#codesys compatible controllers

Explore tagged Tumblr posts

Text

How Codesys Compatible Controllers Are Revolutionising Industrial Automation?

Codesys Compatible Controllers for Motor and Pump Control

For controlling various motors and pumps using electronic circuits, one needs various controllers for doing the work, such as Codesys compatible controllers. Motion control systems can actually control the amount of water or fluid flow in different machinery systems, thus making machines work in perfect order.

Not just better efficiency and less wear and tear, but also the best controllers ensure that the machine operates with less noise, making people do their work comfortably.

Revolution of Electric Drivetrains in E-Mobility

Electric drivetrains from across e-mobility are revolutionizing the way industrial and transport systems are operated in place of today’s combustion engines. For example, DC-DC converters, battery cooling systems, and power electronics are designed expressly for electric vehicles, being supplied by reknowned supplier.

Thermal management is also important to maintain battery performance and increase the power electronics life. These innovations enable OEMs and system integrators to respond to ever-stronger demands for energy-efficient, compact, and environmentally compliant E-mobility solutions.

Advanced Electronics for Industrial Automation

Advanced electronic components are key to modern industrial operations for controlling, monitoring, and managing systems of automation. As a leading supplier of electronics they provides programmable logic controllers (PLCs), pressure switches, and temperature sensors.

These devices are necessary for real-time data processing and fine control for hydraulic and pneumatic systems. Communication protocols such as CANopen or IO-Link are integrated, assuring seamless connectivity with other industrial devices and enabling the building of smart system architecture, deeming it fit for Industrial 4.0 technologies.

Electrical Control Panels for Simplified Operation

Simplifying the operation of a complex industrial machine is done by the use of electrical control panels that combine different control systems to create a single interface. As a manufacturer of custom-built control panels, designs and manufactures power distribution, PLCs, HMIs, relays, and circuit protection components into a single control panel.

The panels have provided the means for the efficient and safe operation of hydraulic and electromechanical systems. They were designed for high-performance environments and can be configured for use in different industries such as manufacturing, mining, energy, and mobile equipment.

Leading Suppliers for Modern Control Parts

Call on the number of leading suppliers of various modern control parts of machines for better efficiency and control.

Source

0 notes

Text

The Mechatronic Design Engineer: Powering Automation with CODESYS

Mechatronic design engineering is a multidisciplinary field that blends mechanical engineering, electronics, control systems, and software development to create intelligent, automated systems. Mechatronic design engineers are at the forefront of innovation, designing solutions for industries like robotics, automotive, aerospace, and manufacturing. CODESYS, an IEC 61131-3-compliant development platform, is a critical tool for these engineers, enabling them to program and integrate control systems for complex mechatronic applications. This article explores the role of a mechatronic design engineer, how CODESYS supports their work, key responsibilities, required skills, and real-world applications, highlighting the impact of this profession on modern automation.

The Essence of Mechatronic Design Engineering

Mechatronic design engineering focuses on creating systems that integrate mechanical components, electronic circuits, sensors, actuators, and software to achieve precise, reliable performance. These systems, such as robotic arms, autonomous vehicles, or CNC machines, require seamless coordination between hardware and software. Mechatronic design engineers ensure that these components work together to meet performance, safety, and efficiency goals, making them essential in industries embracing Industry 4.0 and smart automation.

CODESYS is a cornerstone for mechatronic design engineers, offering a versatile, hardware-independent platform for programming embedded control systems. Its compliance with IEC 61131-3, support for multiple programming languages, and robust tools for simulation and debugging make it ideal for developing sophisticated mechatronic systems.

Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers undertake a variety of tasks to bring complex systems to life:

System Design and Integration: Designing integrated systems that combine mechanical structures, electronics, and control software to meet specific functional requirements.

Control System Programming: Developing control algorithms to manage sensors, actuators, and motion systems, ensuring precise operation.

Simulation and Testing: Using simulation tools to validate system performance before deployment, minimizing errors and risks.

Prototyping and Commissioning: Building prototypes, integrating components, and deploying systems in real-world environments.

Optimization and Troubleshooting: Analyzing system performance, debugging issues, and optimizing designs for efficiency and reliability.

Collaboration: Working with mechanical, electrical, and software teams to ensure cohesive system development.

How CODESYS Empowers Mechatronic Design Engineers

CODESYS provides a comprehensive environment tailored to the needs of mechatronic design engineers:

IEC 61131-3 Programming Languages: CODESYS supports Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). These languages enable engineers to develop control logic for diverse applications, from simple discrete controls to advanced motion systems.

Hardware Flexibility: Compatible with PLCs and embedded controllers from vendors like Beckhoff, WAGO, and Siemens, CODESYS allows engineers to choose hardware that suits project budgets and requirements.

Motion Control Libraries: CODESYS offers libraries for motion control, supporting tasks like servo motor control, trajectory planning, and multi-axis coordination, critical for mechatronic systems like robotics.

Simulation and Debugging Tools: The built-in simulation mode enables testing without physical hardware, while debugging features like breakpoints and real-time monitoring help identify and resolve issues quickly.

HMI Development: CODESYS provides tools to create Human-Machine Interfaces (HMIs) for operator interaction, including graphical displays and web-based visualizations.

Communication Protocols: Support for EtherCAT, CANopen, Modbus, and OPC UA ensures seamless integration with sensors, actuators, and other devices in mechatronic systems.

Safety Standards: For safety-critical applications, CODESYS supports IEC 61508 (SIL 2/3), enabling engineers to design systems for industries like automotive and aerospace.

Example: Robotic Arm Control Program

Below is a sample Structured Text (ST) program for controlling a robotic arm’s position in a mechatronic system:

RoboticArmControl.st

plain

Show inline

This program implements a proportional control loop to adjust a robotic arm’s joint angle, ensuring precise positioning in a mechatronic application.

Essential Skills for Mechatronic Design Engineers

To succeed, mechatronic design engineers need a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, and control systems programming, including CODESYS and IEC 61131-3 languages.

Control Theory: Understanding of control algorithms, such as PID control, for precise system management.

Software Development: Experience with embedded systems programming and real-time operating systems (RTOS).

Problem-Solving: Analytical skills to troubleshoot and optimize complex systems.

Teamwork: Collaboration with cross-functional teams to integrate hardware and software components.

Adaptability: Staying updated with emerging technologies like IoT, AI, and cybersecurity.

Benefits of Using CODESYS

Streamlined Development: The integrated IDE and simulation tools reduce development time and errors.

Cost Efficiency: Hardware independence and code reusability lower project costs.

