#5 axis turn mill

Text

Revolutionizing Manufacturing With The Power of Vertical Turning Lathes and 5-Axis Turnmills

In the ever-evolving world of manufacturing, precision, efficiency and innovation are key drivers of success. The integration of advanced machineries such as Vertical Turning Lathes (VTLs) and 5-axis turnmills has revolutionized the production processes across various industries. These machines are not only enhancing productivity but are also pushing the boundaries of what’s possible in modern manufacturing.

Understanding Vertical Turning Lathes: Precision and Power Combined

A Vertical Turning Lathe (VTL) is a powerful machine tool designed for large, heavy workpieces that require precise turning operations. Unlike traditional lathes, which operate horizontally, VTLs position the workpiece vertically. This vertical orientation provides several advantages, particularly when machining large, heavy parts, as gravity helps to stabilize the workpiece, reducing the risk of distortion.

Key Advantages of VTLs:

Stability and Precision: The vertical orientation allows for greater stability, which is crucial when working with large or heavy components. This stability translates to higher precision in machining operations.

Space Efficiency: VTLs often take up less floor space compared to their horizontal counterparts, making them ideal for factories where space is at a premium.

Versatility: VTLs are highly versatile and can be used for a variety of applications, including turning, boring and milling, making them an essential tool in any modern manufacturing facility.

The Evolution of 5-Axis Turnmills: Unleashing Creativity in Machining

The 5-axis turnmill represents the pinnacle of machining technology, combining the capabilities of turning and milling in a single machine. The "5-axis" refers to the five degrees of movement that the machine offers—three linear axes (X, Y, Z) and two rotational axes (A and B). This advanced configuration allows manufacturers to machine complex shapes and geometries with unparalleled precision.

Benefits of 5-Axis Turnmills:

Complex Machining: The ability to move the workpiece along five axes allows for the creation of intricate and complex shapes that would be impossible or highly challenging with traditional 3-axis machines.

Reduced Setup Time: 5-axis turnmills can machine multiple faces of a component in a single setup, drastically reducing the time and labor required for repositioning the workpiece.

Enhanced Accuracy: By minimizing the need to move the workpiece between different machines or setups, 5-axis turnmills reduce the risk of errors, ensuring higher accuracy and consistency in production.

Special-Purpose Machines: Tailored Solutions for Unique Manufacturing Needs

In addition to VTLs and 5-axis turnmills, special-purpose machines (SPMs) play a crucial role in addressing specific manufacturing challenges. These machines are designed to perform specialized tasks that standard machines cannot, such as intricate drilling, specific cutting operations, or high-speed machining of particular materials.

Advantages of Special-Purpose Machines:

Customized Design: SPMs are built to cater to specific manufacturing needs, offering customized solutions that enhance productivity and efficiency.

Increased Productivity: By focusing on a particular task or process, SPMs can operate faster and more efficiently than general-purpose machines, leading to higher throughput.

Cost-Effectiveness: While the initial investment in an SPM may be higher, the long-term benefits of increased efficiency and reduced production time often result in significant cost savings.

Conclusion: WIDMA – Leading the Way in Advanced Machining Solutions

When it comes to cutting-edge machining solutions like Vertical Turning Lathes, 5-axis turnmills and special-purpose machines, WIDMA stands out as a leader in the industry. With a strong commitment to innovation and quality, WIDMA offers a range of advanced machines that are designed to meet the diverse needs of modern manufacturing.

WIDMA’s state-of-the-art technology, coupled with their expertise in custom machine design, ensures that manufacturers can achieve the highest levels of precision, efficiency and productivity. Whether you’re looking to enhance your production capabilities with a VTL, unlock new possibilities with a 5-axis turnmill, or invest in a special-purpose machine tailored to your unique needs, WIDMA provides the solutions that will drive your business forward.

0 notes

Text

CNC / VMC Machining Job Work & CNC Machining Components in India— Pitrukrupa Engineering

Pitrukrupa Engineering is country’s leading Manufacturer, Exporter and Supplier firm offering high performing CNC Milling and Turning Components since its inception in 2009.

Our CNC Machining Work

We are offering CNC Machining job Work to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

CNC Machining Components & Parts

We are offering CNC Components to our clients. For accomplishing this work, experts bank on innovative machines and important tools.

