#osha injury and illness prevention program

Text

OSHA Workplace Safety Training, Consultancy: PCS Safety, California

PCS Safety: Providing quality workplace safety services Company & training including OSHA training to public/private sectors in California and throught United States..

Cal OSHA safety training for Workers – cal osha training coursesA Mandate: The Cal OSHA training module ensures that cal osha safety training workers are eligible for workplace safety osha citation for their positions regardless of industry. Its Known as california safety training

osha citation response Importance of Safety Work Permit by PCS safety Inc - osha certification California A safe system of work permit is an effective vehicle for communicating critical safety information. Safe Lifting Poster- Employers are encouraged to post this guide osha license to help workers follow OSHA’s ergonomic compliance and meet OSHA’s mandatory training requirement.

osha 40 hours- 40 hour hazwoper

labor law posters california - First Aid Compliance for Your first aid training Workplace California Forklift Certification Requirements for Employers workplace first aid What is PSM – Process Safety Management Program, is it Important

Injury and Illness Prevention (IIP) Program Plan Kit : Under Title 8 of the California Code of Regulations (T8CCR) Section 3203, every California employer is required to have a documentable llness injury preventino program kit. At PCS Safety, Inc., osha injury and illness prevention program our Injury and Illness Prevention Plan Kit injury and illness prevention program osha will help you prepare and meet the legal requirements. The first step is conducting injury illness prevention program california the OSHA Inspections & Citation Representation, injury illness prevention program Citation & Appeals.

CAL-OSHA COMPLIANCE TRAINING

Cal OSHA Compliance Training : The Safety Program or Illness and Injury Prevention Program as required by Cal OSHA training requirements must encompass the following elements:

1)Compliance 2) Communication 3) Hazard Assessment 4) Accident/Exposure Investigation 5) Hazard Correction 6) Training and Instruction 7) Record-keeping Compliance is cal osha training courses something every organization with one or more employees must comply with all of the above-mentioned requirements. Cal OSHA Training materials (e.g., interactive videos, online training, and more) that address the topics required by OSHA, are vital documents that you need to prepare, as well as emergency response plans.

#"llness injury preventino program kit#osha injury and illness prevention program#injury and illness prevention program osha#illness prevention program#injury illness prevention program california#injury illness prevention program#cal osha training requirements#cal osha compliance training#cal osha training courses#cal osha training materials#cal osha safety training#cal osha training#california safety training#safety work permit#safe lifting poster#labor law posters California#first aid compliance#california forklift certification requirements#process safety management program

1 note

·

View note

Text

More good things the Biden administration is doing: OSHA heat safety rules for workers

Remember when Texas and Florida passed laws preventing local and municipal governments from implementing their own heat safety rules and said that if heat is such a big problem, OSHA should make rules that apply to everyone? If not, NPR can remind you. OSHA has now accepted the challenge, moving much faster than they usually do:

OSHA National News Release

U.S. Department of Labor

July 2, 2024

Biden-Harris administration announces proposed rule to protect indoor, outdoor workers from extreme heat

WASHINGTON – The U.S. Department of Labor has released a proposed rule with the goal of protecting millions of workers from the significant health risks of extreme heat. If finalized, the proposed rule would help protect approximately 36 million workers in indoor and outdoor work settings and substantially reduce heat injuries, illnesses, and deaths in the workplace.

Heat is the leading cause of weather-related deaths in the U.S. Excessive workplace heat can lead to heat stroke and even death. While heat hazards impact workers in many industries, workers of color have a higher likelihood of working in jobs with hazardous heat exposure.

“Every worker should come home safe and healthy at the end of the day, which is why the Biden-Harris administration is taking this significant step to protect workers from the dangers posed by extreme heat,” said Acting Secretary of Labor Julie Su. “As the most pro-worker administration in history, we are committed to ensuring that those doing difficult work in some of our economy’s most critical sectors are valued and kept safe in the workplace.”

The proposed rule would require employers to develop an injury and illness prevention plan to control heat hazards in workplaces affected by excessive heat. Among other things, the plan would require employers to evaluate heat risks and — when heat increases risks to workers — implement requirements for drinking water, rest breaks and control of indoor heat. It would also require a plan to protect new or returning workers unaccustomed to working in high heat conditions.

“Workers all over the country are passing out, suffering heat stroke and dying from heat exposure from just doing their jobs, and something must be done to protect them,” said Assistant Secretary for Occupational Safety and Health Douglas L. Parker. “Today’s proposal is an important next step in the process to receive public input to craft a ‘win-win’ final rule that protects workers while being practical and workable for employers.”

Employers would also be required to provide training, have procedures to respond if a worker is experiencing signs and symptoms of a heat-related illness, and take immediate action to help a worker experiencing signs and symptoms of a heat emergency.

The public is encouraged to submit written comments on the rule once it is published in the Federal Register. The agency also anticipates a public hearing after the close of the written comment period. More information will be available on submitting comments when the rule is published.

In the interim, OSHA continues to direct significant existing outreach and enforcement resources to educate employers and workers and hold businesses accountable for violations of the Occupational Safety and Health Act’s general duty clause, 29 U.S.C. § 654(a)(1) and other applicable regulations. Record-breaking temperatures across the nation have increased the risks people face on-the-job, especially in summer months. Every year, dozens of workers die and thousands more suffer illnesses related to hazardous heat exposure that, sadly, are most often preventable.

The agency continues to conduct heat-related inspections under its National Emphasis Program – Outdoor and Indoor Heat-Related Hazards, launched in 2022. The program inspects workplaces with the highest exposures to heat-related hazards proactively to prevent workers from suffering injury, illness or death needlessly. Since the launch, OSHA has conducted more than 5,000 federal heat-related inspections.

In addition, the agency is prioritizing programmed inspections in agricultural industries that employ temporary, nonimmigrant H-2A workers for seasonal labor. These workers face unique vulnerabilities, including potential language barriers, less control over their living and working conditions, and possible lack of acclimatization, and are at high risk of hazardous heat exposure.

#biden harris administration#biden administration#osha#heat safety#worker safety#biden 2024#biden harris 2024#vote for democrats#vote blue#vote biden#us politics#us law

637 notes

·

View notes

Text

The Federal Advisory Committee for Occupational Safety and Health (OSHA) is seeking public comment on reducing injuries and illnesses in the federal workforce and establishing while maintaining effective occupational safety and health programs. It’s important to submit a personalized comment, which could include counting COVID infections as an illness in the workplace, maintaining N95 masks in healthcare settings in care of COVID patients, ensuring access to high quality respirators in the workplace, improving ventilation, and implementing air filtration in all indoor settings. Feel free to use the points or borrow the language in our sample letter below.

Docket No. OSHA-2023-0012

COVID-19 infections continue to injure, harm, and cause mortality among Americans. Based on both case counts and estimates, millions of Americans also are suffering from Long COVID. It is important that Americans, those in the federal workforce and patients cared for in health care settings are also protected from COVID-19 infections. SARS-CoV-2 is spread via inhalation of aerosol particles with a higher risk at indoor settings compared to outdoor settings. Layers of protection including high quality respirators such as N95s, ventilation, and air filtration have been demonstrated to protect individuals from a COVID19-infection.

