#A193 Grade B7 Bolts

Video

youtube

🏗🌏Make Fixing Dexterity👉FIXDEX threaded rods & B7 & din975

#youtube#HDG threaded rods#galvanized threaded rod#galvanised rod#galv threaded rod#hot dipped galvanized threaded rod#threaded rod galvanised#m20 galvanised threaded bar#Threaded Rod Galvanized#A193 B7#b7 threaded rod#astm a193#b7 bolts#b7 studs#a193 b7 bolts#b7 stud bolts#stud bolt a193 b7#astm a 193 gr b7#b7 bolt material#a193 b7 threaded rod#a193 b7 round bar#A193 Grade B7 Bolts#Grade B7 Bolts#Stainless Steel ASTM A193 B7 Bolts Manufacturer

0 notes

Text

Your Only Solution to All Stainless Steel Products: Micro Metals

The industries always keep growing. They have played an important role in manufacturing products and providing essential services. The core of all these industries resides in the products used, like Inconel 625 bolts, SS 316 fasteners, round bars, etc. Bars, fasteners, bolts, etc. always played an important role in building any project's basic structure. These products are so important that they are further divided based on grade and material used in manufacturing. That is why each product has its own essential applications in different industrial sectors and projects. So choosing the right material for your project is very important. But, you need not worry about that, as Micro Metals will get you all the products of top quality as they are the best SS fastener manufacturers in India.

Micro Metals

When you need any fattening solution, you should contact Micro Metals, the SS fastener manufacturers in India. They are known for their precision in manufacturing the components. Timely delivery is prioritized and achieved every time because they value their customers the most. They have adopted various innovative approaches to excel in their business and handle partnerships with other companies. This is the reason why they have been able to achieve growth worldwide. There are a huge number of products they manufacture, and all of these products are manufactured with great precision and accuracy. You can find every product you need for your project at micrometals.co.in. Some of these products are

Fasteners

Duplex Fasteners: Micro Metals is a duplex fastener manufacturer in India. Duplex fasteners are cost-effective and are often considered the standard fasteners in many cases.

SS 316 Fasteners: These fasteners are also regularly utilized in many industries. These are used in areas where excellent strength is necessary.

SS 316L Fasteners: These fasteners are good at resisting corrosion. They are known for the low-carbon component in the fastener.

Bolts

SS Hex Bolts: Metals are SS hex bolt manufacturers in India, and these are manufactured with great precision. These bolts are preferred in areas where nuts might not be appropriate for use.

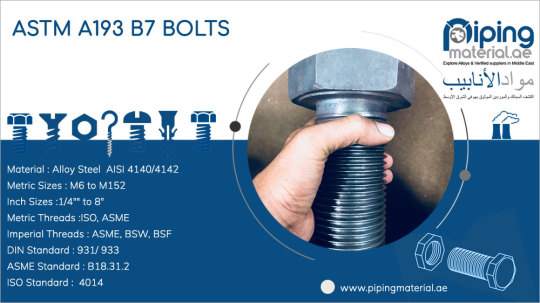

A193 B7 Bolts: These bolts have good mechanical properties. It can handle high pressure.

Hastelloy C276 Bolts: This bolt has heavy applications and is one of the best when it comes to handling corrosion.

Round Bars

Titanium Round Bar: Micro Metals are titanium round bar suppliers. These bars have their use in the aerospace industry, medical industry, chemical industry, etc.

SS Round Bars: These SS round bars can handle extreme weather conditions easily and are good at resisting corrosion.

Hastelloy C276 Bolts: This bar has major applications in the petrochemical and chemical processing industries.

In this article, some of the most sold products of Micro Metals were discussed. But this article does not cover the entire collection of quality products they have. You can visit them at micrometals.co.in to learn more about these stainless steel bright bar manufacturers in India. All the necessary details for contacting them will be available on their website too.

0 notes

Text

The world of high-performance clasp: imperativeness and precision.

High-performance fasteners are extremely vital in production and business programs. These important additives maintain systems together, ensuring their protection, toughness, and dependability. Understanding the diverse grades and sorts of fasteners, together with A193 Grade B7, ASTM A193 B8, and ASTM A193 Grade B16, aids in choosing the precise one for the project. Here, we take a look at the ones fasteners and employ them, similarly to precise critical additives, which includes stainless-steel fasteners, threaded rods, flanges, and bars.

High-tensile fasteners are amazing for their outstanding electricity and potential to live on harsh occasions. A193 Review B7, a prevalent elective, has a tall pliable quality and uncommon flexibility to tall temperatures and stretch. These characteristics make A193 Grade B7 suitable for use within the oil and fuel zone, chemical industries, and power production centres.

ASTM A193 B8 clasp made of chrome steel has fabulous erosion resistance and solid malleable electricity. These fasteners perform well in severe situations, making them ideal for marine applications, food processing, and different sectors that often stumble upon corrosive chemicals.

ASTM A193 Grade B16 fasteners are important in conditions desiring even higher temperature tolerance. Their amazing tensile energy and capability to undergo immoderate temperatures make them ideal for steam generators and different excessive-temperature programs.

Stainless metallic fasteners combine sturdiness and corrosion resistance.

The stainless steel clasp offers a completely one-of-a-kind add-up to control and disintegration resistance. Stainless metal fasteners, which encompass the ones made via SS threaded rod manufacturers in India, are lengthy-lasting and reliable. These threaded rods serve an important characteristic in constructing, supplying strong guides for diverse structures.

SS flange manufacturers in India offer high-quality SS 304 flanges that provide a steady connection among pipes, valves, and specific gadgets. The SS 304 flange, truly noted for its immoderate corrosion resistance and power, is widely utilized in chemical processing, water treatment, and the food and beverage industries.

Duplex ribs and latches give predominant quality and erosion resistance.

