#cal osha training materials

Text

OSHA Workplace Safety Training, Consultancy: PCS Safety, California

PCS Safety: Providing quality workplace safety services Company & training including OSHA training to public/private sectors in California and throught United States..

Cal OSHA safety training for Workers – cal osha training coursesA Mandate: The Cal OSHA training module ensures that cal osha safety training workers are eligible for workplace safety osha citation for their positions regardless of industry. Its Known as california safety training

osha citation response Importance of Safety Work Permit by PCS safety Inc - osha certification California A safe system of work permit is an effective vehicle for communicating critical safety information. Safe Lifting Poster- Employers are encouraged to post this guide osha license to help workers follow OSHA’s ergonomic compliance and meet OSHA’s mandatory training requirement.

osha 40 hours- 40 hour hazwoper

labor law posters california - First Aid Compliance for Your first aid training Workplace California Forklift Certification Requirements for Employers workplace first aid What is PSM – Process Safety Management Program, is it Important

Injury and Illness Prevention (IIP) Program Plan Kit : Under Title 8 of the California Code of Regulations (T8CCR) Section 3203, every California employer is required to have a documentable llness injury preventino program kit. At PCS Safety, Inc., osha injury and illness prevention program our Injury and Illness Prevention Plan Kit injury and illness prevention program osha will help you prepare and meet the legal requirements. The first step is conducting injury illness prevention program california the OSHA Inspections & Citation Representation, injury illness prevention program Citation & Appeals.

CAL-OSHA COMPLIANCE TRAINING

Cal OSHA Compliance Training : The Safety Program or Illness and Injury Prevention Program as required by Cal OSHA training requirements must encompass the following elements:

1)Compliance 2) Communication 3) Hazard Assessment 4) Accident/Exposure Investigation 5) Hazard Correction 6) Training and Instruction 7) Record-keeping Compliance is cal osha training courses something every organization with one or more employees must comply with all of the above-mentioned requirements. Cal OSHA Training materials (e.g., interactive videos, online training, and more) that address the topics required by OSHA, are vital documents that you need to prepare, as well as emergency response plans.

#"llness injury preventino program kit#osha injury and illness prevention program#injury and illness prevention program osha#illness prevention program#injury illness prevention program california#injury illness prevention program#cal osha training requirements#cal osha compliance training#cal osha training courses#cal osha training materials#cal osha safety training#cal osha training#california safety training#safety work permit#safe lifting poster#labor law posters California#first aid compliance#california forklift certification requirements#process safety management program

1 note

·

View note

Text

Spoilers for The Acolyte below. I'm serious. S p o i l e r s

Carrie Anne Moss was a centerpiece for their marketing campaign.

Her character, a Jedi, is killed within the first five minutes.

She is one of about four random Jedi we do not get to know , whom (one of) Amandla Stenberg's characters is seeking revenge against.

For reasons we still don't really know or care about within the first two episodes.

I don't know about anyone else, but when you get Carrie Anne Moss in your production only to drop her like that?

If that gives you any idea as to the quality of the writing, well.

Stenberg plays twins in this one, Osha and Mae, in a standard, hackneyed, "one of them was thought to be dead" scenario. Both twins were once Jedi-in-training, as children, and the one everyone assumed was dead (Mae) went off to join a Sith (how do we know? The red lightsaber and wanting to kill Jedi is a pretty big giveaway), while the other is a Cal Kestis-type mechnec with a pip droid who dropped out of Jedi High to tool around on Trade Federation ships.

Like you do.

It's assumed that Osha is the Jedi killer (in spite having zero reason), and this gets their old Jedi teacher involved and a non-chase to easily find out the truth. I say "easily" since the Jedi are a weird non-presence in this one: they're everywhere and yet they make no impression (unlike the bureaucratic knobs of the Empire in Andor, the Jedi are just....moving wallpaper). Jedi should be at least marginally interesting, but with so much world-building work done in so many other Star Wars shows, this one doesn't care to offer anything new or insightful (and, to be fair, probably doesn't have time to).

These episodes are only 30 minutes long, re-hash a lot of old material and waste pretty much everyone involved. Along with Stenberg, this show has Dafne Keen, Lee Jung-jae, Manny Jacinto, Charlie Barnett and Jodie Turner-Smith in roles that really aren't much to phone home about. Only Keen, as a clever Padawan, leaves any kind of impression (and is also largely unrecognizable). There's a smidgeon of a hint of chemistry between Stenberg and Keen, but as one seems dedicated to her Jedi training, not counting on that going anywhere.

The end of episode two brings us to a world visited in the game Jedi: Survivor, where we meet a Wookie Jedi, presumably in hiding. Well, I mean, they say it's a Wookie, but it looks less like a cousin of Chewbacca and closer to Baby Bigfoot.

So far, this seems like an afternoon kid's special of Star Wars off-cuts that, who knows, might get better over its run. It's got enough talent behind it (not least of which is its queer showrunner, Leslye Headland who last exec produced Russian Doll and is gearing up to direct the film version of The Seven Husbands of Evelyn Hugo).

I'm still just stunned at the laziness of it all though.

You got fucking Trinity to wield a lightsaber for all of one minute and killed her off?

Without even a Padawan around to mourn her, this really looks like a cheap casting stunt.

Will we get to see what these Jedi did to piss off Rue's twin? IMDB has Moss down for only one episode. If this was all they used her for, yikes. For her five minutes of screen time, Moss added more gravity than any of the others combined and if we really don't see her again? What a waste.

7 notes

·

View notes

Text

Workers Compensation Insurance for Roofers In California

Introduction

Workers' compensation insurance is essential for high-risk professions such as roofing. Given the inherent dangers associated with roofing work, it is crucial for roofing companies in California to understand and comply with workers' compensation regulations. This article explores the key elements of workers' compensation insurance for roofing companies in California, including legal requirements, coverage options, challenges, and best practices.

Legal Requirements

In California, employers are required to carry workers' compensation insurance for all employees, including part-time, temporary, and seasonal workers. This mandate is particularly important for roofing companies due to the high-risk nature of the work.

Key Points:

Mandatory Coverage: Roofing companies must provide workers' compensation coverage for all employees, regardless of the duration or nature of their employment.

Compliance with State Laws: The California Department of Industrial Relations (DIR) and the Division of Workers' Compensation (DWC) oversee compliance with workers' compensation regulations. Roofing companies must adhere to these regulations to avoid penalties and ensure employee protection.

Reporting and Record-Keeping: Employers are required to report work-related injuries and illnesses promptly and maintain accurate records.

Coverage Options

Roofing companies in California have several options for obtaining workers' compensation insurance. These include purchasing a policy from a private insurance carrier, utilizing the state's assigned risk pool for high-risk employers, or self-insuring if the company meets specific financial criteria set by the DIR.

Key Points:

Private Insurance: Many roofing companies prefer private insurance for its flexibility and variety of available policies.

State Compensation Insurance Fund (SCIF): SCIF is a state-run program that provides workers' compensation insurance, especially for businesses that have difficulty obtaining coverage through private insurers.

Self-Insurance: Larger companies with substantial financial stability might choose to self-insure. This option requires state approval and a demonstration of financial capability.

Challenges for Roofing Companies

Roofing companies face unique challenges in managing workers' compensation insurance:

High Risk of Injury: Roofing is a high-risk occupation with potential hazards such as falls, tool injuries, and exposure to extreme weather conditions.

Varied Work Environments: Roofers work in different environments, including residential, commercial, and industrial sites, each with unique safety challenges.

High Turnover: The roofing industry often experiences high employee turnover, complicating record-keeping and claims management.

Cost Management: The cost of workers' compensation insurance can be significant due to the high risk associated with roofing work.

