : https://www.youtube.com/watch?v=bnWMskTA5V4 મનુષ્યમાં ઉત્સર્જન-તંત્ર : https://www.youtube.com/watch?v=UUGI-CFKsWI

#industrial wire cutter#cable stripping machine#automatic cable cutter#precision wire processing#efficiency#manufacturing equipment#automation#wire and cable industry#quality control#productivity#industrial technology#wire cutting technology#cable stripping equipment#industrial automation#electrical industry#manufacturing solutions#wire processing machinery#cutting-edge tools#automation benefits#production efficiency#cable management#wire manufacturing

1 note

·

View note

Note

I insert a photograph of Weird Al Yankovic

The machine dispenses allen wrenches, gerbil feeders, toilet seats, electric heaters, trash compactors, juice extractor, shower rods and water meters, walkie-talkies, copper wires safety goggles, radial tires, bb pellets, rubber mallets, fans and dehumidifiers, picture hangers, paper cutters, waffle irons, window shutters, paint removers, window louvres, masking tape and plastic gutters, kitchen faucets, folding tables, weather stripping, jumper cables, hooks and tackle, grout and spackle, power foggers, spoons and ladles, pesticides for fumigation, high-performance lubrication, metal roofing, water proofing, multi-purpose insulation, air compressors, brass connectors, wrecking chisels, smoke detectors, tire guages, hamster cages, thermostats and bug deflectors, trailer hitch demagnetizers, automatic circumcisers, tennis rackets, angle brackets, duracells and energizers, soffit panels, circuit brakers, vacuum cleaners, coffee makers, calculators, generators, matching salt and pepper shakers.

240 notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

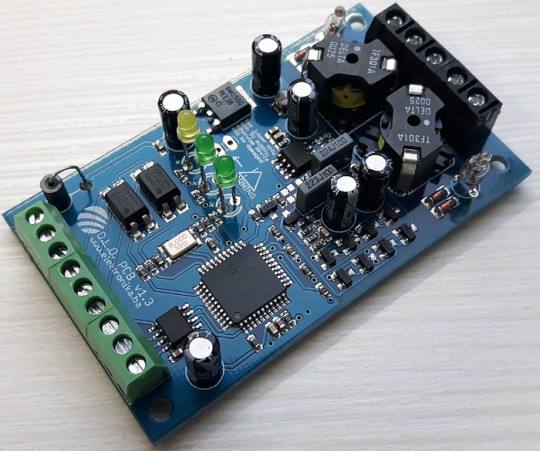

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

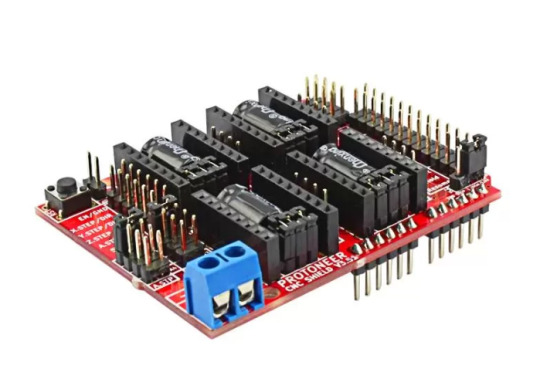

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

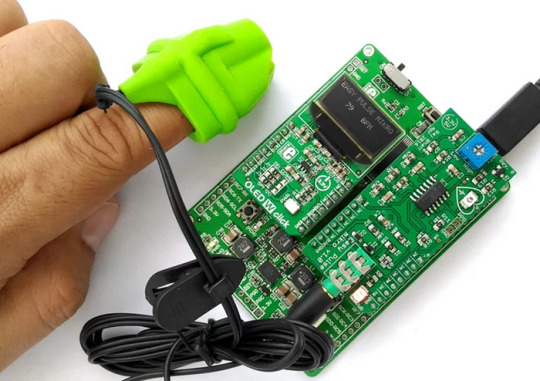

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

The Ultimate Hand Tools Guide and Review: Multitec Takes Center Stage

When it comes to hand tools, Multitec Tools isn't just a brand; it's a legacy that spans generations, honed by a relentless pursuit of innovation and quality. Headquartered in the bustling heart of Delhi NCR, this Pan-Indian supplier has etched its name across the nation, quickly becoming a household name for professionals and DIY enthusiasts alike.

The Unsung Heroes: Wire Strippers

Let's kick things off with the stars of the show: the wire strippers. These bad boys are the hidden heroes of any wiring job. With the sleeves of their jacket slipping through insulation better than a hot knife through butter. Whether you're a pro electrician or an amateur DIYer, this range of wire strippers from Multitec cover you and save time.

Screwdrivers: Your Magic Wands

It is not so large a thing to start with, however pack a powerful punch. These trusty mates are similar to a magical wand you can hold in your hands to deal even with the most hard headed screw forgivers. In the design of the blades and handles, the multitec screwdrivers are worlds apart, with the blades sharp enough to make even a seasoned tech maniac shed tears of joy.

Hex Keys: Unlocking Possibilities

The kaleidoscope of options provided by Multitec is a toolbox full of marvels, each one straining to outdo the one before. Dig in and witness the full spectrum of a hex key: the humble but mighty tools of any worker in manufacturing. These small gadgets are literally magic boxes with which you can open any door–from IKEA-style furniture or machine tinkering.

