#bottle mould manufacturer in japan

Text

Awanti Polymoulds is shaping brand that stand out.

#pet bottle manufacturer#pet blow mould#plastic mould maker#blow mould manufacturer#pharma pet bottle moulds#mould manufacturer & supplier#awantipolymoulds#blow mould#pune#mould maker in india#mould manufacturer & supplier in ghana#mould makers in japan

0 notes

Text

Fishing net glass floats

These beautiful glass balls that many collect today have been around since about 1841, an invention that originated in Norway where old glass and or old bottles were blown into these balls or oval floats to hold fishermen's nets on the surface. However, from the early 20th century, Norway was replaced by Japan as the main producer, where old sake bottles were reused, which is why we are more likely to find these than european models today.

Japanese glass floats

The production process initially required much more skill than one would expect. After blowing, the floats were removed from the blowpipe and sealed with a button of molten glass before being placed in a cooling oven. While the floats were still hot and soft, markings were often stamped on or near the sealing button to brand the floats.

Garnblåser or glass floats

In a later manufacturing method, wooden moulds were used to speed up the float-making process. The glass bottles were blown into a mould to make it easier to achieve a uniform size and shape. The seams on the outside of the floats are a result of this process. This makes it easy to distinguish whether it is a hand-blown float or a float that has been blown into a mould.

Old fishing nets with glass floats hanging at a boathouse wall in Norway.

Most floats are in shades of green because this is the colour of glass from recycled bottles. However, clear, amber, aquamarine, amethyst, blue and other colours have also been produced. The most prized and rare colour is red or cranberry. The production of these colours was expensive as gold was used to produce the colour. Other brilliant colours such as emerald green, cobalt blue, violet, yellow and orange were mainly produced in the 1920s and 30s. Most of the coloured cars available for purchase today are replicas. Originals are difficult to find today. In the past, they were often found on the beaches because they had become detached from the nets and then washed ashore.

Sources below

Glass Ball, A comprehensive Guide for Oriental Glass Fishing Floats found on Pacific Beaches by Walt Pich

Beachcombing for Japanese Glass Floats by Amos L. Wood

370 notes

·

View notes

Text

Plastic Antioxidants Market Unidentified Segments – The Biggest Opportunity Of 2022

Advance Market Analytics released a new market study on Global Plastic Antioxidants Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Plastic Antioxidants Forecast till 2027*.

Plastic Antioxidants Slows Down the Oxidation Cycle of the Polymers by Scavenging Free Radicals. They Assist in Preventing Thermal Oxidation Reactions when Plastics are Processed at High Temperatures. They Provide Long Term Thermal Stability to Resins, Adhesives, Plastics, and Lubricants. They are Used to Either Help in the Processing of the Material, or to Make the Final Product More Appealing, Durable or Useful

Key Players included in the Research Coverage of Plastic Antioxidants Market are

BASF (Germany)

Songwon (South Korea)

Adeka Corporation (Japan)

SI Group (United States)

Clariant (Switzerland)

Solvay (Belgium)

Sumitomo Chemical (Japan)

Dover Chemical Corporation (United States)

3V Sigma S.P.A. (United States)

Ampacet Corporation (United States)

What's Trending in Market: Increasing Usage of the Plastic Antioxidants in the Healthcare Industry for Manufacturing Products like Medical Devices & Implants

Challenges: Problems Associated with the Disposal of the Plastic Products may pose a Challenge

Opportunities: Booming Plastics Industry Utilising Plastic Antioxidants for Providing Better Mechanical Strength in the Manufacturing of Products like Food Packaging Film, Plastic Bottles & Containers, Water Tank, Drums, Boxes, Containers, & Industrial Fittings

Market Growth Drivers: Rapid Growth in the Construction Industry using Plastic Antioxidants for Providing Improved Mechanical Strength to the Products like Coatings, Adhesives, Roofing Tiles & Shakes, Solar Shingles, Shutters, Architectural Coatings, Wire, & Pipes

Rise in Automotive Sector Involving Parts like Bumpers, Door Panels, Seat Back Covers, Pillar Mouldings, Door Trims, & Motorcycle Part Made from Plastics with the Addition of Plastic Antioxidants

The Global Plastic Antioxidants Market segments and Market Data Break Down by Type (Phenolic, Phosphite & Phosphonite, Antioxidant Blends, Others), Application (Automotive, Electronics, Construction, Packaging, Defense, Others), Packaging (Bottle, Bag, Others), Sales Channel (Direct Sales, Indirect Sales {Speciality Stores and E-Commerce}), Appearance (Crystal, Powder)

To comprehend Global Plastic Antioxidants market dynamics in the world mainly, the worldwide Plastic Antioxidants market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas.

• North America: United States, Canada, and Mexico.

• South & Central America: Argentina, Chile, Colombia and Brazil.

• Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa.

• Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia.

• Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia.

Presented By

AMA Research & Media LLP

0 notes

Text

electrical appliance and civil plastic products

Another invention of plastic called celluloid was developed by john Wesley Hyatt. Plastic is the most versatile material that is used in most applications today. Plastic injection molding is commonly used for creating various parts of cars, from tiniest elements to the whole body components.. This machine is a simpler version of today39;s injection molding machine. was initially established in 1988,but presently it is located in Far East Industrial Park, Yuyao City , Zhejiang Province. It is used to produce vast amount of parts. Based on over 10 year of indomitable efforts our company has adopted a service mode for product development ,mould-designing and making ,plastic injection-moulding and finished product-assembly in a coordinated process with the moulds-making and plastic products-processing as the mainstay .

Aside from creating various components of a car, injection molding is also used for almost plastic goods such Twin screw barrel for extruder as bottle caps, wire pools, packaging, pocket combs and some gadget components. This process involves feeding of material into barrel that is heated, afterwards, the material was mixed then placed into a cavity where it is allowed to harden and cooled. The wide range used of this material has made a great impact in most industrial world. This is a process of manufacturing plastic by using thermosetting plastic and thermoplastic substance. The common advantages of plastic mold are low labor cost, scrap losses are minimized, vast rate of production, finishing of parts is minimized and wide range of materials are can be utilized.

This product was an improved version of Parkes39;s invention. This process is widely used way in developing parts.,Ltd . The product was design mostly by an engineer or an industrial engineer. One of the processes in creating plastic product today is called plastic mold.The latters are subcontract products for motors ,intelligence robots ,auto accessories ,electrical teaching equipment ,office belongings ,medical devices ,gymnastic apparatuses ,kitchen minor electrical appliance and civil plastic products ,etc. This product is can be molded, heated and usually retains it shape when it is cooled, thus the downside of this is, it is extremely flammable, expensive and easy to crack. The first plastic product called Parke sine was created by Alexander Parkes in 1851. It is through John Wesley Hyatt and his brother wherein the first molding injection machine was developed. It has had customers throughout the United States ,Japan ,Korea and over 20 domestic provinces and municipalities. After the molded product was harden and cooled, a machine called precision-machined, with the supervision of a mold-maker, is used to form the specific feature of a part of a specified product.

