#countersink

Explore tagged Tumblr posts

Text

i was mudding recently and realised my sheet of drywall wasn't secure so i scraped up the mud and peeled the tape to put in another screw

What's your DIY cardinal sin mine is that I never countersink screws

#i just learned what countersinking is#turns out thats what i did when i anchored the frame of the wall to the concrete floor#i was just scared the bolts wouldn't go deep enough

12K notes

·

View notes

Text

Combined Drill And Countersinks Market Projected to Reach $850.8 Million by 2035

Market Growth Overview

The Combined Drill And Countersinks market is forecasted to grow from $372.4 million in 2024 to $850.8 million by 2035, reflecting a compound annual growth rate (CAGR) of 7.8%. This growth is fueled by rising demand across manufacturing sectors and continuous innovations in tooling technology.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/combined-drill-and-countersinks-market-research-report

Key Applications and Market Segmentation

Combined Drill And Countersinks play an essential role in various high-precision industries, including:

CNC machining

Automotive assembly

Aerospace engineering

Medical equipment manufacturing

The market analysis highlights opportunities by Product Type, Application Area, Technology Adoption, Material Compatibility, and Distribution Channel, enabling stakeholders to pinpoint growth areas and revenue streams.

Industry Leadership and Competitive Landscape

The market is intensely competitive, with major players such as:

Dormer Pramet

YG-1 Tool Company

Cleveland Twist Drill

Melin Tool Company

Harvey Tool

MICRO 100

AB Tools

Jergens Inc

Scientific Cutting Tools Inc

MORSE Industrial

Travers Tool Co. Inc

Monster Tool Company

This sector’s growth is further propelled by advancements in tool design and the rising DIY culture influencing manufacturing and industrial work.

Growth Drivers and Emerging Opportunities

Key factors expected to drive the market include:

Modern manufacturing adoption

Strategic collaborations in industrial applications

Innovations tailored to evolving consumer demands

These drivers are expected to create new revenue pockets across demand hubs such as the U.S., Germany, Japan, China, and India.

Regional Dynamics and Supply Chain Evolution

North America and Asia Pacific remain the leading regions in market activity.

Challenges like increasing raw material costs and technological capability requirements are shaping supply chain improvements—from raw material sourcing through manufacturing to distribution and retail.

Industry players are focusing on emerging markets including Brazil, Russia, and Indonesia to diversify revenue and expand the Total Addressable Market (TAM).

About DataString Consulting

DataString Consulting provides comprehensive market research and business intelligence services across B2C and B2B sectors. With over 30 years of combined expertise, DataString specializes in:

Custom market research tailored to business objectives

Strategic advisory and opportunity assessment

Tracking high-growth segments across more than 15 industries worldwide

Our insights help businesses make informed decisions, drive growth, and solve complex market challenges with precision.

0 notes

Text

Exploring the Countersink Drill Bit: The Essential Tool for Precision Recessed Holes.

#Countersink Drill Bit#CountersinkDrillBit#ScrewFixation#DIYTools#WoodworkingEssentials#DrillingSolutions#HomeImprovement#ToolTips#CarpentryBasics#ConstructionTools#PrecisionDrilling

1 note

·

View note

Text

Generator Turbine Magnets Neo Countersunk Segment Arc

Generator Turbine Magnets Neo Countersunk Segment Arc, Neodymium Segment Tile Arc Fan-shape Neodymium NdFeB Wind Turbine Generator Magnets, N50 N52 N54 N56 N48sh N42h N42uh Arc Magnets with Countersunk for Small Wind Turbines Generators Alternators, Powerful and Industrial N52 Neodymium Arc Segment Magnets with Countersunk Hole in Center Generator Turbine Magnets Neo Countersunk Segment…