Scalability: CODESYS supports projects from small prototypes to large-scale industrial systems.

Flexibility: Multiple programming languages and protocols cater to diverse project needs.

Community Support: A global user base and resources like the CODESYS Store provide access to libraries and tutorials.

Applications in Industry

Mechatronic design engineers leverage CODESYS in various sectors:

Robotics: Developing control systems for industrial and collaborative robots.

Automotive: Designing ECUs for engine management, braking, and autonomous driving.

Manufacturing: Automating production lines, CNC machines, and material handling systems.

Aerospace: Controlling actuators and sensors in aircraft and spacecraft.

Medical Devices: Creating precise control systems for surgical robots and diagnostics.

Challenges in Mechatronic Design Engineering

Interdisciplinary Complexity: Integrating mechanical, electrical, and software components requires broad expertise.

Learning Curve: Mastering CODESYS and IEC 61131-3 languages can be time-intensive for beginners.

Resource Constraints: Embedded systems often have limited processing power, necessitating optimized code.

Safety Requirements: Meeting standards like IEC 61508 for safety-critical applications adds complexity.

Getting Started with CODESYS

To begin as a mechatronic design engineer using CODESYS:

Install CODESYS: Download the free IDE from the official website.

Learn Programming: Study IEC 61131-3 languages through tutorials and documentation.

Select Hardware: Choose a compatible PLC or embedded controller.

Develop and Simulate: Write control logic, test in simulation mode, and debug.

Deploy: Compile and deploy code to the target hardware.

Future Trends

As industries embrace digital transformation, mechatronic design engineers will increasingly use CODESYS for IoT-enabled systems, cloud-based monitoring, and AI-driven control. Support for protocols like OPC UA and MQTT positions CODESYS for smart manufacturing, while advancements in cybersecurity ensure its relevance in safety-critical applications.

Conclusion

Mechatronic design engineers by Servotechinc are key to creating the intelligent systems that drive modern automation, from robotics to autonomous vehicles. CODESYS empowers these professionals with a flexible, IEC 61131-3-compliant platform for programming, testing, and deploying control systems. Its robust features, hardware independence, and support for motion control and communication protocols make it indispensable for mechatronic applications. As technology advances, CODESYS and mechatronic design engineers will continue to shape the future of automation, delivering innovative, efficient, and reliable solutions.

0 notes

Text

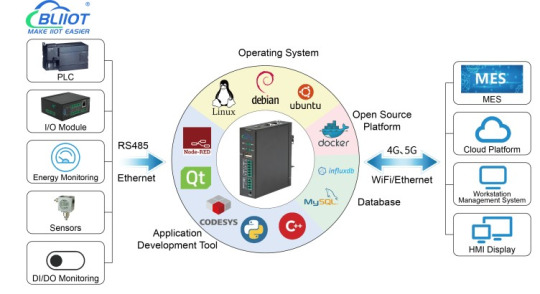

Transforming Industrial Automation with BLIIoT ARM Embedded Edge Gateway Computer EdgeCOM and Codesys

1. What is codesys

CODESYS is a general-purpose, IEC 61131-3-based development environment designed to provide reliable and flexible automation control systems. CODESYS supports multiple programming languages and hardware platforms, including Embedded ARM industrial computers. The core functions of CODESYS include PLC programming, HMI design and real-time monitoring.

2. Why use CODESYS?

Because it can improve the development efficiency and reliability of industrial automation control systems. CODESYS can provide a standardized programming language and framework, making porting and reuse between different hardware platforms easier. In addition, CODESYS also provides powerful debugging and testing tools to help developers complete software development more quickly and reliably.

3. So what is an BLIIoT Embedded ARM Edge Computer EdgeCOM BL300?

Embedded ARM industrial computer is a special computer, which is usually used in industrial automation control system. Compared with traditional desktop computers, embedded ARM industrial computers are smaller and more energy-efficient, and can undertake certain control tasks.

The BLIIoT EdgeCOM Compact ARM Embedded Computer BL300 series is designed for the harsh industrial environment. It adopts industrial grade NXP MCU inside, provides RS485, RS232, CAN, HDMI, USB, RJ45, DI, DO and Mini-PCIe for 4G, 5G, WiFi, etc.

The EdgeCOM Compact ARM Embedded Computer compatible with Linux, Ubantu, Debian OS, Node-red, Python, C++, QT, and MySQL, InfuxDB, SQLite database, Also compatible with IgnitionEdge, Codesys Edge Gateway, etc.

4. Embedded ARM industrial Edge computer supports codesys what can be achieved and the benefits

When the Embedded ARM industrial Edge computer supports CODESYS, it provides a more reliable and efficient solution for the development and operation of industrial automation control systems.

Support multiple communication protocols: Embedded ARM industrial Edge computer supports CODESYS, which can realize multiple communication protocols, such as Modbus, OPC UA, CANopen, etc., to facilitate data exchange and control between industrial equipment.

High performance and low power consumption: Embedded ARM industrial Edge computer uses ARM architecture, which can realize high-performance computing and low power consumption, suitable for long-term operation in industrial automation control systems.

Multi-tasking ability: Embedded ARM industrial Edge computer supports CODESYS to realize multi-tasking processing ability, run different tasks through multiple threads at the same time, and improve the response speed and efficiency of the system.

Hardware and software integration: Embedded ARM industrial Edge computer supports CODESYS, which can realize hardware and software integration, and package the hardware and software of the control system into a whole, which is convenient for installation and maintenance.

Highly customizable: Embedded ARM industrial Edge computer supports CODESYS to achieve high customization, and can flexibly select control algorithms, communication protocols, input and output methods, etc. according to different application scenarios to meet different control needs.

In short, using CODESYS for embedded ARM industrial Edge computers can improve the reliability, stability and efficiency of industrial automation control systems, help enterprises improve production efficiency and reduce operating costs.

More information about BLIIoT Industrial ARM Embedded Edge gateway Computer: https://www.bliiot.com/edge-computing-gateway-p00359p1.html

0 notes

Text

COMPACT PLC WITH HIGH EXPANDABILITY: NX-ERA XPRESS

Messung, India's first indigenous PLC manufacturer and leader in industrial automation has developed NX-ERA Xpress – a mini PLC with macro features.

A compact PLC, NX-ERA Xpress offers full PLC performance with a small footprint.With its compact dimensions and competitive pricing, NX-ERA Xpress has opened up new perspectives in industrial automation. Many applications for which automationwas a difficult option can now benefit from the many advantages of these entry-level programmable logic controllers.

