#customized industrial automation solutions

Explore tagged Tumblr posts

Text

RB Automation, based in Gujarat, is a premier provider of customized industrial automation solutions. Specializing in innovative and tailored automation systems, RB Automation serves a diverse range of industries, enhancing efficiency, productivity, and operational precision. Their expert team collaborates closely with clients to design and implement automation solutions that meet specific needs and objectives. By integrating advanced technologies and offering ongoing support, RB Automation ensures seamless, high-performance automation that drives business success in Gujarat and beyond. For more info visit our website: https://www.rbautomate.com/customized-solutions.html

#Customized Industrial Automation Solutions in Gujarat#industrial automation#customised automation solutions#customized industrial automation solutions

0 notes

Text

#How Digital Marketing Levels the Playing Field for Small Businesses#In today’s fast-paced digital economy#small businesses often face stiff competition from large corporations with significantly higher budgets and established brand recognition.#digital marketing has emerged as a powerful equalizer. At Lavangi IT Solutions#a leading custom software development company Noida#we believe that strategic digital marketing can give small enterprises the edge they need to thrive in a competitive market.#Breaking Barriers Through Digital Channels#Digital marketing eliminates the traditional barriers of advertising by providing cost-effective and highly targeted marketing solutions. W#social media marketing (SMM)#content creation#and paid ads#small businesses can now reach global audiences at a fraction of the cost of traditional marketing.#As a custom software development company Noida#we’ve worked with several startups and SMEs to help them develop scalable digital marketing strategies that produce measurable results.#Tailored Strategies for Maximum Impact#Every small business is unique. Unlike one-size-fits-all solutions#digital marketing allows customization based on specific business needs#industry trends#and customer behavior. Whether it's improving Google rankings through SEO#building brand loyalty on Instagram#or driving traffic with PPC campaigns#our digital marketing experts at Lavangi IT Solutions#a trusted custom software development company Noida#craft strategies that deliver.#We empower our clients with data-driven insights#real-time analytics#and automated marketing tools to help them make informed decisions and stay ahead of the curve.#Leveling the Playing Field#The digital landscape provides equal opportunities to all — whether you're a neighborhood bakery or a tech startup. High-quality content#engaging social media campaigns

0 notes

Text

Exploring Automation Design Services: Innovations and Opportunities

Automation has become a driving force behind the modernization of industries worldwide. In India, the surge in demand for efficient and intelligent manufacturing processes has propelled automation design services India into the spotlight. These services, led by skilled automation designers in India, are creating new opportunities for businesses to innovate, reduce costs, and improve quality.

The Innovation Landscape in Automation Design Services

The core of industrial automation design services India lies in innovation bringing together mechanical engineering, electronics, software, and data analytics to create machines and systems that work smarter. New technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) are increasingly integrated into automation designs, offering unprecedented levels of control and flexibility.

For example, automated systems today can self-diagnose faults, adjust operations in real time, and communicate seamlessly with other equipment on the factory floor. This level of sophistication is reshaping traditional manufacturing into a connected, adaptive ecosystem.

How Automation Designers in India Are Leading the Charge

Automation designers in India play a critical role in translating these technological advances into practical solutions tailored to the unique needs of Indian industries. By combining global best practices with local insights, they design systems that not only improve productivity but also align with cost and operational constraints.

Their work involves conceptualizing custom machinery, integrating robotics, developing control systems, and ensuring that each solution is scalable and maintainable.

Opportunities Created by Automation Design Services India

Increased Competitiveness: Automation enables Indian manufacturers to meet global standards of quality and efficiency, helping them compete in international markets.

Skilled Workforce Development: As automation evolves, there is growing demand for professionals trained in designing, operating, and maintaining automated systems, fostering new career opportunities.

Sustainability Gains: Automated processes often reduce waste and energy consumption, aligning with global sustainability goals.

Customization and Flexibility: Modern automation design allows for greater customization, enabling manufacturers to quickly adapt to changing product designs and market demands.

The Growing Scope of Industrial Automation Design Services India

With sectors such as automotive, pharmaceuticals, FMCG, and electronics embracing automation, the scope for industrial automation design services India continues to expand. These services cover everything from initial design and simulation to prototyping, installation, and after-sales support.

The collaborative approach taken by automation designers in India ensures that solutions are practical, effective, and future-ready.