Best Practices

To effectively manage workers' compensation insurance and minimize risks, roofing companies should implement several best practices:

Comprehensive Training: Provide thorough safety training tailored to the specific tasks and environments where employees will work. This includes fall prevention, proper use of tools, and safe handling of materials.

Regular Safety Audits: Conduct regular safety audits of job sites to identify and mitigate potential hazards. Ensure compliance with Occupational Safety and Health Administration (OSHA) standards and California's specific safety regulations (Cal/OSHA).

Effective Communication: Maintain open lines of communication with employees to quickly address any safety concerns or incidents. Encourage employees to report unsafe conditions and near-misses.

Accurate Record-Keeping: Keep detailed records of employee training, job assignments, and incident reports to streamline the claims process and ensure compliance with state regulations. Proper documentation is crucial for managing claims efficiently.

Return-to-Work Programs: Implement return-to-work programs to help injured employees transition back to their jobs. These programs can reduce the duration and cost of workers' compensation claims and improve employee morale.

Insurance Review: Regularly review insurance policies to ensure they provide adequate coverage for the company's current operations and adjust as necessary. This includes evaluating different insurance providers to find the best coverage options.

California's Unique Considerations

Medical Provider Network (MPN): Employers in California can establish an MPN, a network of healthcare providers to treat workers injured on the job. Employees generally must choose their treating doctor from the MPN.

Benefit Structure: Understanding California's specific benefits structure, including temporary disability, permanent disability, and medical benefits, is crucial for accurate claims management.

Vocational Rehabilitation: California law includes provisions for supplemental job displacement benefits (SJDB) to help injured workers who cannot return to their previous job.

Conclusion

Workers' compensation insurance is a critical component of managing a roofing company in California. By understanding the legal requirements, exploring coverage options, addressing unique challenges, and implementing best practices, roofing companies can protect their employees and their business. Effective management of workers' compensation not only ensures legal compliance but also contributes to a safer and more productive workforce, ultimately leading to a more successful roofing company.

0 notes

Text

Hospitals, Nursing Homes Fail to Separate COVID Patients, Putting Others at Risk

Nurses at Alta Bates Summit Medical Center were on edge as early as March when patients with COVID-19 began to show up in areas of the hospital that were not set aside to care for them.

The Centers for Disease Control and Prevention had advised hospitals to isolate COVID patients to limit staff exposure and help conserve high-level personal protective equipment that’s been in short supply.

Yet COVID patients continued to be scattered through the Oakland hospital, according to complaints to California’s Division of Occupational Safety and Health. The concerns included the sixth-floor medical unit where veteran nurse Janine Paiste-Ponder worked.

COVID patients on that floor were not staying in their rooms, either confused or uninterested in the rules. Staff was not provided highly protective N95 respirators, said Mike Hill, a nurse in the hospital intensive care unit and the hospital’s chief representative for the California Nurses Association, which filed complaints to Cal/OSHA, the state’s workplace safety regulator.

“It was just a matter of time before one of the nurses died on one of these floors,” Hill said.

Two nurses fell ill, including Paiste-Ponder, 59, who died of complications from the virus on July 17.

The concerns raised in Oakland also have swept across the U.S., according to interviews, a review of government workplace safety complaints and health facility inspection reports. A KHN investigation found that dozens of nursing homes and hospitals ignored official guidelines to separate COVID patients from those without the coronavirus, in some places fueling its spread and leaving staff unprepared and infected or, in some cases, dead.

As recently as July, a National Nurses United survey of more than 21,000 nurses found that 32% work in a facility that does not have a dedicated COVID unit. At that time, the coronavirus had reached all but 17 U.S. counties, data collected by Johns Hopkins University shows.

KHN discovered that COVID victims have been commingled with uninfected patients in health care facilities in states including California, Florida, New Jersey, Iowa, Ohio, Maryland and New York.

A COVID-19 outbreak was in full swing at the New Jersey Veterans Home at Paramus in late April when health inspectors observed residents with dementia mingling in a day room — COVID-positive patients as well as others awaiting test results. At the time, the center had already reported COVID infections among 119 residents and 46 virus-related deaths, according to a Medicare inspection report.

The assistant director of nursing at an Iowa nursing home insisted April 28 that they did “not have any COVID in the building” and overrode the orders of a community doctor to isolate several patients with fevers and falling oxygen levels, an inspection report shows.

By mid-May, the facility’s COVID log showed 61 patients with the virus and nine dead.

Federal work-safety officials have closed at least 30 complaints about patient mixing in hospitals nationwide without issuing a citation. They include a claim that a Michigan hospital kept patients who tested negative for the virus in the COVID unit in May. An upstate New York hospital also had COVID patients in the same unit as those with no infection, according to a closed complaint to the federal Occupational Safety and Health Administration.

Federal Health and Human Services officials have called on hospitals to tell them each day if they have a patient who came in without COVID-19 but had an apparent or confirmed case of the coronavirus 14 days later. Hospitals filed 48,000 reports from June 21 through Aug. 28, though the number reflects some double or additional counting of individual patients.

COVID patients have been mixed in with others for a variety of reasons. Some hospitals report having limited tests, so patients carrying the virus are identified only after they had already exposed others. In other cases, they had false-negative test results or their facility was dismissive of federal guidelines, which carry no force of law.

And while federal Medicare officials have inspected nearly every U.S. nursing home in recent months and states have occasionally levied fines and cut off new admissions for isolation lapses, hospitals have seen less scrutiny.

The Scene Inside Sutter

At Alta Bates in Oakland, part of the Sutter Health network, hospital staff made it clear in official complaints to Cal/OSHA that they wanted administrators to follow the state’s unique law on aerosol-transmitted diseases. From the start, some staffers wanted all the state-required protections for a virus that has been increasingly shown to be transmitted by tiny particles that float through the air.

The regulations call for patients with a virus like COVID-19 to be moved to a specialized unit within five hours of identification — or to a specialized facility. The rules say those patients should be in a room with a HEPA filter or with negative air pressure, meaning that air is circulated out a window or exhaust fan instead of drifting into the hallway.

Initially, in March, the hospital outfitted a 40-bed COVID unit, according to Hill. But when a surge of patients failed to materialize, that unit was pared to 12 beds.

Since then, a steady stream of virus patients have been admitted, he said, many testing positive only days after admission — and after they’d been in regular rooms in the facility.

From March 10 through July 30, Hill’s union and others filed eight complaints to Cal/OSHA, including allegations that the hospital failed to follow isolation rules for COVID patients, some on the cancer floor.

So far, regulators have done little. Gov. Gavin Newsom had ordered workplace safety officials to “focus on … supporting compliance” instead of enforcement except on the “most serious violations.”

State officials responded to complaints by reaching out by mail and phone to “ensure the proper virus prevention measures are in place,” according to Frank Polizzi, a spokesperson for Cal/OSHA.

A third investigation related to transport workers not wearing N95 respirators while moving COVID-positive or possible coronavirus patients at a Sutter facility near the hospital resulted in a $6,750 fine, Cal/OSHA records show.

The string of complaints also says the hospital did not give staff the necessary personal protective equipment (PPE) under state law — an N95 respirator or something more protective — for caring for virus patients.

Instead, Hill said, staff on floors with COVID patients were provided lower-quality surgical masks, a concern reflected in complaints filed with Cal/OSHA.

Hill believes that Paiste-Ponder and another nurse on her floor caught the virus from COVID patients who did not remain in their rooms.

“It is sad, because it didn’t really need to happen,” Hill said.

Polizzi said investigations into the July 17 death and another staff hospitalization are ongoing.

A Sutter Health spokesperson said the hospital takes allegations, including Cal/OSHA complaints, seriously and its highest priority is keeping patients and staff safe.

The statement also said “cohorting,” or the practice of grouping virus patients together, is a tool that “must be considered in a greater context, including patient acuity, hospital census and other environmental factors.”

