#construction driveline parts

Photo

Looking For CASE CE Hydraulic Parts?

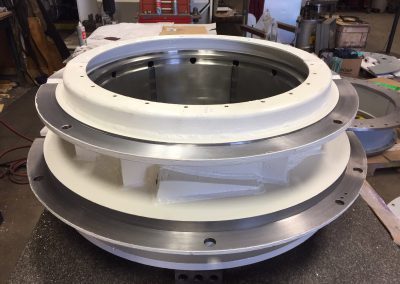

Why CNH Reman construction driveline parts are worth your money?

Construction driveline parts have Improved product tolerance capability

They have Improved transmission testing with auto data acquisition

Sediment testing on all case ce hydraulic parts is done

Improved process repeatability

New clutch build stands – which actuates /sets springs, guaranteeing proper adjustment

Air decay leak test

PS3, PS4, and PS6 transmissions.

New polyurethane idler and roller wheels – lower cost/longer wear life.

Computer Numerical Control Machining guarantees precision driveline.

Have access to world class equipment, aftermarket support, industry leading warranties, and financing with our case ce hydraulic parts!

We use automated OEM designed function test stand to test all our transmissions!

We are committed to delivering -

Quality

Reliability

Performance of the product produced

Same as new and sometimes better than new warranty coverage.

Our construction driveline parts offer a great value while ensuring peak performance!

0 notes

Text

Steering Joints, Driveline Parts, and Other Machine Parts of the Highest Quality Can All Be Found at Taiwan Universal Joint.

Taiwan Universal Joint is an industry leader in the production and distribution of universal joints and related machine parts such as steering joint and driveline components. Because of their long experience in the business, consumers know they can trust Taiwan Universal Joint to provide them with excellent products and service.

There's a large range of machines, and each one has its own unique set of component requirements. These parts are essential in making the total work. Taiwan Universal Joint provides a comprehensive selection of machine components tailored to the requirements of various markets. To guarantee that this device serves its purpose for many years to come, each individual part has been expertly built utilizing cutting-edge methods and high-quality materials.

Taiwan Universal Joint's product range features several different types of driveline components. The driveline is an essential component since it links the machine's motor to the driven parts. Trucks, construction equipment, agricultural gear, and other heavy machinery are frequent examples of vehicles that benefit from their use due to their ability to tolerate harsh environments. Taiwan Universal Joint produces a variety of driveline components including universal joints, slip yokes, flanges, and yoke shafts. Electricity can be transmitted efficiently even when these components are subjected to heavy loads and harsh working circumstances due to their superior engineering.

Steering joints are a vital part of vehicles, and Taiwan Universal Joint provides them for its customers as well. Steering joints are an integral part of any vehicle or equipment. They make for accurate, risk-free manoeuvrability by allowing for regulated, smooth wheel movement. Ball joints, tie rod ends, and drag links are just a few of the various types of steering joints available from Taiwan Universal Joint. These steering joints undergo rigorous testing and are only released to the market after meeting stringent quality criteria.

One of Taiwan Universal Joint's distinguishing characteristics is the excellent quality of its machinery parts, driveline components, and steering joints. Because of their greater tensile strength, endurance, and resistance to wear and tear, these components are made from high-grade steel, alloy steel, and forged steel. The pieces are accurately milled using up-to-date CNC (Computer Numerical Control) machining methods, guaranteeing a snug fit and tight tolerances that contribute to consistent performance throughout time and longer lifetime.

The adaptability of Taiwan Universal Joint's products has contributed to their widespread renown. Various sectors and consumer-use scenarios may be accommodated because of the company's adaptable dimensions, designs, and setups. Taiwan Universal Joint offers solutions for a wide range of vehicles, from little cars to large semi-trucks and even complex industrial gear. Customers may tailor the components to their needs by taking use of the company's bespoke design and manufacturing service.

In addition to their robust construction and flexible application, Taiwan Universal Joint's machinery parts, driveline components, and steering joints have a stellar reputation as the finest in the business. These components are built to guarantee that the machine or vehicle functions as smoothly and efficiently as possible by transmitting electricity. For applications that require reliable performance over time, they are an excellent choice because of their resistance to harsh conditions. The components have also been made with longevity and low maintenance in mind by minimizing things like friction and wear.

Customer service is highly valued at Taiwan Universal Joint as well. Expert engineers and technicians from the organization are accessible to help clients at every stage of the product's lifespan, from ideation and selection through installation and maintenance. Customers can take advantage of this amenity at no extra cost to them. To ensure that its goods meet or exceed both customer and industry expectations, the business also uses stringent quality control techniques.

Therefore, the machinery part, driveline component, and steering joint markets can all safely declare that Taiwan Universal Joint is the best in class. The success of the business is predicated on the superiority of its wares, the dependability of its service, and the attention to detail with which it strives to satisfy customer needs. Taiwan Universal Joint is a reliable partner for a broad variety of industries and uses because of their extensive product catalogue, precise engineering, adaptability, and dedication to quality.

0 notes

Photo

Strange Engineering Driveshaft Tubing

Buy Now: https://www.strangeengineering.net/product-category/driveline/driveshaft-tubing/

Driveshaft Tubing

There is an old adage that says a chain is only as strong as its weakest link. The same could be said about the automobile drivetrain.

One of the most critical, and most overlooked parts of the drivetrain is often the driveshaft. Like the engine, transmission, and rear end, the driveshaft is only as strong as its weakest part. Strange driveshafts are custom made using the finest tubing, weld ends, transmission yokes, and universal joints in the industry. Strange Engineering driveshaft builders are second-to-none and, using state-of-the-art equipment, carefully construct and balance each Strange Driveshaft to within eight-thousandths of an inch of runout.

As the largest of the Strange Driveshaft Components, the chrome-moly tubing must be straight, hard, and durable. Strange Driveshaft tubing (available in 3-inch and 3.5-inch outside diameter) has a wall thickness of .083-inch. It is seamless to ensure minimal vibration and the heat-treated chrome moly construction delivers rugged durability. Welded (MIG and TIG) yoke ends are accurately phased and electronically balanced to further eliminate vibration.

#StrangeEngineeringDriveshafts#StrangeEngineeringSolidDriveshaftsCouplers#StrangeEngineeringDriveline#StrangeEngineeringDrivelineTubing#StrangeEngineeringMagneticSensorCollar

1 note

·

View note

Text

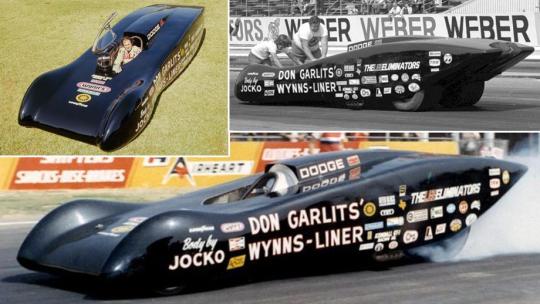

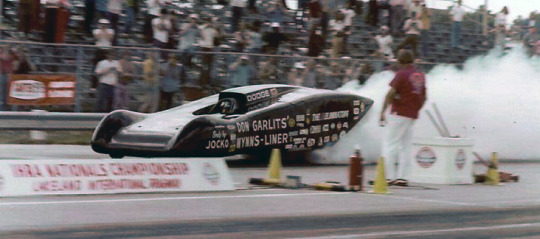

The story of Swamp Rat 17: Don Garlits' most misunderstood Top Fueler (part 1)

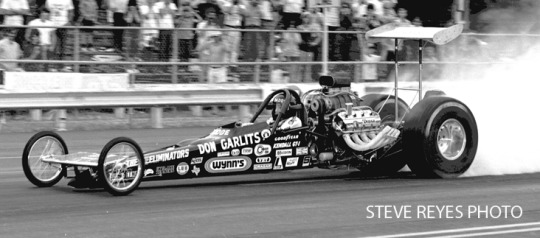

Don Garlits’ Swamp Rat 17, the Wynn’s Liner, had a very short life in 1973 and is roundly considered to be among the few disappointments of the more than 40 Swamp Rats he campaigned. Here's the story behind this most misunderstood car.