0 notes

Text

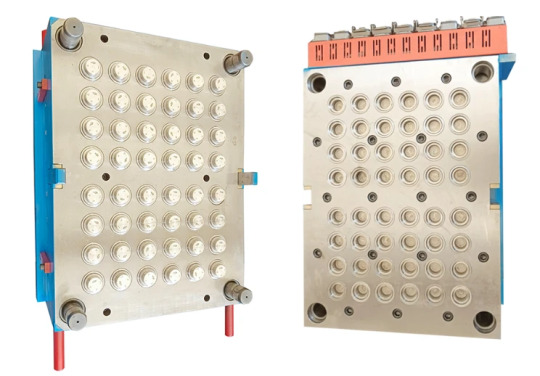

48 cavities cap mould, you deserve it!

The 48 cavities cap mould refers to a mould that can make 48 bottle caps at one time.

48 cavities cap mould customization process and its advantages

1. The steel adopts S136, 2316, 718, etc., we choose according to customer requirements; foreign steel suppliers: ASSAB in Switzerland, SAARS TAHL in Germany, DAIDOU in Japan, BOHLER in Austria, FKL in the United States, etc.

Domestic suppliers: Baosteel, Fugang, Great Wall Steel, etc.

2. Heat treatment and hardness

Different cap die components and steels use different techniques to ensure better polish and longer life. After vacuum quenching, the hardness of the cap model core and cavity can reach HRC 42-45, and the thimble can reach HRC55.

3. Runners

We use cold runners to reduce the cavities of cap molds For cap molds with more cavities, we recommend using a hot runner system. Each cavity is independently controlled by a temperature controller, making the temperature error up to 2 degrees Celsius to improve product quality and production efficiency. Our hot runner systems come from world-renowned brands, such as HUSKY.MASTER.YUDO.SYNVENTIVE, etc. Besides, we recommend you reliable hot runner system (made in China) to get more competitive price for cap mould with hot runner system.

4. Processing

(1) All machining is done by EDM and high-speed CNC machining center;

(2) We grind the moving parts such as the thimble to prolong the service life of the mold;

(3) High-precision mold processing and standard design, so that every part of the cap mold can be interchanged;

(4) The assembly of the cap mold is completed by a professional manufacturer to ensure the quality of the mold;

5. Cap mold cycle time and life

We offer two different options to meet reasonable cycle times:

(1) For water bottle cap molds and ordinary injection molding machines, the cycle time is generally around 12 seconds.

(2) The water bottle cap mold adopts fast cooling material and high-speed injection molding machine, and is equipped with reasonable auxiliary machines. The cycle time is generally 6 to 8 seconds. It uses good steel grades, reasonable heat treatment, and precise processing. The number of cap molds is at least Can reach 2 million times.

48 cavities cap mould supplier

In the past 20 years, we have produced various cap moulds, such as 48-cavity cap moulds, soda caps, beverage caps, etc. With advanced design and technology, we can produce 6s water cover, time is money. We can help you create more and more value.

We design, manufacture and export high quality cap moulds for customers from all over the world. And we have "DRAGON MOLD QUALITY STANDARD" to control the quality of each mold from design to shipment. Our company's mission is to help our customers achieve superior production capabilities at extremely low cost.

After you send your enquiry, the Gragon Tooling sales team is ready to provide you with a 24-hour on-time quote and our analysis of your tooling plans. As an experienced mold maker, Gragon Mould can provide you with budget calculation, mold quotation data calculation, investment return inspection and suggestion, plastic molding feasibility analysis, suitable material recommendation, injection molding machine model selection.

If you have a new plan to invest in the water packaging industry, please contact us by calling +86 18968581216 or sending an email to [email protected]. we can provide high-quality plastic production lines, including cap injection molding production lines, PET preform injection molding production lines. We are a direct mold and injection molding machine manufacturer, we can provide favorable price and convenient service. thanks.

0 notes

Text

Glass Bottles Market Size, Share, Industry Analysis, Future Growth, Segmentation, Competitive Landscape, Trends and Forecast 2021-2031

With a wide range of applications in the pharmaceutical, personal care, chemical, and food and beverage industries the demand for glass bottles is expected to remain strong for the foreseeable future. According to a new Future Market Insights (FMI) report, the market will surpass a valuation of US$ 61 Bn by the end of 2031 at a CAGR of over 5%.

The COVID-19 pandemic has brought the pharmaceutical, manufacturing, logistics, and packaging companies together to deliver the vaccines worldwide. Many COVID vaccines have been approved globally, and 150 + further vaccines are still in clinical trials.

Glass as a primary packaging material will play an essential role in the global vaccine supply chain. Packaging companies are working hard to prevent bottlenecks and shortages. For the vaccine packaging, type I borosilicate molded glass has emerged as a preferred material.

Glass bottles are chemically inert and are highly resistant to enzymes. Consequently, type 1 bottles are ideal to store and deliver vaccines across the globe.

The unprecedented surge in demand for vaccines has pushed manufacturers to increase production capacities to keep up with the supply demand gap. Key players of glass bottles such as Gerresheimer AG and SGD S.A. are committed to supplying type I borosilicate moulded glass vials to meet requirements arising during the crisis.

Key Takeaways from Glass Bottles Market

Type I grade glass bottles are expected to hold more than 50% of the value share owing to applications in storing strong solutions, acids, and alkalis.

Consumption of the 501-1000 ml glass bottles is expected to reflect relatively larger volumes, with notable demand from the beverage industry.

The U.S. is a prominent regional market, accounting for more than 84% of sales in North America owing to a mature food and beverage and pharmaceutical sector.

Germany currently holds the lead in Europe accounting for nearly a fourth of all regional sales in2021.

China accounts for more than 45% of the value share in East Asia, while Japan and South Korea will make small gains in the upcoming decade.

“A significant rise in the use of glass bottle packaging in the food and beverages industry owing to changes in consumer's preferences has generated demand. In addition, Type I borosilicate molded glass vials sales will consistently surge amid the Covid-19 pandemic. As a result, customer-centric, branded and affordable glass bottle offerings will drive developments through 2031” says an FMI analyst.

Customization Efforts to Reinforce the Demand for Glass Bottles

Customization details in the glass bottle industry are increasingly being made using 3D blueprints. Even labels and lids are designed using 3D technology. Manufacturers have come up with digital printing technologies for printing on glass bottles.

Glass bottles can be customized according to their shape, choice of finish, color, and design. The customization reinforces brand image, and helps in information dissemination to the consumer. Customization will make help the brands stand out from their competitors.

Impact of COVID-19 on the Glass Bottles Market

The ongoing COVID-19 pandemic has affected all the sectors. Pharmaceutical companies have leveraged key opportunities during the pandemic as the increased demand for glass vials for medical purposes will drive short-term revenue generation.

Glass bottle companies have been designated as essential services due to their role in food and beverage and pharmaceutical products. Also, glass bottles are regarded as safe packaging for food items; hence the demand for the glass bottles market has recovered and remained relatively consistent.