Concerns at Other Hospitals

CDC guidelines are not strict on the topic of keeping COVID patients sectioned off, noting that “facilities could consider designating entire units within the facility, with dedicated [staff],” to care for COVID patients.

That approach succeeded at the University of Nebraska Medical Center in Omaha. A recent study reported “extensive” viral contamination around COVID patients there, but noted that with “standard” infection control techniques in place, staffers who cared for COVID patients did not get the virus.

The hospital set up an isolation unit with air pumped away from the halls, restricted access to the unit and trained staff to use well-developed protocols and N95 respirators — at a minimum. What worked in Nebraska, though, is far from standard elsewhere.

Cynthia Butler, a nurse and National Nurses United member at Fawcett Memorial Hospital in Port Charlotte, on Florida’s west coast, said she actually felt safer working in the COVID unit — where she knew what she was dealing with and had full PPE — than on a general medical floor.

She believes she caught the virus from a patient who had COVID-19 but was housed on a general floor in May. A similar situation occurred in July, when another patient had an unexpected case of COVID — and Butler said she got another positive test herself.

She said both patients did not meet the hospital’s criteria for testing admitted patients, and the lapses leave her on edge, concerns she relayed to an OSHA inspector who reached out to her about a complaint her union filed about the facility.

“Every time I go into work it’s like playing Russian roulette,” Butler said.

A spokesperson for HCA Healthcare, which owns the hospital, said it tests patients coming from long-term care, those going into surgery and those with virus symptoms. She said staffers have access to PPE and practice vigilant sanitation, universal masking and social distancing.

The latter is not an option for Butler, though, who said she cleans, feeds and starts IVs for patients and offers reassurance when they are isolated from family.

“I’m giving them the only comfort or kind word they can get,” said Butler, who has since gone on unpaid leave over safety concerns. “I’m in there doing that and I’m not being protected.”

Given research showing that up to 45% of COVID patients are asymptomatic, UCSF Medical Center is testing everyone who’s admitted, said Dr. Robert Harrison, a University of California-San Francisco School of Medicine professor who consults on occupational health at the hospital.

It’s done for the safety of staff and to reduce spread within the hospital, he said. Those who test positive are separated into a COVID-only unit.

And staff who spent more than 15 minutes within 6 feet of a not-yet-identified COVID patient in a less-protective surgical mask are typically sent home for two weeks, he said.

Outside of academic medicine, though, front-line staff have turned to union leaders to push for such protections.

In Southern California, leaders of the National Union of Healthcare Workers filed an official complaint with state hospital inspectors about the risks posed by intermingled COVID patients at Fountain Valley Regional Hospital in Orange County, part of for-profit Tenet Health. There, the complaint said, patients were not routinely tested for COVID-19 upon admission.

One nursing assistant spent two successive 12-hour shifts caring for a patient on a general medical floor who required monitoring. At the conclusion of the second shift, she was told the patient had just been found to be COVID-positive.

The worker had worn only a surgical mask — not an N95 respirator or any form of eye protection, according to the complaint to the California Department of Public Health. The nursing assistant was not offered a COVID test or quarantined before her next two shifts, the complaint said.

The public health department said it could not comment on a pending inspection.

Barbara Lewis, Southern California hospital division director with the union, said COVID patients were on the same floor as cancer patients and post-surgical patients who were walking the halls to speed their recovery.

She said managers took steps to separate the patients only after the union held a protest, spoke to local media and complained to state health officials.

Hospital spokesperson Jessica Chen said the hospital “quickly implemented” changes directed by state health authorities and does place some COVID patients on the same nursing unit as non-COVID patients during surges. She said they are placed in single rooms with closed doors. COVID tests are given by physician order, she added, and employees can access them at other places in the community.

It’s in contrast, Lewis said, to high-profile examples of the precautions that might be taken.

“Now we’re seeing what’s happening with baseball and basketball — they’re tested every day and treated with a high level of caution,” Lewis said. “Yet we have thousands and thousands of health care workers going to work in a very scary environment.”

Nursing Homes Face Penalties

More than 40% of the people who’ve died of COVID-19 lived in nursing homes or assisted living facilities, researchers have found.

Patient mixing has been a scattered concern at nursing homes, which Medicare officials discovered when they reviewed infection control practices at more than 15,000 facilities.

News reports have highlighted the problem at an Ohio nursing home and at a Maryland home where the state levied a $70,000 fine for failing to keep infected patients away from those who weren’t sick — yet.

Another facing penalties was Fair Havens Center, a Miami Springs, Florida, nursing home where inspectors discovered that 11 roommates of patients who tested positive for COVID-19 were put in rooms with other residents — putting them at heightened risk.

Florida regulators cut off admissions to the home and Medicare authorities levied a $235,000 civil monetary penalty, records show.

The vice president of operations at the facility told inspectors that isolating exposed patients would mean isolating the entire facility: Everyone had been exposed to the 32 staff members who tested positive for the virus, the report says.

Fair Havens Center did not respond to a request for comment.

In Iowa, Medicare officials declared a state of “immediate jeopardy” at Pearl Valley Rehabilitation and Care Center in Muscatine. There, they discovered that staffers were in denial over an outbreak in their midst, with a nursing director overriding a community doctor’s orders to isolate or send residents to the emergency room. Instead, officials found, in late April, the assistant nursing director kept COVID patients in the facility, citing a general order by their medical director to avoid sending patients to the ER “if you can help it.”

Meanwhile, several patients were documented by facility staff to have fevers and falling oxygen levels, the Medicare inspection report shows. Within two weeks, the facility discovered it had an outbreak, with 61 residents infected and nine dead, according to the report.

Medicare officials are investigating Menlo Park Veterans Memorial Home in New Jersey, state Sen. Joseph Vitale said during a recent legislative hearing. Resident council president Glenn Osborne testified during the hearing that the home’s residents were returned to the same shared rooms after hospitalizations.

Osborne, an honorably discharged Marine, said he saw more residents of the home die than fellow service members during his military service. The Menlo Park and Paramus veterans homes — where inspectors saw dementia patients with and without the virus commingling in a day room — both reported more than 180 COVID cases among residents, 90 among staff and at least 60 deaths.

A spokesperson for the homes said he could not comment due to pending litigation.

“These deaths should not have happened,” Osborne said. “Many of these deaths were absolutely avoidable, in my humble opinion.”

Kaiser Health News (KHN) is a national health policy news service. It is an editorially independent program of the Henry J. Kaiser Family Foundation which is not affiliated with Kaiser Permanente.

USE OUR CONTENT

This story can be republished for free (details).

Hospitals, Nursing Homes Fail to Separate COVID Patients, Putting Others at Risk published first on https://nootropicspowdersupplier.tumblr.com/

0 notes

Text

Hospitals, Nursing Homes Fail to Separate COVID Patients, Putting Others at Risk

Nurses at Alta Bates Summit Medical Center were on edge as early as March when patients with COVID-19 began to show up in areas of the hospital that were not set aside to care for them.

The Centers for Disease Control and Prevention had advised hospitals to isolate COVID patients to limit staff exposure and help conserve high-level personal protective equipment that’s been in short supply.

Yet COVID patients continued to be scattered through the Oakland hospital, according to complaints to California’s Division of Occupational Safety and Health. The concerns included the sixth-floor medical unit where veteran nurse Janine Paiste-Ponder worked.

COVID patients on that floor were not staying in their rooms, either confused or uninterested in the rules. Staff was not provided highly protective N95 respirators, said Mike Hill, a nurse in the hospital intensive care unit and the hospital’s chief representative for the California Nurses Association, which filed complaints to Cal/OSHA, the state’s workplace safety regulator.

“It was just a matter of time before one of the nurses died on one of these floors,” Hill said.