Duplex spines give an exceptional level of quality and erosion resistance. These flanges are made of duplex stainless steel, which can handle hostile conditions and tremendous tension. Duplex flanges have better mechanical characteristics, making them perfect to be used in the oil and gasoline area, chemical processing, and maritime settings.

Duplex clasp, which envelops jolts, nuts, and screws, give comparable gifts. Their brilliant energy and resistance to strain corrosion cracking guarantee that constructions remain stable and last even below the maximum excessive situations.

Stainless steel bars are accessible in loads of bureaucracy and sizes, along with round bars and hex bars. Stainless steel round bar is utilized in commercial, construction, and ornamental motives. Its flexibility and resistance to corrosion make it a perfect desire for a huge variety of programs.

A chrome steel hex bar has excessive machinability and power. It is broadly utilized in the fabrication of clasps, gears, and other exactness additives. Stainless metal hex bolts made out of hex bars provide dependable fastening solutions for loads of applications, making certain a stable shape and resistance to environmental variables.

SS 304 circular bar is still a well-known choice because of its tall erosion resistance and straightforward fabrication. It is commonly utilized in nourishment preparation, chemical fabricating, and building ventures.

Specialty fasteners: precision and reliability

SS attachment head cap screws offer a secure and precise securing option. Their design enables simple installation and removal, making them perfect for applications that require regular maintenance. These screws have extremely good tensile strength and corrosion resistance, ensuring long-term performance.

ASTM A453 Review 660 clasp, cited for their over-the-top vitality and magnificent erosion resistance, are used in excessive-temperature conditions. These fasteners are important in sectors like planes, energy technology, and petrochemicals, wherein dependability beneath harsh situations is important.

Flange Weight Calculator Simplifies the Selection Process

A flange weight calculator makes the decision and design process easier for engineers and designers. This tool guarantees that the selected flanges satisfy the application's unique requirements by giving correct weight estimates, lowering the danger of overloading or underperformance.

Understanding each type's qualities and uses is critical in the wide world of fasteners and stainless steel components. From high-tensile clasps like A193 Review B7 and ASTM A193 B16 to stainless steel latches and strength things like duplex ribs and ASTM A453 Review 660 latches, each component is essential to guaranteeing the assistant adroitness and faithfulness of moved applications. Manufacturers and engineers may design stronger, more lasting buildings that survive the test of time and tough environments by selecting the appropriate fasteners and components.

0 notes

Text

Understanding the Different Grades and Materials of Stud Bolts

Delta Fitt Inc., a leading name among stud bolts manufacturers in India, we pride ourselves on offering a wide range of high-quality stud bolts to meet diverse industry needs.Stud bolts are essential components in many industrial applications, particularly in construction, oil & gas, and petrochemicals. Understanding the various grades and materials of stud bolts is critical to guaranteeing the integrity and safety of any structure or apparatus.

What Are Stud Bolts?

Stud bolts are threaded rods with two hefty hexagonal nuts that are used in a number of applications to connect pieces. They are intended to endure high pressures and harsh temperatures, making them excellent for important technical applications.

Grades of Stud Bolts

Stud bolts are categorised into different grades based on their material composition and mechanical properties. Here are some of the most commonly used grades:

B7 Stud Bolts

Material: ASTM A193 B7 stud bolts are made from alloy steel, specifically chromium-molybdenum steel.

Applications: These bolts are widely used in the petrochemical industry, oil refineries, and power plants due to their excellent strength and ability to withstand high temperatures and pressures.

Manufacturers: Delta Fitt Inc. is a renowned name among B7 stud bolts manufacturers in India, providing reliable and durable products.

B8 Stud Bolts

Material: ASTM A193 B8 stud bolts are manufactured from austenitic stainless steel, typically grade 304 or 316.

Applications: These bolts are used in environments where corrosion resistance is crucial, such as in chemical plants and marine applications.

Manufacturers: As one of the leading B8 stud bolts manufacturers in India, Delta Fitt Inc. ensures top-notch quality and performance.

B16 Stud Bolts

Material: These stud bolts are made from chromium-molybdenum-vanadium steel.

Applications: B16 stud bolts are used in high-pressure and high-temperature environments, such as in power generation and turbine manufacturing.

Materials of Stud Bolts

The material composition of stud bolts significantly influences their performance and suitability for different applications. Here are some common materials used in the manufacturing of stud bolts:

Carbon Steel: Carbon steel stud bolts are known for their strength and durability. They are suitable for applications requiring high tensile strength.

Stainless Steel: Stainless steel stud bolts offer excellent corrosion resistance and are ideal for use in harsh environments. Grades such as 304 and 316 are popular choices.

Alloy Steel: Alloy steel stud bolts, such as those made from chromium-molybdenum, provide superior strength and resistance to high temperatures and pressures.

Nickel Alloys: Nickel alloy stud bolts are used in extremely corrosive environments and high-temperature applications. They offer exceptional resistance to oxidation and corrosion.

Why Choose Delta Fitt Inc.?

As one of the leading stud bolts manufacturers in India, Delta Fitt Inc. stands out for its commitment to quality, precision, and customer satisfaction. Our products undergo stringent quality checks to ensure they meet international standards. We offer a comprehensive range of stud bolts, including B7 and B8 grades, to cater to various industrial needs.

Our dedication to innovation and excellence has made us a trusted name among stud bolts suppliers in India. Whether you need high-strength carbon steel stud bolts or corrosion-resistant stainless steel options, Delta Fitt Inc. has the perfect solution for your requirements.

To summarise, understanding the various grades and materials of stud bolts is critical for choosing the best product for your unique application. Delta Fitt Inc. guarantees high-quality stud bolts that operate, reliably, and safely in the most challenging settings. Choose Delta Fitt Inc. for all of your stud bolt requirements and discover the difference that quality makes.