Across the globe, alcohol consumption has suffered due to lockdown and travel restrictions. However, online sales and relaxation of regulations, has helped to partially mitigate losses through home delivery services.

Get More Information

:

https://www.futuremarketinsights.com/reports/glass-bottles-market

0 notes

Text

A preform mould

A preform mould is a tool for molding plastic parts. It is an important component of a mold. Many manufacturers make preform mould for different types of products. A preform mould has multiple cavities and can be made in various sizes. Its structure is quite complex and is designed by a European company. The steel used in this tool is imported from Germany and Sweden, with high hardness and anti-corrosion properties. It is also equipped with a pneumatic drive pin from Japan for fast open and close actions. A patent-designed rectifying system helps minimize the thickness of a preform. It also eliminates water marks from the preform.

The preform mould can be used for various types of bottles. A well-designed preform mould can be used for different products. It is easy to change the weight of a bottle by replacing the neck ring with a different one. It can also be reused by another company. It is important to choose a preform mould with a split line. If you want to increase the life of your preform mould, you can choose one with a long life expectancy of over 2.5 million injection cycles.

Apart from these advantages, a preform mould can be used for a variety of different products. It is very durable and can withstand up to 2.5 million injection cycles. It can be used for a variety of applications. If you need a more rugged and durable preform mould, you can choose an alloy brass model. Its metal strip plate is made from alloy brass. Its high cooling efficiency and interchangeability of parts ensures its easy use.

The best part of a preform mould is its ease of use and flexibility. It is ideal for a wide range of products and is very versatile. Choosing a mold with this feature is beneficial for your business. You can choose between a series of sizes, a single mold, or a single mold. It is up to you to decide which one you need. You can even ask the manufacturer to provide a list of suppliers.

A preform mould is a great investment in the manufacturing process of plastic parts. It is an ideal tool for manufacturing and processing machinery. If you need it for a long-term product, you can invest in a mould that can handle multiple applications. You can even use a multi-purpose preform mould for your business. A single cavity mold can be used for different purposes. It may be a simple tool, or it can be an intricate system with many cavities.

A preform mould can have a long lifespan. A preform mould can handle 2.5 million injection cycles. This means that it is a durable and efficient tool. A high quality preform mould should last for a long time. It should be used to manufacture plastic parts, and should be reusable for other applications. It should not be reused after the original mold is finished. It should be discarded or sold to another company. Then, it can be used for new products.

The main components of a perform mould are made from S136 material. The base is made of P20 material that is imported from Germany. Its components are heat-treated with a German vacuum stove, which ensures that they are HRC45-48. In addition, it is also designed with advanced processing equipment to increase precision and interchangeability. This means that the preform mould will last a long time and will serve you for a long time.

A production preform mould with three different neck rings has a long lifetime and is suitable for various types of bottles. Its use life is much longer than that of a standard preform mould. It is designed for high-volume productions. The neck rings of the molds must be designed for each specific preform. Similarly, a high-output PET preform mould has a long-life compared to an ordinary one.

A preform mould should be versatile. It should be able to accommodate different types of preforms. It can also share the same cores. This is especially useful for multi-function productions. It is compatible with a large range of materials and is very efficient in manufacturing. It can also be used for a variety of applications. Its longevity is an important factor in selecting the right preform mould. A high-quality preform mould should last for over 2.5 million injection cycles.

0 notes

Text

How to design PET preform mould

PET preform mould for plastics materials (PET) have been made in some manner for centuries. Some of these PET preform moulds were fine works of art, as, for example, the moulds used by craftsmen in glass. The coming of the modern plastics moulding materials brought about great advancement in this old art, and transformed it into a science. Mass production PET preform moulding machinery has been developed, and new PET preform mould steels and alloys have been introduced to withstand severe service. Accuracy is a requirement in modern manufacturing, and PET preform moulded plastics are produced by steadily mounting standards of precision, which have necessitated new machine tool applications and methods.

A PET preform mould may be defined as a form for shaping a plastic material ”PET” into a finished product-here is PET preform. PET preform moulds are made of plain carbon steel or of alloy steels, and are hardened to provide compressive strength and hard surfaces to take and maintain a high polish under severe wearing conditions. PET preform moulding materials require heat and usually pressure to achieve the plasticity necessary for them to flow into the shape of the mould cavity. Pressure is required to force the material into the cavity and to hold it to shape until it is set, and to give the casting or finished product the required strength. A PET preform mould must be polished to give the casting a good finish,and to allow it to be ejected easily.

A mould for the general run of PET parts is divided into two halves which meet at the parting line. These halves are mounted on backing plates which are drilled to allow passage of steam or cooling water, and which carry the guide pins which aligning the halves of the PET preform mould. The mould halves and backing plates assembled constitute the PET preform mould proper.

The fundamentals of mould design are discussed and applied to representative type PET preform moulds. The important compression PET preform mould types are classified for study; transfer and jet moulding are described; injection PET preform moulds are presented both as units and broken down into elements of design and construction. Methods of moulding screw threads are discussed; methods of PET preform mould sinking and applications of mould base standards are shown. mould building methods and equipment, moulded parts finishing, product design considerations and estimating methods are included as background information. A summary of practical points in PET preform mould design and construction, shrinkage charts and a nomenclature section provide a basic fund of data required by the serious learner.

Since many factors enter into the design of plastics PET preform moulds, and into the design of products to be pet bottle mould, it is well for product designers, tool designers, and tool makers to have a common understanding of plastics PET preform moulds and PET preform moulding in order to cooperate to the fullest extent in making possible PET preform moulded products of high standards of quality and economy.

Requirements for PET preform mould Designing

To design plastics preform bottle mould, a plastics engineer should have an intimate knowledge of a proper design procedure which is based upon a knowledge of the characteristics of materials; of the technique of PET preform mould building; of the economics of each production schedule; of the tooling cost both to purchaser and to the PET preform mould manufacturers; of PET preform moulding equipment operation; of the special mould steels and alloys; and of the moulding and finishing facilities of his own plant.

The design of plastics PET preform moulds includes, besides the design of the mould proper, the provision for mounting the mould in a press; the provision of means to eject the finished PET bottle mould casting; and a provision for temperature control. There are also finishing tools to be designed, such as drilling jigs, buffing attachments, holding fixtures, cooling fixtures, gages, and other devices for obtaining accurate and economical production.

Two General Types of Plastic moulding in General Use

There are two general types of moulding in general use compression and injection. A compression Mould is one which is open when the material is introduced, and which forms the material by heat and by the pressure of closing. An injection Mould is one which is closed before the material is introduced from an external heating, or plasticizing cylinder. Compression Moulds are usually operated in hydraulic presses; while injection Moulding presses have been developed for either mechanical or hydraulic operation.

The Mould designer does not always have complete information on the product his Mould must produce. Usually a sketch or drawing is supplied, and sometimes a model. The model is useful since a Moulding or finishing feature may appear in three dimensions which would escape notice on a drawing. A model, while desirable, is not absolutely necessary, and most Moulds are built without their use. As the die or the die casting designer, the Mould designer can very frequently find details which may be altered slightly to allow more convenient and economical Moulding. The Mould designer can render a real service by making such suggestions for approval before completing his design.

