#Composite Manufacturing

Text

Glass Type Polyurethane Composites Driving Growth in Transportation and Construction Industries: Market Analysis and Projections by 2026

The report “Polyurethane Composites Market by Type (Glass, Carbon), Manufacturing Process (Lay-Up, Pultrusion, Resin Transfer Molding), End-Use Industry (Transportation, Building & Construction, Electrical & Electronics), Region – Global Forecast to 2026″, The global polyurethane composites market is projected to reach USD 909.8 Million by 2026, at a CAGR of 5.9% from 2016 to 2026. Increase in…

View On WordPress

#Composite Manufacturing#Composite Materials#Composite Properties#Fiber-Reinforced Composites#Global Polyurethane Composites Market#Key Players in the Polyurethane Composites Market#Lightweight Composites#Market Dynamics of Polyurethane Composites#Market Opportunities for Polyurethane Composites#Market Size of Polyurethane Composites#Market Trends for Polyurethane Composites#Polyurethane Composites#Polyurethane Composites Industry#Polyurethane Composites Manufactures#Polyurethane Composites Market#Polyurethane Composites Market Analysis#Polyurethane Composites Market Forecast#Polyurethane Composites Market Growth#Polyurethane Composites Market Outlook#Polyurethane Composites Market Segmentation#Polyurethane Composites Market Share#Polyurethane Resins#Reinforcement Fibers#Structural Composites

0 notes

Text

Website : https://tighitco.com/

Address : 5 Connecticut South Drive, East Granby, CT 06026

Phone : +1 860-264-2101

TIGHITCO, Inc. is an industry leader in the design, fabrication, and assembly of engineered components for aerospace and industrial applications. TIGHITCO is comprised of three divisions – AeroStructures, Insulation Products, and Overhaul Support Services, supported by six facilities located throughout North America. We have ISO 9001, AS9100 and NADCAP accreditation for our quality and system management. Employing our integrated Program Management Process ensures all aspects are efficiently managed. Starting from a quote through program planning, production verification, qualification, launching process, and its transition into regular production. TIGHITCO focuses on quality, schedule and best value. We partner with our customers to develop tools, plans and targets for price, delivery, inventory and lead-time improvements. Customer expectations are met through professional program management and an entrepreneurial spirit. Our team is always innovating – how can we do this faster, less expensive, better – to come up with a solution that gets around any obstacles. TIGHITCO balances the needs of the industry, production schedules, technology and the customer.

#advanced composite structures#composite manufacturing#aerospace manufacturer#aerospace cnc machining#composite fabrication

1 note

·

View note

Text

Website : https://tighitco.com/

Address : 8450 Palmetto Commerce Pkwy, Ladson, SC 29456

Phone : +1 843-376-0409

TIGHITCO, Inc. is an industry leader in designing, fabricating, and assembling engineered components for aerospace and industrial applications. TIGHITCO is comprised of three divisions – AeroStructures, Insulation Products, and Overhaul Support Services supported by six facilities located throughout North America. We have ISO 9001, AS9100, and NADCAP accreditation for our quality and system management. Employing our integrated Program Management Process ensures all aspects are efficiently managed. We are starting from a quote through program planning, production verification, qualification, launching process, and its transition into regular production. TIGHITCO focuses on quality, schedule, and best value. We partner with our customers to develop tools, plans, and targets for the price, delivery, inventory, and lead-time improvements. Customer expectations are met through professional program management and an entrepreneurial spirit. Our team is constantly innovating – how can we do this faster, less expensive, better – to come up with a solution that gets around any obstacles. TIGHITCO balances the needs of the industry, production schedules, technology, and the customer.

#composite manufacturing#aerospace manufacturer#aerospace CNC machining#composite fabrication#aerospace composites

1 note

·

View note

Text

Researchers unveil new digital twin for precise real-time analysis of composite materials production

Researchers from IMDEA Materials Institute and the Technical University of Madrid (UPM) have developed an innovative digital twin that enables real-time analysis of composite materials manufacturing.

The breakthrough was presented in The International Journal of Advanced Manufacturing Technology in an article titled A digital twin for intelligent manufacturing of structural composites via liquid molding.

The publication is the work of IMDEA Materials researchers, Prof. Carlos González and Drs. Joaquín Fernández-León and Keayvan Keramati, along with Dr. Luis Baumela (UPM).

In the paper, the authors present a digital twin for analyzing the manufacturing process of structural composite materials using resin transfer molding (RTM).

