#basic and advance plc programming courses

Explore tagged Tumblr posts

Text

Title: "Unlocking Tomorrow: Celestial Learning's Robotics and Automation Courses Illuminate Pune's Future"

#basic and advance plc programming courses#plc programming courses in pune#certificate course in plc programming#advanced plc programming courses#plc programming courses

0 notes

Text

In automation industry SIEMENS PLC’s have the highest proliferation in Europe and Allen Bradley is mostly used in the US. But an equally strong brand in PLC domain is Mitsubishi Electric Japan. Different brand of PLCs have their own advantages and limitations. Celestial learning provide one of the best Basic and Advance plc programming courses.

Visit us https://celestiallearning.com/courses/plc-programming-course-mitsubishi-advance-level/

#Basic and Advance plc programming courses#Certificate course in plc programming#PLC Programming Courses in Pune

0 notes

Text

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

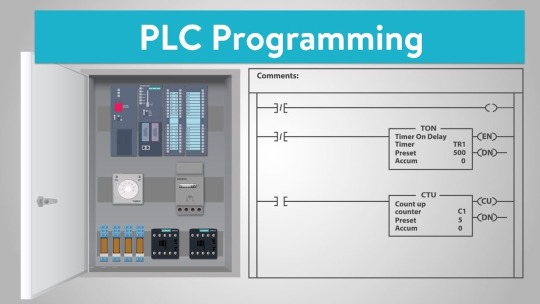

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Designing a Basic SCADA System: A Foundational Guide

Introduction

SCADA (Supervisory Control and Data Acquisition) systems in industrial automation serve a vital purpose in monitoring and controlling processes. From manufacturing, energy management, water treatment, to infrastructure, SCADA systems offer a single platform for data collection, visualization, and control. Designing a basic SCADA system entails knowing its most important components and how they cooperate to facilitate smooth operations.

Key Components of a SCADA System

A well-structured SCADA system includes several core components:

Remote Terminal Units (RTUs) or PLCs: These collect real-time data from sensors and field devices.

Communication Infrastructure: Data from field devices is transmitted to the central system via wired or wireless communication protocols.

SCADA Software: Installed on central servers or PCs, it processes the incoming data, provides visualization through HMI screens, and allows operators to control processes remotely.

Human Machine Interface (HMI): It is the interface that presents data, alarms, and controls in an interactive form.

Steps involved in designing a basic SCADA System

Define System Requirements: Identify the process to be monitored, the number of data points, and control level needed.

Choose Hardware Components: Select suitable PLCs or RTUs, sensors, and network devices according to the needs of the process.

Develop Communication Architecture: Develop an efficient communication network through appropriate protocols (such as Modbus, Ethernet/IP, or wireless systems).

Program and Configure the System: Develop control logic in PLCs and program SCADA software to interact with field devices.

Test and Validate: Test conditions to ensure data collection, alarms, and control functionality.

Deploy and Maintain: Install the system on-site and schedule periodic updates and maintenance.

Learning SCADA Design with Real-Time Exposure

Learning how to develop a SCADA system is a skill that is best acquired in a lab-based training setup. A PLC SCADA Course in Nashik provides the future automation experts a chance to practice on live equipment and industrial-standard projects. Centers like VIATA, in the center of Nashik, have a reputation for combining theoretical knowledge with lab application.

VIATA is headed by an industrialist with more than 20 years of experience in automation. The institute's strategy involves training in Stepper & Servo Motors, Drive Technologies, DCS, and IIoT, all of which are essential for SCADA system design. Students get exposure to HMI configuration, AC motor drives, VFDs, and control panel engineering, so the training is applicable to both fresh graduates and experienced professionals.

Why opt for a PLC SCADA Course in Nashik?

Live Industrial Projects: Learners are exposed to real systems, equipping them for the challenges of the industry.

Best Automation Experts: Training experts with field experience impart real-world perspectives to the class.

Balanced Curriculum: From initial PLC logic to advanced SCADA interfaces, all aspects of control system development are included.

Guaranteed Placement Support: With career guidance and focused interview skills training, students are assisted in making the transition into the workforce.

Conclusion:

Creating a simple SCADA system isn't only about knowing software and hardware, but also real-life integration of these tools within an industrial environment. To gain a good foundation in automation, taking a hands-on PLC SCADA Course in Nashik provides the ideal combination of theory and practice. Under the tutelage of experts and real-time learning facilities such as those provided by VIATA, students are imparted the necessary skills to thrive in contemporary automation jobs.

0 notes

Text

Best PLC Training Institute In Pune

Welcome to Perfecto Robotics Institute, we provide the Best PLC Training In Pune. Our institute has very advanced courses along with the most modern facilities. We do cater to any of your requirements. You might be a fresher or an old-time professional; our institute will give you what you want.

Firstly, Perfecto Robotics Institute offers training led by industry experts.

Students actively participate in practical exercises, which develop a thorough understanding of PLC systems. Additionally, our instructors emphasize real-world applications, preparing graduates for the challenges of various technological environments.

What Is PLC Training?

Prepares technicians to take full advantage of vendor training on specific equipment. We cover the basic operating principles of all PLCs, their inputs and outputs, programming, maintenance, and networking. This course has no prerequisites.

What is PLC?

PLC is the abbreviated form of Programmable Logic Control.

PLC is an industrialized computer, which is in charge of control functions of different sorts, beginning with the inputs, outputs, and central processing units.

What are examples of PLCs?

ManufacturingOil and GasAutomotiveFood and BeverageUtilitiesBuilding AutomationPharmaceuticals

What are the main components of PLC?

