#beryllium copper coil

Text

Beryllium Copper Strip Suppliers | Copper Strip | Copper Beryllium Foil

Looking for reliable Beryllium Copper Strip Suppliers? Look no further! Our website offers a wide range of Copper Strip options, including Copper Beryllium Foil. We provide high-quality products that are durable and efficient for various industrial applications. Explore our website to learn more about our Copper Strip selection and find the perfect fit for your project needs.

#copper strip#beryllium copper strip#beryllium copper strip suppliers#beryllium copper coil#copper beryllium foil#steel strips#copper strip price

0 notes

Text

Unveiling the Intricacies of the Hairspring in Watchmaking

In the intricate world of watchmaking, every tiny component plays a vital role in ensuring precision and accuracy. Among these components, the hairspring stands out as a marvel of engineering, essential for regulating the oscillations of a watch's balance wheel. Let's delve into the fascinating realm of the hairspring, where precision meets craftsmanship in the pursuit of horological perfection. The Essence of the Hairspring At the heart of every mechanical watch movement lies the balance wheel, a delicate oscillating component that divides time into equal segments. The hairspring, often referred to as the balance spring, is a tiny spiral-shaped spring that controls the oscillations of the balance wheel, regulating the timing of the watch with remarkable accuracy. Precision in Design Crafted from thin strips of specialized alloy, typically a form of steel or a copper-beryllium alloy, the hairspring undergoes meticulous manufacturing processes to achieve its desired properties. Its precise dimensions, shape, and elasticity are carefully calibrated to ensure consistent and reliable timekeeping, even in the face of external factors such as temperature changes and mechanical shocks. The Role of the Hairspring As the balance wheel swings back and forth, the hairspring exerts a restoring force, pulling the balance wheel back to its equilibrium position with each oscillation. This delicate interplay between the balance wheel and the hairspring determines the watch's beat rate, or the number of oscillations per hour, ultimately defining its accuracy. Fine-Tuning for Performance Watchmakers meticulously adjust the hairspring to achieve the desired rate of oscillation, often through processes such as bending or shaping the spring's coils. This fine-tuning ensures that the watch maintains accurate timekeeping under various conditions, making the hairspring a critical component in the pursuit of horological excellence. Preserving the Legacy Despite advances in technology, the craftsmanship and precision required to manufacture hairsprings remain a hallmark of traditional watchmaking. From the delicate art of hand-crafting to the cutting-edge techniques of modern production, the hairspring continues to embody the essence of horological mastery, ensuring that each tick of a mechanical watch is a testament to centuries of expertise and innovation.

0 notes

Text

T1, T2 copper is mainly used as conductive, heat-conducting and corrosion-resistant components, such as wires, cables, conductive screws, shells and various conduits, etc. T3 copper is mainly used as structural materials, such as the production of electrical switches, washers, rivets, nozzles and various conduits, etc.; it is also commonly used in some less important conductive components. components.

What Materials are Available in Copper CNC?

Copper classification and characteristics

1. Pure copper in China commonly known as 'purple copper' in Japan and Taiwan commonly known as 'red copper' a common grades: T1, T2, T3, TU1, TU2 b characteristics: conductive with c common uses: electrical switches, motor coils, electronic parts.

2. Brass with zinc a Common grades: H59, H62, H65, H68, HPb59-1 Free-cutting brass b Characteristics Higher strength, wear resistance, water vapor corrosion resistance c Common uses Architectural hardware, heat exchanger tubes, pumps, power cylinders and bushings, munitions.

3. White brass: Nickel-containing Common grades: B19, B25, BFe10-1-1, BZn15-20, BA13-3 b characteristics: stable physical properties at room temperature c common use medical apparatus, precision instruments, thermocouples, watch parts, glasses frame

4. Bronze: a definition: the old name that tin bronze such as the ancient bell, tripod, wine ware New definition: purple, yellow, white copper other than the three categories of the collective name b according to the practical physical and chemical indicators such as hardness, strength, elasticity, high-temperature conductivity, thermal conductivity and so on the engineering composite index and have different formulations. c uses: tin-phosphor bronze, good elasticity, for lamps Spring piece, switch spring piece. Resistance welding electrode material roll welder, butt welder, touch welder, rivet welder. Chrome zirconium copper, beryllium cobalt copper.

About Copper CNC Machining

Using a computer-controlled machining tool, copper is shaped into a variety of components during the copper CNC machining process. Due to its precision and reproducibility, it is one of the most flexible and popular machining methods for copper objects. Both basic pieces with simple shapes and complicated parts with detailed shapes can be produced using this method. For applications requiring high levels of dimensional accuracy, close tolerances, and outstanding surface polish, copper CNC machining is appropriate.

1 note

·

View note

Text

What Is Wire Forming?

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration. The process starts with coiled wire that is straightened before being formed.

Common metals used for wire forming include steel, brass, stainless steel, copper, aluminum, and a variety of different alloys. The diameters of wires vary from 0.5 mm to 6.5 mm, or 1/64th of an inch to a quarter inch and can produce 2 and 3 dimensional wire forms.

The types of equipment to complete wire forming vary between manual crafting to advanced CNC programmable machines. The process includes options for coating and protecting final products for use in harsh conditions.

Methods Used for Wire Forming

Though there are several types of equipment used to perform wire forming, in most cases, wire roof guard

machines are manually or automatically operated. Manual machines include ones that are operated by manual force and ones that are electronic but manually loaded. Automatic machines have advanced computer numerically controlled (CNC) programming and complete production without manual involvement.

Methods For Wire Forming

Wire forming is performed using several different processes each designed to achieve a different shape, pattern, or configuration. The methods of wire forming are used for other part production but have been adjusted for wire forming.