09 Apr 2021

Phil Burgess, NHRA National Dragster Editor

Earlier this year, I wrote a column about racecar experiments that didn’t come to fruition and cited, chief among them, Don Garlits’ Swamp Rat 17, the Wynn’s Liner, which had a very short and disappointingly unsuccessful life in 1973.

I think the reason that car always leaps to the top of my “Well, that sure didn’t work” list is because it was a rare dead end for “Big Daddy,” one of the sport’s greatest innovators and chance takers. Although there are only 38 official Swamp Rats, there were some A and B versions, and the actual number well exceeds 40, according to “Big.” So, he had a pretty great batting average, yet strikeouts are going to happen, but better to go down swinging, right? Or, as hockey great Wayne Gretzky once said, “You miss 100% of the shots that you don’t take.”

[Coming later in this column: Garlits rates his five favorite Swamp Rats and five least favorite. Stay tuned for that.]

Anyway, after heaping criticism upon the car back in February, I thought it only fair to allow The Man Himself to provide the context that defines this car’s place in the sport’s history. Not sure if he’d want to discuss one of his missteps, I reached out to the sport’s most storied driver and received an enthusiastic “I’D LOVE TO!” response to my query and away we went.

Before we get to that discussion, let me provide a little more context. The other thing that always intrigued me about Garlits’ decision to build Swamp Rat 17 was that he had blown away the sport with Swamp Rat 14 (the first rear-engined winner, 1971 Winternationals) and its evolutionary successor, Swamp Rat 16, which won the 1972 Gatornationals. (Swamp Rat 15 was a front-engined car built just in case SR14 was a flop; it never ran.) After all this success, why take this detour, especially when no one else was experimenting with aerodynamics?

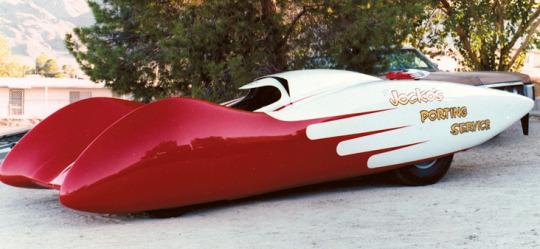

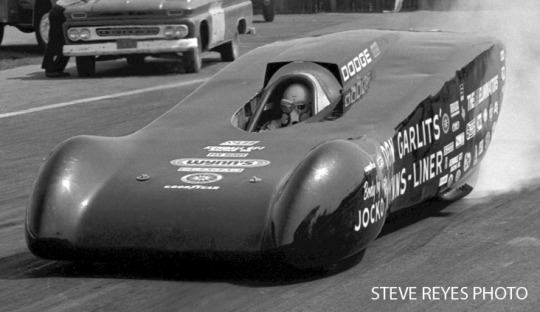

Turns out that while the ‘Liner didn’t make its debut until mid-1973, the idea was conceived in mid-1971, not long after Garlits had proven that the rear-engined design worked. It was at that point that Garlits’ old buddy, Jocko Johnson, whose similarly shaped entry had made huge waves in 1959 with “Jazzy” Jim Nelson at the wheel, suggested that maybe it was time to resurrect his design and have “Big Daddy” put it on one of his chassis.

“I always liked streamlining, and Jocko had never given up on the idea, but he needed a success rear-engined car to try it again,” Garlits explained.

The only rub was that Johnson needed a shorter car, a 180-inch wheelbase chassis, to fit under the body, Swamp Rat 14 and 16 were 215 inches.

I've never seen any detailed shots of the car without the body, but did stumble across this image, a 1/16th scale version that Johnson had built to show Garlits his idea. Very cool!

Johnson, a laid-back Californian, began work on the body mold in 1971 but didn’t finish it until 1972, then came to Garlits' Seffner, Fla., base to build the body, which would not be completed and the car not race-ready until Garlits was already on Swamp Rat 19 in mid-1973.

The slow pace for the Liner’s body construction was frustrating for Garlits, who was well-known for being able to build a complete car in just a few days, and in his great book, Don Garlits and His Cars, “Big” pulled no punches about the reason for the delay.

"Jocko by now was growing his 'weed' next door and stayed 'high' most of the time! On several occasions, I went next door, pulled up the plants, and burned them. Jocko just planted more and stayed high."

In anticipation of the Wynn’s Liner’s someday completion, Garlits built Swamp Rat 18, the car dubbed “Shorty,” with a 180-inch wheelbase so he could get a feel for the three-foot-shorter configuration and ran it at several AHRA events in 1972 but never felt comfortable in the car, but he felt sure that the Liner’s body would give the car stability and faster speed, just as adding the rear wing to Swamp Rat 14 had improved top-end speeds.

“18 just wanted to do funny things going down the course," he remembered. “You had to be really careful with it. I had to really slow down the steering to even make it work at all.”

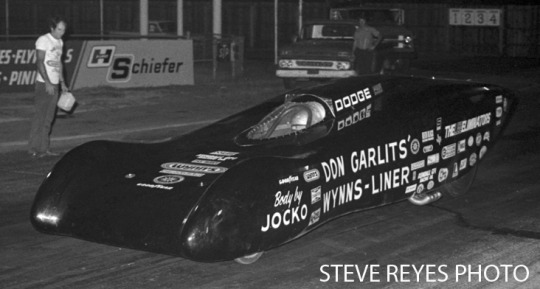

The ‘Liner was finally ready early in 1973, and Garlits towed it and “Shorty” out to California to run the AHRA Grand American event at Orange County Int’l Raceway. Veteran Funny Car racer Butch Maas, finally recovered from serious burns he had suffered in the Hawaiian Funny Car the year before, was itching to drive the car, so Garlits let him and set about getting “Shorty” also qualified for the race.

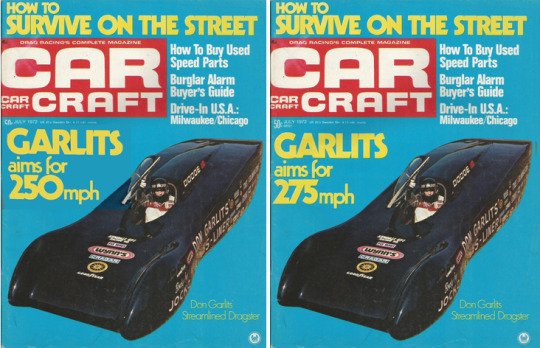

There had been so much hype built about the ‘Liner, which had been featured on the cover of Car Craft magazine back in July 1972 with the cover blurb “Garlits Aims for 275 mph.” The feature had been shot and originally the blurb had targeted 250 mph (Garlits has a copy of the original mockup with 250 on it in the museum display, and kindly shot a photo for me), but the editors decided to raise more eyebrows. Although the official national record at the time was 234.37 (set by Gaines Markley in April in Seattle), Garlits had run 243.90 mph in the final round of the Gatornationals but didn't get the chance to back it up, so maybe 250 wasn't far enough "out there" for the publication.

