#circuitboards

Explore tagged Tumblr posts

Text

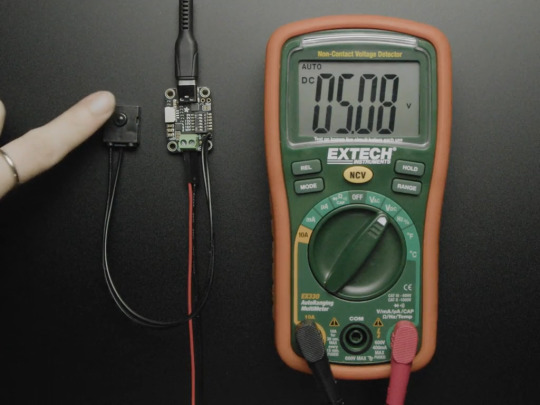

🔌⚡🔧 Perfect for USB Type C wall adapters providing multiple voltages. The standard offerings are 5V, 9V, 12V, 15V, 18V, and 20V. This HUSB238 breakout plugs into the USB C cable and negotiates the PD request and commands over the CC lines. https://www.adafruit.com/product/5991 & https://www.adafruit.com/product/5450

#usbtypec#powerdelivery#breakoutboard#electronicsprojects#openhardware#makercommunity#innovation#usbpower#diyelectronics#embeddeddesign#voltagecontrol#powersupply#techgadgets#electronicsengineering#hardwarehacking#circuitboards#gadgetlover#productdesign#usbcable#engineeringlife

22 notes

·

View notes

Text

A black and white photograph of the underside of a circuit board.

#electronics#tech#technology#circuitboard#circuit board#circuit boards#circuitboards#pictures#photography#photo#photograph#picture#photos#photographs#image#black and white#blackandwhite#black and white photography

3 notes

·

View notes

Text

#PCBDesign#CopperCladLaminate#ElectronicsEngineering#CopperFoil#PCBFabrication#CircuitBoards#PCBManufacturing#CopperPlating#HighPowerPCB#IPCStandards#PCBTechnology#HeavyCopperPCB#ElectronicsIndustry#usa#europe#germany

0 notes

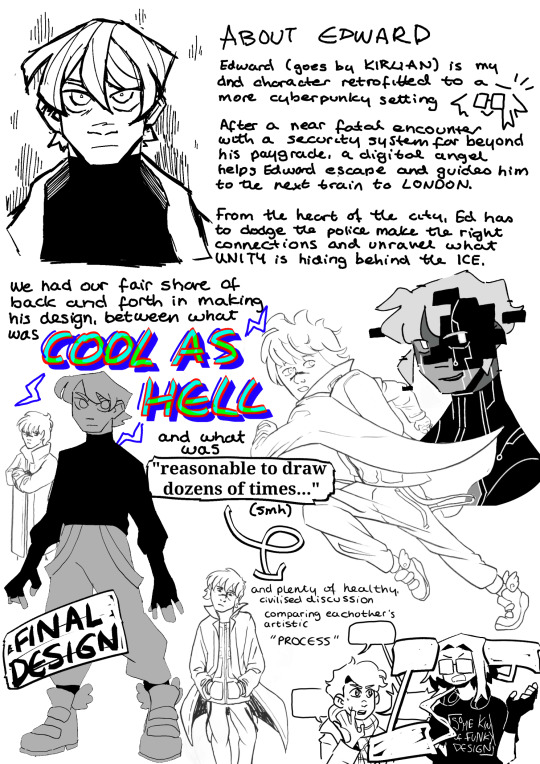

Text

the funny with these losers

#rtshw#hello world mspfa#a511ff#20e9ff#you could do this meme with literally any of the characters btw#[slug image] Mayko...#[lightbulb image] Dia...#[circuitboard image] Fana...

57 notes

·

View notes

Text

L'Ordinateur Individuel (1986)

