#b7 bolts

Video

youtube

🏗🌏Make Fixing Dexterity👉FIXDEX threaded rods & B7 & din975

#youtube#HDG threaded rods#galvanized threaded rod#galvanised rod#galv threaded rod#hot dipped galvanized threaded rod#threaded rod galvanised#m20 galvanised threaded bar#Threaded Rod Galvanized#A193 B7#b7 threaded rod#astm a193#b7 bolts#b7 studs#a193 b7 bolts#b7 stud bolts#stud bolt a193 b7#astm a 193 gr b7#b7 bolt material#a193 b7 threaded rod#a193 b7 round bar#A193 Grade B7 Bolts#Grade B7 Bolts#Stainless Steel ASTM A193 B7 Bolts Manufacturer

0 notes

Text

Leading Stud Bolt Manufacturers in India | Delta Fitt Inc

Delta Fitt Inc. is the leading Stud Bolt Manufacturers in India and B7 Stud Bolts Manufacturers in India. Understand their competitive advantages, manufacturing strategies, and market position.

Delta fitt, obtained the best stud bolts by top Stud Bolt Manufacturer in India, takes centre stage.Stud bolts are used to secure commercial buildings in a wide range of industries, including industry and construction. Examine the advantages, highlight important features, and learn about industry issues. Examine the future risk of stud bolt growth. Choose best quality stud bolts like B7 & B8 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these stud bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.

In search of top Stud Bolt Suppliers in India? Delta Fitt Inc. has you covered with top-quality stud bolts solutions.

For more details,

Also Visit: B7 Stud Bolts Manufacturer in India, B8 Stud Bolts Manufacturers in India

#stud bolt manufacturers in india#B7 Stud Bolts Manufacturer in India#B8 Stud Bolts Manufacturers in India#stud bolt manufacturers

0 notes

Text

http://www.jfeindia.com/heavy-hex-bolts.html

#SS ASTM 182 317 Heavy Hex Bolt fastener#ASTM 182 SS 317L Heavy Hex Bolt fastener#SS ASTM 182 321H Heavy Hex Bolt Fastener#Carbon Steel ASTM 193 B6 Heavy Hex bolt fastener#Carbon Steel ASTM 193 B7 Heavy Hex bolt fastener#Alloy Steel ASTM 320 L7A Heavy Hex Bolt Fastener#Brass C270000 heavy Hex Bolt Fastener#Naval Brass C46200 Heavy Hex Bolt#Hastelloy B2 heavy Hex bolt#Monel 400 Heavy Hex Bolt Fastener

0 notes

Text

Arber Xhekaj's favourite things

23.01.31 | by Montreal Canadiens @CanadiensMTL / canadiens.com

ONE RESTAURANT PEOPLE MUST TRY

Chef's in Buffalo. My junior coach Jay McKee played in Buffalo, so that was his favourite spot. They're famous for their meat sauce, and their chicken parm is my favourite thing on the menu. They give you really good portions. He took our junior team there one time, and I stop by every time I'm in Buffalo ever since. I took the boys there too, and they seemed to really like it. It's a good spot.

ONE ACCOUNT PEOPLE MUST FOLLOW

This guy on TikTok, Bayashi. He has videos of him cooking and putting together food, and it's probably the most satisfying thing. He's good. I get hungry when I watch him.

ONE MOVIE PEOPLE MUST WATCH

Avatar. I like everything about it. It's just cool. I've only watched it, like, three times -- I don't like to watch my top movies a lot because I like them so much. I don't want to ruin them for myself. I haven't seen the second one, but I want to. No one wants to see it with me just because it's so long.

ONE FUN FACT PEOPLE MUST KNOW ABOUT YOU

I like cars. I like working on cars and trying to do things like build them myself. I can do suspensions, spark plugs, intakes, wheels, tires, brakes. I can do most of that stuff. I can't really take engines and all, but...

[What is the most satisfying project you've worked on?] Honestly, none of it is satisfying because you think it's only going to take 30 minutes and then one bolt is rusted in, or something doesn't go right, and you break something. Then you're there for four to five hours and you're wondering why you like cars or why you're working on them.

[Do you work on cars in a shop?] Yeah. I'll go out, work out, skate, and then go to my shop and just mess around in there. My four buddies and I share a rented-out shop in Hamilton. We've got our cars in there and chill, hang out and mess around.

[Has anyone hired you to work on their car?] I practice on my own cars, but I've done some stuff on my siblings' cars. I've done a lot of stuff for my brother's car, whenever he needs me to, and my sister's car too. I'll change their tires if they need it.

ONE CAR PEOPLE SHOULD DRIVE

An Audi RS4 (B7). I'm looking to buy one. I went to go see one, but they're kind of expensive, and I've never spent a lot of money on cars. I looked at one and test drove it. Maybe I'll buy it soon.

ONE MUSIC ALBUM PEOPLE SHOULD ADD TO THEIR COLLECTION

Dangerous by Morgan Wallen. I like all the songs. I know every word to all of them. They're all so good. I like Quittin' Time and Wasted On You. I had tickets to his show once, but I was playing in the Memorial Cup. I have some buddies coming to Montreal, and I'm going to see him here, or I might just buy some tickets in London.

There's also Beerbongs & Bentleys by Post Malone. My favourite song would probably be Better Now.

ONE BRAND/TYPE OF CLOTHING PEOPLE MUST TRY

I have a lot of lululemon, their stuff is really good. It's comfy, and it never shrinks in the dryer or anything. It lasts forever if you take good care of it.