CPU (Central Processing Unit)Input / Output (I/O) ModulesPower SupplyMemoryProgramming Terminal or ComputerCommunication PortsExpansion Modules

Why is PLC used?

Increased dependabilitySafetyReal-time TrackingAble to work 365 days a year 24/7RepeatabilityReduced energy consumptionSpace requirements are reduced.increased user experience flexibilityYou can handle various devices at the same time.Increased machine connectivity and procedure automationManufacturing processes will be increased.Reduced operational costs.

Additionally, PLC services include troubleshooting and repair. In the event of a malfunction or malfunction, skilled technicians diagnose the problem, as well as replace the faulty component if necessary. PLC services also include immediately restoring PLC functionality to minimize production disruptions.

In conclusion, for the Best PLC Training Institute In Pune, Perfecto Robotics Institute is the best choice. With our expertise, dedication, and emphasis on quality and transparency, we guarantee solutions that exceed your expectations. Contact us today to discuss your PLC needs and discover why Perfecto Robotics Institute is the perfect choice for your requirements.

0 notes

Text

Best PLC Training In Pune

Welcome to Perfecto Robotics Institute, we provide the Best PLC Training In Pune. Our institute has very advanced courses along with the most modern facilities. We do cater to any of your requirements. You might be a fresher or an old-time professional; our institute will give you what you want.

Firstly, Perfecto Robotics Institute offers training led by industry experts.

Students actively participate in practical exercises, which develop a thorough understanding of PLC systems. Additionally, our instructors emphasize real-world applications, preparing graduates for the challenges of various technological environments.

What Is PLC Training?

Prepares technicians to take full advantage of vendor training on specific equipment. We cover the basic operating principles of all PLCs, their inputs and outputs, programming, maintenance, and networking. This course has no prerequisites.

What is PLC?

PLC is the abbreviated form of Programmable Logic Control.

PLC is an industrialized computer, which is in charge of control functions of different sorts, beginning with the inputs, outputs, and central processing units.

What are examples of PLCs?

Manufacturing Oil and Gas Automotive Food and Beverage Utilities Building Automation Pharmaceuticals

What are the main components of PLC?

CPU (Central Processing Unit) Input / Output (I/O) Modules Power Supply Memory Programming Terminal or Computer Communication Ports Expansion Modules

Why is PLC used?

Increased dependability Safety Real-time Tracking Able to work 365 days a year 24/7 Repeatability Reduced energy consumption Space requirements are reduced. increased user experience flexibility You can handle various devices at the same time. Increased machine connectivity and procedure automation Manufacturing processes will be increased. Reduced operational costs.

Additionally, PLC services include troubleshooting and repair. In the event of a malfunction or malfunction, skilled technicians diagnose the problem, as well as replace the faulty component if necessary. PLC services also include immediately restoring PLC functionality to minimize production disruptions.

In conclusion, for the Best PLC Training Institute In Pune, Perfecto Robotics Institute is the best choice. With our expertise, dedication, and emphasis on quality and transparency, we guarantee solutions that exceed your expectations. Contact us today to discuss your PLC needs and discover why Perfecto Robotics Institute is the perfect choice for your requirements.

0 notes

Text

Everything You Need to Know About the ETO Course in Merchant Navy

The Merchant Navy is the backbone of global trade, transporting goods and commodities across vast oceans. Behind the scenes, skilled professionals ensure that the intricate systems onboard these vessels run smoothly. Among these key roles is that of the Electro-Technical Officer (ETO), responsible for managing and maintaining a ship’s electrical and electronic systems. If you’re interested in pursuing this exciting career, enrolling in an ETO course in the Merchant Navy is the first step. This blog provides a comprehensive overview of the course, its structure, and the career prospects it offers.

1. What Is the ETO Course?

The Electro-Technical Officer course is a specialized program designed to prepare candidates for the technical challenges of working in the Merchant Navy. The program focuses on equipping students with the knowledge and skills required to handle electrical, electronic, and control systems onboard ships.

The course typically includes a mix of theoretical learning and practical training, covering topics such as power distribution, automation, and shipboard safety. Students also gain hands-on experience with advanced equipment and systems, preparing them for real-world scenarios at sea.

2. Eligibility Criteria for the ETO Course

To enrol in an ETO course in the Merchant Navy, candidates must meet specific eligibility requirements:

Educational Qualifications:

A diploma or degree in Electrical Engineering, Electronics Engineering, or related fields is often required.

Alternatively, candidates with a background in instrumentation or telecommunications may also qualify.

Age Limit:

Most programs have an age limit of 17 to 28 years for applicants.

Medical Fitness:

Physical fitness is essential for working in a demanding maritime environment. Candidates must pass a medical examination conducted by a Directorate General of Shipping (DGS)-approved doctor.

Vision standards include unaided eyesight of 6/6 and no colour blindness.

Meeting these criteria ensures that candidates are well-prepared for the challenges of the course and the profession.

3. Course Structure and Curriculum

The ETO course typically spans 4-6 months and combines classroom learning with hands-on training. The curriculum is designed to provide a deep understanding of the electrical and electronic systems on board a ship. Key topics include:

Electrical and Electronics:

Basics of electrical circuits and components.

Maintenance and troubleshooting of shipboard electrical systems.

Automation Systems:

Study of Programmable Logic Controllers (PLCs) and their application in maritime settings.

Understanding automation in engine and cargo operations.

Power Generation and Distribution:

Managing power supply systems, including generators and transformers.