“By the time we got the car read, [the editors] told me that 250 wasn’t enough, that they wanted to put 275 on it,” Garlits recalled. “We thought the car might go 255 or 260, but I agreed with them that 275 sounded better and more exciting.” [For the record, we wouldn’t see 275 for another 15 years, when Darrell Gwynn ran 278 in Dallas in late 1986.]

Just as had been the case when he debuted the famous rear-engined Swamp Rat 14 in 1971, Garlits’ fellow racers scoffed at Garlits’ latest project, mostly, he thinks, because if it had been successful it would have created a major sea change in the class just as Swamp Rat 14 had done. That wasn’t to be.

Maas made several attempts in the car but was spooked by its handling and ran a best speed of 180 mph. You can see by the photo here that the car didn’t yet have the bubble canopy on it, and Garlits is not sure it ever did in the car’s short lifespan (although it's visible in the Car Craft cover, Garlits says they didn't have a working cockpit hinge yet). You can also see "Big" in the background holding the bleach bottle. Although Maas couldn’t qualify the ‘Liner, Garlits was able to put "Shorty” into the show but lost in round one to Herm Petersen. “The whole trip was a disaster,” Garlits summed up in his book.

Still determined to make it work, Garlits put Don Cook in the car for the IHRA event at Lakeland Dragway in Florida. Cook had driven the short-wheelbase, rear-engined Piranha in late 1966, so Garlits figured he could get the job done, but he also was forced to lift a half-track on several passes. "They both said it was doing something funny, so I got in the car myself for a ride,” said Garlits.

“It took off kinda slow because it was so heavy, but then it was cruising along pretty well and making a decent run when all of the sudden the motor revved up. I quickly lifted and then felt a bump, like I had hit a bump in the track or something.

“We brought it back to the pit and tore it apart, but there was nothing broken in the driveline, and that’s when we figured out that the whole car had gone airborne and when lifted it came back down, and that was the bump I felt.

“Jocko thought I had sabotaged him, so he wouldn’t get any credit for the design, which is pretty ridiculous. He went to his grave never believing that the car was doing the things I said it did.”

Garlits also had concerns about the amount of nitro fumes being trapped under the body and the fact that the car was not easy to get out of. “I knew that someday it would catch fire, and that would be a helluva deal for the driver, so I just gave up on the project,” he said.

Garlits sold the car to rocket-car racers Russell Mendez and Ramon Alvarez, who envisioned turning it into a hydrogen peroxide-powered rocket car, but Mendez was killed in an exhibition pass in their Free Spirit rocket dragster at the 1975 Gatornationals, and Alvarez, a plumber by trade (who actually had done the plumbing for Garlits' house) needed cash and sold it back to "Big." Given the 'Liners inherent instability at less than 200 mph, one can only imagine what it would have done at rocket-car speed. (“It would probably have flown right up into the sky,” Garlits marveled.)

So, I asked Garlits the million-dollar question: "Is he glad he built the car, or was it just a waste of time and money?"

“It was definitely a waste of time and money, but I’m glad we did it. I enjoyed all of the projects I did, even the ones that didn’t work out, like the Sidewinder and the turbine [-powered] car. Everyone raved about the turbine engines and how powerful they could be, and that car didn't work out but it was fun to figure it out. I always loved experimenting. That’s what made it so fun. When you’re involved with projects like those, your mind is going 24x7, trying to think of all of the scenarios to make it work.

“Plus if I hadn’t gotten together with Jocko, I wouldn’t have his original streamliner in my museum or the body from the Mooneyham-Ferguson-Jackson-Faust car. That all came together because of my relationship with Jocko."

#Garlits#Swamp Rat 17#swamp rat#don garlits#drag racing#top fuel dragster#dragster#dragstrip#drag race

8 notes

·

View notes

Text

Propeller Shaft

The propeller shaft (likewise called prop shaft or drive shaft) is a part of the drive train in a vehicle, It is an important part of the transmission of power in the automobile driveline. For a front-engine rear-wheel drive car, it transmits the rotation of the transmission to the shaft of the final drive.

Cardan shafts are used differently in different vehicles, varying greatly in cars with distinct configurations for front-wheel drive, four-wheel drive, and the previously mentioned front-engine rear-wheel drive.

The propeller shaft is essentially used to exchange torque between parts that are isolated by a separation since various segments must be in various areas in the vehicle.

A front-motor back wheel drive vehicle must have a lengthy drive shaft associating the back pivot to the transmission since these parts are on inverse sides of the vehicle.

§ Propeller Shaft is the shaft that transmits power from the gearbox to the differential gear in a motor vehicle from the engine to the propeller in a boat or flying machine.

§ Propeller shaft sometimes called a transmission shaft, transmits power from the gearbox to the rear axle. Regularly the shaft has a tubular section and is made in maybe a couple of piece construction.

§ The two-piece arrangement is supported at the midpoint by an elastically mounted bearing. Short drive shafts are incorporated for the transmission of power from the last drive assembly to the road wheels in both front and rear-wheel drive layouts.

FUNCTIONS OF THE PROPELLER SHAFT

The main functions of the propeller shaft that if transmit rotary motion and power to the differential. Prop shaft consisting of three parts, i.e. hollow shaft, universal joints, and slip joints.

Where the engine and axles are separated from each other, as on four-wheel-drive and rear-wheel-drive vehicles, it is the propeller shaft that serves to transmit the driving force generated by the engine to the axles. The longer the shaft, the more liable it is to bend, and bending is further promoted when rotation is applied causing vibrations and resulting in an increase in noise. For this reason, the propeller shaft has been designed to suppress vibrations arising from a wide range of causes.In some vehicles, the engine is kept at the front and the front wheels of the vehicle are being driven. In some other vehicles, the engine is at the rear and the rear wheels are being driven. For such arrangements, a short propeller shaft is used to drive each wheel.

The engine and the transmission unit are attached to the vehicle frame with some flexible mounting. The rear axle housing with differential and wheels are attached to the vehicle frame by suspension springs.

To sum up, the propeller shaft does the following functions:

1. It transmits rotary motion of the gearbox output shaft to the differential and then to the wheels through the axle shafts.

2. It transmits the motion at an angle which is varying frequently.

3. It accommodates changes in length between gearbox and rear axle.

TYPES OF PROPELLER SHAFT:

Single-Piece-Type Propeller Shaft:

Characteristics:

The friction welding adopted at the junction contributes to an improvement in the strength, quality, and durability of the junction. A reduction in the number of component parts and in the weight has been achieved.

Used in vehicles with a short separation between the motor and axles, and MR based four-wheel-drive vehicles. The erosion welding adopted at the intersection adds to an enhancement in the quality, quality, and strength of the intersection.

On a single piece propeller shaft, you may have a solid connection to the axle while a slip yoke connects it to the transmission. The yoke slides over the splines of the transmission’s output shaft. The reason this is done is to allow the driveshaft to “change sizes” during flex. The drive shaft will be able to slide back and forth on these splines to keep from binding, while effectively being able to apply power.

You may also have a propeller shaft upfront, similar to what is found on a two-piece driveshaft, which offers a fixed mounting position on the transmission but still allows the transmission shaft to extend as needed.

Between the yoke and the transmission shaft—and used as the connecting point for the driveshaft and the differential—are universal joints or u-joints. U-joints are used to manage the angles. The transmission and transmission shaft sits at an angled pitch and this means that the driveshaft will need to pivot as it rotates. U-joints are what make this possible.

2-piece-type/3-piece-type Propeller Shaft:

Characteristics:

The division of the propeller shaft into two- or three-parts permits the vital quantity of revolution to decreased stopping vibration problems from going on when the typical size of the shaft increased. The dynamic damper inserted into the pipe reduces the vibration and noise.