Why Partner with Experts in Automation Design Services

Navigating the complex world of automation requires expertise. Working with experienced providers of automation design services India ensures your project benefits from:

End-to-end project management

Latest design tools and technologies

Compliance with safety and industry standards

Ongoing support and system optimization

Pure Machine Design’s Role in Driving Innovation

At Pure Machine Design, we harness the latest advancements in automation to deliver cutting-edge automation design services India. Our dedicated team of automation designers in India focuses on creating innovative, reliable, and scalable solutions that empower businesses to transform their manufacturing processes.

Conclusion

The landscape of automation design is rich with innovation and opportunity. As industrial automation design services India evolve, they unlock new potential for efficiency, quality, and sustainability. Forward-thinking companies that engage expert automation designers in India can seize these opportunities to lead in their industries.

Up next: Meet the Leading Automation Designers in India

#Automation Design Services India#Industrial Automation Design Services India#Automation Designers in India#Innovations in Automation India#Smart Manufacturing India#AI in Industrial Automation#IoT in Indian Manufacturing#Intelligent Automation Solutions#Custom Machine Design India#Manufacturing Automation India#Future of Automation in India

0 notes

Text

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

#Life Insurance Policy Administration Systems Market#Insurance Technology Solutions#Policy Administration Software#Market Research Report#Life Insurance Industry Trends#Insurance Software Systems#Digital Transformation in Insurance#Insurance Policy Management#Market Size and Forecast#Insurance IT Solutions#Cloud-Based Policy Administration#Automation in Insurance#Competitive Landscape#Insurance Software Providers#Customer-Centric Insurance Solutions#Regulatory Compliance in Insurance#Emerging Trends in Insurance Tech#Global Insurance Market#Life Insurance Policy Automation#Insurance Industry Innovations

0 notes

Text

iShivax, established in 2019, is a leading global IT solutions provider specializing in software, web, and mobile app development, as well as IoT and automation services. With offices in the USA, India, Canada, and Dubai, they offer end-to-end solutions to clients across over 25 countries. Their mission is to transform business perceptions into reality through technological innovation and a client-centric approach. iShivax has been recognized with several industry awards, including the Tech Innovator Award and the Global IT Leadership Award, underscoring their commitment to excellence and client satisfaction.

#best it companies in jaipur#it company in jaipur#best software companies in jaipur#website development company in jaipur#website designing company in jaipur#ecommerce website development company in jaipur#web development company Jaipur#website design agency nyc#website design company nyc#mobile app development company in new york city#mobile app development companies nyc#custom software development company nyc#iphone app development company nyc#mobile app development company in nyc#website development company nyc#software development companies nyc#software development companies new york#web design company in new york city#it company in Los Angeles#software company in Los Angeles#software development company in Los Angeles#app developer Los Angeles#app development Los Angeles#automation solutions company#industrial automation companies#industrial automation companies near me#performance automation company#iot solutions company#iot development company#iot development services

0 notes

Text

https://flowrocket.com/finance

#Accounting Advisory Servies USA#Accounting and Bookkeeping services for Business#Accouting and Bookkeeping services USA#Best Auditing Services in USA#Hire Accounting Associates in USA#Hire Audit Supervisor in USA#Hire Bookkeeping Associates in USA#Best CRM Software with Collaboration Tools#CRM solutions for Team Colloboration#Best construction CRM Software#CRM Solutions for Construction Management#Best contract management systems in USA#CRM Software for document management#Best CRM for customer support#CRM for customer service solutions#Customer service software in USA#Agile software development services USA#Business Process Automation USA#IT Consulting Service in USA#Lead management CRM software#Lead tracking CRM software#Best CRM for Financial Services#Financial Services CRM Software#Best GRC Software Solutions in USA#CRM for small businesses#CRM Solutions#Top CRM Software USA#Best CRM Software in USA#Industry Specific CRM Solutions#best free crm for insurance agents