#such 22 year old vibes this guy#i'm so sorry abt the m*rgan w*llen mention#hockey players all love him fr#trash person but like.. i enjoy that album too...... unfortunately#i'll have the songs play in my head so i can listen to them without supporting him 🤣#anyway um#hey arber can i hire you to fix my car and change my tires#i'll pay you in uhh.. compliments#why did they have kaiden drive in the timmies video if arber loves cars so much#the whole thing is a copy pasta except for the 'favorite's 🙄🙄🙄#could we honour our team name and actually be canadian ffs#ok i'm done yapping now#WAIT NO IM NOT#WE LITERALLY JUST TALKED ABT AVATAR WITH MY FRIENDS#AND HOW NONE OF US WANTED TO GO CAUSE IT WAS SO LONG#HAHAHAHAHA ok that was only funny to me anyway#arber xhekaj#montreal canadiens#*a

103 notes

·

View notes

Text

ORIGINAL CHARACTERS

Self-inserts and 'sonas are written in ORANGE

Name (Fandom/Species/Etc.)

Furry

Shadow Grey (he/him, anthro raccoon)

Rocket Rider (he/him, anthro Boston terrier)

Rose (it/its, feral calico cat)

Honeybee (it/its, feral cream-and-white cat)

Ruby Velvet (she/her, lop-eared rabbit)

Tyler Fraser (he/him, cereal puppy)

Snowy Winters (he/him, Oriental longhair)

Val (he/him, wolf)

Tabby (she/her, gray tabby cat)

Micah (he/him, raccoon)

Pikapup (it/he, Pikachu puppy, fursuit)

Fallout

Thomas Ray (T.R.) Bancroft (he/him, good, wildcard/legion, F:NV)

A5-50 (it/its, Fallout 4)

Dan Redd (he/him, NCR, NV)

Max Caldwell (he/him, institute, 4)

Jonas Stone (he/him, neutral, BOS, 3/4)

Josh Ward (he/him, evil, 1/2/NV)

Brandon Ward (he/him, good, 2)

B7-67 (he/they, minutemen, 4)

G4-18 (it/its, 4)

Jamie Rowe (he/they, 76!AU)

Chadwick Moore (he/him, good, wildcard, NV)

Salvius (he/him, evil, legion, NV)

Blair Morgan-Blaze (he/him, 4)

The Elder Scrolls

Voka Oakenthorn (he/him, bosmer, destruction mage, HOK, Oblivion/Skyrim)

Suuriil Loraethan (he/him, altmer, destruction mage, agent, Daggerfall/Oblivion)

Dandril (it/they/none, dunmer, staves, nerevarine, Morrowind)

J'idzo (he/him, khajit, archer, dragonborn Skyrim)

Minecraft / Minecraft: Story Mode

Wulfric Grant (he/him, MCSM)

Randolf Wolfe (he/him)

RAZE (it/its)

Saints Row

Kyle Taylor (he/him, ex-saint, STAG, SR2/SRTT)

Wylliam Fuchs (he/him, saint, 3/4)

Neil Adori (he/him, ex-roller, saint, 1/2/3/4)

Tiger (he/him, saints, Reboot)

Pokemon

Archie Caldewell (he/him, Human, Trainer/Champion)

Spark (it/baby, Pichu)

Palmer (he/him, Human, Summerland, Pokemon Ranger)

Passion (she/her, Mew)

Tanachu (she/her, Pikachu)

Savannah (she/her, Skitty, PMD)

Bubbles (she/her, Wartortle, PMD)

Bolt (he/him, Pikachu, PMD)

Momoka (she/her, Skitty)

Stardew Valley

Carson (he/him)

My Little Pony

Lovebird (it/he, MLP G4)

Sew Pink (she/her, MLP G3)

Sunsong (he/him, MLP G1)

Paint Splatter (they/them, G4)

Harvest Moon

Lajos Ezstergalyos (he/him, HM: DS Cute)

Dungeons and Dragons

Aeryn Amanodel (it/he, chaotic neutral, wood elf, sorcerer)

Other

Walker (he/him, original, based on Whitney from Degrees of Lewdity)

Last updated 02/22/24

3 notes

·

View notes

Text

S Chrome Interlude: Chess Player Ch 3

Chapter 3: Martyr

Well… Even if we do win this war, there’s no “future” for us.

The match atop the chess board continued.

White’s knight continued to attack and Black presumed defense in response.

John: c4 to f7.

Chrome: h6 to f7.

John: …Queen, move from b3 to b7.

Black’s knight on c6 and rook on a8 were threatened by White’s queen. Either one of them could be taken by the opposing player.

Two of Black’s pawns and one knight were already captured.

—”Well then, what kind of decision will you make?”—

Chrome had his entire focus on the chess board, precisely because this was a trial his father was giving him.

Chrome: (If I don’t find the most optimal move… I won’t be able to persuade Father.

And above all, I won’t be able to convince myself.)

Chrome reached his hand out as he was thinking.

The hologram projections of the chess pieces primarily moved using voice command alone, but Chrome grasped the piece with his hand.

His next move put the rook on the right side of his board in jeopardy.

The pale blue light of the holographic chess piece shined through the gaps of his fingers and was left on top of the board.

(......)

(—Kabooom!

The grenade the Infected threw exploded 50m just before the base. The shattered rubble flew all over the place, even reaching inside the Structures’ line of defense.

Structure Captain: Guard our flank! They might be hiding somewhere! First Division, mark the Infected’s location. Don’t let them break through our line of defense!