COVID-19 infections must be counted as an illness in any workplace setting. Designating COVID-19 as an illness will allow federal workers sick with COVID-19 to have enough time to properly rest and recover from an infection, Furthermore, it will protect coworkers and clients from a COVID-19 infection, which will ultimately prevent outbreaks.

OSHA plays an important role in ensuring healthcare workers are protected from infections when caring for COVID-19 patients, and patients are protected from workers infected with COVID-19. Policies must remain in place to ensure healthcare workers have access to high quality N95 respirators when caring for COVID-19 patients and that COVID-19 patients must be quarantined in a negative pressure room. If healthcare workers stop wearing N95 respirators while caring for COVID-19 patients, many more will develop COVID-19. Because over 50% of COVID-19 transmission occurs before people develop symptoms, they may pass it to their coworkers or patients in a maskless healthcare setting. Policies must also be established that allow workers to use a high quality respirator in their workplace setting at all times.

I ask OSHA to fulfill its mission, which is “to protect the safety and health of America’s workers.” COVID-19 remains a serious safety and health issue for America’s workers. I ask that you ensure agencies such as CDC provide the best recommendations that employ a multi-layer approach to protect federal workers and their clients from COVID-19 infections.

Submitted comments to Docket No. OSHA-2023-0012 must be received by OSHA no later than September 29, 2023 11:59 p.m., EST

#op#covid#osha#uspol#covid-19#workplace safety#health and safety#occupational health and safety#labor#covid19#covid 19#coronavirus#pandemic

5 notes

·

View notes

Text

From “USPS is Falsifying Safety Docs As Its Workers Die Of Heat” by McHam Investigative Reporting Fellow Josephine Lee, in the Texas Observer:

USPS MAIL CARRIER HEAT-RELATED FATALITIES 2012-2023 (SOURCE: OSHA)

July 24, 2012, Independence, MO: John Watzlawick died delivering mail when the temperature hit 102 degrees.

July 6, 2013, Medford, MA: James Baldassarre died from a heat stroke. The temperature was 94 degrees; the heat index was 117.

July 11, 2017, Charleston, WV: Ronnie Bowles died after experiencing heart problems induced by heat stress. The heat index was 88.

July 6, 2018, Woodland Hills, CA: Peggy Frank died in a non-air-conditioned mail truck. The temperature hit a record-setting high of 115.

July 22, 2020, Washington, D.C.: A mail carrier died in a non-air-conditioned vehicle. The high temperature was 94 degrees, and the heat index was 104.

June 17, 2021, San Jose, CA: Dalvir Bassi died from a heat stroke. The temperature was 94 degrees.

June 20, 2023, Dallas, TX: Eugene Gates died when the temperature hit 98 degrees with a heat index of 116.

After Watzlawick’s death, USPS agreed to a limited heat-illness prevention program that would only include Independence, Missouri. The program wasn’t instituted nationally until May 2018. By then, 62 more USPS carriers around the country had been hospitalized for severe heat-related illnesses, according to the Observer’s analysis of OSHA records. At least two others had died.

In the summer of 2020, mail carriers were dealt a blow after USPS won an administrative law judge decision that overturned an OSHA penalty of $511,000 for five heat-related injuries. Without a specific OSHA standard for heat safety, judges decided that the mail carriers’ unprotected exposure to extreme heat did not qualify as a “hazard likely to cause death or serious physical harm” under OSHA’s general duty clause, which requires employers to provide general protections for a safe workplace.

But, according to OSHA records, from 2015 to 2022, heat-related injuries accounted for 173 of 1,200 severe injuries—16 percent—among USPS carriers that required hospitalization. This does not include the heat illnesses experienced by mail carriers during the extreme heat this summer. According to the data, Texas mail carriers experienced the most hospitalizations from work-related heat illnesses. The state had 28 recorded incidents, compared to 10 in Nevada, which came second.

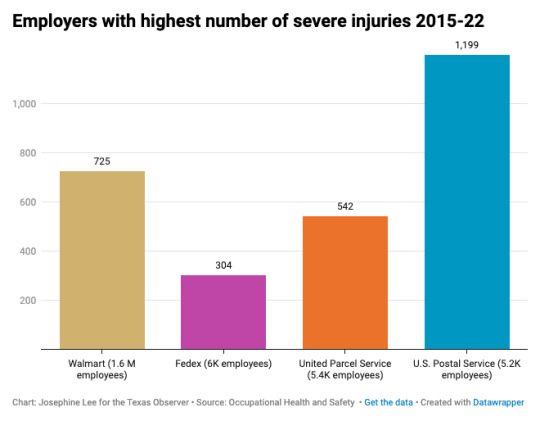

Notably, even though USPS is not the largest employer in the United States.—it employs roughly half the workers at Walmart, Amazon, or McDonald's—its workers reported the highest number of severe workplace injuries overall, 1,200 over that same time period.

Read more at the Texas Observer.

#texas#usps#save the usps#workers#worker rights#government#heatwave#environmental justice#climate crisis

2 notes

·

View notes

Text

Is your trash costing you cash?

For a small business, one injury can mean financial disaster. Costs to a business include:

• Production losses

• Wages for work not performed

• Increased workers' compensation insurance costs

• Damage to equipment or machinery

• Hiring and/or training new employees

• Decline in product quality and worker morale

• Decline in worker morale

• High turnover and lost work time

A safe and healthy workplace not only protects workers from injury and illness, it can also lower injury/illness costs, reduce absenteeism and turnover, increase productivity and quality, and raise employee morale. In other words, safety is good for business. Plus, protecting workers is the right thing to do.

OSHA reports that employers can save $4.00 to $6.00 for every dollar spent on a safety and health program. Workplaces with successful safety and health management systems reduce injury and illness costs 20-40%, according to OSHA.

0 notes

Text

Workers Compensation Insurance for Roofers In California

Introduction

Workers' compensation insurance is essential for high-risk professions such as roofing. Given the inherent dangers associated with roofing work, it is crucial for roofing companies in California to understand and comply with workers' compensation regulations. This article explores the key elements of workers' compensation insurance for roofing companies in California, including legal requirements, coverage options, challenges, and best practices.

Legal Requirements

In California, employers are required to carry workers' compensation insurance for all employees, including part-time, temporary, and seasonal workers. This mandate is particularly important for roofing companies due to the high-risk nature of the work.

Key Points:

Mandatory Coverage: Roofing companies must provide workers' compensation coverage for all employees, regardless of the duration or nature of their employment.

Compliance with State Laws: The California Department of Industrial Relations (DIR) and the Division of Workers' Compensation (DWC) oversee compliance with workers' compensation regulations. Roofing companies must adhere to these regulations to avoid penalties and ensure employee protection.

Reporting and Record-Keeping: Employers are required to report work-related injuries and illnesses promptly and maintain accurate records.

Coverage Options

Roofing companies in California have several options for obtaining workers' compensation insurance. These include purchasing a policy from a private insurance carrier, utilizing the state's assigned risk pool for high-risk employers, or self-insuring if the company meets specific financial criteria set by the DIR.