CNC Lathe Machining Component

5 Axis Milling Components

4 Axis Milling Components

CNC Turn Mill Components

CNC Turn Mill Machining Parts

Aerospace and Defence Machining Parts Manufacturing

Aluminium And Steel Precision Welding Fabrication

Aluminium High Pressure Die Casting

Aluminium Extrusion

For More Details

Click Here : https://www.pitrukrupaengineering.com/

#Machining Job Work#CNC Machining Work#CNC Job Work#5 Axis Milling Components#4 Axis Milling Components#CNC Turn Mill Machining Parts

0 notes

Text

We offer a wide range of CNC machining services including milling and turning of various materials, as well as drilling, tapping, EDM (Electrical Discharge Machining), and wire EDM.

#cnc milling services#cncmachining#cnc turning#cnc machining services#5 axis machining#cnc machining parts

0 notes

Text

Narcissist: Antedesertium

Narcissist: Antedesertium, Aetherco, 2006?

Narcissist is a dimension-traveling game that revolves around a central timeline, ostensibly our own world. Your characters ("Drifters" or "Crashers") skip in and out of that timeline, creating new worlds in an attempt to generate the perfect one they want. You can find my review of Narcissist back in mid-November 2023.

The future of the central timeline is home to the Inheritors, post-human people with advanced technology and incredible psychic power. In its past, from the years of about 18,000 BC to 14,000 BC, is a period known as Antedesertium. This era is home to the Inheritors' opposite numbers: the Kings of Yrnë.

The Inheritors seek to preserve the central timeline, apparently successfully. The Kings of Yrnë seek to splinter it, a task at which they eventually fail. There are millions of Inheritors; they may actually compose the majority of living beings after the Hour of Inheritance (sometime around 2221). There are twenty Kings of Yrnë. The Inheritors look like "grey" aliens, but still basically humanoid. The Kings of Yrnë look like nothing that was ever remotely human - and yet each of them once was.

The Antedesertium supplement for Narcissist details the era when the Kings of Yrnë ruled the world. It describes the Kings themselves, the non-dimension-traveling people of Yrnë, and the many forking timelines that clutter these four thousand years. It's an incredibly chaotic period. The farther downstream (into the future) one goes, the more overlapping, shattered worldlines stack up upon one another, until the Interregnum, when a massive explosion shifts the Earth's axis and turns the Sahara into a desert.

The descriptions of the Kings of Yrnë set them up as driving forces for the game, the same way that 13th Age does with its Icons or Exalted does with the Deathlords. Seven of them get multi-page writeups of their personality, powers, goals, and supporting characters. The rest get about a half-page each. The people of Yrnë get a 20-page chapter, which honestly feels a little short to cover 4000 years of history. Three main time periods are covered: the rise of the Narcissists when the Kings were still honorable, the turning point when things start to go wrong, and the chaotic end-times before the Interregnum. The book does a good job of not falling into the usual tropes one sees depicting Africa and/or prehistoric times. People are described as, well, people, rather than as animalistic idiots.

Art and layout are very similar to the rest of the books in the series. Each King gets an illustration, some of them simple and concrete (a black dome), others abstract and confusing. It's serviceable.

The best part of Antedesertium is that it's full of plot hooks. There are over a hundred mysteries, side characters, cool moments, and whims of the Kings that could provide grist for the adventure mill. The weak part is that there isn't much that ties them together. The book seems to assume that the GM will be creating antagonists using Span 4 or 5 characters from Continuum. I suspect a lot of games will pit a group of Narcissists against the servants of other Kings in an attempt to bend the timeline to their will, rather than protecting Yrnë from its actual enemies. Still, I'll take 100+ plot hooks over the one half-baked adventure that most games have. The best piece of GM advice it gives is that most of the inconsistencies in the book are intentional. In a game like Narcissist, every plot hole is a plot hook.

My copies of Narcissist and Antedesertium arrived unexpectedly in the mail quite a while back. I still haven't found any reputable sources for physical or PDF copies of the books, but I'll keep looking.