Single Stage Blow Molding Machine

While PET bottle development was proceeding in the US, a large manufacturer of injection molding machines in Japan, was leading a project to develop a machine to make biaxially oriented PP (polypropylene) containers. They recognized that the prototype machine could be used to produce the new PET bottles and, in December 1975, the One-stage ASB-150 injection stretch blow moulding machine for making the new biaxial oriented PET bottles was unveiled. All one-stage injection stretch blow moulding machines derived from this original Stretch Blow design are referred to as classic one-stage machines, as the concept has long since been extended into other PET developments. The classic one-stage machines design is extremely versatile in that the same basic machine design can be used to make a wide variety of bottles and jars in all shapes and sizes.

Two Stage Blow Molding Machine

In the early developments, performs were made by continuously extruding a PET tube. To make these prefroms, a perform manufacturing machine that took a continuously extruded PET tube, heated and closed one end, and then heated the other and formed a thread finish by blow moulding. This process had a faster output rate, at 12000 preforms per hour, than the early injection moulding routes of 8 and 16 cavity moulds. Being extruded, the performs could be multilayered with barrier materials. The system was overtaken by injection moulded performs as the cavitation increased to 32 and beyond. The quality of the injection moulded (IM) neck, adding for example vent slots, made the IM finish preferable. Moreover, IM technology is available from more than one company, giving customers greater technical and commercial choice. Two-stage technology machines with six blow moulds operating at around 4000 bottles per hour. Subsequent mould and cooling development increased the output to 6000 bottles per hour.

Two stage PET processing includes:

Making performs by Injection Molding

Blowing bottles by Stretch Blow Molding

Because it is more flexible than one step processing, it is widely accepted in Plastic packaging market. You may choose to make preforms only or blow bottles only if you want to do one of them specially.

Integrated Two Stage Blow Molding Machine

In Integrated Two Stage approach the performs were made by more conventional injection moulding routes (with the number of cavities optimized to match the required output) and then, while still hot, were carried to a separate blowing machine with the optimized number of blow moulds to suit the required output. This was the first ‘integrated ‘approach to PET bottle making. Equipment developers took the ‘single-stage’ approach. Here the equipment had the same number of injection cavities as PET blowing mould. This was a more compact approach and proved ideal for small batch output with excellent glossy surfaces.

Blow molding is a type of plastic forming process for creating hollow plastic products made from thermoplastic materials. The process involves heating and inflating a plastic tube known as a parison or preform. The parison is placed between two dies that contain the desired shape of the product. Air is then supplied to expand the tube causing the walls to become thinner and conform to the shape of the mold. Once the blowing process is complete, the product is then cooled, ejected, trimmed, and prepared for the secondary processes.Bottling and packaging are the main applications of blow molding which comprise about 49% of the global blow molding market share. This is followed by building and construction, consumer products, and transportation industries.

The global market share of blow molding was estimated at around $78 billion in 2019 and is expected to grow annually by 2.8% from 2020 to 2027. Typical raw materials used are polyethylene (PE), polyethylene terephthalate (PET), and polypropylene (PP).Plastic blow molding originated from the ancient process of glass blowing. Both glass and plastic in their molten state can be formed easily by introducing small amounts of air inside the molten material. The first injection molding process for glass, known as free-blowing, was created around the 1st century BC. Glass mold-blowing was later developed as an alternative process that came about around the 1st century AD.The first blow molding material used other than glass was natural rubber. The process was patented by Samuel Armstrong in the 1850s. The next major advancement came around the 1930s with the development of the first blow molding machine by Plax Corporation. The process uses cellulose acetate as the raw material. Come 1939, low-density polyethylene (LDPE) was introduced by Imperial Chemical Industries from England. LDPE is more suitable for blow molding which then paved the way for further process development. By the 1950s, the commercialization of blow molding was completed, and the industry grew exponentially.

This chapter discusses the general blow molding process. Blow molding is a fairly straightforward process that includes melting, homogenizing, extruding, molding (blowing), cooling, and ejection. Different manufacturing plants can employ additional processes such as additional cooling or heating cycles and additives and colorants compounding. These additional processes depend on the design and intended application of the final product.

Plastic Resin Feeding or Charging: The first step in the blow molding process is plastic feeding. This is done by conveying the plastic pellets into the extruder hopper. Vacuum pumps draw pellets from big bags or bulk containers and transfer them into the raw material silos or hoppers. A rotary feeder at the bottom of the silo controls the rate of feeding into the plastifier or extruder. Compressed air is then used to convey the stored pellets to the extruder hopper. In other systems, plastic pellets from big bags or bins can be vacuum conveyed directly to the extruder hopper without the need for a separate conveying air system.

Plasticizing or Melting: As the plastic resin enters and goes through the extrusion machine, it is melted by continuous kneading and heating. Electric heating elements or heating bands are wrapped around the extruder barrel to provide heat for melting the polymer. The extruder screw has different sections that serve a specific purpose. These are feeding, compressing, and metering. The extruder screw is designed to provide sufficient shearing and compression to homogenize and extrude the plastic.

Parison Extrusion or Preform Injection: This process is the preparation of the parison or preform to be inflated. This is done by extruding the plastic through free extrusion or injection into a preform mold. The different processes in producing the preform are discussed in detail.

Sealing or Clamping: Sealing or clamping involves a split die that captures the preform. The ends of the parison (extrusion blow molding) are sealed except for one hole, typically the container opening, where the compressed air will be injected.

Inflation or Blow Molding: This step is where the plastic takes its form. Compressed air is introduced inside the preform. This inflates the preform until it is molded according to the profile of the die.

Cooling and Ejecting: The next step is the cooling process. Typically, as the plastic touches the die, it cools at a predefined rate which stabilizes the dimensions of the product. After cooling, the mold opens and ejects the product.

Trimming: Flashing is generally evident in extrusion blow molding. Most blow molding machines have auto deflashing features as the dies clamp the preform. But in some instances, flash is present at the top and bottom parts of the product, especially at the opening where compressed air is injected. This excess material is trimmed by a rotating knife. To minimize wastage, some systems collect the excess materials, grind them, and feed them back to the extrusion machine.

Leak Test: This is the typical quality control method used in manufacturing bottles or packaging materials. In this step, either vacuum or compression is generated inside the container. The machine will then check if air enters or escapes the container by monitoring the pressure. If a leak is sensed from the container, it is rejected and fed back into the system.

0 notes

Text

Bottled water industry in India

The global bottled water market estimated at USD 250 billion in 2018 is growing because of an acute awareness of the importance of safe drinking water for maintaining good health. Even the taste offered by the bottled water is playing a major role in the increasing demand in the market. Key players include Nestle, Danone, Coca-Cola and PepsiCo, and the maximum sale of water bottles comes from the retail sector.