This is the last fort where we can stop these monsters!

A handful of Structures rushed forward following the command of their captain and suppressed the advancing Infected through offensive firepower.

Then, a lone white silhouette appeared, and as quick as a bolt of lightning, he swung his scythe down and instantly dispatched the Infected.

Chrome: My apologies for being late! Captain of the Second Division, please mobilize everyone in your unit and head to the area near the Purification Tower!

Structure Captain: You’re…

Chrome: Chrome from Strike Hawk. The Infected in areas C2 to C4 have already been exterminated. We’re here to provide support.

Structure Captain: But if we were to retreat now, the Infected will breach through our line of defense.

Chrome: It’ll be alright.

There’s a facility used during the Immunization Period in the area. If we lure the Infected there, we can use an EMP attack against them.

The Structure troops will also be affected by that attack if they don’t withdraw from this area ASAP.

Structure Captain: H-how did you—

Chrome: Evacuation comes first. I’ll provide support for them!

(——)

Chrome: The Second Division is incredibly exhausted… They need to retreat without encountering any fighting.

The remaining Infected in this area need to be eliminated until reinforcements arrive!

Chrome: Threats in the main area have been cleared! Second Division, please report your platoon’s coordinates and give me the status of your evacuation!

Structure A: …We…retreat…get in the way…carrying out…

…mission…

System Voice: Transmission has been disconnected.

Chrome: The only way I can determine a minimum coordinate range is to simulate their mobilization route according to the Infected’s distribution in the area.

That way!

(——)

Kamui: Captain! We got a transmission from the division near the Catastrophe Zone! They’re gathering at Area C right now!

Wanshi: The evacuation route has been secured. Commencing rendezvous with the other units.

Chrome: Good work.

Next, if we manage to succeed in letting the Second Division rendezvous with the other divisions that evacuated…

According to their previous plan, however, they were supposed to have retreated from the area already…

This is Chrome from Strike Hawk. Second Division, please respond.

We’ve already arrived at the planned rendezvous point. Please promptly head to the destination area.

???: That won’t be necessary, I’m the only one left.

Chrome: ?!

???: The entire Second Division was completely annihilated… (Cough) I’m currently executing our commander’s final order.

Chrome: What kind of order was given…? That information wasn’t provided—

Structure: The order was to blow up the factory.

That’s why… I have to lure in as many nearby Infected as I can…

Chrome: Understood. There’s enough time for you to retreat from the factory before you detonate the bombs. I’ll meet you there as planned.

Structure: No need to go out of your way for that.

This will be my final destination.

Chrome: What are you saying, there’s still time for you to—

Structure: I was only able to survive this far by pure luck this time around.

But what about next time?

Will I also be this lucky and survive then?

Chrome: If you’re unable to move due to grave injuries, stay where you are right now! I’ll go search for you!

Structure: Chrome, sir… please take a good look around you.

No matter where you look, it’s all rubble blown to pieces. The living would only struggle to survive in sewage and rusted tin cans.

The Punishing is always one move ahead of us, no matter how fervently we fight against it. I think… they’re… evolving.

The teammates from my previous platoon are still recovering in the Structure maintenance room in the Star of Life. They were inflicted with heavy injuries during our last mission together and they’ve never come out from that hospital ward.

I’m sure… we’ll never meet again.

We’ll only keep fighting for the rest of eternity and the day we’d triumph will never come.

Chrome: We will prevail.

A dry, bitter laugh was heard along with the noise of static coming from the communication’s jamming.

Structure: Well… Even if we do win this war, there’s no “future” for us.

Do those people living peacefully on Eden even know how we’re risking our lives here on Earth, fighting against the Infected? Doesn’t that bother you?

(......)

Person from the Top Management: “We expect great things from you. The future of Earth is in the hands of you and your team.”

“Earn more war accolades. I’m sure your father will also be proud.”

(......)

Chrome: You…

Structure: We are nothing more than tools used to achieve the goals of those people in the clouds.

Even if our human form were to be destroyed by the grenades of the Infected, we can still fight so long as it doesn’t have an adverse impact on our Sea of Consciousness.

We carry the risk of losing our memories, failing to remember the reason why we fight, and having our loved ones slip by our memories.

The reason I became a Structure… was because someone wished for me to become one. But… I haven’t met that person for a long time already.

Have you ever lost a friend or comrade in this war? Aren’t you quite familiar with the attitude of those people in the clouds have towards Structures who were heavily injured, and those who sacrificed their lives fighting in peril?

(......)

Chrome: What happened to the unit I was assigned to before, Mr. Smith?

John: They already have served their purpose, it’s something you shouldn’t be mindful of. The Science Council has taken the best course of action in response to the situation.

Chrome: ...Then does that mean they have been discharged?

John: Those men have their place that they must return to. That is the nature of war.

(......)

Chrome: ……

Structure: Even the end of this war is a pipe dream; is there any point in thinking about what comes after for us once the war ends?

Chrome heard the Structure from the other side of the transmission murmuring softly, bearing a heavy burden both mentally and emotionally, reminiscent of someone who can no longer take another step forward.

Structure: I’m… already tired of everything, really…

This kind of ending isn’t bad…

Chrome: …I better hurry…!

No matter how many comforting words he told him, all of it was ineffective. Chrome dashed toward that Structure’s direction as fast as he could.

Sparks flew from his model running at full velocity and his model’s cooling system barely kept up as Chrome ran at the highest speed he could achieve. Even the slightest change in his center of gravity could cause him to tumble.