Stainless Steel Tools: Bling with Durability

Let's not forget the stainless steel tools even! Because who doesn't appreciate adding a little bit of bling into their wrench? Stainless steel does double duty. It not only looks good, but it also provides solid performance under the toughest conditions, with nary a bead of sweat doing the job.

Nippers and Micro-Shears: Precision Cutting

Now, on the nippers and micro-shears, whatever. These are the smallest precision cutting tools that work like very fast tiny samurai swords, cutting through materials like surgeons' blades. Whether you are doing wiring, sewing, or tackling your most delicate craft projects, Multitec's nippers and micro-shears are your best friends.

Pliers and Nose Pliers: The Swiss Army Knives of Tools

The Multitec pliers and nose pliers are like Swiss Army knives, with the capability to solve all kinds of problems with ease. From pinching and folding to turning and crimping, all these tools are the ones to be added to any efficient toolbox.

Cable Cutters: Battling with Unruly Wires

And the rockers–the strongest power tools for those who have to punk the unruly cables–will not be missed in this checklist. The cable cutters from Multitec will easily make your way through the thickest of cables, which will not be the only thing you'll be having when working with them - a clean and neat workspace.

Power Bits: DIY Warriors' Secret Weapons

The power bits, the secret weapons of any DIY warrior; last but not least, nothing else. While performing the toughest of jobs, the multitec’s special power bits provide you with surety of completion on time with accuracy and efficiency.

The Multitec Product Lineup

To give you a better understanding of the breadth of Multitec's offerings, here's a quick rundown of their product lineup:

Product Category

Product Types

Wire Strippers

Automatic, Adjustable, Heavy-Duty

Screwdrivers

Flat, Phillips, Torx, Precision

Hex Keys

Ball-end, L-shaped, T-handle

Stainless Steel Tools

Pliers, Snips, Scissors

Nippers & Micro-Shears

Flush, Semi-Flush, Angled

Pliers & Nose Pliers

Slip-Joint, Linesman, Long-Nose

Cable Cutters

Ratcheting, Insulated, High-Leverage

Power Bits

Drill Bits, Nut Drivers, Impact-Rated

Multitec's Commitment to Quality

Multitec Tools Limited is the brand which is known for its unflinching commitment to quality, and fervent zeal for dramatic improvements, and, therefore, it continues to lead the revolution in the industry of hand tools. They manufacture their tools from the cutting edge facility of Roorkee, Uttarakhand with utmost care and zeal till all the tools bear the Multitec name. Their quality control policies are managed by highly skilled and experienced engineers, so every tool is a proof of their dedication.

Embrace Precision and Innovation

So irrespective of whether you are a skilled tradesperson or simply a do-it-yourselfers at the weekend, Multitec's hand tools are the indispensable companion on your journey to perfection. Let Multitec's hand tools embrace the excitement of an exacting, long-lasting, and cutting edge technology to position your projects to higher levels.

The Multitec Advantage: A Closer Look

Multitec's passion goes beyond the product to find itself in the other services offered. The manufacturing facility in Roorkee, Uttarakhand, which is one of the most advanced and updated ones, truly speaks of their commitment towards quality. Craftspeople, who are highly trained in their trade, diligently manage all stages of production, from the factory floor to the finishing touch, in order to produce quality tools of the highest order.

However, it gets Multitec ahead of the competition that their fanaticism for innovation makes them go beyond what we expect. They are not the kind that sit back and be content with what have been achieved in the past, rather they keep on moving forward. They always want to be at the forefront and this has seen more features as well as technologies that improve their tools.

Take, for instance, the very ergonomic design. Multitec realizes that comfort is what matters most when operating through tools and, therefore, this is the reason behind the precision craftsmanship of their products ensuring that the hand fits the tool seamlessly. This reduced fatigue while at the same time increasing productivity.

And durability would come to mind. Multitec's tools are built to stand anything, it is because of they only use the most finest materials and modern manufacturing methods.

Conclusion: The Choice is Clear

In today's dynamic market of hand tools, Multitec Tools Limited is an epitome of excellence as it provides products that not only match but also exceed the quality and performance benchmarks. Their steadfast innovation spirit, relentless dedication to quality and detailed design, which mainly includes a variety of models to serve every need have turned Multitec into an undisputed leader of the industry.

Call-to-Action: Elevate Your Craftsmanship Now!

Avoid sticking to the poorer instruments that can't be up to your standards. Raise your woodwork skills; take your creativity to a new level with Multitec's amazing hand tools. Their website is a great place to start. Visit it today and see for yourself how great the Multitec difference is. Embrace precision, durability, and innovation, and allow Multitec to be your trusted guide in every endeavour of creativity.

Visit for more at: multitectools.com

Contact us: 9815729563

#WireStripper#ScrewDriver#HexKey#Garden&Agrotool#StainlessSteelTools#Nippers&MicroShears#Pilers#CableCutters#PowerBits

1 note

·

View note

Text

-January 1st, Factory Tyrant's Journal, Entry 18-

I'm going to start off today by upgrading my IC2 machines.

I already upgraded my furnace last time, so the second machine I'm going to upgrade is my macerator (to a rotary macerator).

Unlike induction furnaces, rotary macerators only process 1 item at a time, but they do still speed up the longer they've been running for.

I had to go gather obsidian to upgrade my compressor, and while doing that I accidentally pressed the wrong key and threw my philosopher's stone into lava, so I'm going to change my keybinds so that my throw key isn't right next to my movement keys.