The bottled water market in India was estimated at 160 billion Indian Rupees in 2018 and is growing at a CAGR of 20%. It was expected to cross 400 billion rupees by 2023. In terms of volume, it translates to a whopping 35 billion litres. But these figures could see de-growth because of the COVID pandemic. The four main pack-sizes are 250 ml, 500 ml, 1000 ml and 2000 ml. 5 litre and 20 litre jars are also widely available. The 1 litre bottle is the most common and widely sold pack-size, contributing to nearly 40 percent of the market share, followed by 500 ml, 250 ml and 2 litres.

There are around 150 registered brands being bottled over 6000 locations across India. As per government bodies, namely Bureau of Indian Standards (BIS) and Food Safety and Standards Authority of India (FSSAI), bottled water is governed under two categories: Packaged Natural Mineral Water and Packaged drinking water. The bottling plants are concentrated in the southern part of India, with 55% plants in four states. A bottling plant typically comprises machineries for water processing, bottle blowing, filling and capping, labelling and packing. Blowing machines are the starting point of the water bottle, and they range from manual and semi-automatic to fully automatic, producing bottles in the magnitude of thousands to lakhs every single day. The speed of these machines is expressed in terms of bottles per minute (bpm) or bottles per hour (bph). Key brands include Bisleri, Bailley, Kinley, Aquafina, Himalayan, Oxyrich, Rail Neer and Vedica, to name a few. Bisleri has the largest market share and is bottled across over 120 plants in India, followed by Kinley, Aquafina and Bailley.

Awanti Polymoulds manufactures blow moulds for water bottles of all pack-sizes to suit various blowing machines made by Sidel Synergy, Electropneumatic, Shyam Plastic among many others. With an experience of over 3 decades in the industry, Awanti is proudly associated with Bisleri, Bailley, Kinley, Oxyrich, Himalayan and many other brands for years together.

Bottled water industry is an ever-growing industry and Awanti aims to be a part of the success story of every Indian water brand!

#blow mould manufacturer in india#bottle mould manufacturer in japan#blow mould manufacturer in thailand

0 notes

Note

Could you tell us what you know/anything interesting about glass fishing floats? I think they're very neat looking!

Hi,

I love the glass fishing floats, I have a small replica of one in my living room. Now what do I know about… glass fishing floats are usually round glass balls filled with air to keep the fishing nets from sinking. They were probably first used in Norway (some say Japan, but there they have only been known since 1930) in the 1840s and can vary in shape and size.

These are replicas

They are usually between the size of a kiwi and a ball and can be round, egg-shaped, hemispherical or oval. The first ones were mouth-blown and made of sturdy glass in various shades, but mostly green because old bottles were reused. For this, the bottles were melted down and pressed into a wooden mould and blown out. There is also the variant that the glass dimensions are taken from the oven and blown into the desired shape by a glassblower, but this makes them relatively expensive to produce and so pressing them into moulds and blowing them out was easier and cheaper.

Different shapes of glass floats

However, it is rarely possible to identify only one manufacturer or owner, as they are quite clouded or even damaged by use on the lake. Finding whole specimens is rarely possible today. They are usually washed up on the beach as so-called sea glass or as shards. In other countries, this type of buoyancy aid appeared in the late 19th or even early 20th century, but was soon replaced by wooden or cork buoyancy aids.

Well, I hope I could help you and wish you a pleasant evening.

144 notes

·

View notes

Text

48 cavities cap mould, you deserve it!

The 48 cavities cap mould refers to a mould that can make 48 bottle caps at one time.

48 cavities cap mould customization process and its advantages

1. The steel adopts S136, 2316, 718, etc., we choose according to customer requirements; foreign steel suppliers: ASSAB in Switzerland, SAARS TAHL in Germany, DAIDOU in Japan, BOHLER in Austria, FKL in the United States, etc.

Domestic suppliers: Baosteel, Fugang, Great Wall Steel, etc.

2. Heat treatment and hardness

Different cap die components and steels use different techniques to ensure better polish and longer life. After vacuum quenching, the hardness of the cap model core and cavity can reach HRC 42-45, and the thimble can reach HRC55.

3. Runners

We use cold runners to reduce the cavities of cap molds For cap molds with more cavities, we recommend using a hot runner system. Each cavity is independently controlled by a temperature controller, making the temperature error up to 2 degrees Celsius to improve product quality and production efficiency. Our hot runner systems come from world-renowned brands, such as HUSKY.MASTER.YUDO.SYNVENTIVE, etc. Besides, we recommend you reliable hot runner system (made in China) to get more competitive price for cap mould with hot runner system.

4. Processing

(1) All machining is done by EDM and high-speed CNC machining center;

(2) We grind the moving parts such as the thimble to prolong the service life of the mold;

(3) High-precision mold processing and standard design, so that every part of the cap mold can be interchanged;

(4) The assembly of the cap mold is completed by a professional manufacturer to ensure the quality of the mold;

5. Cap mold cycle time and life

We offer two different options to meet reasonable cycle times:

(1) For water bottle cap molds and ordinary injection molding machines, the cycle time is generally around 12 seconds.

(2) The water bottle cap mold adopts fast cooling material and high-speed injection molding machine, and is equipped with reasonable auxiliary machines. The cycle time is generally 6 to 8 seconds. It uses good steel grades, reasonable heat treatment, and precise processing. The number of cap molds is at least Can reach 2 million times.

48 cavities cap mould supplier

In the past 20 years, we have produced various cap moulds, such as 48-cavity cap moulds, soda caps, beverage caps, etc. With advanced design and technology, we can produce 6s water cover, time is money. We can help you create more and more value.

We design, manufacture and export high quality cap moulds for customers from all over the world. And we have "DRAGON MOLD QUALITY STANDARD" to control the quality of each mold from design to shipment. Our company's mission is to help our customers achieve superior production capabilities at extremely low cost.

After you send your enquiry, the Gragon Tooling sales team is ready to provide you with a 24-hour on-time quote and our analysis of your tooling plans. As an experienced mold maker, Gragon Mould can provide you with budget calculation, mold quotation data calculation, investment return inspection and suggestion, plastic molding feasibility analysis, suitable material recommendation, injection molding machine model selection.

If you have a new plan to invest in the water packaging industry, please contact us by calling +86 18968581216 or sending an email to [email protected]. we can provide high-quality plastic production lines, including cap injection molding production lines, PET preform injection molding production lines. We are a direct mold and injection molding machine manufacturer, we can provide favorable price and convenient service. thanks.

0 notes

Photo

Jul 10, 2020

Project Blu Turns Fishing Net Into Eco-Chic Pet Products

Emanuela Barbiroglio

Rockfish trapped in lost Fishing Net, Scorpaena scrofa, Cap de Creus, Costa Brava

Project Blu will launch its new ‘ghost fishing net’ collection made of recycled gear in September 2020. The UK based business with manufacturing facilities in Tuscany, Italy, wants to use discarded nets to make sustainable design accessories for pets.

Behind the initiative, there is the goal to solve two issues at the same time: harmful materials in the oceans and harmful materials in pet owners' houses.

“We are on a mission to prove sustainability and style can work in harmony,” they state. “We call it Eco-Chic.”

