#beryllium copper strip

Text

Beryllium Copper Strip Suppliers | Copper Strip | Copper Beryllium Foil

Looking for reliable Beryllium Copper Strip Suppliers? Look no further! Our website offers a wide range of Copper Strip options, including Copper Beryllium Foil. We provide high-quality products that are durable and efficient for various industrial applications. Explore our website to learn more about our Copper Strip selection and find the perfect fit for your project needs.

#copper strip#beryllium copper strip#beryllium copper strip suppliers#beryllium copper coil#copper beryllium foil#steel strips#copper strip price

0 notes

Text

Unveiling the Intricacies of the Hairspring in Watchmaking

In the intricate world of watchmaking, every tiny component plays a vital role in ensuring precision and accuracy. Among these components, the hairspring stands out as a marvel of engineering, essential for regulating the oscillations of a watch's balance wheel. Let's delve into the fascinating realm of the hairspring, where precision meets craftsmanship in the pursuit of horological perfection. The Essence of the Hairspring At the heart of every mechanical watch movement lies the balance wheel, a delicate oscillating component that divides time into equal segments. The hairspring, often referred to as the balance spring, is a tiny spiral-shaped spring that controls the oscillations of the balance wheel, regulating the timing of the watch with remarkable accuracy. Precision in Design Crafted from thin strips of specialized alloy, typically a form of steel or a copper-beryllium alloy, the hairspring undergoes meticulous manufacturing processes to achieve its desired properties. Its precise dimensions, shape, and elasticity are carefully calibrated to ensure consistent and reliable timekeeping, even in the face of external factors such as temperature changes and mechanical shocks. The Role of the Hairspring As the balance wheel swings back and forth, the hairspring exerts a restoring force, pulling the balance wheel back to its equilibrium position with each oscillation. This delicate interplay between the balance wheel and the hairspring determines the watch's beat rate, or the number of oscillations per hour, ultimately defining its accuracy. Fine-Tuning for Performance Watchmakers meticulously adjust the hairspring to achieve the desired rate of oscillation, often through processes such as bending or shaping the spring's coils. This fine-tuning ensures that the watch maintains accurate timekeeping under various conditions, making the hairspring a critical component in the pursuit of horological excellence. Preserving the Legacy Despite advances in technology, the craftsmanship and precision required to manufacture hairsprings remain a hallmark of traditional watchmaking. From the delicate art of hand-crafting to the cutting-edge techniques of modern production, the hairspring continues to embody the essence of horological mastery, ensuring that each tick of a mechanical watch is a testament to centuries of expertise and innovation.

0 notes

Text

Constant Force Spring Manufacturers in India

Nexim Alloys is the primary manufacturers, stockist, supplier & exporter of Constant Force Spring. Consistent Force springs are an extraordinary variety of enlargement spring. They involve a twisting of strip material with manufactured incurvature. Right when the strip is widened the common weight contradicts the stacking power, correspondingly as in a run of the mill development spring, yet at an about steady rate. A constant force Spring is an excellent device for applications where a constant load is required. These Constant Force spring have its application in cable retractors, door closers, tool head returns, cabinet furniture component, electric motors, appliances and more. These Spring are made using best quality raw material and do match national & international quality standard and this helps us to have high demand in the market from our customers. When it comes to packaging it is done with tremendous care because we know the challenges faced while import & export of product hence we see through it that the products are delivered in good conditions without any harm to it. These Springs are made in different size, dimension & thickness & are delivered to customers as per their need & requirement.

Specifications :

Material Stainless Steel High CarbSizes

Usage Garage, Electrical Connection, Earthing, Fire Damper, Railway Window, Industrial

Dimension thickness 0.005 to 0.70mm width 3.00 to 35.mm

Guide to Mounting Constant Force Spring :

A Constant Force Spring is usually mounted by first tightly wrapping it on a drum, then attaching the free end to the loading force such as in a counterbalance application. This relationship can also be reversed.

The drum diameter should be 10% to 20% larger than its natural inside diameter.

One and one-half wraps should remain on the drum at maximum extension.

The strip becomes unstable at long extensions and should be guided to prevent twisting or kinking on recoil.

Idler pulleys must be larger in diameter than the natural diameter and should never be used to cause back-bending against the natural radius of curvature.

Belt webbing, tape measures and dog leads, seat recliner, window regulator mechanisms etc Diameter. 10 to 6.00 in2.54 to 152.4 mm

Free Length. 25 to 120 inch6.35 to 3048 mm

Wire Size. 010 to .375 in.254 to 9.525 mm Direction of Winding Right Hand Left Hand Optional

Loop Types Machine Hooks Extended Single Full LoopSide Hooks Cross Over Double Full Loop

Material Beryllium Copper Music WireInconel Chrome Silicon Chromium Vanadium Phosphor Bronze Stainless Steel 302Stainless Steel 304Stainless Steel 316FinishPlainBlack Oxide Painted Cadmium Passivate Zinc Gold Zinc Silver

0 notes

Video

youtube

Big Size Beryllium Copper bar plates sheet strip ring C17200 C17300 C175...

