#composite materials

Text

Brightest tears in the purple night sky

#art#natural hair#minecraft youtube#original painting#original art#composite materials#new painting#expressionism

2 notes

·

View notes

Text

We manufacture manhole covers!!

#naphogagoat ;#napgacomposite ;#naphogacomposite;#baogianaphogacomposite#manhole cover#Drain covers#composite materials#Cast iron

2 notes

·

View notes

Text

Professional Composite Decking Singapore

Composite decking has become a popular choice for homeowners in Singapore looking to enhance their outdoor spaces. AS DECO & CONSTRUCTION PTE. LTD. offers professional composite decking services, providing quality materials, expert craftsmanship, and exceptional customer satisfaction. In this article, we'll explore the benefits of composite decking, why AS DECO & CONSTRUCTION PTE. LTD. stands out, the installation process, maintenance tips, popular designs, and more.

Introduction to Composite Decking

Composite decking is a versatile alternative to traditional wood decking, made from a blend of recycled wood fibers and plastic materials. It offers several advantages over wood, including enhanced durability, resistance to rot and decay, and minimal maintenance requirements. AS DECO & CONSTRUCTION PTE. LTD. specializes in providing high-quality composite decking solutions tailored to the unique needs of each client.

Advantages of Composite Decking

Durability and Longevity

Composite decking is known for its durability, withstanding Singapore's humid climate and harsh weather conditions without warping, cracking, or splintering. It is also resistant to pests, mold, and mildew, ensuring long-lasting performance and beauty.

Low Maintenance Requirements

Unlike wood decking, which requires regular staining, sealing, and maintenance, composite decking is virtually maintenance-free. It doesn't require sanding or sealing and only needs occasional cleaning with soap and water to maintain its appearance.

Aesthetic Appeal

With a wide range of colors, textures, and finishes available, composite decking offers endless design possibilities. Whether you prefer a traditional wood look or a more contemporary style, AS DECO & CONSTRUCTION PTE. LTD. can customize composite decking to suit your preferences and complement your outdoor space.

Why Choose AS DECO & CONSTRUCTION PTE. LTD.?

AS DECO & CONSTRUCTION PTE. LTD. is a trusted name in the construction industry, known for its commitment to quality, professionalism, and customer satisfaction. When you choose AS DECO & CONSTRUCTION PTE. LTD. for your composite decking needs, you can expect:

Expertise and Experience: With years of experience in the industry, AS DECO & CONSTRUCTION PTE. LTD. has the knowledge and skills to deliver superior results.

Quality Materials and Craftsmanship: AS DECO & CONSTRUCTION PTE. LTD. uses only the highest quality composite decking materials and employs skilled craftsmen to ensure precision and attention to detail in every project.

Customer Satisfaction: Customer satisfaction is a top priority for AS DECO & CONSTRUCTION PTE. LTD., and they strive to exceed expectations with every installation, providing personalized service and support from start to finish.

Composite Decking Installation Process

The installation process for composite decking typically involves several steps:

Consultation and Design: AS DECO & CONSTRUCTION PTE. LTD. works closely with clients to understand their needs and preferences, offering design suggestions and recommendations.

Material Selection: Choose from a variety of composite decking materials, colors, and finishes to achieve the desired look and feel.

Installation and Finishing Touches: Skilled technicians handle the installation process with precision and efficiency, ensuring proper fitting and alignment. Finishing touches such as railings, lighting, and accessories are added to enhance the overall appearance and functionality of the deck.

Cost Considerations

The cost of composite decking installation varies depending on factors such as the size of the deck, the complexity of the design, and the chosen materials. While composite decking may have a higher upfront cost compared to wood, the long-term savings on maintenance and repairs make it a cost-effective investment.

Maintenance Tips for Composite Decks

To keep your composite deck looking its best, follow these maintenance tips:

Regular Cleaning and Care: Sweep or hose off debris regularly and clean stains with mild soap and water.

Repairs and Refinishing: Address any scratches, dents, or damage promptly to prevent further deterioration. Periodic refinishing may be necessary to maintain the deck's appearance.