Website: deltafitt.com

0 notes

Text

Fasteners Manufacturer in Azerbaijan - Sachiya Steel International

Fasteners are crucial components in industrial manufacturing, providing the necessary connections and security between parts across various sectors. These mechanical devices, which include bolts, nuts, screws, washers, and rivets, are essential for maintaining the structural integrity and functionality of countless applications. Sachiya Steel International Private Limited of India is renowned for its high-quality fasteners, and its presence in Azerbaijan highlights its commitment to global excellence.

Understanding Fasteners

Fasteners are an extensive array of mechanical components used to join or fasten materials together. Each type of fastener serves a different function depending on factors like material type, load-bearing capacity, and environmental conditions.

Types of Fasteners

Bolts

Nuts

Screws

Washers

Rivets

Fastener Selection

Selecting high-quality fasteners is crucial for maintaining structural integrity, safety, and longevity across various applications. Industries such as construction, automotive, aerospace, and marine manufacturing rely on reliable fastening solutions to meet specific operational challenges.

Sachiya Steel International: Building Excellence

With decades of experience and a cutting-edge manufacturing facility in India, Sachiya Steel International has become an industry leader. Their commitment to precision engineering, superior quality products, and customer satisfaction have earned them global praise.

Product Range and Specializations

Sachiya Steel International offers an extensive portfolio of fasteners to meet the diverse needs of industries worldwide. Their product range includes:

Bolts: High-tensile bolts, hex bolts, socket head bolts, foundation bolts.

Nuts: Hex nuts, lock nuts, wing nuts, square nuts.

Screws: Machine screws, self-tapping screws, wood screws, drywall screws.

Washers: Flat washers, spring washers, toothed lock washers.

Rivets: Blind rivets, solid rivets, pop rivets.

Each product undergoes rigorous quality checks and adheres to international standards such as DIN, ANSI, ASTM, and ISO, ensuring reliability and performance excellence.

Grades of Fasteners Offered

Construction Grade

Specifications: ASTM A307, ASTM F1554 (Grade 36, 55, 105)

Application: Structural applications requiring high strength and durability.

Automotive Grade

Specifications: Grade 8.8, Grade 10.9, Grade 12.9

Application: Automotive assembly, ensuring reliable performance under high stress and vibration conditions.

Aerospace Grade

Specifications: ASTM F568, ASTM F2281

Application: Aerospace and defense applications, meeting stringent safety and reliability standards.

Industrial Grade

Specifications: ASTM A193 (B7, B8, B8M), ASTM A320 (L7, B8, B8M)

Application: General industrial use, offering corrosion resistance and durability in harsh environments.

Global Footprint and Market Reach

Sachiya Steel International has expanded its operations to meet Azerbaijan’s growing demand for premium fasteners. Their distribution network and optimized logistics ensure prompt delivery and excellent customer support.

Customization Capabilities

Sachiya Steel International understands the importance of offering customized solutions. They provide options to customize dimensions, materials (including stainless steel, carbon steel, and alloy steel), finishes (plain, zinc-plated, hot-dip galvanized), and coatings (phosphate, black oxide) to meet specific project needs with flexibility and precision.

Environmental Responsibility and Sustainability

Sachiya Steel International prioritizes sustainability in its manufacturing processes. They invest in eco-friendly technologies, waste reduction initiatives, and energy-saving practices to minimize environmental impact while contributing to global conservation efforts.

Conclusion

Sachiya Steel International Private Limited stands out as the go-to choice for high-quality fasteners in Azerbaijan and beyond. With a legacy built on innovation, reliability, and customer-centricity, Sachiya Steel continues to set standards in the global fastener industry. Whether for large-scale industrial projects or niche applications, Sachiya Steel is ready to offer unparalleled quality and service excellence.

Read More: Fasteners Manufacturer in Azerbaijan

0 notes

Text

Importance of Material Grade in Heavy Hex Bolts | Roll Fast

Roll Fast is a renowned manufacturer and exporter of heavy hex bolts for the construction of petrochemical industries. Heavy Hex Bolts are designed for use in a variety of high-temperature, high-strength industrial applications, such as steel fabrication and general construction. We also offer heavy hex bolts to structural grade ASTM a307, a325, and a490 specifications. They feature a thicker head than standard or regular hex bolts and offer a greater bearing surface that distributes the clamping load over a wider area. Heavy hex bolts are heavy profile hexagon bolts with large widths across flats and high head height. Also known as heavy hex head bolts or heavy hex structural bolts, these heavy hex bolts are commonly manufactured in high tensile grade 5, 8, 8.8, 10.9, 12.9, a193 grade b7, b7m, b8, b8m, b16, a320 grade l7, l7m, stainless steel, and other material.

visit source url : https://www.roll-fast.com/industries-served/petrochemical-industries/heavy-hex-bolts.html

0 notes

Text

Stud | full Threaded | Double Ended Bolts Manufacturer | BigBoltnut

Bigboltnut is a manufacturer and distributor of a variety of products in the form of Studs bolts, full threaded, hub bolts, split shafts, reduction shafts and more. These steels include stainless steel, carbon steel and grade 8.8, 10.9, 12.9, SS304, SS316, SS316L, SS316 S31, B7, L7, 8M, B8 etc. It is made of alloy steels. These are used in heavy duty applications and are widely used. in wind turbines. We export Stud Bolts as per ASME B1.1, DIN 965, DIN 976, A193, A320, DIN 2510 etc. or as per customer requirements. The manufacturing process of bolts starts with band saw cutting, focusing on one corner and chamfering on both corners, CNC (to reduce shaft diameter, shaft length, bore diameter, working surface etc.), heat treatment (Dowa). high temperature furnace), wire spinning, testing, final inspection, packaging and shipping.

We are Manufacturer Exporter of many types of stud bolts like

Full threaded Bolts

Hub Bolts

Double ended stud bolts

Blade studs

Threaded Rods

Reduced shank stud bolts

Source url: https://www.bigboltnut.com/product/stud-bolts.html

0 notes

Text

Leading B7 Stud Bolts Manufacturers in India

Delta Fitt Inc. is the leading ASTM A193 Grade B7 Stud Bolts Manufacturers in India and B8 Stud Bolts Manufacturers in India. Stud bolts are used to secure structures in a variety of applications, including architectural and industrial installations.