#Countersink magnet#countersunk hole magnet#countersunk magnet#countersunk magnetic ring#Countersunk pot magnet#countersunk screw magnet#NdFeB magnets#NdFeB rectangular#Pot Magnets with Countersunk#rare earth magnets#rare earth neodymium magnets#Rectangular Countersunk Magnet#Rectangular Neodymium Magnets with countersunk hole#Rectangular Pot Magnets

0 notes

Text

i lied. we aren't having sex. put your clothes back on. its time for me to tell you about acceptable metal standards, attachment styles, and surface finish on body jewellery

#body piercing#IMPLANT GRADE (ASTM-f136) titanium or 14/18k gold. mirror polish. threadless or internally threaded with a good countersink where applicable

1 note

·

View note

Text

chamfer bits are so sexy. just looking at them makes me really want to countersink some holes

12 notes

·

View notes

Text

Our shop's air hose broke & I wanted to make some trinket organizer trays for my toolbox & I remembered I could rivet the yee old fashioned way with an anvil and a hammer so that's what I did half the day. Turned out pretty good too!

I need practice with my countersink cages tho. I never learned how to adjust the style I have properly. Haven't used em much either. But I definitely want the practice cause my countersinks today would have made Howard Hughes want to haunt me (it was his engineers who designed the countersunk rivet right? 😶)

5 notes

·

View notes

Text

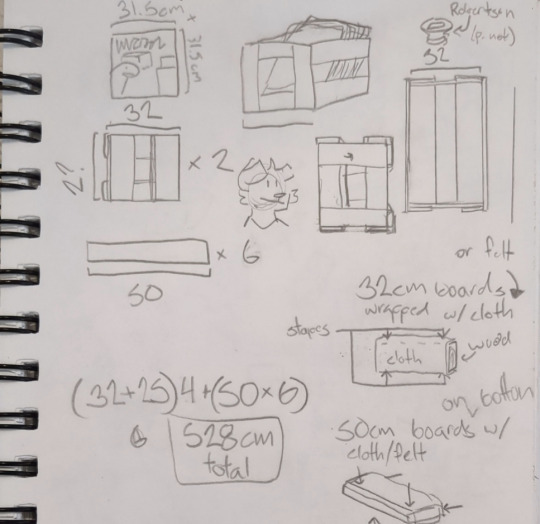

A wooden record crate I made a little bit ago!

I was starting to gather a lot of vinyls and up until now I was using a USPS box that didn't really fit them. So when I out grew that, I decided I really wanted a cool, wooden record crate. Looking online, the nice ones were upwards of $50!!! I thought, "I could probably do that. I did set construction and planning for Theater in High School and made a trebuchet in Middle School!"

More Details and Pictures below the cut!

I did research online of what people have used for record crates in the past. One I really liked was New Zealand ABC Swappa Crates. Their design was industrial, customizable, and simple. Read Read 2

I quickly measured a typical record sleeve and drew up a schematic.

Afterwards, I headed to the hardware store to buy wood. After marveling at all the wood types, I eventually settled on redwood, for its local-ness and icon-status in California, its pretty, soft red color, and its interesting inconsistency in its grain. (Plus it was cheaper than most other woods :') ). It was pretty soft compared to other woods, and prone to splitting, so I had to just be careful using the predrill/countersink I also bought there.

I'm extremely happy with it, and plan to do some other things, such as considering a nice stain and wood burning my name and the date into it, but that's for later. I'd be willing to make another as a commission because it was really fun to plan and make!

^ An older picture, before I added the black felt to the bottom

7 notes

·

View notes

Text

IT Lasers Inc. AIM-1/DLR Aiming Designator

In most of the post-1993 photos of Delta using the AIM-1 series lasers on the Model 723 Carbine, the DLR model seems to be the most common over the original AIM-1/D.

The DLR can be identified by the extended guard protruding from the diode window (however, some of the early DLR models had the same flat glass diode window as the original AIM-1/D model.) This feature allows it to mount an accessory lens cap or a special blue diffuser cap with a variable density aperture (both of which are sadly missing with my example).