(......)

Chrome: The cooling system… still isn’t fully functional… along with the mobility…

"Faster…!"

Structure: It was an honor to be able to talk with you until the end.

You are a person worthy of respect. There’s… something I’ve wanted to ask you… I heard… you voluntarily became a Structure.

I thought you were someone who was nothing more than a fancy palanquin put up by those people in power to mitigate our suffering.

But now, seeing your every move… My thoughts have changed.

I deeply respect you. Maybe… you could truly live in safety on Eden one day.

If it’s you, then perhaps……

The Structure’s voice slowly became faint. It had already weakened enough that it was hard to catch what was previously said.

(......)

Chrome: I think I can arrive at the target area right away from here.

"...This isn’t a good time to be emotional.

I have to act now, so this won’t ever happen again in the future."

(......)

Chrome stormed into the factory and began searching for signals of allied troops.

He then finally tracked down the Structure from the Second Division lying down on the ground in a corner of the assembly factory.

His eyes were closed, and he had finally lost consciousness.

Chrome: …His model still has the bare minimum life support running. I made it in time!

This is Chrome from Strike Hawk, I successfully located the target. I’ll be escorting him back.

5 notes

·

View notes

Text

The Strength of Threads: A Guide to ASTM Stud Bolts and Nuts - Bigboltnut

ASTM stud bolts and nuts are essential components in various industrial applications, known for their reliability and compliance with stringent standards. ASTM, or the American Society for Testing and Materials, provides specifications that ensure these fasteners meet rigorous quality and performance criteria. Stud bolts, which are fully threaded rods with no head, are commonly used in flange connections and high-pressure environments. They are designed to withstand significant mechanical stress and are often paired with heavy hex nuts to secure components in place.

The materials used for ASTM stud bolts and nuts are carefully selected to meet specific mechanical properties, including tensile strength, hardness, and resistance to environmental factors like corrosion. Common materials include carbon steel, alloy steel, and stainless steel, each chosen based on the application requirements. For instance, ASTM A193 specifies alloy and stainless steel for high-temperature or high-pressure service, while ASTM A194 covers nuts that pair with these bolts.

These components are critical in sectors such as petrochemical, oil and gas, power generation, and construction. Their adherence to ASTM standards ensures compatibility, durability, and safety in demanding environments. Proper selection and use of ASTM stud bolts and nuts are crucial for maintaining the integrity and performance of industrial installations.

Source Url: https://www.bigboltnut.com/product/astm-a193-gr-b7.html

0 notes

Text

Importance of Material Grade in Heavy Hex Bolts | Roll Fast

Roll Fast is a renowned manufacturer and exporter of heavy hex bolts for the construction of petrochemical industries. Heavy Hex Bolts are designed for use in a variety of high-temperature, high-strength industrial applications, such as steel fabrication and general construction. We also offer heavy hex bolts to structural grade ASTM a307, a325, and a490 specifications. They feature a thicker head than standard or regular hex bolts and offer a greater bearing surface that distributes the clamping load over a wider area. Heavy hex bolts are heavy profile hexagon bolts with large widths across flats and high head height. Also known as heavy hex head bolts or heavy hex structural bolts, these heavy hex bolts are commonly manufactured in high tensile grade 5, 8, 8.8, 10.9, 12.9, a193 grade b7, b7m, b8, b8m, b16, a320 grade l7, l7m, stainless steel, and other material.

visit source url : https://www.roll-fast.com/industries-served/petrochemical-industries/heavy-hex-bolts.html

0 notes

Video

youtube

Double End Studs Threaded Rod Stud Bolt High Strength 8 8 ASTM A193 B7 C...

0 notes

Text

Purpose of choosing ASTM A193 grade strength

Alloy steel bolting materials meeting ASTM A193 Grade B16 criteria are the norm for strain vessels, valves, flanges, and fittings meant to face up to excessive temperatures and pressures. The maximum frequent users of these applications are the petrochemical, oil & gas, and power generation fields.

The chemical make-up of grade B16 bolts is as follows: silicon (0.15-zero.35%), chromium, manganese, phosphorus, sulfur, vanadium, and carbon. Grade B16 bolts are the maximum broadly used sort of alloy metal amongst numerous versions. These bolts' precise composition offers them with exquisite resistance to oxidation and sulfidation in addition to excessive temperature power.

To make certain that Grade B16 bolts are suitable and reliable for use in excessive-temperature and high-strain settings, the ASTM A193 widespread specifies necessities for his or her manufacturing, warmth treatment, and testing.

Could you explain the differences between B16 and B7 bolts?

While B7 and B16 bolts have similar features, what sincerely distinguishes them are their mechanical houses and material composition.

Enterprises coping with accelerated temperatures and pressures regularly make use of bolts with the B7 and B16 classifications. This is specially actual for the petrochemical, power era, and oil and gasoline sectors.

In order to achieve the required hardness and electricity, the medium carbon alloy metallic (4140) used to create B7 bolts and ASTM A193 B8 Bolts is often heated to the best temperature and then tempered. They have minimal yield and tensile strengths of 105 ksi and 125 ksi, respectively.

But the metal used to make B16 bolts is a higher alloy metal with molybdenum, chromium, and vanadium combined collectively. B16 bolts are stronger and extra proof against oxidation and sulfidation in warm conditions way to those additives. Moreover, B16 bolts have minimal yield and tensile strengths which can be corresponding to B7 bolts.