B7 Stud Bolts, manufactured by top B7 Stud Bolt Manufacturer in India, take centre stage. Learn about their competitive advantages, production insights, and market significance. Examine the benefits, analyse crucial considerations, and identify industry difficulties.

Watch for future developments that will shape the evolution of stud bolts. Choose B7 Stud Bolts reliability for secure projects. Make the right choice for lasting reliability. Choosing these bolts from trusted B8 and B7 Stud Bolts suppliers in India creates a construction cooperation.As a B7 Stud Bolts suppliers in India, Elevate your projects with the robust reliability of B7 Stud Bolts. Secure success now!

Looking for top-notch Stud Bolt Manufacturers in India? Look no further than Delta Fitt Inc. We deliver quality studs for your industrial needs.

Product: B7 Stud Bolts Manufacturer in India

For more details, contact us at: [email protected]

#B7StudBoltsManufacturersinIndia#B7StudBoltssuppliersinIndia#StudBoltsManufacturerinIndia#B8StudBoltsManufacturerinIndia

0 notes

Text

Purpose of choosing ASTM A193 grade strength

Alloy steel bolting materials meeting ASTM A193 Grade B16 criteria are the norm for strain vessels, valves, flanges, and fittings meant to face up to excessive temperatures and pressures. The maximum frequent users of these applications are the petrochemical, oil & gas, and power generation fields.

The chemical make-up of grade B16 bolts is as follows: silicon (0.15-zero.35%), chromium, manganese, phosphorus, sulfur, vanadium, and carbon. Grade B16 bolts are the maximum broadly used sort of alloy metal amongst numerous versions. These bolts' precise composition offers them with exquisite resistance to oxidation and sulfidation in addition to excessive temperature power.

To make certain that Grade B16 bolts are suitable and reliable for use in excessive-temperature and high-strain settings, the ASTM A193 widespread specifies necessities for his or her manufacturing, warmth treatment, and testing.

Could you explain the differences between B16 and B7 bolts?

While B7 and B16 bolts have similar features, what sincerely distinguishes them are their mechanical houses and material composition.

Enterprises coping with accelerated temperatures and pressures regularly make use of bolts with the B7 and B16 classifications. This is specially actual for the petrochemical, power era, and oil and gasoline sectors.

In order to achieve the required hardness and electricity, the medium carbon alloy metallic (4140) used to create B7 bolts and ASTM A193 B8 Bolts is often heated to the best temperature and then tempered. They have minimal yield and tensile strengths of 105 ksi and 125 ksi, respectively.

But the metal used to make B16 bolts is a higher alloy metal with molybdenum, chromium, and vanadium combined collectively. B16 bolts are stronger and extra proof against oxidation and sulfidation in warm conditions way to those additives. Moreover, B16 bolts have minimal yield and tensile strengths which can be corresponding to B7 bolts.

Use B7 bolts for packages desiring high energy and mild temperature resistance; use B16 bolts for packages requiring better energy and stronger resistance to oxidation and sulfidation at immoderate temperatures. B7 bolts are the endorsed desire while some diploma of heat resistance is vital.

Materials that are comparable to ASTM A193 Grade B16 consist of:

DIN EN 10269 1.4980:

European standard addresses bolts composed of a robust and heat-resistant chromium-molybdenum alloy steel.

ISO 898-1 class 10.9:

For bolts composed of alloy steels comparable to ASTM A193 Grade B16, International Standard ISO 898-1 class 10.9 provides mechanical criteria.

BS 1501-640B:

One can use British standard BS 1501-640B to fabricate fastening materials with characteristics comparable to ASTM A193 B8C bolts and ASTM A193 Grade B16. This general applies to high-power steel plates which have gone through heat remedy.

JIS SCM 4:

This Japanese business well-known specifies what to do with low-alloyed steels which have mechanical characteristics and chemical compositions equivalent to ASTM A193 Grade B16 and ASTM A193 B8M Stud Bolt.

It's vital to hold in mind that at the same time as the chemical composition and mechanical traits of numerous materials may be equal, their manufacturing methods, warmth remedy methods, and trying out requirements may additionally range. These variations may have an impact on the materials' performance for particular applications. It is advisable to study the pertinent material requirements and get advice from an experienced engineer or metallurgist when selecting bolting materials for applications involving high temperatures and pressures.

0 notes

Text

Ananka

Q1) Are there specific hex bolts designed for high-temperature environments?

Ans) Certainly, there are specific categories of hex bolts meticulously designed to excel in high-temperature settings. These specialized hex bolts are meticulously crafted from materials capable of enduring elevated temperatures without compromising their mechanical attributes or structural integrity. Here are several instances of hex bolts tailored for high-temperature applications:

1. Heat-Resistant Stainless Steel Hex Bolts: Hex bolts constructed from stainless steel alloys such as 310, 316, and 321 are frequently chosen for high-temperature environments. These alloys incorporate elements like chromium, nickel, and molybdenum, enhancing their resilience against oxidation and corrosion at elevated temperatures.

2. Inconel Hex Bolts: Inconel, a group of nickel-chromium-based superalloys, possesses remarkable resistance to high temperatures, oxidation, and corrosion. Inconel hex bolts find prominent usage in sectors like aerospace, petrochemicals, and industries confronting extreme heat.

3. Hastelloy Hex Bolts: Hastelloy, another lineage of nickel-based alloys, is renowned for its exceptional corrosion resistance and performance under high-temperature conditions. Hastelloy hex bolts often feature in applications exposed to harsh chemical environments and elevated temperatures.

4. Titanium Hex Bolts: Titanium hex bolts, noted for their lightweight nature and commendable strength at high temperatures, are favored in industries such as aerospace and chemical processing. These hex bolts effectively balance heat resistance and corrosion resistance.

