#Lightweight Composites

Text

Glass Type Polyurethane Composites Driving Growth in Transportation and Construction Industries: Market Analysis and Projections by 2026

The report “Polyurethane Composites Market by Type (Glass, Carbon), Manufacturing Process (Lay-Up, Pultrusion, Resin Transfer Molding), End-Use Industry (Transportation, Building & Construction, Electrical & Electronics), Region – Global Forecast to 2026″, The global polyurethane composites market is projected to reach USD 909.8 Million by 2026, at a CAGR of 5.9% from 2016 to 2026. Increase in…

View On WordPress

#Composite Manufacturing#Composite Materials#Composite Properties#Fiber-Reinforced Composites#Global Polyurethane Composites Market#Key Players in the Polyurethane Composites Market#Lightweight Composites#Market Dynamics of Polyurethane Composites#Market Opportunities for Polyurethane Composites#Market Size of Polyurethane Composites#Market Trends for Polyurethane Composites#Polyurethane Composites#Polyurethane Composites Industry#Polyurethane Composites Manufactures#Polyurethane Composites Market#Polyurethane Composites Market Analysis#Polyurethane Composites Market Forecast#Polyurethane Composites Market Growth#Polyurethane Composites Market Outlook#Polyurethane Composites Market Segmentation#Polyurethane Composites Market Share#Polyurethane Resins#Reinforcement Fibers#Structural Composites

0 notes

Text

Basalt Fiber Reinforcement in Construction: A Sustainable Paradigm Shift

Introduction

In the contemporary construction landscape, a notable shift towards sustainable and eco-friendly building materials is underway. Among the alternatives gaining prominence is basalt fiber reinforcement, positioning itself as a compelling substitute for traditional steel reinforcement. This transition is fueled by a collective desire to reduce environmental impact and elevate the…

View On WordPress

#alternative to steel reinforcement#basalt fiber applications#basalt fiber properties#Basalt fiber reinforcement#basalt mesh in concrete#BFRP composites#construction industry sustainability#corrosion-resistant materials#durability in construction#eco-friendly building#environmental impact of construction#future of construction materials.#green building practices#lightweight construction materials#seismic resilience in buildings#steel replacement in construction#strength-to-weight ratio#Sustainable Construction Materials#sustainable structural design#thermal insulation in construction

2 notes

·

View notes

Text

guys i am so.. i can’t even put this into words idk. brain yearn

#if i don’t stop getting high around this girl i will fall in love fully i mean it my brain will explode#last night was so funnn got to show rhps to a rocky horror virgin and The Girl#i was higher than both of them combined. like literally i’m a lightweight i think And i took more than them#ohh it was awesome#i get mad twitchy when i’m high though. like i’ll be shivering and twitching for no reason#anyway watching rhps as the high hit and then watching the grand budapest hotel super stoned was soo fun#i hope they appreciated the grand budapest & my rambles about shot compositions every ten seconds#aesthetically pleasing ass movie#anyway we got off topic here. being high around her is addicting literally

3 notes

·

View notes

Text

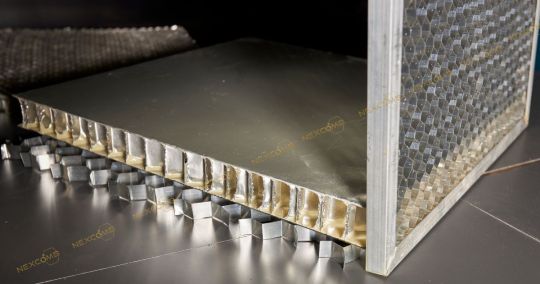

#aluminium composite panel#Honeycomb Panels#Aluminium Honeycomb Panels#Aluminium Honeycomb Core#Lightweight Honeycomb Panels

0 notes

Text

#Ceramic Matrix Composites Market#Strength#Resilience#Lightweight#High-Temperature Resistance#Aerospace#Automotive#Energy#Market Trends#Innovations#Key Players#Emerging Technologies#Regulatory Factors

0 notes

Text

Epoxy Resin Carbon Fiber Composite Material Helps Lighten New Energy Vehicles

In recent years, as global environmental protection standards have become stricter and consumer demand has increased, many countries have introduced industrial support policies to support the research and development of new energy vehicle technologies and further promote the entire industry chain and ecological construction of new energy vehicles.