Use B7 bolts for packages desiring high energy and mild temperature resistance; use B16 bolts for packages requiring better energy and stronger resistance to oxidation and sulfidation at immoderate temperatures. B7 bolts are the endorsed desire while some diploma of heat resistance is vital.

Materials that are comparable to ASTM A193 Grade B16 consist of:

DIN EN 10269 1.4980:

European standard addresses bolts composed of a robust and heat-resistant chromium-molybdenum alloy steel.

ISO 898-1 class 10.9:

For bolts composed of alloy steels comparable to ASTM A193 Grade B16, International Standard ISO 898-1 class 10.9 provides mechanical criteria.

BS 1501-640B:

One can use British standard BS 1501-640B to fabricate fastening materials with characteristics comparable to ASTM A193 B8C bolts and ASTM A193 Grade B16. This general applies to high-power steel plates which have gone through heat remedy.

JIS SCM 4:

This Japanese business well-known specifies what to do with low-alloyed steels which have mechanical characteristics and chemical compositions equivalent to ASTM A193 Grade B16 and ASTM A193 B8M Stud Bolt.

It's vital to hold in mind that at the same time as the chemical composition and mechanical traits of numerous materials may be equal, their manufacturing methods, warmth remedy methods, and trying out requirements may additionally range. These variations may have an impact on the materials' performance for particular applications. It is advisable to study the pertinent material requirements and get advice from an experienced engineer or metallurgist when selecting bolting materials for applications involving high temperatures and pressures.

0 notes

Text

Van cầu Bellows seal là gì?

Van cầu bellows seal (Bellow seal globe valve) cũng là dòng van cầu chuyên sử dụng để đóng mở và điều tiết lưu lượng trên đường ống. Tên gọi của dòng van này xuất phát từ cấu tạo bên trong của nó có thêm một lớp bellow seal có chức năng là lớp đệm thứ hai của van giúp tăng khả năng làm kín, đảm bảo chống rò rỉ tốt hơn các dòng van cầu thông thường.

Đặc điểm của van cầu Bellows seal

Van cầu dạng bellows seal- bellow seal globe valve là dòng van mang đầy đủ các điểm về cấu tạo cũng như các điểm ưu việt của dòng van cầu bình thường trên thị trường hiện nay. Nhưng nó có thêm lớp đệm bellow để tăng độ kín nên nó sẽ kín và chống rò rỉ tốt hơn rất nhiều so với các dòng van cầu hiện nay

Rất khó để nhận biết được nó là van cầu lớp grand Parking(gland seal) hay lớp Bellow seal nếu chúng ta chỉ nhìn bên ngoài thực tế. Đặt cạnh 2 dòng van này với nhau không thể nhận biết nếu không có kinh nghiệm thực tế. Nó khác với van cầu thường ở phần trục van kết nối với cổ van và quan trọng nhất là phần bên trong của trục van có thêm lớp đệm seal dạng ống lồng vào trục van.

Van cầu bellow seal thực tế có giá thành cao hơn so với các dòng van cầu hơi nóng thông thường. Chính vì vậy khi thực sự cần thiết và các ứng dụng quan trọng người ta mới sử dụng dòng van cầu này với mục đích chính là chống rò rỉ gây ảnh hưởng tới hệ thống và nhất là các hệ thống sử dụng năng lượng như dầu nóng, khí gas, hơi nóng, tuabin cần độ chính xác và chống rò rỉ

Ngoài ra với kiểu thiết kế ty van có thêm lớp Bellow seal thì khả năng lưu chất ảnh hưởng tới các bộ phận khác trên thân van cũng giảm thiểu hoàn toàn nhờ đó tăng độ bền và tuổi thọ sử dụng van

Thông số kỹ thuật chi tiết

MODEL: NST-41H

Thương hiệu: Nordsteam

Xuất xứ: Thổ Nhĩ Kỳ

SPARE PARTS

No

Description

Material

1

BODY

GS-C25+13Cr

2

DISC

STAINLESS STEEL 304

3

PIN

STAINLESS STEEL 304

4

BELLOWS

STAINLESS STEEL 304

5

GASKET

GRAPHITE+SS304

6

BOLT

B7

7

NUT

2H

8

COVER

GS-C25

9

PACKING

GRAPHITE

10

GLAND

13Cr

11

PIN

25

12

BEARING

CARBON STEEL

13

SHAFT

STAINLESS STEEL 304

14

SHAFT NUT

CU ALLOY

15

FLY WHEEL

CARBON STEEL

16

LOCK NUT

ALIMINIUM ALLOY

SIZE

PN 16

L

d

d1

N-Ø

H

DN15

130

95

65

4*14

174

DN20

150

105

75

4*14

176

DN25

160

115

85

4*14

207

DN32

180

140

100

4*18

207

DN40

200

150

110

4*18

210

DN50

230

165

125

4*18

225

DN65

290

185

145

4*18

250

DN80

310

200

160

8*18

260

DN100

350

220

180

8*18

345

DN125

400

250

210

8*18

370

DN150

480

285

240

8*22

430

DN200

600

340

295

12*22

488

DN250

730

405

355

12*26

530

DN300

850

460

410

12*26

600

CONNECTION

FLANGED

SIZES

DN15

DN20

DN25

DN32

DN40

DN50

DN65

DN80

DN100

DN125

DN150

DN200

DN250

DN300

WEIGHTS (KGS)

4,5

5

5,8

7,5

10

12,5

18,5

23

38,5

53

81

144

230

450

OPERATING CONDITIONS

MAX. ALLOWABLE PRESSURE PMA (BAR)

24

MAX. ALLOWABLE TEMPERATURE TMA (ºC)

350

MAX. OPERATING PRESSURE PMO BAR)

16

Liên hệ tư vấn báo giá van cầu

Công Ty TNHH Thương Mại Thiết Bị Công Nghiệp Tân Thành

Địa chỉ: Số 1 Đông Hồ, phường 8, Quận Tân Bình, TP.HCM, Việt Nam

Số điện thoại: 028 3971 7214 | 0904 635 106

Email: [email protected]

Website: https://valvecongnghiep.com/

0 notes

Video

youtube

The Korea Metal Week 2023 that FIXDEX & GOODFIX participated in came to ...

