#Fiber-Reinforced Composites

Text

Glass Type Polyurethane Composites Driving Growth in Transportation and Construction Industries: Market Analysis and Projections by 2026

The report “Polyurethane Composites Market by Type (Glass, Carbon), Manufacturing Process (Lay-Up, Pultrusion, Resin Transfer Molding), End-Use Industry (Transportation, Building & Construction, Electrical & Electronics), Region – Global Forecast to 2026″, The global polyurethane composites market is projected to reach USD 909.8 Million by 2026, at a CAGR of 5.9% from 2016 to 2026. Increase in…

View On WordPress

#Composite Manufacturing#Composite Materials#Composite Properties#Fiber-Reinforced Composites#Global Polyurethane Composites Market#Key Players in the Polyurethane Composites Market#Lightweight Composites#Market Dynamics of Polyurethane Composites#Market Opportunities for Polyurethane Composites#Market Size of Polyurethane Composites#Market Trends for Polyurethane Composites#Polyurethane Composites#Polyurethane Composites Industry#Polyurethane Composites Manufactures#Polyurethane Composites Market#Polyurethane Composites Market Analysis#Polyurethane Composites Market Forecast#Polyurethane Composites Market Growth#Polyurethane Composites Market Outlook#Polyurethane Composites Market Segmentation#Polyurethane Composites Market Share#Polyurethane Resins#Reinforcement Fibers#Structural Composites

0 notes

Text

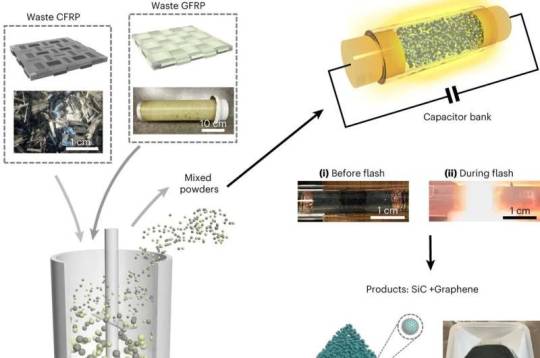

Recycling research finds new process to transform glass fiber-reinforced plastic into silicon carbide

Glass fiber-reinforced plastic (GFRP), a strong and durable composite material, is widely used in everything from aircraft parts to windmill blades. Yet the very qualities that make it robust enough to be used in so many different applications make it difficult to dispose of—consequently, most GFRP waste is buried in a landfill once it reaches its end of life.

According to a study published in Nature Sustainability, Rice University researchers and collaborators have developed a new, energy-efficient upcycling method to transform glass fiber-reinforced plastic (GFRP) into silicon carbide, widely used in semiconductors, sandpaper, and other products.

"GFRP is used to make very large things, and for the most part, we end up burying the wing structures of airplanes or windmill blades from a wind turbine whole in a landfill," said James Tour, the T.T. and W.F. Chao Professor and professor of chemistry and of materials science and nanoengineering. "Disposing of GFRP this way is just unsustainable. And until now, there has been no good way to recycle it."

Read more.

#Materials Science#Science#Recycling#Composites#Fiber reinforcement#Plastics#Polymers#Glass fibers#Fibers#Glass#Waste#Rice University#Materials processing

24 notes

·

View notes

Text

Basalt Fiber Reinforcement in Construction: A Sustainable Paradigm Shift

Introduction

In the contemporary construction landscape, a notable shift towards sustainable and eco-friendly building materials is underway. Among the alternatives gaining prominence is basalt fiber reinforcement, positioning itself as a compelling substitute for traditional steel reinforcement. This transition is fueled by a collective desire to reduce environmental impact and elevate the…

View On WordPress

#alternative to steel reinforcement#basalt fiber applications#basalt fiber properties#Basalt fiber reinforcement#basalt mesh in concrete#BFRP composites#construction industry sustainability#corrosion-resistant materials#durability in construction#eco-friendly building#environmental impact of construction#future of construction materials.#green building practices#lightweight construction materials#seismic resilience in buildings#steel replacement in construction#strength-to-weight ratio#Sustainable Construction Materials#sustainable structural design#thermal insulation in construction

2 notes

·

View notes

Text

Summary of 25 plastic reinforced modification formulas and 20 key points involved