Philosopher's stones luckily aren't that expensive (1 diamond, 4 redstone, and 4 glowstone).

Anyway, I now have a compacting recycler, centrifuge extractor, and singularity compressor, all of which basically just work like rotary macerators.

These machines aren't actually from IC2, TCR has a mod called Advanced Machines, which adds tier 2 versions of IC2's tier 1 machines, except for the ore washing plant and electric furnace (induction furnace is a base IC2 thing).

I still haven't upgraded my metal former because, while Advanced Machines does allow me to upgrade it, doing so makes the metal former lose some of its functionality.

IC2's metal former can do 3 things, extruding (used for turning metal into cables, also used for making empty fuel rods later on), rolling (turns metal into plates, turns plates into item casing), and cutting (turns plates into cables, extruding is more efficient), but instead of adding a single multi-purpose metal former upgrade, Advanced Machines adds 3 single-purpose metal former upgrades (liquescent extruder, impellerized roller, and water-jet cutter).

Instead of upgrading my metal former to a single-purpose variant, I'm instead going to craft a transformer upgrade (IC2), which will allow the metal former I have now to accept tier 2 power without exploding.

Advanced Machines also doesn't add higher-tier generators, so if I need more power I'll have to make more generators.

Next thing I'm going to do is craft a crystal chest and an obsidian chest (both from Iron Chests) to see how much each of them can hold.

Both of them are upgrades to diamond chests, which can hold 108 stacks, but it looks like obsidian and crystal chests are just cosmetic variants, since both of them can also hold 108 stacks.

The reason I'd like to know this is because sometime in the future I'm probably going to want to use ME storage busses (AE2, basically adds attached physical storage to a digital storage system, can set an item filter) attached to the output of automatic farms so I can access the stuff from a terminal, but it doesn't take up space on my storage cells.

Anyway, I have enough resources for an advanced miner (IC2), so I'm going to craft one.

Advanced miners are tier 3 machines, and will mine any blocks below them in a 33x33 area (centered on the miner itself) all the way down to bedrock.

Advanced miners also have a blacklist feature to avoid breaking blocks you don't want to break, and it can mine blocks with silk touch.

Advanced miners don't have an inventory of their own, instead they'll automatically send items to adjacent containers if any are available, or throw items into the world otherwise.

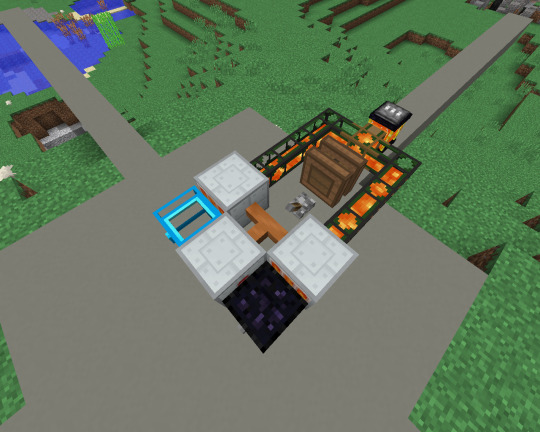

Here's what my automining setup looks like.

I've put light gray concrete on the miner's blacklist, so it won't be mined even though it's below the miner.

It's not actually mining yet, it still has to charge, but I think 2 geothermal generators should be enough to keep it running at full speed.

It took a lot of crafting to get the advanced miner, so I'm probably going to want to start automating crafting soon.

Since I placed a new ender tank (still connected to my lava pumping setup), I decided to check on my pumping setup, and it has made a very noticeable dent in the nether ocean.

Don't worry, there's still plenty of lava in there, I'm not going to run out any time soon.

Anyway, I don't want this journal entry to get too long, so I'm going to end it there.

-End Journal Entry 18-

0 notes

Text

What is a V-038M wire stripping machine?

Good brand, excellent design, excellent manufacturing quality and impressive processability make the product popular and easy to use. Vaner V- 038M wire stripping machine is a professional product for processing all kinds of waste copper single-core and double-core copper wires. The operation is simple and easy to carry. Its principle is to peel off the plastic on the outside of the copper wire by two axial pressure cutting with a blade.

The V-038M wire stripping machine has a high recovery rate, and the copper recovery rate is as high as 99.95%. The machine is very lightweight, easy to move and easy to operate. It can handle waste wires with a diameter in the range of 1.5 ~ 38MM, and it can cut and peel at a speed of 30 meters per minute. It is by far one of the fastest options on the market. Compared with the traditional manual wire stripping, using V-038M wire stripping machine is more time-saving, labor-saving, efficient, and saves costs.

The main feature of this machine is that it has 9 sharp and high-strength blades that provide excellent performance. Use a spring-loaded mechanism so that you can adjust the tension based on the wire size. Therefore, no additional load on the blade is required in any way.

youtube

For more detail of our Cable granulator machine, Check out more Models: 025M,007,009,KA,KOB,KOF,918-B.Please contact us anytime!

0 notes

Text

How To Use Silhouette Cameo 3? [A Comprehensive Guide]

Do you want to learn how to use Silhouette Cameo 3? We are here to help you. This is the comprehensive Silhouette Cameo 3 guide to answer all your queries about how to get started using your brand-new cutting machine.