Understanding energy efficiency and sustainability in maritime operations.

Safety and Regulations:

Learning about international maritime safety standards.

Familiarity with protocols for dealing with emergencies, such as fires or equipment failure.

Practical Training:

Many institutions provide practical sessions using simulators or onboard training to give students hands-on experience in handling ship equipment.

Reputable institutes like the AMET Institute of Science and Technology excel in blending theoretical and practical learning, offering a world-class education for aspiring electro-technical officers.

4. Career Opportunities After Completing the Course

Completing an ETO course in the Merchant Navy opens doors to a range of career opportunities. As an ETO, you’ll play a vital role in ensuring the efficient and safe operation of ships. Here are some career paths available:

Onboard Roles:

Junior Electro-Technical Officer: Entry-level role focusing on basic maintenance tasks.

Electro-Technical Officer: Responsible for the smooth functioning of all electrical and electronic systems on the ship.

Chief ETO: Supervisory role managing a team of technical officers.

Shore-Based Roles:

Marine Surveyor: Inspecting ships to ensure compliance with maritime regulations.

Technical Superintendent: Overseeing the technical operations of a fleet of ships.

Equipment Designer: Developing innovative technologies for the maritime industry.

With experience, ETOs can also transition to research and development roles, contributing to advancements in sustainable and automated shipping technologies.

5. Skills Needed for Success as an ETO

A successful career as an Electro-Technical Officer requires a combination of technical expertise and personal attributes. Here are some key skills:

Technical Skills:

Strong understanding of electrical and electronic systems.

Proficiency in troubleshooting and problem-solving.

Personal Qualities:

Resilience and adaptability to handle the challenges of life at sea.

Teamwork and communication skills are essential for collaborating with diverse crew members.

Lifelong Learning:

Staying updated on advancements in maritime technology is crucial for long-term success in this dynamic field.

Conclusion

The ETO course in the Merchant Navy is a gateway to a challenging and rewarding career. With its comprehensive curriculum, practical training, and global career opportunities, the course prepares candidates for a vital role in the maritime industry. As technology continues to evolve, the demand for skilled Electro-Technical Officers will only grow, making it an excellent career choice for those with a passion for engineering and a spirit of adventure.

By enrolling in a reputable institute like the AMET Institute of Science and Technology, aspiring ETOs can gain the skills and knowledge needed to thrive in this exciting field. With dedication and the right training, you can embark on a career that combines technical excellence with the thrill of life at sea.

0 notes

Text

Upskill Your Career with PLC and SCADA Training and Data Analytics in Jaipur

In the age of technology and automation, staying ahead means acquiring specialized skills that employers demand. Whether you’re diving into industrial automation or aiming for a career in data analytics, mastering the right tools and techniques is essential. That’s where Seldom India steps in, offering premium PLC and SCADA Training and an in-depth data analyst course in Jaipur. These programs are designed to help you thrive in competitive industries by providing practical knowledge and industry insights.

Why Specialized Training Is the Key to Success

As industries continue to automate and digitize their processes, having expertise in niche areas like automation and data analysis gives professionals a competitive edge. Both fields promise high demand, lucrative career paths, and opportunities for continuous growth. Let’s explore how Seldom India’s training programs can prepare you for these exciting domains.

Master Automation with PLC and SCADA Training

Industrial automation is reshaping manufacturing, energy, and infrastructure. Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) are the cornerstones of automation systems, making them essential tools for engineers and technicians.

What is PLC and SCADA Training?

PLC and SCADA training equips individuals with the skills needed to program, operate, and troubleshoot automation systems. These systems control machinery, monitor processes, and ensure efficiency in industries like manufacturing, oil and gas, and power generation.

Why Choose Seldom India for PLC and SCADA Training?

Comprehensive Curriculum: The course covers everything from PLC programming basics to advanced SCADA visualization techniques.

Hands-On Experience: Gain practical knowledge by working on real-world automation systems.

Expert Trainers: Learn from industry professionals with years of experience in automation and control systems.

Job-Ready Skills: The training prepares you for roles such as automation engineer, control systems technician, and industrial programmer.

The Growing Demand for Data Analysts

On the flip side, the data revolution is taking over businesses across the globe. Every organization now relies on data-driven decisions to improve operations, reach customers, and forecast trends. If you’re a problem solver with an analytical mindset, a career in data analytics might be your calling.

What Does a Data Analyst Do?

A data analyst collects, organizes, and interprets data to provide actionable insights. They use tools like Excel, Python, SQL, and Tableau to transform raw data into visualizations and reports that help companies make informed decisions.

Why a Data Analyst Course in Jaipur is Worth It

Jaipur is emerging as a hub for professional education, offering world-class training opportunities. Seldom India’s data analyst course in Jaipur is tailored to meet the growing demand for skilled analysts in industries such as finance, healthcare, and e-commerce.

Highlights of the Data Analyst Course

Practical Learning: Work on live projects to develop hands-on experience.

Updated Curriculum: Learn the latest tools and technologies used in data analytics.

Industry Mentors: Get guidance from professionals with expertise in analytics.

Career Support: Benefit from placement assistance and resume-building workshops.

A Day in the Life: PLC & SCADA Professionals vs. Data Analysts

Wondering what your day-to-day might look like in these fields? Let’s break it down.

PLC & SCADA Professionals

Oversee the functioning of automated systems in factories.

Troubleshoot machinery issues using SCADA interfaces.

Work closely with engineers to improve system efficiency.

Travel to various sites for system installations and maintenance.

