#difference between inductive and capacitive proximity sensors

Explore tagged Tumblr posts

Text

The Amazing World of Sensor Detectors are devices that detect and respond

What are Detectors? Detectors are devices that detect and respond to some type of input from the physical environment. The specific input could be light, heat, motion, moisture, pressure, or any other physical phenomenon that can be measured. By converting the input to an electronic signal, detectors enable monitoring and automating real-world processes.

Types of Common Detectors There are many different types of detectors based on the specific input they are designed to detect. Here are some of the most common detectors used today:

Light Detectors Light detectors detect illumination levels and are used commonly in automatic lighting controls, camera auto-focus systems, and digital clocks that glow in the dark. Common light detectors include photo resistors, photo diodes, and photo transistors that change their electrical properties depending on the amount of light striking their active surface.

Temperature Sensor Temperature detectors measure ambient or surface temperature and often output an analog voltage that varies with temperature. Sensor Thermistors and thermocouples are widely used temperature detectors. Thermocouples generate a small voltage proportional to the temperature difference between two junctions of dissimilar metals. Thermistors change their electrical resistance with temperature in a known manner. Temperature detectors find applications in thermostats, medical equipment, heating/cooling systems and more.

Motion Detectors Motion detectors detect movement of objects and people. Passive infrared (PIR) motion detectors are commonly seen in outdoor lighting and security systems. Ultrasonic motion detectors detect motion by sensing changes in ultrasonic patterns. Optical mouse detectors also fall into this category as they sense motion and movement. Industrial robots often use motion detectors to detect position and speed.

Pressure Detectors Pressure detectors measure the force per unit area applied on their surface. Strain gauge pressure detectors change their electrical resistance with the amount of applied pressure. They are used to measure everything from tire pressure to blood pressure. Capacitive pressure detectors use capacitance changes to sense pressure. Piezoresistive pressure detectors alter their electrical resistance when strained under pressure.

Proximity Detectors Proximity detectors indicate if an object is near or within a given distance range without physically touching it. Common proximity detector technologies include ultrasonic, infrared, inductive loops, and laser optical. They find widespread use in industrial machine automation, assembly lines, and object detection applications.

Advancing Micro-Detector Technology As microchip fabrication technology advances, detectors are becoming smaller, cheaper, and more powerful. Microelectromechanical systems (MEMS) allow detector features to be integrated directly onto silicon chips alongside digital circuits. This opens up many new possibilities for pervasive sensing across diverse industries.

Tiny environmental detectors based on MEMS accelerometers and gyroscopes enable motion-activated user interfaces and electronic stability control in vehicles. MEMS pressure detectors monitor engine performance and structural stress. MEMS microphone arrays support speech-enabled user interfaces and noise cancellation. Miniature biodetectors based on chemical detectors, bio-implants, and DNA/RNA identification promise to revolutionize personal healthcare.

The Internet of Things (IoT) is accelerating detector innovations further by connecting everyday objects and environments to the internet. Embedded with detectors, things like home appliances, industrial equipment, vehicles, medical devices, infrastructure, and consumer goods continuously monitor their own status and environmental conditions. Wireless MEMS pressure and temperature loggers track shipments. Smart lighting uses embedded motion and light detectors for enhanced efficiency and user experiences. Detectors will further shrink and proliferate in the coming years towards realizing a fully sensed world.

Future Directions in Sensor Technologay By combining multiple detector capabilities on single chips, we can sense increasingly complex phenomena. Multidetectory systems merge data from MEMS accelerometers, magnetometers, gyroscopes, and microphones to accurately track motion, orientation, and location in three-dimensional spaces. Advanced data processing allows taking inputs from diverse detector arrays to identify odors, flavors, textures, and properties beyond the scope of individual detectors.

Biodetectors and chemical detectors hold much promise in areas like biomedical testing, environmental monitoring, and healthcare. Rapid DNA sequencing using nanodetectors may enable non-invasive, real-time medical diagnostic tests. Taste detectors that mimic human physiology could revolutionize food quality assessment. Small, low power gas detectors networked throughout smart buildings may help detect hazardous leaks instantly. Continued research is sure to yield new types of detectors we have not even imagined yet.

Sensor play a huge role in our world by enabling the interaction between electronics and the real world. Constant advancements in microfabrication and computing power are expanding sensing capabilities to unprecedented levels with each new generation of technology. In the future, sensing will become even more pervasive, intelligent and seamlessly integrated into our daily lives for enhanced convenience, safety, sustainability and scientific discovery. Get More Insights On, Sensor About Author: Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

0 notes

Text

Proximity Sensors: Enhancing Efficiency and Safety Across Industries

What are Proximity Sensors

Proximity sensors identify an object's presence even in the absence of physical touch. Without coming into direct touch with the item, they are made to recognize when it enters the sensor field. In a variety of manufacturing applications, proximity sensors are used to identify the proximity of metallic and non-metallic items.