NX-ERA XPRESS HIGHLIGHTS

· High density I/O both Digital & Analog

· Programming by Codesys (r) - IEC 61131 based software

· Ethernet Port - TCP/IP, Modbus TCP/IP

· Industry 4.0 ready - OPC-UA, MQTT features

· RS-485 port with Modbus RTU Master protocol

· CANopen Master/Slave protocol

· SCADA and HMI interfaces available

· Built in HTML web server

There are several options to choose from, allowing the best solution for entry-level applications.

This product portfolio targets small control systems, offering models containing from a few digital inputs and outputs up to options with 43 I/O points concentrated in a single controller, including an alog inputs and outputs with temperature support (RTD sensors).

In case of additional I/O needs, the PLC system can be easily expanded through CANopen using the Remote I/O Mode. This mode transforms the product into a non-programmable slave I/O device, which can then be connected to a XP3xx controller with CANopen Manager protocol. It can also be expanded using other available ports like Ethernet and RS-485.

NX-ERA XPRESS APPLICATIONS

With Messung’s NX-ERA Xpress, implementing automation tasks is fast and flexible, while keeping the footprint to a minimum.

NX-ERA Xpress is suitable for small applications and remote distributed I/O. It may be applied in verticals such asfactory automation, machines, infrastructure, building automation, water, wastewater, food, textiles, and several other OEMsolutions. Additionally, it is an ideal solution for complementing big applications along with NX-ERA Series portfolio,extending the range of applications using the same technology and engineering environment.

(list of applications below may be deleted since we covered them in previous blog) Messung has successfully applied NX-ERA Xpress to:

· Bandsaw

· Dust analyser

· Continuous furnace

· Pressure testing

· Hydraulic press

· Robotic cell

· Boiler automation

· Battery management system

· Salt spray chamber

· AHU application

· Milling machine

· Flat dipping machine

· Trunnion fixer machine

NX-ERA XPRESS' FLEXIBLE I/O CAPABILITIES

Generally, compact PLCs are integrated units built by several moduleswithin a single case. Therefore, the I/O capabilities are usually decidedby the manufacturer. With NX-ERA Xpress, Messung offers up to 42I/Os in a single unit.

With the use of Remote I/Os, users can greatly increase the capacity oftheir automation solutions. NX-ERA Xpress can connect to external devices such as sensors,electro mechanical actuators, VFDs and servo motors located far away fromthe main control cabinet via various protocols, namely Modbus, CANopen, and Messung's own'Mesbus'.

MESSUNG’S XM-PRO SERIES OF REMOTE I/O

The XM-PRO Series of remote I/Os is the result of Messung’s ongoing commitment to innovation and excellence in Industrial automation. For four decades, Messung has designed and manufactured cutting-edge technology at cost-effective prices for Indian industry, enabling them to automate processes, improve operations and minimise downtime.

Messung’s XM-PRO Series offers a wide range of advanced Remote I/O modules for CANopen, Modbus and Mesbus protocols. The Remote I/Os are CE marked and certified for usage in harsh industrial environments.

The CANopen range includes:

CAN-DI 16 16 Channel digital Input (2 groups of 8 channel Sink/Source)

CAN-DO 16 16 Channel digital output channels (relay) (2 groups of 8 channel)

CAN-DI 8-DO 6 8 Channel digital input (Sink/Source) & 6 Channel relay output

The Modbus range includes:

MOD-DI-8 8 Channel Digital Input (Two independent groups of 4 inputs each which can be used as a sink or source inputs)

MOD-DO-16R 16 Channel Relay Output (250VAC-2A/30VDC-2A); Two isolated group of 8 output channel each

MOD-CFC-4 4 Channel Ceiling Fan Controller with control up to 5 speed for each channel

MOD-AI-4 4 Channel Analog input – (12bit- 0-10v/0-20mA/4-20mA)

MOD-AO-4 4 Channel Analog Output – (12bit- 0-10v/4-20mA)

Messung’s Mesbus range is equivalent to the KNX bus and can directly be used in any KNX environment. Currently it offers:

MES-DO-16R (KNX compatible) 16 Individual outputs / 8 Shutter Channels

MES-CFC-4 (KNX Compatible) 4 Channel Ceiling Fan Controller with control up to 5 speed for each channel

INDUSTRY 4.0 READINESS

Industry 4.0 is all about digitization and networking of the manufacturing process via the internet. It stands for seamless communication between applications, devices and machines with corporate IT systems.

NX-ERA Xpress is Industry 4.0 ready with OPC-UA, MQTT features inbuilt. Thus, data generated by the machines can be used along the entire value chain. In smart home orbuilding automation applications, status information from sensors can be sent tomobile devices from where control commands can be sent back.

CONCLUSION

NX-ERA Xpress is the power-packed, feature-rich micro PLC controller developed by Messung for OEM or end-users with entry-level applications for automation.

Messung is a leading PLC automation company with four decades of experience and expertise in the field.Its goal is to empower businesses with the foremost technologies and high-performance products backed by deep domain knowledge and reliable support.

NX-ERA Xpress represents the ongoing innovation of Messung, under its ‘Navonmesh – Make in India initiative’. Messung continuously designs and manufactures world-class industrial solutions at an affordable price. With its inhouse R&D centre plus proven all-India reach and service support, Messung is the preferred partner for all your small to large industrial automation needs.

#plc#plc system#programmable logic controller#Plc Manufacturers#micro plc#plc automation company#remote IO#canopen#servo drive#vfd

0 notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.

Licensing: While the core IDE is free, certain add-ons, libraries, or runtime licenses may incur costs, depending on the application.

Conclusion

CODESYS PLC by Servotechinc is a cornerstone of modern industrial automation, offering a robust, flexible, and scalable platform for PLC programming. Its adherence to IEC 61131-3, support for multiple programming languages, and extensive feature set make it a preferred choice for engineers worldwide. Whether you’re developing a small control system or a complex, distributed automation solution, CODESYS provides the tools to streamline development and ensure reliable performance. As industries continue to embrace digital transformation, CODESYS remains at the forefront, empowering automation professionals to build the systems of the future.

0 notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.

Licensing: While the core IDE is free, certain add-ons, libraries, or runtime licenses may incur costs, depending on the application.

Conclusion

CODESYS PLC by Servotechinc is a cornerstone of modern industrial automation, offering a robust, flexible, and scalable platform for PLC programming. Its adherence to IEC 61131-3, support for multiple programming languages, and extensive feature set make it a preferred choice for engineers worldwide. Whether you’re developing a small control system or a complex, distributed automation solution, CODESYS provides the tools to streamline development and ensure reliable performance. As industries continue to embrace digital transformation, CODESYS remains at the forefront, empowering automation professionals to build the systems of the future.