Popular Composite Decking Designs

AS DECO & CONSTRUCTION PTE. LTD. offers a variety of composite decking designs to suit different preferences and styles, including:

Traditional Wood Look: Mimics the appearance of natural wood for a classic and timeless aesthetic.

Contemporary Designs: Sleek and modern designs with clean lines and minimalist features.

Customized Options: Tailored designs to fit specific dimensions and requirements, incorporating unique elements and features.

Case Studies: Successful Composite Decking Projects

Here are some examples of successful composite decking projects completed by AS DECO & CONSTRUCTION PTE. LTD.:

Residential Deck Renovation: Transforming a dull and outdated deck into a stylish and functional outdoor living space.

Commercial Deck Installation: Creating an inviting outdoor area for customers and employees to enjoy.

FAQs About Composite Decking Installation

How long does composite decking last?

Composite decking can last up to 25 years or more with proper maintenance and care.

Is composite decking environmentally friendly?

Yes, composite decking is made from recycled materials and is considered a sustainable choice for outdoor decking.

Can composite decking be painted or stained?

While composite decking doesn't require painting or staining, some products may be painted or stained to achieve a custom look.

Is composite decking slippery when wet?

Most composite decking products have textured surfaces that provide traction, reducing the risk of slipping when wet.

Are composite decks prone to fading?

High-quality composite decking products are UV-resistant and resistant to fading, ensuring long-lasting color retention.

Conclusion

AS DECO & CONSTRUCTION PTE. LTD. offers professional composite decking services in Singapore, providing durable, low-maintenance, and aesthetically pleasing outdoor solutions. With their expertise, quality materials, and commitment to customer satisfaction, AS DECO & CONSTRUCTION PTE. LTD. is the trusted choice for composite decking projects of any size or complexity.

#composite#decking#singapore#composite decking#composite materials#composite chart#decking boards & tiles#decking lights

0 notes

Text

Mastering the Art of Bonding with Composite Adhesive Techniques

Understanding the composition of composite adhesive is essential for mastering bonding techniques. Typically composed of resins, fillers, and additives, composite adhesive is engineered to create a strong and durable bond between different materials. The precise formulation of these components determines the adhesive's properties, such as curing time, strength, and resistance to environmental factors.

Surface preparation plays a crucial role in ensuring the effectiveness of Composite Adhesive bonding. Before applying the adhesive, surfaces must be clean, dry, and free of any contaminants that could compromise the bond. Proper surface preparation ensures maximum adhesion strength and promotes long-term durability.

Selecting the right application method is vital for achieving optimal bonding results with composite adhesive. Depending on the materials being bonded and the specific requirements of the application, various techniques can be employed, including brush application, spray application, and automated dispensing systems. Each method offers unique advantages and considerations, allowing for precise control over adhesive application and distribution.

Proper curing is essential for maximizing the strength and durability of composite adhesive bonds. Curing refers to the process by which the adhesive undergoes chemical reactions to harden and create a strong bond between the bonded surfaces. Factors such as temperature, humidity, and curing time must be carefully controlled to ensure consistent and reliable bonding results.

Get More Insights On This Topic: Composite Adhesive

#Composite Adhesive#Bonding Agents#Structural Adhesives#Composite Materials#Adhesive Bonding#Industrial Adhesives#Aerospace Adhesives#High Performance Adhesives#Composite Repair Materials

0 notes

Text

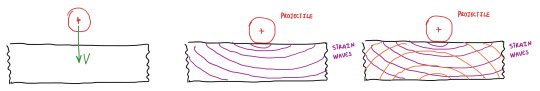

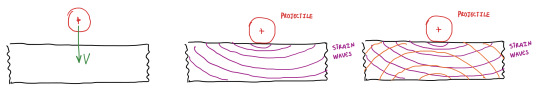

Impact and crash in composite materials - Part 1-2: Impact damage, parameters and testing

When something hit a carbon fiber chassis occurs an indentation, which is the superficial damaged caused by an impact. In racing field, usually it is caused by debris or small shanks. The problem is that an indentation can hide a critical damage. For this reason it is important to go deeper in this subject. This article proposes a summary of the main the details of the impact damage, its main…

View On WordPress

#composite materials#crash in composite materials#impact and crash analysis#impact in composite materials

0 notes

Text

Composites manufacturing process

Composites manufacturing is a process that involves combining two or more materials with significantly different physical or chemical properties to produce a new material with enhanced characteristics. This process is widely used in various industries such as aerospace, automotive, marine, and construction due to the ability of composites to offer lightweight, high strength, corrosion resistance, and design flexibility.