Key Points:

Private Insurance: Many roofing companies prefer private insurance for its flexibility and variety of available policies.

State Compensation Insurance Fund (SCIF): SCIF is a state-run program that provides workers' compensation insurance, especially for businesses that have difficulty obtaining coverage through private insurers.

Self-Insurance: Larger companies with substantial financial stability might choose to self-insure. This option requires state approval and a demonstration of financial capability.

Challenges for Roofing Companies

Roofing companies face unique challenges in managing workers' compensation insurance:

High Risk of Injury: Roofing is a high-risk occupation with potential hazards such as falls, tool injuries, and exposure to extreme weather conditions.

Varied Work Environments: Roofers work in different environments, including residential, commercial, and industrial sites, each with unique safety challenges.

High Turnover: The roofing industry often experiences high employee turnover, complicating record-keeping and claims management.

Cost Management: The cost of workers' compensation insurance can be significant due to the high risk associated with roofing work.

Best Practices

To effectively manage workers' compensation insurance and minimize risks, roofing companies should implement several best practices:

Comprehensive Training: Provide thorough safety training tailored to the specific tasks and environments where employees will work. This includes fall prevention, proper use of tools, and safe handling of materials.

Regular Safety Audits: Conduct regular safety audits of job sites to identify and mitigate potential hazards. Ensure compliance with Occupational Safety and Health Administration (OSHA) standards and California's specific safety regulations (Cal/OSHA).

Effective Communication: Maintain open lines of communication with employees to quickly address any safety concerns or incidents. Encourage employees to report unsafe conditions and near-misses.

Accurate Record-Keeping: Keep detailed records of employee training, job assignments, and incident reports to streamline the claims process and ensure compliance with state regulations. Proper documentation is crucial for managing claims efficiently.

Return-to-Work Programs: Implement return-to-work programs to help injured employees transition back to their jobs. These programs can reduce the duration and cost of workers' compensation claims and improve employee morale.

Insurance Review: Regularly review insurance policies to ensure they provide adequate coverage for the company's current operations and adjust as necessary. This includes evaluating different insurance providers to find the best coverage options.

California's Unique Considerations

Medical Provider Network (MPN): Employers in California can establish an MPN, a network of healthcare providers to treat workers injured on the job. Employees generally must choose their treating doctor from the MPN.

Benefit Structure: Understanding California's specific benefits structure, including temporary disability, permanent disability, and medical benefits, is crucial for accurate claims management.

Vocational Rehabilitation: California law includes provisions for supplemental job displacement benefits (SJDB) to help injured workers who cannot return to their previous job.

Conclusion

Workers' compensation insurance is a critical component of managing a roofing company in California. By understanding the legal requirements, exploring coverage options, addressing unique challenges, and implementing best practices, roofing companies can protect their employees and their business. Effective management of workers' compensation not only ensures legal compliance but also contributes to a safer and more productive workforce, ultimately leading to a more successful roofing company.

0 notes

Text

The Imperative of Safety Compliance Training in Modern Corporate Environments

In the rapidly evolving landscape of modern corporations, safety compliance training has emerged as a crucial component of organizational risk management and employee well-being. As workplaces become more complex and regulations more stringent, companies must ensure that their workforce is well-equipped to navigate potential hazards and adhere to safety standards. This article explores the importance of safety compliance training, effective strategies for its implementation, and the emerging trends that are shaping its future in the corporate world.

Why Safety Compliance Training Matters

1. Legal and Regulatory Adherence

Organizations are bound by law to comply with safety regulations specific to their industry. These regulations, set by authorities such as OSHA or industry-specific bodies, are designed to protect workers and the public. Non-compliance can lead to severe penalties, legal repercussions, and significant damage to a company's reputation. Effective safety compliance training ensures that employees are aware of these regulations and understand how to apply them in their daily work.

2. Risk Mitigation

The primary goal of safety compliance training is to reduce workplace hazards and prevent accidents. Training programs equip employees with the knowledge to identify potential risks, understand safe practices, and respond appropriately in emergency situations. This proactive approach to risk management can significantly lower the incidence of workplace injuries and illnesses.

3. Enhancing Workplace Safety Culture

A strong safety culture within an organization not only protects employees but also enhances morale and productivity. Safety compliance training reinforces the message that safety is a priority, fostering a culture where employees are more likely to engage in safe behaviors and report potential hazards.

4. Protecting Organizational Assets

Workplace accidents can result in damage to equipment, facilities, and other assets, leading to operational disruptions and financial losses. By training employees in safety compliance, organizations can protect their assets and ensure smooth, uninterrupted operations.

5. Reputation Management

Companies known for their commitment to safety and compliance often enjoy better relationships with stakeholders, including employees, customers, and regulatory bodies. A robust safety compliance training program can enhance a company's reputation as a responsible and ethical organization.

Core Components of Effective Safety Compliance Training

1. Comprehensive Risk Assessment

Effective safety compliance training begins with a thorough risk assessment. This involves identifying potential hazards in the workplace, assessing the likelihood and impact of these hazards, and determining the specific training needs of different employee groups.

2. Regulatory Knowledge

Training programs must cover relevant safety regulations and standards applicable to the organization. This includes understanding the legal requirements for reporting incidents, maintaining safety records, and complying with industry-specific safety protocols.

3. Practical Safety Skills

Employees should be trained in practical safety skills relevant to their roles. This includes proper use of personal protective equipment (PPE), safe operation of machinery, handling hazardous materials, and emergency response procedures.

4. Interactive Learning Methods

Engaging training methods such as simulations, role-playing, and hands-on exercises can enhance understanding and retention of safety practices. Interactive learning allows employees to apply their knowledge in realistic scenarios, reinforcing their ability to respond effectively in real-life situations.

5. Ongoing Training and Updates

Safety compliance training should not be a one-time event. Regular refresher courses and updates are necessary to keep employees informed about new regulations, emerging hazards, and best practices. Continuous learning opportunities help maintain high standards of safety compliance.

Implementing Safety Compliance Training: Best Practices

1. Customizing Training Programs

Training programs should be tailored to the specific needs of the organization and its employees. This includes considering the nature of the work, the types of hazards present, and the diverse backgrounds and experience levels of the workforce. Customization ensures that training is relevant and effective.

2. Leveraging Technology

Modern technology offers numerous tools for enhancing safety compliance training. E-learning platforms, mobile apps, and virtual reality (VR) simulations can provide flexible, accessible training options that cater to different learning styles and preferences. Technology also enables adaptive learning, where training content is adjusted based on the learner’s performance and progress.

3. Incorporating Real-World Examples

Using real-world examples and case studies in training can make the material more relatable and memorable. These examples help employees understand the practical implications of safety compliance and how it applies to their specific roles and responsibilities.

4. Engaging Leadership

Leadership plays a critical role in promoting a culture of safety. Management should actively participate in and support safety compliance training, demonstrating their commitment to safety and encouraging employees to prioritize safety in their work.

5. Measuring Training Effectiveness

Organizations should establish metrics to evaluate the effectiveness of their safety compliance training programs. This includes tracking incident rates, conducting employee surveys, and analyzing performance on training assessments. Feedback and data-driven insights can help refine and improve training programs over time.