0 notes

Photo

Beryllium Copper Alloy - Busby Metals carries the largest inventory globally of copper beryllium alloy, in a variety of forms including rod, bar, wire, tube, strip and plate forms. With applications in demanding fields such as aerospace, automotive design, industrial machining, and petroleum drilling, copper beryllium demonstrates its superior strength in numerous ways.

0 notes

Text

How Tech Etch Products Help with EMI RFI Shielding Issues

Electronic devices need robust protection from outside interferences to continue performing accurately. Tech Etch is an industry leader in EMI RFI shielding products. Through their Innovation Center, clients have access to advanced solutions and fast turn times. For more than 60 years, this company has worked to become a one-stop shop for design input, prototyping, and production.

Tech Etch Products Resolve Complex EMI RFI Shielding Issues

Sourcing the right EMI RFI shielding product is what it takes to secure your electronics from electromagnetic interference (EMI) and radio frequency interference (RFI) problems. Consider these options from Tech Etch for your company’s electronic device protection needs:

1. Fingerstock Gaskets

When looking for gaskets that can withstand frequent opening and closing, Tech Etch fingerstock gaskets are the right choice. You will find a variety of lengths and sizes. For example, you can find strips between 16 and 24 inches in length, have custom lengths cut, or choose a continuous roll up to 35 feet long. Additionally, you can find them in uncompressed heights of 0.03” to 0.44”.

These gaskets are found in beryllium copper (BeCu) or stainless steel. When looking for effective EMI RFI shielding over a broad range of frequencies with extreme durability, choose BeCu. It has maximum spring properties to hold up under fatigue resistance. Stainless steel is an economical alternative that is stiffer than copper and does not have electrical conductivity. Stainless steel is a good choice when working with a product with low-profile strips and twisted contacts.

Tech-Etch meets customer demands by producing the “V” series of Variable Finger Snap-on BeCu gaskets, which increase the EMI shielding effectiveness up to 100db attenuation.

0 notes

Text

Why thin wall cup mould so expensive?

Why thin wall cup mould price is so high? General speaking, thin wall cup mould are using better steel, hot runner, better cooling, better venting and better demolding effectiveness.

The thin wall cup mould runs on high speed machine which needs withstand high pressure during cup molding, so the mould moving plate and fixed plate thickness are thicker than common mould. There need many interlocks inside the thin wall mould to ensure accuracy and pillar support to avoid deform and eccentric. The plastic airline cup mould need use high hardness steel, high-wear and high-erosion with HRC 55 or above. This means thin wall mould steel cost is higher.

The hot runner design is larger than the common plastic moulds, and at the same time, need limit the melt residence tome to prevent the resin degradation. When the mould is mult-cavities, the gating balance is much higher than that of common molds. Which means thin wall cup mould hot runner cost is higher.

Thin-walled products do not withstand the large residual stresses due to heat transfer irregularities like traditional wall thickness parts. In order to ensure the dimensional stability of the product, and to control the shrinkage and warpage within an acceptable range, it is necessary to strengthen the cooling of the mold to ensure the cooling balance. Which means need better cooling design to enhance the cooling effect, adding high conductivity metal inserts where necessary to accelerate heat transfer, like BeCu beryllium copper. The cooling cost is higher than common moulds.

Due to the short filling time and high injection speed, it is very important to fully exhaust the mold, especially the exhaust in the flow front gathering area, to prevent air trap. The air is usually discharged through mould cores, rams, ribs, studs, and parting surfaces.

The airline cup walls and ribs are very thin, they are very easy to damage, and the shrinkage in the thickness direction is small, the ribs and other small structures are hard to separate, to avoid sticking, there need use more ejector pins when thin wall injection molding.

In a word, thin wall mould structure is more complicated than common moulds. That’s why the thin wall cup mould is so expensive.

Cutlery mould exhaust problem

In the process of producing cutlery mould, sometimes will have unfilled parts, air bubbles etc, this is caused by air exhaust.

1. The source of air in the injection cutlery mold.

(1) The air contained in the gating system and the mould cavity. (2) Some raw materials contain moisture that is not removed by drying, and they are vaporized into water vapor at a high temperature. (3) Air generated by decomposition of some unstable plastics due to excessive temperature during injection molding. (4) Air formed by volatilization or chemical reaction of certain additives in plastic raw materials.

Poor exhaust of the knife and fork mold will bring a series of hazards to the quality of the plastic parts. The main performance is as follows:

(1) In the injection molding process, the melt will replace the air in the cavity. If the air is not discharged in time, the melt filling will be difficult, resulting in insufficient injection volume to fill the cavity.

(2) Excluding the unsatisfactory air will form a high pressure in the cavity and penetrate into the plastic inside under a certain degree of compression, resulting in quality defects such as pores, voids, tissue sparseness, and silver streaks.

(3) Due to the high compression of the air, the temperature in the cavity rises sharply, which causes decomposition and burning of the surrounding melt, causing local carbonization and charring of the plastic part. It mainly occurs at the junction of the two melts at the gate flange.

(4) The air is not well removed, so that the melt velocity entering each cavity is different, so flow marks and fusion marks are easily formed, and the mechanical properties of the plastic parts are lowered.

(5) Due to the obstruction of air in the cavity, the filling speed will be reduced, the molding cycle will be affected, and the taxation efficiency will be reduced.