Before Project Blu was formed, its founder Geryn Evans had been designing and manufacturing pet products for over four years. The original brand (Ralph & Co) was created as a disruptive concept brand that offered high quality, scalable and affordable designs. It offered dog beds, collars, leashes and toys all made in Italy and available in retailers like John Lewis and Joules.

During this time, he realized that the market was dominated by mass produced, unsustainable and low quality articles. For instance, the production and recycling of virgin polyester as well as traditional leather used for these articles can have a strong impact on the environment.

“There has been very little eco-friendly innovation in this category,” Evans says. “It became quite clear that pet accessories had a significant negative impact on our planet.”

It was just a matter of finding the right materials to substitute the wrong ones.

The brand, launched in May 2019, initially produced beds, collar and leads by converting ocean-bound plastic and recycled clothing. Since then, other product innovations like recycled leather were introduced. In the first 12 months, they sold over 87,000 products made from over 6 million plastic bottles.

Yet, bottles are only part of the waste problem. It is estimated that over 640,000 tons of fishing gear is lost or discarded in the oceans every year, not really dissolving for centuries and so causing detrimental problems to the marine life that gets caught in.

The fishing net solution was inspired by the work of Bureo, a brand that converts fishing nets into skateboards and that is now working closely with Patagonia to expand the offering. After researching the production methods required and identifying a source of fishing nets in Europe, the idea started to become a reality.

“Project Blu was born from a desire to drive positive change within the pet industry and tackle these harmful issues,” Evans says. “ It is our mission to prove that brands can be sustainable, stylish and profitable.”

They partnered with the Danish recycling company Plastix Global to convert nets into a number of ‘plastic style’ pet products like feeding bowls and litter trays.

After they finalized the designs and samples, Project Blu analyzed if the products were feasible in terms of affordable, competitiveness along the supply chain, scalability and secondary environmental impacts.

The production process starts by sourcing fishing nets, trawls and ropes from a number of ports, net makers and plastics collectors globally. The materials are sorted, divided into the different types of plastics and colors, shredded, washed, separated and converted into pellets. Project Blu then combines these pellets with post-consumer plastic waste and injection mould the materials to convert the end product.

Evans says that “Project Blu is on a mission to revolutionize the pet accessories market” and he adds: “Consumer appetite to our products has been overwhelmingly positive but the truth is, we are only just getting started.”

“Our ambition is to offer a full range of sustainable pet products that can compete in terms of price, placement and style on a global scale. Our main focus has been on the European market but we aim to prioritize direct-to-consumer channels and expand into North America in September, and other key pet markets including Brazil, Japan, South Korea and Australia in 2021.”

Project Blu received investment from Mars, R/GA and Michelson Found Animals. They would like to expand into new markets, for example home furnishings, next year.

0 notes

Text

Smart Plant-Based Food Packaging Market Analysis & Forecast with 2020

Global Smart Plant-based Food Packaging Market: Snapshot

The global smart plant-based food packaging market is expected to gain a lasting impetus with continuous research and development activities for promoting bioplastic innovation. The market could provide food packaging products that are favorable for the health of the planet and also keep ingredients fresh for a longer period of time. Smart plant-based food packaging is projected to revolutionize the way people utilize, store, and purchase groceries without worrying much about waste.

Leading players operating in the global smart plant-based food packaging market are foreseen to come up with new offerings that could not only improve the shelf life of various food products but also protect the ingredients from the damaging effects of their surroundings. Smart plant-based food packaging is predicted to ride on their enhanced and novel preservation properties for increasing its demand in the market. This could be due to the implementation of value-added oxygen barriers in bioplastic. A new type of green plastic is envisaged to take shape in the market with the combination of complex technologies such as nanoparticle components and biopolymers.

Request A Sample Copy Of The Report https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=14936

The usage of sensors in smart plant-based food packaging could be a significant addition envisioned to up the demand in the market at a high rate. Such sensors could notify consumers when the food was sourced, its temperature, and also pH levels. Even seafood could be held inside smart plant-based food packaging with the introduction of pot and bottle type products. Furthermore, food manufacturers are forecasted to reduce their carbon footprint with the implementation of smart plant-based food packaging.

Food packaging is essential for containment of products, preservation and protection, to reduce food spoilage, eliminating the risk of adulteration and present food in a hygienic and aesthetically attractive way. According to the Agriculture and Food Organization, one third of the food in the world is wasted and most of this wasted food is generated by retailers and consumers who follow dates on packages and throw away edible food due to a label. Therefore, a project was initiated in order to develop plant-based bioplastic food packaging which increases the shelf life of food and the researchers also have formulated sensors that notify the consumers and retailers whether the food inside can be consumed or not.

These smart plant-based food packaging not only extend the life of the food product but also eliminates the need for environment-harming plastic. The smart plant-based food packaging market can be segmented on the basis of product type, material type and as per the region. On the basis of product type, the market is segmented into blow moulded, pot designed and others. On the basis of material type, it is divided into cellulose based film and blow moulded film. On the basis of region, the market is segmented into North America, Europe and the emerging countries of Asia Pacific.

Safety of food products has become a top priority of consumers on a global scale. Increasing awareness among the consumers regarding the environmental concerns and gradual change in buying habits is likely to propel the smart plant based food packaging market. Biodegradable plant based polymers in plant based food packaging is manufactured by cultivating carbohydrates via bacteria, while bio plant based polymers are macromolecules derived from plant residues. This provides the plant based food packaging improved food preservative properties. It is mainly designed to extend shelf life of the food and also to protect the contents from its surroundings. Standard packaging permits the entry of air which places limitations on shelf life of the food.

There is a lot of opportunity existing in the food packaging market in the developing economies as the food packaging technology is making huge progress in these regions. North America is leading the food packaging market followed by Asia Pacific and Europe. But somehow the growth rate shown in these regions have subsided considerably as the market is close to its peak. This growth is however restored by the high growth rate regions of Asia Pacifica which includes China, India and Latin America.

Smart plant based food packaging is one of the areas where food packaging companies can emphasize on refining their practices. Reutilizing in-house and using eco-friendly and/or recyclable packaging is another step, but making plant based material and packaging means using more biodegradable products. Heinz, Coca-Cola and SINTEF are the major companies participating in the movement towards the use of smart plant based food packaging. Coca-Cola uses Brazilian sugarcane but is also looking into other plant based materials. Currently all of the company’s bottles are made of fully recyclable plastic using bio-based products whereas SINTEF is now ready to present the first demonstration of packaging made from polyactic acid. The company has partnered with other collaborators like Logoplaste and Greek company Agro to develop plant based food packaging. Other food packaging companies need to find if they can alter their packaging necessities and fit plant based packaging material in their budget for which the USDA has proposed a loan guarantee program which will give these manufacturers easy access to loan and also cheaper interest rates in order to build a new plant.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

The study is a source of reliable data on:

Market segments and sub-segments

Market trends and dynamics

Supply and demand

Market size

Current trends/opportunities/challenges

Competitive landscape

Technological breakthroughs

Value chain and stakeholder analysis

The regional analysis covers:

North America (U.S. and Canada)

Latin America (Mexico, Brazil, Peru, Chile, and others)

Western Europe (Germany, U.K., France, Spain, Italy, Nordic countries, Belgium, Netherlands, Luxembourg)

Eastern Europe (Poland, Russia)

Asia Pacific (China, India, Japan, ASEAN, Australia and New Zealand)

Middle East and Africa (GCC, Southern Africa, North Africa)

The report has been compiled through extensive primary research (through interviews, surveys, and observations of seasoned analysts) and secondary research (which entails reputable paid sources, trade journals, and industry body databases). The report also features a complete qualitative and quantitative assessment by analyzing data gathered from industry analysts and market participants across key points in the industry’s value chain.