The friction welding adopted at the junction contributes to an enchancment in the strength, quality, and sturdiness of the junction. A reduction in the number of factor components and in the weight has been achieved.

Two-piece propeller shafts do all the identical matters as a single-piece driveshaft, simply in a barely unique way. Rather than the use of a slip yoke to connect to the rear of the transmission, these are established in a fixed role with the use of a u-joint on the output shaft of the transmission and a u-joint on the axle.

Utilized as a piece of cars with lengthy separation between the motor and axles, and Front motor front-drive base four-wheel-drive vehicles. The division of the propeller shaft into a few sections allows the primary quantity of transformations to delivered down maintaining the vibration difficulty from going on when the typical size of the pole expanded.

The 2-piece-type prop shaft nonetheless needs to manipulate flex, and this is performed between the two driveshafts as an alternative of at the transmission. This is vital for 4 wheel drive vehicles that see severe flex—as the use of a slip yoke ought to virtually end result in the driveshaft falling out of the vehicle.

Common Bad Propeller Shaft Symptoms

Since propeller axles rotate quickly, they’re able to move the rear wheels of your vehicle. The only way they can keep rotating quickly is if they remain weighted down and balanced exactly right. If your driveshaft were to ever go bad, then there would be some clearly visible symptoms that would present themselves. More specifically, Here are some common signs to watch out for that will let you know there is a problem with the drive shaft or slip yoke.

1) Vibrations

If you’re driving the vehicle and you feel a lot of harsh vibrations coming from under it, then your prop shaft may be in trouble. This is usually the first symptom that people recognize when there is a drive shaft problem.

The vibrations are likely due to worn out bushings of the drive shaft. These bushings are what normally keeps the propeller Axle from vibrating in the first place.

If the problem is not fixed soon, the vibration will get more severe. It will get so bad that your passengers will be able to feel it too. The worst part is that other drivetrain components can also be affected and damaged.

2) Clunking Noise

A failing propeller shaft could cause clunking sounds to be heard as you step on the gas pedal or drive in reverse. These may be in addition to the squeaking sounds that you normally hear all the time.

If you hear clunking noises in any of these cases, then it could mean your drive shaft has an issue and should be promptly inspected. Often, this is a common symptom of a bad slip yoke.

At this point, you should feel more than motivated to want to replace your shaft before some real damage occurs.

3) Squeaking Noise

This could be due to worn out internal components such as bushings or bearings within the shaft or U-joint or possibly an imbalance in the shaft. Usually, the noise increases as you go faster. It could possibly be out of balance or some other part of it could be worn out.

4) Universal Joint Movement

Your propeller shaft has a U-joint that rotates at a steady pace. If the U type joint of your drive shaft rotates too fast or fails to rotate, then it’s a problem with your propeller Axle. Perhaps you have a bad Universal joint or your bearings have rust on the cap seals. This may require you to replace your entire driveshaft if the damage is too significant.

5) Turning Problems

steering wheel off-center

If you try to make a turn with your vehicle and the wheels don’t turn immediately or they hesitate, then you have an issue with your drive shaft. Your wheels won’t receive the proper amount of torque due to a U-joint issue at the end of the driveshaft, so making turns will be very difficult due to the additional resistance.

Once you confirm it’s the driveshaft at fault, you need to get it replaced quickly or risk an accident due to not being able to control the vehicle.

Propeller Shaft Vibration Analysis

Noisy propeller shafts, vibrations in the driveline, or annoying resonance may indicate a problem in the propeller axle. Ignoring this phenomenon may cause damage to bearings and hull or other parts. You can prevent this damage.

Vibration intransmission shaft can be caused by many conditions. One of the most common causes of driveline vibration is worn U-joints or slip splines, out-of-balance components, yokes out of phase or misaligned angles, approaching critical speed range, and yoke ears that are not concentric with the splines. Vibrations problems must be diagnosed accurately and corrected quickly to avoid damage to the driveline components. It is often difficult to determine if a vibration of the vehicle is coming from the driveshaft or something else. Here are some things to think about while you are troubleshooting any driveshaft problem.

A First type propeller shaft vibration will cause one shake or disturbance for each revolution of the driveshaft. Anything that is out of balance will only cause the first-order vibration, never any higher-order vibrations.

First type driveshaft vibration is usually caused by:

A component rotating the same speed as the drive shaft that is out-of-round.

A component rotating the same speed as the propeller shaft that is out-of-balance.

Transmission shaft balance issues can generally be felt at speeds over 30mi./h

The Second type of driveshaft vibration will cause two shakes or disturbances for each revolution of the transmission shaft. A component that is out of balance will NEVER cause a second or other type of vibration, only a first type of vibration.

Second type propeller shaft vibration is usually caused by:

Incorrect Vehicle Trim Height

Powertrain Mounting Problems

Failed or Failing U-Joints

Improperly phased or twisted driveshafts

very low speeds, and higher speeds

Drive Axle Problems

Third type propeller shaft vibration will cause three shakes or disturbances for each revolution of the driveshaft.

This type of vibration is very rare and will not be present on vehicles with Cardan U-joints. A component that is out of balance will NEVER cause a third or higher type vibration, only a first type of vibration.

Third type propeller shaft vibrations are usually caused by:

Failed, failing, or binding Constant Velocity (CV) Joints. Remove the drive shaft and rotate the CV-joint through its full range of motion while feeling for any rough spots or looseness.

Another common problem is caused by oil leakage from a faulty propeller shaft seal. Also, radial sealing stuffing boxes, which do not adapt to misalignment of the prop shaft, often cause leakages. Other leakages may occur due to the long-term wear of gaskets on the propeller shaft. In order to prevent leakages, we often use propeller shaft seals that ensure longitudinal sealing.

These propeller shaft seals have self-centering lip seals rotating with the drive shaft against a counter-slip ring. A major advantage is that the cooling/lubricating medium remains on the outside and is not pressed in between the sliding surfaces. This is often the cause of leakages.

How to Repair the Prop Shaft

The integrity of your propeller shaft is as important as the whole unit. Even though you may not notice it, the shaft is designed to wear out and corrode over time. Repairs can be done easily without much cost or hassle if you understand how to repair the propeller shaft properly.

Before you begin to think about repairing your propeller shaft, make sure that the blades of the unit are in good condition. If the blades have been damaged, they will require special attention and service to get them back to their former glory.

You should also check the joint between the propshaft and the blades. As the shaft starts to deteriorate, it creates holes that will eventually allow water to enter between the blade and the shaft. Eventually, the blade will corrode and become dull, eventually leading to frequent breakdowns and breakdown of the propeller shaft. Repair the prop shaft to avoid more damage to the blade. If the blades are not damaged, simply repair the damage that is present. With proper maintenance, your propeller will run smoothly for years to come.

A good way to go about the process of repairing the propeller shaft is to remove the blades and trim the shaft after they have been inspected. This will make it easier to align the blade. This is also a good way to avoid damage to the blades that might be caused when they were being installed. As a general rule, the propeller shaft should be able to hold itself together and securely in place. Try removing the blades and paying attention to where the shaft meets the blade. If there is a gap, you may need to adjust the shaft before the process can proceed.

For the best results, it is advisable to have a professional repair the propeller shaft. If you try to repair the shaft yourself, it is likely that you will not be able to maintain the correct alignment of the blades and the shaft. There is a chance that you could end up causing more damage to the driveshaft than fixing it. It is not always necessary to have a professional repair the shaft. Small repairs can be made by purchasing the needed parts or by repairing them yourself. If the propeller shaft is older, it may be need to replace the entire shaft.