0 notes

Text

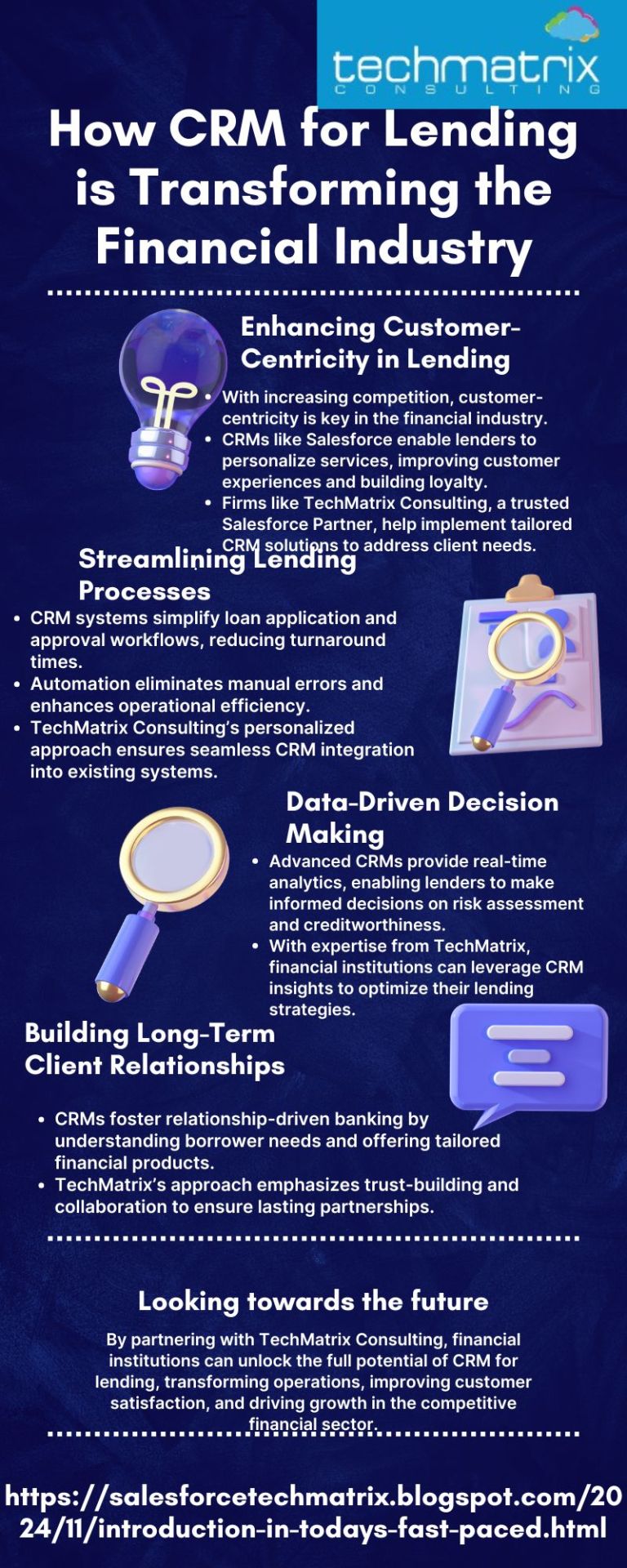

Customer Relationship Management (CRM) solutions are revolutionizing the financial industry by streamlining lending processes, enhancing customer experiences, and driving data-driven decision-making. Companies like TechMatrix Consulting, a trusted Salesforce Partner with a global presence, empower lenders with personalized CRM for lending implementations to meet evolving business needs. CRMs help automate workflows, improve communication, ensure compliance, and deliver actionable insights. With over a decade of expertise and a team of 250+ certified professionals, TechMatrix ensures long-term benefits by building trust, enabling scalability, and fostering collaboration. You can just transform your lending operations with CRM solutions tailored to your goals.

#CRM for lending#Financial industry transformation#Salesforce CRM solutions#TechMatrix Consulting#Customer-centric CRM for banks#CRM benefits in lending#Streamlining loan processes#Lending automation with CRM#Data-driven decisions in lending

0 notes

Text

Valmet's papermaking line for Asia-Pacific customer

Valmet will supply a complete papermaking line from stock preparation to reel and winders with services and a comprehensive automation solution package to one of its major customers in Asia-Pacific. The papermaking line will produce uncoated woodfree grades. The start-up is scheduled for 2026.

The order is included in Valmet's orders received in the fourth quarter 2024. The value of the order will not be disclosed, but such a papermaking line is typically worth between 90 million Euros and 120 million Euros.

This order follows the customer’s previous papermaking line order to the same site, announced in June 2024. “This other fine papermaking line order is strengthening Valmet's position as a supplier for high-speed fine paper machine lines and continues our good co-operation and long-term partnership with the customer,” says Markus Veikkola, Sales Director, China and Asia Pacific, Board and Paper Mills, Paper business line, Valmet.