0 notes

Text

Importance of Control Valve & Fuel Separators in Hydraulics

It takes a variety of controllers, such as Codesys compatible controllers, to operate different motors and pumps utilising electronic circuits along with a control valve for controlling the flow of liquids.

In fact, motion control systems may regulate the flow of water or other fluids in various industrial systems, ensuring that everything operates as it should.

The best controllers guarantee that the machine runs with less noise, allowing people to work more comfortably, in addition to increased efficiency and reduced wear and tear.

Understand Electronic Components and Condition Monitoring Systems

Modern industrial processes rely on sophisticated electronic components along with condition monitoring systems to monitor, operate, and manage automation systems, which is important from a maintenance point of view.

HYDAC is a prominent electronics provider that offers temperature sensors, pressure switches, and programmable logic controllers (PLCs). These tools are essential for fine-tuning hydraulic and pneumatic systems and analysing data in real time.

The integration of communication protocols such as IO-Link and CANopen ensures smooth interaction with other industrial equipment, makes it possible to construct intelligent system designs, and qualifies it as compatible with Industrial 4.0 technologies.

Fuel Contamination and Checking it with Technology

Fuel contamination is actually a problem with many machines and engines working on fuels like diesel, and it needs to be monitored strictly since undesirable substances in fuel can cause damage to machines. Modern-day diesel fuel filter systems are robust and can handle harsh conditions.

Today's combustion engines are being replaced by electric drivetrains from e-mobility, which is transforming the way industrial and transportation systems are run. For instance, HYDAC supplies DC-DC converters, battery cooling systems, and power electronics that are specifically made for electric vehicles.

In order to preserve battery performance and extend the life of power devices, thermal control is also crucial. These developments give OEMs and system integrators the ability to meet the growing demand for small, energy-efficient, and ecologically friendly e-mobility solutions.

Electrical control panels, which integrate many control systems into a single interface, simplify the operation of complicated industrial machinery. Power distribution, PLCs, HMIs, relays, and circuit protection components are all designed and manufactured by HYDAC, a maker of specialised control panels.

The panels have made it possible for hydraulic and electromechanical systems to operate effectively and safely. They may be set up for usage in a variety of industries, including manufacturing, mining, energy, and mobility equipment, and were created for high-performance settings.

For improved efficiency and control, call the number of the top suppliers of different contemporary machine control parts.

Source

0 notes

Text

Unlocking Industrial Automation with CODESYS PLC

In the ever-evolving world of industrial automation, the demand for intelligent, flexible, and efficient control systems has reached new heights. At the forefront of this transformation is CODESYS PLCs, a widely recognized and powerful development environment for Programmable Logic Controllers (PLCs). Designed to streamline automation programming and enhance functionality, CODESYS PLC enables industries to accelerate innovation, improve productivity, and future-proof their automation infrastructure.

What is CODESYS?

CODESYS (Controller Development System) is an IEC 61131-3 compliant development platform used to program industrial controllers, such as PLCs, PACs (Programmable Automation Controllers), and embedded systems. Developed by 3S-Smart Software Solutions, CODESYS supports all five IEC standard programming languages, including:

Ladder Diagram (LD)

Function Block Diagram (FBD)

Structured Text (ST)

Instruction List (IL) (now deprecated)

Sequential Function Chart (SFC)

It also includes support for Continuous Function Chart (CFC), which is an additional graphical programming method offered by CODESYS.

This flexibility allows engineers and developers to choose the best language suited for a particular application, making it a universal and highly adaptable development platform.

Why CODESYS for PLC Programming?

CODESYS has become one of the most widely used platforms for industrial automation due to several compelling features:

1. Vendor-Independent

CODESYS is hardware-agnostic, which means it can run on a wide variety of controller hardware from different manufacturers. This interoperability simplifies integration across diverse hardware systems.

2. All-in-One Development Tool

The CODESYS Development System combines programming, debugging, simulation, and monitoring tools into a single environment. This eliminates the need for multiple software packages and enhances productivity.

3. Integrated Visualization

CODESYS offers integrated HMI (Human Machine Interface) visualization tools. Developers can create operator interfaces directly within the development platform, reducing time and cost associated with separate HMI development.

4. Web and Remote Access

With support for web-based visualization and remote maintenance, CODESYS allows users to monitor and control PLCs from anywhere, enhancing operational flexibility.

5. Scalability and Modularity

From small embedded controllers to large industrial PCs, CODESYS can scale to fit various applications. Its modular architecture supports plug-ins, extensions, and customized libraries.

Key Features of CODESYS PLC

1. Real-Time Capabilities

CODESYS can be used with real-time capable operating systems, enabling deterministic behavior and time-sensitive control processes essential in manufacturing, robotics, and motion control.

2. Fieldbus Support

CODESYS natively supports a wide range of industrial communication protocols including:

CANopen

Modbus (TCP/RTU)

EtherCAT

PROFINET

OPC UA

This broad fieldbus compatibility makes integration into existing factory networks easier and more flexible.

3. Simulation and Debugging

CODESYS offers an integrated simulation environment that allows for testing PLC logic before deployment. Debugging tools such as breakpoints, variable watch, and trace functionality provide deeper insights during development.

4. Version Control and Collaboration

With support for SVN (Subversion), CODESYS facilitates team collaboration, version control, and project management—ideal for large teams and critical automation projects.

5. Add-On Tools

CODESYS Store offers extensions such as motion control, safety programming, CNC features, and more. These tools allow for domain-specific customization and expansion of the system.

Applications of CODESYS PLC

CODESYS is used extensively across various industries where automation plays a key role. Common applications include:

Factory Automation: Controlling production lines, conveyor belts, robotic arms, and machine tools.

Building Automation: Managing HVAC systems, lighting controls, elevators, and smart building infrastructure.

Process Control: Operating chemical plants, water treatment facilities, and food processing units.

Energy Management: Monitoring and controlling renewable energy systems such as wind turbines and solar farms.

Automotive Testing: Used in HIL (Hardware-in-the-Loop) systems for automotive electronics validation.

Benefits of Using CODESYS PLC

1. Reduced Development Time

The intuitive interface and comprehensive toolset allow engineers to develop, test, and deploy automation programs faster than traditional platforms.