5. Alloy Steel Hex Bolts: Certain alloy steels, including ASTM A193 Grade B7, undergo heat treatment to cater to high-temperature requirements. These hex bolts find common application in pressure vessels, boilers, and piping systems that operate at elevated temperatures.

6. Ceramic-Coated Hex Bolts: In specific scenarios, hex bolts can be coated with ceramic materials, furnishing them with a thermal barrier. This coating empowers the hex bolts to endure elevated temperatures while retaining their mechanical properties.

When selecting hex bolts for high-temperature environments, meticulous consideration should be given to factors such as the specific temperature range, the presence of corrosive elements, and the mechanical prerequisites of the application. Consulting experts or referring to industry standards is advised to make an informed choice regarding the most suitable type of hex bolts that can offer reliable performance under the desired high-temperature conditions.

Hastelloy Fasteners

Q2) Are there hex nuts specifically designed for high-temperature applications?

Ans) Yes, indeed, hex nuts tailored for high-temperature applications are available. These specialized hex nuts are meticulously fashioned from materials capable of enduring elevated temperatures without compromising their structural soundness. Here are several instances of hex nuts designed specifically for high-temperature environments:

1. Heat-Resistant Stainless Steel Hex Nuts: Hex nuts crafted from stainless steel alloys such as 310, 316, and 321 are commonly employed for high-temperature scenarios. These alloys incorporate elements like chromium, nickel, and molybdenum, bolstering their capacity to withstand oxidation and corrosion in elevated temperature settings.

2. Inconel Hex Nuts: Inconel, a lineage of nickel-chromium-based superalloys, enjoys renown for its exceptional resistance to high temperatures, oxidation, and corrosion. Inconel hex nuts are frequently harnessed in aerospace, petrochemical, and similar industries where extreme heat prevails.

3. Hastelloy Hex Nuts: Hastelloy, another category of nickel-based alloys, is esteemed for its remarkable corrosion resistance and performance in high-temperature environments. These hex nuts find favor in scenarios involving harsh chemicals and elevated temperatures.

4. Titanium Hex Nuts: Boasting lightweight attributes and commendable strength at high temperatures, titanium hex nuts find their niche in sectors like aerospace and chemical processing, where both heat resistance and corrosion resistance are paramount.

5. Alloy Steel Hex Nuts: Certain alloy steels, such as ASTM A194 Grade 7, are subject to heat treatment to suit high-temperature requisites. These hex nuts commonly find purpose in pressure vessels, boilers, and piping systems functioning at elevated temperatures.

6. Ceramic-Coated Hex Nuts: In certain instances, hex nuts can be treated with ceramic coatings that confer thermal insulation, enabling them to withstand elevated temperatures while preserving their structural integrity.

When opting for hex nuts tailored for high-temperature environments, meticulous contemplation of factors such as the specific temperature range, the presence of corrosive agents, and the mechanical prerequisites of the application is indispensable. Seeking counsel from experts or referring to industry standards is a prudent step in ascertaining the most fitting type of hex nuts capable of delivering reliable performance under the desired high-temperature conditions.

Carbon Steel Fasteners

Q3) What are the implications of using the wrong size or type of plain washer?

Ans) Using the wrong size or type of plain washer in a fastened assembly can have several significant implications, potentially leading to compromised joint integrity, safety hazards, and functional issues. Here are some of the implications:

1. Reduced Clamping Force: The primary function of a plain washer is to distribute the load and provide a larger surface area for even pressure distribution. Using a washer that is too small or not suitable for the application can lead to uneven clamping force, resulting in insufficient joint compression. This can cause components to come loose over time and reduce the overall stability of the assembly.

2. Increased Stress Concentrations: Choosing a washer with inadequate dimensions or material properties can lead to localized stress concentrations. These concentrated stress points can weaken the fastened components, making them more prone to deformation, cracking, or failure under load.

3. Loss of Friction Control: Plain washers can help control friction between the fastener and the material being fastened. Incorrectly sized or inappropriate washers may not provide the necessary friction management, potentially leading to loosening of the joint due to vibration or other external forces.

4. Potential for Galling or Seizing: If the wrong type of washer material is used, such as a washer with a rough surface, there's a risk of galling (metal-to-metal adhesion) or seizing between the washer and the fastener head or nut. This can make future disassembly difficult or even cause damage to the fastener and washer.

5. Inadequate Load Distribution: Using a washer that doesn't match the shape or size of the fastener head or nut can result in poor load distribution. This may lead to indentations, deformations, or damage to the components being fastened, reducing their overall lifespan.

6. Leakage and Seal Failure: In applications involving gaskets or seals, using the wrong size washer can lead to improper compression of the gasket, resulting in leaks or seal failure. This is particularly critical in environments where sealing integrity is crucial, such as fluid or gas systems.

7. Compromised Aesthetics and Functionality: In certain applications, the aesthetics of the assembly might matter. Using the wrong size or type of washer can lead to misalignment, improper fit, or visible gaps, affecting both the appearance and the functionality of the assembly.

8. Safety Hazards: Depending on the application, using incorrect washers can compromise the safety of the assembly. In critical structures, machinery, or equipment, failure due to incorrect washers can lead to accidents, injuries, or costly downtime.

To avoid these implications, it's crucial to select plain washers that are appropriate for the specific application. This includes considering factors like washer size, material, shape, and load-bearing capacity. It's recommended to follow manufacturer guidelines, industry standards, and engineering best practices to ensure that the chosen plain washers provide effective load distribution, proper clamping force, and overall joint integrity.

Stainless Steel Fasteners Manufacturers in Mumbai

Q4) Are there stud bolts specifically designed for high-temperature applications?