#youtube#korea metal week 2023#Korea Metal Week#대한민국 금속주간#Wedge Anchor#Wedge Anchor Bolts#Wedge Bolt#Stainless Steel Wedge Anchors#Trubolt#Through Bolt#Threaded Rods#Threaded Bar#Stainless Steel Threaded Rod#Galvanized Threaded Rod#Din975#Galvanized Threaded Bar#B7 Galvanized Threaded Rod#Chemical Anchors#Wood Screw#Self Drilling Screws#Self Tapping Screw#Drop In Anchor#Stainless Steel Drop In Anchors#Knurled Drop In Anchors#Hex Bolt#Hex Head Bolt#Galvanized Hex Bolts#Ss Hex Bolt#Din933#Din934

0 notes

Text

Leading Stud Bolt Manufacturers in India | Delta Fitt Inc

Delta Fitt Inc. is the leading Stud Bolt Manufacturers in India and B7 Stud Bolts Manufacturers in India. Understand their competitive advantages, manufacturing strategies, and market position.

Delta fitt, obtained the best stud bolts by top Stud Bolt Manufacturer in India, takes centre stage.Stud bolts are used to secure commercial buildings in a wide range of industries, including industry and construction. Examine the advantages, highlight important features, and learn about industry issues. Examine the future risk of stud bolt growth. Choose best quality stud bolts like B7 & B8 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these stud bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.

In search of top Stud Bolt Suppliers in India? Delta Fitt Inc. has you covered with top-quality stud bolts solutions.

For more details,

Also Visit: B7 Stud Bolts Manufacturer in India, B8 Stud Bolts Manufacturers in India

#stud bolt manufacturers in india#B7 Stud Bolts Manufacturer in India#B8 Stud Bolts Manufacturers in India#stud bolt manufacturers

0 notes

Text

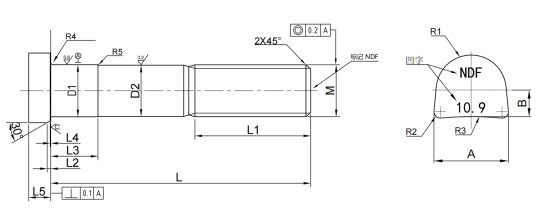

Horseshoe head hub bolts

Horseshoe head hub bolts are fasteners used to secure wheels to the hub of a vehicle. They are typically made of steel and have a horseshoe-shaped head that allows them to be tightened using a wrench or socket. The horseshoe shape of the head provides a larger surface area for the wrench or socket to grip, which helps to distribute the force of the tightening more evenly and prevent the head from rounding out.

Horseshoe head hub bolts are commonly used in applications where the bolt needs to be tightened securely and may be subject to frequent adjustments, such as in machinery or equipment. The flat surface of the horseshoe head provides a large area for tightening, which can help distribute the clamping force evenly and prevent damage to the hub or shaft.

Outer diamater of thread: M14-M24

Heat treatment grade: 10.9/12.9

Surface treatment:

Phosphating/ Galvanizing/ Zinc-nickel alloy/ Zinc-aluminium coated

Material: 40Cr/35CrMo/SCM435/42CrMo/B7

Performance and application scenarios:

Suitable for drive axles for commercial buses, coaches, mining, engineering, light trucks, medium trucks, heavy trucks, trailers, etc.

Yield greater than or equal to 940MPa, tensile strength greater than or equal to 1040MPa, absorption energy -20°CKV/J greater than or equal to 27.

Fatigue resistance, safe and reliable during service, suitable for extremely cold and hot environment.

0 notes

Text

Ananka

Q1) Are there specific hex bolts designed for high-temperature environments?

Ans) Certainly, there are specific categories of hex bolts meticulously designed to excel in high-temperature settings. These specialized hex bolts are meticulously crafted from materials capable of enduring elevated temperatures without compromising their mechanical attributes or structural integrity. Here are several instances of hex bolts tailored for high-temperature applications:

1. Heat-Resistant Stainless Steel Hex Bolts: Hex bolts constructed from stainless steel alloys such as 310, 316, and 321 are frequently chosen for high-temperature environments. These alloys incorporate elements like chromium, nickel, and molybdenum, enhancing their resilience against oxidation and corrosion at elevated temperatures.

2. Inconel Hex Bolts: Inconel, a group of nickel-chromium-based superalloys, possesses remarkable resistance to high temperatures, oxidation, and corrosion. Inconel hex bolts find prominent usage in sectors like aerospace, petrochemicals, and industries confronting extreme heat.

3. Hastelloy Hex Bolts: Hastelloy, another lineage of nickel-based alloys, is renowned for its exceptional corrosion resistance and performance under high-temperature conditions. Hastelloy hex bolts often feature in applications exposed to harsh chemical environments and elevated temperatures.