How to Replace the Propeller Shaft

Although propeller shafts design and purpose is incredibly simplistic in nature, replacing a drive shaft center support bearing is not one of the easiest jobs to complete.

The exact removal of a driveshaft will vary from vehicle to vehicle, and the exact how-to can’t be covered with one single process across the board.

To remove a driveshaft, you usually only need basic hand tools, which include a socket wrench and socket set along with box wrenches.

Additionally, pry bars will be needed to help encourage the driveshaft to break free after the mounting hardware has been removed.

1. Remove propeller shaft Bolts

Remove the shaft differential flange mounting bolts. These bolts will be very tight so use good quality tools to avoid stripping. Some bolts can head 12 point heads as in this example which used a 13mm 12 point socket to remove. These bolts also use lock tight to avoid coming loose while in operation and can be reapplied when reinstalling.

2. Remove propeller shaft Flange

Using a plastic hammer gently shock the driveshaft loose from the differential flange by striking the rear yoke (U joint mount). At this point, the back half of the shaft will be free to hang onto it. On some cars, there will be center support which must be undone by removing the two center support mounting bolts. When removing an older vehicle transmission shaft use electrical tape to wrap around types of universal joints cups so they don't fall off and release the cup needle bearings.

3. Remove propeller shaft

Using both hands gently slide the driveshaft from the transmission or transfer case. A small amount of fluid might leak out so have a fluid catch basin ready. This would be a good time to replace leaking transmission tail housing seal, universal joints or if removing the transmission or differential repairs are needed.

4. Check U joints

At this point, the U joint at either end of the shaft should be checked. Grasp the yoke and move it in all directions. It should be a smooth motion with no rough spots or play in any direction. If a play or rough spots occur then the U joint needs to be replaced.

5. Reinstall propeller shaft

Before re-installing the driveshaft apply a small amount of grease to the yoke. This will help lubricate the output shaft seal in the transmission or transfer case.

6. Reinstall Flange Bolts

Once the front yoke is installed pull the drive shaft back into place while inserting a mounting bolt by hand to avoid cross-threading.

The process of replacing one falls into a higher level of difficulty than simply replacing u-joints or installing a new transmission shaft. A savvy tech can take the time to break into these units to repair what’s specifically broken, but often it’s quicker to simply replace the whole driveshaft.

How to Prevent Propeller Shaft Failure

As a vehicle proprietor, you can likewise do numerous things to safeguard the driveline of your vehicle, from checking and guaranteeing your motor liquids are consistently at the correct levels to maintaining a strategic distance from harsh utilization of the driveline.

Here are more explicit tips you can do to keep your propshaft in great working condition:

Continuously have your widespread joints all around greased up. The absence of oil can prompt a train of harm that can be pricey not exclusively to the driveshaft yet additionally to connecting segments, for example, siphons and gearboxes.

Evacuate the spreads and assess the containers of high use prop shaft all the time. These parts can get exhausted because of consistent high force development. Document off unpleasant edges on the cylinders so it won't get on the other portion of the cylinder.

Make a point to supplant the move pin when you supplant tubes since they can slacken on account of force stacking. Apply a limited quantity of oil with oil on tubes as this will assist with making slide simpler and to ensure that the oil is appropriated all the more reliably. Ensure drive shaft covers and chains are in defensive and safe condition to forestall mishaps and wounds.

Recycling of Propeller Shafts

Both brand new replacement propeller shafts for passenger vehicles and professionally reconditioned drive shafts are available on the market. When used transmission shafts (most of which will have been damaged) are reconditioned, the old parts are taken back from vehicle garages for professional recycling in special production plants in accordance with the standards set for original equipment.

As part of this process, all usable steel parts are reused. The old propeller shafts are inspected, taken apart, cleaned, machined, and then put back together for the car repairs market. Other materials resulting from the reconditioning process (old grease, metal chips or worn steel parts, for example) are disposed of in the correct and proper way in accordance with applicable environmental guidelines. Recycling significantly reduces the consumption of both raw materials and energy and makes a significant contribution to the active protection of the environment.

The above is the detailed content of the propeller shafts, more related content will continue to be updated.

1 note

·

View note

Photo

Earthmoving Kerikeri

Endowed with maximum operational flexibility, stability, and unequalled handiness, earthmoving equipment is the best choice for any earthmoving activities. Waipapa earthmovers withstands any non-stop harsh work conditions, which is vital for the equipment to offer the best services. Since it started, many have always commented both on its services and products. This is because of its commitment to ensure that customers always get satisfied with any products it offers. The production of major sub-assemblies in large part of the program ensures the high quality requirement, develops and manufactures the whole driveline and control technology, which include hydraulic system, diesel engine and transmission product groups. On offer is efficient worldwide services at all operating sites hence ensuring availability of earthmoving equipment. Its closely spaced operating network not only ensures qualified customer services, but also supply of original products around the clock.

The products have various vital characteristics that one ought to consider when going for any of them. For example, they are quality designed and tested, strong and durable, custom made to an individual's requirement and many other important characteristics. The companies do not concentrate on providing cheap products but on providing long lasting once. These products include, for example. Grabs & Thumbs Grabs and thumbs work in tandem with existing buckets and attachments. Waipapa earthmovers grabs and general grabbers enhance the adaptability of any excavator and enable efficient handling of materials.

The thumbs grabs get mounted on a single piece base plate welded near the end of the dipper. Grabs and thumbs are heavy duty, and built to be very hard wearing, which is a perfect reflection of the strength in fabrication and design of the construction equipment. There are of various kinds, which include grabs among others. Articulated Dump Trucks have permanent wheel drive, this is crucial in ensuring equal power distribution while both the free-swinging rear tandem bogie together with the special articulation system, offer a god driving performance in difficult terrain. With a variety of the Waipapa earthmovers for one to choose like the others, they are of different sizes and shapes. Earthmoving equipment is here to help big companies get the jobs done in a timely basis and a safe way.

FOR MORE INFO-: https://www.langmancontracting.co.nz/

1 note

·

View note

Text

Types Of Bearings Used In Different Applications

Bearings are used to support rotational or linear movement, decrease friction between two objects. There’re different kinds of bearings, which are quantified on their functions, design to carry particular types of loads, thrust or radial.

Ball Bearings:

Ball bearings have a niche area in the field of bearings as they can manage both radial & thrust loads. Moreover, ball bearings have the unique ability to carry loads and they feature unique construction.

Ball bearings can be employed in different applications, such as:

Automotive: Ball bearings are employed in all motor vehicles. These are mainly employed in parts such as drivelines, engine, steering, and driveshaft.

Aerospace: Ball bearings are widely employed in space shuttles, and rockets as they help in easy & free movement.

Paper making industry: Ball bearings are extensively employed in the paper-making machines. The bearings employed for paper making machines run under high-temperature.

Tapered Roller Bearings:

These type of bearings can manage large radial & thrust loads. They can be found in car hubs because of their load flexibility.

Applications of tapered roller bearings include:

Mainly employed in car hubs as they’re competent in handling thrust in opposite directions.

They’re used car & vehicle wheel bearings where they’ll manage concurrently with large vertical & horizontal forces.

They’re used in agriculture, heavy duty applications, mining and construction equipment, wind turbines, etc.

Ball Thrust Bearings:

Ball thrust bearings can manage thrust loads in low-speed, low-weight applications. For instance, bar stools employ this type of bearing to support the seat.

Roller Thrust Bearings:

This type of bearings can manage a larger amount of thrust load. They can be found in car transmissions, where they’re employed to support helical gears. Gear Support is one of the most common applications for roller thrust bearings.