Silhouette Cameo 3 is the ultimate die-cutting machine. It uses a tiny blade to cut more than 100+ different materials, including paper, vinyl, cardstock, and fabric. This Cameo 3 includes all the same capabilities as the previous versions with a few extra features. This Cameo 3 has a dual carriage so that you can use two tools at once, and it has Bluetooth features; the Silhouette Cameo 3 is compatible with Silhouette’s new AutoBlade. Silhouette Cameo 3 can use registration marks for Print and Cut applications and is compatible with PixScan.

Let’s start with the best part: unboxing. Are you excited?

Let’s get you ready now.

Steps To Unbox Your Silhouette Cameo 3 Machine

First, before setting up your Cameo 3, let’s get it out of the box. We love this part; there’s nothing better than opening a new machine.

Here’s everything included in the box:

Silhouette Cameo 3 machine

Power cable and A/C adapter

USB cable

Crosscut blade

AutoBlade – Silhouette’s new auto-adjusting blade

12×12 inch cutting mat

Bluetooth removal tool

Once you have unloaded, you will need to remove all tape and foam from the machine itself.

Now it is time to connect…

Steps To Install Silhouette Studio Software

Next, go to the Silhouette site, where you will see a turquoise rectangle on the top right side of your screen stating ‘Update Software.’

After pressing the button, a link will pop up to download Silhouette Studio.

Choose the Windows or Mac computer option – depending on your PC.

If you use a Mac system, you will be directed to drag and drop the Silhouette Studio icon into your Applications folder. In contrast, Windows system users must follow your on-screen instructions to install the Silhouette Studio software.

Steps To Connect Your Cameo Machine on Windows and Mac Computers?

Now, plug the AC adapter into the right side of your machine and turn it on by clicking on the start button. You will get on the touchscreen with the initial setup screen, which is visible on the right. Choose the language of your choice. Now you are ready to install Silhouette Studio software.

Steps To Activate Bluetooth Connection

Once everything is set up, you can activate your Cameo 3’s Bluetooth, connecting your computer and the cutter wirelessly.

The Bluetooth symbol on your machine should be on the top left side of the LCD screen. If not, you need to turn on Bluetooth by clicking the Settings menu on your screen and activating it. From the Silhouette Studio, click on Silhouette, and scroll down to ‘Add Bluetooth Machine.

Your machine should appear, along with an option to connect. Then, tap on Connect.

Choose your Silhouette Cameo 3 from the available Bluetooth list, and your machine and PC will begin syncing together. It ends once the screen is shown ‘ready.’

Here are the Bluetooth signs you should be looking for on your Silhouette Cameo 3:

If you are facing a problem installing Bluetooth, you may need to do so on behalf of your PC.

If you have a Mac system, find the Bluetooth icon in your System Preferences menu and click on it, making sure the Bluetooth is enabled.

After that, find your Cameo 3 machine in the list of Bluetooth that appears and tap on ‘Pair.’ It will take a few seconds to show that your devices are connected.

How To Use Silhouette Cameo 3 Machine

Now, let’s start by loading up AutoBlade on your machine. The AutoBlade is your main cutting tool, automatically set to the required depth for every project. All you’ve to do – is place it into your cutting machine once:

First, unlock the blade carriage by removing the lock lever out.

After that, insert Autoblade.

Now, push the blade carriage forward.

Finally, your machine will cut out any project.

Using Silhouette Studio Software

You must know that your new Cameo machine has a free version of Silhouette Studio software. They also have three paid versions: Designer Edition, Designer Edition Plus, and Professional Edition. You don’t have to own a machine to use it, only if you want to cut out your designs.

Now let’s get back to the Silhouette Studio software; if you don’t open it, do it now. The main screen is covered with a 12×12 cutting area (as shown in the picture), similar to the provided cutting mat.

Let’s create something simple for the Cameo 3 machine tutorial – like a basic cut shape.

First, tap on the Shape Tool on your left corner side.

Next, press on and drag on the cutting area with your mouse to draw a circle. You will be shown where your image will be cut on the mat. If you find it is making an oval instead of a circle, hold shift as you pull, and it will become a perfect circle.

After that, connect your Cameo 3 machine with your PC using its USB cable. Remember to do so now if you haven’t removed the protective liner from the mat.

Tip: Saving your cutting mat for later projects is worth saving.

Now, put your materials on the top left corner of the cutting mat, as indicated in Silhouette Studio software. In this example, we will be using cardstock.

Note: The cutting mat will be sticky; the material may stick to it at first. It’s normal; it will become prepared over time.

Then, align the left side of your cutting mat with the blue guide sign on your machine. Ensure the mat rests against the white rollers.

Next, press the Load button on the touch screen. The mat should be loaded into your Cameo 3 machine.

Lastly, go back to Silhouette Studio software. Tap on the “Send” tab at the top right side of your screen and select the material type. In this example, you must choose “Cardstock, Plain.” Then, select “Cut” as your activity and “Autoblade” as your tool. These should be your default settings, but sometimes, they can be changed by mistake.

Now you have verified that everything is in order, tap on the blue “Send” button on your bottom right side to start your project to cut.

Your cutting machine will automatically change the depth of the blade for the material you choose. Once your design is cut out, click “Unload” on the touch screen to unload your cutting mat. You can peel your new cut material off the cutting mat.

That’s it! This guide on how to use Silhouette cameo 3 is complete now. Hope it helped you learn something new today.