Composites manufacturing process passes through several steps: design and material selection, mold preparation, layup, resin infusion or injection, curing, demolding, post processing, and quality control.

1. Design and Material Selection

The process begins with the design phase where engineers specify the desired properties and requirements of the final composite product, and selection of appropriate reinforcement materials (such as fibers like carbon, glass, or aramid) and matrix materials (such as thermoset resins like epoxy, polyester, or vinylester) based on the desired characteristics of the composite.

2. Mold Preparation

A mold or tool is created based on the desired shape and dimensions of the final product. This mold can be made from various materials like metal, fiberglass, or composite materials. The mold is prepared by cleaning, applying mold release agents, and sometimes adding surface treatments to ensure easy release of the finished composite part.

3. Layup

The layup process involves arranging layers of reinforcement materials (fibers) in the desired orientation within the mold. The reinforcement materials can be in the form of woven fabrics, unidirectional tapes, or chopped fibers depending on the specific application and desired mechanical properties. Layers of reinforcement are often combined with the matrix material, either in the form of pre-impregnated (prepreg) fibers or by applying liquid resin during layup.

Read more:

#composites#composite materials#materials science#science#materials science and engineering#materials#engineering

1 note

·

View note

Text

Reinventing Infrastructure: The Role of Polymer Composites in Bridge Rehabilitation

Introduction

Bridges are critical components of our transportation infrastructure, facilitating the smooth flow of goods and people. However, over time, these vital structures undergo wear and tear due to factors like heavy traffic, weathering, and aging. To address these challenges, engineers and researchers have been exploring innovative materials and techniques for bridge rehabilitation. One…

View On WordPress

#Bridge Maintenance#bridge rehabilitation#composite materials#construction innovation#corrosion resistance#Durability#engineering advancements#FRP technology#infrastructure enhancement#innovative materials#long-term savings#Polymer composites#seismic retrofitting#structural strengthening#sustainable solutions#transportation systems

0 notes

Text

Bonding Excellence: Navigating Trends in the Epoxy Adhesive Market

Adhesives are essential products that are often overlooked. They’re noticed, until they fail. If your supports aren’t correctly fused, it could bring about disjointed parts, damaged equipment, and worn-out piping systems.

So, this blog has the ins and outs of epoxy adhesives, which can help you secure the pipe supports with confidence.

What Is an Epoxy Adhesive?

From time-to-time epoxy adhesives are confused with bonding products like glue. However, they’re far more complex than most adhesives. These are often called structural adhesives These terms make their role clearer: They’re high-performance adhesives meant for applications calling for powerful bonding, such as aircraft, automobiles, aerospace technology, or heavy process piping systems.

Uses of Epoxy Adhesives

Coming to process piping systems, the epoxy adhesives have a vital role to play. These systems frequently require to join unlike materials together, like composite pipe shoes and metal piping. Besides, adhesives need to hold structures together in heavy vibrations, high pressure, and corrosive environments.

An area where epoxy adhesives have advantage is when you’re including pipe supports like wear pads, pipe shoes, and Flat Plates. That’s since this mixture enables to install without welding.

Benefits of Epoxy Adhesives?

• By safeguarding pipes or adding wear pads to the system, raw piping can be insulated. Suddenly, you’ve protected pipes from metal-on-metal contact deprived of the high cost of specialized labor. Also, by eliminating welding, you’ll be evading susceptible spots requiring special heat treatments.

• These pipe supports can increase the life of the systems, need to be held together. These adhesives work pretty well since they are sturdy and can stand extreme environments.

• An epoxy can also work as a sealant filling open gaps. This guards pipes and supports from corrosion.