There are many common plastic modification technologies, mainly reinforcement technologies, including fiber reinforcement, self-reinforcement, and molecular reinforcement; toughening technology; filling modification; blending and plastic alloy technology; flame retardant technology; nanocomposite technology; reaction grafting modification; aging resistance; functional modification, including…

View On WordPress

#Antistatic glass fiber reinforced PA6 impeller#Chopped glass fiber reinforced PP#Compatibilizer#Composite reinforced PP#Engineering plastic reinforced formula#Enhanced PF for chemical anti-corrosion pipelines#Epoxy fiberglass#Epoxy phenolic fiberglass#Flame retardant and antistatic reinforced PA6#Flame retardant glass fiber reinforced PA6 impeller#GF enhanced RJM-PU#Glass fiber reinforced PP#Glass fiber reinforced PVC#Glass fiber reinforced PVDC special-shaped components#High performance glass fiber reinforced PP#High strength unsaturated polyester board#Long glass fiber reinforced PA6#Mica reinforced PP#No. 771 unsaturated polyester fiberglass#plastic modification technologies#plastic reinforced modification formulas#PS coloring formula#thermoplastic reinforced formulations#Thermoset reinforced formulations#Transparent glass fiber reinforced PC#UHMWPE/carbon fiber composite materials#Wollastonite fiber-filled reinforced PP

0 notes

Text

New Process Allows Full Recovery of Starting Materials From Tough Polymer Composites - Technology Org

New Post has been published on https://thedigitalinsider.com/new-process-allows-full-recovery-of-starting-materials-from-tough-polymer-composites-technology-org/

New Process Allows Full Recovery of Starting Materials From Tough Polymer Composites - Technology Org

In a win for chemistry, inventors at the Department of Energy’s Oak Ridge National Laboratory have designed a closed-loop path for synthesizing an exceptionally tough carbon-fiber-reinforced polymer, or CFRP, and later recovering all of its starting materials.

A polymer, functionalized carbon fibers and a crosslinker are mixed and cured. The components can be retrieved by addition of an alcohol, pinacol. Credit: Philip Gray and Anisur Rahman/ORNL, U.S. Dept. of Energy

A lightweight, strong and tough composite material, CFRP is useful for reducing weight and increasing fuel efficiency of automobiles, airplanes and spacecraft. However, conventional CFRPs are difficult to recycle. Most have been single-use materials, so their carbon footprint is significant. By contrast, ORNL’s closed-loop technology, which is published in Cell Reports Physical Science, accelerates addressing that grand challenge.

“We incorporated dynamic crosslinking into a commodity polymer to functionalize it. Then, we added a crosslinker to make it like thermoset materials,” said ORNL chemist and inventor Md Anisur Rahman. “Dynamic crosslinking allows us to break chemical bonds and reprocess or recycle the carbon fiber composite materials.”

A conventional thermoset material is permanently crosslinked. Once synthesized, cured, molded and set into a shape, it cannot be reprocessed. ORNL’s system, on the other hand, adds dynamic chemical groups to the polymer matrix and its embedded carbon fibers. The polymer matrix and carbon fibers can undergo multiple reprocessing cycles without loss of mechanical properties, such as strength and toughness.

Rahman led the study with ORNL chemist Tomonori Saito, who was honored by Battelle in 2023 as ORNL Inventor of the Year. Rahman and ORNL postdoctoral fellow Menisha Karunarathna Koralalage conducted most of the experiments. The trio has applied for a patent for the innovation.

“We invented a tough and recyclable carbon fiber composite,” said Saito. “The fiber and the polymer have a very strong interfacial adhesion due to the presence of dynamic bonds.” The interface locks materials together through covalent interactions and unlocks them on demand using heat or chemistry. Saito added, “The functionalized fiber has dynamic exchangeable crosslinking with this polymer. The composite structure is really tough because of the interface characteristics. That makes a very, very strong material.”

Conventional polymers like thermoset epoxies are typically used to permanently bond materials such as metal, carbon, concrete, glass, ceramic and plastic to form multicomponent materials such as composites. However, in the ORNL material, the polymer, carbon fibers and crosslinker, once thermoset, can be reincarnated back into those starting materials. The material’s components can be released for recycling when a special alcohol called a pinacol replaces the crosslinker’s covalent bonds.

Closed-loop recycling at laboratory scale results in no loss of starting materials. “When we recycle the composites, we recover 100% of the starting materials — the crosslinker, the polymer, the fiber,” Rahman said.