Case Studies: Impact of Safety Compliance Training

1. Logistics and Transportation

Global Logistics Inc. faced challenges with compliance due to the high-risk nature of transportation and handling of goods. They implemented a comprehensive safety compliance training program that included regular drills, online modules, and in-person workshops. This holistic approach led to a 35% reduction in safety incidents and improved compliance with transportation safety regulations.

2. Manufacturing Industry

Precision Manufacturing Ltd. needed to address safety concerns related to heavy machinery and hazardous materials. They introduced a VR-based training program that allowed employees to practice operating machinery and handling materials in a virtual environment. This innovative approach enhanced employee engagement and led to a 40% decrease in machinery-related accidents.

3. Healthcare Sector

Healthcare Network introduced a mobile app for safety compliance training, providing on-the-go access to training materials, quizzes, and safety updates. This mobile solution catered to the busy schedules of healthcare workers, resulting in higher completion rates of safety training and improved compliance with health and safety regulations.

Future Trends in Safety Compliance Training

1. Artificial Intelligence and Predictive Analytics

Artificial intelligence (AI) and predictive analytics are set to revolutionize safety compliance training by providing personalized learning experiences and predictive risk assessments. AI can analyze data from past incidents and training performance to identify patterns and suggest targeted training interventions.

2. Virtual and Augmented Reality

Virtual reality (VR) and augmented reality (AR) technologies will continue to enhance safety compliance training by offering immersive learning experiences. These technologies can simulate complex and hazardous scenarios, allowing employees to practice responses and procedures in a controlled environment, leading to better preparedness and response in real situations.

3. Mobile Learning Solutions

As mobile devices become integral to daily life, mobile learning solutions will make safety compliance training more accessible and convenient. Employees can complete training modules, receive updates, and access safety resources on their smartphones, supporting continuous learning and compliance.

4. Gamification and Interactive Content

Gamification techniques, such as quizzes, leaderboards, and interactive challenges, will make safety compliance training more engaging and effective. Gamified training programs can enhance motivation, retention, and application of safety practices.

5. Holistic Approaches to Safety

Future safety compliance training programs will take a more holistic approach, integrating physical, mental, and ergonomic aspects of workplace safety. This comprehensive approach will address not only the traditional safety concerns but also emerging issues related to mental health and ergonomic practices.

Conclusion

Safety compliance training is an essential element of modern corporate risk management. By equipping employees with the knowledge and skills to adhere to safety regulations and best practices, organizations can mitigate risks, reduce workplace incidents, and foster a culture of safety. The integration of technology, real-world scenarios, and emerging trends such as AI and VR will further enhance the effectiveness of safety compliance training programs.

In summary, safety compliance training is not merely a regulatory requirement but a strategic investment in employee well-being and organizational success. By adopting innovative training approaches and leveraging technology, companies can create safer work environments, protect their assets, and build a resilient, safety-conscious culture.

0 notes

Text

10 Simple Steps to Significantly Enhance Workplace Safety

Workplace Safety

Workplace safety is a crucial issue for all organizations, as it can not only prevent accidents and injuries, but also improve productivity, increase employee morale, and reduce the costs of workplace injuries and illnesses.

According to a study by the Occupational Safety and Health Administration (OSHA), businesses that have implemented safety programs have saved an average of 26% on workers' compensation costs. With the outbreak of COVID-19, it is now more important than ever to prioritize the health and safety of employees in the workplace by protecting them from accidents, hazards, and infectious diseases.

In this guide, we will explore how to effectively implement simple safety practices in the workplace.

1. Train Your Personnel:

Having a comprehensive safety program in place is an important step toward protecting your employees and your business. However, it is not enough to simply create a safety manual and expect your employees to read and understand it on their own.

To ensure that your safety program is effective, it is essential to also develop a training program to go along with it. This can involve scheduling regular training sessions throughout the year, where you review the safety manual with your employees, answer any questions they may have, and discuss best practices for maintaining a safe work environment.

By providing your employees with the knowledge and tools they need to stay safe on the job, you can help to prevent accidents and injuries, as well as improve overall productivity and morale in the workplace.

2. Make a commitment to cleanliness:

A disorganized and cluttered workplace can increase the risk of accidents, such as tripping and slipping. To prevent these accidents, it is important to keep the workplace tidy and organized. This includes reducing clutter, untangling cords, and ensuring walkways are clear of potential tripping hazards.

Additionally, encouraging regular breaks for employees can help them work more efficiently and reduce the risk of accidents caused by overwork and fatigue.

3. Promote break times:

Some states, such as California, Colorado, and Nevada, have laws that mandate rest breaks for employees. It is important to check your state's labor laws to ensure compliance. However, it is generally a good practice to include breaks in an eight-hour workday.

Allowing employees to take two regular breaks during the workday, in addition to a lunch break, can help prevent accidents caused by overwork and fatigue. Encouraging breaks can also help employees feel refreshed and rejuvenated.

4. Maintain a safety leader board:

One way to monitor and improve safety in the workplace is to use a scoreboard. This is a visible sign that records the number of days that have passed without an accident, as well as the previous record.

Keeping a safety scoreboard has several benefits. It serves as a public reminder to motivate employees to prioritize safety, and it can also help inform and educate employees about safety practices.

5. Encourage employee safety:

Instead of singling out one employee for recognition, consider recognizing the efforts of all employees who prioritize safety in the workplace. You can incentivize adherence to safety protocols by offering rewards, such as additional time off, when certain safety milestones are achieved.

For example, you could set a goal for the number of days that your workplace goes without an accident, and then celebrate the team when that goal is met. This can help to create a culture of safety and encourage all employees to prioritize safety in their work.

6. Facilitate Reporting:

If employees find it hard to report potential or actual hazards in the workplace, they will likely not do so. This is because no one wants to be seen as a complainer.

However, if an employee fails to report a hazard, it could lead to another employee getting injured. To prevent this, you can set up a system for reporting hazards.

Designate a safety supervisor on your team to handle reports and ensure that hazards are promptly addressed. This will streamline the process and prevent confusion caused by multiple people being responsible for receiving reports.

7. Establish a safe website:

Consider creating a safety section on your organization's intranet, which is a private and secure internal website. This section can serve as a digital safety manual and include your official safety policy, as well as tips, training videos, tutorials, and resources.

You can also use this space to address frequently asked questions about safety. By providing this information, you can help employees identify and address potential risks.

8. Maintain a pleasant and hygienic workplace:

To prevent the spread of infectious diseases in the workplace, it is important to keep the environment clean. This is especially important in the current COVID-19 pandemic, but can also help prevent the transmission of other illnesses such as the flu and the common cold.

Some ways to maintain a hygienic workplace include: regularly disinfecting common surfaces such as desks, tables, keyboards, and phones; making hand sanitizer easily accessible to all individuals present in the workplace; providing disposable face masks to clients or requiring employees to wear them; and promoting hand washing with soap and water among employees.

9. Display Safety Warnings:

Safety signs serve as constant visual reminders for all employees and have been shown to reduce workplace accidents by drawing attention to hazards.

