#brass cnc turned parts

Text

Brass CNC Turned Parts and Components Manufacturer in India

GK Metals is Jamnagar, India based manufacturer, supplier and exporter of high-quality customized brass CNC turned parts, brass CNC turned components and brass CNC machining parts with great precision & accuracy. Our CNC turned parts are made from brass, copper, bronze and stainless steel materials.

#brass cnc turned parts#brass cnc turned components#brass cnc machining parts#customized brass cnc turned parts#brass cnc turned parts manufacturers#brass cnc turned components manufacturers#brass#brass parts#brass components#gk metals

0 notes

Text

We know the value of your business. So, choosing us to provide CNC parts will be a great investment for your manufacturing unit. Our delivery team ensures that you receive the highest quality stainless steel parts on time. Read more…..

0 notes

Text

#precision-cnc-turning#precision-turned-parts#brass-precision-turned-components#custom-precision-machining#precision-turned-components-manufacturers

0 notes

Text

What are Brass Turned Parts??

Brass is a non-ferrous material that is used to manufacture a range of precision turned parts for various industries across the globe. This material is extremely appealing to engineers as it machines with ease and is ideal for the production of high-volume components due to its low tool wear properties. Many different grades are produced for applications including home & leisure, gas industry and marine. Some of these include CW614N, CW602N & CW606N amongst many others.

Turned components are machined from brass on both conventional and CNC machinery in both low to high volume. Machining operations such as turning, boring and drilling are common practice along with tapping. Newer machines allow brass components to be milled due to the addition of having live-tooling. This capability allows for the production of complex shaped components that are aesthetically appealing to consumers. By this, i mean for decorative components such as door knobs etc.

I hope this post gives you a clear insight into brass component production and the types of parts that can be manufactured using precision engineering methods.

Thanks for reading!!

0 notes

Text

https://www.mxmparts.com China CNC Turning Service customize stainless steel turned parts, Aluminium turned parts, Copper and Brass turned parts.

#China CNC Turning#China Turned Parts#China Turning Service#China CNC Turned Parts#Stainless Steel parts#Steel Turned Parts#Aluminium Turned Parts#Brass Turned Parts#CNC Turned Aluminium Parts#Turned Brass Parts#mxmparts

1 note

·

View note

Text

youtube

Aluminum cnc turning part with cnc machining turning accessories

We specialize in cnc turning service, we have more than 15 year's experience in this field, we can make 5 axis cnc machining parts, machined parts stainless steel and brass parts, parts anodized aluminum laser service, motorcycle cnc parts, machining center cnc, high quality turning parts accessories , services stainless cnc machining parts etc

-------------------------------------------

https://mxymachining.com

0 notes

Video

youtube

CNC turning customized precision brass parts by drawings and samples #fa...

0 notes

Text

Precision in Motion: Exploring the World of Metal CNC Machining

Share Post:

LinkedIn

Twitter

Facebook

Reddit

Metal CNC machining represents the pinnacle of precision engineering, offering unparalleled accuracy, efficiency, and versatility in the fabrication of metal components and parts. In this comprehensive overview, we delve into the intricacies of metal CNC machining, exploring its technology, applications, benefits, and the future of precision manufacturing.

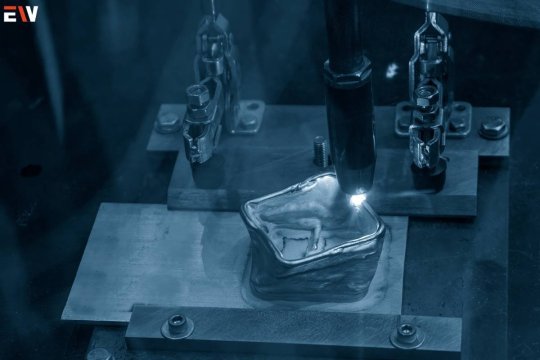

Understanding Metal CNC Machining

CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to automate the operation of machine tools, such as lathes, mills, and routers. Metal CNC machining specifically focuses on the fabrication of metal components, utilizing specialized CNC machines equipped with cutting tools to shape and refine metal workpieces with exceptional precision.

Key Components:

1. CAD (Computer-Aided Design)

The design phase begins with the creation of a digital model of the desired part using CAD software. This digital model serves as the blueprint for the machining process.

2. CAM (Computer-Aided Manufacturing)

CAM software translates the CAD model into instructions for the CNC machine, generating tool paths and specifying machining operations such as milling, drilling, and turning.

3. CNC Machine

The CNC machine executes the programmed instructions, utilizing cutting tools to remove material from the workpiece and create the desired shape and features with high precision.

4. Cutting Tools

Various cutting tools, such as end mills, drills, and inserts, are used to remove material from the workpiece during the machining process. These tools are selected based on factors such as material type, geometry, and surface finish requirements.