Distribution of bubbles in plastic parts

(1) The bubbles generated by the accumulation of air in the mould cavity of the cutlery spoon are often distributed on the opposite part of the gate.

(2) Bubbles generated by decomposition or chemical reaction in the plastic raw material are distributed along the thickness of the plastic part.

(3) The bubbles generated by the vaporization of residual water in the plastic raw material are irregularly distributed on the entire plastic part.

Injection molding is a process in which a molten plastic is injected into a closed mold having a relatively low temperature through a nozzle under high pressure. Both thermoplastics and thermosets can be injection molded. It can be used to make various box-type packaging buckets and pails, such as various pails boxes and small boxes mould. For box-type packaging containers, China bucket mold manufacturers will consider the following aspects in bucket mould structural design.1. The wall thickness of the

bucket mould

The design of the wall thickness mainly considers three aspects: one is thickness; the other is uniformity; the third is gentle transition.1 Thickness: The wall thickness of the bucket is mainly determined by its use, plastic type, structure and so on. For thermoplastics, generally not less than 0. 6mm, often choose 2~4mm; for thermosetting plastics, because of its poor fluidity, the thickness is larger, the small pieces are 1. 6~2. 5ram, the large pieces are 3. 2 ~ 8mm, the maximum is no more than 10mm.2 Uniformity: The uniformity of wall thickness has a great influence on the quality of the bucket. If the thickness difference of a bucket is too large, the shrinkage will be uneven, causing defects such as deformation and crack. Therefore, the structure should be designed with an equal thickness structure.3 Smooth transition: In some buckets, some parts must have different thicknesses due to structural requirements, such as the bucket turning point. At this time, a gentle transition should be adopted to avoid the sudden change of the section.2. Improve stiffness of the bucketThe plastic is relatively flexible, the bucket is made of poor rigidity, and the turnover box type container sometimes has a large load capacity, so various measures for improving the rigidity should be adopted in the structure.1 Add reinforcement: Reinforcement can enhance the strength and rigidity of the container. The basic requirements for the ribs are: the number should be more, the wall thickness should be thin, the height should be short, and the slope should be sufficient. The bottom of the rib should be a circular arc transition. The direction of the rib should be consistent with the flow direction to improve the plastic. toughness;2 Improve the shape: the box-shaped bucket is mostly rectangular thin-walled parts, which are easy to be deformed. Various reinforcement measures should be taken to slightly extend the four side walls of the bucket to improve the rigidity; it is a strip shape on the side wall to prevent distortion. Enhancement; edge reinforcement at the edge of the bucket to prevent deformation of the mouth; bottom reinforcement at the bottom of the bucket designed in a corrugated, arched shape.3 Reasonable support: The bottom area of the box-shaped bucket is large, but it is unreasonable to use the whole bottom surface as the support. Because the bottom is slightly curved, it is not flat. Therefore, the surface support should be changed into a line support or a point support, and the convex side support (ie, the line) Support); raised foot support (ie point support); the height of the protrusion is generally 0. 3 ~ 0. 5mm.4 Corner: The corner is the intersection of two faces or three faces. Regardless of the shape of the bucket, the intersection of the faces must be rounded, which can greatly improve the rigidity of the bucket and improve the plastic filling model. Sex, and can disperse stress and reduce deformation.3. Demoulding slopeIn order to facilitate the demolding of the molded part, a suitable draft angle must be considered when designing the bucket. The draft is too small, the demoulding is difficult, and the surface of the bucket is damaged; if it is too large, the dimensional accuracy is affected.The draft angle varies depending on the shape of the plastic part, the type of plastic, the mold structure, the surface roughness, the molding method, and the like. Generally speaking, the commonly used slope of the plastic part along the demolding direction is 1o~1.5o, and the minimum is not less than 0.5o.

Household molds are a form of fungus. There are many different types, and they can occur both indoors and outdoors.

Molds produce spores, which spread by floating around in the air. Mold spores are present in all indoor environments. There is no way to prevent spores, and they can persist in conditions where mold itself cannot grow.

Mold spores thrive in environments that are moist and warm, so when they land on a damp spot, they begin to grow.

Molds can grow on a variety of different surfaces, including fabric, paper, wood, glass, and plastic. As they grow, they may digest the material they are growing on.

0 notes

Text

How e waste is recycled in India

Technology has become an important a part of our lives. Each and each individual also as organizations upgrade us! Starting from latest smartphones or a laptop or else tablet, we will not rest until we purchase the upgraded model of the gadgets available in the market. No doubt we've made our life easier and cozy with the access to modern gadgets, but have you ever ever imagined what happens to those old and outdated gadgets. How e-waste is recycled in India? Well, they eventually become electronic waste or e-waste.

If you're new this term, you want to be wondering what's e-waste?

E-Waste is defined because the electronics products that are obsolete or no more needed. It has become a luxury to have quite one television receiver alternatively smartphone. Besides this, there are numerous multinational companies worldwide those that throw away huge amount of old equipment and replace them with new ones, adding to the e-waste menace.

Even one mobile becomes a hazard to the earth that's fighting a losing battle against global warming? These wastes also can lead serious health also as environmental issues. Numerous electronics goods like beam tube TV sets, computers, mobile phones, contain toxic elements like beryllium, lead, cadmium etc. in large amounts that pose serious health risks.