Two nurses fell ill, including Paiste-Ponder, 59, who died of complications from the virus on July 17.

The concerns raised in Oakland also have swept across the U.S., according to interviews, a review of government workplace safety complaints and health facility inspection reports. A KHN investigation found that dozens of nursing homes and hospitals ignored official guidelines to separate COVID patients from those without the coronavirus, in some places fueling its spread and leaving staff unprepared and infected or, in some cases, dead.

As recently as July, a National Nurses United survey of more than 21,000 nurses found that 32% work in a facility that does not have a dedicated COVID unit. At that time, the coronavirus had reached all but 17 U.S. counties, data collected by Johns Hopkins University shows.

KHN discovered that COVID victims have been commingled with uninfected patients in health care facilities in states including California, Florida, New Jersey, Iowa, Ohio, Maryland and New York.

A COVID-19 outbreak was in full swing at the New Jersey Veterans Home at Paramus in late April when health inspectors observed residents with dementia mingling in a day room — COVID-positive patients as well as others awaiting test results. At the time, the center had already reported COVID infections among 119 residents and 46 virus-related deaths, according to a Medicare inspection report.

The assistant director of nursing at an Iowa nursing home insisted April 28 that they did “not have any COVID in the building” and overrode the orders of a community doctor to isolate several patients with fevers and falling oxygen levels, an inspection report shows.

By mid-May, the facility’s COVID log showed 61 patients with the virus and nine dead.

Federal work-safety officials have closed at least 30 complaints about patient mixing in hospitals nationwide without issuing a citation. They include a claim that a Michigan hospital kept patients who tested negative for the virus in the COVID unit in May. An upstate New York hospital also had COVID patients in the same unit as those with no infection, according to a closed complaint to the federal Occupational Safety and Health Administration.

Federal Health and Human Services officials have called on hospitals to tell them each day if they have a patient who came in without COVID-19 but had an apparent or confirmed case of the coronavirus 14 days later. Hospitals filed 48,000 reports from June 21 through Aug. 28, though the number reflects some double or additional counting of individual patients.

COVID patients have been mixed in with others for a variety of reasons. Some hospitals report having limited tests, so patients carrying the virus are identified only after they had already exposed others. In other cases, they had false-negative test results or their facility was dismissive of federal guidelines, which carry no force of law.

And while federal Medicare officials have inspected nearly every U.S. nursing home in recent months and states have occasionally levied fines and cut off new admissions for isolation lapses, hospitals have seen less scrutiny.

The Scene Inside Sutter

At Alta Bates in Oakland, part of the Sutter Health network, hospital staff made it clear in official complaints to Cal/OSHA that they wanted administrators to follow the state’s unique law on aerosol-transmitted diseases. From the start, some staffers wanted all the state-required protections for a virus that has been increasingly shown to be transmitted by tiny particles that float through the air.

The regulations call for patients with a virus like COVID-19 to be moved to a specialized unit within five hours of identification — or to a specialized facility. The rules say those patients should be in a room with a HEPA filter or with negative air pressure, meaning that air is circulated out a window or exhaust fan instead of drifting into the hallway.

Initially, in March, the hospital outfitted a 40-bed COVID unit, according to Hill. But when a surge of patients failed to materialize, that unit was pared to 12 beds.

Since then, a steady stream of virus patients have been admitted, he said, many testing positive only days after admission — and after they’d been in regular rooms in the facility.

From March 10 through July 30, Hill’s union and others filed eight complaints to Cal/OSHA, including allegations that the hospital failed to follow isolation rules for COVID patients, some on the cancer floor.

So far, regulators have done little. Gov. Gavin Newsom had ordered workplace safety officials to “focus on … supporting compliance” instead of enforcement except on the “most serious violations.”

State officials responded to complaints by reaching out by mail and phone to “ensure the proper virus prevention measures are in place,” according to Frank Polizzi, a spokesperson for Cal/OSHA.

A third investigation related to transport workers not wearing N95 respirators while moving COVID-positive or possible coronavirus patients at a Sutter facility near the hospital resulted in a $6,750 fine, Cal/OSHA records show.

The string of complaints also says the hospital did not give staff the necessary personal protective equipment (PPE) under state law — an N95 respirator or something more protective — for caring for virus patients.

Instead, Hill said, staff on floors with COVID patients were provided lower-quality surgical masks, a concern reflected in complaints filed with Cal/OSHA.

Hill believes that Paiste-Ponder and another nurse on her floor caught the virus from COVID patients who did not remain in their rooms.

“It is sad, because it didn’t really need to happen,” Hill said.

Polizzi said investigations into the July 17 death and another staff hospitalization are ongoing.

A Sutter Health spokesperson said the hospital takes allegations, including Cal/OSHA complaints, seriously and its highest priority is keeping patients and staff safe.

The statement also said “cohorting,” or the practice of grouping virus patients together, is a tool that “must be considered in a greater context, including patient acuity, hospital census and other environmental factors.”

Concerns at Other Hospitals

CDC guidelines are not strict on the topic of keeping COVID patients sectioned off, noting that “facilities could consider designating entire units within the facility, with dedicated [staff],” to care for COVID patients.

That approach succeeded at the University of Nebraska Medical Center in Omaha. A recent study reported “extensive” viral contamination around COVID patients there, but noted that with “standard” infection control techniques in place, staffers who cared for COVID patients did not get the virus.

The hospital set up an isolation unit with air pumped away from the halls, restricted access to the unit and trained staff to use well-developed protocols and N95 respirators — at a minimum. What worked in Nebraska, though, is far from standard elsewhere.

Cynthia Butler, a nurse and National Nurses United member at Fawcett Memorial Hospital in Port Charlotte, on Florida’s west coast, said she actually felt safer working in the COVID unit — where she knew what she was dealing with and had full PPE — than on a general medical floor.

She believes she caught the virus from a patient who had COVID-19 but was housed on a general floor in May. A similar situation occurred in July, when another patient had an unexpected case of COVID — and Butler said she got another positive test herself.

She said both patients did not meet the hospital’s criteria for testing admitted patients, and the lapses leave her on edge, concerns she relayed to an OSHA inspector who reached out to her about a complaint her union filed about the facility.

“Every time I go into work it’s like playing Russian roulette,” Butler said.

A spokesperson for HCA Healthcare, which owns the hospital, said it tests patients coming from long-term care, those going into surgery and those with virus symptoms. She said staffers have access to PPE and practice vigilant sanitation, universal masking and social distancing.

The latter is not an option for Butler, though, who said she cleans, feeds and starts IVs for patients and offers reassurance when they are isolated from family.

“I’m giving them the only comfort or kind word they can get,” said Butler, who has since gone on unpaid leave over safety concerns. “I’m in there doing that and I’m not being protected.”

Given research showing that up to 45% of COVID patients are asymptomatic, UCSF Medical Center is testing everyone who’s admitted, said Dr. Robert Harrison, a University of California-San Francisco School of Medicine professor who consults on occupational health at the hospital.

It’s done for the safety of staff and to reduce spread within the hospital, he said. Those who test positive are separated into a COVID-only unit.

And staff who spent more than 15 minutes within 6 feet of a not-yet-identified COVID patient in a less-protective surgical mask are typically sent home for two weeks, he said.

Outside of academic medicine, though, front-line staff have turned to union leaders to push for such protections.

In Southern California, leaders of the National Union of Healthcare Workers filed an official complaint with state hospital inspectors about the risks posed by intermingled COVID patients at Fountain Valley Regional Hospital in Orange County, part of for-profit Tenet Health. There, the complaint said, patients were not routinely tested for COVID-19 upon admission.

One nursing assistant spent two successive 12-hour shifts caring for a patient on a general medical floor who required monitoring. At the conclusion of the second shift, she was told the patient had just been found to be COVID-positive.