Data Analysts

Analyze large datasets to uncover trends and patterns.

Create dashboards and reports for business leaders.

Collaborate with marketing, finance, and operations teams.

Stay updated on the latest data tools and industry practices.

Both roles require problem-solving skills, attention to detail, and a passion for technology.

Why Seldom India Stands Out

Choosing the right training institute is as crucial as selecting your career path. Here’s why Seldom India should be your first choice:

Tailored Programs: Courses are designed to meet the needs of beginners and professionals.

State-of-the-Art Facilities: Training is conducted in modern labs with the latest equipment.

Flexible Learning Options: Attend classes online or in-person based on your convenience.

Proven Track Record: Many Seldom India alumni have landed jobs at top companies.

Affordable Fees: Quality education doesn’t have to break the bank.

The Career Benefits of Specialized Training

Investing in PLC and SCADA training or a Data Analyst Course in Jaipur can open doors to high-growth careers. Here are just a few benefits:

High Demand: Industries need skilled professionals to navigate automation and data-driven strategies.

Competitive Salaries: Both fields offer attractive pay scales and growth potential.

Diverse Opportunities: Work across various sectors, from manufacturing to IT.

Global Scope: Skills like these are valued worldwide, offering international career prospects.

Real-Life Success Stories

At Seldom India, students don’t just learn; they thrive. Meet a few of our success stories:

Rohit Sharma, an electrical engineer, transitioned into a thriving career as an automation specialist after completing our PLC and SCADA training.

Pooja Verma, a mathematics graduate, landed a job as a data analyst at a leading e-commerce firm after mastering analytics tools through our course.

These stories prove that with the right training, the sky's the limit.

How to Enroll at Seldom India

Starting your journey with Seldom India is easy:

Visit our website to explore course details.

Contact our team for a free consultation.

Choose a schedule that works for you.

Begin your journey towards a rewarding career.

Final Thoughts: Invest in Your Future

Whether you’re drawn to the intricate world of industrial automation or the dynamic field of data analytics, Seldom India has the perfect training program for you. With expert guidance, hands-on experience, and a commitment to your success, we help you unlock your true potential.

Don’t wait—start building the career of your dreams with PLC and SCADA training or a data analyst course in Jaipur today.

0 notes

Text

Cognidel offers comprehensive training in PLC and SCADA, designed to prepare professionals for the fast-evolving world of industrial automation. These courses emphasize hands-on learning and real-world applications, covering a wide range of topics from the basics to advanced techniques in PLC (Programmable Logic Controller) programming and SCADA (Supervisory Control and Data Acquisition) systems.

0 notes

Text

IPCS GLOBAL KOCHI

IPCS Global Kochi is an ISO certified company that operates in several fields of education which includes Automation, BMS and CCTV, Embedded and IOT, Python and Data Science, Digital Marketing, Artificial Intelligence, Software Testing, Corporate Training, In Campus Training and Technical Partners. IPCS Global offers a wide range of goods to students including drives, sensors, DCS systems,Supervisory Control and Data Acquisition, HMI systems, and PLCs.

Software Testing

Master software testing from methodologies to test case execution. Their program enhances your skills with comprehensive training. Learn testing approaches, design test cases effectively, and gain hands-on experience. Become a proficient tester, ready for industry challenges. Elevate your career with IPCS Global today.

Digital Marketing

Enhance your online presence and become a digital marketing expert with their comprehensive course. Learn cutting-edge strategies, tools, and techniques to boost your brand's visibility and achieve exceptional results. Join IPCS Global and leverage the power of digital marketing to propel your brand's success.

Python

Explore with python and data science. Enrol in their Python course to begin an exceptional journey that will take you forward as an expert programmer. Their vast program thoughtfully covers the fundamentals and advanced elements of Python, providing you with the data and skills you need to succeed as a developer.

Industrial Automation

Explore industrial automation with their specialised course. Develop essential skills for success in this dynamic field through hands-on projects and real-world case studies. Gain practical experience and stay ahead in the ever-evolving world of industrial automation. Enrol now to propel your career forward with confidence.

Embedded System and IOT

Discover CCTV system fundamentals and delve into Building Management Systems (BMS) principles with IPCS Cochin's specialised course. Gain insights into surveillance technology and optimise building operations. Enhance your skills for the evolving security and facility management industries.

BMS and CCTV

Master CCTV system basics and explore Building Management Systems (BMS) principles with IPCS Cochin's specialised course. Dive into surveillance technology fundamentals and optimise building operations. Elevate your skills for evolving security and facility management industries.

Many people with IPCS GLOBAL training today work successfully in well known international corporations and they take precautions to guarantee total student satisfaction.

1 note

·

View note

Text

https://celestiallearning.com/courses/plc-programming-course-basic-level/

Title: "Unlocking Tomorrow: Celestial Learning's Robotics and Automation Courses Illuminate Pune's Future"

#basic and advance plc programming courses#plc programming courses in pune#plc programming courses#basic and advance robotics courses in pune

0 notes

Text

Career In Industrial Automation

IPCS GLOBAL KOTTAYAM

Kick-start Your Career in Industrial Automation with Our Premier Training Course Led by the Top Experts in Town!

Why Automation course?