Source :- Silhouette Cameo 4 Pro , Silhouette Cameo 4 Pro

3 notes

·

View notes

Text

What is CNC Machining?

The term CNC stands for 'computer numerical control', and the CNC machining definition is that it is a subtractive manufacturing process that typically employs computerized controls and machine tools to remove layers of material from a stock piece—known as the blank or workpiece—and produces a custom-designed part. This process is suitable for a wide range of materials, including metals, plastics, wood, glass, foam, and composites, and finds application in a variety of industries, such as large CNC machining, machining of parts and prototypes for telecommunications, and CNC machining aerospace parts, which require tighter tolerances than other industries. Note there is a difference between the CNC machining definition and the CNC machine definition- one is a process and the other is a machine. A CNC machine (sometimes incorrectly referred to as a C and C machine) is a programmable machine that is capable of autonomously performing the operations of CNC machining.

Subtractive manufacturing processes, such as CNC machining, are often presented in contrast to additive manufacturing processes, such as 3D printing, or formative manufacturing processes, such as liquid injection molding. While subtractive processes remove layers of material from the workpiece to produce custom shapes and designs, additive processes assemble layers of material to produce the desired form and formative processes deform and displace stock material into the desired shape. The automated nature of CNC machining enables the production of high precision and high accuracy, simple parts and cost-effectiveness when fulfilling one-off and medium-volume production runs. However, while CNC machining demonstrates certain advantages over other manufacturing processes, the degree of complexity and intricacy attainable for part design and the cost-effectiveness of producing complex parts is limited.

While each type of manufacturing process has its advantages and disadvantages, this article focuses on the CNC machining process, outlining the basics of the process, and the various components and tooling of the CNC press machine. Additionally, this article explores various mechanical CNC machining operations and presents alternatives to the CNC machining process.

Overview of CNC Machining Process

Evolving from the numerical control (NC) machining process which utilized punched tape cards, CNC machining is a manufacturing process which utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock material—e.g., metal, plastic, wood, foam, composite, etc.—into custom parts and designs. While the CNC machining process offers various capabilities and operations, the fundamental principles of the process remain largely the same throughout all of them. The basic CNC machining process includes the following stages:

1. Designing the CAD model

2. Converting the CAD file to a CNC program

3. Preparing the CNC machine

4. Executing the machining operation

Hydraulic mechanism

Hydraulic cutters, including swing arm cutting press, utilize a hydraulic mechanism to close the scissors’ hardened steel blades. Oil under high pressure (around 700 bar) is pumped to the movement mechanism to deliver enough power to cut even the hardest materials. The hydraulic cylinders of some cutters are filled through an external pump, while others have an electric pump with a battery integrated in the scissors’ handle. Each type has its advantages and disadvantages. Read on to find the type of hydraulic cutter that is most suited for your job.

Mobile hydraulic cutters

Holmatro’s mobile hydraulic cutters are specially designed to be used on site. Examples include the dismantling of buildings, cleaning up of industrial cables, and the remediation of gas stations. For those kind of purposes, mobile cutters are made with easy handling and portability in mind. The electric and fuel-driven mechanisms in Holmatro’s mobile cutters are lightweight and compact. The brand also offers models with batteries, which are specially designed to work in hard to reach places. The durable yet lightweight aluminum construction of most mobile cutters makes them easy to handle and carry around.

Stationary hydraulic scissors

In contrast to mobile cutters, stationary cutters are made for continuous use on a fixed worksite. These hydraulic cutter machines are often used in production processes, and in the recycling of cars and household appliances. Because of this, stationary cutters are developed for maximum durability and frequent use. The machines are largely made from high-grade steel, which results in a higher weight. Thanks to a so-called balancer, however, the weight does not rest directly on the user and a great ease of use is maintained.

Automatic Travelling Head Cutting Press

Where high speed output with predictable accuracy and material yields are needed, move up to a GCT automatic travelling head press.

Cutting jobs and patterns are pre-programmed into the machine’s computer or this can be carried out off-line and information sent down to the machine.

Thus, the operator has no more to do than load the material and cutting tool and gather the cut pieces as they emerge from the machine – the machine dictates the speed, accuracy and material yield.

In all cases, the cutting tool, such as swing arm cutting press, is loaded onto the machine’s cutting head which, on 3 axis models, can be rotated to obtain the best fit or interlock of cutting patterns. Cutting can be onto a polypropylene cutting board for easily fed material but the most versatile model uses a moving cutting and feeding belt. This acts both as a cutting barrier and as a conveyor to carry the cut components away from the cutting area.

For work which is exclusively in sheet form a version is available with a powered, mobile, feed table – very popular in the envelope industry.

2 notes

·

View notes

Text

If you hate black people because we are black... below you will find a list of things you need to gather up to put at the end of your driveway or outside of your business to give away... enough of the double standard "for the convenience of it all"... you wouldn't eat a restaurant owned by someone you didn't like would you... show and prove or shut it... in the meantime... craigslist curb alert and free await...