According to statistics from the authoritative organization EV-Volumes: In May 2023, global electric vehicle sales exceeded one million units for the first time, reaching 1,057,509 units. This is the fifth time in history that this feat has been achieved.

As the global electric vehicle market continues to grow and consumer demand for environmentally friendly travel increases, the sales momentum of electric vehicles will continue to grow. In order to meet market demand, major automobile manufacturers are continuously increasing investment and launching more electric vehicle products.

However, the electric vehicle market still faces some challenges. How to further improve the performance of new energy vehicles? The answer is automobile lightweighting.

Lightweighting of automobiles--reducing the mass of the automobile body as much as possible without reducing the strength and safety performance of the automobile.

How to choose lightweight materials?

From the performance comparison between carbon fiber composite materials and other lightweight materials, we can clearly see that carbon fiber composite materials have the smallest density and their strength performance is far superior to other lightweight materials. Using carbon fiber reinforced epoxy resin composites (CFRP) to partially replace traditional metal materials is currently one of the most effective ways to achieve lightweighting in automobiles.

How are carbon fiber composite materials produced?

High-pressure resin transfer molding process, referred to as HP-RTM molding process. It refers to the molding process of using high-pressure pressure to mix and inject resin into a vacuum-sealed mold pre-laid with fiber reinforced materials and pre-set inserts, and then through resin flow filling, impregnation, curing and demoulding to obtain composite products. Low-cost, short-cycle (large-volume), and high-quality production can be achieved.

Carbon fiber composite products for automotive use

These exquisite carbon fiber composite materials are made from high-performance epoxy resin systems and carbon fiber materials through the HP-RTM process, and have been used in new energy vehicles on a large scale, effectively achieving the effect of lightweighting the vehicle.

What are the characteristics of the epoxy resin formula system used in HP-RTM process?

The epoxy resin formula system used in the HP-RTM process has the characteristics of fast curing speed, high defoaming, high wettability, low viscosity, low volatility, low curing shrinkage, low exothermic peak, and etc.

The 0164 series epoxy resin produced by YQXPOLYMER, combined with the HP-RTM special epoxy resin curing agent system, has the advantages of fast curing and molding speed, low exothermic peak during the curing process, good wettability with reinforcing fibers, and high physical and mechanical strength of the product. It is completely suitable for HP-RTM molding process and is a high-quality material for preparing carbon fiber composite materials for automobiles.

YQXPOLYMER will use its consistent high quality to protect automotive carbon fiber composite materials and efficiently promote the development of the new energy vehicle lightweight industry.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#carbon fiber composite material#automobile lightweighting#YQXPOLYMER

1 note

·

View note

Text

Explore a Master's in Lightweight Engineering Composites in Germany. Learn about advanced materials and design high-performance structures. Join the best university and become skilled in technology for a sustainable future. Start your journey in engineering excellence today.

0 notes

Text

Continuous Bending-mode Elastocaloric Composite Refrigeration System for Compact Lightweight High-Efficiency Cooling

Nenad Miljkovic University of Illinois at Urbana-Champaign Traditional elastocaloric refrigeration systems are based on uniaxial compression of the elastocaloric material which makes them highly constrained by actuator requirements, the physics of column buckling, and limited surface area for heat transfer. Professor Miljkovic will investigate a novel elastocaloric system based on bending of the elastocaloric material, […]

from NASA https://ift.tt/0RUkMI1

#NASA#space#Continuous Bending-mode Elastocaloric Composite Refrigeration System for Compact#Lightweight#High-Efficiency Cooling#Michael Gabrill

0 notes

Text

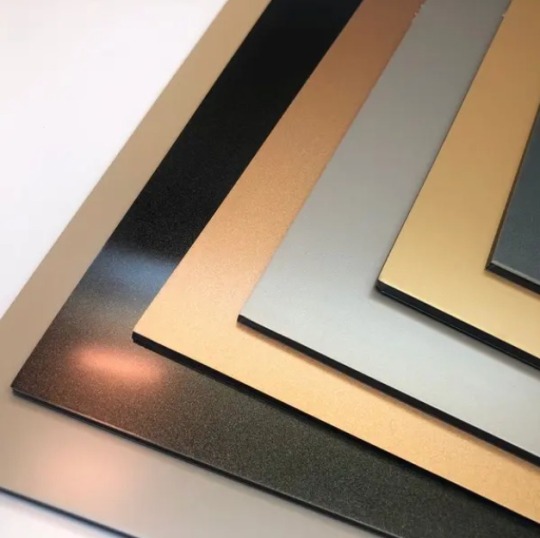

Aluminum composite panels (ACM) are a type of composite material made from two thin sheets of aluminum bonded to a polyethylene core. They are lightweight, durable, and easy to maintain. ACM panels are often used in exterior applications, such as cladding, roofing, and signage.