#rpg#indie ttrpg#imaginary#ttrpg#crash free#still haven't figured out where these stamps are from#review

8 notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

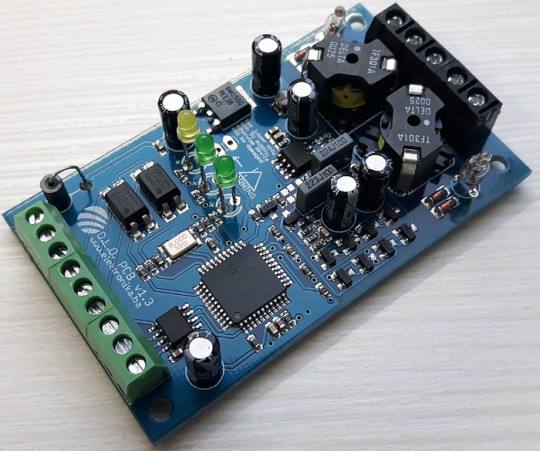

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

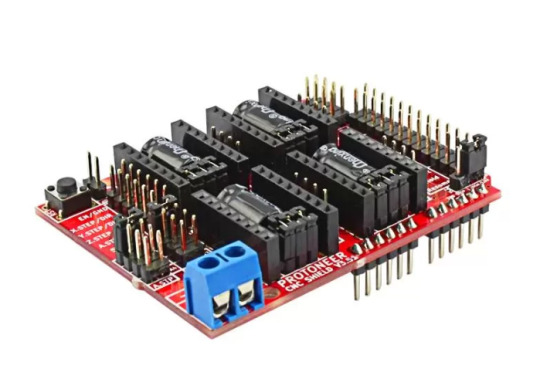

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

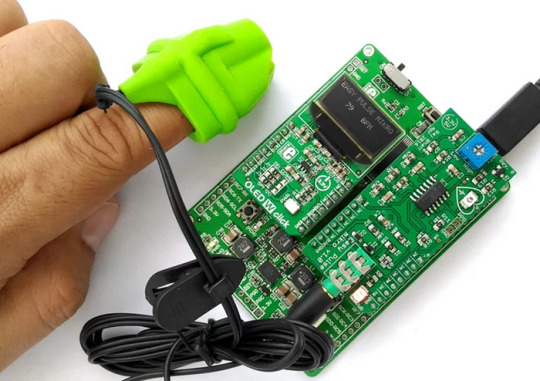

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

The different shafts of the Swiss lathe

Hello everyone, here at HANBS, I'm Sonya, and today I'm sharing with you the different shafts of the Swiss lathe, mainly to introduce the role of the shafts in the swiss lathe, why do we need so many shafts? What is its role embodied?

The swiss lathe (Swiss type cnc lathe/Sliding headstock cnc lathe) is known for its high precision and efficiency, and is especially suitable for small parts machining. They are divided into different types according to the number of axes and different configurations, today we will introduce 3-axis, 5-axis, 6-axis (Y2 axis) and so on. The following is a detailed explanation of each type.

1. 3-axis swiss lathe.

Involved axes: X1, X2, C-axis

Key features:

X1 axis: Controls the movement of the tool in the radial direction (perpendicular to the workpiece).

X2 axis: controls the movement of the tool in the longitudinal direction (along the length of the workpiece).

C-axis: Controls the rotation of the spindle for drilling and milling operations on the radial and end faces of the workpiece.

Although there are only 3 axes, it is possible to add other accessories to make it more unique by making it a specialized machine for parts.

APPLICATIONS:

This lathe is mainly used for simple turning, drilling and basic milling operations, and is suitable for machining cylindrical or slightly curved parts, but has limited ability to machine complex geometries.

2. 5-axis swiss lathe

Axes involved: X1, Y1, Z1, C1, C2 axes

Key Features:

X1, Z1: Used for turning and basic milling operations, similar to a 3-axis lathe.

Y1 axis: adds an extra lateral movement for eccentric milling and drilling operations.

C1/C2 axis: Controls the rotation of the main spindle (C1) and sub-spindle (C2) to realize machining of both ends of the workpiece.

The swiss lathe at this time can process the main and sub-spindles at the same time, which greatly improves the working efficiency.

Applications:

The 5-axis swiss lathe is capable of machining parts with more complex part geometries, and is especially suitable for parts that require multi-face milling, off-center drilling or contouring. Commonly used in aerospace, medical and other industries that require high precision and complexity.

3. 6-axis (Y2) swiss lathe

Axes involved: X1, Y1, Z1, X2, Y2, Z2

Key Features:

X1, Y1, Z1: Mainly used for turning and milling operations on the spindle side, providing complete machining freedom.