Manual Wire Forming:

The oldest method for wire forming is manually operated machines, which involves a hand lever and spindle. Manual machines can be drawn or rotary die and have gears that increase the applied bending force.

Coil Wire Forming:

Coil, or spring wire forming, involves winding wire around a metal blank. It is also used for the manufacture of electrical coils where a conductive wire is evenly wound around a ferromagnetic core. Coil winding takes different forms depending on the final product. Electrical coils have to be more precisely wound than springs and can require more than one winding.

Roll Wire Forming:

Roll forming is a cost efficient method for the production of flat, round, and other shapes of wire parts. The process can manufacture undercuts, knurls, pointing, chamfers, grooves, surface finishes, collars, and threads. Roll formed wire parts have extra strength after being hardened, having rounded edges, and being prefinishing.

Bend Wire Forming:

In the wire bending process, wire can be shaped into unlimited configurations to fit any application. Diameters of 0.4 mm to 16 mm, or 0.016 in to 0.625 in, can be easily formed. Since the bend in the wire is made prior to the wire being cut, the process has no scrap or waste and does not need secondary finishing.

CNC Wire Bending:

CNC wire bending machines can be pneumatic or hydraulic for efficient and rapid production. They can bend and shape rebar to 180o using single or double wire. The machine straightens the bar prior to the bending process. CNC machines have exceptional accuracy and cut wire to the exact required dimensions. The types of wire a CNC machine can be programmed to shape includes music, hard drawn, basic or coated metals, 300 series stainless steel, brass, and beryllium copper. Wire diameters vary between 0.008 in to 0.250 in or 0.0203 mm to 6.35 mm.

0 notes

Text

A Fantastic Spring Producer Engineers Over You Think

Mankind has normally relied on know-how to enhance our way of everyday living. To start with, we discovered and made uncomplicated things that aided to create heat, mobility, storage, and more, points which more developed into our recent state of domesticity and productiveness. Basic equipment were being among the the first issues invented and among The best mechanisms is usually one of the smallest: the spring. Many people almost certainly forget about the significance of the spring through heritage but any high-quality spring company will show you that don't just has the same type of technology been used Because the fifteenth century but also that there is a fantastic disparity involving the numerous kinds of springs in use today.

So that you can definitely recognize the effect this machine has experienced on present day technologies, it is important to be familiar with the definition on the phrase "spring." Plenty of people most likely imagine the coiled bit of metallic observed bed frames or that toy that just entertains kids by traversing down the stairs. Whilst they're, without a doubt, sorts of springs, so to talk, The easy comprehension of the expression is any devised contraption with elastic Homes that will shop mechanical Power. The very to start with spring company, then, might have been anyone who might have constructed bows for archery (both of those looking and Activity).

The earliest spring producer, like the kind Which may develop the categories of springs we're most acquainted with today, likely labored inside the timepiece company. Indeed, the commonest form of spring is likely the type you should come across in an old pocket check out, The type that requires winding so as to carry on running effectively. Obviously, springs are now used in absolutely anything that possibly needs stored mechanical Electrical power (like springboard or trampoline) or demands resistance (like a mattress mattress or maybe a door hinge).

There exist only a few types of useful springs. The most common variety of spring is referred to as the tension spring, the sort that the majority of people picture when thinking of a spring company. This kind of spring stores mechanical Electricity if you stretch the fabric. Yet another category is referred to as the compression spring which retailers mechanical energy in the other way: by compacting, or "compressing" the material. The torsion spring suppliers Strength whenever you twist the fabric (just like a mousetrap). In just these groups, obviously, additionally, you will locate several sub-groups that much better explain the kind of mechanical Electrical power stored or more correctly how the mechanism will work.

Steel is a standard materials utilized to make springs but an excellent spring manufacturer possibly also lists springs produced away from other fortified metals within their catalog. This could contain just about anything from phosphor bronze, Beryllium copper, and titanium. The different sorts of metals are necessary due to the fact springs are used in lots of industries and are essential to accommodate differing types of environments. Indeed, a spring may possibly need to current market components which offer electrical present transference Houses or corrosion resistance Along with The fundamental mechanical properties of the standard spring.

Visit To learn more about Small Spring Making Machine Manufacturer.

0 notes

Text

What should you know about an Extension Spring?

Superior steel grades that can store mechanical energy are usually made of the wound, which is present in the spring in an elastic object. The spring exerts a force directly proportional to the change in its length as the spring is compressed or stretched while operating. Spring might be manufactured by using several different configurations and materials as made by the coil spring

manufacturer.

Some metals such as titanium, beryllium copper, and phosphor bronze might be used for manufacturing springs that require a higher degree of corrosion and protection from the different corrosive situations. However, in some applications, one can even find springs manufactured using plastics, which means if the material demonstrates the desired amount of flexibility and rigidity, it can simulate a spring.

What is precisely a good extension spring?

A good extension spring creates the right amount of resistance to a pulling force by absorbing and storing energy in it. The spring's initial tension equals the minimum pressure required to separate the coils of the spring that have been wound together. The Extension spring manufacturer in Los Angeles manufactures more tightly together the waves are incorporated, the higher would be the spring's initial tension. Depending on your application's load requirements, the chosen spring manufacturer will supply you with springs that have varying levels of initial stress by appropriately winding the coils with the spring on them.

Spring needs to be fitted with a hook or an end loop to integrate it with the desired application. There is a myriad of hoop and loop varieties that can be done to your spring type, while some end configurations of spring include: centered hooks and eyes, swivel hooks, cross-over center loops, full loops, and machine hooks. Thus, these are the constituents of an excellent extension spring.