The recycling processes of e-waste are quite hazardous. PCBs are scrapped by acid bath as well as de-soldering. Plastics wont to make keyboards also as other components are outmoded by chemical stripping using nitric also as acid , copper wires utilized in computers are burnt as well as stripped in the open to obtain copper, thus resulting in severe air pollution.

Virogreen is the e waste recycling in india ,recycles ewaste in an efficient manner.

The company may be a government authorized e waste recyclers in bangalore puts effort on systematic electronics reuse also as responsible recycling.

Three processes of E-waste management in India

Reduce – avoid buying products that plays a touch importance in our lifestyle . Avert purchasing gadgets as a standing of symbol.

Return – when bored with your old phone, do not throw it; instead return it to the manufacturer. There are a couple of brands that ensure their old products are returned after usage for recycle. If there is no recycling company in your vicinity, try donating or else selling online.

Recycle – Fragment that are usually buried alternatively cremated are often directed to recycling centers for conversion into raw materials which will help conserve finite natural resources.

Virogreen is one of the leading e-waste disposal and pick up near me that is becoming popular due to its unique e-waste management treatments and techniques. We also offer complete data destruction program and ensure each of your device is totally cleaned before destruction.

0 notes

Text

Beryllium Copper Market With Emerging Trends And Revenue Estimation By 2027

Data Lab Forecast, one of the world’s prominent market research firms has released a new report on Beryllium Copper Market. The report is full of crucial insights on the market which will help the clients in making correct business decisions. This research will help both existing and new aspirants for Beryllium Copper Market to figure out and study market requirements, market size, market share, growth and competition. This market report offers an overall scope of the market which includes future supply and demand scenarios, changing market trends, high growth opportunities, and in-depth analysis of the future prospects of the market.

The recently published Beryllium Copper market report helps readers in understanding the factors that will impel the industry growth in the forthcoming years, as well as the challenges and threats that are likely to obstruct the progression. The study maps out the various regions where business has thrived while highlighting the potential areas for expansion. Beryllium Copper data documented in the study includes market share, market size, application spectrum, market trends, supply chain, and revenue graph.

For More Information, Get a Sample PDF @ https://www.datalabforecast.com/request-sample/84661-beryllium-copper-market

Beryllium Copper Market with 100+ market data Tables, Pie Chat, Graphs & Figures spread through Pages and easy to understand detailed analysis. The information is gathered based on modern floats and requests identified with the administrations and items.

Competitive Landscape:

Leading players operating in the global Beryllium Copper Market include Key Manufacturers Analysis: Materion, NGK, ULBA, NBM Metals, IBC Advanced Alloys, Belmont Metals, CNMNC, FHBI, Jinfeng Metal, Lanfeng Non-ferrous Metal, Yinke, Shenyang Kehang Metal.

Detailed Segmentation:

Global Beryllium Copper Market, By Product Type:

⇛ Rod, Bar, Wire, Tube, Plate, Strip, Forgings.

Global Beryllium Copper Market, By End User:

⇛ Plastic Molds & Tooling, Electronic Springs & Connectors, Oil & Gas Equipment Components.

Data Lab Forecast, understand the economic impact on Beryllium Copper markets. Using our holistic market research methodology, we are focused on aiding your business sustain and grow during COVID-19 pandemics. With deep expertise across various industries-no matter how large or small- and with a team of highly experienced and dedicated analysts, we will offer you an impact analysis of coronavirus outbreak across industries to help you prepare for the future.

We are currently offering Quarter-end Discount to all our high potential clients and would really like you to avail the benefits and leverage your analysis based on our report.

Avail 30-50% Discount on various license type on immediate purchase (Use Corporate email ID to Get Higher Priority) @ https://www.datalabforecast.com/request-discount/84661-beryllium-copper-market

Beryllium Copper Market

10 Key Benefits of Beryllium Copper Market Research Report:

• It helps businesses strengthen their position.

• It minimises any investment risk.

• It identifies potential threats and opportunities.

• It helps to discover yours and your competitor’s strengths and weaknesses.

• It facilitates strategic planning.

• It helps in spotting emerging trends.

• It assists businesses to stay ahead of the competition.

• It provides revenue projections.

• It focuses on customer needs and demands.

• It helps to evaluate the success of a business against benchmarks.

Top-down and bottom-up approaches were used to validate the size of the global Beryllium Copper market and estimate the size of various other dependent submarkets. Major players in the market were identified through secondary sources secondary sources, directories and databases. Secondary research included the study of the annual and financial reports of top market players, whereas primary research included extensive interviews with the key opinion leaders such as CEOs, directors, and marketing executives. The percentage splits, shares, and breakdowns of the product markets were determined using secondary sources and verified through primary sources.

Do You Have Any Query Or Specific Requirement? Drop Your Query Here @ https://www.datalabforecast.com/request-enquiry/84661-beryllium-copper-market

Business Opportunities in Following Regions and Countries:

Like any other research material, the report has covered key geographical regions such as Europe, Japan, United States, India, Southeast Asia and Europe. Researchers have given their opinion or insights of Beryllium Copper value, product sales, and industry share besides availability opportunities to expand in those regions. As far as the sub-regions, North America, Canada, Medico, Australia, Asia-Pacific, India, South Korea, China, Singapore, Indonesia, Japan, Rest of Asia-Pacific, Germany, United Kingdom, France, Spain, Italy, Rest of Europe, Russia, Central & South America, Middle East & Africa are included.