X2, Y2, Z2: Used for machining operations on the sub-spindle side, enabling simultaneous machining of both ends of the workpiece.

Y2 axis: Allows complete milling, drilling and contouring operations on the sub-spindle side.

Simultaneous machining: the main spindle and the subspindle can be operated independently of each other, allowing two different machining operations to be carried out in different positions on the same workpiece.

The 6-axis swiss lathe allows for simultaneous machining of the main and sub-spindles, and with the addition of the Y2 axis, allows both the main and sub-spindles to be independent machining fields, further reducing machining times.

Applications:

The 6-axis (Y2) configuration is ideally suited for the machining of complex parts, especially those requiring multiple operations. The simultaneous machining function of the main spindle and the sub-spindle significantly reduces machining cycles and increases efficiency. Commonly used for mass production of medical devices, watch components and complex aerospace parts.

Summary

3-axis swiss lathe: for basic turning, drilling and face milling operations.

5-axis swiss lathe: offers greater flexibility in machining skills, the ability to machine complex geometries, support for eccentric milling, and the ability to control both the spindle and the subspindle simultaneously.

6-axis (Y2) swiss lathe: offers maximum flexibility, allowing simultaneous machining of both main and sub spindles, working in tandem, suitable for efficient machining of precise and complex parts.

Today's sharing is here, I hope to help those who need it, we will be the next chapter of these different types of axis machines for further derivation of the explanation. See you in the next installment.

www.hanbscnc.com

0 notes

Text

youtube

High precision parts cnc turning machining

We make aluminium cnc machining parts, cnc machining, component metal machining parts cnc aluminium parts, cnc parts machining service, 5 axis cnc milling machining services, 5 axis cnc milling machining services, cnc machining parts manufacturers.

-----------------------------------------------

https://mxymachining.com

0 notes

Text

youtube

Cnc machining milling turning parts

We make cnc machining services parts, cnc alumimum stainless steel turning part, custom industrial 5 axis cnc milling turning parts, cnc machining milling turning, high precision cnc turning service manufacturing parts, cnc milling turning components metal parts, cnc milling and turning parts.

------------------------------------------

0 notes

Text

What are Machining Parts: Types, Advantages & Design Guide

Machining turns raw materials into highly carved components that power many businesses. CNC machine works with many metals and other materials and produces components fast without tooling. These machined components offered by a top machine parts supplier are cost-effective for demanding applications and are used throughout industries.

When should CNC Machining Parts be used?

Companies, product designers, and other professionals use flexible machining components for several reasons. Machined pieces are strong and may be shaped in many ways.

Industries have used machining components for decades as the standard production method. Thus, machined components may meet industrial certifications.

Types of Machining Parts

Machined parts offered by the top machine parts manufacturer in Texas can be divided according to their application and the materials used. Usual examples include:

Fasteners: Such as bolts and screws, used in assembly.

Valve Bodies: Components in fluid control systems.

Ball Joints: These are used for automobile and machinery applications requiring flexible movements.

Gears: Essential for transmitting motion and torque in machinery.

Shafts: These are used to transmit power in different mechanical systems.

Housings: Enclosures for protecting internal components.

Brackets: The support structures in various applications.

Rollers: These are used in conveyor systems and machinery.

What are the Advantages of Machining Parts?

Machining parts offers several advantages, making it a widely used manufacturing process across various industries. Here are some key advantages of machining parts Texas:

Precision and Accuracy

CNC-based machining is precise and accurate. Aerospace and medical device production needs precise tolerances and dimensions.

Material versatility

Machining works on metals, polymers, and composites. This adaptability lets components with different material qualities be made to match application needs.

Quality Surface Finish

Machining produces high-quality surface finishes for aesthetic and practical needs. This is crucial in businesses where product appearance matters.

Machining Complex Shapes

With modern CNC technology, machines can make detailed and complicated geometries that conventional production techniques cannot.

Guidelines to design machining parts

Consider these part design suggestions for reliable and efficient CNC milling of mechanical parts, taking into account internal radii, machining tolerances, milling, and lathe capabilities.

Machined faces:

Repositioning components offered by a top machine parts manufacturer on machines increases setup time and costs. However, 4-axis and 5-axis milling machines minimize repositioning, reducing the risk of feature variations on distinct surfaces.