0 notes

Text

Features of stamping Parts and custom springs

Stamping parts are the components that are made of different materials that are formed according to the desired shape. Accordingly, stamping a metallic part is the practice of forming a component by cutting and shaping a metal sheet into a required curve with the dies and relevant tools.

Earlier, metal stamping has often changed other metal forming processes, including die-casting and forging. This is chiefly due to the low production expenses. Moreover, metal stamped components can be stronger and more enduring than other parts that are made using different other metal shaping processes. The process is largely used in an extensive diversity of industries, as these stamping parts can be shaped quickly thus, dipping the overall production time as well as the cost.

Nowadays, many manufacturers are committed to offering innovative cost-cut options at the design stage itself. To achieve this, they use a unique design process, known as Design for Manufacturing, meaning your metal stamped parts will be designed individually according to your specifications.

Metal stamping can be useful to various materials to make components according to their unique metalworking characteristics for numerous applications across a wide variety of industries. This type of stamping may need the sharpening as well as the processing of base metals to uncommon alloys for their application-precise benefits. Some industries need the thermal conductivity or electrical conductivity of beryllium copper in manufacturing fields, such as electrical, aerospace, and the defense industry. Some automotive industries use steel as well as its different alloys for high strength applications.

Custom springs are made-to-order springs, which are used in an extensive array of settings. These applications may range from clothespins to cars, and they are used in several other common appliances and devices. Although these springs are so ordinary, they need the most precise manufacturing methods and exact fittings to make sure that they function properly and offer reliable performance. Higher quality of these custom--made springs can be achieved by making use of the correct material, coil thickness, as well as the correct workmanship,

Custom springs that are made of materials of these characteristics will offer long-lasting performance. These springs will usually encompass a strong construction as well as sturdy design and they are available in different forms, such as torsion springs, compression springs, and extension springs according to the application needs of users. Furthermore, as they are available in different sizes and specifications, you can rest guaranteed that they would exactly fit your needs, no matter what the prerequisites of your application are.

Custom springs are made of different materials, as well, including brass and stainless steel. Brass springs are considered one of the most adaptable products. This is for the reason that they are appropriate for a huge range of applications. Their strong flexibility allows these springs to store substantial amounts of potential as well as mechanical energy inside.

When it comes to springs that are made of stainless steel, they will not lose their tension even in their inactive condition. During the idle condition, the coils of these springs will boast shear stress. The utmost shear pressure occurs on the inner face of the coils of these springs and increases the loads.

0 notes

Text

Tension Spring Manufacturers

Tension spring manufacturers in India

Industrial springs should be reliable and the spring quality matters a great deal. If you’re looking for good-quality industrial springs like – tension spring then your search for good tension spring manufacturer ends here.

Khodiyar Spring Industries have gained recognition as one of the best metal tension spring manufacturers in India, and are known for their man-made supreme quality tension springs. Made of good quality steel, our products are strong and highly reliable with a better capacity to pull a load.

Our tension springs are known for remarkable performance across industries and their widespread industrial applications are in – electric switches, mechanical seals, automobile parts, weighing scales, oil seals, electronic parts, etc.

At Khodiyar Spring Industries, you can place orders for customized tension springs as per your requirements.

The tension springs

Tension springs are also known as extension springs. Drawbar springs are also an example of extension spring.

To get an idea of tension spring in action, you can compare it with a trampoline. When an outside force creates tension in the spring then it uses that energy to pull the components (the spring is attached to) back together.

Tension springs are tightly wound coils and are designed to operate with the force known as ‘tension’.

Tension springs or you can call them the extension springs are helical wound coils with a hook, loop, or end coil designed at its one or both the ends. Hence, the extension spring or tension springs can be of many types depending upon their end design.

This spring can be attached from both the ends to the other components and the tension is created in the spring which in turn attempts to bring the components back together if they try to move further apart.

The coils of the spring touch and are tightly bound until a force is applied then spring coils are pulled apart as the components are moved in the outward direction.

The process of spring making involves hot and cold coiling procedures.

Different types of tension spring designs

The distance between the end design and spring body can be adjusted to get the desired spring design and depending upon this variety of spring designs can be created.

Tension spring hook types

One more spring design customization that’s attainable is done by providing variations in hook types of the tension springs to fit the customer’s need.

The variations in spring designs based on spring hook types are -

Double twisted full-loop over the center.

Long round end hook over the center.

Hand loop and hook at right angles.

Machine loop and machine hook.

Tension springs can be made from different materials – stainless steel, music steel (spring steel), hard drawn, beryllium copper, oil tempered, and phosphor bronze. At Khodiyar Spring Industries we make stainless steel tension springs.

What are the common uses of tension springs?

The primary function of tension spring is to absorb and store energy and resist the pulling force or the tension applied to them. When the load is applied the tension spring gets stretched and tries to get back in its shape by pulling the components or loads attached to the ends of the spring.

Tension springs are often deemed fit for lever-based mechanisms. They absorb energy and create resistance towards the pulling force.

Applications of tension springs

There are many uses of tension springs that solely rely on their unique properties of absorbing, storing energy, and pulling back to regain its normal shape. These are versatile springs and their usage spans across different industries.

Extension springs/tension springs are mostly used in –

Automotive interiors and exteriors.

Washing devices.

Toys.

Trampolines.

Garage door assemblies.

Carburetors.

Vise-grip pliers.

Small medical devices.

Machine’s brake springs.

Farm machinery.

Levers.

Robotics.

Construction components.

Benefits of using tension springs

The benefit of using tension spring is that they differ from other springs in the tightness of their coils. If you compare tension springs with compression springs the latter one is usually has more loosely held coil. This tightly wound coil design of tension springs is thus an essential feature that enables the spring to stretch more.