Major Points Covered in TOC:

Overview: Along with a broad overview of the global Beryllium Copper market, this section gives an overview of the report to give an idea about the nature and contents of the research study.

Analysis on Strategies of Leading Players: Market players can use this analysis to gain competitive advantage over their competitors in the Beryllium Copper market.

Study on Key Market Trends: This section of the report offers deeper analysis of latest and future trends of the Beryllium Copper market.

Market Forecasts: Buyers of the report will have access to accurate and validated estimates of the total market size in terms of value and volume. The report also provides consumption, production, sales, and other forecasts for the Beryllium Copper market.

Regional Growth Analysis: All major regions and countries have been covered in the report. The regional analysis will help market players to tap into unexplored regional markets, prepare specific strategies for target regions, and compare the growth of all regional Beryllium Copper markets.

Buy Now This Premium Report to Grow your Business@ https://www.datalabforecast.com/buy-now/?id=84661-beryllium-copper-market&license_type=su

Years Considered to Estimate the Beryllium Copper Market Size:

History Year: 2015-2019

Base Year: 2020

Estimated Year: 2021

Forecast Year: 2021-2028

Why Choose Data Lab Forecast?

• Deliver updated information on the current industry trends

• Available 24/7 to facilitate clients with unbiased solutions

• Embrace digital technologies to offer accurate business ideas

• Exhaustive supply chain augmentation analysis

• Provide reports strictly according to the requirements of the clients

Thank you for reading our report. To know more about customization options, please get in touch with us. Our team will ensure the report is tailored to suit your requirements.

About Us

Transforming Information into Insights

We pride ourselves in being a niche market intelligence and strategic consulting and reporting firm driven towards resulting in a powerful impact on businesses across the globe. Our accuracy estimation and forecasting models have earned recognition across majority of the business forum.

We source online reports from some of the best publishers and keep updating our collection to offer you direct online access to the world’s most comprehensive and recent database with skilled perceptions on global industries, products, establishments and trends. We at ‘Data Lab Forecast’, wish to assist our clients to strategize and formulate business policies, and achieve formidable growth in their respective market domain. Data Lab Forecast is a one-stop solution provider right from data collection, outsourcing of data, to investment advice, business modelling, and strategic planning. The company reinforces client’s insight on factors such as strategies, future estimations, growth or fall forecasting, opportunity analysis, and consumer surveys, among others.

Contact:

Henry K

Data Lab Forecast

86 Van Wagenen Avenue, Jersey,

New Jersey 07306, United States

Phone: +1 917-725-5253

Email: [email protected]

Website: https://www.datalabforecast.com/

Follow Us on: LinkedIN | Twitter |

0 notes

Video

youtube

Beryllium Copper Rod bar plates sheet strip C17200 C17300 C17500 C17510 ...

0 notes

Text

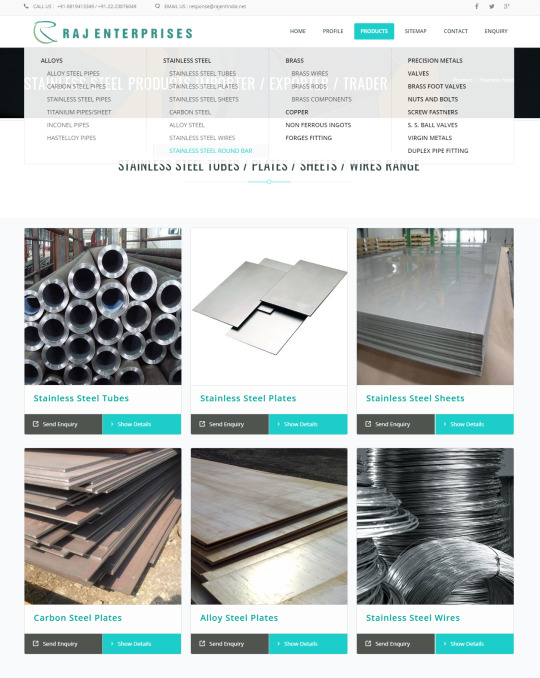

Stainless Steel Plates, Stainless Steel Tubes, Stainless Steel Wires, Mumbai, India

Raj Enterprises, Mumbai, Are a Renowned Importer, Exporter, Trader And Stockist of Mumbai, India.