These signs can be used for a variety of purposes, including identifying the location of fire extinguishers, prohibiting unauthorized access to certain areas, identifying hazards such as fall risks, and requiring the use of protective equipment such as hard hats.

10. Establish workplace emergency protocols:

Creating a comprehensive emergency plan is crucial for ensuring the safety and well-being of your employees. This plan should outline specific procedures for handling a range of potential emergencies, including fires, medical emergencies, suspicious behavior, active shooters, severe weather, bomb threats, and hazardous spills.

It is essential to educate your employees on these procedures, including how to safely evacuate the building or seek shelter, as well as how to access first aid and call for help if necessary. Providing this training during employee onboarding and regularly reviewing the procedures can help ensure that everyone is prepared in the event of an emergency.

In addition to training your employees, consider posting signs around the workplace to remind them of the emergency procedures. This can be particularly helpful in high-stress situations, where employees may need a quick reference to follow the correct protocol.

By taking the time to create and implement a comprehensive emergency plan, you can help ensure the safety and preparedness of your employees in the face of unexpected events.

Conclusion:

To ensure the safety of you, your employees, and your organization, it is important to implement safe practices in your workplace. These practices can help reduce the risk of injuries and improve the overall safety of your organization. Use the above tips as a starting point to implement safe practices in your workplace.

0 notes

Text

10 Simple Steps to Significantly Enhance Workplace Safety

Workplace Safety

Workplace safety is a crucial issue for all organizations, as it can not only prevent accidents and injuries, but also improve productivity, increase employee morale, and reduce the costs of workplace injuries and illnesses.

According to a study by the Occupational Safety and Health Administration (OSHA), businesses that have implemented safety programs have saved an average of 26% on workers' compensation costs. With the outbreak of COVID-19, it is now more important than ever to prioritize the health and safety of employees in the workplace by protecting them from accidents, hazards, and infectious diseases.

In this guide, we will explore how to effectively implement simple safety practices in the workplace.

1. Train Your Personnel:

Having a comprehensive safety program in place is an important step toward protecting your employees and your business. However, it is not enough to simply create a safety manual and expect your employees to read and understand it on their own.

To ensure that your safety program is effective, it is essential to also develop a training program to go along with it. This can involve scheduling regular training sessions throughout the year, where you review the safety manual with your employees, answer any questions they may have, and discuss best practices for maintaining a safe work environment.

By providing your employees with the knowledge and tools they need to stay safe on the job, you can help to prevent accidents and injuries, as well as improve overall productivity and morale in the workplace.

2. Make a commitment to cleanliness:

A disorganized and cluttered workplace can increase the risk of accidents, such as tripping and slipping. To prevent these accidents, it is important to keep the workplace tidy and organized. This includes reducing clutter, untangling cords, and ensuring walkways are clear of potential tripping hazards.

Additionally, encouraging regular breaks for employees can help them work more efficiently and reduce the risk of accidents caused by overwork and fatigue.

3. Promote break times:

Some states, such as California, Colorado, and Nevada, have laws that mandate rest breaks for employees. It is important to check your state's labor laws to ensure compliance. However, it is generally a good practice to include breaks in an eight-hour workday.

Allowing employees to take two regular breaks during the workday, in addition to a lunch break, can help prevent accidents caused by overwork and fatigue. Encouraging breaks can also help employees feel refreshed and rejuvenated.

4. Maintain a safety leader board:

One way to monitor and improve safety in the workplace is to use a scoreboard. This is a visible sign that records the number of days that have passed without an accident, as well as the previous record.

Keeping a safety scoreboard has several benefits. It serves as a public reminder to motivate employees to prioritize safety, and it can also help inform and educate employees about safety practices.

5. Encourage employee safety:

Instead of singling out one employee for recognition, consider recognizing the efforts of all employees who prioritize safety in the workplace. You can incentivize adherence to safety protocols by offering rewards, such as additional time off, when certain safety milestones are achieved.

For example, you could set a goal for the number of days that your workplace goes without an accident, and then celebrate the team when that goal is met. This can help to create a culture of safety and encourage all employees to prioritize safety in their work.

6. Facilitate Reporting:

If employees find it hard to report potential or actual hazards in the workplace, they will likely not do so. This is because no one wants to be seen as a complainer.

However, if an employee fails to report a hazard, it could lead to another employee getting injured. To prevent this, you can set up a system for reporting hazards.

Designate a safety supervisor on your team to handle reports and ensure that hazards are promptly addressed. This will streamline the process and prevent confusion caused by multiple people being responsible for receiving reports.

7. Establish a safe website:

Consider creating a safety section on your organization's intranet, which is a private and secure internal website. This section can serve as a digital safety manual and include your official safety policy, as well as tips, training videos, tutorials, and resources.

You can also use this space to address frequently asked questions about safety. By providing this information, you can help employees identify and address potential risks.

8. Maintain a pleasant and hygienic workplace:

To prevent the spread of infectious diseases in the workplace, it is important to keep the environment clean. This is especially important in the current COVID-19 pandemic, but can also help prevent the transmission of other illnesses such as the flu and the common cold.

Some ways to maintain a hygienic workplace include: regularly disinfecting common surfaces such as desks, tables, keyboards, and phones; making hand sanitizer easily accessible to all individuals present in the workplace; providing disposable face masks to clients or requiring employees to wear them; and promoting hand washing with soap and water among employees.

9. Display Safety Warnings:

Safety signs serve as constant visual reminders for all employees and have been shown to reduce workplace accidents by drawing attention to hazards.

These signs can be used for a variety of purposes, including identifying the location of fire extinguishers, prohibiting unauthorized access to certain areas, identifying hazards such as fall risks, and requiring the use of protective equipment such as hard hats.

10. Establish workplace emergency protocols:

Creating a comprehensive emergency plan is crucial for ensuring the safety and well-being of your employees. This plan should outline specific procedures for handling a range of potential emergencies, including fires, medical emergencies, suspicious behavior, active shooters, severe weather, bomb threats, and hazardous spills.

It is essential to educate your employees on these procedures, including how to safely evacuate the building or seek shelter, as well as how to access first aid and call for help if necessary. Providing this training during employee onboarding and regularly reviewing the procedures can help ensure that everyone is prepared in the event of an emergency.

In addition to training your employees, consider posting signs around the workplace to remind them of the emergency procedures. This can be particularly helpful in high-stress situations, where employees may need a quick reference to follow the correct protocol.

By taking the time to create and implement a comprehensive emergency plan, you can help ensure the safety and preparedness of your employees in the face of unexpected events.

Conclusion:

To ensure the safety of you, your employees, and your organization, it is important to implement safe practices in your workplace. These practices can help reduce the risk of injuries and improve the overall safety of your organization. Use the above tips as a starting point to implement safe practices in your workplace.

0 notes

Text

OSHA Proposes $296K Against Green Bay Sanimax Facility

Federal Investigators Responding to Report of Employee's Severe Burns Find Multiple Safety Hazards at Green Bay Sanimax Facility

OSHA proposes $296K in penalties to Wisconsin facility

GREEN BAY, WI (STL.News) Federal safety inspectors responded to a Green Bay rendering plant after an employee suffered severe burns when a pump seal released steam and hot oil as workers tried to clear a blockage in January 2023.