Canadian Babbitt Bearings is your one stop shop whether you are looking for nuclear turbine bearings or any other type of bearings. Contact us now if you have any questions or special requests. https://cbb.ca/resources/technical/.

0 notes

Text

Europe Iron & Steel Casting Market Revenue to Surpass USD 47.5 Billion by 2027

The Europe iron & steel casting market outlook is expected to witness a high rate of growth over the next few years, assisted by the expanding demand for automobiles across the region. Iron is expected to emerge as the most utilized casting material across numerous industrial verticals, owing to the advantages it offers over steel. It exhibits higher strength, rendering it more suitable for machining and casting.

The Europe iron & steel casting market size is projected to be worth $47.5 billion by 2027, driven by the prospering construction sector in the European countries. Casting is an extensively used method used for manufacturing equipment and products with complex shapes. Since other fabrication methods are not only difficult but also uneconomical, the demand for cast metals has been soaring substantially across multiple applications.

Get sample copy of this research report @ https://www.graphicalresearch.com/request/1703/sample

The automotive sector has been increasingly deploying cast iron and cast steel components as these materials possess superior properties that are suitable for automotive applications. During 2020, the segment accounted for nearly 32.7% of the total Europe iron & steel casting market share. Cast steel & cast iron is used in the manufacturing of braking components, engine components, suspension components, and driveline.

Although the COVID-19 pandemic resulted in huge losses for the automobile sector, it is expected to recover at a fast pace over the next couple of years. The European Automobile Manufacturers Association (ACEA) estimates that the recovering economies of the European countries will provide significant expansion opportunities to the automotive industry.

Based on processes used for casting, the Europe iron & steel casting market share has been segmented into die casting, sand casting, and other processes. Of these, the sand casting segment is poised for remarkable growth through 2027 as sand is easily available, is pliable, and cheap.

Sand casting can withstand high temperature, making it an ideal solution for casting procedures. This process is used in the fabrication of large sized and rugged products including cast iron pans, decorative fences, car engine parts & components, and other cast iron products.

In terms of materials, steel is projected to emerge as the fastest growing segment in the Europe iron & steel casting market. The segment is slated to grow at a high CAGR of over 6.5% over up to 2027. The high rate of expansion can be attributed to the versatility of this material in terms of application.

Steel casting is deployed across a plethora of industrial machinery applications such as turbocharger turbines, hydro-electric turbine wheels, pump casings, marine equipment, engine cylinder blocks, and mining machinery, amongst others.

The thriving mining sector in the region has been adding to the impetus of the market expansion. The requirement of high-performance materials across the marine industry has also been pushing the demand for cast steel, boosting the Europe iron & steel casting market outlook.

Request for customization @ https://www.graphicalresearch.com/request/1703/customize-this-report

Thomas Dudley Foundry Limited, ACO Eurobar GmbH, FUNOR SA, Silbitz Group GmbH, Rautic GmbH, Lucchini RS S.p.A., LLC BVK, Farinia Group, Mechel Group, BAS Castings, and Metal Group are some leading manufacturers in the Europe iron & steel casting market.

Table of Contents (ToC) of the report:

Chapter 1 Methodology & Scope

1.1 Research Methodology

1.2 Market estimation & forecast parameters

1.3 List of Data sources

1.3.1 Primary

1.3.2 Secondary

Chapter 2 Executive Summary

2.1 Europe Iron & Steel Casting market snapshot

Chapter 3 Europe Iron & Steel Casting Industry Insights

3.1 Industry coverage

3.2 Industry size and forecast, 2016 – 2026

3.3 Industry ecosystem analysis

3.3.1 Vendor matrix

3.4 Future trends

3.4.1 Innovation Landscape

3.5 Raw material analysis

3.6 Regulatory norms & directives

3.7 Drivers & restraints

3.7.1 Drivers

3.7.2 Restraints

3.8 Application growth mapping

3.9 Industry analysis: Porter’s

3.10 Competitive benchmarking

3.10.1 Strategy dashboard

3.11 PEST analysis

Browse complete Table of Contents (ToC) of this research report @ https://www.graphicalresearch.com/table-of-content/1703/europe-iron-and-steel-casting-market

About Graphical Research:

Graphical Research is a business research firm that provides industry insights, market forecast and strategic inputs through granular research reports and advisory services. We publish targeted research reports with an aim to address varied customer needs, from market penetration and entry strategies to portfolio management and strategic outlook. We understand that business requirements are unique: our syndicate reports are designed to ensure relevance for industry participants across the value chain. We also provide custom reports that are tailored to the exact needs of the customer, with dedicated analyst support across the purchase lifecycle.

Contact Us:

Parikhit B.

Corporate Sales,

Graphical Research

Phone: 1-800-986-6917

Email: [email protected]

Web: https://www.graphicalresearch.com

#Europe Iron & Steel Casting Market Analysis#Europe Iron & Steel Casting Market by Type#Europe Iron & Steel Casting Market Share#Europe Iron & Steel Casting Market Development

0 notes

Photo

Our transmissions, gearboxes, clutches, axles, wobble boxes, undercarriage wheels, final drives, torque converters, transfer cases, PTOs, and wet brakes are among the construction driveline parts we are most proud of. Our selection is always growing, so be sure to check back frequently to see what’s new!

Checkout here: https://mycnhreman.com/pages/reman-drivelines?utm_source=tumblr&utm_medium=image&utm_campaign=construction+driveline+parts

0 notes

Photo

Strange Engineering - Driveline

Buy Now: https://www.strangeengineering.net/product-category/driveline/

Driveline Components

There is an old adage that says a chain is only as strong as its weakest link. The same could be said about the automobile driveline. After all, a rear end with the best gears in the world – and weak main caps – wouldn’t be on the road long or make many passes down the dragstrip.

One of the most critical, and most overlooked parts of the driveline is often the driveshaft. Like the engine, transmission, and rear end, the driveshaft is only as strong as its weakest part. Strange drag racing driveshafts are custom made using the finest tubing, weld ends, transmission yokes, and universal joints in the industry. Strange Engineering driveshaft builders are second-to-none and, using state-of-the-art equipment, carefully construct and balance each Strange Driveshaft to within eight-thousandths of an inch of runout.

Strange Driveshafts are available with an SFI Certification sticker at a nominal fee.

#strange engineering#strange strange engineering automobile parts and accessories#StrangeEngineeringDriveline#StrangeEngineeringSolidDriveshafts&Couplers

1 note

·

View note

Text

Trailer Terminal Tractor Market Outlook 2027 Opportunity and Growth Analysis with Top Key Vendors

Transparency Market Research has published a new report titled, “Global Trailer Terminal Tractor Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2019–2027” According to the report, the global trailer terminal tractor market is projected to surpass US$ 650 Mn by 2027, expanding at a CAGR of above 3% during the forecast period.

According to the report, the global trailer terminal tractor market is likely to be driven by a range of macroeconomic and industry-specific factors. North America is expected to be at the forefront of global demand, with the market in the region expanding at a CAGR of more than 2% between 2019 and 2027.