The unit I received also came with a PVS-4 rail grabber mount, which with some examples, were machined with a wider countersink and a custom slot to fit the laser in place of the typical carry handle/bracket adapter block.

Admittedly, my unit is in much poorer aesthetic condition than my AIM-1/D, but both work equally the same, and really I was just after the proper remote cable that the DLR kit came with.

My unit was assembled August 1995 and inspected on Christmas of the following year.

^AIM-1/D vs AIM-1/DLR

#delta force#oldschool gear#vintage tactical#car15#gangster grip#aim1d laser#ir laser#colt ar15#colt 723#carry handle

6 notes

·

View notes

Text

Countersink Drill Bit#CountersinkDrillBit #ScrewFixation #DIYTools #WoodworkingEssentials #DrillingSolutions #HomeImprovement #ToolTips #CarpentryBasics #ConstructionTools #PrecisionDrilling

#Countersink Drill Bit#CountersinkDrillBit#ScrewFixation#DIYTools#WoodworkingEssentials#DrillingSolutions#HomeImprovement#ToolTips#CarpentryBasics#ConstructionTools#PrecisionDrilling

1 note

·

View note

Text

Small Wind Turbine Alternator Permanent Magnets Neodymium Segment

Small Wind Turbine Alternator Permanent Magnets Neodymium Segment Tile Arc Fan-shape Neodymium NdFeB Wind Turbine Generator Magnets, N50 N52 N54 N56 N48sh N42h N42uh Arc Magnets with Countersunk for Small Wind Turbines Generators Alternators, Powerful and Industrial N52 Neodymium Arc Segment Magnets with Countersunk Hole in Center Small Wind Turbine Alternator Permanent Magnets Neodymium…

#Countersink magnet#countersunk hole magnet#countersunk magnet#countersunk magnetic ring#Countersunk pot magnet#countersunk screw magnet#NdFeB magnets#NdFeB rectangular#Pot Magnets with Countersunk#rare earth magnets#rare earth neodymium magnets#Rectangular Countersunk Magnet#Rectangular Neodymium Magnets with countersunk hole#Rectangular Pot Magnets

0 notes

Text

Precision Pillar Drill Machines for Heavy-Duty Performance

Need accurate and consistent drilling in your workshop? DIMAKIN’s pillar drill machines are built for strength, stability, and precision. Ideal for drilling into tough metals, these machines are an essential tool for any fabrication or engineering environment.

With a heavy-duty cast iron base and adjustable table height, they ensure stability and smooth operation.

Our pillar drills are commonly used across the automotive, manufacturing, and metalworking sectors for precise hole placement, tapping, and countersinking.

· Reliable performance for industrial drilling

· Suitable for thick metals and hard materials

· Easy adjustment for multiple job types

Looking for dependable drilling performance? Choose a DIMAKIN pillar drill machine and experience professional-grade results!

#industrial pillar drills#industrial pillar drills for sale#heavy duty pillar drill#pillar drills#pillar drill machine

0 notes

Text

5 Common Blind Riveting Mistakes and How to Avoid Them

Blind riveting may seem simple, but even experienced technicians can make costly errors that compromise joint integrity. After training hundreds of professionals across aerospace, automotive, and manufacturing sectors, we've identified the most frequent mistakes that lead to:

Premature joint failure

Costly material damage

Safety hazards

Production delays

In this comprehensive guide, we'll reveal these common pitfalls and provide actionable solutions to help you achieve perfect rivets every time.

1. Choosing the Wrong Rivet Type

The Mistake:

Using standard rivets for specialized applications or selecting incorrect sizes.

Real-World Consequences:

A marine equipment manufacturer used aluminum rivets in saltwater environments, resulting in premature corrosion

An automotive shop used too-short rivets for thick composite panels, causing joint failure

How to Avoid:

Material matching guide:

Aluminum rivets - for aluminum substrates

Stainless steel - for corrosive environments

Monel - for high-temperature applications

Length calculation formula: Rivet length = Material thickness + 1.5 x rivet diameter

2. Improper Hole Preparation

The Mistake:

Drilling holes that are either too large, too small, or have rough edges.