Importing, Exporting And Stocking Of Stainless Steel Products, Nickel Alloys, SS Pipes, MS Pipes, Alloys, Alloy Steel Pipes, Carbon Steel Pipes, Stainless Steel Pipes, Titanium Pipes, Titanium Sheet, Inconel Pipes, Hastelloy Pipes, Stainless Steel, Stainless Steel Tubes, Stainless Steel Plates, Stainless Steel Sheets, Carbon Steel Plates, Alloy Steel Plates, Stainless Steel Wires, Stainless Steel Round Bar, Steel Coils, 316 Stainless Steel CR Coils, 304 Stainless Steel CR Sheets, 316 Flat Bars, Stainless Steel Designer Sheets, 316 SS Designer Sheets, SS Designer Sheets, Stainless Steel Checkered Sheet, SS Gold Mirror Sheet, Non Ferrous Metals, Chequered Plate, Duplex Steel Sheets, 316 Stainless Steel Slitting Coil, Slitting Coil, Duplex Sheet, Seamless SS Tubes, Brass, Brass Wires, Brass Rods, Brass Round Bar, Brass Soft Wire, Brass Components, Copper, Copper Wire, Air Conditioning Copper Tubes, Earthing Copper Rods, Copper Strips Bus Bars, Copper Plates, Copper Circle, Copper Alloys Products, Copper Tubes, Copper Strips, Copper Earthing Plates, Copper Coils, Copper Flats, Copper Rods, Copper Nickle Rod, Non Ferrous Ingots, Non Ferrous Alloy Ingots, Antimony Ingot 99.65, Antimony Ingot, Nickel Inco, Backed Bismuth Ingots, Tin Ingots, Forges Fitting, Weld Neck Flange, Slip On Forged Flanges, Ring Joint Flange, Forged Flanges, Virgin Metals, Precision Metals, Valves, Manifold Valves, Gauge Valves, Stainless Steel 316 Needle Valves, Diaphragm Valve Cast Iron, Gate Valve Bronze, Heavy Brass Gate Valve, Swing Check Valve Brass, Check Valve (Spring) Brass, 3 Way Port Ball Valve Brass, Mini Ball Valve Brass, Root Valves, Brass Foot Valves, Nuts And Bolts, Screw Fastners, S.S.Ball Valves, Duplex Pipe Fitting, Stainless Steel Duplex Butt Weld Fitting, Duplex Steel Buttweld Fittings, Alloy Pipe, Beryllium Copper Alloy Products, Tantalum Plates, Tantalum Strip, Tantalum Tubes, Nimonic Alloy 90, Molybdenum Bolts, Hex Bolts, Tungsten Bolts, Nuts Fasteners, Mumbai, Maharashtra, India

0 notes

Text

Connector manufacturer contact material types

The production of a connector is inseparable from the choice of raw materials. Different materials can bring different effects. Therefore, it is very necessary for the connector industry practitioners to understand the knowledge of the connector materials. So, do you know what the connector contacts are? In the following, Konnra Electronics engineers will focus on what the connector manufacturer's contact materials are.

Konnra Electronics engineers pointed out that the connector contact materials are generally three kinds: brass, phosphor bronze and beryllium copper. As for how to choose these three materials, it depends on the type of contact, the frequency of plugging and the connector. Depending on the electrical and environmental conditions of the work, the materials and usage of the commonly used contacts are as follows;

1. Brass: Copper-zinc alloy, high conductivity (26%), but the elasticity is poor, the appearance is yellow. According to the different copper content, it is divided into different grades, such as C2600, C2680 (JIS model). Each model is also divided into different hardness grades, such as 1/2H, H, EH, SH. Commonly used for PIN pins, grounding strips, etc.

2. Phosphor bronze: copper-tin alloy, low conductivity (13%), but the elasticity is better, the appearance is red. According to the different copper content, it is divided into different grades, such as C5195, C5210 (JIS model). Each model is also divided into different hardness grades, such as 1/2H, H, EH, SH. Commonly used for terminals with shrapnel, such as various wire terminals.

3. Beryllium copper: It has the advantages of the above two kinds of alloy copper, high conductivity (40%), good elasticity, but expensive, less used in the connector.

#connector#connectors#connector manufacturer#connectors manufacturer#connector supplier#connectors supplier

0 notes

Link

0 notes

Text

How to Use Scarcity and Urgency to Increase Sales – How To Sell High-Ticket Products & Services Ep12

youtube

7 psychological triggers to sell high-priced products and services very very very important, psychological triangle number one is call, scarcity, when motivated by fear of loss instead of potential, desecrate documentary, call The Diamond Empire, the diamond Empire on YouTube, social Security example images of diamond example, okay, diamond the whole thing about diamond, it’s did not wear at all, what happened in 1920s and evidence do they have all these diamonds, idea in 1920s that came up with the idea wash it nobody’s buying, nobody’s buying a diamonds what should we do, brilliant idea, well, you know what how can we get people to buy it, yeah diamonds are forever, how can you do it in a way that it mixed is part of our culture, so they came up with it’s a symbol for love, it’s a symbol for marriage, wow no but that’s not enough, they so evil, that that’s that’s put pressure on them so they will Strip This Supply, Big they had to have high prices which resupply, how much do produce how much they make how they cut, everything, and they do it through Hollywood the all day all these celebrities modern my Van Helsing a lot of marketing, a lot of social pressure for men, if you want to propose right, honey I love you but I don’t have a diamond ring, you know what just like a silver ring to, they just like you don’t love me, write 11 the ladies okay, what is she going to tell their friends, oh yeah let me see the rain, i’m talking about so just the Kimmel this whole thing, the creepiest manufacturer, the scarcity when does nose look at rubies and Rose actually much more rare than diamond, accumulated, $4, right, $4, good margin for them, a good business like I think whoever came up with that crudele, What is beryllium, something nobody wants to something that you must have, to prove your love, otherwise you’re bad as a man right, bass bass business right supply-demand so my question, to you is how can you create scarcity within your business, how can you restrict, supply, uncrate multi-man, is a service business, you can only work with so many clients, do you know what love to work with you but I only take on so many clients at a time, no more than 5 no more than 61 + 10, because I can, giving a service business, you wish trick, supply, they probably mad, can you get a provider service for me man I’m so busy one month waiting list, i did this actually very early there are only one in my copper in career and I was and I got this early on, Call bring career at home I had like a handful of clients like not many clients.