Read more.

8 notes

·

View notes

Note

i hope this isn't overstepping but how are you deciding what wheelchair you'll get?

So, I have to pick a vendor that works with my insurance and is reasonably close. DME vendors usually don't work with Every Single manufacturer, typically they only work with a couple. So immediately I am narrowed down to only a few manufacturers who each do not have that many models available. Most of the vendors around me supply 2-3 each of about 5 total different manufacturers: Ki Mobility, Quickie, Permobil, Motion Composites, and Sunrise Medical.

I don't really like Quickie or Ki Mobility manual chairs based on past experiences. They're not bad, I just dislike them. Sunrise from what I know basically just sells Quickies and RGKs (which are ok in theory but RGK is UK based which makes me antsy about any potential repairs or parts ordering). So I'm left with Permobil and Motion Composites unless somehow I get talked into an RGK. Some of the vendors offer both Permobil and Motion Composites, but several of them do not, so which vendor I feel the most comfortable working with will basically determine my next chair.

#If Motion Composites Apex came in titanium it would not even be a competition#The main thing I'm deciding between is if I want to sacrifice more adjustability (Apex) or sacrifice durability/shock absorption (Tilite)#But of course I'll still be trying out chairs and such at the wheelchair fitting. This is all just preliminary decisions because#picking a vendor automatically preselects what manufacturer I'll be going with#ask#anonymous

2 notes

·

View notes

Text

Aluminium Composite Panels - Eva Alu Panel Ltd

Eva Alu Panel Ltd has achieved success in the production of strong and sturdy aluminum panels that last for decades. We have an impressive portfolio of manufacturing, marketing and exports. Our exterior protective shield for new buildings and renovation applications consists of a polyethylene core and 2 Aluminium skins each of 0.5mm/0.25mm thick.

#Aluminium Composite Panel Manufacturers#ACP Sheet Manufacturer#Partition Panel Manufacturer#Aluminium Partition Panel#HPL Sheet Manufacturers#Aluminium Composite Panel#ACP sheet

2 notes

·

View notes

Text

Explore reliable plastic testing services in Chennai at our accredited lab. From material analysis to quality assurance, our expert team ensures compliance with industry standards for all your plastic testing needs.

#Plastic Testing#Lab Services#Plastic Properties#plastic manufacturing#maeon laboratory#chennai#composite testing laboratory

1 note

·

View note

Text

https://www.futureelectronics.com/p/passives--resistors--fixed-resistors/wsl25127l000fea-vishay-9135757

Vishay, WSL25127L000FEA, Resistors, Fixed Resistors

WSL Series 2512 1 W 0.007 Ohm ±1% ±75 ppm/°C SMT Power Metal Strip® Resistor

#Vishay#WSL25127L000FEA#Resistors#Fixed Resistors#Networks#motion control Resistor manufacturers#voltage dividers#value#Carbon Composition Resistors#Wire Wound Resistors#Thin Film Resistors

1 note

·

View note

Text

0 notes

Text

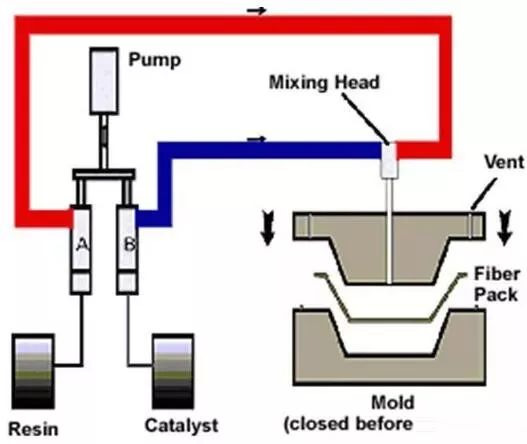

What is the RTM Molding Process for Composite Material?

RTM refers to a process technology in which low-viscosity resin flows in a closed mold, infiltrates reinforced materials and solidifies into shape. It belongs to the category of liquid forming or structural liquid forming technology of composite materials. The specific method is to pre-place reinforced materials that have been rationally designed, cut or mechanized pre-formed into the designed mold. The mold needs to be sealed and tightened around the perimeter to ensure smooth resin flow. After the mold is closed, a certain amount of resin is injected. And after the resin solidifies, the desired product can be obtained by demoulding.