Different Kinds of Epoxy Adhesives

There are numerous epoxy adhesives, but they can be split into two one-component and two-component

One-Component Adhesives

These more often than not come as a single paste. Though, the name can deceive a few. Though they come as only a single physical substance, they still require external elements to start the curing process. That means they require moisture, heat treatment, or special lighting for bonding.

Two-Component Adhesives

These require you to blend two elements. When applied properly, the outcome is a powerful bond. Though, since two-part adhesives need mixing, there’s the likelihood for a human error.

What’s the Solution?

If you desire to get the paybacks of a two-component adhesive without mixing the right ratio or getting it on the skin, use a static applicator. This loads onto a standard epoxy cartridge and brings a two-part epoxy in a flawless mixing ratio, saving the mess and guesswork that from time to time come with physically mixing two-component epoxies.

Due to the increasing demand for these adhesives in numerous industries, the total value of the epoxy adhesives will reach $13,484 million by 2030.

#epoxy adhesive#adhesive technology#market trends#industrial applications#construction industry#global market outlook#bonding solutions#market dynamics#epoxy resin#research and development#composite materials#market growth factors#aerospace applications

0 notes

Text

Glass Type Polyurethane Composites Driving Growth in Transportation and Construction Industries: Market Analysis and Projections by 2026

The report “Polyurethane Composites Market by Type (Glass, Carbon), Manufacturing Process (Lay-Up, Pultrusion, Resin Transfer Molding), End-Use Industry (Transportation, Building & Construction, Electrical & Electronics), Region – Global Forecast to 2026″, The global polyurethane composites market is projected to reach USD 909.8 Million by 2026, at a CAGR of 5.9% from 2016 to 2026. Increase in…

View On WordPress

#Composite Manufacturing#Composite Materials#Composite Properties#Fiber-Reinforced Composites#Global Polyurethane Composites Market#Key Players in the Polyurethane Composites Market#Lightweight Composites#Market Dynamics of Polyurethane Composites#Market Opportunities for Polyurethane Composites#Market Size of Polyurethane Composites#Market Trends for Polyurethane Composites#Polyurethane Composites#Polyurethane Composites Industry#Polyurethane Composites Manufactures#Polyurethane Composites Market#Polyurethane Composites Market Analysis#Polyurethane Composites Market Forecast#Polyurethane Composites Market Growth#Polyurethane Composites Market Outlook#Polyurethane Composites Market Segmentation#Polyurethane Composites Market Share#Polyurethane Resins#Reinforcement Fibers#Structural Composites

0 notes

Text

Introducing Composite Ballast Boards

We are proud to introduce to the UK market our lightweight, structurally sound composite ballast boards — perfect for protecting railway lines and trackside facilities on embankments from hazards such as rockfall or snowslide.

Traditional concrete ballast boards are heavy and time-consuming to install, particularly over lengthy lines of track, so our glass-fibre reinforced polyester (GRP) model…

View On WordPress

#Complete Composite Systems (CCS)#Composite Materials#Infrastructure#Rail Safety#Safety Barriers#Supplier News#Track

0 notes

Photo

Brick Exterior in Chicago

Example of a large classic brown three-story brick exterior home design

0 notes

Text

New composite decking could reduce the global warming effects of building materials - Technology Org

New Post has been published on https://thedigitalinsider.com/new-composite-decking-could-reduce-the-global-warming-effects-of-building-materials-technology-org/

New composite decking could reduce the global warming effects of building materials - Technology Org

Buildings and production of the materials used in their construction emit much carbon dioxide (CO2), a potent greenhouse gas contributing to global warming and climate change. However, storing CO2 in building materials could help make them more environmentally friendly. Scientists report that they have designed a composite decking material that stores more CO2 than is required to manufacture, providing a “carbon-negative” option that meets building codes and is less expensive than standard composite decking.

[embedded content]

The researchers will present their results today at the American Chemical Society (ACS) spring meeting. ACS Spring 2024 is a hybrid meeting held virtually and in person March 17-21; it features nearly 12,000 presentations on a range of science topics.

Apart from a few types of cement, carbon-negative composites are scarce, according to David Heldebrant, an organic chemist who is one of the project’s principal investigators. His team’s composite decking “is one of the first composite materials to be demonstrably CO2 negative over its life cycle,” he says.