Ans) Yes, there are stud bolts specifically designed to excel in high-temperature applications. These specialized stud bolts are crafted from materials that can withstand elevated temperatures without compromising their mechanical properties or structural integrity. Here are a few examples of stud bolts designed for high-temperature environments:

1. Heat-Resistant Stainless Steel Stud Bolts: Stainless steel alloys like 310, 316, and 321 are commonly chosen for stud bolts in high-temperature applications. These alloys contain elements like chromium, nickel, and molybdenum, which enhance their resistance to oxidation and corrosion at elevated temperatures.

2. Inconel Stud Bolts: Inconel is a family of nickel-chromium-based superalloys renowned for their exceptional resistance to high temperatures, oxidation, and corrosion. Inconel stud bolts are frequently used in industries such as aerospace, petrochemicals, and power generation, where extreme heat is encountered.

3. Hastelloy Stud Bolts: Hastelloy is another family of nickel-based alloys known for their excellent corrosion resistance and high-temperature performance. Hastelloy stud bolts are often used in environments involving harsh chemicals and elevated temperatures.

4. Titanium Stud Bolts: Titanium stud bolts are lightweight and possess good strength at high temperatures. They find application in industries such as aerospace, chemical processing, and marine, where both heat resistance and corrosion resistance are essential.

5. Alloy Steel Stud Bolts: Some alloy steels, such as ASTM A193 Grade B7, are heat-treated and designed for high-temperature applications. These stud bolts are commonly used in pressure vessels, boilers, and piping systems operating at elevated temperatures.

6. Ceramic-Coated Stud Bolts: In certain cases, stud bolts can be coated with ceramic materials that provide a thermal barrier, allowing them to endure higher temperatures while maintaining their mechanical properties.

When selecting stud bolts for high-temperature environments, it's crucial to consider factors such as the specific temperature range, the presence of corrosive elements, and the mechanical requirements of the application. Consulting with experts or referring to industry standards is recommended to choose the appropriate type of stud bolts that can reliably perform under the desired high-temperature conditions.

Phosphor Bronze Bolts

0 notes

Text

Carbon Steel Flanges: Experts’ Top Recommendations for Optimal Performance

Carbon steel flanges are widely used in various industries due to their excellent durability, strength, and cost-effectiveness. However, to ensure optimal performance and longevity, it is crucial to follow experts’ recommendations. In this article, we will discuss the top recommendations from experts for carbon steel flange performance.

Material Selection: Choosing the right carbon steel material is the first step to ensure optimal performance. Experts recommend selecting carbon steel with the appropriate grade and composition for the specific application. Factors like corrosion resistance, temperature stability, and pressure requirements should be considered when choosing the material.

Flange Design: The design of carbon steel flanges should be in accordance with industry standards and specifications, such as ASME B16.5 or API 605. It is essential to ensure proper dimensions, bolt hole sizes, flange face type, and class ratings. Using flanges designed for specific applications helps in preventing leakage and ensures a secure connection.

Flange Surface Finish: Experts emphasize the importance of achieving the correct surface finish for carbon steel flanges. A smooth surface finish reduces the risk of corrosion, enhances sealing performance, and prevents gasket damage. Commonly used surface finishes include an oil-based rust preventive coating or an epoxy-based paint finish.

Gasket Selection: The selection of the appropriate gasket is critical for achieving optimal performance in carbon steel flange joints. Gaskets should be compatible with the operating conditions, such as temperature, pressure, and fluid type. It is recommended to use gaskets made of materials like graphite, PTFE (Polytetrafluoroethylene), or spiral wound gaskets for better sealing capabilities.

Bolt Selection and Torque: Proper bolt selection and tightening torque are crucial for achieving a leak-free connection. Experts advise using bolts made from high-strength carbon steel or alloy steel, such as ASTM A193 Grade B7, and complying with standard specifications, such as ASME B18.2.1. Following the recommended bolt torque values ensures proper tensioning and prevents flange leakage.

Proper Installation: Correct installation practices play a vital role in the performance of carbon steel flanges. Experts suggest cleaning the flange surfaces thoroughly and removing any dirt or debris. It is important to align the flanges properly and apply an even bolt load during the tightening process. Over-tightening or uneven loading can lead to flange distortion or gasket failure.

Regular Inspection and Maintenance: Regular inspection and maintenance are essential for ensuring continued optimal performance of carbon steel flanges. Periodic checks for leaks, corrosion, or damage should be conducted. Any detected issues should be addressed promptly to prevent further deterioration or failure. It is recommended to follow industry guidelines for maintenance activities like bolt retightening or gasket replacement.

Corrosion Prevention: Carbon steel flanges are susceptible to corrosion, especially in harsh environments. Experts recommend applying suitable corrosion protection strategies, such as the use of coatings or cathodic protection techniques. Regular cleaning, painting, or applying anti-corrosion coatings can significantly enhance the longevity and performance of carbon steel flanges.

Training and Expertise: Having trained personnel with expertise in carbon steel flanges and their installation is crucial for optimal performance. Experts suggest providing comprehensive training to technicians and engineers involved in flange installation and maintenance. This ensures that best practices are followed, reducing the risk of errors or improper handling.

0 notes

Text

Moving into the flanged stainless steel realm.

When joining two tubes, a flange is an essential component. In most cases, it joins the ends of two tubes with a threaded connection or some other type of welding. Therefore, there are primarily two types of fasteners: threaded attachment flanges and welding flanges. Flanges, a gasket, and a number of bolts and nuts are needed whenever two tubes are ready to be linked together via a flange junction.

The first step is to place the gasket in between the seals. Once that's done, you may tighten the bolts. When the surface pressure of a gasket reaches a critical point, it deforms to fill in any gaps or imperfections in the sealing surface, thereby sealing the joint. Duplex pipe suppliers have proven invaluable.

One sort of removable connection is a flange junction. It appears that there are two sorts of removable parts, namely container flanges and tube flanges. You can benefit greatly from working with Duplex tube suppliers.