“That’s the importance of our work,” Saito said. “Other composite recycling technologies tend to lose the component starting materials during the recycling process.”

Other advantages of the reversibly crosslinked CFRPs are quick thermosetting, self-adhesive behavior and repair of microcracks in the composite matrix.

In the future, closed-loop recycling of CFRPs may transform low-carbon manufacturing as circular lightweight materials become incorporated into clean-energy technologies.

The researchers drew inspiration from nature, which employs dynamic interfaces to create robust materials. Nacre, the iridescent mother-of-pearl inside the shells of marine mussels and other mollusks, is exceptionally tough: it can deform without breaking. Moreover, marine mussels strongly adhere to surfaces but dissipate energy to release when necessary.

The researchers aimed to optimize interfacial chemistry between the carbon fibers and the polymer matrix to boost interfacial adhesion and enhance CFRP toughness. “Our composite’s strength is almost two times higher than a conventional epoxy composite,” Rahman said. “Other mechanical properties are also very good.”

The tensile strength, or the stress a material can bear when it is pulled, was the highest ever reported among similar fiber-reinforced composite materials. It was 731 megapascals — stronger than stainless steel and stronger than a conventional epoxy-based CFRP composite for automobiles.

In the ORNL material, the dynamic covalent bonding between the fiber interface and the polymer had 43% greater interfacial adhesion compared to polymers without dynamic bonds.

The dynamic covalent bonds enable closed-loop recycling. In a conventional matrix material, the carbon fibers are difficult to separate from the polymer. ORNL’s chemical method, which clips fibers at the functional sites, makes it possible to separate fibers from the polymer for reuse.

Karunarathna Koralalage, Rahman and Saito modified a commodity polymer, called S-Bpin, with assistance from Natasha Ghezawi, a graduate student at the Bredesen Center for Interdisciplinary Research and Graduate Education of the University of Tennessee, Knoxville. They created upcycled styrene ethylene butylene styrene copolymer, which incorporates boronic ester groups that covalently bond with a crosslinker and fibers to generate the tough CFRP.

Because CFRP is a complex material, its detailed characterization required diverse expertise and instrumentation. ORNL’s Chris Bowland tested tensile properties. With Raman mapping, ORNL’s Guang Yang showed the distribution of chemical and structural species.

Catalin Gainaru and Sungjin Kim, both of ORNL, captured rheological data, and Alexei Sokolov, a UT-ORNL Governor’s Chair, elucidated it. Scanning electron microscopy by Bingrui Li, of ORNL and UT, revealed that carbon fiber maintained its quality after recycling.

Vivek Chawla and Dayakar Penumadu, both of UT, analyzed interlaminar shear strength. With X-ray photoelectron spectroscopy, ORNL’s Harry Meyer III confirmed what molecules attached to fiber surfaces. ORNL’s Amit Naskar, a renowned expert in carbon fiber, reviewed the paper.

The scientists found that the degree of dynamic crosslinking is important. “We found 5% crosslinking works better than 50%,” Rahman said. “If we increase the crosslinker amount, it starts making the polymer brittle. That’s because our crosslinker has three hand-like bulky structures, able to make more connections and decrease the polymer’s flexibility.”

Next, the research team would like to conduct similar studies with glass-fiber composites, which maintain high performance while lowering the cost and carbon footprint of applications in aerospace, automotive, marine, sporting, construction and engineering. They also hope to reduce costs of the new technology to optimize commercial prospects for a future licensee.

“This step will open more applications, especially for wind turbines, electric vehicles, aerospace materials and even sporting goods,” Rahman said.

The Vehicle Technologies Office in DOE’s Office of Energy Efficiency and Renewable Energy sponsored the research. DOE’s Office of Electricity sponsored Raman mapping.

UT-Battelle manages ORNL for DOE’s Office of Science. The single largest supporter of basic research in the physical sciences in the United States, the Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit energy.gov/science.

Source: Oak Ridge National Laboratory

You can offer your link to a page which is relevant to the topic of this post.