Delivery’s technical information

Valmet’s delivery will include stock preparation and a high-speed papermaking line from headbox to winders. The delivery also includes a wide range of automation solutions, flow control solutions, Valmet Industrial Internet solutions, paper machine clothing, spare parts, and consumables packages.

#Valmet will supply a complete papermaking line from stock preparation to reel and winders with services and a comprehensive automation solut#The order is included in Valmet's orders received in the fourth quarter 2024. The value of the order will not be disclosed#but such a papermaking line is typically worth between 90 million Euros and 120 million Euros.#This order follows the customer’s previous papermaking line order to the same site#announced in June 2024. “This other fine papermaking line order is strengthening Valmet's position as a supplier for high-speed fine paper#” says Markus Veikkola#Sales Director#China and Asia Pacific#Board and Paper Mills#Paper business line#Valmet.#Delivery’s technical information#Valmet’s delivery will include stock preparation and a high-speed papermaking line from headbox to winders. The delivery also includes a wi#flow control solutions#Valmet Industrial Internet solutions#paper machine clothing#spare parts#and consumables packages.

0 notes

Text

Are you struggling to piece together your business puzzle? 🧩 Magtec ERP Solutions is here to provide you with the missing pieces! 🧩 Join us for a free demo and discover how our innovative software can streamline your operations and drive growth. 📈

#erpsoftware#enterprise#resource#planning#management#solution#software#business#automation#efficiency#productivity#growth#innovation#technology#cloud#saas#onpremises#customization#integration#scalability#security#support#industry#smallbusiness#mediumsizedbusiness#erpsolutions#magtecerp#magtec#magtecsolutions

0 notes

Text

Weldarc India is a leading welding machine manufacturer in India, specializing in custom-made welding solutions to meet the unique demands of various industries. Our cutting-edge technology and innovative designs ensure precision, efficiency, and durability in every machine we manufacture. From automated systems to specialized welding equipment, we cater to various needs, providing reliable, high-quality products that enhance productivity. Committed to excellence, Weldarc India offers exceptional customer service and support, making us the preferred choice for businesses looking for top-notch, custom-made welding machines across the country.

#Custom Welding Machine#Welding Machine Manufacturer in India#Weldarc India#Welding Equipment#Industrial Welding Solutions#Automated Welding Systems#Custom-Made Welding Machines#Indian Welding Manufacturers#Welding Technology#Precision Welding Machines

0 notes

Text

Transform Your Hotel's Guest Experience with SMS & WhatsApp Messaging

Is your hotel struggling to keep up with guest communication? Streamline your communication with SMSGatewayCenter.com Instant Booking Confirmations Personalized Guest Engagement Seamless Check-in & Check-out Real-time Support Promote Special Offers & Loyalty Programs

Simple Setup. Powerful Results. Elevate Your Guest Experience Today! Sign up for a free trial now!

#Hotel Marketing#SMS Marketing#WhatsApp Marketing#Hospitality Industry#Guest Experience#Hotel Communication#SMS Gateway#WhatsApp Business#Hotel Technology#Digital Marketing#Hotel Management#Hospitality Solutions#Customer Engagement#Hotel Offers#Hotel Guest Services#Hotel Automation#Hotel SMS Services#Hotel WhatsApp Integration#SMS Campaigns#Hotel Guest Satisfaction

1 note

·

View note

Text

Custom Welding Machines by Top Raycus Power Source Maker

Weldarc India is a leading custom-made welding machine manufacturer, specializing in providing tailored solutions for diverse industrial requirements. As a reliable power source Raycus machine manufacturer in India, Weldarc India integrates state-of-the-art Raycus laser technology in its welding systems, ensuring precision, efficiency, and reliability. With a commitment to quality and innovation, our custom welding machines are designed to meet our customers' specific requirements, increasing productivity and reducing operating costs. Choose Weldarc India for advanced, custom-engineered welding machines that set new standards in the industry.