Automation training courses are designed to equip professionals with the knowledge and skills needed to implement and manage automated systems in various industries. To resolve the automation and control issues, industries use the ever-changing technologies in control systems for efficient production or manufacturing processes. These requires the high quality and reliable control systems. New trends in industrial automation deals with latest control devices and communication protocols to control field devices like control valves and other final control elements. These courses cover a wide range of topics, from the basics of automation and control systems to advanced programming and robotics and is designed to teach individuals the skills and knowledge needed to work with automated systems and technologies. Industrial Automation is the use of control systems, including machines, actuators, sensors, processors, and networks to perform tasks, with the goal of automating production. The history of industrial automation started with simple conveyor belts pulling parts through an assembly line. Machines performed basic tasks and work that reduced manual labor. Today, industrial automation is a wide range of machines, actuators, sensors, processors, and networks that work to connect an industrial environment. From PLCs, AI, Machine Learning, and IIoT devices, modern industrial automation is focusing on the best way to leverage technology.

These courses cover a broad range of topics and are aimed at equipping students with the ability to design, implement, operate, and maintain automated processes in various industries. Here are some key aspects of automation training courses:

Introduction to Automation:

Basics of automation and its applications in different industries.

Overview of automation systems and components.

Control Systems:

Understanding control theory and its practical applications.

Learning about Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and other control systems.

Programming:

Writing and troubleshooting PLC programs.

Learning programming languages such as ladder logic, structured text, and function block diagrams.

Human-Machine Interface (HMI):

Designing and operating HMI systems.

Creating user-friendly interfaces for monitoring and controlling automated systems.

Supervisory Control and Data Acquisition (SCADA):

Implementing SCADA systems for real-time data acquisition and control.

Integrating SCADA with other automation systems.

Sensors and Actuators:

Understanding different types of sensors and their applications.

Learning about actuators and their role in automation.

Industrial Networking:

Setting up and managing industrial communication networks.

Ensuring secure and reliable data transmission.

Robotics:

Basics of robotic systems and their programming.

Implementing robots in automated production lines.

Safety and Standards:

Learning about safety standards and protocols in automation.

Ensuring compliance with industry regulations.

Advanced Topics:

Exploring advanced automation topics like AI integration, machine learning, and IoT.

Implementing predictive maintenance and other modern automation strategies.

Practical Applications:

Hands-on training with real-world automation systems and tools.

Project-based learning to apply theoretical knowledge.

Benefits of Industrial Automation:

Increased Productivity: Automation allows for continuous operation without breaks, leading to higher production rates.

Improved Quality: Automated systems ensure consistency and precision, reducing the likelihood of errors and defects.

Enhanced Safety: Automation minimizes human exposure to hazardous environments and reduces the risk of accidents.

Cost Savings: Reduced labor costs and improved efficiency lead to significant cost savings over time.

Data Collection and Analysis: Automated systems provide valuable data that can be used for performance analysis and process optimization.

Applications of Industrial Automation:

Manufacturing: Automation in assembly lines, machining, welding, and packaging.

Energy: Automation of power generation, distribution, and renewable energy systems.

Chemical and Pharmaceutical: Precise control of chemical reactions and drug manufacturing processes.

Food and Beverage: Automation in food processing, packaging, and quality control.

Automotive: Use of robots and automation in vehicle manufacturing and assembly.

Overall, industrial automation is a crucial component of modern manufacturing and production, driving efficiency, safety, and innovation across various sectors.

Features of Industrial Automation:

1. Identify Requirements

Needs Assessment: Determine the specific needs and goals of adding the new features. Consider factors such as increasing efficiency, enhancing safety, reducing costs, or improving quality.

Stakeholder Input: Gather input from all stakeholders, including operators, engineers, and management, to understand their requirements and expectations.

2. Conduct Feasibility Study

Technical Feasibility: Evaluate if the existing system can support the new features. Check for compatibility with current hardware and software.

Economic Feasibility: Analyze the cost-benefit ratio to ensure the investment is justified.

3. Design the Solution

System Architecture: Develop a detailed design of the new features, including hardware components (sensors, actuators, PLCs, etc.), software modules, and network architecture.

Integration Plan: Plan how the new features will integrate with the existing system. Consider interoperability and data flow between new and old components.

4. Select Appropriate Technologies

Hardware: Choose reliable and compatible hardware components such as advanced sensors, actuators, and controllers.

Software: Select suitable software for control, monitoring, and data analysis. Ensure it supports the new features and integrates seamlessly with existing software.

Communication Protocols: Use standard communication protocols (e.g., Modbus, OPC UA, Ethernet/IP) to ensure interoperability and scalability.

5. Develop and Test

Prototyping: Create a prototype to test the new features in a controlled environment. This helps identify potential issues and make necessary adjustments.

Simulation: Use simulation tools to model and test the new features before actual implementation.

6. Implementation

Installation: Install the new hardware components and configure the software. Ensure proper wiring, connections, and placement of sensors and actuators.

Integration: Integrate the new features with the existing system. Ensure seamless communication and data exchange between old and new components.

7. Testing and Validation

Functional Testing: Test the new features to ensure they operate as intended. Check for correct functionality, accuracy, and performance.

Safety Testing: Conduct safety tests to ensure the new features do not introduce hazards or risks.

User Acceptance Testing: Get feedback from end-users to ensure the new features meet their needs and expectations.

8. Training and Documentation

User Training: Provide training sessions for operators and maintenance personnel on the new features. Ensure they understand how to use and maintain them.

Documentation: Update system documentation to include details of the new features, including design, operation, and troubleshooting guides.

9. Deployment and Monitoring

Deployment: Roll out the new features in the live environment. Ensure minimal disruption to ongoing operations.

Monitoring: Continuously monitor the new features to ensure they are performing optimally. Use feedback to make any necessary adjustments.