The RTM molding process has the following main characteristics

RTM is a closed mold molding process. The infiltration of the reinforcement and the resin is completed by the rapid flow of pressurized resin in a closed mold cavity, instead of manual infiltration in hand lay-up and spraying processes, nor expensive mechanized infiltration in prepreg and SMC processes. RTM is a low-cost, high-quality semi-mechanized fiber/resin impregnation method.

The RTM molding process uses reinforced material preform technology that is similar to the shape of the product. Once the fiber/resin infiltration is completed, it can be cured, so a low-viscosity fast-curing resin system can be used. It can also heat the RTM mold to further improve production efficiency and product quality.

The reinforced material preform in the RTM molding process can be prepared from chopped strand mat, fiber cloth, wrinkle-free fabric, three-dimensional knitted fabric, three-dimensional braided fabric, etc. And according to the performance requirements, selective reinforcement, local reinforcement, hybrid reinforcement, and embedded and sandwich structures can be used, which can give full play to the performance designability of FRP/composite materials.

The closed-mold resin injection method of the RTM molding process can greatly reduce the toxicity of harmful resin components to the human body and the environment, and meet the increasingly stringent restrictions on the volatilization concentration of harmful gases such as styrene in advanced industries.

The RTM molding process generally adopts a low-pressure injection process, which is conducive to the preparation of complex overall structures with large sizes, complex shapes, and two-sided surfaces.

According to the requirements of the production scale, RTM molds can be selected from different grades of molds such as polyester molds, epoxy molds, surface nickel-plated material molds, alloy molds, aluminum molds and steel molds to reduce costs.

Requirements of RTM technology on epoxy resin systems

Epoxy resin has low viscosity at room temperature or lower temperature, and has a certain storage period.

Epoxy resin has good wettability, matching and adhesion to reinforced materials.

The epoxy resin system has good curing reactivity and does not produce volatile matter and other undesirable side reactions during the curing reaction. The curing temperature should not be too high, and the curing speed should be appropriate.

As a high-performance composite material, epoxy resin is also required to have high heat resistance and moisture resistance, excellent mechanical properties, especially toughness. In some special applications, it should also have certain functionalities, such as low dielectric loss, high conductivity, excellent flame retardancy, etc.

High-performance epoxy resin system is still the most widely used high-performance composite matrix. Epoxy resin systems usually used to make prepregs are difficult to mold using the RTM process due to their high viscosity and short storage life. In order to be suitable for RTM molding, YQXPOLYMER launched the 9320A/B epoxy resin curing system. 9320A/B is a special epoxy resin curing system for RTM process. This system product is composed of special epoxy resin and modified amine curing agent. The 9320A/B epoxy resin curing system has the characteristics of fast curing speed, good water resistance, high hardness, good adhesion, mechanical properties of the cured material and high Tg temperature. It can be widely used in automotive composite materials for RTM molding, cultural and sports products (fishing rods, badminton rackets, golf clubs, etc.) and other carbon fiber composite materials. The RTM process has a wide range of advantages. The molded parts have high fiber system content, low porosity, low water absorption, and good mechanical properties. Conventional resins and reinforcing materials can be used in the RTM process.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#RTM#RTM molding process#epoxy resin supplier#epoxy resin system#RTM process#resin transfer molding#epoxy composite material#epoxy resin curing system#composite material

0 notes

Text

High-Temperature Composite Materials Industry: Global Overview, Size, Analysis, Growth Opportunities, Top Manufacturers, Market Share, Trends, Segmentation, Regional Analysis, and Forecast

High-temperature composite materials are a class of composite materials that are designed to withstand extreme temperatures. These materials are used in a variety of applications, including aerospace, automotive, and industrial applications. The materials are composed of a combination of two or more components, such as carbon fibers, glass fibers, and resin, which are designed to retain their…

View On WordPress

#High-temperature Composite Materials#High-temperature Composite Materials Market#High-temperature Composite Materials Market Size#High-Temperature Composite Materials Market Companies#High-Temperature Composite Materials Market Manufacturers#High-Temperature Composite Materials Market Market Analysis#High-Temperature Composite Materials Market Market Forecast#High-Temperature Composite Materials Market Market Opportunities#High-Temperature Composite Materials Market Market Share#High-Temperature Composite Materials Market Market Trends

0 notes

Text

Alloy analyzer

Labmate alloy analyzer is an XRF spectrometer that exmines an extensive array of elements from sodium to uranium with an analytical range of PPM to 99.99% it provide an ambient temperature of 15°C to 30°C for proper and accurate analysis.