Internal corners radii:

Designing parts with larger internal radii allows faster machining with larger tools, reducing material removal passes, machining time, and production cost.

Depth of the cavity:

CNC mills can only machine deep, so long mills are avoided to avoid vibration and rough surfaces. Limit internal cavity depth to four times tool diameter.

Machined feature alignment:

The recommended machining part designs include the following:

Basic designs with part symmetry.

Ensuring faster milling with minimal tool movement.

Avoiding complex designs for cost-effective fabrication.

Drawings vs 3D files:

Design engineers often send 3D files to suppliers for quotes or part fabrication but often lack threaded holes. Include a manufacturing drawing for accurate calculations and reduced errors.

Tolerances:

Tolerances on precision parts are often used for certainty or repetitiveness without considering the higher cost, making them harder to control and potentially increasing production costs.

Materials and surface treatment:

Choose materials based on processing ease and surface treatment needs, not requesting a finish on unnecessary parts. Work with a machine partner to quickly obtain good parts, as they know their machines and capabilities.

Conclusion

Machining parts are crucial in modern manufacturing because they are precise, versatile, and have complex geometries. Understanding their types, advantages, and design guidelines helps businesses optimize production and meet industrial requirements.

Machining parts are CNC-carved components with precision, material diversity, superb surface polish, and complex shapes. Internal radii, machining tolerances, and part symmetry should be considered for cost-effective manufacture.

Arek Solutions produces precision machined components that improve machinery performance in many industries.

#machine parts manufacturer#machining components#machine parts manufacturer texas#machine parts supplier#machining parts texas

0 notes

Text

Mudar-M Metalworking Machine Tools: Precision, Innovation, and Excellence

Introduction

Mudar-M Metalworking Machine Tools, headquartered in Sofia, Bulgaria, stands at the forefront of the metalworking industry. With a rich history spanning over three decades, Mudar-M has consistently delivered cutting-edge solutions to meet the evolving needs of manufacturers, machinists, and engineers worldwide. Let's delve into the details of this remarkable company.

Origins and Founding Vision

Founded in 1990 by visionary Rakan Mhissen, Mudar-M emerged as a response to the growing demand for reliable and efficient metalworking machinery. Rakan passion for precision engineering and his unwavering commitment to customer satisfaction laid the foundation for the company's success. From its modest beginnings as a small workshop specializing in lathe repairs, Mudar-M expanded its operations, embracing technological advancements and diversifying its product range.

CNC Lathes

Mudar-M's CNC lathes are renowned for their accuracy, versatility, and robust construction. Whether it's turning intricate components for aerospace applications or creating precision parts for automotive manufacturing, these machines consistently deliver exceptional results. Features include:

- High Precision: Mudar-M CNC lathes achieve micron-level tolerances, ensuring flawless surface finishes.

- User-Friendly Controls: Intuitive interfaces allow operators to program complex machining sequences effortlessly.

- Customization Options: Customers can choose from various spindle configurations, tool changers, and automation solutions.

Vertical Lathes

Vertical lathes play a crucial role in heavy-duty machining. Mudar-M's vertical lathes excel in handling large workpieces, such as turbine components, gearboxes, and hydraulic cylinders. Key attributes include:

- Stability: The robust column design minimizes vibrations during heavy cuts.

- Swing Diameter: Mudar-M offers a range of swing diameters to accommodate diverse applications.

- Live Tooling: Some models feature live tooling for milling, drilling, and tapping operations.

Milling Machines

Mudar-M's milling machines combine precision with versatility. From 3-axis to 5-axis configurations, these machines empower manufacturers to create complex geometries efficiently. Notable features include:

- Rigidity: Sturdy construction ensures stability during high-speed machining.

- Advanced Controls: Mudar-M integrates state-of-the-art control systems for optimal performance.

- Tool Changers: Automatic tool changers enhance productivity.

Cylindrical Grinding Machines

For achieving precise cylindrical shapes and superior surface finishes, Mudar-M's cylindrical grinding machines are indispensable. These machines excel in applications like bearing manufacturing, toolmaking, and precision engineering. Highlights include:

- Grinding Accuracy: Mudar-M's machines maintain tight tolerances, critical for cylindrical components.

- Wheel Dressing Systems: Automatic wheel dressing ensures consistent results.