#custom welding machines#welding automation#welding automation machine manufacturers in India#custom-made welding solutions#Weldarc India#automated welding technology#industrial welding machines#precision welding systems#Raycus power sources#Indian welding machine manufacturers

0 notes

Text

#Accounting Advisory Servies USA#Accounting and Bookkeeping services for Business#Accouting and Bookkeeping services USA#Best Auditing Services in USA#Hire Accounting Associates in USA#Hire Audit Supervisor in USA#Hire Bookkeeping Associates in USA#Best CRM Software with Collaboration Tools#CRM solutions for Team Colloboration#Best construction CRM Software#CRM Solutions for Construction Management#Best contract management systems in USA#CRM Software for document management#Best CRM for customer support#CRM for customer service solutions#Customer service software in USA#Agile software development services USA#Business Process Automation USA#IT Consulting Service in USA#Lead management CRM software#Lead tracking CRM software#Best CRM for Financial Services#Financial Services CRM Software#Best GRC Software Solutions in USA#CRM for small businesses#CRM Solutions#Top CRM Software USA#Best CRM Software in USA#Industry Specific CRM Solutions#best free crm for insurance agents

0 notes

Text

SCADA Integrators

The Essential Guide to SCADA Integrators: Enhancing Efficiency and Control

In today’s fast-paced industrial landscape, the role of SCADA (Supervisory Control and Data Acquisition) systems is more crucial than ever. These systems allow businesses to monitor, control, and optimize their operations in real time. However, the effectiveness of a SCADA system often hinges on the expertise of SCADA integrators. In this blog, we’ll delve into what SCADA integrators do, why they are important, and how they can help businesses unlock the full potential of their SCADA systems.

What Are SCADA Integrators?

SCADA integrators are specialists who design, implement, and manage SCADA systems tailored to a company’s specific needs. They play a critical role in ensuring that all components of a SCADA system work harmoniously together. This includes integrating hardware, software, and network elements to create a cohesive system that provides real-time monitoring and control.

Why SCADA Integrators Are Vital

Customization and Optimization: SCADA integrators bring a wealth of expertise in tailoring systems to fit unique operational requirements. They ensure that the SCADA system is not just a generic solution but a customized tool that enhances the specific processes of a business. This includes configuring dashboards, setting up alarms, and optimizing data collection methods.

Seamless Integration: Integrators are adept at bridging various components of a SCADA system. This means connecting sensors, PLCs (Programmable Logic Controllers), and other field devices with the central SCADA software. Their work ensures that data flows seamlessly from the field to the control room, facilitating accurate and timely decision-making.

Enhanced Security: Security is a major concern for SCADA systems, as they are often linked to critical infrastructure. SCADA integrators implement robust security measures to protect against cyber threats and ensure that sensitive data remains secure. This involves setting up firewalls, encryption protocols, and regular security audits.

Scalability: As businesses grow, their SCADA systems need to evolve. SCADA integrators help in scaling the system by adding new components, expanding data storage, and integrating with other enterprise systems. This scalability ensures that the SCADA system continues to meet the changing needs of the business.

Troubleshooting and Support: Even the most well-designed SCADA systems can encounter issues. SCADA integrators provide ongoing support and troubleshooting services to resolve any problems quickly. Their expertise minimizes downtime and ensures that operations continue smoothly.

Choosing the Right SCADA Integrator

When selecting a SCADA integrator, consider the following factors:

Experience and Expertise: Look for integrators with a proven track record and experience in your industry. Their familiarity with specific applications and standards can significantly impact the success of your SCADA system.

Customization Capabilities: Ensure that the integrator can tailor the system to your specific needs rather than offering a one-size-fits-all solution. Customization can lead to better efficiency and effectiveness.

Support Services: Assess the level of ongoing support and maintenance offered. A reliable SCADA integrator should provide comprehensive support to address any issues that arise post-implementation.

Security Measures: Verify that the integrator has a strong focus on security, implementing best practices to safeguard your system against potential threats.

Conclusion

SCADA integrators are indispensable partners in harnessing the full power of SCADA systems. Their expertise in customization, integration, security, scalability, and support ensures that businesses can achieve optimal performance and reliability from their SCADA solutions. By choosing the right SCADA integrator, companies can not only enhance their operational efficiency but also stay ahead in an increasingly competitive market.

If you’re considering upgrading or implementing a SCADA system, investing in a skilled SCADA integrator can make all the difference. With their help, you can unlock new levels of control, insight, and efficiency in your operations.

#SCADA Integrators#SCADA Systems#Industrial Automation#Control Systems#Data Acquisition#SCADA Integration#Industrial Control#System Optimization#SCADA Security#Automation Solutions#Industrial Efficiency#Custom SCADA Solutions#SCADA Support#PLC Integration#Real-Time Monitoring

0 notes