34 notes

·

View notes

Text

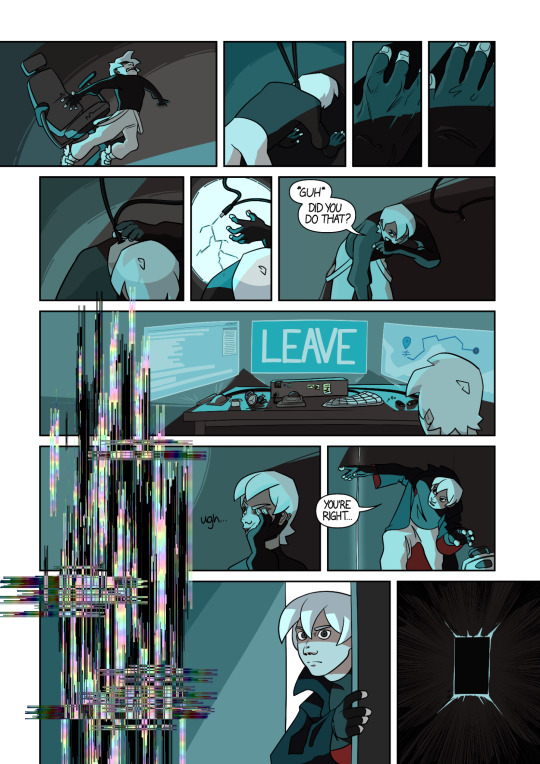

Linework by @dibleopard

Colouring by meeeee

36 notes

·

View notes

Text

made some pins out of hot glue a while ago but i forgot to post them so. :P

i was gonna make more cause its actually a fairly good medium to make durable + cheap + okay looking (depending on how long you wanna spend smoothing glue out @_@) pins out of. but then i used the rest of my hot glue to make my hot glue wheatley sculpture & i keep forgetting to get more lol ^^;

#objectum#art#how do i tag this. hot glue. eye ball. yeah i dont know. whatever#.png.zip#the objectum pin is kinda meant to be stealth heh#so i just made it a tech pin even though im obj for more than just tech x3#also it has a circuitboard pattern on it in glow in the dark paint#awoo

10 notes

·

View notes

Text

#animated gif#animated gifs#gif#gifs#old advertisements#old ads#retro#vhs#computers#old tech#old computers#tech#90s#motherboard#circuitboard#violin#for some fucking reason

30 notes

·

View notes

Text

SELECTIVE SOLDER 🔬🔥🔧

Selectively soldering components to printed circuit board (PCBs), while avoiding heat-sensitive parts - ensuring that only the desired areas are soldered, minimizing potential damage to the components and making high quality finished boards!

#adafruit#electronics#selective#solder#selectivesolder#pcb#opensource#opensourcehardware#manufacturing#factory#electronicsproduction#qualitycontrol#heatsensitive#componentprotection#circuitboards#innovation#precisionengineering#techmanufacturing

14 notes

·

View notes

Text

A photo which shows a part of a circuit board.

#circuitboard#circuit boards#circuit board#circuitboards#technology pictures#tech photography#tech photos#technology#tech#photography#photo#photograph#picture#photos#photographs#image#black and white#blackandwhite#black and white photography#black and white picture#black and white photo#blackandwhitephotography#electronics

1 note

·

View note

Text

also how did I convince myself this wouldn't take long.

6 notes

·

View notes

Note

Because it’s a coil, and it’s hard to show depth in a pixel drawing

*sounds of rage*

22 notes

·

View notes

Text

Obviously I have nostalgia goggles but I think digimon adventure may still be one of the best childrens shows of all time

#suchobabbles#the kids in digimon adventure are so much more PEOPLE than the characters in any other kids show ive seen#they kids they have limited life experience and they act like it but futdamentally theyre still people#with unique personalities and perspectives on life that are shaped by their unique circumstances#and the way the show handles those circumstances with so much grace is something i just rarely see#especially not from a kids anime whos main draw is cool monster buddy battles lmfao#not even to mention the fascinating absurdism of the way it portrays the digital world#the way the show eschews all the motifs we associate with 'digitas worlds'#like circuitboards and pixels#and instead shows a very realistic world thats just... not right. its put together wrong#and it doesnt explain it right away. you just have to discover it alongside the kids#they dont even say 'its the digital world'#its just a weird place where deserts arebfilled with telephone poles and beaches have phone booths that say nonsense#where unmanned factories build and take apart the same useless contraption over and over again#ITS SO WEIRD! ITS SO FASCINATING! NOTHING DOES IT LIKE DIGIMON ADVENTURE

6 notes

·

View notes

Text

Plenty of fun being had rn

7 notes

·

View notes

Video

youtube

FPC flexible circuit board production process #fpc #circuitboard #pcb #technology #factory #customer #icgoodfind

2 notes

·

View notes

Text

I would pay Seventy five Two hundred bajilion dollars to frolic through the probably massive echoing facility that AM is kept in and study him under a microscope. for science

#ihnmaims#am ihnmaims#poke at it's wires with a stick. marvel at a whole wall of circuitboard.#psychoanalyze the sentient ai advanced enough to have human senses but is thusforth deprived of them. etc etc#i have no mouth and i must scream#he's like a neglected lonely kid in a driveway crushing ants i could not be and more fascinated

5 notes

·

View notes