Inspectors with the U.S. Department of Labor's Occupational Safety and Health Administration determined Sanimax USA LLC failed to develop and implement hazardous energy control procedures when clearing blocked pumps and piping at its Badgerland Drive facility.

OSHA officials also found workers exposed to the following hazards:

- Fall dangers related to broken guardrails, unprotected sides and edges of walking and working surfaces, and walking surfaces covered with production liquids.

- Risks associated with failing to prevent explosion hazards caused by allowing the build-up of combustible dust and not training employees to recognize dust hazards and protective measures.

- Dangers related to electrical hazards and unguarded pulleys, shafts, belts, and production equipment.

- Unguarded or unlabeled hot steam and process pipes throughout the rendering area.

The agency issued citations to Sanimax for three repeat and 10 serious safety and health violations and proposed $296,668 in penalties. OSHA cited the company for similar violations in 2022 and 2019.

"In the past five years, OSHA has cited Sanimax for violations like those found in this investigation. The company is well aware of the need to guard equipment and keep surfaces free of liquids that can create slip and fall hazards. Failing to heed previous OSHA citations and correct deficiencies puts employees at risk," explained OSHA Area Director Robert Bonack in Appleton, Wisconsin. "Employers can prevent injuries by following required safety procedures and by training workers to recognize and mitigate hazards."

OSHA expanded the inspection under its Local Emphasis Program for Wisconsin's food manufacturing industry instituted in April 2022. LEPs are created when OSHA sees industry injury rates exceed national averages. Food manufacturing workers often face hazards related to improper machine guarding and lockout/tagout failures that expose them to serious injury, illness, and death. These inspections often include second and third shifts, as well as sanitation operations and associated cleaning contractors.

Based in Green Bay, Sanimax USA LLC is a subsidiary of Sanimax of Canada. The company transforms organic materials from the agri-food industry into industrial ingredients used to manufacture everyday items such as fats and oils and pet food and proteins. In the U.S., the company operates facilities in Wisconsin in Green Bay and DeForest and in St. Paul, Minnesota.

The company has 15 business days from receipt of the citations and penalties to comply, request an informal conference with OSHA's area director, or contest the findings before the independent Occupational Safety and Health Review Commission.

Source: U.S. Department of Labor

Read the full article

0 notes

Text

Construction Classes

Be Safe and Smart: Build Up Your Skills Through Construction Safety Training!

As the construction industry continues to grow and evolve, so does the focus on safety. While there have been major improvements in safety protocols over the years, the fact of the matter are that accidents still happen.

It's important for those who work in this sector to be aware of their responsibilities and to regularly undertake construction training courses to ensure they are up-to-date with best practices.

That's why construction site safety training is crucial, not just for your well-being but also for overall workplace efficiency. It helps people develop the skills and knowledge to properly identify, assess, and control potential hazards.

By doing so, construction workers can become proactive in preventing workplace accidents and injuries. These courses also help build awareness of the different tools available for mitigating risk on a job site.

What Do These Courses Include?

When you enroll yourself in classes for construction safety training, you will focus on topics such as:

Risk assessment

Risk assessments are a key part of any construction project. They help identify potential hazards and determine their level of risk.

With proper training, workers can learn to recognize risks and take the necessary steps to minimize them.

Personal protective equipment (PPE)

Construction workers must be aware of the different types of PPE available, such as hard hats, goggles, respirators, gloves, etc., and how to properly wear it for optimal protection from hazards.

Everyone on the job site must be correctly outfitted with the right gear to keep themselves safe from injury or illness due to exposure to hazardous substances.

youtube

First aid

Basic first aid knowledge is essential in any workplace, even more so on a construction site. Workers must be aware of the different types of injuries that could occur and know how to treat them properly until help can arrive.

Training courses also teach people how to use fire extinguishers, defibrillators, rescue devices, etc., when needed.

Electrical safety

Electrical hazards are among the most common causes of accidents on construction sites.

To protect workers, they need to know how to identify electrical hazards and use proper grounding techniques when necessary. Construction classes help people understand the different types of protective measures they can take to avoid injury or death due to electrocution.

OSHA standards

Aside from the above, construction safety training often includes OSHA construction training programs. These provide a comprehensive overview of the safety rules and regulations that must be followed according to OSHA (Occupational Safety and Health Administration) standards.

Conclusion:

At the end of the day, construction safety training is important for keeping workers safe and creating an efficient working environment.

By equipping people with the right tools and knowledge, they can become better at identifying hazards and taking appropriate action to prevent them from becoming dangerous. As such, construction safety training should be a top priority in every workplace!

So don't wait; enroll yourself with SQ Safety Intelligence and get the best safety training today!

Look at our homepage to get more information about Construction Training Courses!

0 notes

Text

Maintain Employee Safety on the Year's Hottest Day

Employers must understand how to keep their staff safe in the heat. Heat-related ailments are potentially fatal. For example, heat stroke and heart disease can result from overexposure to heat and exacerbate pre-existing health issues. Excessive heat exposure might also have an impact on staff productivity. One to three percent of productivity can be lost due to a single degree of heat exposure. Furthermore, too hot or cold working environments might increase employee turnover.

The Occupational Safety and Health Administration (OSHA) has launched a new National Emphasis Program (NEP) to address workplace heat-related dangers. Rest, cool water, and cool locations are the preventative techniques outlined in the NEP. Furthermore, OSHA emphasizes early intervention and outreach to educate employers about the risks and how to protect their employees from heat-related diseases. As a result, employers may help keep employees safe during record-breaking heat by following these procedures.

Heat-related diseases and fatalities are becoming increasingly common as temperatures climb. According to the Bureau of Labor Statistics, the number of occupational fatalities and illnesses caused by heat exposure has more than doubled since the early 1990s. As a result, OSHA has announced a new heat-related workplace inspection program to prevent heat-related diseases.

During warmer portions of the day, employers must also provide shade and ample drinking. Employees should also take frequent pauses to rehydrate. A water cooler in a shady location is a fantastic choice. In addition, check that your air conditioning equipment and fans are operational if your staff work indoors. Finally, always wear the right safety equipment.

Oregon OSHA has also accepted final standards on heat sickness and wildfire smoke. These regulations are set to take effect on June 15, 2022. Federal OSHA is expected to seek advice on federal heat rules from Oregon OSHA. For example, the final rule of the Oregon OSHA mandates companies to provide adequate protection for individuals working in hot settings, indoors or outdoors.

While OSHA has requirements to protect employees from heat-related illnesses and injuries, the regulations do not entirely protect workers. Furthermore, OSHA compels employers to keep track of all injuries and illnesses, even if not all of them require medical care. This includes hydration, treated as first aid and not a recordable injury.

Heat stroke is the most prevalent heat-related sickness and can be deadly if not addressed. A malfunction in the body's temperature-regulating mechanisms causes heat stroke. High body temperature, a lack of sweat, and heated, dry skin are all signs. Heat stroke, if left untreated, can result in unconsciousness, convulsions, and death.

Heat stress is a serious problem in the workplace, and employees must be safeguarded. Fortunately, numerous states have implemented legislation to make workplaces safer for employees. California and Minnesota, for example, have already established heat stress laws, while Washington has passed House Bill 722. Under this new legislation, employers must safeguard their employees from heat stress.