Industry Data:

NASA research shows 38% of rivet failures originate from poor hole quality.

Professional Solutions:

Use sharp, high-quality drill bits specifically for rivet holes

Maintain proper drill speed:

Aluminum: 3,000 RPM

Steel: 1,500 RPM

Composites: 2,000 RPM with backing plate

Deburring techniques:

Countersinking for flush finishes

Diamond-coated deburring tools for composites

3. Incorrect Rivet Gun Handling

The Mistake:

Using wrong pressure settings or improper gun alignment.

Case Study:

An aircraft assembly team experienced 20% rework due to:

Over-compressed rivets (cracking material)

Under-set rivets (loose joints)

Expert Techniques:

Pressure calibration:

Hand tools: 2-3 full squeezes

Pneumatic tools: 60-90 PSI (material dependent)

Proper alignment:

Maintain 90° angle to work surface

Use guide attachments for tight spaces

4. Ignoring Environmental Factors

The Mistake:

Failing to account for temperature, vibration, or chemical exposure.

Industry Examples:

Solar panel mounts failing in desert heat

Truck body rivets loosening from road vibrations

Advanced Solutions:

Environmental adaptation table:ConditionRecommended Rivet TypeHigh vibrationStructural rivetsExtreme tempsMonel or stainlessChemical exposureSealed rivets

5. Skipping Quality Control

The Mistake:

Assuming all installed rivets are good without verification.

Shocking Statistic:

Boeing's QA data shows 7% of production rivets require adjustment after installation.

Professional Inspection Methods:

Visual checks for:

Proper mandrel break

Flush seating

No annular rings

Measurement tools:

Rivet gauges for diameter verification

Ultrasonic testers for aerospace applications

Bonus: Pro Tips from Industry Experts

The "Two-Second Rule": Hold pressure for 2 seconds after mandrel break

Color-coding system for different rivet types/sizes

Monthly tool calibration schedule

Conclusion

Mastering blind riveting requires more than just basic knowledge - it demands attention to detail and proper technique implementation. By avoiding these common mistakes, you'll: ✓ Increase joint reliability ✓ Reduce material waste ✓ Improve production efficiency

0 notes

Video

youtube

centering machine with milling head for axle ends process

Self-centering clamping, One-time clamping and debugging, permanent and automatic acquisition of the center hole position, One-time clamping, complete double-end milling, center hole drilling, chamfering, tapping, countersinking, reaming, and other processing requirements, can be customized and expanded automatic tool magazine,

0 notes

Text

Tube Sheet Drilling: Precision Engineering for Heat Exchanger Efficiency

Introduction to Tube Sheet Drilling

Tube sheet drilling is a highly specialized machining process used to create accurate and aligned holes in tube sheets—critical components in heat exchangers, boilers, pressure vessels, and condenser systems. These precision-drilled holes allow for the insertion and secure mounting of heat exchange tubes, ensuring optimal thermal transfer efficiency and mechanical stability.

With increasing demands in petrochemical, oil & gas, power generation, and chemical industries, high-precision tube sheet drilling has become more essential than ever for leak-proof, high-pressure, and high-temperature applications.

What is a Tube Sheet?

A tube sheet is a thick metal plate, typically made from carbon steel, stainless steel, copper alloys, or nickel-based alloys, that holds tubes in position within a heat exchanger or similar device. These plates are drilled with hundreds or even thousands of holes, each of which must be precisely located and dimensioned to ensure proper tube alignment and flow dynamics.

Tube sheets may be:

Flat or flanged

Cladded or solid

Fixed or floating

The integrity of tube sheet drilling directly influences the operational efficiency and lifespan of the entire equipment.