The worker had worn only a surgical mask — not an N95 respirator or any form of eye protection, according to the complaint to the California Department of Public Health. The nursing assistant was not offered a COVID test or quarantined before her next two shifts, the complaint said.

The public health department said it could not comment on a pending inspection.

Barbara Lewis, Southern California hospital division director with the union, said COVID patients were on the same floor as cancer patients and post-surgical patients who were walking the halls to speed their recovery.

She said managers took steps to separate the patients only after the union held a protest, spoke to local media and complained to state health officials.

Hospital spokesperson Jessica Chen said the hospital “quickly implemented” changes directed by state health authorities and does place some COVID patients on the same nursing unit as non-COVID patients during surges. She said they are placed in single rooms with closed doors. COVID tests are given by physician order, she added, and employees can access them at other places in the community.

It’s in contrast, Lewis said, to high-profile examples of the precautions that might be taken.

“Now we’re seeing what’s happening with baseball and basketball — they’re tested every day and treated with a high level of caution,” Lewis said. “Yet we have thousands and thousands of health care workers going to work in a very scary environment.”

Nursing Homes Face Penalties

More than 40% of the people who’ve died of COVID-19 lived in nursing homes or assisted living facilities, researchers have found.

Patient mixing has been a scattered concern at nursing homes, which Medicare officials discovered when they reviewed infection control practices at more than 15,000 facilities.

News reports have highlighted the problem at an Ohio nursing home and at a Maryland home where the state levied a $70,000 fine for failing to keep infected patients away from those who weren’t sick — yet.

Another facing penalties was Fair Havens Center, a Miami Springs, Florida, nursing home where inspectors discovered that 11 roommates of patients who tested positive for COVID-19 were put in rooms with other residents — putting them at heightened risk.

Florida regulators cut off admissions to the home and Medicare authorities levied a $235,000 civil monetary penalty, records show.

The vice president of operations at the facility told inspectors that isolating exposed patients would mean isolating the entire facility: Everyone had been exposed to the 32 staff members who tested positive for the virus, the report says.

Fair Havens Center did not respond to a request for comment.

In Iowa, Medicare officials declared a state of “immediate jeopardy” at Pearl Valley Rehabilitation and Care Center in Muscatine. There, they discovered that staffers were in denial over an outbreak in their midst, with a nursing director overriding a community doctor’s orders to isolate or send residents to the emergency room. Instead, officials found, in late April, the assistant nursing director kept COVID patients in the facility, citing a general order by their medical director to avoid sending patients to the ER “if you can help it.”

Meanwhile, several patients were documented by facility staff to have fevers and falling oxygen levels, the Medicare inspection report shows. Within two weeks, the facility discovered it had an outbreak, with 61 residents infected and nine dead, according to the report.

Medicare officials are investigating Menlo Park Veterans Memorial Home in New Jersey, state Sen. Joseph Vitale said during a recent legislative hearing. Resident council president Glenn Osborne testified during the hearing that the home’s residents were returned to the same shared rooms after hospitalizations.

Osborne, an honorably discharged Marine, said he saw more residents of the home die than fellow service members during his military service. The Menlo Park and Paramus veterans homes — where inspectors saw dementia patients with and without the virus commingling in a day room — both reported more than 180 COVID cases among residents, 90 among staff and at least 60 deaths.

A spokesperson for the homes said he could not comment due to pending litigation.

“These deaths should not have happened,” Osborne said. “Many of these deaths were absolutely avoidable, in my humble opinion.”

Kaiser Health News (KHN) is a national health policy news service. It is an editorially independent program of the Henry J. Kaiser Family Foundation which is not affiliated with Kaiser Permanente.

USE OUR CONTENT

This story can be republished for free (details).

Hospitals, Nursing Homes Fail to Separate COVID Patients, Putting Others at Risk published first on https://smartdrinkingweb.weebly.com/

0 notes

Text

Hospitals, Nursing Homes Fail to Separate COVID Patients, Putting Others at Risk

Nurses at Alta Bates Summit Medical Center were on edge as early as March when patients with COVID-19 began to show up in areas of the hospital that were not set aside to care for them.

The Centers for Disease Control and Prevention had advised hospitals to isolate COVID patients to limit staff exposure and help conserve high-level personal protective equipment that’s been in short supply.

Yet COVID patients continued to be scattered through the Oakland hospital, according to complaints to California’s Division of Occupational Safety and Health. The concerns included the sixth-floor medical unit where veteran nurse Janine Paiste-Ponder worked.

COVID patients on that floor were not staying in their rooms, either confused or uninterested in the rules. Staff was not provided highly protective N95 respirators, said Mike Hill, a nurse in the hospital intensive care unit and the hospital’s chief representative for the California Nurses Association, which filed complaints to Cal/OSHA, the state’s workplace safety regulator.

“It was just a matter of time before one of the nurses died on one of these floors,” Hill said.

Two nurses fell ill, including Paiste-Ponder, 59, who died of complications from the virus on July 17.

The concerns raised in Oakland also have swept across the U.S., according to interviews, a review of government workplace safety complaints and health facility inspection reports. A KHN investigation found that dozens of nursing homes and hospitals ignored official guidelines to separate COVID patients from those without the coronavirus, in some places fueling its spread and leaving staff unprepared and infected or, in some cases, dead.

As recently as July, a National Nurses United survey of more than 21,000 nurses found that 32% work in a facility that does not have a dedicated COVID unit. At that time, the coronavirus had reached all but 17 U.S. counties, data collected by Johns Hopkins University shows.

KHN discovered that COVID victims have been commingled with uninfected patients in health care facilities in states including California, Florida, New Jersey, Iowa, Ohio, Maryland and New York.

A COVID-19 outbreak was in full swing at the New Jersey Veterans Home at Paramus in late April when health inspectors observed residents with dementia mingling in a day room — COVID-positive patients as well as others awaiting test results. At the time, the center had already reported COVID infections among 119 residents and 46 virus-related deaths, according to a Medicare inspection report.

The assistant director of nursing at an Iowa nursing home insisted April 28 that they did “not have any COVID in the building” and overrode the orders of a community doctor to isolate several patients with fevers and falling oxygen levels, an inspection report shows.

By mid-May, the facility’s COVID log showed 61 patients with the virus and nine dead.

Federal work-safety officials have closed at least 30 complaints about patient mixing in hospitals nationwide without issuing a citation. They include a claim that a Michigan hospital kept patients who tested negative for the virus in the COVID unit in May. An upstate New York hospital also had COVID patients in the same unit as those with no infection, according to a closed complaint to the federal Occupational Safety and Health Administration.

Federal Health and Human Services officials have called on hospitals to tell them each day if they have a patient who came in without COVID-19 but had an apparent or confirmed case of the coronavirus 14 days later. Hospitals filed 48,000 reports from June 21 through Aug. 28, though the number reflects some double or additional counting of individual patients.

COVID patients have been mixed in with others for a variety of reasons. Some hospitals report having limited tests, so patients carrying the virus are identified only after they had already exposed others. In other cases, they had false-negative test results or their facility was dismissive of federal guidelines, which carry no force of law.

And while federal Medicare officials have inspected nearly every U.S. nursing home in recent months and states have occasionally levied fines and cut off new admissions for isolation lapses, hospitals have seen less scrutiny.

The Scene Inside Sutter

At Alta Bates in Oakland, part of the Sutter Health network, hospital staff made it clear in official complaints to Cal/OSHA that they wanted administrators to follow the state’s unique law on aerosol-transmitted diseases. From the start, some staffers wanted all the state-required protections for a virus that has been increasingly shown to be transmitted by tiny particles that float through the air.

The regulations call for patients with a virus like COVID-19 to be moved to a specialized unit within five hours of identification — or to a specialized facility. The rules say those patients should be in a room with a HEPA filter or with negative air pressure, meaning that air is circulated out a window or exhaust fan instead of drifting into the hallway.