Whether your workplace is hot or cold, it is critical to protect employees from heat-related diseases. The goal is to educate your employees on the symptoms of heat-related ailments. They should be taught and encouraged to take breaks, drink water, and seek shade. If they do have symptoms, they should seek medical assistance right away.

Employers should create a heart disease prevention program, according to OSHA. Unfortunately, over 80% of heat-related diseases occur in businesses that do not take preventive steps. Your program should be suited to your location and the job demands of your staff. It should also be backed by management.

Occupational heat exposure is a huge health risk for millions of Americans and is avoidable. Heat sickness at work might result in death or lifelong disability. Most heat-related diseases develop during the first few days of working in a hot setting. Occupational heat exposure accounted for 50% to 70% of mortality. Regardless of the problem, it is simple to limit the danger of occupational heat disorders and keep employees comfortable.

The surveys are designed to gather data on how companies safeguard their employees from heat-related diseases. They also want to see how successful heat-related preventative measures are. Employers may be asked to show examples of their programs and how they safeguard workers in some queries.

0 notes

Text

Occupational Health Service

Occupational health services include pre-placement exams, surveillance exams, immunizations, and other administrative exams. They also help employers comply with OSHA regulations and other required safety standards. In addition, these specialists provide case management and communications support to employees. They also work closely with safety, human resources, and industrial hygiene. Learn more about Meridian Occupational Services, go here.

As the responsibility for workplace health is shared by both employees and employers, the occupational health service should inform employees about potential hazards and protect them from these hazards. The occupational health service should also educate employees on protective measures such as protective clothing and face masks. First aid facilities should be organized and employees should be trained in how to use them if necessary.

Occupational health services also aim to educate employees about the risks they face in their work environment. This includes educating employees about how to deal with injuries and illnesses and how to protect their health. They also educate them on how to properly use protective gear, such as face masks and protective clothing. In addition, first aid facilities must be organized and employees should be trained on how to use them. This way, if an accident does occur, the workers can receive immediate medical assistance.

The objective of occupational health services is to reduce the number of workplace accidents, illnesses and disease. They are often combined with primary care in an integrated manner. Occupational health providers help injured workers return to work and prevent the risk of further illness and injury. Prevention is the best form of health care, as it is more effective than treatment. A basic occupational health service also provides access to health services, such as health assessment, digital mental health resources, and wellness programs. Take a look at this link https://en.wikipedia.org/wiki/Occupational_safety_and_health for more information.

Occupational health services can include pre-placement exams, workplace injuries, and immunizations. Other services include monitoring of employees for certain conditions and illnesses, monitoring health conditions, and organizing quality OH programs. They can also manage and administer workplace safety programs. In addition, they may provide services related to employee wellness programs and respiratory fit testing.

In developing countries, occupational health services may also provide general medical care and health education. Their main purpose is to reduce illness in the workplace and improve worker health. They may also organize health surveillance programs. They also provide services such as counseling and health education. It is important to ensure that an occupational health service is effective in order to protect employees.

1 note

·

View note

Text

Top 5 Fire Safety Courses In UAE

Peruse the top Fire and Safety courses in Dubai, Abu Dhabi, and Sharjah, UAE beneath. Each business requires an arrangement to plan for crises identifying with fire. Fire can obliterate property, makes serious wounds laborers and individuals influenced by it, and can take life.

In case of a fire crisis, you need somebody who (ought to be certificated, ex: CFPS) to be available in your working environment appropriately outfitted with the information and capacity to handle a fire ejecting situation to guarantee the safety of different representatives and the property. Enlisting and training your representatives to confront fire crises intensely will assist your workers with act normally on such an occasion.

You will see many fire and safety courses and training in Dubai, Abu Dhabi, and different emirates to set you up for a fire crisis circumstance. A portion of this accreditation site is considered fundamental and mandatory by the neighborhood specialists of the UAE. Many reasons cause a fire, and it is generally uncertain. Being outfitted with the right abilities to handle such uncertainty is gainful for all. Peruse the rundown of alternatives and look into the organizations offering fire safety training all over UAE.

Fire represents the most serious and powerful danger to life and property because of which it is fundamental to have somebody in your working environment to guarantee the safety of different representatives. Fire and safety concerns are most extreme in all enterprises from both lawful and moral viewpoints. Fire and safety designing training courses presented in Dubai and Abu Dhabi helps in the mindfulness cycle to face and respond to such circumstances. It likewise gives crucial data about the job of fire marshals, fire safety precautions, enactment identified with fire safety and assurance training, causes and counteraction of fire, fire departure and fire safety bore, and quite a lot more.

Quest for all accessible Rundown of Fire and safety courses in Dubai, Abu Dhabi, and Sharjah, UAE.

In the wake of leading top to bottom examination, our group of worldwide specialists has gathered this rundown of Best Five Fire Safety Courses, Classes, Instructional exercises, Training, and Confirmation programs accessible online for 2021. This rundown incorporates both free and paid courses to assist you with finding out with regards to Fire Safety. Additionally, it is great for amateurs, intermediates, just as specialists.

1. Fire Safety Courses by OSHA Grounds

People who work in electrical divisions or fire offices need the OSHA training declaration to be qualified for a task. This course centers around giving you every one of the rules for fire and fire security measures to assist you with understanding how you can save your and others' lives with cautious arranging and precautionary measures. The course is molded by master educators of 360 Training, who are OSHA confirmed coaches. During the course, they will help you actually to understand the prerequisites of getting the OSHA fire safety authentication.

– Figure out how to distinguish different kinds of fires and fire dousers while getting a short depiction of fire security frameworks.

– Figure out how to analyze departure plans and how to get ready for fire crises with the information on gear.

– Think about normal fire-related wounds and the cures that can be utilized right away to fix those wounds.

– Gain admittance to a simple to utilize LMS innovation so you can realize precisely what you need to clear the affirmation test.

– Benefit to examine from the solace of your home as it is an independent learning program.

2. Online Fire Safety Training and Affirmation (Public Fire Security Affiliation)

Public Fire Security and Affiliation are a main data and information asset of fire dangers, which furnish you with on the web and live virtual training on fire safety. Made by experienced educators, this program permits you to learn at your speed, whenever, at any area with the solace of your PC. There are numerous training programs, which incorporate NFPA 70 – Public Electrical Code, Standard for Electrical Safety in the Work environment, Life Safety Code Basics, and some more. Finishing these projects will enable you to clear the Fire safety confirmation tests so you can land the position that you're searching for. Examine our arrangement of Best Gadgets Courses.

– Get a unique opportunity to rehearse in an intuitive online climate that depends on a situation in a certifiable setting.

– Profit great taking in experience and master guidelines from learned educators with in-person study hall training.

– Think about different fire security frameworks with an assortment of courses, like Public Fire Caution and Flagging Code, Standard for the Establishment of Sprinkler Frameworks, Stockpiling Assurance Necessities, and Evaluations, and so on

– Find out with regards to safety efforts that you need to take while handling a fire issue in medical services ventures.