4. Titanium Hex Bolts: Titanium hex bolts, noted for their lightweight nature and commendable strength at high temperatures, are favored in industries such as aerospace and chemical processing. These hex bolts effectively balance heat resistance and corrosion resistance.

5. Alloy Steel Hex Bolts: Certain alloy steels, including ASTM A193 Grade B7, undergo heat treatment to cater to high-temperature requirements. These hex bolts find common application in pressure vessels, boilers, and piping systems that operate at elevated temperatures.

6. Ceramic-Coated Hex Bolts: In specific scenarios, hex bolts can be coated with ceramic materials, furnishing them with a thermal barrier. This coating empowers the hex bolts to endure elevated temperatures while retaining their mechanical properties.

When selecting hex bolts for high-temperature environments, meticulous consideration should be given to factors such as the specific temperature range, the presence of corrosive elements, and the mechanical prerequisites of the application. Consulting experts or referring to industry standards is advised to make an informed choice regarding the most suitable type of hex bolts that can offer reliable performance under the desired high-temperature conditions.

Hastelloy Fasteners

Q2) Are there hex nuts specifically designed for high-temperature applications?

Ans) Yes, indeed, hex nuts tailored for high-temperature applications are available. These specialized hex nuts are meticulously fashioned from materials capable of enduring elevated temperatures without compromising their structural soundness. Here are several instances of hex nuts designed specifically for high-temperature environments:

1. Heat-Resistant Stainless Steel Hex Nuts: Hex nuts crafted from stainless steel alloys such as 310, 316, and 321 are commonly employed for high-temperature scenarios. These alloys incorporate elements like chromium, nickel, and molybdenum, bolstering their capacity to withstand oxidation and corrosion in elevated temperature settings.

2. Inconel Hex Nuts: Inconel, a lineage of nickel-chromium-based superalloys, enjoys renown for its exceptional resistance to high temperatures, oxidation, and corrosion. Inconel hex nuts are frequently harnessed in aerospace, petrochemical, and similar industries where extreme heat prevails.

3. Hastelloy Hex Nuts: Hastelloy, another category of nickel-based alloys, is esteemed for its remarkable corrosion resistance and performance in high-temperature environments. These hex nuts find favor in scenarios involving harsh chemicals and elevated temperatures.

4. Titanium Hex Nuts: Boasting lightweight attributes and commendable strength at high temperatures, titanium hex nuts find their niche in sectors like aerospace and chemical processing, where both heat resistance and corrosion resistance are paramount.

5. Alloy Steel Hex Nuts: Certain alloy steels, such as ASTM A194 Grade 7, are subject to heat treatment to suit high-temperature requisites. These hex nuts commonly find purpose in pressure vessels, boilers, and piping systems functioning at elevated temperatures.

6. Ceramic-Coated Hex Nuts: In certain instances, hex nuts can be treated with ceramic coatings that confer thermal insulation, enabling them to withstand elevated temperatures while preserving their structural integrity.

When opting for hex nuts tailored for high-temperature environments, meticulous contemplation of factors such as the specific temperature range, the presence of corrosive agents, and the mechanical prerequisites of the application is indispensable. Seeking counsel from experts or referring to industry standards is a prudent step in ascertaining the most fitting type of hex nuts capable of delivering reliable performance under the desired high-temperature conditions.

Carbon Steel Fasteners

Q3) What are the implications of using the wrong size or type of plain washer?

Ans) Using the wrong size or type of plain washer in a fastened assembly can have several significant implications, potentially leading to compromised joint integrity, safety hazards, and functional issues. Here are some of the implications:

1. Reduced Clamping Force: The primary function of a plain washer is to distribute the load and provide a larger surface area for even pressure distribution. Using a washer that is too small or not suitable for the application can lead to uneven clamping force, resulting in insufficient joint compression. This can cause components to come loose over time and reduce the overall stability of the assembly.

2. Increased Stress Concentrations: Choosing a washer with inadequate dimensions or material properties can lead to localized stress concentrations. These concentrated stress points can weaken the fastened components, making them more prone to deformation, cracking, or failure under load.

3. Loss of Friction Control: Plain washers can help control friction between the fastener and the material being fastened. Incorrectly sized or inappropriate washers may not provide the necessary friction management, potentially leading to loosening of the joint due to vibration or other external forces.

4. Potential for Galling or Seizing: If the wrong type of washer material is used, such as a washer with a rough surface, there's a risk of galling (metal-to-metal adhesion) or seizing between the washer and the fastener head or nut. This can make future disassembly difficult or even cause damage to the fastener and washer.

5. Inadequate Load Distribution: Using a washer that doesn't match the shape or size of the fastener head or nut can result in poor load distribution. This may lead to indentations, deformations, or damage to the components being fastened, reducing their overall lifespan.

6. Leakage and Seal Failure: In applications involving gaskets or seals, using the wrong size washer can lead to improper compression of the gasket, resulting in leaks or seal failure. This is particularly critical in environments where sealing integrity is crucial, such as fluid or gas systems.

7. Compromised Aesthetics and Functionality: In certain applications, the aesthetics of the assembly might matter. Using the wrong size or type of washer can lead to misalignment, improper fit, or visible gaps, affecting both the appearance and the functionality of the assembly.

8. Safety Hazards: Depending on the application, using incorrect washers can compromise the safety of the assembly. In critical structures, machinery, or equipment, failure due to incorrect washers can lead to accidents, injuries, or costly downtime.