Before the tension springs are ready to be sold they undergo a series of tests so these springs are reliable and the spring seller lists the properties of the spring. Features like -seat pressure and coil bind height are mentioned.

0 notes

Text

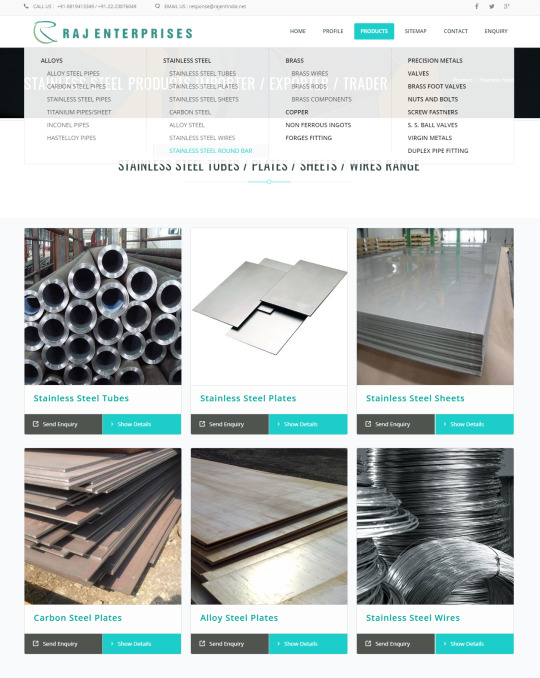

Stainless Steel Plates, Stainless Steel Tubes, Stainless Steel Wires, Mumbai, India

Raj Enterprises, Mumbai, Are a Renowned Importer, Exporter, Trader And Stockist of Mumbai, India.

Importing, Exporting And Stocking Of Stainless Steel Products, Nickel Alloys, SS Pipes, MS Pipes, Alloys, Alloy Steel Pipes, Carbon Steel Pipes, Stainless Steel Pipes, Titanium Pipes, Titanium Sheet, Inconel Pipes, Hastelloy Pipes, Stainless Steel, Stainless Steel Tubes, Stainless Steel Plates, Stainless Steel Sheets, Carbon Steel Plates, Alloy Steel Plates, Stainless Steel Wires, Stainless Steel Round Bar, Steel Coils, 316 Stainless Steel CR Coils, 304 Stainless Steel CR Sheets, 316 Flat Bars, Stainless Steel Designer Sheets, 316 SS Designer Sheets, SS Designer Sheets, Stainless Steel Checkered Sheet, SS Gold Mirror Sheet, Non Ferrous Metals, Chequered Plate, Duplex Steel Sheets, 316 Stainless Steel Slitting Coil, Slitting Coil, Duplex Sheet, Seamless SS Tubes, Brass, Brass Wires, Brass Rods, Brass Round Bar, Brass Soft Wire, Brass Components, Copper, Copper Wire, Air Conditioning Copper Tubes, Earthing Copper Rods, Copper Strips Bus Bars, Copper Plates, Copper Circle, Copper Alloys Products, Copper Tubes, Copper Strips, Copper Earthing Plates, Copper Coils, Copper Flats, Copper Rods, Copper Nickle Rod, Non Ferrous Ingots, Non Ferrous Alloy Ingots, Antimony Ingot 99.65, Antimony Ingot, Nickel Inco, Backed Bismuth Ingots, Tin Ingots, Forges Fitting, Weld Neck Flange, Slip On Forged Flanges, Ring Joint Flange, Forged Flanges, Virgin Metals, Precision Metals, Valves, Manifold Valves, Gauge Valves, Stainless Steel 316 Needle Valves, Diaphragm Valve Cast Iron, Gate Valve Bronze, Heavy Brass Gate Valve, Swing Check Valve Brass, Check Valve (Spring) Brass, 3 Way Port Ball Valve Brass, Mini Ball Valve Brass, Root Valves, Brass Foot Valves, Nuts And Bolts, Screw Fastners, S.S.Ball Valves, Duplex Pipe Fitting, Stainless Steel Duplex Butt Weld Fitting, Duplex Steel Buttweld Fittings, Alloy Pipe, Beryllium Copper Alloy Products, Tantalum Plates, Tantalum Strip, Tantalum Tubes, Nimonic Alloy 90, Molybdenum Bolts, Hex Bolts, Tungsten Bolts, Nuts Fasteners, Mumbai, Maharashtra, India

0 notes

Link

0 notes

Text

spring manufacturer The Essence of Various Industries

Air ship industry, vehicle and designing industry - these three enterprises frame the higher part in the request of different sorts of springs. As a rule, springs can be named as spring manufacturer versatile articles utilized for solid mechanical vitality. The Material of Construction (MoC) is solidified steel, yet these days Titanium, Phosphor Bronze and Beryllium Copper are additionally utilized as a part of their assembling. Beryllium Copper Springs have low electrical resistance and henceforth are broadly utilized as a part of those parts that pass on electrical streams.

Key Element of Spring Production, Costs Vs Tolerances

"More tightly the resilience - progressively the assembling rate and dismissal!!"

Cost of springs is the overwhelming element in the present competing condition. In accordance with this, the springs makers must be given plentiful resiliences to that they can utilize insignificant strategies for the reason. The most pragmatist and perfect route is to utilize resiliences on the premise of utilization prerequisites. This will allow the extent of required modifications in MoC properties and spring's size.

Each sort of spring assumes a critical part in the present innovation. Distinctive sorts of Industrial Springs for arranged applications are said beneath:

Loop Springs

Pressure and Extension Springs (Round Wire and Square or Rectangular Section)

Consistent Force Springs

Plate Springs

Level Springs

Hot Coiled Springs

Metal Springs

Power Springs

Winding Springs

Strip Springs

Torsion Springs and some more.