Here are some of the benefits of using ACM panels:

Lightweight. ACM panels are lightweight, which makes them easy to install and maintain.

Durable. ACM panels are durable and can withstand the elements.

Easy to maintain. ACM panels are easy to maintain and do not require regular cleaning or painting.

Versatile. ACM panels can be used in a variety of applications, including cladding, roofing, signage, and insulation.

Cost-effective. ACM panels are a cost-effective option for a variety of applications.

If you are looking for a material for an exterior application, ACM panels are a good option. They are lightweight, durable, easy to maintain, and versatile.

Please call or fill out our online form to request an estimate or ask general questions about our services. We are excited to serve you!

(718) 517-9178

https://www.skywindowsnj.com/

#aluminumcompositepanels#acppanels#compositepanels#aluminiumcompositepanels#exteriorpanels#cladding#roofing#signage#insulation#cost-effective#lightweight#contractor#brooklyn windows#window installation nyc#design#nyc windows#Aluminum composite panels

0 notes

Text

#Composite materials market#Carbon fiber technology market#Thermoplastic resins market#Lightweight materials market

0 notes

Text

Types of Fillers in Construction

Introduction

Fillers play a pivotal role in construction, providing stability, strength, and insulation. Their selection is critical, affecting the cost, durability, and environmental impact of a project. This article delves into the various types of fillers utilized in the construction industry.

1. Natural Fillers

Natural fillers like sand, gravel, and stone are ubiquitous in construction due to…

View On WordPress

#aerogel insulation in construction#carbon fiber for structural reinforcement#composite fillers in construction#construction aggregate materials#construction filler selection guide#construction fillers#construction industry standards for fillers#construction material innovation#cost-effective fillers for construction#durable fillers for construction#eco-friendly construction fillers#EPS beads in construction#fiber-reinforced concrete#fiberglass in concrete#fly ash concrete filler#graphene in building materials#insulation panels in construction#lightweight construction fillers#mineral fillers in concrete#natural fillers in construction#organic fillers for construction#silica fume in construction#specialty construction fillers#sustainable building materials#synthetic fillers for building#thermal insulation fillers#types of construction fillers

2 notes

·

View notes

Text

Sixaluminium - Devasa+

Aluminum extrusion is a process used to create parts with specific cross-sectional profiles by pushing heated alloy material through a die. This process allows for the creation of various shapes and sizes, making it a versatile method for manufacturing aluminum profiles. Despite its importance, many people may not even notice the prevalence of aluminum extrusions in their homes. In Turkey aluminium manufacturer, companies like Aluminance Aluminum Industry and Trade Inc. and Ş. are leading manufacturers of aluminum extrusion profiles and composite panels. These companies play a crucial role in providing high-quality aluminum extrusion products for various industries, including construction. The construction industry greatly benefits from the use of aluminum extrusion profiles. Aluminum construction are lightweight, strong, and corrosion-resistant, making them ideal for construction applications. They are commonly used in windows, doors, and other architectural elements due to their structural integrity and cost benefits. Additionally, aluminum extrusions offer sustainability advantages as they are recyclable and can be repurposed for other projects . The use of aluminum extrusions in construction also contributes to faster construction timelines, as they can be easily fabricated and installed. Overall, aluminium systems profiles have become an essential component in the construction industry, offering a range of benefits for architects, builders, and homeowners alike. In Turkey aluminium extrusion manufacturers like Ş. have played a significant role in supplying the construction industry with high-quality aluminum profiles. These profiles are used in various applications, including aluminum systems for windows, doors, and facades . The 40-Series Aluminium Extrusion Profile produced in the EU is a popular choice for construction pr aluminium veranda ojects due to its quality and durability. The use of aluminum extrusion profiles in construction not only enhances the aesthetics of buildings but also provides structural stability and longevity. With the continued advancements in aluminum extrusion technology, the construction industry can expect further innovation and development in the utilization of aluminum profiles for various architectural and structural applications.