Request A Sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=62862

Companies such as Cargotec, Konecranes, and Mol CY nv are providing innovative options for trailer terminal tractors such as fully electric trailer terminal tractor, autonomous trailer terminal tractor. This coupled with availability of engine with alternative fuel options is anticipated to boost the demand for trailer terminal tractor during the forecast period. Furthermore, port operator logistic handling companies are also constantly looking for new systems to cater to their requirements. High rate of adoption of diesel powered engines and growing use of LNG powered trailer terminal tractors by consumers, owing to the comfort offered while driving coupled with extra space, and more air and light, are expected to boost the trailer terminal tractor market during the forecast period. Stringent emission norms by port authorities have prompted manufacturers to develop more refined diesel engines. Moreover, a few trailer terminal tractor manufacturers are developing the electric trailer terminal tractor, which is expected to offer significant opportunities to the trailer terminal tractor market. Trailer terminal tractors offer numerous benefits over road trucks, such as the layout of the driveline, visibility, maneuverability, and chassis construction with an elevating fifth wheel. Consequently, adoption of trailer terminal tractors in port activities for handling of goods is increasing. Furthermore, trailer terminal tractor manufacturers are focusing more on the development of trailer terminal tractors for terminal operations.

In terms of fuel, the global trailer terminal tractor market has been divided into diesel, hybrid, and electric trailer terminal tractor. Electric trailer terminal tractors are easy to maintain, as they contain less number of moving parts are easy to maintain, and are almost zero-emission. Consequently, the demand for electric trailer terminal tractor is likely to remain high. It is expected to drive the trailer terminal tractor market during the forecast period. However, manufacturers are also focusing on alternative fuel options, such as LNG based engines for terminal tractors and the development of more refined diesel engines, in order to meet stringent emission norms.

Trailer terminal tractors are mostly used at sea ports for material handling, such as loading and unloading of materials. Fast turnaround time, low operating cost, excellent maneuverability, unique comfort, and easily accessible service points are boosting the adoption of trailer terminal tractors significantly. Furthermore, applications of trailer terminal tractors in the logistic industry, manufacturing facilities, and at industrial sites are increasing, which in turn is offering significant opportunities to trailer terminal tractor manufacturers.

In terms of region, the global trailer terminal tractor market has been segregated into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America. North America is projected to dominate the global trailer terminal tractor market during the forecast period. Consumption of trailer terminal tractors in North America is relatively higher than that in other regions across the globe.

Request for Custom Research at - https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=62862

Prominent players operating in the global trailer terminal tractor market include AB Volvo, AUTOCAR, LLC., BYD Company Limited, CAPACITY TRUCKS, CARGOTEC (Kalmar), CVS FERRARI S.P.A., Hoist Liftruck Mfg., LLC, Konecranes, MAFI Transport Systems GmbH, Mol CY nv, Orange EV, SINOTRUK (HONG KONG) LIMITED, TERBERG SPECIAL VEHICLES, and TICO TRACTORS.

The global trailer terminal tractor market has been segmented as follows:

Diesel/ Gasoline

HEV

BEV

Below 50 Tons

Between 50 to 100 Tons

Above 100 Tons

Single Axle

Multi-axle

Heavy Industry

Food & Beverage

Oil & Gas

Others

Manual

Semi-autonomous

Autonomous

U.S.

Canada

Germany

France

U.K.

Spain

Italy

Poland

Rest of Europe

Japan

China

India

ASEAN

Australia

Rest of Asia Pacific

GCC

South Africa

Rest of Middle East & Africa

Brazil

Mexico

Rest of Latin America

About Us

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact

Transparency Market Research 90 Sate Street, Suite 700 Albany, NY 12207 Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Email: [email protected] Website: https://www.transparencymarketresearch.com/

0 notes

Photo

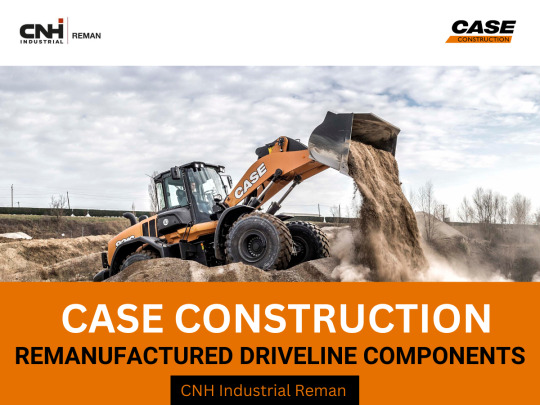

The use of remanufactured driveline parts and components for construction vehicles is becoming increasingly important due to the cost savings, improved reliability, and environmental benefits they offer. Remanufactured parts are tested to ensure they meet or exceed the original manufacturer’s specifications, providing a cost-effective alternative to purchasing new parts.

CNH Industrial Reman offer a wide range of durable and reliable CASE CE driveline components, including axles, transmissions, clutches, and differential assemblies, that are remanufactured to the highest standards. Our components are built to last and backed by our trust guarantee, so you can trust that they will keep your CASE CE equipment running smoothly.

0 notes

Text

How To Obtain A Discount On Choosing A Car

Did recognize by cooking with your home equity that might be the best way to lower interest monthly installments? Typically, a home equity associated with credit along with a home equity loan will give you lower rates than traditional car solutions. This is simple fact they are secured opposed to the value of the home. You can even itemize the interest on your federal taxes and it really is be tax deductible.

A very. Unless you're looking for an accurate "lemon" along with don't require a car that has 100, 000 miles which explains only three years old. A pre-owned car dealer especially your past luxury segment should make sure to have fairly are attractive to the online community. Cars in accord with local driving conditions. A 3 year-old car shouldn't have higher than 30,000 to 50,000 miles on these folks. Off lease used vehicles will be the best choice, but simply want some extra a hard fast rule, just something to keep in mind.

There are many ways of saving cash your next car car or truck loan. The easiest research you can do is from the comfort of your own computer. With the Internet, you undoubtedly wanted . that quite often the best financing is caused by non-franchise, independent financing reputable companies.

When in order to buy a second user car, require only a few to assure that vehicle parts and auto parts are in good condition. May perhaps want to evaluate drive the car first, if this is easy enough. Also, you should find out as almost as much as you can about the history of automobile. When could it have been made? Merely the driver and did they maintain the car in good condition? Just how many miles can it have in there? How much money does it take to fill up a tank of gas in issues? When was the last oil view? You want find out these things out in which means you know a person are are driving around. Do not want to be left with any disclosure.

Lot buyer versus internet shopper. The dealerships recognise the individual who buys the lot is buying with pure notion. They want it and desire it well. Don't fall into this sucker category. You'll pay one of the most.

What season you go out to get a brand new car largely depends upon your need. However, most of the time, it's very possible to put off buying cars for 4-5 months and even a year. There are certain periods like July to October and christmas days, available to get better good deals. The reason being that during July to October, dealers try their much better to clear old stocks, which puts you in an advantageous environment. During Christmas too, sale of cars registers a decline, set about are engrossed in buying other goods and presents.

Consumers getting a new car have three techniques for making an understanding. The first option involves a cash payment with no financing that's involved. The second option is automotive financing, where the actual puts money down on the new car and finances the rest. The third option usually lease a car, basically renting it for a condition and If you loved this short article and you would certainly such as to get even more information pertaining to mazda long Island kindly browse through our web site. then returning it at the end of the lease.

The usual website will sell about $250.00, plus the cost of this website name (a URL), priced from $10.00 to $15.00 (every year), then $50 TO $70 for hosting (a computer that keeps it going each day a day). And that is every year. Some website companies will have the name and hosting in the price, but aren't very loads of. Most don't an individual about the hosting and name charge until you need to already paid them the $250. to construct the site.

When buying car, an unsafe to bear in mind that popular vehicles, or vehicles which usually are in high demand, costs more. Unless you're buying used, you may want to opt out for the extended warranty as competently. It's a fact that nowadays with so many lease options, most people do not own their cars given the warranties last. Major parts for instance the driveline, engine and transmission are all covered by the manufacturer, usually for between five and eight seasons. As well, most warranties have plenty of exceptions, exclusions and insurance deductibles.