Some particular sorts of Industrial are talked about underneath:

Loop Springs

Smaller scale alloyed spring steel is the most widely recognized material of development for such sorts of springs. The material is prepared such that specific elements of finished results are found out. Some of these elements are better resistance than droop and increased capacity to prop high working anxiety. Contingent upon application prerequisites, quality curl are accessible in different sizes. Winding machine is utilized as a part of their creation and it is fueled by pressure driven power pack. Altering, hot stamping, rolling and warmth treatment are other standard assembling forms.

Hot-Coiled Springs

These sorts of Industrial Sprin are utilized as a part of procedures that call for higher temperature, high load applications and are done is an erosive domain. These metal springs are broadly requested by producers of rural actualizes and development gear. These are likewise utilized hugely in transportation industry. Hot snaked springs have bar breadth of more than 12.7mm (0.5 in.). Their material of development is carbon or combination steel bars.

Circle Sprigs

Narrowly formed, these are rakish circle mounted pivotal way. These give clear answers for different complex building issues. Contingent upon the application engagement, these modern sprin can be orchestrated in stacks or utilized as a solitary plate. Further, these are accessible in choices of with/without contact pads.

Applications

Car and Engines

Brakes and Clutches

Dampers

Derricks

Machine Tools

Stun Mounts

Vibrators and some more.

Points of interest

Adaptable to stacking in bounteous setups

Blend use as a measured spring component.

Explosive utilization of space and high spring power with little diversions

More noteworthy security

Drifting vitality stockpiling limit

To a great extent self-damping, giving great stun retention and vitality dispersal

Long administration life

Low support cost

No disfigurement or exhaustion under typical burdens

Space sparing

Stock keeping is limited as the individual spring sizes can be consolidated all around

0 notes

Photo

Spring

Helical or coil springs designed for tension. A heavy-duty helical spring designed for compression and tension. The English longbow – a simple but very powerful spring made of yew, measuring 2 m (6 ft 6 in) long, with a 470 N (105 lbf) draw force Spring characteristics: (1) progressive, (2) linear, (3) degressive, (4) almost constant, (5) progressive with knee A machined spring incorporates several features into one piece of bar stock Military boobytrap firing device from USSR (normally connected to a tripwire) showing spring-loaded firing pin A spring is an elastic object used to store mechanical energy. Springs are usually made out of spring steel. There are a large number of spring designs; in everyday usage the term often refers to coil springs. When a spring is compressed or stretched from its resting position, it exerts an opposing force approximately proportional to its change in length (this approximation breaks down for larger deflections). The rate or spring constant of a spring is the change in the force it exerts, divided by the change in deflection of the spring. That is, it is the gradient of the force versus deflection curve. An extension or compression spring's rate is expressed in units of force divided by distance, for example lbf/in or N/m. A torsion spring is a spring that works by twisting; when it is twisted about its axis by an angle, it produces a torque proportional to the angle. A torsion spring's rate is in units of torque divided by angle, such as N·m/rad or ft·lbf/degree. The inverse of spring rate is compliance, that is: if a spring has a rate of 10 N/mm, it has a compliance of 0.1 mm/N. The stiffness (or rate) of springs in parallel is additive, as is the compliance of springs in series. Springs are made from a variety of elastic materials, the most common being spring steel. Small springs can be wound from pre-hardened stock, while larger ones are made from annealed steel and hardened after fabrication. Some non-ferrous metals are also used including phosphor bronze and titanium for parts requiring corrosion resistance and beryllium copper for springs carrying electrical current (because of its low electrical resistance).

More details Android, Windows

0 notes

Text

Wall Sconce With Switch

In assembling wires, a light button is a switch, most frequently used to run electric wall sconce, lasting joined equipment, or electrical channels. Handy lamps such as table lamps will have a light button on the socket, base, or in link with the cord. Physically run on/off switches may be exchanged by remote control switches, or light dimmers that allow adjusting the brightness of lamps as well as rotating them on or off. Light switches are also found in torches and vehicles and other means of transportation.

Controls for lighting may possibly be in hand-held devices, moving automobiles and structures. Domestic and profitmaking buildings commonly have wall-mounted light buttons to regulate lighting in a room. Mounting height, reflectivity, and other design factors differ from state to state. Switches are regularly dug in within a finished partition. External mounting is also justly shared though is seen more in profit making industrialized and outhouse locations than in households. A light button box that has plastic, earthenware or metallic cover to prevent unintentional contact with live workstations of the control. Partition plates are accessible in different styles and colors to combine in with the flair of an apartment. They are however fairly stress-free to stand.

The principal light switch commissioning "quick-break knowhow" was created by John Henry Holmes in 1884 in the Shieldfield district of Newcastle upon Tyne. The "quick-break" control overpowered the difficulty of a switch's linksincreasing electric arcing at whatever time the circuit was unlocked or shut. Arcing would root pitting on one connection and the build-up of filtrate on the extra, and the switch's beneficial life would be lessened. Holmes' developmentguaranteed that the contacts would disperse or come unruffled very fast, on the other hand, the much or little force was put forth by the user on the control actuator. The deed of this "quick break" deviceintended that there was in short supply time for an arc to form, and the shift would, therefore, have a long functioning life. This "quick break" skill is still in use in more or less every commonplace light switch in the world in the present day, totaling in the billions, as well as in numerous other forms of electroniccontrol.

The clasp light switch was conceived in 1917 by William J. Newton.

As a constituent of a building wiring scheme, the connection of light controls will be structured by some expert alarmed with care and principles. In diverse countries, the customary length of the wall sconce with switch intensifying hardware containers, plates etc.canvary. Since the face-plates used must shield this hardware, these principles govern the smallest possible sizes of all wall fixed tools. Henceforth, the form and dimension of the cases and face-plates, as well as what is combined, differs from nation to nation.