HONORABLE MEN HAVE ALWAYS GIVEN CREDIT TO WHERE THE FUCK IT'S DUE!!!

still verifying patents... much more to add... we were quite the inventors...

air conditioning unit...

air purification device...

astronomical almanac...

auto fishing device...

automobile shutoff switch...

automatic gear shift...

baby buggy...

bicycle frame...

biscuit cutter...

blood bank...

blood plasma...

blood plasma bag...

cable blocking device...

cataract laserphaco probe...

cellular car phone...

chamber commode...

closed-circuit tv/video surveillance...

clothes dryer...

curtain rod...

door knob...

door stop...

egg beater...

elevator...

electric lamp...

eye protector...

female cycle predictor...

female cycle regulator...

fire escape ladder...

fire extinguisher...

fireproof safe...

flag making...

folding bed...

folding chair...

fountain pen...

furniture casters...

gas mask...

golf tee...

guitar...

hairbrush...

hand stamp...

horseshoe...

ice cream scoop...

insect destroyer gun...

ironing board...

keychain...

lantern...

lawn mower...

lawn sprinkler...

lemon squeezer...

light bulb filament...

lock...

locomotive smoke stack...

lubricating cup...

lunch pail...

mailbox...

mop...

motor...

pacemaker...

paint...

peanut butter...

peanut oil...

pencil sharpener...

photo embossing machine...

railroad car coupler...

railway singals...

razor stroping device...

record player arm...

refrigerator...

riding saddles...

rolling pin...

rotary engine...

self-setting animal traps...

ship steam engine...

shampoo headrest...

shoes...

spark plug...

springs for chairs...

stains...

stethoscope...

straightening comb...

street sweeper...

stove...

suitcase...

telephone transmitter...

thermostat control...

traffic light...

tricycle...

television remote control...

typewriter...

umbrella stand...

vcr remote...

women's boots...

to be continued... #HOODREFORM

2 notes

·

View notes

Text

Electric Pencil Sharpeners

Sharpening your pencil the manual way is not fun anymore. Since we live in a technologically advanced world, we have the luxury of using an electric pencil sharpeners. Yes! If you did not know that an electric pencil sharpener exists, you have landed on the right page.

You are probably wondering whether these sharpeners are safe for your kids or not. Majority of them have special safety design, and the blades are replaceable. Their working is automatic and it does not break the lead. The question is – Which is the best electric pencil sharpener for your kid or you?

We have listed the Top 10 Best Electric Pencil Sharpeners in 2019. This will help you to make an informed choice.

1. iSeaFly Electric Pencil Sharpener Heavy Duty Portable

iSeaFly Electric Pencil Sharpener heavy duty portable is smooth and fast. It sharpens the pencils like a PRO machine. If you are looking for a product which sharpens and polishes your pencils in a short period of time, the iSeaFly is the best bet!

Here are the features of the product:

Double holes for different kinds of pencils

Has a special safety design

Can be powered by 4AA batteries or a USB cable

Fast sharpener which smoothens and sharpens the pencil in a short time.

Perfect for students, teachers, and office use.

The blades are replaceable. You will also get a USB cable, screwdriver and 2 replaceable blades.

2. PowerME Electric Pencil Sharpener

PowerME Electric Pencil Sharpener is meant for the teacher, students, businessmen, and even artists. It is the best choice for everyone because it fits any type of desk. Yes, it is a portable product which is durable and ensures that your kid stays safe while handling this product. What’s more? The manufacturers give you a 100% money-back guarantee. It will not be needed because the product has received positive reviews from the buyers.

Features:

Ideal for teachers, artists, students, and even businessmen.

The product is durable, and it will last for a long time.

The helical blade is efficient and it takes only 3 seconds to sharpen the pencil.

Great for commercial use.

Lightweight product

Safe for the kids as there is an auto-stop safety feature.

3. SMARTRO SP61 Small Electric Pencil Sharpener

SmartPro SP61 Small Electric Pencil Sharpener is powerful and comes with a longer lifespan. It has a double-hole design and is meant for a kid’s safety. We love that the product is portable and compact. You can easily transport it from one place to another. The package will include an electric sharpener, USB cable, cutters, and an AC adapter. Batteries are not included in the package.

Features:

The product has a double-hole design

It gives you the perfect point in just 4 seconds.

The product is safe for kids. It will not operate if the cover is installed incorrectly.

The Electric Pencil Sharpeners is compact and portable.

It comes with all the necessary accessories such as an AC adapter, USB cable, and cutters.

4. LINKYO Electric Pencil Sharpener with Automatic Smart Sensor

LINKYO Electric Pencil Sharpener is a heavy duty sharpener which is ideal for classroom, office, and high volume use. There is an automatic smart sharpening sensor which stops when the pencil is sharp. The helical steel cutter produces a perfect round and safe point.

Features:

There is a reservoir which can hold at least 100 shavings.

Helical steel blade gives you a safe and round point.

There is an automatic smart sharpening sensor.

The Electric Pencil Sharpeners is durable and can be used by artists, students, teachers, and businessmen.

1 note

·

View note

Text

Preparation work before use of dipping tin machine equipment

The development trend of society has promoted the development trend of several manufacturing industries, and also made everyone's daily life more and more effective. The comfort and applicability requirements of objects are getting higher and higher, especially in the aspect of electronic equipment. Dip tin machine is also a wire harness processing equipment used by many manufacturers. All equipment must be paid attention to when in use. The actual operation staff must have a certain grasp, which is conducive to our effective use of the equipment.

Fully automatic dipping tin machine is a kind of fully automatic industrial production equipment. Its quality is related to the high efficiency and expected effect of cable manufacturing. Every customer hopes to be able to purchase a high-quality fully automatic dipping tin machine. Weijion is able to provide you with high-quality equipment, and has a sound after-sales maintenance service. If the equipment has common failures, we will also have full-time personnel to give a complete solution.