What are its Applications?

CNC machining finds wide-ranging applications across industries and sectors, including:

1. Aerospace: Precision components for aircraft, spacecraft, and satellites, such as engine parts, structural components, and avionics.

2. Automotive: Engine components, transmission parts, chassis components, and precision tooling for automotive manufacturing.

3. Medical: Surgical instruments, implants, prosthetics, and medical device components require high precision and biocompatibility.

4. Electronics: Enclosures, heat sinks, connectors, and components for electronic devices and consumer electronics.

5. Industrial Manufacturing: Tooling, fixtures, molds, and production components for various manufacturing processes.

Benefits of Metal CNC Machining

1. Precision and Accuracy

CNC machining offers unparalleled precision and accuracy, with the ability to achieve tight tolerances and intricate geometries that are difficult or impossible to replicate with traditional machining methods.

2. Efficiency and Productivity

CNC machines operate with high speed and efficiency, allowing for rapid production of metal components with minimal downtime and waste. Automated tool changes, material handling, and process monitoring further enhance productivity.

3. Versatility and Flexibility

CNC machining can accommodate a wide range of materials, including metals such as aluminum, steel, titanium, and brass. Moreover, CNC machines are capable of machining complex shapes and features, making them highly versatile for diverse manufacturing applications.

4. Consistency and Repeatability

With CNC machining, each part produced is identical to the next, ensuring consistency and repeatability in quality and performance. This reliability is essential for industries with stringent quality standards and regulatory requirements.

Future Trends in Metal CNC Machining

1. Advanced Materials

As demand grows for lightweight, high-strength materials, such as titanium alloys and composites, metal CNC machining will continue to evolve to accommodate the machining challenges posed by these advanced materials.

2. Additive Manufacturing Integration

The integration of additive manufacturing (3D printing) with CNC machining processes, known as hybrid manufacturing, offers new possibilities for producing complex metal parts with enhanced efficiency and functionality.

3. Smart Manufacturing Technologies

Advancements in automation, robotics, artificial intelligence, and data analytics are transforming CNC machining into a smarter, more interconnected ecosystem, enabling predictive maintenance, real-time monitoring, and optimization of manufacturing processes.

4. Sustainable Practices

With a growing emphasis on sustainability and environmental stewardship, CNC machining will increasingly adopt eco-friendly practices, such as recycling metal chips and coolant, energy-efficient machining processes, and reduction of material waste.

Conclusion

Metal CNC machining stands at the forefront of precision manufacturing, offering unparalleled capabilities, efficiency, and versatility in the fabrication of metal components and parts. From aerospace to automotive, medical to electronics, CNC machining plays a critical role in driving innovation and advancement across industries. As technology continues to evolve and demand for high-quality, custom metal components grows, CNC machining will remain indispensable for delivering precision in motion and shaping the future of manufacturing.

Also Read: Industrial IoT: Transforming Manufacturing through Connected Intelligence

#metalcnc#PrecisionEngineering#manufacturing#Technology#cncmachining#metalfabrication#aerospace#medical#electronics#industrialmanufacturing

0 notes

Text

One of the reasons CNC machining is innovative is its better performance. Components that have been CNC Turned Parts can run continuously before any maintenance is necessary. Read more….

0 notes

Text

CNC turning custom H59 brass parts丨RuiXing MFG

0 notes

Text

Look For CNC Machining Metal Materials

As an advanced CNC metal machining manufacturer in Guangdong, China, Flourish Legend is committed to providing high-quality and precision custom parts and component solutions. With years of experience and excellent technical capabilities, we can machine various metal materials, including aluminum, stainless steel, brass, steel, copper, titanium, and more. These materials are widely used in various industries, including automotive manufacturing, electronic devices, medical instruments, aerospace, and more.

Types of CNC Metal Materials Available

CNC Machining Aluminium

Flourish Legend specializes in CNC machining of aluminum alloys. With advanced technology and precision equipment, we ensure high precision and stringent quality standards in manufacturing complex aluminum alloy parts and meeting your fine machining requirements. We strive to deliver premium and durable aluminum alloy products that meet your highest expectations.

CNC Machining Stainless Steel

CNC machining stainless steel can provide precision products for various industries, the durability, corrosion resistance and aesthetics of stainless steel products make them the first choice in industries such as aerospace, automotive and medical. Use CNC technology to meet complex designs and tight tolerances, create complex product shapes, and improve product performance while maintaining the inherent strength and longevity of the material.

CNC Machining Tool Steels

CNC machining of tool steel enables high-precision part manufacturing. With its excellent hardness, wear resistance and heat resistance, tool steel is widely used in fields such as molds, knives and mechanical parts. CNC machining technology ensures the consistency of precision design and tight tolerances to manufacture components such as blades and molds. This process enables the fabrication of complex shapes, improving performance and reliability in harsh environments while maintaining the strength and durability of the material. Whether in the automotive, aerospace or manufacturing industries, CNC machining of tool steels provides the key support for the production of high-quality parts.