#2023#adhesion#aerospace#airplanes#alcohol#applications#Automobiles#automotive#Behavior#carbon#carbon fiber#carbon footprint#carbon-fiber-reinforced polymer#cell#challenge#chemical#chemical bonds#chemistry#Chemistry & materials science news#composite materials#composites#concrete#construction#data#dept#education#efficiency#electric vehicles#electricity#electron

0 notes

Text

Fiber-reinforced Polymer (FRP) Composites Market Outlook, Analysis, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global fiber-reinforced polymer (FRP) composites market size at USD 238.7 billion in 2022. During the forecast period between 2023 and 2029, the global fiber-reinforced polymer (FRP) composites market size is projected to grow at an impressive CAGR of 7.21% reaching a value of USD 385.79 billion by 2029. Expanding automotive and consumer electronics manufacturing in nations like China and India is one of the key driving reasons for the global fiber-reinforced polymer (FRP) composites industry. Government spending on infrastructure development is also contributing to the growth in the market for FRP composites.

Global Fiber-reinforced Polymer (FRP) Composites Market – Overview

Fiber-reinforced Polymer (FRP) is a composite material composed of a polymer matrix reinforced with fibers. The most common fibers used are glass, carbon, or aramid, although other fibers, such as paper, wood, or asbestos, have occasionally been utilized. Fibers and a polymer matrix are the two main building blocks of FRP composite materials. FRP enables the alignment of thermoplastics' glass fibers to meet specified design objectives. The strength and resistance to deformation of the polymer can be increased by specifying the orientation of the reinforcing fibers.

Sample Request @ https://www.blueweaveconsulting.com/report/fiber-reinforced-polymer-composites-market/report-sample

Global Fiber-reinforced Polymer (FRP) Composites Market – By Application

Based on application, the global fiber-reinforced polymer (FRP) Composites market is segmented into automotive, construction, firefighting, electronics, defense, and others. The construction sector accounts for the largest market share, as these materials offer a wide range of applications in this industry. Fiber-reinforced polymers are prominently used as reinforcements in concrete structures and underwater piping to prevent corrosion and impact. The automotive industry also covers a substantial market share owing to expanding automobile production, particularly in China and India, as they are used for the production of low-cost and light automobile parts.

Impact of COVID-19 on the Global Fiber-reinforced Polymer (FRP) Composites Market

The COVID-19 pandemic negatively impacted the growth of the global fiber-reinforced polymer (FRP) composites market. The lockdown implemented by the governments of various economies to curb the spread of the virus halted the operations of the end user sectors, particularly in the construction and automobile industries. In addition, constraints on FRP composites' production processes and supply networks themselves resulted in a severe scarcity of supplies, even after the pandemic, forcing the producers to suffer significant losses. However, the market is projected to pick up its pace during the forecast period as industries resume their operations.

Competitive Landscape

Major players operating in the global fiber-reinforced polymer (FRP) Composites market include American Fiberglass Rebar, American Grating, LLC, Engineered Composites Ltd., B&B FRP Manufacturing Inc., TUF-BAR, FRP Composites Inc., Ten Cate NV, Zoltek Companies, Inc., Hyosung Corporation, Mitsubishi Rayon Co., Ltd., SGL Group, and DowAksa. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Best Quality Composite material supplier | Dreamboat partners

Dreamboat Partners is leading composite material supplier and manufacturer in market. Through continuous technological innovation and competent strategies, we are a provider of innovative, cost-effective, and high-quality products.

1 note

·

View note

Text

0 notes

Text

Massive growth of Short Fiber Reinforced Thermoplastic Composite Market 2030

The short fiber reinforced thermoplastic composite market is a rapidly growing industry that involves the use of composite materials made up of a thermoplastic matrix reinforced with short fibers, typically made of materials such as glass, carbon, or aramid.

For Sample Report Click Here:-https://www.globmarketreports.com/request-sample/215466

These materials are used in a wide range of applications, including automotive parts, electrical and electronic components, consumer goods, and construction materials. They offer numerous advantages over traditional materials, such as improved strength, stiffness, and durability, as well as reduced weight and cost.

The market for short fiber reinforced thermoplastic composites is expected to continue growing in the coming years, driven by the increasing demand for lightweight and high-performance materials in various industries. The Asia-Pacific region is expected to be the largest market for these composites due to the high demand from industries such as automotive and construction.

Key players in the market include BASF SE, Lanxess AG, Celanese Corporation, DSM Engineering Plastics, and SABIC, among others. These companies are investing heavily in research and development to improve the properties of their materials and expand their applications.