10. Maintenance and Support

Regular Maintenance: Schedule regular maintenance to ensure the new features continue to function correctly and efficiently.

Support: Provide ongoing support to address any issues or improvements needed.

Additional Considerations:

Scalability: Ensure the new features can be scaled up or adapted to future needs.

Security: Implement robust security measures to protect the system from cyber threats.

Compliance: Ensure the new features comply with relevant industry standards and regulations.

By following these steps, you can systematically add new features to your industrial automation system, ensuring they are integrated smoothly and deliver the desired benefits.

Why IPCS Global?

IPCS Global offers a comprehensive automation course designed to provide you with the expertise and skills needed to excel in the field of industrial automation. Led by seasoned industry professionals, our course covers a wide range of topics, including PLC programming, SCADA systems, HMI, VFD, and more. With a strong emphasis on hands-on training and real-world applications, IPCS Global ensures that you gain practical experience and a deep understanding of automation technologies. Join us to transform your career and become a proficient automation specialist with the guidance of the best experts in the industry.

Available Automation Courses in IPCS Global Kottayam

Automation System Enginner

Professional Diploma in Industrial Automation

Advanced Automation System Professional

VFD Installation Professional

Advanced VLC Program Professional

IPCS Global Kottayam Branch is famous for Automation course in kottayam. We Provide PLC, SCADA, DCS, HMI, VFD, Panel Design & Electrical Controls with our state-of-the-art Training Programs. Our courses cater to both freshers and professionals, ensuring they meet and exceed industry expectations. Explore our custom-built programs tailored for freshers, professionals, and industry experts. Explore your potential and thrive in the competitive world of automation. Upon completing the Automation Course in Kottayam guarantees better job opportunities. we also assist companies with their projects, resolving any problems in Industrial and Marine PLC, SCADA, DCS, and Industrial 4.0

Launch Your Career in Automation with IPCS Global's Industry-Leading Automation Training Course!

0 notes

Text

Career in Industrial Automation | IPCS GLOBAL Kottayam

IPCS GLOBAL KOTTAYAM

Kick-start Your Career in Industrial Automation with Our Premier Training Course Led by the Top Experts in Town!

Why Automation course?

Automation training courses are designed to equip professionals with the knowledge and skills needed to implement and manage automated systems in various industries. To resolve the automation and control issues, industries use the ever-changing technologies in control systems for efficient production or manufacturing processes. These requires the high quality and reliable control systems. New trends in industrial automation deals with latest control devices and communication protocols to control field devices like control valves and other final control elements. These courses cover a wide range of topics, from the basics of automation and control systems to advanced programming and robotics and is designed to teach individuals the skills and knowledge needed to work with automated systems and technologies. Industrial Automation is the use of control systems, including machines, actuators, sensors, processors, and networks to perform tasks, with the goal of automating production. The history of industrial automation started with simple conveyor belts pulling parts through an assembly line. Machines performed basic tasks and work that reduced manual labor. Today, industrial automation is a wide range of machines, actuators, sensors, processors, and networks that work to connect an industrial environment. From PLCs, AI, Machine Learning, and IIoT devices, modern industrial automation is focusing on the best way to leverage technology.

These courses cover a broad range of topics and are aimed at equipping students with the ability to design, implement, operate, and maintain automated processes in various industries. Here are some key aspects of automation training courses:

Introduction to Automation:

Basics of automation and its applications in different industries.

Overview of automation systems and components.

Control Systems:

Understanding control theory and its practical applications.

Learning about Programmable Logic Controllers (PLCs), Distributed Control Systems (DCS), and other control systems.

Programming:

Writing and troubleshooting PLC programs.

Learning programming languages such as ladder logic, structured text, and function block diagrams.

Human-Machine Interface (HMI):

Designing and operating HMI systems.

Creating user-friendly interfaces for monitoring and controlling automated systems.

Supervisory Control and Data Acquisition (SCADA):

Implementing SCADA systems for real-time data acquisition and control.

Integrating SCADA with other automation systems.

Sensors and Actuators:

Understanding different types of sensors and their applications.

Learning about actuators and their role in automation.

Industrial Networking:

Setting up and managing industrial communication networks.

Ensuring secure and reliable data transmission.

Robotics:

Basics of robotic systems and their programming.

Implementing robots in automated production lines.

Safety and Standards:

Learning about safety standards and protocols in automation.

Ensuring compliance with industry regulations.

Advanced Topics:

Exploring advanced automation topics like AI integration, machine learning, and IoT.

Implementing predictive maintenance and other modern automation strategies.

Practical Applications:

Hands-on training with real-world automation systems and tools.

Project-based learning to apply theoretical knowledge.

Benefits of Industrial Automation:

Increased Productivity: Automation allows for continuous operation without breaks, leading to higher production rates.

Improved Quality: Automated systems ensure consistency and precision, reducing the likelihood of errors and defects.

Enhanced Safety: Automation minimizes human exposure to hazardous environments and reduces the risk of accidents.

Cost Savings: Reduced labor costs and improved efficiency lead to significant cost savings over time.

Data Collection and Analysis: Automated systems provide valuable data that can be used for performance analysis and process optimization.

Applications of Industrial Automation:

Manufacturing: Automation in assembly lines, machining, welding, and packaging.

Energy: Automation of power generation, distribution, and renewable energy systems.

Chemical and Pharmaceutical: Precise control of chemical reactions and drug manufacturing processes.

Food and Beverage: Automation in food processing, packaging, and quality control.

Automotive: Use of robots and automation in vehicle manufacturing and assembly.