Request For Covid19 Impact Analysis https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=14936

A separate analysis of prevailing trends in the parent market, macro- and micro-economic indicators, and regulations and mandates is included under the purview of the study. By doing so, the report projects the attractiveness of each major segment over the forecast period.

Highlights of the report:

A complete backdrop analysis, which includes an assessment of the parent market

Important changes in market dynamics

Market segmentation up to the second or third level

Historical, current, and projected size of the market from the standpoint of both value and volume

Reporting and evaluation of recent industry developments

Market shares and strategies of key players

Emerging niche segments and regional markets

An objective assessment of the trajectory of the market

Recommendations to companies for strengthening their foothold in the market

Note: Although care has been taken to maintain the highest levels of accuracy in TMR’s reports, recent market/vendor-specific changes may take time to reflect in the analysis.

This study by TMR is all-encompassing framework of the dynamics of the market. It mainly comprises critical assessment of consumers’ or customers’ journeys, current and emerging avenues, and strategic framework to enable CXOs take effective decisions.

Our key underpinning is the 4-Quadrant Framework EIRS that offers detailed visualization of four elements:

Customer Experience Maps

Insights and Tools based on data-driven research

Actionable Results to meet all the business priorities

Strategic Frameworks to boost the growth journey

The study strives to evaluate the current and future growth prospects, untapped avenues, factors shaping their revenue potential, and demand and consumption patterns in the global market by breaking it into region-wise assessment.

The following regional segments are covered comprehensively:

North America

Asia Pacific

Europe

Latin America

The Middle East and Africa

The EIRS quadrant framework in the report sums up our wide spectrum of data-driven research and advisory for CXOs to help them make better decisions for their businesses and stay as leaders.

Below is a snapshot of these quadrants.

1. Customer Experience Map

The study offers an in-depth assessment of various customers’ journeys pertinent to the market and its segments. It offers various customer impressions about the products and service use. The analysis takes a closer look at their pain points and fears across various customer touchpoints. The consultation and business intelligence solutions will help interested stakeholders, including CXOs, define customer experience maps tailored to their needs. This will help them aim at boosting customer engagement with their brands.

2. Insights and Tools

The various insights in the study are based on elaborate cycles of primary and secondary research the analysts engage with during the course of research. The analysts and expert advisors at TMR adopt industry-wide, quantitative customer insights tools and market projection methodologies to arrive at results, which makes them reliable. The study not just offers estimations and projections, but also an uncluttered evaluation of these figures on the market dynamics. These insights merge data-driven research framework with qualitative consultations for business owners, CXOs, policy makers, and investors. The insights will also help their customers overcome their fears.

3. Actionable Results

The findings presented in this study by TMR are an indispensable guide for meeting all business priorities, including mission-critical ones. The results when implemented have shown tangible benefits to business stakeholders and industry entities to boost their performance. The results are tailored to fit the individual strategic framework. The study also illustrates some of the recent case studies on solving various problems by companies they faced in their consolidation journey.

4. Strategic Frameworks

The study equips businesses and anyone interested in the market to frame broad strategic frameworks. This has become more important than ever, given the current uncertainty due to COVID-19. The study deliberates on consultations to overcome various such past disruptions and foresees new ones to boost the preparedness. The frameworks help businesses plan their strategic alignments for recovery from such disruptive trends. Further, analysts at TMR helps you break down the complex scenario and bring resiliency in uncertain times.

You May Also Like PRNewswire on

https://www.prnewswire.com/news-releases/sake-brewery-industry-to-play-a-positive-role-in-cubitainers-market-growth-from-2020-to-2028-transparency-market-research-301104740.html

You May Also Like PRNewswire on

https://www.prnewswire.com/news-releases/penetration-of-advanced-technologies-to-bring-a-paradigm-shift-in-growth-of-warranty-management-system-market-north-america-to-add-numerous-feathers-of-growth-opines-tmr-301110185.html

The report sheds light on various aspects and answers pertinent questions on the market. Some of the important ones are:

1. What can be the best investment choices for venturing into new product and service lines?

2. What value propositions should businesses aim at while making new research and development funding?

3. Which regulations will be most helpful for stakeholders to boost their supply chain network?

4. Which regions might see the demand maturing in certain segments in near future?

5. What are the some of the best cost optimization strategies with vendors that some well-entrenched players have gained success with?

6. Which are the key perspectives that the C-suite are leveraging to move businesses to new growth trajectory?

7. Which government regulations might challenge the status of key regional markets?

8. How will the emerging political and economic scenario affect opportunities in key growth areas?

9. What are some of the value-grab opportunities in various segments?

10. What will be the barrier to entry for new players in the market?

0 notes

Text

Sustainable Packaging Market Analysis, growth with Top Manufactures and Business Opportunities

Sustainable Packaging Market Report is a collective informative report that goes through the fundamental characteristics of the Market Research Store, essential to be understood by the client including an expert. Sustainable Packaging market’s financial condition by taking into consideration various factors such supply chain, demand, size, manufacture analysis, forecast trends, share, production, sales, growth of Sustainable Packaging Markey By Few of the major competitors Amcor Limited, Bemis Company Inc., Tetra Laval International SA, Mondi, WestRock Company, BASF SE, Sonoco Products Company, Smurfit Kappa, Sealed Air, Huhtamaki, Gerresheimer AG, BALL CORPORATION, Ardagh Group S.A., Crown, DS Smith, International Paper, Berry Global Inc., Reynolds, Genpak LLC., DuPont, Plastipak Holdings Inc., Uflex Ltd., ELOPAK, and Evergreen Packaging LLC.

Sustainable Packaging Market solves one of the major issues for the authority that is of waste management. These factors are seen responsible for the Sustainable Packaging Market’s CAGR of 6% in the forecast period of 2018-2025, which will witness a rise in the estimated value of USD 168.3 billion in 2017 to an estimated value of USD 268.2 billion by 2025.

Request a sample copy at: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-sustainable-packaging-market

Market Drivers:

Rise in non-bio-degradable plastic waste is one of the main reasons for the adoption of Sustainable Packaging methods

Backing of government and authorities producing bio-degradable packaging is one of the major factors regarding the growth of the market

Market Restraints:

High set-up and initialisation costs for these packaging methods is one of the major reasons for the market growth to be halted

Municipal Solid Waste’s inefficiency related to recycling is also halting the production of Sustainable Packaging products.