2. Cost-Effective

CODESYS reduces licensing costs by eliminating the need for proprietary vendor-specific tools. It also minimizes hardware dependency, offering more choices and competitive pricing.

3. Improved Quality and Reliability

With simulation, validation, and diagnostic tools built-in, CODESYS helps reduce errors and ensures high-quality control logic.

4. Future-Proof Architecture

CODESYS supports Industry 4.0 and IIoT (Industrial Internet of Things) integration. Its compatibility with modern protocols ensures adaptability for future innovations.

5. Strong Community and Support

A large global community, extensive documentation, and regular updates from the developers ensure continuous improvement and user assistance.

Challenges and Considerations

While CODESYS is highly versatile, some challenges must be considered:

Learning Curve: Engineers new to IEC 61131-3 languages or integrated development environments may need training to become proficient.

Hardware Compatibility: Although CODESYS is hardware-agnostic, some advanced features may only be supported on specific platforms.

Cybersecurity: As with all networked systems, securing CODESYS-enabled PLCs against unauthorized access and cyber threats is essential.

Future of CODESYS in Industrial Automation

As automation grows more intelligent, connected, and autonomous, platforms like CODESYS will play an increasingly critical role. Integration with cloud services, AI-powered analytics, and digital twin simulations are on the horizon for CODESYS-based systems. Its ongoing development ensures that it remains a cornerstone of modern automation technologies.

Conclusion

CODESYS PLC by servotechinc represents a powerful, flexible, and cost-effective solution for modern industrial automation needs. Whether you're building a simple control panel or a complex manufacturing execution system, CODESYS offers the tools and capabilities required to develop robust, scalable, and intelligent automation applications.

With its open architecture, broad industry adoption, and future-ready features, CODESYS is not just a programming tool—it is a platform driving the future of smart automation.

1 note

·

View note

Text

CODESYS PLC: Empowering Industrial Automation with Flexible Control Solutions

In the fast-evolving world of industrial automation, flexibility, interoperability, and ease of programming have become key requirements for Programmable Logic Controllers (PLCs). CODESYS PLC (Controller Development System) has emerged as a leading software platform that enables engineers and developers to program and deploy powerful automation solutions. Known for its open-source adaptability, user-friendly interface, and broad device compatibility, CODESYS PLC is transforming how industries implement control systems.

What is CODESYS PLC?

CODESYS PLC is a hardware-independent IEC 61131-3 programming environment for industrial automation applications. Developed by 3S-Smart Software Solutions, CODESYS allows engineers to develop controller applications using standardized programming languages like Structured Text (ST), Ladder Diagram (LD), Function Block Diagram (FBD), Instruction List (IL), and Sequential Function Chart (SFC).

Unlike traditional PLC systems locked into specific hardware brands, CODESYS is hardware-agnostic, meaning it can run on a wide variety of devices—whether it's a dedicated PLC, an industrial PC, or even a Raspberry Pi. This flexibility significantly reduces development costs and enhances scalability across diverse industrial applications.

Key Features of CODESYS PLC

1. IEC 61131-3 Compliance

CODESYS supports all five standard programming languages defined by IEC 61131-3, offering flexibility and choice based on the developer's preference or the specific application requirements.

2. Integrated Development Environment (IDE)

The CODESYS IDE is intuitive and feature-rich, offering tools for debugging, simulation, and version control. Its graphical and textual editors streamline application development.

3. Real-Time Control

CODESYS can turn standard hardware into powerful real-time controllers. Real-time tasks ensure high-performance and deterministic control necessary for complex automation processes.

4. Extensive Hardware Support

CODESYS works with a broad range of devices from manufacturers like WAGO, Beckhoff, Schneider Electric, and Bosch Rexroth. This interoperability simplifies integration in mixed-vendor environments.

5. Fieldbus Integration

CODESYS supports standard fieldbus protocols like EtherCAT, CANopen, Modbus, and PROFINET, enabling seamless communication with sensors, actuators, and other networked devices.

6. Web and Remote Visualization

With CODESYS WebVisu and CODESYS HMI, users can create web-based dashboards and remote HMIs for real-time monitoring and control, accessible from any browser-enabled device.

7. Motion Control and CNC

CODESYS includes modules for motion control, robotics, and CNC, making it suitable for highly dynamic and precise applications in manufacturing and packaging industries.

Benefits of Using CODESYS PLC

1. Vendor Independence

One of CODESYS’s standout features is its independence from specific hardware vendors. Users can select the most appropriate or cost-effective hardware without being tied to proprietary ecosystems.

2. Cost Efficiency

By using general-purpose hardware with CODESYS, organizations can avoid expensive proprietary controllers while achieving similar, if not better, performance.

3. Scalability

CODESYS applications can scale from small embedded controllers to large distributed systems, making it ideal for projects of all sizes—from simple automation tasks to complex industrial systems.

4. Rapid Development

The development environment supports simulation and debugging without requiring physical hardware. This allows developers to test applications thoroughly before deployment, reducing on-site troubleshooting time.

5. Community and Ecosystem

CODESYS has a strong global developer community and a marketplace for add-ons and libraries, helping users access additional features and prebuilt solutions that accelerate development.

Applications of CODESYS PLC

CODESYS is used across multiple industries due to its flexibility and robust capabilities:

Factory Automation: Control of conveyors, robotic arms, production lines, and safety systems.

Building Automation: Lighting, HVAC, and security systems using intelligent, responsive controls.

Renewable Energy: Monitoring and managing wind turbines, solar farms, and battery storage systems.

Automotive Manufacturing: Precision motion and robotic control in assembly lines.

Food and Beverage: Ensuring consistent product quality and compliance in automated processes.

CODESYS PLC in Industry 4.0

The rise of Industry 4.0 and smart manufacturing has increased the demand for flexible, connected, and data-driven control systems. CODESYS aligns perfectly with these trends by supporting modern protocols like OPC UA, MQTT, and REST APIs for data exchange with cloud platforms, MES, and ERP systems.

With edge computing gaining ground, many organizations deploy CODESYS on industrial PCs or edge devices to perform local processing and analytics before sending data to the cloud. This reduces latency and improves system responsiveness.

Challenges and Considerations

While CODESYS offers many benefits, it’s essential to be aware of potential challenges:

Initial Learning Curve: For teams unfamiliar with IEC 61131-3 or transitioning from proprietary PLC platforms, some training may be needed.

License Management: Although the IDE is free, deploying applications on certain devices may require a runtime license.

Security: As with any connected control system, cybersecurity measures must be in place to prevent unauthorized access.