Overall, industrial automation is a crucial component of modern manufacturing and production, driving efficiency, safety, and innovation across various sectors.

Features of Industrial Automation:

1. Identify Requirements

Needs Assessment: Determine the specific needs and goals of adding the new features. Consider factors such as increasing efficiency, enhancing safety, reducing costs, or improving quality.

Stakeholder Input: Gather input from all stakeholders, including operators, engineers, and management, to understand their requirements and expectations.

2. Conduct Feasibility Study

Technical Feasibility: Evaluate if the existing system can support the new features. Check for compatibility with current hardware and software.

Economic Feasibility: Analyze the cost-benefit ratio to ensure the investment is justified.

3. Design the Solution

System Architecture: Develop a detailed design of the new features, including hardware components (sensors, actuators, PLCs, etc.), software modules, and network architecture.

Integration Plan: Plan how the new features will integrate with the existing system. Consider interoperability and data flow between new and old components.

4. Select Appropriate Technologies

Hardware: Choose reliable and compatible hardware components such as advanced sensors, actuators, and controllers.

Software: Select suitable software for control, monitoring, and data analysis. Ensure it supports the new features and integrates seamlessly with existing software.

Communication Protocols: Use standard communication protocols (e.g., Modbus, OPC UA, Ethernet/IP) to ensure interoperability and scalability.

5. Develop and Test

Prototyping: Create a prototype to test the new features in a controlled environment. This helps identify potential issues and make necessary adjustments.

Simulation: Use simulation tools to model and test the new features before actual implementation.

6. Implementation

Installation: Install the new hardware components and configure the software. Ensure proper wiring, connections, and placement of sensors and actuators.

Integration: Integrate the new features with the existing system. Ensure seamless communication and data exchange between old and new components.

7. Testing and Validation

Functional Testing: Test the new features to ensure they operate as intended. Check for correct functionality, accuracy, and performance.

Safety Testing: Conduct safety tests to ensure the new features do not introduce hazards or risks.

User Acceptance Testing: Get feedback from end-users to ensure the new features meet their needs and expectations.

8. Training and Documentation

User Training: Provide training sessions for operators and maintenance personnel on the new features. Ensure they understand how to use and maintain them.

Documentation: Update system documentation to include details of the new features, including design, operation, and troubleshooting guides.

9. Deployment and Monitoring

Deployment: Roll out the new features in the live environment. Ensure minimal disruption to ongoing operations.

Monitoring: Continuously monitor the new features to ensure they are performing optimally. Use feedback to make any necessary adjustments.

10. Maintenance and Support

Regular Maintenance: Schedule regular maintenance to ensure the new features continue to function correctly and efficiently.

Support: Provide ongoing support to address any issues or improvements needed.

Additional Considerations:

Scalability: Ensure the new features can be scaled up or adapted to future needs.

Security: Implement robust security measures to protect the system from cyber threats.

Compliance: Ensure the new features comply with relevant industry standards and regulations.

By following these steps, you can systematically add new features to your industrial automation system, ensuring they are integrated smoothly and deliver the desired benefits.

Why IPCS Global?

IPCS Global offers a comprehensive automation course designed to provide you with the expertise and skills needed to excel in the field of industrial automation. Led by seasoned industry professionals, our course covers a wide range of topics, including PLC programming, SCADA systems, HMI, VFD, and more. With a strong emphasis on hands-on training and real-world applications, IPCS Global ensures that you gain practical experience and a deep understanding of automation technologies. Join us to transform your career and become a proficient automation specialist with the guidance of the best experts in the industry.

Available Automation Courses in IPCS Global Kottayam

Automation System Enginner

Professional Diploma in Industrial Automation

Advanced Automation System Professional

VFD Installation Professional

Advanced VLC Program Professional

IPCS Global Kottayam Branch is famous for Automation course in kottayam. We Provide PLC, SCADA, DCS, HMI, VFD, Panel Design & Electrical Controls with our state-of-the-art Training Programs. Our courses cater to both freshers and professionals, ensuring they meet and exceed industry expectations. Explore our custom-built programs tailored for freshers, professionals, and industry experts. Explore your potential and thrive in the competitive world of automation. Upon completing the Automation Course in Kottayam guarantees better job opportunities. we also assist companies with their projects, resolving any problems in Industrial and Marine PLC, SCADA, DCS, and Industrial 4.0

Launch Your Career in Automation with IPCS Global's Industry-Leading Automation Training Course!

1 note

·

View note

Text

Best PLC Training Institute In Pune

Welcome to Perfecto Robotics Institute, we provide the Best PLC Training In Pune. Our institute has very advanced courses along with the most modern facilities. We do cater to any of your requirements. You might be a fresher or an old-time professional; our institute will give you what you want.

Firstly, Perfecto Robotics Institute offers training led by industry experts.

Students actively participate in practical exercises, which develop a thorough understanding of PLC systems. Additionally, our instructors emphasize real-world applications, preparing graduates for the challenges of various technological environments.

What Is PLC Training?

Prepares technicians to take full advantage of vendor training on specific equipment. We cover the basic operating principles of all PLCs, their inputs and outputs, programming, maintenance, and networking. This course has no prerequisites.

What is PLC?

PLC is the abbreviated form of Programmable Logic Control.

PLC is an industrialized computer, which is in charge of control functions of different sorts, beginning with the inputs, outputs, and central processing units.

What are examples of PLCs?

ManufacturingOil and GasAutomotiveFood and BeverageUtilitiesBuilding AutomationPharmaceuticals

What are the main components of PLC?