0 notes

Text

China Ming Xiao Mfg custom high quality brass parts in low price. mxmparts.com

0 notes

Text

youtube

Custom Cnc Machining Service Factory

We specialize in machining center 5 axis cnc, we have more than 15 year's experience in this field, we can make 5 axis cnc machining parts, machined parts stainless steel and brass parts, parts anodized aluminum laser service, motorcycle cnc parts, machining center cnc, high quality turning parts accessories , services stainless cnc machining parts etc

--------------------------------------------------

https://mxymachining.com

0 notes

Text

Battery Cover, a precision-engineered accessory designed to protect and secure your device's power source. Crafted from high-quality, durable materials, this sleek and stylish cover ensures a snug fit, while providing easy access for battery replacement. Enhance your gadget's longevity and performance with this reliable safeguard.

Functions and Importance of Battery Terminal Covers in Vehicles

Protection: Battery caps are designed to protect the battery from external elements such as dust, dirt, moisture, and road debris. They shield the battery from physical damage and prevent contaminants from entering the battery compartment. This protection is crucial for maintaining the battery's integrity and preventing potential malfunctions or short circuits.

Thermal Management: Batteries generate heat during operation, especially during charging and discharging cycles. Battery covers often have built-in insulation and ventilation features to manage the battery's temperature. They help dissipate heat and maintain optimal operating conditions for the battery, enhancing its performance and extending its lifespan.

Safety: Battery covers play a significant role in ensuring the safety of both the vehicle and its occupants. They help contain any potential acid leaks or spills from the battery, preventing them from coming into contact with other components or causing harm. Battery covers also act as a barrier between the battery terminals and any conductive material, reducing the risk of electrical shorts or accidental contact.

Noise Reduction: In electric vehicles (EVs) and hybrid vehicles, battery covers can contribute to reducing noise levels. They act as sound barriers, minimizing the transmission of noise and vibrations generated by the battery, thereby enhancing the overall driving experience for passengers.

Aesthetics and Integration: Battery covers are designed to integrate seamlessly with the vehicle's overall design and aesthetics. They provide a neat and finished appearance to the battery compartment, contributing to the overall visual appeal of the vehicle.

Specification of Battery Terminal Cap

Material

Iron, stainless steel, brass, copper, galvanized steel, titanium, Aluminium, etc.

Surface treatment

Zinc/Nickel/Tin/Ag-Plated/Au-Plated, etc.

Type

High-Precision nonstandard parts

(OEM Service)

Process

Stamping/Punching/Pressing, CNC machining/Turning/Milling, Deep Drawing and other process.

Certificate

IATF16949 2016;I SO9001 2015; ISO14001:2015;RoHS&REACH, etc.

Usage

Automotive/ Car Thermostat, Switch, Electric Heating, Aerospace, New energy, etc.

Factors to Consider in Choosing the Right Battery Cover for Your Vehicle

When choosing the right battery cover for your vehicle, there are several factors to consider. These factors can help ensure that the battery cover is compatible with your vehicle's specifications and provides the necessary protection and functionality. Here are some key factors to consider:

Vehicle Make and Model

Material and Construction of Battery covers

The ventilation and thermal management features of the battery cover

The level of protection and safety features provided by the battery cover

Ensure that the battery cover is easy to install and remove

Manufacturer Reputation and Warranty

Budget.

0 notes

Text

Brass Turning Parts Manufacturers and Exporters in India, Australia, Canada, UK

When it comes to precision engineering and manufacturing, few materials match the versatility and durability of brass. With a history that dates back centuries, brass has been a go-to choice for producing a wide range of components, from decorative hardware to intricate mechanical parts. However, the key to harnessing the full potential of brass lies in the hands of custom brass-turned parts manufacturers and suppliers in USA, Europe, UK, Canada, Russia, Australia and South Africa.

In this article, we’ll delve into the world of Custom Brass turned parts manufacturers in USA, Europe, UK, Canada, Russia, Australia and South Africa, exploring the significance of these specialized manufacturers and the role they play in various industries.

Parts turned bras are important for countless applications, from plumbing and musical instruments to automotive components and electrical connections. The accuracy and precision in the metal conversion process make them essential for achieving the desired results in these industries. So, what are custom turned brass parts, Brass Threaded Insert, and why are they so important?

Custom brass turned parts are precisely machined components made from brass, a metal alloy composed primarily of copper and zinc. These parts are crafted with meticulous attention to detail, often on specialized machinery called CNC (Computer Numerical Control) lathes. This precision machining process transforms brass rods or bars into a variety of shapes and sizes, meeting the specific requirements of clients.