The Future of CODESYS PLC

CODESYS continues to evolve, with ongoing updates focused on cloud integration, cybersecurity, and support for AI and machine learning. As automation systems become more complex and interconnected, CODESYS is positioning itself as a forward-looking solution that meets the demands of modern industrial environments.

Efforts to integrate CODESYS with containerization platforms like Docker also suggest a future where automation control can be more modular, portable, and easier to deploy.

Conclusion

CODESYS PLC by Servotechinc stands as a versatile and powerful platform for modern industrial control applications. Its openness, scalability, and broad feature set make it a compelling alternative to proprietary PLC systems. By enabling cost-effective development, cross-platform compatibility, and enhanced functionality, CODESYS empowers engineers and businesses to build smarter, more adaptive automation solutions that align with the future of industry.

Whether you are upgrading legacy systems, launching new automation projects, or transitioning to Industry 4.0, CODESYS offers the tools and flexibility to bring your vision to life.

0 notes

Text

Mechatronic Design: Engineering the Future of Intelligent Systems

In today’s rapidly evolving technological landscape, the boundaries between mechanical systems and electronics are increasingly blurred. Enter Mechatronic Design—a multidisciplinary engineering approach that combines mechanical engineering, electronics, computer science, and control systems to design and build intelligent products and systems. Mechatronic Design lies at the heart of modern automation, robotics, automotive systems, and advanced manufacturing, driving innovation across industries.

What is Mechatronic Design?

Mechatronic Design is the process of creating products that incorporate mechanical components with electrical and electronic elements, governed by intelligent control systems. This integration enables the development of smart devices that can sense, analyze, and act with precision. Examples range from everyday items like washing machines and drones to advanced industrial robots and autonomous vehicles.

The term “mechatronics” originated in Japan in the 1960s, combining the words “mechanics” and “electronics.” Today, it has evolved into a key enabler of Industry 4.0 and intelligent automation.

Core Disciplines in Mechatronic Design

Mechatronic systems blend multiple engineering disciplines to function cohesively. Key areas include:

Mechanical Engineering Involves the design of physical structures, moving parts, actuators, gears, and systems that generate motion or perform mechanical tasks.

Electrical and Electronics Engineering Supports the integration of sensors, microcontrollers, power systems, and electronic circuits that interpret signals and power various components.

Computer Science and Software Engineering Responsible for developing the software and algorithms that control the system’s behavior, including embedded programming and real-time control logic.

Control Systems Engineering Focuses on how machines respond to inputs and maintain stability, accuracy, and performance through feedback systems and control loops.

The Mechatronic Design Process

Designing a mechatronic system requires a structured and collaborative process involving several stages:

1. Requirements Definition

Engineers begin by understanding user needs, environmental conditions, functional goals, and performance constraints.

2. System Architecture Design

This phase involves selecting the components (sensors, actuators, microcontrollers, mechanical assemblies) and defining how they will interact.

3. Modeling and Simulation

Designers create virtual models to simulate behavior and performance using tools like MATLAB/Simulink, SolidWorks, or CODESYS, allowing for optimization before building physical prototypes.

4. Hardware and Software Integration

Mechanical parts, sensors, embedded systems, and software code are integrated into a cohesive unit, ensuring compatibility and seamless operation.

5. Prototyping and Testing

Physical prototypes are built and subjected to rigorous testing. Feedback from testing is used to improve performance, safety, and reliability.

6. Production and Deployment

After successful validation, the design moves into production, with ongoing support for maintenance and potential upgrades.

Applications of Mechatronic Design

The versatility of mechatronic systems makes them ideal for a wide range of applications:

🤖 Industrial Automation and Robotics

Robots in manufacturing plants rely on mechatronic design to handle tasks like assembly, welding, painting, and material handling with speed and precision.

🚗 Automotive Systems

Modern vehicles use mechatronic systems in automatic braking, steering, engine control units (ECUs), and driver-assistance features.

✈️ Aerospace Engineering

Aircraft systems use mechatronics for flight control, engine monitoring, and landing gear automation.

🏥 Medical Devices

Surgical robots, prosthetics, and diagnostic machines are examples of mechatronic innovations in healthcare that improve precision and patient care.

🌱 Agricultural Machinery

Tractors, seeders, and drones equipped with sensors and control systems support precision farming, enhancing efficiency and yield.

🏢 Smart Home and Building Automation

Systems like smart thermostats, automated lighting, and security systems use mechatronic design to improve comfort and energy efficiency.

Benefits of Mechatronic Design

✅ Higher Efficiency and Productivity

Integrated systems perform tasks faster and more accurately than conventional mechanical systems.

✅ Compact and Intelligent Systems

Mechatronics allows for the development of compact devices with multiple functions, reducing the need for separate systems.

✅ Improved User Experience

From adaptive cruise control in cars to robotic assistants, users benefit from intuitive and responsive technologies.

✅ Reduced Development Costs

Simulation and modeling tools help optimize designs early, reducing trial-and-error cycles and minimizing costly mistakes.

✅ Increased Reliability and Safety

With real-time monitoring and control, mechatronic systems can detect issues proactively and take corrective actions.

Tools and Technologies Used in Mechatronic Design

CAD Software (e.g., SolidWorks, AutoCAD) for mechanical modeling

Simulation Tools (e.g., MATLAB/Simulink, ANSYS) for control logic and behavior testing

Embedded Programming (e.g., C/C++, Python, Arduino, Raspberry Pi) for control systems

Microcontrollers (e.g., STM32, PIC, Arduino) for hardware integration

Sensor and Actuator Libraries for interfacing physical systems with control logic

Challenges in Mechatronic Design

Despite its benefits, mechatronic design also presents challenges:

Interdisciplinary Coordination: Requires collaboration between mechanical, electrical, and software engineers.

Complex Integration: Synchronizing all systems for real-time functionality can be challenging.

Cost of Development: High-precision sensors, components, and tools can increase initial development costs.

Maintenance and Upgrades: As systems become more complex, maintaining or upgrading components without disrupting the entire system is a key consideration.

Future of Mechatronic Design

As industries adopt smart manufacturing and the Internet of Things (IoT), mechatronic systems will play an even more significant role. The integration of AI, machine learning, and cloud computing with mechatronics will enable adaptive and predictive systems that can learn from their environment and improve performance over time.

Technologies like digital twins, edge computing, and real-time analytics are also being incorporated into mechatronic systems, pushing the boundaries of automation and smart design.