According to the World Green Building Council, the materials and processes used to construct buildings account for 11% of all energy-related carbon emissions. Significant efforts have gone into developing building supplies to offset these emissions, such as using recycled or plant-derived products. However, in many cases, these sustainable alternatives are more expensive than traditional materials or can’t match their properties, such as strength or durability.

One type of construction material — decking — is a multibillion-dollar industry. Decking boards made from a wood plastic composite are a popular alternative to lumber boards because they are less prone to damage from ultraviolet radiation and can last longer. Composite decking is typically made from a blend of wood chips or sawdust and plastic, such as high-density polyethylene (HDPE). To make these composites more sustainable, one alternative is to use fillers that are waste products or would otherwise be burned.

That’s an approach Heldebrant’s colleague Keerti Kappagantula was taking: using low-quality brown coal and lignin, a wood-derived product left over from papermaking, as the filler in decking composites. To make the pulverized coal and lignin particles mix with and stick to plastics, the research team needed to add ester functional groups to the particles’ surfaces. Heldebrant, who works at Pacific Northwest National Laboratory (PNNL) and develops specialized liquids to capture CO2, found out about this work while chatting over coffee with Kappagantula.

Satish Nune, another project investigator, and Heldebrant were excited when they heard about this. “Esters are essentially carboxylic acids, which are a captured form of CO2,” Heldebrant explains. So, the team wanted to do the same thing and put CO2 onto the surface of the particles in the composite to make the material even more environmentally friendly while improving the composites’ mechanical performance.

To test the feasibility of this approach, the team turned to a classic chemical reaction to form a new chemical bond between CO2 and a functional group called a phenol, which is abundant in wood products like coal and lignin. After undergoing the reaction, the lignin and coal particles contained 2–5% CO2 by weight.

The team then mixed varying ratios of these particles with HDPE to form brownish-black composites, and they tested the resulting properties. A composite containing 80% filler maximized the amount of CO2 content while demonstrating strength and durability that meet international building codes for decking materials. It was manufactured via friction extrusion using PNNL’s shear assisted processing and extrusion (ShAPETM) machine. The researchers used this material to form 10-foot-long composites that look and feel similar to any standard wood composites found in decking or lawn furniture.

In addition to their favorable physical properties, the new composite boards offer a substantial price and sustainability advantage. They are 18% cheaper than standard decking composite boards. They also store more CO2 than is released during their manufacture and lifetime, Heldebrant says. If the 3.55 billion feet of decking sold in the U.S. every year were replaced with the researchers’ CO2-negative composite decking, he says, 250,000 tons of CO2 could be sequestered annually, which is equivalent to the yearly emissions from 54,000 cars.

Next, the researchers plan to make additional composite formulations and test the properties. They envision that carbon-negative composites could be developed for a range of building materials, such as fencing and siding. In the meantime, the team is working to commercialize its decking boards. This new carbon-negative decking could be available at building supply retailers as soon as next summer.

Source: acs.org

You can offer your link to a page which is relevant to the topic of this post.

#000#2024#250#acids#approach#billion#boards#Building#buildings#Capture#carbon#Carbon dioxide#carbon emissions#Cars#cement#change#chemical#chemical reaction#chips#climate#climate change#CO2#coal#coffee#composite materials#composites#construction#content#effects#Emissions

0 notes

Text

Impact and crash in composite materials - Part 1-1: Types of impact and testing

In racing cars engineering there is a great concern regarding when the laminate will fail and how they reacts to an impact. This situation is very common in motorsports since race cars are exposed, to shanks, rubbing, debris and crashes. The main objective is to protect the driver against the impact, thus the monocoque must not deform and driver must be fit. However, there are components that…

View On WordPress

0 notes

Text

Composite Materials Market 2022 Dynamics Trends , Comprehensive Analysis, Business Growth, Prospects and Opportunities 2028

The research reports provide deep insights into the global market revenue, market trends, macro-economic indicators, and governing factors, along with market attractiveness per market segment. The report provides an overview of the growth rate of Composite Materials market during the forecast period, i.e., 2022–2030. The report, most importantly, identifies the qualitative impact of various market factors on market segments and geographies. The research segments the market on the basis of product type, application type, technology type, and region. To offer more clarity regarding the industry, the report takes a closer look at the current status of various factors, including but not limited to supply chain management, distribution Trade, channels, supply and demand, and production capability differ across countries.