- Coolant Filtration: Efficient coolant management prolongs wheel life.

Horizontal Boring Machines

Mudar-M's horizontal boring machines tackle large-scale projects with ease. Whether it's boring engine blocks or creating intricate molds, these machines offer:

- Spindle Power: High-torque spindles handle heavy cutting loads.

- Linear Guideways: Smooth movement across axes ensures precision.

- Digital Readouts: Accurate positioning for intricate machining tasks.

Commitment to Quality

Mudar-M's success hinges on its unwavering commitment to quality. Rigorous testing, continuous research, and collaboration with industry experts ensure that every machine leaving their facility meets the highest standards. The ISO 9001 certification underscores their dedication to excellence.

Global Reach

Mudar-M ships its machines to more than 50 countries across Europe, Asia, the Middle East, and beyond. From small workshops to large manufacturing plants, their footprint extends across continents. By empowering businesses with reliable tools, Mudar-M contributes to the advancement of global manufacturing capabilities.

Conclusion

Mudar-M Metalworking Machine Tools embodies precision, innovation, and excellence. As technology evolves, the company remains steadfast in its mission: to equip the world with cutting-edge machinery, enabling manufacturers to shape the future. Whether it's a CNC lathe, a vertical mill, or a cylindrical grinder, Mudar-M's legacy continues to shape the metalworking industry, one precision cut at a time.

#metalmachining#metalworking#lathe#machinery#machinetools#engineering#manufacturing#forsale#metalwork#milling#industrial

0 notes

Video

youtube

Precision Turning and Composite Machining ServicesDiscover the advanced capabilities of 5-Axis CNC Machining at KD Hardware Co., Ltd. Our precision turning and milling processes ensure the highest quality in manufacturing complex components. With state-of-the-art technology and expert craftsmanship, we deliver exceptional results for a wide range of industries.

Contact us at [email protected] for more information.

#cncmachiningmillingturning#cncmachiningturning#cncmillingandcncturning#cncmillingandturning#cncmillingandturningservices#cncmillingturning#youtube

0 notes

Text

Transforming Precision Engineering with Advanced Machinery

In the realm of precision engineering, the demand for sophisticated machinery that can deliver high accuracy and efficiency is ever-increasing. Industries spanning automotive, aerospace and manufacturing require cutting-edge solutions to meet their stringent specifications. Among the innovative solutions available, Vertical Turning Lathes (VTLs), 5-axis turnmills and special-purpose machines stand out for their exceptional capabilities.

The Revolution of Vertical Turning Lathes

Vertical Turning Lathes have revolutionized the machining landscape by offering unparalleled stability and precision in handling large, heavy workpieces. Unlike traditional horizontal lathes, VTLs position the workpiece vertically, ensuring gravity-assisted centering and minimizing deflection. This configuration is particularly advantageous for machining large-diameter components such as turbine casings and flywheels.

The design of VTLs allows for robust construction, capable of supporting massive workpieces with ease. The vertical orientation not only enhances accuracy but also simplifies the loading and unloading process, making it a preferred choice for industries requiring precise and efficient machining of substantial components.

5-Axis Turnmills: The Pinnacle of Versatility

The advent of 5-axis turnmill machines has marked a significant leap in machining technology. These machines integrate turning and milling functions into a single setup, drastically reducing the need for multiple machine setups and manual interventions. The 5-axis capability enables the machining of complex geometries with a single clamping, enhancing precision and reducing cycle times.

5-axis turnmills excel in producing intricate components that demand multi-faceted machining. By offering simultaneous control over five axes, these machines can handle the most challenging contours and shapes, making them indispensable in aerospace and medical device manufacturing. The integration of advanced CNC controls ensures seamless operation, paving the way for enhanced productivity and superior surface finishes.

Special-Purpose Machines: Tailored for Excellence

In industries where standard machinery falls short, special-purpose machines (SPMs) come into play. These machines are custom-designed to address specific manufacturing needs, delivering optimal performance and efficiency. SPMs are engineered to perform dedicated tasks, often combining multiple operations into a single machine.

The flexibility of SPMs allows manufacturers to achieve high throughput and consistency, particularly in mass production environments. By eliminating the need for multiple machines and setups, SPMs streamline the production process, reducing downtime and operational costs. From automated assembly lines to specialized drilling and tapping operations, SPMs are the epitome of tailored engineering solutions.