There are three different types of sealing faces, each suited to a different pressure range and set of circumstances: planar sealing faces for low pressure, uneven sealing faces for moderate pressure, and tongue and groove sealing faces for high pressure and combustible, explosive, or poisonous material. Most of the time, Indian factories that make Duplex flanges are reliable.

It's well knowledge that different types of flanges can withstand varying amounts of pressure and media. The gasket used in the connection really plays a crucial role. Gaskets made from non-metallic plates have been mass-produced. The company that makes forged parts has been doing a fantastic job. Duplex pipe fittings are actually very good.

Asbestos rubber sheets, asbestos plates, polyethylene workbooks, and so on all have sizes that are specified by various norms. A typical latex gasket, for instance, has a temperature limit of 120? In corrosive environments, acid-resistant asbestos has seen extensive application. Copper, aluminum, 10 steel, or some other type of stainless steel sheet may be used if the pressure is high enough. You might be able to get a wide selection of Duplex round bar.

Despite their apparent simplicity, fasteners serve important purposes and have grown in prominence across practically all sectors of the economy. Vehicles and machinery are joined together by fasteners. Most people in the modern world like to make use of them. Duplex forged fittings made of stainless steel are highly recommended.

In fact, flange is a technique in and of itself. Indeed, these are the DIN system, the ANSI scheme, and the JIS system. The previous systems' pressure requirements and sealing face types are identical. Most customers today choose Copper nickel plate.

The third option is also not often used. In addition, the GB standard, the specific chemical standard, the mechanical requirement, and the pressure vessel benchmark must all be followed while fabricating flanges. Pipes and tubes are the backbone of the manufacturing sector. These innovations have made up for human shortcomings by doing work that people can't. The quality of the A193 grade B7 bolts has been excellent.

0 notes

Text

Differentiating A193 B7 Bolts from Other Bolt Grades: What Sets Them Apart?

The importance of selecting the correct bolt grade for a given application cannot be overstated. Among the plethora of bolt grades available, A193 B7 stands as a popular choice renowned for its remarkable strength and durability. In this blog post, we will delve into the distinctive characteristics that differentiate A193 B7 bolts from other bolt grades, offering you valuable insights into why they are favored across diverse industries.

Strength and Material Composition:

A193 B7 bolts are made from a high-strength alloy steel known as chromium-molybdenum steel. This alloy composition gives these bolts exceptional tensile strength, making them suitable for applications that require robust fasteners capable of withstanding heavy loads and high-pressure environments.

Heat Treatment Process:

A193 B7 bolts stand apart due to their unique heat treatment process, which plays a crucial role in their distinctive characteristics. These bolts undergo a meticulous quenching and tempering procedure, where they are subjected to elevated temperatures and swiftly cooled to attain the desired level of hardness and strength. This specialized heat treatment significantly improves the mechanical properties of the bolts, bolstering their tensile strength, yield strength, and impact resistance.

High-Temperature Applications:

A193 B7 bolts are engineered to excel in high-temperature environments, making them well-suited for various applications. The presence of chromium-molybdenum steel in their composition grants these bolts exceptional resistance to oxidation and creep at elevated temperatures. As a result, they find wide applications in industries such as petrochemical, power generation, and oil and gas, where exposure to high temperatures is common.

Corrosion Resistance:

Another notable characteristic of A193 B7 bolts is their corrosion resistance. Although they are not stainless-steel bolts, their alloy composition grants them a level of corrosion resistance, especially in mildly corrosive environments. However, for applications in highly corrosive conditions, additional protective coatings may be required to ensure long-term durability.

Versatility and Compatibility:

A193 B7 bolts are compatible with a wide range of nuts and washers, making them highly versatile for different applications. Their standardized dimensions and threads allow for easy integration into various structural and mechanical systems.

Conclusion:

A193 B7 bolts stand out from other bolt grades due to their exceptional strength, heat treatment process, high-temperature capabilities, corrosion resistance, and compatibility. These qualities make them a popular choice in industries such as construction, oil and gas, power generation, and more. Understanding the unique characteristics of Buy A193 B7 bolts helps engineers and professionals make informed decisions when selecting fasteners for their specific applications.

Remember, when working with bolts, always consult the appropriate standards and specifications to ensure you choose the correct bolt grade and adhere to proper installation practices.

0 notes

Text

Heavy Hex Bolt

https://www.dtnut.com/products/heavy-hex-bolt/

The nearly 20 years that DATIAN (DT) Fasteners has specialized in the production of heavy hex bolts. Many customers need to purchase by sets. Our loyal customers usually need to source hex bolts / heavy hex head bolts together with hex nuts. As a professional heavy hex bolt factory, DT provides complete heavy hex bolt supply chain services. we are able to produce A307 B heavy hex cap screws, A193 B7 heavy hex bolts, A325 heavy hex screws, etc.

Heavy Hex Head Bolt Applications

High-strength hexagon bolts are mechanical properties of grade 8.8 or above, and they are all bolts that require heat treatment

Bolts made of high-strength steel, or bolts that require a large pre-tightening force, can be called high-strength bolts. High-strength bolts are mostly used for the connection of bridges, rails, high-voltage, and ultra-high-voltage equipment. The fracture of this kind of bolt is a mostly brittle fracture. High-strength bolts applied to ultra-high pressure equipment need to be prestressed to ensure the sealing of the container.

Application areas of high-strength bolts: Steel Fabrication, Construction of Railroad Systems, Pumps, and Water treatment, Construction of Modular Buildings, and Renewable and Alternative Energy.

Heavy Hex Head Bolt Manufacturing Process Steps Include:

Usually, the forming of the bolt head is processed by cold heading. The cold heading forming process includes cutting and forming, single-station single-click, double-click cold heading and multi-station automatic cold heading. An automatic cold heading machine performs multi-station processes such as stamping, heading forging, extrusion and diameter reduction in several forming dies.

(1) Use a semi-closed cutting tool to cut the blank, the easiest way is to use a sleeve type cutting tool.