To avoid these implications, it's crucial to select plain washers that are appropriate for the specific application. This includes considering factors like washer size, material, shape, and load-bearing capacity. It's recommended to follow manufacturer guidelines, industry standards, and engineering best practices to ensure that the chosen plain washers provide effective load distribution, proper clamping force, and overall joint integrity.

Stainless Steel Fasteners Manufacturers in Mumbai

Q4) Are there stud bolts specifically designed for high-temperature applications?

Ans) Yes, there are stud bolts specifically designed to excel in high-temperature applications. These specialized stud bolts are crafted from materials that can withstand elevated temperatures without compromising their mechanical properties or structural integrity. Here are a few examples of stud bolts designed for high-temperature environments:

1. Heat-Resistant Stainless Steel Stud Bolts: Stainless steel alloys like 310, 316, and 321 are commonly chosen for stud bolts in high-temperature applications. These alloys contain elements like chromium, nickel, and molybdenum, which enhance their resistance to oxidation and corrosion at elevated temperatures.

2. Inconel Stud Bolts: Inconel is a family of nickel-chromium-based superalloys renowned for their exceptional resistance to high temperatures, oxidation, and corrosion. Inconel stud bolts are frequently used in industries such as aerospace, petrochemicals, and power generation, where extreme heat is encountered.

3. Hastelloy Stud Bolts: Hastelloy is another family of nickel-based alloys known for their excellent corrosion resistance and high-temperature performance. Hastelloy stud bolts are often used in environments involving harsh chemicals and elevated temperatures.

4. Titanium Stud Bolts: Titanium stud bolts are lightweight and possess good strength at high temperatures. They find application in industries such as aerospace, chemical processing, and marine, where both heat resistance and corrosion resistance are essential.

5. Alloy Steel Stud Bolts: Some alloy steels, such as ASTM A193 Grade B7, are heat-treated and designed for high-temperature applications. These stud bolts are commonly used in pressure vessels, boilers, and piping systems operating at elevated temperatures.

6. Ceramic-Coated Stud Bolts: In certain cases, stud bolts can be coated with ceramic materials that provide a thermal barrier, allowing them to endure higher temperatures while maintaining their mechanical properties.

When selecting stud bolts for high-temperature environments, it's crucial to consider factors such as the specific temperature range, the presence of corrosive elements, and the mechanical requirements of the application. Consulting with experts or referring to industry standards is recommended to choose the appropriate type of stud bolts that can reliably perform under the desired high-temperature conditions.

Phosphor Bronze Bolts

0 notes

Text

Carbon Steel Flanges: Experts’ Top Recommendations for Optimal Performance

Carbon steel flanges are widely used in various industries due to their excellent durability, strength, and cost-effectiveness. However, to ensure optimal performance and longevity, it is crucial to follow experts’ recommendations. In this article, we will discuss the top recommendations from experts for carbon steel flange performance.

Material Selection: Choosing the right carbon steel material is the first step to ensure optimal performance. Experts recommend selecting carbon steel with the appropriate grade and composition for the specific application. Factors like corrosion resistance, temperature stability, and pressure requirements should be considered when choosing the material.

Flange Design: The design of carbon steel flanges should be in accordance with industry standards and specifications, such as ASME B16.5 or API 605. It is essential to ensure proper dimensions, bolt hole sizes, flange face type, and class ratings. Using flanges designed for specific applications helps in preventing leakage and ensures a secure connection.

Flange Surface Finish: Experts emphasize the importance of achieving the correct surface finish for carbon steel flanges. A smooth surface finish reduces the risk of corrosion, enhances sealing performance, and prevents gasket damage. Commonly used surface finishes include an oil-based rust preventive coating or an epoxy-based paint finish.

Gasket Selection: The selection of the appropriate gasket is critical for achieving optimal performance in carbon steel flange joints. Gaskets should be compatible with the operating conditions, such as temperature, pressure, and fluid type. It is recommended to use gaskets made of materials like graphite, PTFE (Polytetrafluoroethylene), or spiral wound gaskets for better sealing capabilities.

Bolt Selection and Torque: Proper bolt selection and tightening torque are crucial for achieving a leak-free connection. Experts advise using bolts made from high-strength carbon steel or alloy steel, such as ASTM A193 Grade B7, and complying with standard specifications, such as ASME B18.2.1. Following the recommended bolt torque values ensures proper tensioning and prevents flange leakage.

Proper Installation: Correct installation practices play a vital role in the performance of carbon steel flanges. Experts suggest cleaning the flange surfaces thoroughly and removing any dirt or debris. It is important to align the flanges properly and apply an even bolt load during the tightening process. Over-tightening or uneven loading can lead to flange distortion or gasket failure.

Regular Inspection and Maintenance: Regular inspection and maintenance are essential for ensuring continued optimal performance of carbon steel flanges. Periodic checks for leaks, corrosion, or damage should be conducted. Any detected issues should be addressed promptly to prevent further deterioration or failure. It is recommended to follow industry guidelines for maintenance activities like bolt retightening or gasket replacement.

Corrosion Prevention: Carbon steel flanges are susceptible to corrosion, especially in harsh environments. Experts recommend applying suitable corrosion protection strategies, such as the use of coatings or cathodic protection techniques. Regular cleaning, painting, or applying anti-corrosion coatings can significantly enhance the longevity and performance of carbon steel flanges.

Training and Expertise: Having trained personnel with expertise in carbon steel flanges and their installation is crucial for optimal performance. Experts suggest providing comprehensive training to technicians and engineers involved in flange installation and maintenance. This ensures that best practices are followed, reducing the risk of errors or improper handling.

0 notes