0 notes

Text

How Multilayer Composite Pipe Technology is Reshaping Industries

Introduction

Multilayer composite pipe technology, a novel technology is a driver of the revolution in industrial processes and transportation of water and fluids via pipelines around the world. Nexgen Composite Services, a leading company manufacturing Multilayer Composite Pipe Manufacturers Company in India, is spearheading this revolution in the field.

The undisputed player in innovation and quality, Nexgen is on a mission to revolutionize industries and enhance workability by producing some of the most advanced pipes in the world, which are specially designed to suit the unique needs of the different sectors.

By concentrating on being the first to implement new technologies, Nexgen’s devotion implies that enterprises have best-of-class products that help improve endurance and productivity.

Serving as an integrated partner, Nexgen Composite Services recreates, remaps, and reimagines the internal landscape of the oil and gas, water, pulp, and paper industry to a sustainable, robust, and prosperous future.

The Evolution of Multilayer Composite Pipes

The two-layer composite pipe structure signifies a major advancement in the piping system as the components are not only inherently durable but also, more flexible than many other existing pipes.

These pipes show up in different sections, with each serving its own operational need as part of the composite whole. The inside layer, which is normally made of protein cross-linked (PEX), provides friction-free flow of the fluid; the outer layers, however, give the tube strength and protection from damage.

Developing cutting-edge design, multilayer composite pipes can cater to high pressure and temperature fluctuation, thus this makes them among the best products to be used in diverse fields.

Advantages of Multilayer Composite Pipe Manufacturers Company in India

Switching from the currently used multiple piping methods to composite multi-layer piping technology creates a huge number of advantages for industries. Another advantage of this is improved resilience since pipes reduce corrosion, abrasion, and chemical wear.

Besides, their lightness and easy installation are the factors that make their installation simple and low cost concerning both time and labor. Composite-layer pipelines also have high thermal insulation intrinsic to their structures, meaning that they can dispel the heat they are generating well and are electricity-efficient.

Offering the benefit that they will surpass the lifespan of the piping materials of the past, this takes care of cost savings and overall sustainability.

Applications across Industries

Multilayer composite pipes are best known as very punctual and effective pipes with a wide range of applications both in industries and beyond. The pipes for residential constructions especially for plumbing systems are a sort of preference since they can withstand corrosion better and flex easily in case of the need.

Since they are capable of tolerating many adverse conditions, their use in residential areas should be promoted for long-term dependability outcomes are needed.

In commercial buildings or industrial facilities, multilayer composite pipes play a fundamental role in heating, ventilation, and air conditioning (HVAC) systems compressed air lines, or process piping. Their bulky designs allow them to cope with high pressures and temperature varying, and they cannot be replaced by any other devices in an extremely regulated environment.

Businesses for example, oil and gas, chemical processing, or marine engineering fields widely benefit from these multiply layered pipeline approaches because they offer efficiency and sturdiness of the materials.

For whatever purpose, multilayer composite pipes can always be mixed with the versatility and performance features of the pipe systems which can frequently be found in residential, commercial, and industrial settings as well as other fields of application.

Environmental Impact and Sustainability

Being environmentally friendly has become an essential that has made the use of multilayer the material pipes as eco-friendly substitutes to conventional materials. A notable eco-friendly and carbon-reducing feature of the structure is its lightweight construction.

Transport and installation processes emit less carbon, which has a positive effect on the environment and eventually lowers the overall carbon footprint of the project. In addition, because of the durability and life service of multilayer composite pipes, there will be fewer replacements and as a result waste production has been reduced.

The use of recyclable materials and reduction of waste through this may thus put the fluid conveyance systems on the ‘sustainable’ foot. With the help of resource conservation and energy savings, the multilayer composite pipes are seeing the day of the day in achieving a green tomorrow.

Factories that value sustainability may show extensive gains via piping application, which can be seen not only in the realization of environmental goals but also a long-term cost savings and operational efficiency.

Nexgen Composite Services

Nexgen Composite Services is the pioneer in setting in motion the Multilayer Composite Pipe Manufacturers Company in India revolution and comes up as the first-ever Multilayer Composite Pipe Manufacturers Company in India.

The company achieves this by integrating advanced production methods with best-in-class materials creating a resultant pipe that not only meets the strictest quality and performance standards but also exceeds them.