2K notes

·

View notes

Text

explaining f1: the cars

chassis

modern day f1 cars are constructed from composites of carbon fibre and other ultra-lightweight materials. the minimum weight currently permissible is 740kg including the driver but not the fuel.

engines

as of the 2014 season, all f1 cars have been equipped with turbocharged 1.6 l v6 engines, which were previously banned in 1989. this change gave up to a 29% increase in fuel efficiency.

transmission

f1 cars use highly automated semi-automatic sequential gearboxes, with regulations stating that 8 forward gears and 1 reverse gear must be used, with rear-wheel drive. fully automatic gearboxes are illegal to keep driver skill. the last f1 car fitted with a conventional manual gearbox was the forti fg01 which raced in 1995.

as of 2009, all teams use seamless-shift transmissions, which allow a near instantaneous changing of gears for minimal time loss. shift times for modern f1 cars are in the range of 2-3ms.

steering wheel

the wheel can be used to change gears, adjust the fuel/air mix, change the break balance and call the radio among other things, allowing the driver a huge amount of control. data such as engine rpm, lap times and tyre temperature etc. are displayed.

fuel

the fuel in f1 cars is fairly similar to ordinary petrol.

to make sure teams and fuel suppliers are within regulation, the fia requires fuel teams like shell, petronas etc. to submit samples of the fuels they are providing for races. at any time, fia inspectors can request a sample from the fuelling rig to compare. the teams usually abide by rules but in 1997 mika hakkinen was stripped of his third place finish in spa due to his fuel being the incorrect formula.

tyres

you can read all about tyres in f1 here!

breaks

the brakes used in f1 cars are designed to work in up to 1,000 degrees celsius.

drivers can control brake force to compensate for changes in track condition or fuel load.

notable cars

the victorious red bull racing rb18 from the 2022 season, driven max verstappen.

the dominant mclaren mp4/4 driven by ayrton senna in 1988.

the highly successful ferrari f2004 driven by micheal schumacher at the 2004 united states grand prix.

the 1994 williams fw15c, widely considered to be one of the most technologically advanced f1 car of all time

the first f1 car to be powered by a turbocharged engine; the 1997 renault rs01.

the lotus 78, which exploited the aerodynamic effects of downforce, or ground effect, which was banned by the fia in 1983 (though it was later brought back for the 2022 season onwards).

the 2009 brawn bgp001, using a 'double diffuser' (to harness downforce) which was banned by the fia in 2011.

#f1#alex albon#carlos sainz#charles leclerc#fernando alonso#formula one#george russell#lance stroll#lando norris#lewis hamilton#formula 1#f1 2024#imola 2024#imolagp#italy 2024#logan sargeant#oscar piastri#sebastian vettel#jenson button#kimi raikkonen#kimi räikkönen#mercedes f1#ferrari#mclaren#aston martin#mark webber

106 notes

·

View notes

Note

What do you think about Khorne as not only the god of blood, but also bones? Bone is not uniformly solid, and he is the "skulls for the skull throne" anyways haha. Bone, hey, strong, but consists of a flexible matrix (about 30%) and bound minerals (about 70%), which are intricately woven and continuously remodeled by a group of specialized bone cells.

This isn't even to mention Nurgle. And bones.. Their unique composition and design allows bones to be relatively hard and strong, while remaining lightweight.

Bone matrix is 90 to 95% composed of elastic collagen fibers, also known as ossein, and the remainder is ground substance. Maybe more in Age of Sigmar than 40k? The elasticity of collagen improves fracture resistance. The matrix is hardened by the binding of inorganic mineral salt, calcium phosphate, in a chemical arrangement known as bone mineral, a form of calcium apatite. It is the mineralization that gives bones rigidity. Just my two cents.

I mean, he’d have to fight Nagash for bones in AoS, but I do like the idea of a warband devoted to Khorne who are focused on the skull-taking as part of some wider aspect of bone collection. In fact, I think a Khornate group based out of the realm of death who are causing issues with the Bonereapers because of this would be super cool. Plus, you would be able to explore how the culture of Shyish intermingled with Khorne worship to creates such a particular facet of chaos worship.

I like it!

38 notes

·

View notes

Text

ReShade Preset Recommendations

I'll start a content boost with some preset recommendations for the crowd adjusting to the post-gshade world.