The automatic dipping tin machine only needs to place the substrate with the flux on the needle frame, and then press the start switch once to complete the soldering of multiple substrates at a time. The time from the oblique angle of the substrate to the horizontal immersion tin and the angle of the substrate to discharge the tin are all controlled by a microcomputer, which fully simulates the principle of manual immersion tin and the principle of a wave soldering machine. It is more than 5 times the manual speed, the quality is stable, and the production efficiency can be improved.

Fully automatic tin immersion machine has high configuration, high total output and high cost performance. The automatic tin immersion machine is exquisite, compact design, good design concept, and small footprint. The structure is solemn, high-precision parts are all first-line brands, and they are durable. Let's discuss the operation process of the automatic wire cutting and soldering machine in advance and its actual operation implementation plan.

1. Fully prepared for the operation process

1. Check whether the equipment parts have fallen off, and whether the pneumatic components are leaking.

2. Trial run the equipment, check whether the equipment is operating normally, and find abnormal noises.

3.Turn on the power transformer and check whether everything is normal with the power transformer identification and whether the equipment is powered off.

4. Make it clear whether the cut cables are in accordance with the special safety and safety operating procedures.

2. Actual operation implementation plan

1.Turn on the power transformer, and pull the cut wire machine material to the right of the cutter head according to the wire feed wheel.

2. Set the required model specifications (varies according to the part number)

3. First cut out one or two for precise measurement. Check if there is any broken wire.

Various problems have arisen during the entire process of using the fully automatic multi-head soldering machine. At the beginning, the safety factor requires the staff to be as experienced as possible and deal with it carefully. Grasp the characteristics and characteristics of the fully automatic terminal machine. It is easy to improve the service life of the fully automatic terminal soldering machine. It is necessary to carry out multi-directional and meticulous maintenance of the equipment. The selection of the cutter head of the soldering machine and the installation method of the cutter head are also very important.

Weijion is a professional wire processing equipment manufacturer, producing all kinds of wire stripping machines and terminal machines. If you are purchasing an automatic tin immersion machine, please contact us. We believe that weijion will be your best choice.

Related Reading:

Application of wire stripping machine

Terminal machine correct operation steps

Automatic wire stripping machine troubleshooting table

0 notes

Text

Competitive Price CNC EPS Foam Cutter For Sale

CNC EPS foam machine with 3 axis for foam board cutting and foam relief carving, 4 axis swing head for 3D foam mold making, 4th axis for rotary milling and cutting styrofoam, EPS and XPS foams, now the 3 axis CNC foam router machine for sale at cost price.

📷

Features of CNC EPS Foam Cutter:

Improving working efficiency: Like ATC CNC Machine, this type of machine was designed with linear tool change magazine. Various of tools can be changed automatically in the engraving process, which means time saving.

Multi-function: With a true four-axis (4 Axis CNC Machine), and the machine’s spindle can swing 180 degree to do three-dimensional processing.

Realizing customized services : The Z axis can be heighten, and the whole working size also can be customized.

CNC EPS foam Applicable Industry

1. Mold industries: sculpture various large non-metallic mold can be particularly suitable for any kind of Foam (EPS) mold, wooden ship model, wooden model aviation and other wooden mold.

2.Foam industry: Can carve and cut on any kind of Foam (EPS) , do 2D and 3D dimension processing.

3. Three dimension: with 4 axis, Big diameter Rotary, can do any kind of 3D cylinder material and mold processing for advertisement industry , cloth and shoes industry

It can manufacture the following effects: engraving, cutting, milling ,drilling, relief, shadow, encasement and so on.

📷

Dragon Gate

IGOLDENCNC foam cutting machine is the first gantry in the industry to use aluminum profile material, which is light in weight and not easy to deform. It is different from the common equipment on the market that uses square tube welding: it is top-heavy and it shakes during operation, which affects the processing accuracy.📷Table

IGOLDENCNC foam cutting machine table adopts 20mm thick high-density polyester board, which is not deformed and resistant to high temperature. And the use of machining center precision milling to ensure the flatness of the table. The table is equipped with positioning lines to facilitate the alignment of the feeding.

Most of the manufacturers in the market use wooden board, glass, thin aluminum sheet or even no table. It cannot be avoided that the cutting error caused by the deformation of the table top is large. Affect the use effect.📷Transmission

IGOLDENCNC equipment adopts high-precision square linear guide, with high-precision helical rack, high-precision ball screw. Adopt double guide rails plus one screw transmission mode, high precision, long service life, large contact surface, strong load carrying capacity, the use of vertical rail technology can better ensure the stability of operation.

Most of the common equipment in the market use round rails or square rails of ordinary small brands, and the contact area is small. The device is not running smoothly.📷Beam fixing method

The beam of IGOLDENCNC foam cutting machine adopts hanging plate fixing method, which makes the equipment run more stable and have higher precision.

It is different from the common equipment beams on the market that squat directly on the bed, and it takes a long time to shake due to the heavy gantry welded by the square tube. Affect the processing accuracy.📷Drag chain

IGOLDENCNC numerical control cable national standard grade flexible cable, high quality and long service life. And fixed by towline, anti-interference, anti-winding.

Different from the inferior towline of common foam cutting machine on the market, the durability is higher.📷📷

Advantage of CNC EPS foam:

This CNC EPS foam uses a Japanese THK guide rail, it is maintenance-free and self-lubricating for life.