Conclusion: WIDMA – Pioneering Precision Engineering Solutions

As the demand for advanced machining solutions continues to rise, WIDMA stands at the forefront of innovation, delivering state-of-the-art machinery that meets the evolving needs of modern industries. With a strong commitment to precision engineering, WIDMA offers a comprehensive range of Vertical Turning Lathes, 5-axis turnmills and special-purpose machines designed to enhance productivity and accuracy.

WIDMA's expertise in developing customized solutions ensures that clients receive machinery tailored to their specific requirements, driving efficiency and quality in their operations. By leveraging cutting-edge technology and a deep understanding of industry challenges, WIDMA remains a trusted partner for manufacturers seeking to elevate their machining capabilities.

In conclusion, the advancements in Vertical Turning Lathes, 5-axis turnmills as well as special-purpose machines underscore the importance of precision engineering in today's competitive landscape. WIDMA's dedication to innovation and excellence positions them as a leader in delivering transformative solutions that empower industries to achieve new heights of performance and productivity.

0 notes

Text

Precision CNC Machine Job Work — CNC Machining Components Manufacturer

Pitrukrupa Engineering is ISO 9001:2015 certified Manufacturer, Exporter and Supplier of high performing CNC machine Components. Pitrukrupa Engineering is engaged in Service Providing in providing CNC Machine Job Work, VMC Machine Job Work, EDM Wire Cut Work and CNC Lathe Machine Job Work since its inception in 2009. We provide CNC Machining Components and Services job Work in India, USA, Canada, Brazil, UAE, Australia, Oman, South Africa, Vietnam, Afghanistan, Israel, UK.

CNC Machining Components & Parts

CNC Machine Components

VMC Machine Components

CNC Turn Mill Components

5 Axis Milling Components

4 Axis Milling Components

CNC Lathe Machine Components

CNC EDM Components

CNC Turn Mill Components

Aluminium Extrusion

Aluminium High Pressure Die Casting

Aluminium And Steel Precision Welding Fabrication

CNC Machining Job Work Services

CNC Machining Work

CNC Job Work

Precision Machining Work

VMC Machining Work

Milling Machining Work

HMC Machining Work

CNC Turning Machining Work

EDM Wire Cutting Work

CNC laser Cutting Work

CNC Bending Work

For More Details

Click Here : https://www.pitrukrupaengineering.com/

0 notes

Text

We provide precision CNC machining services, CNC Milling and Turning (3 axis, 4 axis, 5 axis), can manufacture complex and multi-structure plastic and metal parts.

#cncmachining#5 axis machining#cnc milling services#cnc machining parts#rapid prototyping#precision machining

2 notes

·

View notes

Text

Jewelry CNC Machines

Jewelry CNC (Computer Numerical Control) machines are sophisticated tools designed for the precise and automated production of jewelry components and designs. These machines combine advanced computer technology with traditional jewelry-making techniques to produce intricate and high-quality pieces with remarkable accuracy and efficiency. Here's an in-depth exploration of the components, functions, types, and applications of Jewelry CNC machines:<br><br>

### **Components and Functionality**<br><br>

1. **CNC Controller**: The heart of the CNC machine, the controller is a computer that interprets and executes commands from the design software. It translates digital designs into precise movements of the machine's cutting tools. <br><br>

2. **Spindle**: The spindle is the rotating component that holds and drives the cutting tools. It can operate at varying speeds and is critical for shaping and detailing the jewelry. <br><br>

3. **Cutting Tools**: These are specialized tools used to carve, mill, or engrave the material. Common cutting tools include end mills, ball mills, and engraving bits, each suited for different aspects of jewelry production. <br><br>

4. **Work Table**: The work table or bed is where the material (such as metal or wax) is placed. It may be equipped with clamps or fixtures to hold the material securely in place during the machining process. <br><br>

5. **Axis Mechanisms**: CNC machines typically operate along multiple axes (X, Y, and Z), allowing for precise movement in three-dimensional space. Some advanced machines may have additional axes for greater flexibility and precision. <br><br>

6. **Tool Changer**: In more advanced CNC machines, a tool changer automatically swaps out cutting tools during the machining process, allowing for more complex and varied operations without manual intervention. <br><br>

7. **Cooling System**: To prevent overheating and ensure smooth cutting, CNC machines often include a cooling system that sprays or circulates coolant around the cutting area.