Key Features of Tube Sheet Drilling

1. Ultra-Precision Hole Placement

Hole pitch accuracy within ±0.02 mm

Accurate alignment for seamless tube-to-sheet welding or expansion

Support for complex configurations like square, triangular, or staggered pitch patterns

2. Custom Hole Diameters

Hole diameters typically range from 10 mm to 50 mm

Precision tools for countersinking, reaming, and chamfering as per design requirements

3. CNC and Multi-Spindle Drilling Options

CNC drilling offers repeatability, speed, and automation

Multi-spindle heads reduce cycle time by drilling multiple holes simultaneously

Option to program tool paths, feed rates, and depths

4. Compatibility with Multiple Materials

High-speed steel and carbide-tipped drill bits for superior performance

Capability to drill cladded tube sheets (e.g., stainless steel + carbon steel)

Coolant-fed tools and optimized cutting conditions to handle exotic alloys

Applications of Tube Sheet Drilling

1. Heat Exchangers

Critical for U-tube heat exchangers, shell & tube designs, and double-pipe configurations

Precise drilling ensures efficient thermal conductivity and mechanical locking

2. Boilers and Pressure Vessels

Supports high-pressure operations

Helps in achieving zero-leakage expansion joints

3. Oil Refineries and Chemical Plants

Used in corrosive environments where precision and metallurgy are key

Hole alignment ensures uninterrupted flow of process fluids

4. Power Generation and Nuclear Plants

Used in superheaters, economizers, and condenser systems

Requires radiographic inspection compliance for nuclear-grade tube sheets

Tube Sheet Drilling Process: Step-by-Step

1. Design and Layout Preparation

3D CAD models or 2D technical drawings created for hole mapping

Pitch, margin, and hole count are finalized

2. Material Preparation

Tube sheets undergo annealing, cleaning, and marking

Plate thickness checked (often ranges from 20 mm to 200 mm)

3. CNC Drilling Operation

CNC-controlled drill head moves in X-Y coordinates

Drilling depth, diameter, and tolerance pre-set for each hole

Coolant system active to prevent heat build-up and tool wear

4. Finishing

Chamfering or reaming if needed

Deburring for smooth hole edges

Non-destructive testing (NDT) to check hole accuracy and spacing

Advanced Technologies in Tube Sheet Drilling

1. Deep Hole Drilling Machines

Capable of handling thick tube sheets over 150 mm

Specialized gun drilling or BTA (Boring & Trepanning Association) methods used

2. Laser Drilling (For Special Alloys)

Non-contact, heat-concentrated drilling

Used where traditional tooling may not work (e.g., titanium, Inconel)

3. Robotic Drilling Systems

Fully automated arms integrated with CAD/CAM

Ideal for custom tube sheets or small production batches

Quality Control and Inspection

1. Dimensional Inspection

Coordinate Measuring Machines (CMM) used for verifying hole positions

Ensures compliance with ASME, TEMA, and ISO standards

2. Surface Integrity Checks

Inspection for burrs, cracks, or work hardening

Use of penetrant testing (PT) and ultrasonic testing (UT)

3. Fit-Up Verification

Tube insertion test to validate hole alignment and tightness

Simulates real working conditions under thermal and hydraulic stress

Choosing the Right Tube Sheet Drilling Partner

When selecting a supplier for tube sheet drilling, consider the following:

Experience in large-diameter tube sheets

Capability for high-volume or prototype jobs

Access to modern CNC drilling machines

Compliance with international QA/QC standards

In-house NDT and post-drilling inspection systems

Conclusion

Tube sheet drilling is more than just a machining task—it is an engineering-critical operation that demands micron-level accuracy, repeatability, and material adaptability. As industries continue to evolve towards energy efficiency and system reliability, precision-drilled tube sheets form the backbone of high-performance heat exchange systems. Investing in advanced tube sheet drilling solutions means investing in long-term operational safety, energy conservation, and system longevity.

1 note

·

View note

Text

0 notes