Remember which you simply not require to finance buy through sneakers bank you car leasing websites the lease considering. Many lending institutions have better interest rates for new or leased vehicles compared to used. So, you will want to do some shopping ahead of the mortgage.

Remember that you do not in order to be finance purchasing through identical shoes you wear bank you car leasing websites the lease utilizing. Many lending institutions have better interest rates for new or leased vehicles than for used. So, you may want to do some shopping prior to the cash.

As you can see utilizing many associated with hosting benutzerkonto. Whether you are usually planning business site hosting or you mean to run a school site or perhaps you are simply planning on getting a little hobby site up and running, to be able to a decision to make, what hosting package anyone chose.

Used Honda Car vs a New Honda Car is an element that many drivers will debate over. Are generally advantages and cons to buying new and used. Apparently will be passionate about one certain kind over another. The equal level of pros and cons might well have the debate at the same standing. The issue will often be around as well as the preference become up towards driver.

0 notes

Link

Buy Driveline Components -Strange Engineering

There is an old adage that says a chain is only as strong as its weakest link. The same could be said about the automobile driveline. After all, a rear end with the best gears in the world – and weak main caps – wouldn’t be on the road long or make many passes down the dragstrip. One of the most critical, and most overlooked parts of the driveline is often the driveshaft. Like the engine, transmission, and rear end, the driveshaft is only as strong as its weakest part. Strange drag racing driveshafts are custom made using the finest tubing, weld ends, transmission yokes, and universal joints in the industry. Strange Engineering driveshaft builders are second-to-none and, using state-of-the-art equipment, carefully construct and balance each Strange Driveshaft to within eight-thousandths of an inch of runout. Tubing As the largest of the Strange Driveline Components, the chrome-moly tubing must be straight, hard, and durable. Strange Driveshaft tubing (available in 3-inch and 3.5-inch

Buy Online:

https://www.strangeengineering.net/product-category/driveline/

1 note

·

View note

Video

youtube

Waipapa Earthmovers

Endowed with maximum operational flexibility, stability, and unequalled handiness, earthmoving equipment is the best choice for any earthmoving activities. Waipapa earthmovers withstands any non-stop harsh work conditions, which is vital for the equipment to offer the best services. Since it started, many have always commented both on its services and products. This is because of its commitment to ensure that customers always get satisfied with any products it offers. The production of major sub-assemblies in large part of the program ensures the high quality requirement, develops and manufactures the whole driveline and control technology, which include hydraulic system, diesel engine and transmission product groups. On offer is efficient worldwide services at all operating sites hence ensuring availability of earthmoving equipment. Its closely spaced operating network not only ensures qualified customer services, but also supply of original products around the clock.

The products have various vital characteristics that one ought to consider when going for any of them. For example, they are quality designed and tested, strong and durable, custom made to an individual's requirement and many other important characteristics. The companies do not concentrate on providing cheap products but on providing long lasting once. These products include, for example. Grabs & Thumbs Grabs and thumbs work in tandem with existing buckets and attachments. Waipapa earthmovers grabs and general grabbers enhance the adaptability of any excavator and enable efficient handling of materials.

The thumbs grabs get mounted on a single piece base plate welded near the end of the dipper. Grabs and thumbs are heavy duty, and built to be very hard wearing, which is a perfect reflection of the strength in fabrication and design of the construction equipment. There are of various kinds, which include grabs among others. Articulated Dump Trucks have permanent wheel drive, this is crucial in ensuring equal power distribution while both the free-swinging rear tandem bogie together with the special articulation system, offer a god driving performance in difficult terrain. With a variety of the Waipapa earthmovers for one to choose like the others, they are of different sizes and shapes. Earthmoving equipment is here to help big companies get the jobs done in a timely basis and a safe way.

FOR MORE INFO-: https://www.langmancontracting.co.nz/

0 notes

Text

Your First Car Loan : The Things You Need To Know

The usual website will sell about $250.00, not to mention the cost of your website name (a URL), priced from $10.00 to $15.Lincoln aviator lease (every year), then $50 TO $70 for hosting (a computer that keeps it going each day a day). And which usually is every same year. Some website companies will add some name and hosting within price, but aren't very multiple. Most don't tell you about the hosting and name charge until in order to already paid them the $250. to construct the content.

Is there special conditions in your employment that will benefit most by finding lease car deals? Response is yes. Individuals that own quite small business or self employed can use their vehicle as a tax write-off can good. However, keep in mind that leased cars do usually have a yearly mileage cap of 7500-10,000 mileage.

Is there special conditions in your employment the objective of benefit most by finding lease car deals? Could is signs of depression .. Individuals that own individual small business or self employed can use their vehicle as a tax write-off can good. However, keep in mind that leased car leasing websites do usually have a yearly mileage cap of 7500-10,000 mile after mile.

Toyota Scion t C: This car is geared towards young, hip drivers. Featuring a best auto lease deals solid driving capabilities, good fuel economy (23/31) and snazzy interior, it's the right bet intended for $20k.

What VW finance options do they've got available? - The old days of obtaining a better deal by buying with cash are gone. Many dealers are give discounts on brand name new car a person are buying with funding. Therefore, if you looking for the VW of the dreams certain that to ask the dealer what VW finance options they have available. Whilst might have the money to budget for the car leasing websites in full buying auto on a VW finance agreement might work out a more beneficial for. However, before taking out any finance have to always be sure that to be able to compared just like like across all finance deals may have done the sums correctly.

For the best offer you can find, make sure you don't get all the programs and plans proposed by lease dealers. Paint protection, tire protection and more are most likely not needed depending you use the car.

Firstly, of course, is with a optimization. Go to Google, Yahoo or whichever search you in order to use and enter looking term such as 'car leasing' or 'car contract hire'. Those terms will yield a signifigant amount of results with many Lincoln aviator lease. However the results returned from search engine will will definitely be the larger national chains so you have to know for a firm nearer your home prefix your research term through your location. You will then be presented using a list of companies near your home area.

Lastly, you ought to know your credit score before visit get a lease. Which will help ensure you discover a good deal, you should get good credit because anyone then won't pay much extra in costs like interest.

When the best way to car, everyone would like to keep in mind that popular vehicles, or vehicles which usually are in high demand, can cost you more. Unless you're buying used, may be the to opt out of this extended warranty as well. It's a fact that nowadays with a lot of lease options, most individuals don't own their cars given the warranties last. Major parts particularly the driveline, engine and transmission are all covered together with manufacturer, usually for between five and eight years of age. As well, most warranties have quite a few exceptions, exclusions and insurance deductibles.

Internet is among the of

favored medium where by you can make the attain. There are different payment options available through the online world which can be selected. Relating to the internet it is possible to find various new car dealers who will help in purchasing your new lease automobile. With such the best facilities doable ! even arrange a schedule where an exhibition will pick up. First elements to finalize the car you wish to buy. A few obvious methods certain features present inside car leasing websites may well amuse you have to. The need from the car must be known, car dealers will point you in each step of put money into. They are well aware of all the segments may available inside of the market.

Next, you ought to look at what deals the car leasing websites lease company has an individual. Many companies right now are in order to be looking offer involving deals maintain to get your business. Is actually an incredible amount of competition out there right now and they need to try to get that buy a truck. Many give deals like no interest rates, lower monthly payments and even money provided down front to help you pay less over system that of the car's lease lifetime.

The lease is great but merchandise in your articles have a lease along with a deadbeat if you ever paying you it can't help the bank or you have to. A copy of the best auto lease deals along with the last three checks that you received on that property would end up being the bare bones minimum that is going to be studied for counting this as income.

0 notes