Major Market Competitors/Players

Few of the major competitors currently working in the Sustainable Packaging Market are Amcor Limited, Bemis Company Inc., Tetra Laval International SA, Mondi, WestRock Company, BASF SE, Sonoco Products Company, Smurfit Kappa, Sealed Air, Huhtamaki, Gerresheimer AG, BALL CORPORATION, Ardagh Group S.A., Crown, DS Smith, International Paper, Berry Global Inc., Reynolds, Genpak LLC., DuPont, Plastipak Holdings Inc., Uflex Ltd., ELOPAK, and Evergreen Packaging LLC.

Get Detailed TOC: @ https://www.databridgemarketresearch.com/toc/?dbmr=global-sustainable-packaging-market

Sustainable Packaging Market Segmentation

By Material (Paper & Paperboard, Plastic, Metal, Others)

By Function (Active, Moulded Pulp, Alternate Fiber)

By Process (Recycled Content, Reusable, Degradable)

By Layer (Primary, Secondary, Tertiary)

By Packaging Type (Trays, Bags, Boxes, Bottles & Jars, Films, Pouches & Sachets, Drums, IBC, Others)

By End-User (Food, Beverage, Automobile & Electronics, Chemical, Pharmaceutical, Agriculture, Personal Care)

Market Segment by Regions, regional analysis covers:

North America (USA, Canada and Mexico)

Europe (Germany, France, UK, Russia and Italy)

Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

South America (Brazil, Argentina, Columbia, etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

The Global Sustainable Packaging market research report offers the predictable forecast market growth trend on the basis of past business strategy, current market growth patterns the market is following, and the different guidelines and strategies authorized by the organization, which have been affecting or could affect the market development. In general, the global Sustainable Packaging market report provides the complete and in-depth survey of the Sustainable Packaging market at the global level.

The Global Sustainable Packaging Market Research Report Scope

• The global Sustainable Packaging market research report elucidates the market characteristics—from market description to its regional analysis.

• Regional segmentation analysis has been thoroughly researched in the global Sustainable Packaging market research report.

• Competitive study of the global market is evaluated on production capability as well as production chain, along with the key Sustainable Packaging market.

• The global Sustainable Packaging market is also analyzed on the production size, product price, demand, supply information and income generated by goods.

• For thorough analysis of the global Sustainable Packaging market, multiple analysis parameters such as asset returns, market appearance analysis and the probability have been used.

Browse full table of contents and data tables at: https://www.databridgemarketresearch.com/reports/global-sustainable-packaging-market

Reasons for Buying this Sustainable Packaging Report

1. Sustainable Packaging market report aids in understanding the crucial product segments and their perspective.

2. Initial graphics and exemplified that a SWOT evaluation of large sections supplied from the Sustainable Packaging industry.

3. Even the Sustainable Packaging economy provides pin line evaluation of changing competition dynamics and retains you facing opponents.

4. This report provides a more rapid standpoint on various driving facets or controlling Sustainable Packaging promote advantage.

5. This worldwide Sustainable Packaging report provides a pinpoint test for shifting dynamics that are competitive.

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Text

Bottle Filling Machines: a Growing Market

Across the world, bottles account for one-third of the world’s rigid packaging market. Bottles have always been preferred for consumable and industrial liquids and their use is expected to grow despite increasing shift to flexible packaging.

Bottle filling machines are available primarily in automatic and semiautomatic versions, however some manufacturers are using custom filling & packaging systems to improve the efficiency of their operations. Driving the market for bottle filling machines is the growing demand for bottle packaging which mainly includes PET and glass bottles.

PET bottle market

Polyethylene terephthalate (PET) refers to a thermoplastic polymer resin of the polyester family which is widely used for manufacturing plastic bottles. In comparison with PP, HDPE and PVC bottles, PET bottles are more durable, transparent, lightweight, non-reactive, cost-effective and thermally stable. Moreover, they are environment-friendly and can be recycled repeatedly which further reduces their manufacturing cost. Primarily used in the packaging of drinking water and beverages, PET bottles are also gaining prominence as a packaging solution for salad dressings, household cleaners, medicines, dish detergents and mouthwashes.

According to imarc, the global PET bottle market reached a volume of more than 17 Million Tons in 2018, and is further projected to reach a volume of nearly 19 Million Tons by 2024.

Although there are growing concerns about plastic packaging, advancements in technology have created a positive outlook for the PET bottle market. For instance, manufacturers have introduced a plasma-based coating which makes PET bottles more impervious in nature. Apart from this, they have also started utilizing silver to increase the product shelf life. In Germany, manufacturers are inventing new interior coating processes like FreshSafe PET that makes bottle-to-bottle recycling possible.

Glass bottle market

Glass is a recyclable packaging material with superior attributes that include hygiene, reusability, chemical stability, durability and the capability to preserve the aroma, strength and flavor of the product. It is also eco-friendly, water-proof, and can be moulded into aesthetically pleasing shapes which makes it the preferred option for packaging beverages, food products, pharmaceuticals, cosmetics and chemicals.

As per Glass Container Market Research Report 2019 from Market Research Future, the glass bottles and containers market was valued at USD 62.01 million in 2018, and it is expected to reach a value of USD 76.16 million by 2024, at a CAGR of 4.20% over the forecast period 2019-2024. Europe is the largest glass bottle container market, primarily because it is the largest alcohol and beer producing region of the world.

Bottle Filling Machines

Broadly speaking, bottle filling machines are of two types: Rotary and Inline. The type of machine depends on the product to be filled. For example, a bottle filling machine that fills bottled water cannot be used for filling cold cream; nor can a bottle filling line for liquid chemicals be used for dairy products. The choice of filling machine depends on the range of viscosities, temperature, particulate size, chemical compatibility, hazardous environment considerations, etc.

Some of the dynamics driving the Bottle Filling Machine market are:

Improving supply chain capabilities which enable manufacturers to penetrate new markets and regions.

Increased consumption/demand for alcoholic and non-alcoholic beverages across the globe

Increasing penetration of modern retail outlets

Rising trend of Westernization, changing food habits and increasing disposable income, especially in the Asia-Pacific region (excluding Japan)

Hectic urban lifestyles that make consumers opt for on-the-go beverages

Growing preference for bottle packaging for chemicals and other liquids

These factors are also generating the need for using different machines for filling different type of products which in turn, are pushing up the demand for bottle filling machines. So for bottle filling machine manufacturers, who can provide machines for diverse products, and in economical to high-end models, the prospects look bright.

0 notes

Link

To find out which moulding process is better suits you, contact Awanti Polymoulds, one of the largest mould manufacturers in India. We are the leading blow mould manufacturers in India and a prominent provider of advanced blow moulding technology. We specialize in blow moulds for rotary machines and PET blow moulds. Awanti Polymoulds is known for its commitment to quality products and client satisfaction.

#mould maker in japan#blow mould manufacturer in thailand#pet bottle manufacturer#moulding process'#difference between blow mould & injection moul

0 notes