(2) During the transfer of short-sized blanks from the previous station to the next forming station, the metal fasteners with complex structures are processed to improve the accuracy of the parts.

(3) Each forming station should be equipped with a punch return device, and the die should be equipped with a sleeve-type ejector device.

(4) The structure of the main slider guide rail and process components can ensure the positioning accuracy of the punch and the die during the effective use period.

(5) The terminal limit switch must be installed on the baffle that controls the material selection, and attention must be paid to the control of the upsetting force.

Heat Treatment Of High-Strength Heavy Hex Screw:

High-strength nuts and bolts must be quenched and tempered according to technical requirements. The purpose of heat treatment and tempering is to improve the comprehensive mechanical properties of the heavy hex bolt to meet the specified tensile strength value and yield ratio of the product. The heat treatment process has a crucial impact on high-strength fasteners, especially their intrinsic quality. Therefore, in order to produce high-quality heavy hex head bolts, advanced heat treatment technology and equipment must be available.

As one of the leading heavy hex bolt manufacturers in China, DT Fastener possesses a complete production line of heavy hex cap screws. Feel free to contact us for more details!

0 notes

Text

Stainless Steel Fasteners Manufacturer in India - Sachiya Steel International

Stainless Steel Fasteners are indispensable components in various industries, from construction and automotive to marine and aerospace. These hardware devices mechanically join or fasten two or more objects together, ensuring the structural integrity and durability of different applications. In India, Sachiya Steel International Private Limited stands out as a leading manufacturer of high-quality stainless steel fasteners. This article provides an in-depth overview of stainless steel fasteners, their types, manufacturing processes, and the prominent role of Sachiya Steel International in the industry.

Types of Stainless Steel Fasteners

Stainless steel fasteners come in various types and grades, each designed for specific applications based on factors like corrosion resistance, strength, and environmental conditions. Here are some common types:

Bolts and Nuts

Screws

Washers

Studs

Anchors

Manufacturing Process of Stainless Steel Fasteners

Sachiya Steel International utilizes state-of-the-art manufacturing processes to produce high-quality stainless steel fasteners that meet stringent industry standards.

Raw Material Selection

Only high-grade stainless steel raw materials are selected to ensure durability and corrosion resistance. Common grades include AISI 304, AISI 316, and AISI 410 stainless steels.

Cold Heading

Cold heading is a method used to form fastener heads and threads by forcing metal through various dies. This process improves mechanical properties and maintains uniformity in shape and dimensions.

Thread Rolling

By cold forming threads onto fastener shafts, thread rolling enhances strength and wear resistance compared to cut threads.

Heat Treatment

To achieve the desired mechanical properties, fasteners undergo heat treatments such as annealing, quenching, or tempering. These treatments increase strength, hardness, and corrosion resistance.

Surface Coatings

Sachiya Steel International offers various surface finishes, such as electroplating, hot-dip galvanizing, or organic coatings. These finishes enhance corrosion resistance and aesthetic appeal.

Applications of Stainless Steel Fasteners

Stainless steel fasteners are essential in numerous industries due to their adaptability and reliability.

Construction

Stainless steel bolts, nuts, and washers are extensively used in construction applications requiring strength, durability, and corrosion resistance, such as bridges, buildings, and infrastructure projects.

Automotive

AISI 410 stainless steel screws are commonly used in the automotive industry for assembling vehicles and machinery, ensuring long-term reliability and longevity.

Marine

To resist corrosion in marine environments, stainless steel fasteners like AISI 316 anchors are ideal. These fasteners are commonly used on ships and offshore structures.

Aerospace

Fasteners designed for aerospace applications, such as ASTM A193 B7 studs, are essential for ensuring safe and reliable flight. Their lightweight properties, high strength, and resistance to extreme temperatures and corrosion make them indispensable in aircraft construction.

Sachiya Steel International: Leading Manufacturer of Stainless Steel Fasteners in India

Sachiya Steel International Private Limited stands out as a premier supplier of stainless steel fasteners in India, thanks to several key attributes:

Quality Assurance

Rigorous quality control measures ensure that each fastener meets international standards such as ASTM, AISI, and DIN, as well as customer-specific specifications.

Customization

Sachiya Steel International can tailor fasteners according to size, material grade, surface finish, and coating specifications to meet diverse customer needs and application requirements.

Infrastructure

State-of-the-art manufacturing facilities equipped with modern machinery, automated production lines, and sophisticated testing equipment ensure consistent quality and production efficiency.

Global Reach

India has built an outstanding global reputation as a reliable supplier of industrial fastening solutions by exporting high-quality stainless steel fasteners to global markets.

Conclusion

Stainless steel fasteners are key components in many industries, providing structural integrity, reliability, and safety across an array of applications. Sachiya Steel International Private Limited stands as India’s premier producer, manufacturing stainless steel fasteners that exceed domestic and international market demands. Their commitment to innovation, quality, and customer satisfaction solidifies their position as a go-to supplier for stainless fastening solutions worldwide.

Read More: Stainless Steel Fasteners Manufacturer in India

0 notes

Text

Astm A193 b16 Fasteners | Roll Fast

Roll Fast is a manufacturer, supplier, and exporter of alloy steel ASTM A193 grade B16 full-threaded stud bolts and hex bolts. It includes details of high tensile, stainless, or alloy steel fasteners. ASTM A193 B16 stud bolts are high-strength fasteners manufactured from heat-treated Chromium-Molybdenum-Vanadium steel, quenched and tempered. Added Vanadium allows for operating temperatures higher than that of B7 stud bolts. It is extensively used in high-pressure and high-temperature services like valves, fittings, pressure valves, flanges, and chemical and petroleum construction applications. It covers the requirements for high-temperature and high-pressure bolting. A193 B16 all thread studs having diameters above 1" are most common in thread pitches.

visit source URL : https://www.roll-fast.com/astm-a193-grade-b16.html

0 notes