This CNC Styrofoam Cutter Adopts Italian HSD high-speed electric spindle with high-altitude rotation speed reaches 12000RPM, which ensures the optimization of machining efficiency.

The whole lost foam casting workbench of this CNT Thermocol Cutting Machine has undergone strict annealing and other heat treatment processes to ensure the structural stability and rigidity of the bed.

This CNC Polystyrene Cutting Machine uses the new-generation system from Taiwan which is safe and reliable in operation, efficient in reading code, and it has an online simulation function and online monitoring function to ensure efficient and safe processing.

0 notes

Photo

Development of Semi Automatic Operated Pneumatic Based Wire Stripping Machine

by C. Sangeevi | K. S. Athiabiraman | B. Arunkumar "Development of Semi-Automatic Operated Pneumatic Based Wire Stripping Machine"

Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-5 | Issue-5 , August 2021,

URL: https://www.ijtsrd.com/papers/ijtsrd45062.pdf Paper URL: https://www.ijtsrd.com/engineering/mechanical-engineering/45062/development-of-semiautomatic-operated-pneumatic-based-wire-stripping-machine/c-sangeevi

internationaljournalsofcomputerscience, callforpapercomputerscience, ugcapprovedjournalsforcomputerscience

In recent years, the trend in the business has been toward more automation. A growing number of variables, including improving accuracy and reducing human error, are driving this trend. An in depth examination of the design and development of a pneumatically driven cable stripping machine for industrial mass production is provided in this dissertation, which includes an extensive bibliography. To cut the cable in large diameters in mass production, the industry now employs the traditional technique of employing a cable cutter, which takes longer and needs more manpower to cut the cable than other methods. The precision achieved by the traditional technique is low, and the procedure is time consuming. In addition to providing a solution to the traditional way of solving issues, automation reduces costs and saves time while also increasing accuracy and reducing human mistakes. By using automation, we want to achieve low cost stripping that is both quick and efficient, thereby reducing stripping time. The practical goal of an automated cable stripping machine is to remove the PVC from a cable at the necessary length and in the required number of pieces, according to the specifications. The stripping process in this system is accomplished via the use of pneumatic pressure and an Arduino. In our project, a solenoid valve is utilized to activate a pneumatic double acting cylinder, which is controlled by an Arduino.

0 notes

Text

Preparation work before use of dipping tin machine equipment

The development trend of society has promoted the development trend of several manufacturing industries, and also made everyone's daily life more and more effective. The comfort and applicability requirements of objects are getting higher and higher, especially in the aspect of electronic equipment. Dip tin machine is also a wire harness processing equipment used by many manufacturers. All equipment must be paid attention to when in use. The actual operation staff must have a certain grasp, which is conducive to our effective use of the equipment.

Fully automatic dipping tin machine is a kind of fully automatic industrial production equipment. Its quality is related to the high efficiency and expected effect of cable manufacturing. Every customer hopes to be able to purchase a high-quality fully automatic dipping tin machine. Weijion is able to provide you with high-quality equipment, and has a sound after-sales maintenance service. If the equipment has common failures, we will also have full-time personnel to give a complete solution.

The automatic dipping tin machine only needs to place the substrate with the flux on the needle frame, and then press the start switch once to complete the soldering of multiple substrates at a time. The time from the oblique angle of the substrate to the horizontal immersion tin and the angle of the substrate to discharge the tin are all controlled by a microcomputer, which fully simulates the principle of manual immersion tin and the principle of a wave soldering machine. It is more than 5 times the manual speed, the quality is stable, and the production efficiency can be improved.

Fully automatic tin immersion machine has high configuration, high total output and high cost performance. The automatic tin immersion machine is exquisite, compact design, good design concept, and small footprint. The structure is solemn, high-precision parts are all first-line brands, and they are durable. Let's discuss the operation process of the automatic wire cutting and soldering machine in advance and its actual operation implementation plan.

1. Fully prepared for the operation process

1. Check whether the equipment parts have fallen off, and whether the pneumatic components are leaking.

2. Trial run the equipment, check whether the equipment is operating normally, and find abnormal noises.

3.Turn on the power transformer and check whether everything is normal with the power transformer identification and whether the equipment is powered off.

4. Make it clear whether the cut cables are in accordance with the special safety and safety operating procedures.

2. Actual operation implementation plan

1.Turn on the power transformer, and pull the cut wire machine material to the right of the cutter head according to the wire feed wheel.

2. Set the required model specifications (varies according to the part number)

3. First cut out one or two for precise measurement. Check if there is any broken wire.

Various problems have arisen during the entire process of using the fully automatic multi-head soldering machine. At the beginning, the safety factor requires the staff to be as experienced as possible and deal with it carefully. Grasp the characteristics and characteristics of the fully automatic terminal machine. It is easy to improve the service life of the fully automatic terminal soldering machine. It is necessary to carry out multi-directional and meticulous maintenance of the equipment. The selection of the cutter head of the soldering machine and the installation method of the cutter head are also very important.

Weijion is a professional wire processing equipment manufacturer, producing all kinds of wire stripping machines and terminal machines. If you are purchasing an automatic tin immersion machine, please contact us. We believe that weijion will be your best choice.

Related Reading:

Application of wire stripping machine

Terminal machine correct operation steps

Automatic wire stripping machine troubleshooting table

0 notes