Conclusion

Mechatronic Design is not just about combining mechanical and electrical systems—it’s about creating intelligent solutions that interact with the real world in smarter ways. Whether it's enhancing automation, improving healthcare, or powering the next generation of vehicles, mechatronic engineering is a cornerstone of innovation. As industries continue to evolve, embracing mechatronic design will be key to staying competitive, efficient, and future-ready.

0 notes

Text

PLC Programming Using CODESYS: A Comprehensive Guide

Programmable Logic Controllers (PLCs) are integral to industrial automation, serving as the backbone for controlling machinery and processes. Among the various platforms available for PLC programming, CODESYS stands out as a versatile and manufacturer-independent development environment. This article delves into the intricacies of PLC programming using CODESYS, exploring its features, benefits, and practical applications.

Understanding CODESYS

CODESYS, an acronym for "Controller Development System," is a comprehensive software suite designed for industrial automation applications. Developed by 3S-Smart Software Solutions, it adheres to the IEC 61131-3 standard, which defines programming languages for PLCs. This compliance ensures that users can program PLCs using standardized languages, facilitating consistency and interoperability across different hardware platforms.

Key Features of CODESYS

Support for Multiple Programming Languages CODESYS supports all five programming languages defined by the IEC 61131-3 standard:

Instruction List (IL): An assembler-like language.

Structured Text (ST): Similar to high-level languages like Pascal or C.

Ladder Diagram (LD): Resembles electrical relay logic schematics.

Function Block Diagram (FBD): Utilizes graphical blocks to represent functions and operations.

Sequential Function Chart (SFC): Ideal for programming sequential processes.

Additionally, CODESYS offers Continuous Function Chart (CFC), a freehand FBD editor that allows for flexible function block placement.

Integrated Development Environment (IDE) The CODESYS Development System provides a user-friendly IDE that integrates various tools necessary for PLC programming, including editors, compilers, and debuggers. This cohesive environment streamlines the development process, allowing for efficient coding, testing, and deployment.

Fieldbus and Protocol Support CODESYS offers extensive support for numerous fieldbus systems such as EtherCAT, CANopen, Modbus, and PROFIBUS. This compatibility ensures seamless communication between the PLC and other industrial devices, facilitating robust and scalable automation solutions.

Visualization and HMI Integration With integrated visualization tools, CODESYS enables developers to create user interfaces for monitoring and controlling processes. These interfaces can be deployed on various platforms, including embedded displays, PCs, and web browsers, providing flexibility in human-machine interaction.

Motion Control and RoboticsCODESYS extends its capabilities to motion control and robotics applications, offering libraries and tools for controlling complex movements, including CNC and robotic kinematics. This integration simplifies the development of advanced automation systems.

Benefits of Using CODESYS for PLC Programming

Manufacturer Independence One of the most significant advantages of CODESYS is its hardware-agnostic nature. Developers can program PLCs from various manufacturers using a single platform, reducing the learning curve and increasing flexibility in hardware selection.

Scalability CODESYS caters to a wide range of applications, from small-scale projects to large industrial systems. Its modular architecture allows for scalable solutions, accommodating the evolving needs of industrial automation.

Community and Support A vibrant community surrounds CODESYS, offering tutorials, forums, and shared libraries. This collaborative environment provides valuable resources for both beginners and experienced developers, fostering continuous learning and problem-solving.

Compliance with Industry Standards By adhering to the IEC 61131-3 standard, CODESYS ensures that applications meet industry requirements, promoting reliability and interoperability in industrial automation systems.

Practical Applications of CODESYS

Industrial Automation CODESYS is widely used in manufacturing for automating production lines, machinery, and process control. Its support for various fieldbus systems allows seamless integration with sensors, actuators, and other industrial devices.

Building Automation In building management systems, CODESYS facilitates the control of HVAC systems, lighting, and security, contributing to energy efficiency and occupant comfort.

Energy Management CODESYS plays a role in monitoring and controlling energy production and distribution, including renewable energy sources, ensuring efficient and reliable operations.

Transportation Systems From traffic light control to railway signaling, CODESYS is employed in various transportation applications, enhancing safety and efficiency.

Getting Started with CODESYS

For those interested in exploring PLC programming with CODESYS, the following steps provide a roadmap to begin:

Download and Install CODESYS The CODESYS Development System can be downloaded for free from the official CODESYS Store. The setup includes the development environment and a demo version of the SoftPLC CODESYS Control Win SL.

Explore Tutorials and Documentation Numerous tutorials and documentation are available to help beginners get acquainted with CODESYS. The official CODESYS website offers step-by-step guides and video tutorials.

Join the Community Engaging with the CODESYS community through forums and discussion groups can provide additional support and insights. Platforms like Reddit host communities where users share experiences and advice.

Conclusion

CODESYS is a powerful, manufacturer-independent PLC programming by Servotechinc platform that enhances industrial automation with flexibility, scalability, and compliance with IEC 61131-3 standards. Its support for multiple programming languages, visualization tools, and motion control makes it ideal for diverse applications. With a strong community and extensive resources, CODESYS continues to drive innovation in automation and control systems.

0 notes

Text

PLC Coding with CODESYS at Servotech: A Beginner’s Guide

Introduction to PLC and CODESYS

Programmable Logic Controllers (PLCs) play a crucial role in industrial automation, enabling the control of machinery and processes with precision. One of the most widely used platforms for PLC programming is CODESYS, a powerful and flexible software environment designed for industrial control applications. At Servotech, a leading provider of automation solutions, learning PLC coding with CODESYS can enhance efficiency and optimize production processes.

This guide provides beginners with a foundational understanding of PLC programming using CODESYS at Servotech, covering essential concepts, programming techniques, and practical applications.

Understanding PLCs and Their Importance

What is a PLC?

A Programmable Logic Controller (PLC) is an industrial digital computer designed for automation and control of electromechanical processes. It replaces traditional relay-based control systems with software-driven logic, improving efficiency, reliability, and scalability.

Why are PLCs Important?

PLCs are essential in industries such as manufacturing, energy, transportation, and infrastructure. They help:

Automate repetitive tasks

Enhance operational efficiency

Reduce human error

Improve safety and reliability

Enable remote monitoring and control

Introduction to CODESYS

What is CODESYS?

CODESYS (Controller Development System) is an IEC 61131-3 compliant software suite used for PLC programming. It provides an integrated development environment (IDE) for programming, simulation, and debugging of automation applications.

Key Features of CODESYS

Support for multiple programming languages (Ladder Diagram, Structured Text, Function Block Diagram, etc.)