And someone would come up with the comments as a friend of mine told me about you I want you to to write them, some coffee for me, man I’m just like, okay I need the Cline like like now, i always say you know what I can’t do it this week, automatic reply I cannot do it this week, women can do it, i got nothing I can do it this week, because Nixon pillow you you’re busy, can you imagine someone calls me to ask for me when you want it tonight, no problem, you see the problem, he was tricked scarcity, cuban Pete’s, so the whole Diamond thing it’s quite fascinating you’ll be like oh my God, you’ll be you’ll be shocked how the whole Industries created, but they’re not worried at all 10 times your finances 10 times your business 10 times, * your marketing 10 times your life hit the Subscribe button now.

from WordPress https://top1course.com/how-to-use-scarcity-and-urgency-to-increase-sales-how-to-sell-high-ticket-products-services-ep12/

0 notes

Video

instagram

The Question of the Day is "What is Beryllium Copper used for?" Answer: Beryllium Copper has few grades used for various applications, The rods, the bars, the plates are highly used in moulds because of high conductivity for faster heating and cooling, the strips are highly used for the spring action in switches, EMI Shielding, and many other applications, you can also use beryllium copper wire for springs. Beryllium Copper foils are also used where they need EMI shielding in some places. If you need to know more about Beryllium Copper, you need to visit https://www.domadia.net to download our catalogue or ask us more questions. Presented by @KairavDomadia Please Do Like, Comment and Follow... (at Mumbai, Maharashtra) https://www.instagram.com/p/B5UQhDjA7gs/?igshid=1hwgupnwkl3tf

0 notes

Text

6 Himalayan Rock Salt Benefits Over Iodized Salt

“Add just a pinch of salt for taste” is often quoted in recipes- this pinch of salt has the ability to bring out the taste in a dish.

However, there are many rock salt benefits to show that our salt can be way more than taste boosters.

From a health point of view, it is very important to have salt and even more important to have the right amount of salt.

Too much of salt can bring diseases like hypertension, heart strokes, kidney problems whereas too little salt in the diet leads to a condition called hyponatremia which can also be harmful causing a number of side effects such as a headache, confusion or altered mental state, seizures as well as decreased consciousness and much more.

That is why it is very important to have a balanced salt intake. But the question is, which types of salts are healthy? Usually, the salt chosen depends on the tastes, nutritional status and diet.

If a person is eating iodine-rich foods, regularly then he/she can choose sea salts/ rock salts for their beautiful array of colours, textures and flavours.

But, if a person is pregnant, hypothyroid or deficient in iodine, then he/she has to choose table salt fortified with iodine.

Most of us aren’t even aware of the types of salt or simply rock salt for that matter.

Don’t worry, we are here to the rescue. But before jumping right into the Himalayan rock salt benefits or the demerits of iodized salt that we commonly use, let us know about the history of rock salt.

Content Summary

History of Himalayan rock salt formation

The mineral constituent of Himalayan rock salt

6 Differences Between Rock Salt and Iodized Salt

6 health benefits of rock salt that will compel you to include it in your diet

History of Himalayan rock salt formation

The Himalayan salt aka halite hails from the Punjab region of Pakistan. The region is almost 190 miles from the Himalayas.

The crystals of Himalayan salt are in their purest forms because the area where they are seen as not only one of the richest salt areas in the world but also they are believed to be composed of remnants of the original primal sea.

This rock salt is formed with an overlying pressure, lying under about 5,000 feet of Himalayan ranges. The rock salt crystals hence formed, are the purest with all the natural minerals remaining intact.

The mineral constituent of Himalayan rock salt

Himalayan rock salt is blessed with 84 minerals which also include important trace elements that are not found in normal food sources.

On spectral analysis of Himalayan salt, it is found to contain macro minerals, such as iodine, sodium, calcium, phosphorus, and chloride, and trace minerals like iron, zinc, boron, magnesium, as well as gold, silver, arsenic, nickel etc.[1]

The importance of trace elements is that although they are required in small amounts their absence can lead to deficiency diseases.

Also, trace elements are required for many bodily functions like enzymatic actions.

Apart from these mineral sources Himalayan salt also contains minerals that are toxic in huge quantities such as lead and plutonium, but in trace amounts, these are safe and even beneficial.

The amount of salt recommended:

United States Department of Agriculture (USDA): 2300 mg.

American Heart Association (AHA): 1500 mg (2).

Academy of Nutrition and Dietetics (AND): 1500 to 2300 mg.

American Diabetes Association (ADA): 1500 to 2300 mg. [2]

Read to know how Much of Salt or Sodium is Required in a Day!

Rock Salt Benefit over Iodized Salt

Below are the different benefits of rock salt in terms of its constituent and processing. These points are somewhat useful to make the right choice regarding the type of salt we use.