Purple Cocoon Reborn, Maya

I've been using Purple Cocoon a lot these days since they updated it for compatibility with ReShade. Free, versatile, and very comprehensive; the link below provides excellent instructions for those wondering how to properly set up your ReShade installation. Make sure you download parts 1 and 2.

Download

Wi-Fi Presets

WiFi_photospire is the creator of a preset collection with custom textures for sophisticated compositions; an excellent choice with gorgeous results if you like to play with light sources.

Download

Expresso Glow

espressolala's Expresso Glow is an old favorite that's also available for Reshade. Excellent performance and awesome, crisp results with great color balance.

You can use the Espresso Glow program to install just the presets and textures by selecting "Install with Compatibility Mode": It'll preserve your current ReShade version and all installed presets.

Install Instructions and download

Yomigami Okami

One that I recently rediscovered is Yomigammy's Yomigami Okami, ported to vanilla ReShade 5.6 by meynan_ffxiv. A very flexible, lightweight collection of 14 presets, and the aspect I like the most is how it handles wood tones in general, lovely enhancing warmth without oversaturating.

Download

Do you have any other ReShade preset collections that you like? Let me know!

225 notes

·

View notes

Text

Moreno 2681 by palca estudio

The project is located in Balvanera, a central neighbourhood of Buenos Aires that presents a heterogeneous built profile with a strong commercial presence and an identity characterised by cultural diversity. This pattern is further consolidated when understanding its direct link with the building of the Argentine National Congress, with the large number of hotels distributed throughout the area or with the Miserere Square, that acts as a hub for trains, buses and subways. Balvanera could be interpreted as a neighbourhood of national identity.

Architecture as identity. The assignment originates from the clients' need to have administrative offices in new building that determines their identity as an institution. These offices had to be complemented by apartments to be used by people travelling from the provinces of Argentina to Buenos Aires for a certain period of time. Among the clients' initial demands was the use of a glass façade as an image towards the city, which for us was an essential part of the initial program.

The potential of mixed uses. The initial idea was to locate work and domesticity in the same block. This option was rapidly discarded after the first tests when the incompatibility of the circulation dynamics was verified. Taking advantage of the long proportion of the site (7.60 x 47.60 m) it was then decided to divide the uses into two independent blocks: the office one in the front, more exposed to the street and the domestic one in the back, more reserved in the centre of the block. In this way, a daily relationship is generated between all the people who inhabit the building while providing privacy in each of the parts.

Adapt to the given conditions. Both blocks adjust their buildable profile to the limits determined by the internal front line. This imaginary line is determined by the Government of the City of Buenos Aires to delimit a non-buildable area in the centre of the block. Instead of looking for alternatives to deal with this restriction, the project adapts to the resulting silhouette. In this way, two individual blocks are proposed to take advantage of all the possible footprint and are developed with the necessary height to deal with the proposal.

The void as a meeting place. Both building blocks are connected through a central void that works as a meeting point. This void is projected through a garden of organic shapes, white stones and growing vegetation that aims to generate meeting places for the people who work and inhabit the building.

Versatile and timeless from the beginning. The office block is planned on four levels with open spaces that allow to deal with the constant changes in today's work dynamics. Each level has outdoor spaces materialised by balconies on the lower floors and a terrace on the upper floor. The domestic block is also planned on four levels but made up of two stacked duplex apartments. Each one of them operates as an individual unit designed with the minimum elements necessary to be temporarily inhabited.

How to be efficient in the Argentine context. In an economic context as complex and variable as the Argentine one, it is necessary to be rational and efficient in the materialisation of architecture. In that sense, the construction of the building is proposed in a synthetic and traditional way through the implementation of few elements, but optimising their use. To do this, we proposed a reinforced concrete skeleton and lightweight masonry walls, textured white anodised aluminium frames in the windows and airtight double glazing for greater thermal efficiency. In this way, we make it easier to deal with suppliers while achieving efficiency and durability in the use of the elements.

A new way of perceiving the environment. Faced with a complex and heterogeneous urban context, the project is created from synthesis as contrast. Pure lines, geometric composition and white elements characterise a building that aims to communicate order and timelessness.

Design: palca estudio

Location: Balvanera, Buenos Aires, Argentina

Year: 2023

Photography: Javier Agustín Rojas

22 notes

·

View notes