Graphical user interface (GUI) for intuitive programming

Integrated simulation environment

Cross-platform compatibility

Scalability for different PLC hardware

Setting Up CODESYS for PLC Programming at Servotech

Step 1: Installing CODESYS

To begin PLC coding at Servotech, follow these steps to install CODESYS:

Download the latest version of CODESYS from the official website.

Install the software by following the on-screen instructions.

Activate the license if required.

Step 2: Creating a New Project

Open CODESYS and click on File > New Project.

Select the PLC device from the hardware list.

Choose the programming language (Ladder Logic, Structured Text, etc.).

Click OK to start coding.

Step 3: Connecting to a PLC at Servotech

Ensure the PLC is powered on and connected to the network.

Navigate to Device Communication Settings in CODESYS.

Select the PLC type and establish a connection.

Test the connection to verify communication.

Basic PLC Programming Concepts in CODESYS

Understanding IEC 61131-3 Programming Languages

CODESYS supports multiple programming languages under the IEC 61131-3 standard, including:

Ladder Diagram (LD): Graphical representation using relay logic.

Structured Text (ST): Text-based coding similar to Pascal.

Function Block Diagram (FBD): Graphical representation using function blocks.

Sequential Function Chart (SFC): Used for step-based processes.

Instruction List (IL): Low-level assembly-like language.

Writing a Simple Ladder Logic Program

Open Ladder Diagram (LD) editor in CODESYS.

Add contacts (inputs) and coils (outputs).

Define logic conditions using NO (normally open) and NC (normally closed) contacts.

Save and compile the program.

Download the program to the PLC and test the functionality.

Implementing Advanced PLC Logic at Servotech

Using Timers and Counters

Timers and counters help manage operations that require delays or repetitive actions.

TON (On Delay Timer): Delays activation of an output.

TOF (Off Delay Timer): Delays deactivation of an output.

CTU (Up Counter): Counts upward when triggered.

CTD (Down Counter): Counts downward when triggered.

Working with Function Blocks

Function blocks (FBs) allow modular programming by encapsulating logic into reusable components.

Create a new Function Block in CODESYS.

Define input and output variables.

Write the logic inside the function block.

Use the function block in the main program.

Implementing Communication Protocols

Servotech PLCs often interact with external devices via communication protocols such as:

Modbus TCP/IP for industrial networking

OPC UA for data exchange

CANopen for real-time control

Testing and Debugging in CODESYS

Using the Simulator

CODESYS provides an inbuilt simulation tool that allows testing programs without physical hardware.

Open the Simulator Mode.

Load the program and execute it.

Monitor variable states in real-time.

Debugging Techniques

Breakpoints: Pause execution at specific points.

Watch List: Monitor real-time values of variables.

Online Mode: Test the program directly on the PLC.

Error Logs: Identify and resolve programming errors.

Practical Applications of PLC Coding at Servotech

At Servotech, CODESYS-based PLC programming is used in:

Factory Automation: Controlling assembly lines and robotic arms.

Energy Management: Optimizing power usage.

Building Automation: HVAC, lighting, and security control.

Material Handling: Conveyor belt and warehouse automation.

Conclusion

Learning PLC coding with CODESYS at Servotech opens doors to exciting opportunities in industrial automation. By understanding the basics of PLCs, setting up CODESYS, and implementing logical programming concepts, beginners can build effective automation solutions. As you progress, explore advanced functionalities such as function blocks, communication protocols, and debugging tools to optimize industrial processes efficiently.

Start your PLC coding journey today and take the first step toward mastering industrial automation with CODESYS at Servotech!

0 notes

Text

Messung’s NX-ERA Xpress: The Micro PLC With Macro Features

Messung, one of India's leading industrial automation companies presents NX-ERA Xpress, a powerful yet compact Programmable Logic Controller (PLC) for entry-level applications. Developed by Messung. NX-ERA Xpress brings you world-class technology at a cost-effective price.

Packed with advanced features, this micro PLC delivers high-speed processing power in a compact design with embedded I/O. The PLC system can be easily expanded through CANopen using the Remote I/O Modules - a great advantage for OEMs with needs of small, scalable applications.

Nx-ERA Xpress Highlights

· High density I/O both Digital & Analog

· Programming by Codesys (r) - IEC 61131 based software

· Ethernet Port - TCP/IP, Modbus TCP/IP

· Industry 4.0 ready - OPC-UA, MQTT features

· RS-485 port with Modbus RTU Master protocol

· CANopen Master/Slave protocol

· SCADA and HMI interfaces available

· Built in HTML web server

There are several options to choose from, allowing the best solution for entry-level applications.

This product portfolio targets small control systems, offering models containing from a few digital inputs and outputs up to options with 43 I/O points concentrated in a single controller, including analog inputs and outputs with temperature support (RTD sensors).

In case of additional I/O needs, the PLC system can be easily expanded through CANopen using the Remote I/O Mode. This mode transforms the product into a non-programmable slave I/O device, which can then be connected to a XP3xx controller with CANopen Manager protocol. It can also be expanded using other available ports like Ethernet and RS-485.

Remote I/O Highlights

· Readily usable with Xpress micro PLC

· Available with CANopen and Modbus RTU interface

· Range of models for DI/DO and AI/AO

NX-ERA Xpress Applications

NX-ERA Xpress micro PLC system is suitable for small applications and remote distributed I/O. Messung has successfully applied it to:

· Bandsaw

· Dust analyser

· Continuous furnace

· Pressure testing

· Hydraulic press

· Robotic cell

· Boiler automation

· Battery management system

· Salt spray chamber

· AHU application

· Milling machine

· Flat dipping machine

· Trunnion fixer machine

Additionally, this micro PLC is an ideal solution for complementing big applications along with NX-ERA Series portfolio, extending the range of applications using the same technology and engineering environment.

About Messung Industrial Automation

Messung is a pioneer and market leader in industrial automation since 1981. It has an impressive track record of developing cutting-edge, custom-built solutions for factory automation, process automation and special purpose machine automation.

Messung partners throughout the complete life cycle of your plant, and customises industrial automation & control solutions that meet the highest technical demands for speed, quality, operational reliability, system availability and more.

Counted among the top 10 PLC manufacturers, Messung offers a range of world-class Programmable Logic Controllers (PLC), Remote I/O Modules, and Human Machine Interface (HMI) for a gamut of applications across diverse industries.

Through its technology tie-ups with Fuji Electric (Japan) and Sigmatek (Austria), Messung also offers a wide range of Variable Frequency Drives (VFDs) and Servo & Motion Control solutions for simple to complex industrial applications.