The measurements, machine-driven designs, and even the overall appearance of light buttons fluctuates slowly with while. They often endure in service for many periods, over and over again being improved only when a portion of a house is redone. It is not rare to see century-old light buttons still in useful practice. Producersfamiliarizenumerous new methods and flairs, but for the most part adornment and style concerns are limited to the face-plates or wall-plates. Even the "modern" rheostat switch with the button is at minimum four decades old and in even the most recent production the acquainted last and rocker switch looks to lead.

The route which signifies "on" also differs with a nation. In the US and Canada, it is typical for the "on" point of a toggle control to be "up", while in many other nations such as the UK, Ireland, Australia, and New Zealand it is "down". In multiway, substituting the letters amongst a single switch's state and whether lights are on or off depends on other switches in the circuit.

The switches may be solo or numerous, intended for enclosed or open-air use. Non-compulsory extras may comprise dimmer-controls, environmentally friendly guard, and weather conditions and security defense. In suburban and light profitmaking lighting schemes, the light switch openly controls the circuit nourishing the spotlights. In greater lighting structures, for instance, stores or open-air lighting schemes, the obligatory current may be too great for a physical switch. In these systems light buttons control lighting contactors, a relay that permits the labour-intensive will sconce with a switch to function on a lower electrical energy or with reduced wiring than would be mandatory in the main lighting circuit.

In the UK, putting 13A BS1363 sockets on the igniting circuit is frowned upon even though not openly forbidden, but then again 2A or 5A BS546outlets are every so often put on lighting circuits to permit controller of free-standing lamps from the apartment's light controls. In North American site-built and mobile homes, frequently living rooms and sleeping quarters have a switched depot for a ground or bench lamp.

The connections of a switch are under their utmost stress while initial or terminating. As the switch is closed, the resistance amongst the connection alteration from almost endless to almost nothing. At endless resistance, no present flows and no control are degenerate. At nil resistance, there is no current fall and no power is dissolute. On the other hand, when the links change state, there is a short-term immediate of limited contact when resistance is neither nil nor endless, and electrical power is transformed into warmth. If the warming is extreme, the contacts may be broken, or might even repair themselves shut.

A switch ought to be intended to make its alteration as quickly as likely. This is realized by the early prowess of the switch pedal mechanism storage potential energy, frequently as a powered pressure in a spring. When adequate automated energy is stockpiled, the device in the switch "breaks over", and rapidly drives the connections through the shift from open to shut, or shut to open, without additional by the switch machinist. This quick-break act of the switch is vital to a long life for the control connections, as referred to in Holmes' 1884 patent.

Despite the fact that the contacts are unraveling, any electrical energy stowed in the inductance of the circuit being incoherent is dissolute as an arc inside the switch, extending the changeover and deteriorating the warming ends product on the contacts. Switches are normally ranged by the current they are intended to halt, understated current and power factor situations, as this is the greatest inflexible curb.

The arc that effects when the switch unlocks erodes the switch links. As a result, any switch has a limited life, frequently graded at a given number of cycles of withdrawal at a stated current. Task outside of its indicated operating ability will radically cut the life of the button.

To fight contact erosion, a switch is frequently premeditated to have a "wipe" action so that the connections are washed. Huge switches possibly will be intended for an extra consumable contact that ends and opens before the key interaction, shielding the main current-carrying connections from wear owing to arcing. The contact zone of the switch is built of materials that fight erosion and arcing.

A lot of advanced current switch projects depend on the separation arc to assist in scattering contact erosion. A switch intended for great current/high current use might turn out to be untrustworthy if activated at very low flows and low voltages because the touching base erosion builds up exceptionally without an arc to scatter it.

There are two types of flashes which can take place for the period of switch setup. On closing, a few flashes, similar to those from a flint-and-steel, may perhaps seem as a tiny bit of steel is animated by friction to luminosity, liquefied, and flung off. On introductory, a bluish arc powerfulness takes place, with a noticeable "electrical" ozone scent.Successively, the contacts can be seen to be pitch-black and potholed. Injuredacquaintances have a greater confrontation, rendering them more susceptible to additional harm and causing a cycle in which the connections soon could fail totally.

In the building of numerous minors switches, the coil that stores the power-driven energy obligatory for the snap action of the buttons device is made of a beryllium copper blend that is hard-boiled to form a mechanism as part of the construction of the touching base. The same part every also forms the figure of the contact itself, and is, therefore, the existing path. Abusing the switch device to hold the associates in a change state, or harshly contest the switch, will warm and therefore anneal the coil, decreasing or removing the "snap action" of the button, leading to slower changes, more energy degenerate in the adjustment, and liberal-down.

The push-button light control has two keys that otherwise close and opens the connections. Pushing the elevated key opens or closes the associates and pops out the beforehand law button so the procedure can be upturned.

0 notes

Text

Plastic Bucket Mold, thin wall container mould

Plastic Paint Bucket(pail) Mold, thin wall container mould

As a custom Plastic Paint Bucket Mold (or paint pail mould), thin wall container mould manufacturer with more than 10 years of experience, Topworks focuses on providing our customers the best quality in plastic mold created with the latest technology.

During our ten years of business, Topworks has contributed a significant amount of experience and expertise within the plastic injection mold industry, and we provide our customer with a skilled, knowledgeable, and dedicated staff for paint bucket molds making.

In the manufacturing process, Topworks is capable of manufacturing a full set of paint bucket (lid,bucket and handles), in a timely manner, and has the ability to manufacture custom assembling, stamping, and packaging services when necessary.