Their broad range of products has different industries such as construction, plumbing, HVAC, and utilities, a characteristic which shows product adaptability and versatility in meeting different needs because of their client’s requirements in various sectors.

Nexgen is unique from other competitors in that it has a forever big ambition in the index of customer satisfaction and technology innovation. With client needs first in priority and the piping technology always at the front, Nexgen is a go-to and trusted partner of all businesses forged to supply their dependable piping needs.

In a world where industrial practices continue to adapt and improve, Nexgen Composite Services itself will remain the reliable and innovative pilot that will steer multilayer composite pipes toward becoming the most advanced technical solution for pipe-related systems in the industry.

FAQs about Multilayer Composite Pipe Manufacturers Company in India

Q1. How does Nexgen Composite Services ensure product quality and reliability?

Nexgen Composite Services ensures that there is no detour from the normal quality standards throughout production; thereby the quality control is constant. Compliance with industry standards and protocols is ensured by their selection of first-grade material, starting from raw material selection to the final product inspection process. They guarantee that every Multilayer Composite Pipe Manufacturers Company in India is manufactured according to the highest quality criteria as a result.

Q2. How do multilayer composite pipes beat the traditional piping materials?

Plastic composites, particularly multilayer pipe, possess properties like corrosion resistance, flexibility, and thermal insulation, unlike monolayer pipe made out of metal materials. In contrast to single-layer materials of a conventional type such as metal or PVC, Multilayer Composite Pipe Manufacturers Company in India systems not only give the best performance but also the most durable, which makes them suitable for industrial use that is more complex and demanding.

Q3. Multilayer composite pipes advancement impacts industries in these ways: What benefits do industries get from multilayer technology adoption?

Industries are set to benefit from several advantages by embracing Multilayer Composite Pipe Manufacturers Company in India technology such as reduced cost, greater improvement in the durability aspects, and enhanced sustainability consideration. Through the application of Nexgen Composite Services’ innovative piping systems, companies will get the best efficiency and will keep their leadership position in a competitive market.

Conclusion

There are no doubts left that the emergence of Multilayer Composite Pipe Manufacturers Company in India technology brings about implementation in different industries and leads the conveyance systems of fluids to innovative phases.

The Nexgen Composites Services with a reputation for excellence in the field of Nigeria holds a front seat in this transformation-inclined journey. In pursuit of perfection and by using constant innovation, Nexgen becomes a driving force in all industries leading to overcoming difficulties and embracing new horizons.

With the rise of people’s awareness about efficiency and environmental sustainability, the demand for multilayer composite pipes will be always high. As a result, these pipes will remain among the essential infrastructure elements that will lead the world to a more resilient and connected environment.

0 notes

Photo

Eco‐friendly 3D printed polymer composite parts made from chitosan of terrestrial insects

An international interdisciplinary team of researchers from India, Malaysia, Singapore and Thailand has successfully developed a method of using chitosan from terrestrial insects to manufacture eco‐friendly polymer composite parts using the 3D printing method.

3D printing is a form of additive manufacturing technology that is becoming increasingly popular in recent times due to its ability to produce complex shapes and geometries that were difficult to achieve using traditional manufacturing techniques. As a result, the demand for raw material for 3D printing is on the rise. It is crucial to ensure responsible usage of raw materials for 3D printing to meet the UN Sustainable Development Goal 12, i.e., promoting sustainable consumption and production patterns.

Chitosan is a natural biopolymer that is derived from chitin, a polysaccharide found in the exoskeletons of arthropods such as insects, as well as in sea creatures such in the shells of crabs. Terrestrial insects are a potential source of chitosan due to their abundance, accessibility, and relatively high chitin content in their exoskeletons. There are several potential benefits to extracting chitosan from terrestrial insects, including sustainable and eco-friendly production.

Read more.

#Materials Science#Science#3D printing#Chitosan#Insects#Polymers#Composites#Biomaterials#Additive manufacturing

16 notes

·

View notes

Text

#Accredited Testing labs in Chennai#material testing laboratories in chennai#plastic manufacturing#maeon laboratories#chennai#composite testing laboratory

1 note

·

View note

Text

Viva, the stand-out company among all aluminium composite panel manufacturers, has been pioneering breakthroughs for the past 20 years in the field of ACP manufacturing.

#Aluminium Composite Panel manufacturers#Aluminium Composite Panel Suppliers#ACP Panel Manufacturers

0 notes