Get Exclusive Sample Pages of this Report@ https://iconmarketresearch.com/inquiry/sample/IMR0487

Composite Materials Market Company Profiles Analysis:

Teijin Ltd

Toray Industries, Inc.

Owens Corning

PPG Industries, Inc.

Huntsman Corporation LLC

SGL Group

Hexcel Corporation

DuPont

Compagnie de Saint-Gobain S.A

Weyerhaeuser Company

Momentive Performance Materials, Inc.

Cytec Industries (Solvay. S.A.)

Jushi Group Co., Ltd.

Note – The Covid-19 (coronavirus) pandemic is impacting society and the overall economy across the world. The impact of this pandemic is growing day by day as well as affecting the supply chain. The COVID-19 crisis is creating uncertainty in the stock market, massive slowing of supply chain, falling business confidence, and increasing panic among the customer segments. The overall effect of the pandemic is impacting the production process of several industries. This report on ‘Composite Materials Market’ provides the analysis on impact on Covid-19 on various business segments and country markets. The reports also showcase market trends and forecast to 2030, factoring the impact of Covid -19 Situation.

Market Segmentation:

In 2021, the Global Composite Materials Market’s size was valued at USD 11.46 billion and is estimated to reach USD 17.56 billion by 2028 and is expected to be growing at a CAGR of 12.94% throughout the forecast period.

For More Discount Datils @ https://iconmarketresearch.com/inquiry/discount/IMR0487

Regional Framework

The report provides a detailed overview of the industry including both qualitative and quantitative information. It provides an overview and forecast of the global Composite Materials Market based on various segments. It also provides market size and forecast estimates from the year 2022 to 2028 with respect to five major regions. The Composite Materials Market by each region is later sub-segmented by respective countries and segments. The report covers the analysis and forecast of 18 countries globally along with the current trend and opportunities prevailing in the region.

Promising Regions & Countries Mentioned in The Composite Materials Market Report:

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Major Features of Composite Materials Market Report:

Save and reduce time carrying out entry-level research by identifying the growth, size, leading players and segments in the global Composite Materials market.

Highlights key business priorities in order to assist companies to realign their business strategies.

The key findings and recommendations highlight crucial progressive industry trends in the global Composite Materials market, thereby allowing players across the value chain to develop effective long-term strategies.

Develop/modify business expansion plans by using substantial growth offering developed and emerging markets.

Scrutinize in-depth global market trends and outlook coupled with the factors driving the market, as well as those hindering it.

Enhance the decision-making process by understanding the strategies that underpin commercial interest with respect to client products, segmentation, pricing and distribution.

Purchase a Copy of this Study @ https://iconmarketresearch.com/inquiry/buying/IMR0487

Note: If you have any special requirements, please let us know and we will offer you the report as you want.

About Us:

Icon Market Research is a one-stop industry research provider of actionable intelligence. Through our syndicated and consulting research services, we help our clients get solutions to their research requirements. We specialise in industries such as Semiconductor and Electronics, Aerospace and Défense, Energy, Automotive and Transportation, Healthcare, Manufacturing and Construction, Media and Technology, Chemicals, and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please contact us:

Contact Person: Gaurav B

E-mail: [email protected]

Phone: (+1) 812 506 4440.

0 notes

Text

What is the difference between composite and alloy?

Alloys must contain at least one metal, and blending elements to form a new material with unique properties which different from the properties of each element. Composites mix distinct materials (metal or not) that retain their identities, with a reinforcing element embedded in a supporting matrix, to form a new material With properties that combine the characteristics of each element. This difference leads to composites being only heterogeneous, while alloys can be homogeneous or heterogeneous.

Read more:

#composites#composite materials#materials science#materials science and engineering#science#engineering#materials

0 notes