As we employ highly skilled labor and all of our employees possess specific skills in their selected areas of paint bucket(pail) Mold and thin wall container mould, we are able to design, manufacture and supply your plastic mold requirements, regardless of the complexity and or complexity of the designs. Prototypes and bucket mold production are completed in-house, so that we can meet the individual requirements of each project.

Our plastic paint bucket mould, thin wall container mould and paint pail mould cover 0.5L,1L,3L,5L,10L,18L,20L,25L and Beryllium Copper(BeCu) for cooling.

Beryllium copper for neck

The beryllium copper on the core top and cavity neck lead to a very good cooling for the mould,and our latest deisgn for the core and cavity would prelong the mold life:the original paint bucket mould alignment and lock system is a round one,while we design an octagon step to have a better alignment and lock for the core and cavity,also which change would prelong the paint bucket mould life.

paint bucket mould 10L-new design:an octagon step design for better alignment and prelonged paint bucket mould life

paint bucket mould 10L -old design:previous design ,a round step

paint bucket mould trail video

paint bucket lid mould trial video

10L thin wall paint bucket mould and thin wall bucket mould

- Hotrunner:1 drops with “HOTSET” heating coils

- paint bucket mould cavity steel:DIN 1.2738+ Beryllium Copper

- mold core steel:DIN 1.2311+Beryllium Copper

- Plastic material:HDPE

- Cycle time:19 Secs(High speed injection machine)

- Ejection:Air Poppet Valve

- mold life span:1 million

- Delivery time:60 days

thin wall container mould

500ML thin wall container mold

- mold cavity:1

- Hotrunner:1 drops with “HOTSET” heating coils

- mold cavity steel:DIN 1.2316+Beryllium Copper

- mold core steel:DIN 1.2738+Beryllium Copper

- Plastic material:PE

- Cycle time:5 Secs(High speed injection machine)

- Ejection:Air Poppet Valve

- mold life span:5 million

- Delivery time:50 days

Ten Pointers for Better paint bucket Mold Production

Although the criteria and the technology used to produce paint bucket Mold have changed dramatically in recent years, the basic rules for developing a mold that meets the original design criteria, and functions effectively, have not changed at all. These tips are based on more than 30 years experience in the field of paint bucket Mould manufacturing. Many of these tips talk about communication. As any paint bucket Mould manufacturers will tell you, all too often there is incomplete information available at the onset of a program. This is like having only half the map; the chances of getting to the final destination on time are very slim.

1. Design with specified cost and time criteria.

The old rule of “good, fast and cheap” still applies. There always seems to be time for rework or adjustment after meeting that ultra short deadline, but it is better to allow reasonable time in the design stage for review and correction.

2. Make sure your design specifications can be produced using existing technology.

Programs like Solidworks and the availability of rapid prototyping can provide early insight into potential problems that might occur before metal gets cut. Provide the engineering group with full specifications, do not leave anything out. If something is left out here it will cost time and money to fix later in the process.

3. Share your company’s design philosophy with your moldmaker and allow the moldmaker’s design team the opportunity to contribute.

Many paint bucket Mould manufacturers design new molds and dies based on their current inventory and their operating environment.

It may be possible to speed up production with some very simple modifications to a design. Invite your paint bucket Mould manufacturers to make suggestions that can enhance moldability.

4. Set clear guidelines on required minimum thin wall bucket mould life and capacity before manufacturing starts.

A clear definition of the expected performance and service requirements on a mold or die can help to save money upfront. If your product is likely to be modified or replaced in a relatively short period of time the moldmaker’s engineering group can design accordingly.

5. Have the moldmaker establish a production timetable that allows reasonable time for bench testing prior to delivery.

All too often a mold is delivered to meet a production deadline without being fine-tuned in a lab situation. Your moldmaker should have the opportunity to run sample parts at his facility. If there is a problem he can correct it before delivery.

6. Set up a weekly progress report call/e-mail with your sales representative during the manufacturing process.

Sales reps are busy people. It helps to establish a regular contact point to ensure the project is on schedule and on budget. It doesn’t matter what size the project is, it’s worth a weekly call to eliminate assumptions.

7. Ask the moldmaker for clear guidelines on how to maintain the thin wall bucket mould once it is installed.

paint bucket moulds may be operated in less than ideal conditions.Poor storage of materials, mold cleaning on an irregular basis, bad press maintenance and ill-trained operators can all contribute to poor mold performance. Your moldmaker should include a set of instructions for care and maintenance based on the specifications for usage.

8. Have a field sales representative from the mold shop present during initial start-up and try-out.

A buy-off is very important. Many molds and dies have sustained serious damage and require immediate repairs due to poor installation. Having a technical representative on site the first time the mold or die is installed is good insurance.

9. Remember that the design and manufacture of a mold or die is a collaborative effort.

Mold and die making is a combination of science and art. Building a tool that will work 24/7 if required, demands careful planning and checking at every phase of production. Allow the time and expense for your staff to visit the mold shop facility during production.

10. Don’t cut corners!

Giving the job to the lowest bidder might not make sense. There is a reasonable price to pay for a mold or die. If your budget is too low the chances are that you will be rebuilding or repairing the thin wall bucket mould within a fairly short period. Trying to squeeze the last dollar out of a paint bucket Mould manufacturers’s estimate can end up doubling the cost of the project. After all, price is what you pay for a mold. Cost is what you continue to pay for a mold that was not built correctly in the first place.