<br><br>

8. **Software**: The design and operation of the CNC machine are controlled by software that includes CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) programs. These programs allow designers to create detailed digital models and generate the necessary instructions for the machine. <br><br>

### **Types of Jewelry CNC Machines**<br><br>

1. **CNC Milling Machines**: These machines are used for cutting and shaping jewelry components from solid blocks of material, such as metal or wax. They are ideal for creating detailed and complex designs, including intricate patterns and settings. <br><br>

2. **CNC Engraving Machines**: Specialized for adding detailed engravings and inscriptions to jewelry, these machines can create precise and intricate designs on surfaces. <br><br>

3. **CNC Wax Carving Machines**: These machines are used to carve wax models for lost-wax casting, a common technique in jewelry making. The wax models are then used to create molds for casting the final metal pieces. <br><br>

4. **CNC Lathes**: CNC lathes are used for turning operations, where a rotating piece of material is cut into shape. They are particularly useful for creating symmetrical designs and detailed bands. <br><br>

5. **CNC 3D Printers**: Although not strictly a CNC machine in the traditional sense, 3D printers are used in jewelry making to create precise prototypes and models. They are often used in conjunction with CNC machines for a complete jewelry production process. <br><br>

### **Applications**<br><br>

- **Custom Jewelry Design**: Jewelry CNC machines allow for the creation of bespoke designs with high precision, making them ideal for custom jewelry pieces and unique creations. <br><br>

- **Mass Production**: For larger production runs, CNC machines provide consistency and efficiency, allowing jewelers to produce high volumes of identical or similar pieces with minimal variation. <br><br>

- **Prototyping**: Designers use CNC machines to create prototypes of new jewelry designs, allowing them to test and refine their concepts before mass production. <br><br>

- **Repairs and Restoration**: CNC machines can be used to repair or restore intricate jewelry pieces, ensuring that replacements or repairs match the original design perfectly. <br><br>

### **Advantages**<br><br>

- **Precision**: CNC machines offer unparalleled accuracy, ensuring that each piece of jewelry meets exact specifications and quality standards. <br><br>

- **Efficiency**: Automated operations reduce production time and labor costs, allowing for faster turnaround and higher production volumes. <br><br>

- **Consistency**: The use of CNC technology ensures that every piece produced is uniform, minimizing variations and defects. <br><br>

- **Flexibility**: CNC machines can be programmed to produce a wide range of designs and modifications, providing flexibility for both custom and mass-produced jewelry. <br><br>

- **Complexity**: Advanced CNC machines can execute complex designs and intricate details that would be challenging or impossible to achieve manually. <br><br>

### **Conclusion**<br><br>

Jewelry CNC machines have revolutionized the jewelry-making industry by combining technological precision with creative design. Their ability to produce detailed, consistent, and high-quality pieces has made them indispensable tools for modern jewelers. As technology continues to advance, these machines are likely to become even more sophisticated, further enhancing their capabilities and applications in the world of jewelry design and production. <br><br>

0 notes

Text

Fair Friend Group (FFG) was established in 1979 with the founding principles of reliability, rowth,continuous advancement,best in quality,and strive for excellence.

FFG consists of three major divisions of businesses:

(1) Machine Tool Division, (2) Industry Equipment Division and (3) Green Energy Division.

Machine Tool Division is the main business. Which overall performance of all group is 50%。 Machine Tool Division of the group(FFG) was established in 1985. FFG is the original machining factory of the group. The main products during its beginning stage were Sawing Machines and Grinding Machines. Realizing the industry trend toward high automation and unmanned operations in the machine tool industry, the development in CNC Machine Tool was launched in the same year, and the brand name FEELER was established for the overseas marketing. In 1986, the first moving column vertical machining center in Taiwan was built and it was highly regarded by the market. After this success, the development of CNC Lathes was launched in order to complete the FEELER product line. The product range is contain as follow: Vertical/Horizontal turning and milling, 5-axis machining center, automatic production system and all line equipment...etc.

For any kind of query, contact us with the details below.

Call: +91 011-41608833

Website:www.mdcorpindia.com

#5axismachiningcenter,#cncmachine,#cncmachinetools,#verticalmachine,#mdcorporation,#feelergroup

0 notes