The most important elements of Brass Terminals | Brass Connectors based on their appearance. They can be designed and manufactured to great detail, ensuring that they fit perfectly into the intended application. Whether it’s a special plumbing fixture, a critical electrical connection, or a critical infrastructure component, custom metal parts turn out to be essential to get the job done perfectly and efficiently.

THE ROLE OF CUSTOM BRASS TURNED PARTS MANUFACTURERS

Expertise in Material Selection: Brass Turning parts manufacturers and Exporters in Jamnagar, India are well-versed in different brass alloys. They understand the unique properties of each alloy and can recommend the most suitable one for a particular application. This expertise ensures that the final product will have the desired strength, corrosion resistance, and aesthetic appeal.

Precision Machining: These manufacturers utilize advanced CNC machining technology to transform brass raw materials into precise components. This precision is vital, especially in industries where the slightest deviation can lead to malfunction or inefficiency.

Customization: One of the primary advantages of partnering with custom brass turned parts manufacturers is the ability to customize components. They can produce parts with intricate designs, tight tolerances, and various finishes to meet specific requirements.

Quality Assurance: Manufacturers of Custom Brass turned parts manufacturers and exporters in India, USA, Europe, UK, Canada, Russia, Australia and South Africa. to strict quality control measures. This ensures that each component meets the highest standards of quality and durability. This is especially crucial in industries like aerospace and automotive, where safety and reliability are paramount.

Cost Efficiency: While custom manufacturing may seem expensive, it often leads to cost savings in the long run. Custom brass turned parts can be optimized for efficiency, reducing waste and enhancing overall performance.

THE SIGNIFICANCE OF BRASS TURNED PARTS SUPPLIERS

Manufacturers alone cannot meet the diverse and ever-changing needs of various industries. This is where brass turned parts suppliers in Gujarat India, come into play. These suppliers act as a bridge between manufacturers and end-users, offering several crucial advantages:

Wide Range of Inventory: Brass Threaded Inserts suppliers maintain extensive inventories of standard and custom components. This means that customers can quickly source the parts they need without waiting for production lead times.

Reduced Lead Times: For urgent projects or unexpected component failures, brass turned parts suppliers in India provide fast access to replacement parts, reducing downtime and minimizing disruptions.

Cost-Effective Sourcing: Suppliers often benefit from economies of scale, allowing them to offer competitive pricing on both standard and custom components.

Expert Guidance: Suppliers have in-depth knowledge of brass turned parts, Brass Fittings | Brass Sanitary Parts and can assist customers in selecting the right components for their applications. This expertise helps customers make informed decisions.

Reliability: Established Brass Terminals | Brass Connectors manufacturers in USA, Europe, UK, Canada, Russia, Australia and South Africa, have a reputation for reliability and quality. Customers can trust that the components they receive will meet their specifications and perform as expected.

Custom brass turned parts manufacturers and suppliers in India are the unsung heroes of many industries. Their expertise, precision machining capabilities, and commitment to quality ensure that critical components meet strict specifications and perform reliably. As industries continue to evolve and demand ever more specialized components, the role of these professionals becomes even more significant. In essence, they are the artisans crafting excellence from brass, enabling progress in countless fields.

1 note

·

View note

Text

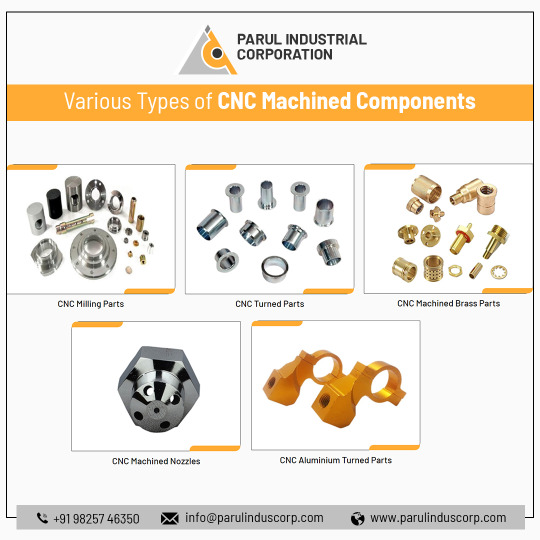

Parul Industrial Corporation presents a world of precision with a diverse range of CNC machined components. From CNC Milling and Turned Parts to CNC Machined Brass Parts and Nozzles, as well as CNC Aluminium Turned Parts – our collection covers it all.

For more details, visit- https://www.parulinduscorp.com/products/cnc-machined-components

#parulindustrialcorporation#cncmachinedparts#cncmachinedbrassparts#cncaluminiumturnedparts#cncmilling#cncmillingparts#cncturnedparts

0 notes