Read the full article

0 notes

Text

Alloy Steel, Seamless Alloy Steel Pipe, Alloy Steel Tee, Alloy Steel Concentric Reducer, Mumbai, India

Raj Enterprises, Mumbai, Are a Renowned Importer, Exporter, Trader And Stockist of Mumbai, India

http://www.rajentindia.net/alloy-steel.html

Importing, Exporting And Stocking Of Stainless Steel Products, Nickel Alloys, SS Pipes, MS Pipes, Alloys, Alloy Steel Pipes, Carbon Steel Pipes, Stainless Steel Pipes, Titanium Pipes, Titanium Sheet, Inconel Pipes, Hastelloy Pipes, Stainless Steel, Stainless Steel Tubes, Stainless Steel Plates, Stainless Steel Sheets, Carbon Steel Plates, Alloy Steel Plates, Stainless Steel Wires, Stainless Steel Round Bar, Steel Coils, 316 Stainless Steel CR Coils, 304 Stainless Steel CR Sheets, 316 Flat Bars, Stainless Steel Designer Sheets, 316 SS Designer Sheets, SS Designer Sheets, Stainless Steel Checkered Sheet, SS Gold Mirror Sheet, Non Ferrous Metals, Chequered Plate, Duplex Steel Sheets, 316 Stainless Steel Slitting Coil, Slitting Coil, Duplex Sheet, Seamless SS Tubes, Brass, Brass Wires, Brass Rods, Brass Round Bar, Brass Soft Wire, Brass Components, Copper, Copper Wire, Air Conditioning Copper Tubes, Earthing Copper Rods, Copper Strips Bus Bars, Copper Plates, Copper Circle, Copper Alloys Products, Copper Tubes, Copper Strips, Copper Earthing Plates, Copper Coils, Copper Flats, Copper Rods, Copper Nickle Rod, Non Ferrous Ingots, Non Ferrous Alloy Ingots, Antimony Ingot 99.65, Antimony Ingot, Nickel Inco, Backed Bismuth Ingots, Tin Ingots, Forges Fitting, Weld Neck Flange, Slip On Forged Flanges, Ring Joint Flange, Forged Flanges, Virgin Metals, Precision Metals, Valves, Manifold Valves, Gauge Valves, Stainless Steel 316 Needle Valves, Diaphragm Valve Cast Iron, Gate Valve Bronze, Heavy Brass Gate Valve, Swing Check Valve Brass, Check Valve (Spring) Brass, 3 Way Port Ball Valve Brass, Mini Ball Valve Brass, Root Valves, Brass Foot Valves, Nuts And Bolts, Screw Fastners, S.S.Ball Valves, Duplex Pipe Fitting, Stainless Steel Duplex Butt Weld Fitting, Duplex Steel Buttweld Fittings, Alloy Pipe, Beryllium Copper Alloy Products, Tantalum Plates, Tantalum Strip, Tantalum Tubes, Nimonic Alloy 90, Molybdenum Bolts, Hex Bolts, Tungsten Bolts, Nuts Fasteners, Mumbai, Maharashtra, India

0 notes

Text

Stainless Steel Sheets, 304 Stainless Steel CR Sheets, 316 SS Designer Sheets, Mumbai, India

Raj Enterprises, Mumbai, Are a Renowned Importer, Exporter, Trader And Stockist of Mumbai, India

http://www.rajentindia.net/stainless-steel-sheets.html

Importing, Exporting And Stocking Of Stainless Steel Products, Nickel Alloys, SS Pipes, MS Pipes, Alloys, Alloy Steel Pipes, Carbon Steel Pipes, Stainless Steel Pipes, Titanium Pipes, Titanium Sheet, Inconel Pipes, Hastelloy Pipes, Stainless Steel, Stainless Steel Tubes, Stainless Steel Plates, Stainless Steel Sheets, Carbon Steel Plates, Alloy Steel Plates, Stainless Steel Wires, Stainless Steel Round Bar, Steel Coils, 316 Stainless Steel CR Coils, 304 Stainless Steel CR Sheets, 316 Flat Bars, Stainless Steel Designer Sheets, 316 SS Designer Sheets, SS Designer Sheets, Stainless Steel Checkered Sheet, SS Gold Mirror Sheet, Non Ferrous Metals, Chequered Plate, Duplex Steel Sheets, 316 Stainless Steel Slitting Coil, Slitting Coil, Duplex Sheet, Seamless SS Tubes, Brass, Brass Wires, Brass Rods, Brass Round Bar, Brass Soft Wire, Brass Components, Copper, Copper Wire, Air Conditioning Copper Tubes, Earthing Copper Rods, Copper Strips Bus Bars, Copper Plates, Copper Circle, Copper Alloys Products, Copper Tubes, Copper Strips, Copper Earthing Plates, Copper Coils, Copper Flats, Copper Rods, Copper Nickle Rod, Non Ferrous Ingots, Non Ferrous Alloy Ingots, Antimony Ingot 99.65, Antimony Ingot, Nickel Inco, Backed Bismuth Ingots, Tin Ingots, Forges Fitting, Weld Neck Flange, Slip On Forged Flanges, Ring Joint Flange, Forged Flanges, Virgin Metals, Precision Metals, Valves, Manifold Valves, Gauge Valves, Stainless Steel 316 Needle Valves, Diaphragm Valve Cast Iron, Gate Valve Bronze, Heavy Brass Gate Valve, Swing Check Valve Brass, Check Valve (Spring) Brass, 3 Way Port Ball Valve Brass, Mini Ball Valve Brass, Root Valves, Brass Foot Valves, Nuts And Bolts, Screw Fastners, S.S.Ball Valves, Duplex Pipe Fitting, Stainless Steel Duplex Butt Weld Fitting, Duplex Steel Buttweld Fittings, Alloy Pipe, Beryllium Copper Alloy Products, Tantalum Plates, Tantalum Strip, Tantalum Tubes, Nimonic Alloy 90, Molybdenum Bolts, Hex Bolts, Tungsten Bolts, Nuts Fasteners, Mumbai, Maharashtra, India

0 notes