0 notes

Text

Examining how fiber content affects mechanical properties in flax and pineapple leaf fiber-reinforced plastic composites

A new study has compared the reinforcing efficiency of pineapple leaf fiber (PALF) and cultivated flax fiber in poly(butylene succinate) composites. PALF, a less explored but potentially sustainable alternative, outperformed flax at 20 wt.%, showcasing its potential in high-performance bio-composites and aligning with environmental goals.

The focus of this research revolves around a comprehensive exploration of the reinforcing capabilities of two distinct natural fibers, namely pineapple leaf fiber (PALF) and cultivated flax fiber, within the context of unidirectional poly(butylene succinate) (PBS) composites. The primary objective is to discern and compare the mechanical efficiency of these fibers as potential reinforcements in polymer composites.

Flax, renowned for its robust mechanical properties, is a benchmark for comparison against PALF, which represents a less investigated yet potentially sustainable alternative. To systematically assess their performance, short fibers with a length of 6 mm were incorporated into the composites at varying weight percentages, specifically at 10% and 20% levels.

Read more.

#Materials Science#Science#Fibers#Biomaterials#Mechanical properties#Plants#Composites#Fiber reinforced composites#Polymers#Flax#Newcastle University in Singapore

17 notes

·

View notes

Text

Types of Fillers in Construction

Introduction

Fillers play a pivotal role in construction, providing stability, strength, and insulation. Their selection is critical, affecting the cost, durability, and environmental impact of a project. This article delves into the various types of fillers utilized in the construction industry.

1. Natural Fillers

Natural fillers like sand, gravel, and stone are ubiquitous in construction due to…

View On WordPress

#aerogel insulation in construction#carbon fiber for structural reinforcement#composite fillers in construction#construction aggregate materials#construction filler selection guide#construction fillers#construction industry standards for fillers#construction material innovation#cost-effective fillers for construction#durable fillers for construction#eco-friendly construction fillers#EPS beads in construction#fiber-reinforced concrete#fiberglass in concrete#fly ash concrete filler#graphene in building materials#insulation panels in construction#lightweight construction fillers#mineral fillers in concrete#natural fillers in construction#organic fillers for construction#silica fume in construction#specialty construction fillers#sustainable building materials#synthetic fillers for building#thermal insulation fillers#types of construction fillers

2 notes

·

View notes

Text

The carbon fiber reinforced thermoplastic composites (CFRTP) market is expected to witness market growth at a rate of 9.4% in the forecast period of 2021 to 2028.

#Carbon Fiber Reinforced Thermoplastic Composites (CFRTP) Market#Carbon Fiber Reinforced Thermoplastic Composites (CFRTP) Market scope

0 notes

Text

CONTINUOUS FIBER REINFORCED THERMOPLASTIC COMPOSITES FOR ELECTRIC VEHICLE MARKET - GROWTH, TRENDS, COVID-19 IMPACT, AND FORECASTS (2022 - 2028)

Continuous Fiber Reinforced Thermoplastic Composites for Electric Vehicles Market is expected to hold a significant market share in 2021 and is expected to grow during the period of 2022-2028.

Global Continuous Fiber Reinforced Thermoplastic Composites for Electric Vehicles market included in this report are analysis of the impact of COVID-19 outbreak on the points influencing the market growth. Additionally, the Continuous Fiber Reinforced Thermoplastic Composites for Electric Vehicles market by major key players, by type, by application and by major region, breaks down the outlook, business assessment, competitive scenario, trends and forecasts by upcoming years. The study of the Report is conducted on the basis of an important research methodology which provides an analytical examination of the global market on the basis of the various segments which have been marginalized by the industry as a summary and pre-scale of the market due to their different prospects

Continuous fiber reinforced thermoplastic composites are durable and lightweight, resulting in significant weight reduction, as well as increased strength and stiffness in final products. CFRTP compounds are used in many end-use industries such as automotive, aerospace, electronics, and others due to their many advantages, such as a high strength-to-weight ratio, excellent load-bearing capacity, low coefficient of thermal expansion, and creep resistance and cracks Electric vehicles (EVs) are eco-friendly and have gained popularity in recent years. CFRTP compounds are extremely useful in the manufacture of electric vehicle parts because they have high strength and contribute significantly to vehicle weight reduction.

Read More: https://introspectivemarketresearch.com/reports/continuous-fiber-reinforced-thermoplastic-composites-for-electric-vehicles-market/

0 notes