CPU (Central Processing Unit)Input / Output (I/O) ModulesPower SupplyMemoryProgramming Terminal or ComputerCommunication PortsExpansion Modules

Why is PLC used?

Increased dependabilitySafetyReal-time TrackingAble to work 365 days a year 24/7RepeatabilityReduced energy consumptionSpace requirements are reduced.increased user experience flexibilityYou can handle various devices at the same time.Increased machine connectivity and procedure automationManufacturing processes will be increased.Reduced operational costs.

Additionally, PLC services include troubleshooting and repair. In the event of a malfunction or malfunction, skilled technicians diagnose the problem, as well as replace the faulty component if necessary. PLC services also include immediately restoring PLC functionality to minimize production disruptions.

In conclusion, for the Best PLC Training Institute In Pune, Perfecto Robotics Institute is the best choice. With our expertise, dedication, and emphasis on quality and transparency, we guarantee solutions that exceed your expectations. Contact us today to discuss your PLC needs and discover why Perfecto Robotics Institute is the perfect choice for your requirements.

0 notes

Text

Best PLC Training Institute In Pune

Welcome to Perfecto Robotics Institute, we provide the Best PLC Training In Pune. Our institute is known for its advanced courses and modern facilities. Whether you are a beginner or an experienced professional looking to enhance your skills. We offer customized programs to meet your needs.

Firstly, Perfecto Robotics Institute offers training led by industry experts.

Students actively participate in practical exercises, which develop a thorough understanding of PLC systems. Additionally, our instructors emphasize real-world applications, preparing graduates for the challenges of various technological environments.

What Are PLC Training?

Prepares technicians to take full advantage of vendor training on specific equipment. We covers the basic operating principles of all PLCs, their inputs and outputs, programming, maintenance, and networking. This course has no prerequisites.

What is PLC?

PLC stands for Programmable Logic Control.

PLC is a type of industrialized computer that is responsible for controlling various functions, including inputs, outputs, and central processing units.

What are examples of PLCs?

Manufacturing

Oil and Gas

Automotive

Food and Beverage

Utilities

Building Automation

Pharmaceuticals

What are the main components of PLC?

CPU (Central Processing Unit)

Input / Output (I/O) Modules

Power Supply

Memory

Programming Terminal or Computer

Communication Ports

Expansion Modules

Why is PLC used?

increased dependability

Safety

Real-time Tracking

Able to work 365 days a year 24/7

Repeatability

Reduced energy consumption

Space requirements are reduced.

increased user experience flexibility

You can handle various devices at the same time.

Increased machine connectivity and procedure automation

Manufacturing processes will be increased.

Reduced operational costs

0 notes

Text

UEE40420 Certificate IV in Electrical Instrumentation – Improve your Skills as a Certified Electrician

Looking beyond the basics, the Electrical Instrumentation course delves into advanced concepts crucial for thriving in today's dynamic industrial landscape. Participants explore cutting-edge technologies, such as advanced PLC programming techniques and the integration of smart sensors for enhanced process control and optimization.

Moreover, the course emphasizes industry best practices in safety protocols and regulatory compliance, ensuring that graduates are well-equipped to navigate complex work environments with confidence and proficiency.

Why choose the Instrumentation course?

What sets��PMV's training apart is its commitment to providing a truly immersive learning experience. The state-of-the-art training centers in Perth, Karratha, and Adelaide boast fully equipped instrumentation and control skids that replicate real-world industrial settings. This hands-on approach allows students to gain practical experience in a safe and controlled environment, preparing them to tackle the challenges of the field head-on.

In addition to technical skills, the course also emphasizes soft skills development, such as communication, teamwork, and problem-solving. These skills are invaluable for success in the field, where collaboration and adaptability are often as critical as technical expertise. Contact PMV for Instrumentation and Control Courses

Furthermore, PMV's industry-aligned curriculum ensures that graduates are not only technically proficient but also familiar with the latest industry standards and practices. This alignment with industry requirements enhances the employability of graduates, making them highly sought after by employers across various sectors.

Whether you're a seasoned professional looking to upskill or a newcomer to the field seeking to kickstart your career, the UEE40420 Certificate IV in Electrical Instrumentation at PMV offers a comprehensive and practical learning experience that sets you up for success in the exciting and rewarding field of instrumentation and control.

Read More:

1. What are the key components of nationally accredited training in hazardous area classification and design?2. What specific qualifications are necessary for someone to be considered competent in high voltage switching?3. What are the top 10 common mistakes that individuals should avoid when setting up solar grid-connected systems?4. What are some common types of hazardous area equipment, and how are they typically utilized in industrial settings?5. What are the key requirements and procedures for conducting an EEHA audit and ensuring compliance with AS/NZS 3000:2018 standards?

CONTACT US:

Website: https://www.pmv.net.au/

Email: [email protected]

Perth

10/22 Shields Crescent, Booragoon, WA, 6154 Contact no.: (08) 9317 2146

Adelaide

1042 Port Road, Albert Park, SA, 5014 Contact no.: (08) 9317 2147

Karratha

Unit 48, 5-15 Sharpe Ave, Karratha WA, 6714 Contact no.: (08) 9317 2147

Also, follow us:

Youtube: https://www.youtube.com/@PmvNetAu/

Facebook: https://www.facebook.com/pmvaustralia/

Instagram: https://www.instagram.com/pmv.australia/

#pmv training#pmv#Electrical Instrumentation#uee40420#advanced PLC programming#instrumentation courses perth#electrical instrumentation course#certificate iv in instrumentation

0 notes