1. Rock salt doesn’t undergo refining

First of all, the common iodized salt is formed after undergoing heavy refining processes. In order to make the salt “look good”, it is mechanically processed to be finer and whiter.

This makes it lose all the mineral content. Whereas, rock salt is naturally crystallized and then mined, which retains its mineral richness.

The result is, we don’t get salt but also a natural source of important as well as trace minerals.

Rock salt doesn’t undergo refining

2. Rock salt doesn’t have additives

Common salt has bleaching agents as well as anti-caking agents. Whereas, the Himalayan rock salt is devoid of any of these.

The anti caking agent brings side-effects like constipation as well as kidney issues.

Examples of anti-caking agents are E341 Tricalcium Phosphate, E500 Sodium bicarbonate, E535 Sodium ferrocyanide, E536 Potassium ferrocyanide, E538 Calcium ferrocyanide. [3]

Rock salt doesn’t have additives

3. Rock salt’s mineral content remains intact

While the common refined salt is stripped off all the important minerals, the Himalayan rock salt retains all its minerals as well as important electrolytes.

It contains 6 electrolytes sodium, potassium, chloride, magnesium, phosphorus and calcium.

Rock salt’s mineral content remains intact

Electrolytes help

a] Controlling the stability in the cell membranes.

b] Maintaining coordination among different cells in the body.

c] Carrying electrical impulses between nerve cells.

4. Rock salt has minerals that are easy to be absorbed

The crystalline nature of rock salt ensures that the mineral content is virgin and not affected.

Moreover, these crystalline salt have the energy content of the minerals in a balanced form which makes it easily metabolized by the body.

However, this crystalline nature isn’t found in the common refined salt.

Rock salt has minerals that are easy to be absorbed

5. Rock salt helps in maintaining pH

The minerals found in Himalayan rock salt also help in maintaining the correct pH as well as elevate low blood pressure in the body. [4]

Rock salt helps in maintaining pH

6. Rock salt doesn’t hamper body hydration

The chemicals that are added to our regular salt jeopardize the main function of the salt, which is to regulate hydration in the body. However, this is not the case with rock salt. [5]

Rock salt doesn’t hamper body hydration

Iodised Salt Vs Rock Salt

Differences between Iodized common salt and Himalayan Rock salt

Tips to choose rock salt

a] So now when you know the benefits of rock salt, here are its salient features:

b] The pink colour of Himalayan salt is caused by iron oxide or rust deposits in the mountains. It is said that darker the pink, richer the salt in minerals

c] The salt is crystalline in nature. For common use, you will get a somewhat finer version too.

If we go through the pages of history, we can see that people in the earlier times used rock salt without showing any major health concern because of the salt.

Therefore, this is a strong indication that it can be an easy and healthy replacement of our commonly used refined salt.

Are you still wondering if you should take up the Himalayan rock salt as your household salt?

Rock Salt Benefits to compel you to include it in your diet

Rock salt is found to be helpful in promoting digestion as well as improving loss of appetite.

Due to its trace elements, rock salt helps in boosting body’s metabolism. This further improves different body functions as well as the immune system of the body.

Rock salt is found to be useful in curing problems like rheumatic pain, inflammation, arthritis.

Having one spoon of rock salt along with water can be useful in fighting muscle cramps.

Rock salt lamps are used as air purifiers. These Himalayan rock salt lamps have bulbs inside them. The lamps emit negative ions that clear the harmful ions present in the air. This improves breathing and respiratory ailments.

It is found that rock salt has the ability to stimulate insulin in the body that prevents sugar cravings. This can be a help for losing weight.

Elements found in Himalayan salt in addition to sodium and chloride.

In alphabetical order, they are: actinium, aluminum, antimony, arsenic, astatine, barium, beryllium, bismuth, boron, bromine, cadmium, calcium, carbon, cerium, cesium, chlorine, chromium, cobalt, copper, dysprosium, erbium, europium, fluorine, francium, gadolinium, gallium, germanium, gold, hafnium, holmium, hydrogen, indium, iodine, iridium, iron, lanthanum, lead, lithium, lutetium, magnesium, manganese, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, osmium, oxygen, palladium, phosphorus, platinum, plutonium, polonium, potassium, praseodymium, protactinium, radium, rhenium, rhodium, rubidium, ruthenium, samarium, scandium, selenium, silicon, silver, sodium, strontium, sulfur, tantalum, tellurium, terbium, thallium, thorium, thulium, tin, titanium, uranium, vanadium, wolfram, yttrium, ytterbium, zinc and zirconium. [6]

We intake salt not just as an external source. Salt is found in many food products, especially in the processed foods.

That is why we should at least replace the common salt we use as a table salt or in cooking with Himalayan rock salt.

After all, why not add the naturally occurring high mineral content rock salt instead of the refined unhealthy one?

Next Read:

5 Weight Loss Mistakes Self Dieters tend to Make!

{ "@context": "http://schema.org", "@type": "Product", "name": "Benefits of Rock Salt", "aggregateRating": {"@type": "AggregateRating", "ratingValue": "4.8", "reviewCount": "5" } }

The post 6 Himalayan Rock Salt Benefits Over Iodized Salt appeared first on Blog.

6 Himalayan Rock Salt Benefits Over Iodized Salt published first on https://dietariouspage.tumblr.com/

0 notes