Initially, in March, the hospital outfitted a 40-bed COVID unit, according to Hill. But when a surge of patients failed to materialize, that unit was pared to 12 beds.

Since then, a steady stream of virus patients have been admitted, he said, many testing positive only days after admission — and after they’d been in regular rooms in the facility.

From March 10 through July 30, Hill’s union and others filed eight complaints to Cal/OSHA, including allegations that the hospital failed to follow isolation rules for COVID patients, some on the cancer floor.

So far, regulators have done little. Gov. Gavin Newsom had ordered workplace safety officials to “focus on … supporting compliance” instead of enforcement except on the “most serious violations.”

State officials responded to complaints by reaching out by mail and phone to “ensure the proper virus prevention measures are in place,” according to Frank Polizzi, a spokesperson for Cal/OSHA.

A third investigation related to transport workers not wearing N95 respirators while moving COVID-positive or possible coronavirus patients at a Sutter facility near the hospital resulted in a $6,750 fine, Cal/OSHA records show.

The string of complaints also says the hospital did not give staff the necessary personal protective equipment (PPE) under state law — an N95 respirator or something more protective — for caring for virus patients.

Instead, Hill said, staff on floors with COVID patients were provided lower-quality surgical masks, a concern reflected in complaints filed with Cal/OSHA.

Hill believes that Paiste-Ponder and another nurse on her floor caught the virus from COVID patients who did not remain in their rooms.

“It is sad, because it didn’t really need to happen,” Hill said.

Polizzi said investigations into the July 17 death and another staff hospitalization are ongoing.

A Sutter Health spokesperson said the hospital takes allegations, including Cal/OSHA complaints, seriously and its highest priority is keeping patients and staff safe.

The statement also said “cohorting,” or the practice of grouping virus patients together, is a tool that “must be considered in a greater context, including patient acuity, hospital census and other environmental factors.”

Concerns at Other Hospitals

CDC guidelines are not strict on the topic of keeping COVID patients sectioned off, noting that “facilities could consider designating entire units within the facility, with dedicated [staff],” to care for COVID patients.

That approach succeeded at the University of Nebraska Medical Center in Omaha. A recent study reported “extensive” viral contamination around COVID patients there, but noted that with “standard” infection control techniques in place, staffers who cared for COVID patients did not get the virus.

The hospital set up an isolation unit with air pumped away from the halls, restricted access to the unit and trained staff to use well-developed protocols and N95 respirators — at a minimum. What worked in Nebraska, though, is far from standard elsewhere.

Cynthia Butler, a nurse and National Nurses United member at Fawcett Memorial Hospital in Port Charlotte, on Florida’s west coast, said she actually felt safer working in the COVID unit — where she knew what she was dealing with and had full PPE — than on a general medical floor.

She believes she caught the virus from a patient who had COVID-19 but was housed on a general floor in May. A similar situation occurred in July, when another patient had an unexpected case of COVID — and Butler said she got another positive test herself.

She said both patients did not meet the hospital’s criteria for testing admitted patients, and the lapses leave her on edge, concerns she relayed to an OSHA inspector who reached out to her about a complaint her union filed about the facility.

“Every time I go into work it’s like playing Russian roulette,” Butler said.

A spokesperson for HCA Healthcare, which owns the hospital, said it tests patients coming from long-term care, those going into surgery and those with virus symptoms. She said staffers have access to PPE and practice vigilant sanitation, universal masking and social distancing.

The latter is not an option for Butler, though, who said she cleans, feeds and starts IVs for patients and offers reassurance when they are isolated from family.

“I’m giving them the only comfort or kind word they can get,” said Butler, who has since gone on unpaid leave over safety concerns. “I’m in there doing that and I’m not being protected.”

Given research showing that up to 45% of COVID patients are asymptomatic, UCSF Medical Center is testing everyone who’s admitted, said Dr. Robert Harrison, a University of California-San Francisco School of Medicine professor who consults on occupational health at the hospital.

It’s done for the safety of staff and to reduce spread within the hospital, he said. Those who test positive are separated into a COVID-only unit.

And staff who spent more than 15 minutes within 6 feet of a not-yet-identified COVID patient in a less-protective surgical mask are typically sent home for two weeks, he said.

Outside of academic medicine, though, front-line staff have turned to union leaders to push for such protections.

In Southern California, leaders of the National Union of Healthcare Workers filed an official complaint with state hospital inspectors about the risks posed by intermingled COVID patients at Fountain Valley Regional Hospital in Orange County, part of for-profit Tenet Health. There, the complaint said, patients were not routinely tested for COVID-19 upon admission.

One nursing assistant spent two successive 12-hour shifts caring for a patient on a general medical floor who required monitoring. At the conclusion of the second shift, she was told the patient had just been found to be COVID-positive.

The worker had worn only a surgical mask — not an N95 respirator or any form of eye protection, according to the complaint to the California Department of Public Health. The nursing assistant was not offered a COVID test or quarantined before her next two shifts, the complaint said.

The public health department said it could not comment on a pending inspection.

Barbara Lewis, Southern California hospital division director with the union, said COVID patients were on the same floor as cancer patients and post-surgical patients who were walking the halls to speed their recovery.

She said managers took steps to separate the patients only after the union held a protest, spoke to local media and complained to state health officials.

Hospital spokesperson Jessica Chen said the hospital “quickly implemented” changes directed by state health authorities and does place some COVID patients on the same nursing unit as non-COVID patients during surges. She said they are placed in single rooms with closed doors. COVID tests are given by physician order, she added, and employees can access them at other places in the community.

It’s in contrast, Lewis said, to high-profile examples of the precautions that might be taken.

“Now we’re seeing what’s happening with baseball and basketball — they’re tested every day and treated with a high level of caution,” Lewis said. “Yet we have thousands and thousands of health care workers going to work in a very scary environment.”

Nursing Homes Face Penalties

More than 40% of the people who’ve died of COVID-19 lived in nursing homes or assisted living facilities, researchers have found.

Patient mixing has been a scattered concern at nursing homes, which Medicare officials discovered when they reviewed infection control practices at more than 15,000 facilities.

News reports have highlighted the problem at an Ohio nursing home and at a Maryland home where the state levied a $70,000 fine for failing to keep infected patients away from those who weren’t sick — yet.

Another facing penalties was Fair Havens Center, a Miami Springs, Florida, nursing home where inspectors discovered that 11 roommates of patients who tested positive for COVID-19 were put in rooms with other residents — putting them at heightened risk.

Florida regulators cut off admissions to the home and Medicare authorities levied a $235,000 civil monetary penalty, records show.

The vice president of operations at the facility told inspectors that isolating exposed patients would mean isolating the entire facility: Everyone had been exposed to the 32 staff members who tested positive for the virus, the report says.

Fair Havens Center did not respond to a request for comment.

In Iowa, Medicare officials declared a state of “immediate jeopardy” at Pearl Valley Rehabilitation and Care Center in Muscatine. There, they discovered that staffers were in denial over an outbreak in their midst, with a nursing director overriding a community doctor’s orders to isolate or send residents to the emergency room. Instead, officials found, in late April, the assistant nursing director kept COVID patients in the facility, citing a general order by their medical director to avoid sending patients to the ER “if you can help it.”

Meanwhile, several patients were documented by facility staff to have fevers and falling oxygen levels, the Medicare inspection report shows. Within two weeks, the facility discovered it had an outbreak, with 61 residents infected and nine dead, according to the report.

Medicare officials are investigating Menlo Park Veterans Memorial Home in New Jersey, state Sen. Joseph Vitale said during a recent legislative hearing. Resident council president Glenn Osborne testified during the hearing that the home’s residents were returned to the same shared rooms after hospitalizations.