3. Fire Safety The executive’s Courses (Worldwide Training Place)

These fire safety executive programs are exceptionally intended for managers, laborers, and their agents, who are involved in jobs and obligations identified with fire safety. It will give them all the data that they need to check that satisfactory measures are set up to forestall fires happening. There are three distinct courses remembered for the program, which incorporate a Distance adapting course on word-related safety and wellbeing, an E-adapting course on work injury plans and the anticipation of word-related mishaps and infections, and Experts in word-related programs about safety and wellbeing. Finishing every one of these courses will furnish you with the testament of culmination that could be utilized to exhibit your abilities.

– Work on your ability of business injury establishments to oversee working mishaps and illnesses while elevating preventive ways to deal with OSH.

– Components a wide scope of learning arrangements where members can upgrade their insightful and critical thinking abilities.

– Made by master teachers who are guaranteed in OSHO fire safety standards and rules.

– Get consistent help from a group of specialists to understand complex questions and resolve your issues identified with the course.

4. Top Fire Safety Courses (Udemy)

In case you are thinking that it is trying to choose a course that could assist you with clearing the OSHA training certificate test, then, at that point, this rundown of fire safety courses can help you in your journey. Udemy gives a rundown of skilled fire safety courses that are incorporated with important data, tests, recordings, practice tests, and considerably more. Among the rundown, probably the best courses are Fire Safety and Anticipation Arranging, Fire Safety Expert Course, Firefighter Code: Pass the Firefighter Oral Board, and so forth Every one of these courses is planned by master teachers who are knowledgeable about all parts of fire safety and standards. During the meetings, you can converse with teachers to talk about any issues identified with the course material.

– Learn and understand fire safety and anticipation making arrangements for your working environment, and how you can try not to happen fire right away.

– Be a specialist in fire safety, fire perils control, fire clearing plans, fire hazard the board, and numerous different things identified with fire.

– Find out with regards to fundamental fire mindfulness, fire anticipation and control, and best practices for proficient fire safety from industry specialists.

– Cover themes like fire investigation of steel structures, essential firefighting, fire caution framework establishment, and some more.

For more: Fire Safety Training Abu Dhabi, Fire Safety Training UAE, Fire and Safety Companies in Abu Dhabi, fire and safety companies in Dubai, Safety consultants in Abu Dhabi.

#Fire Safety Training Abu Dhabi#Fire Safety Training uae#Fire and Safety Companies in Abu dhabi#fire and safety companies in Dubai#Safety consultants in Abu Dhabi

1 note

·

View note

Text

How to Negotiate With an OSHA Compliance Officer

The US Department of Labor can give one of their inspectors with proper credentials a task to conduct an OSHA compliance test at your local office. Most of the small shop and business owners feel confused and overwhelmed when one of the OSHA officers arrive at their place. However, there is always a reason for a compliance officer to visit and do an inspection of the site. They may come to inspect one of the operations like heating and cooling measures. Usually, employers have the right to ask for a warrant before permitting them entry at their business area or jobsite. Employment Compliance Attorneys can help in finding more about violations and inspections.

Initial Talks with the Compliance Officer

In initial conference, you may ask for the nature of the visit and the extent of the inspection. If the inspection is because of an employee’s compliant, you can ask for its copy. Officers can edit this copy to conceal that particular employee’s identity. One of the employer’s representatives mostly accompanies these officers during inspections. This allows employers in knowing the problem closely and avoiding such future examinations.

Negotiating the scope of the inspection

A workplace, company, shop, store, or factory can be both very large and normal sized. It’s better to know if the complaint is about a specific area within the premises and whether it will remain confined to that area only. Mostly, inspections concentrate on particular areas and certain hazards. However, companies are suggested to be prepared for full inspections especially in case they don’t possess a safety program. Hiring employment compliance attorneys help in keeping the workplace in compliance with necessary labor and OSHA laws. You can also Contact- Tremiti LLC for professional help.

What Does a Compliance Officer Do at the Worksite?

Companies that work with ten or more employees are required to keep an OSHA log (OSHA form 300) which consists of injuries and illnesses recorded at the site. Frequently, OSHA compliance offers review and verifies these logs. They will probably ask for your hazard control and management program, check list of any hazardous materials you’re working with, and look for noticeable OSHA poster. Companies are also required to have an accident prevention program. When employers or companies fail to produce proper records and documents, they are charged heavily in fines. To avoid making a poor impression and bad outcome of the inspection, employers can work with law firms such as Tremiti LLC for professional assistance and legal help.

It would be beneficial to inform employees at the training stage about potential inspections and that they are all working in a safe workplace. During the training period, employers should give assurance of no retaliation to their employees for anything they say in front of officers or when they are interviewed about workplace conditions. Many employees feel intimidated and naturally, they say what compliance officers want to hear. To avoid that situation, employers can hire employment compliance attorneys who will help them training the employees properly and drafting clear guidelines.

#law#lawyers#bestemploymentlawyerswallstreetny#employmentlaw#bestlawyersinny#employmentcomplianceattorneyny

1 note

·

View note

Photo

According to OSHA and NIOSH, the #1 thing employers should focus on, is “Protecting the musculoskeletal system of employees.” Is your company doing everything possible and required by OSHA to protect your employees from soft-tissue and spinal injuries?

The main goal of health and safety programs is to prevent workplace injuries and illnesses, as well as the suffering and financial hardship these events can cause for employers, workers and their families. Once a safety and health program is established, it should be evaluated periodically and at least annually to verify what is working and what is not, and whether a program is on track to achieve positive outcomes.

The General Duty Clause requires employers to provide their employees with a workplace free from recognized hazards likely to cause serious physical harm. One of the "root causes" of workplace injuries is the failure to identify or recognize hazards and risk that are present, or that could have been anticipated. A proactive, ongoing process to identify and assess workplace hazards and risk includes a work site evaluation and musculoskeletal risk assessment designed to prevent costly injuries.

Title 8, Section 3203 (IIPP) states than employers should perform periodic assessments to ensure their injury prevention program is up to date and effective. This should occur at least annually, whenever new tools or equipment are introduced, a process changes, and when a new hazard or risk factor is discovered as the result of an injury or incident investigation. Section 5110 (RMI - Repetitive Motion Injuries) also requires employers to evaluate risk and provide training whenever there is more than one RMI in the last 365 days, caused by an identical work activity.

Accurate Ergonomics (AE) is the perfect resource to ensure compliance and prevent loss. An AE worksite evaluation and musculoskeletal risk assessment will identify your worksite’s strengths, highlight areas for improvement and provide an opportunity to implement effective control measures, including changing workforce behaviors.

Has it been a year or longer since your last worksite evaluation? You owe it to your company, workforce and bottom-line to have AE’s musculoskeletal injury prevention specialists perform an assessment. No matter where your company currently stands regarding health and safety excellence, AE will help you raise your health and safety bar even higher.

Take the Accurate Ergonomics challenge today. Our specialists will provide an objective analysis of your injury history, measure behaviors and risk against performance objectives, and share a report of findings and control measure recommendations with stakeholders.

With budget season approaching fast, an AE risk assessment will allow you to plan for total success.

1 note

·

View note