Osborne, an honorably discharged Marine, said he saw more residents of the home die than fellow service members during his military service. The Menlo Park and Paramus veterans homes — where inspectors saw dementia patients with and without the virus commingling in a day room — both reported more than 180 COVID cases among residents, 90 among staff and at least 60 deaths.

A spokesperson for the homes said he could not comment due to pending litigation.

“These deaths should not have happened,” Osborne said. “Many of these deaths were absolutely avoidable, in my humble opinion.”

Kaiser Health News (KHN) is a national health policy news service. It is an editorially independent program of the Henry J. Kaiser Family Foundation which is not affiliated with Kaiser Permanente.

USE OUR CONTENT

This story can be republished for free (details).

from Updates By Dina https://khn.org/news/hospitals-nursing-homes-fail-to-separate-covid-patients-putting-others-at-risk/

0 notes

Text

Is My Job Protected If I Refuse to Work Due to Health & Safety Risk of COVID-19?

What are my specific workplace health and safety rights during the COVID-19 crisis?

Your employer is required to take steps to ensure your safety and health, and to provide you with enough training and protection to do your job safely. Under the law, your rights include:

The right to be properly trained by your employer about safety on the job.

The right to be warned about hazardous materials to which you are exposed.

The right to be given protective gear if you work with hazardous or contaminated materials.

The right to make a confidential request for an inspection of your workplace by the Division of Occupational Safety & Health for safety and health standard violations.

The right to file a confidential complaint with the Division of Occupational Safety & Health if you observe or suspect a problem with safety or health at your workplace.

Employer retaliation over COVID-19 concerns

California Labor Code Section 6311 prohibits an employer to demote, terminate, harass or otherwise retaliate against "essential workers" who refuse to work in the presence of a health & safety risk. For example, your employer cannot retaliate against employees, including "essential workers," who refuse to establish social distancing rules and/or provide reasonable Personal Protection Equipment (e.g., masks, face shields, whatever else may be appropriate depending upon the work) where COVID-19 presents a risk.

In fact, the health and safety issue need not be related to COVID-19. Employees can refuse to perform work that presents workers with health or safety risks, regardless of the risk. If an employee has a reasonable concern for their health and safety (e.g., employer is violating Cal-OSHA and/or OSHA regulations), then they can choose not to work and be protected by statutes like Labor Code Section 6311.

For additional information, please contact Christopher Taylor of Taylor Labor Law, P.C. at (626) 219-6008 for an immediate, no-cost consultation.

#COVID-19

#non-essential worker

#essential worker

0 notes

Text

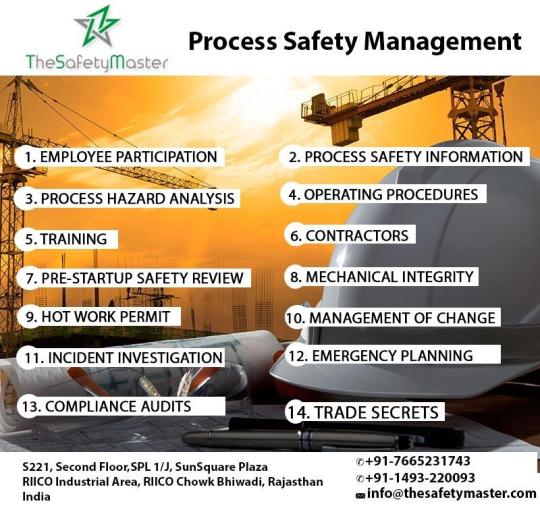

Process Safety Management for Hazardous Industry TheSafetyMaster™

Process Safety Management is one of the most important functions of the management of any of the industries that are within the Oil & Gas, Pharmaceutical, Chemical, Petrochemical, fuel-based Power Generation, and similar domains. This is because these industries generally handle tons of hazardous materials, that have the danger of fireside, explosion, damage to have assets, adverse effects on people, toxic leaks and environmental destruction. It has played an important role within the chemical processing industries in order to handle flammable liquids and gases could proceed without undesirable consequences.

The process design and technology, changes within the method, materials, and changes in materials, operations, and maintenance practices and procedures, training, emergency preparedness and other elements affecting the tactics must all be considered within the systematic identification and evaluation of hazards so on to determine whether or not they need the potential to steer to a catastrophe within the workplace and surrounding community.

Process safety management is an integral part of the chemical processing facility safety program. An effective process safety management program requires the leadership, support, and involvement of top management, facility management, supervisors, employees, contractors and contractor employees.

The PSM standard targets highly hazardous chemicals that have the potential to cause a catastrophic incident. The purpose of the quality as an entire is to assist employers in their efforts to stop or mitigate episodic chemical releases that would cause a catastrophe in the workplace and possibly in the surrounding community. Organizations need to develop the specified experience, expertise, judgment, and initiative within their workforce to properly implement and maintain an efficient PSM program and to prevent these sorts of hazards.

Even a robust process safety management program is subject to wear and tear if not properly maintained. In order to maintain the optimal performance of your PSM program, it’s very important that you continually review your plan that can support its integrity. This requires ongoing support from organization leadership, keeping your employees engaged and informed, and helping your team feel fulfilled, committed, and motivated across the board.

Additionally, TheSafetyMaster assists clients in implementing PSM programs and Process Safety Management Training that satisfy state regulatory requirements for their specific industry, such as the Cal/OSHA Process Safety Management for Refineries. This includes PSM elements such as the hierarchy of controls analysis, safeguard protection analysis, damage mechanism reviews, process safety culture assessments and management of change.

How TheSafetyMaster can Help

1. TheSafetyMaster provides training and certification for process safety management.

2. We have refined our models and methodologies in ways during which are often replicated, put into practice, tested and fine-tuned for nearly any situation or industry based on this vast operational experience.

3. TheSafetyMaster has a proven ability to customize solutions to help your organization prevent major process-related disaster incidents. Our team approach to preventing process-related injuries and managing operational risk and incidents addresses both the cultural and technical aspects of your organization.

4. We also provide proper documentation for the process safety management

Send us your enquiry to [email protected] or speak to our expert at +917665231743

0 notes

Text

Process Safety Management for Hazardous Industry

Process Safety Management is one of the most important functions of the management of any of the industries that are within the Oil & Gas, Pharmaceutical, Chemical, Petrochemical, fuel-based Power Generation, and similar domains. This is because these industries generally handle tons of hazardous materials, that have the danger of fireside, explosion, damage to have assets, adverse effects on people, toxic leaks and environmental destruction. It has played an important role within the chemical processing industries, in order to handle flammable liquids and gases, could proceed without undesirable consequences.

The process design and technology changes within the method, materials, and changes in materials, operations, and maintenance practices and procedures, training, emergency preparedness and other elements affecting the tactics must all be considered within the systematic identification and evaluation of hazards so on to determine whether or not they need the potential to steer to a catastrophe within the workplace and surrounding community.

Process safety management is an integral part of the chemical processing facility safety program. An effective process safety management program requires the leadership, support, and involvement of top management, facility management, supervisors, employees, contractors and contractor employees.

The PSM standard targets highly hazardous chemicals that have the potential to cause a catastrophic incident. The purpose of the quality as an entire is to assist employers in their efforts to stop or mitigate episodic chemical releases that would cause a catastrophe in the workplace and possibly in the surrounding community. Organizations need to develop the specified experience, expertise, judgment, and initiative within their workforce to properly implement and maintain an efficient PSM program and to prevent these sorts of hazards.

Even a robust process safety management program is subject to wear and tear if not properly maintained. In order to maintain the optimal performance of your PSM program, it’s very important that you continually review your plan that can support its integrity. This requires ongoing support from organization leadership, keeping your employees engaged and informed, and helping your team feel fulfilled, committed, and motivated across the board.

Additionally, TheSafetyMaster assists clients in implementing PSM programs and Process Safety Management Training that satisfy state regulatory requirements for their specific industry, such as the Cal/OSHA Process Safety Management for Refineries. This includes PSM elements such as the hierarchy of controls analysis, safeguard the protection analysis, damage mechanism reviews, process safety culture assessments and management of change.

How TheSafetyMaster can Help

1. TheSafetyMaster provides training and certification for process safety management.

2. We have refined our models and methodologies in ways during which are often replicated, put into practice, tested and fine-tuned for nearly any situation or industry based on this vast operational experience.

3. TheSafetyMaster has a proven ability to customize solutions to help your organization prevent major process-related disaster incidents. Our team approach to preventing process-related injuries and managing operational risk and incidents addresses both the cultural and technical aspects of your organization.

4. We also provide proper documentation for the process safety management.

0 notes

Text

California Cannabis: Breaking Down the CDPH Permanent Regulations

The State of California finally adopted permanent cannabis regulations earlier this month. In a series of posts, we’re going to cover the highlights of each agency’s permanent rules so that you know what big changes to expect during 2019. This post will cover the main changes (in our opinion) regarding the California Department of Public Health Manufactured Cannabis Safety Branch’s (“CDPH-MCSB”) permanent regs. Without further ado:

No more Farm Bill hemp-CBD ingredients or additives. It’s no secret that the California Department of Health Food and Drug Branch (“FDB”) has an issue with hemp-CBD. Specifically, an FAQ that issued from FDB last year made clear that FDB prohibits hemp-CBD in “Food” for humans and pets. Now, CDPH-MCSB is following suit (indirectly). Pursuant to new regulation 40175(c), “a manufacturer licensee shall only use cannabinoid concentrates and extracts that are manufactured or processed from cannabis obtained from a licensed cannabis cultivator.” What this means is that using Farm Bill hemp-CBD as an ingredient or addictive to cannabis manufactured products is not allowed unless it comes from a licensed cannabis cultivator. The protections of the Farm Bill won’t apply.

Owners and financial interest holders. I recently wrote about how it’s unclear as to how far the state will now go in finding and vetting entity owners and entity financial interest holders, especially since the Bureau of Cannabis Control (“BCC”) articulates in its rules that it intends to locate and vet every human possible in pretty much any ownership structure. But what about MCSB? MCSB entity owner regulations now state that “if the owner . . . is an entity, then the chief executive officer and members of the board of directors of the entity shall be considered owners,” and for financial interest holders, MCSB rules mandate only that “financial interest holders shall be disclosed on the application for licensure.” On balance, the BCC’s owner and financial interest holder rules are much more aggressive than MCSB, and the BCC’s comments to its owner and financial interest holder rules was that all agencies would apply the same standards for vetting. However, this clearly isn’t going to be the case if stakeholders go off of a plain reading of the law. Though it will be strange, the MCSB will very likely stick to its minimal vetting requirements while the BCC goes full bore on retailer, distributor, and lab owners and financial interest holders.

Changes in ownership. Again in contrast with the BCC, the MSCB is going to be much easier on changes in ownership of licensees. Under BCC regulations, if there’s a full buy-out of all existing owners, the entity can no longer operate while the change of ownership is being reviewed and processed by the BCC. The MCSB however has no such standard, at least not one that’s codified under the new regs. Specifically, for any changes of ownership or changes to financial interest holders, the MCSB expects the following protocol:

“The licensee shall notify the [MCSB] of the addition or removal of an owner through [the agency’s online system] within 10 calendar days of the change; Any new owner shall submit the information required [by law]; The [MCSB] shall review the qualifications of the new owner in accordance with [state law] and these regulations to determine whether the change would constitute grounds for denial of the license. The [MCSB] may approve the addition of the owner, deny the addition of the owner, or condition the license as appropriate, to be determined on a case-by-case basis; An owner shall notify the [MCSB] through [the state agency’s online system] of any change in their owner information . . . within 10 calendar days of the change; and a licensee shall notify the [MCSB] through [the state’s online system] of any change in the list of financial interest holders . . . within 10 calendar days of the change.”

Labeling. Labeling is still just as intense and comprehensive as it was under the emergency regulations. Now though, manufacturers need to ensure that, if a product container is separable from the outer-most packaging (e.g., a container placed inside of a box), the product container includes the following: (1) For edible cannabis products, topical cannabis products, suppositories, or orally-consumed concentrates, all information required for the primary panel except for cannabinoid content, and (2) for inhaled products (e.g., dab, shatter, and wax), the universal symbol (which is the black triangle with a cannabis leaf and an “!” with “CA” underneath). We also now (finally) have specific labeling requirements for pre-roll and packaged flower that didn’t exist before outside of the statute, itself. Overall, there are additional technical change requirements for labeling, including the weight of the product now needing to be in metric and U.S. customary units, specific labeling for flavoring in line with federal law, and more specific labeling restrictions for cannabinoid content.

Packaging. Until 2020, manufacturers are off the hook for providing child resistant packaging (“CRP”). Until then, retailers will bear the burden of CRP through the continued use of CRP exit packaging. Once CRP for manufacturers kicks in though, they’ll need to adhere to a litany of requirements, including compliance with the Poison Prevention Packaging Act of 1970 Regulations.

New product definitions. Via the permanent regulations, MCSB has introduced a number of newly defined terms, which is ultimately better for licensees so that confusion doesn’t abound as product development continues. For example, we now have as recognized definitions like:

“Infused pre-roll,” which means “a pre-roll into which cannabis concentrate (other than kief) or other ingredients have been incorporated”;

“Kief,” which means “the resinous trichomes of cannabis that have been separated from the cannabis plant”; and

“Orally-consumed concentrate,” which means “a cannabis concentrate that is intended to be consumed by mouth and is not otherwise an edible cannabis product. ‘Orally-consumed concentrate’ includes tinctures, capsules, and tablets . . .”

OSHA training. Given that cannabis remains federally illegal, people often think that violating one federal law somehow gives you a license to violate every federal law, which is entirely untrue. Under the permanent MCSB regulations:

“for an applicant entity with more than one employee, the applicant employs, or will employ within one year of receiving a license, one supervisor and one employee who have successfully completed a Cal/OSHA 30-hour general industry outreach course offered by a training provider that is authorized by an OSHA Training Institute Education Center to provide the course.”

Clearly, safety and federal compliance in the workplace still applies, even to cannabis operators, which is now demoralized under the permanent MCSB rules.

Changes to operations that now require state approval. As the state moves along with licensing and enforcement, it was inevitable that certain licensee actions would first require state approval. What this usually means is that major changes to your business or SOPs can’t go down without the state’s blessing, which can take weeks or months to secure. Specifically, for the MCSB, licensees will now have to report to and clear with the state the following action items before the licensee pulls the trigger on them (all to the tune of a $700 change application fee, which is non-refundable):

the addition of any closed-loop extraction method;

the addition of any other extraction method that necessitates a substantial or material alteration of the premises;

the addition of infusion operations if no infusion activity is listed in the current license application on file with the [MCSB] (you’ll also have to tell the state about “any changes to the product list on file with the [MCSB] and provide a new product list within 10 business days of making any change” to the products you’re making”); or

a substantial or material alteration of the licensed premises from the current premises diagram on file with the [MCSB].

Importantly, a “substantial or material alteration” includes: “the removal, creation, or relocation of an entryway, doorway, wall, or interior partition; a change in the type of activity conducted in, or the use of, an area identified in the premises diagram; or remodeling of the premises or portion of the premises in which manufacturing activities are conducted.” Be advised!

California Cannabis: Breaking Down the CDPH Permanent Regulations posted first on http://ronenkurzfeld.blogspot.com

0 notes

Text

California Cannabis: Breaking Down the CDPH Permanent Regulations