How Do Proximity Sensors Function?

In the least complex terms, proximity sensors work by communicating information about the presence or movement of an item into an electrical sign. They yield an ON signal when the article enters their reach. There are a few critical contrasts in the manner that different closeness sensors work, as made sense below:

Capacitive Nearness Sensor Working Guideline Capacitive

Proximity sensors work by identifying changes in capacitance between the sensor and an item. Factors, for example, distance and the size of the article will influence how much capacitance. The sensor just recognizes any progressions in the limit produced between the two.

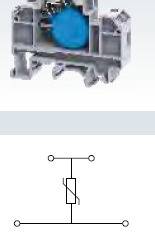

Inductive Nearness Sensor Working Standard

Inductive sensors work by recognizing vortex flows causing attractive misfortune, created by outer attractive fields on a conductive surface. The discovery curl produces an air conditioner attractive field, and impedance changes are distinguished because of the created whirlpool flows.

Attractive Vicinity Switches Working Rule Attractive

Proximity switches are similarly basic and clear. The reed end of the switch is worked by a magnet. At the point when the reed switch is enacted and ON, the sensor additionally turns ON.

It is additionally significant that proximity sensors are not impacted by the surface shade of the article identified. They depend simply on actual development and the movement of an item, so its tone doesn't assume a part in that frame of mind of the sensor.

The Role of Proximity Sensors in Modern Industries

Sensors have become indispensable in today's automated world, serving important functions such as tracking and positioning control. In this field, location and proximity sensors are reshaping several industries. By detecting nearby vehicles in the automotive industry and accurately tracking the location of delivered packages in production, these sensors show their versatility and potential in several fields.

Robotics

Both position and proximity sensors are used in many applications in the field of robotics. For example, linear position sensors are commonly used in robotics and industrial settings for object detection, part fixation, and machine control. These sensors play an essential role in detecting the location, distance, and proximity of moving objects and provide important information for robot navigation and manipulation.

Industrial Automation

Today many manufacturers use these sensors to improve work productivity and efficiency. Integrating position and proximity sensors into production systems enables accurate detection and tracking of objects on conveyor belts, robotic arms, and assembly lines. This combination enables precise object positioning and motion control in industrial processes.

Security systems

Combining proximity and location sensors, security systems can be used to track and control the movement of objects in a certain area. It is useful in surveillance, burglar alarms, and access control systems.

Automotive Applications

The combination of these position and proximity sensors can be used in parking systems to detect open spaces and nearby cars in a parking lot, and accurately track the location of a vehicle for parking assistance. These sensors are also used to improve the safety and performance of Advanced Driver Assistance Systems (ADAS) vehicles.

Smart Healthcare

Location and proximity sensors play a vital role in healthcare, facilitating the monitoring and management of various aspects of medical facilities. Wearable proximity sensors play an important role in both acute and chronic health conditions, as they allow non-contact detection and monitoring of physical movements and interactions.

Food and Beverage Industry

A proximity sensor for food is a type of sensor that is designed specifically for use in the food industry. It is used to detect the presence or absence of food items during various stages of food processing, packaging, and handling.

As technology advances, the integration of location and proximity sensors is expected to increase security, automation, and sensor innovation. based systems in various industries.

#proximity sensors#inductive proximity sensor#proximity sensor types#inductive sensor#what is proximity sensor#proximity sensor price#proximity sensor working#working of proximity sensor#omron proximity sensor#sensors working principle#magnetic proximity sensor#optical proximity sensor#proximity switch sensor#inductive sensor working principle#an inductive proximity sensor comprises#autonics proximity sensor#features of sensors#proximity sensor definition#proximity switch function#capacitive sensor#capacitive proximity sensor#capacitive level sensor#capacitive sensor working

0 notes

Text

Difference Between Inductive And Capacitive Proximity Sensors

Brush up on the fundamentals with this quick guide - understanding the difference between inductive and capacitive proximity sensors. #automation #industrialautomation #sensors #plc #plcprogramming #manufacturing #automationengineer #factoryautomation

Have you recently found yourself staring at two identical-seeming proximity switches? Have you wondered, what the heck is the difference between these two? Or maybe you’re getting ready to buy some sensors. You want to make sure you pick up the right device for the right application. Below, we’ll illustrate the differences between capacitive and inductive proximity sensors. We’ll look at how…

View On WordPress

#capacitive sensors#difference between inductive and capacitive proximity sensors#inductive sensors#industrial automation#proximity sensors#proximity switches

0 notes

Text

Get Close to Proximity Sensors: A Look at the Different Types and Their Applications

Proximity sensors are an essential part of many electronics and industrial applications, helping to detect the presence of objects without physical contact. But did you know that there are different types of proximity sensors, each with their unique characteristics and applications? In this post, we’ll explore the different types of proximity sensors and their various applications in the world of electronics.

Inductive Sensors:

Inductive sensors are a popular choice for detecting metallic objects. They work by generating an electromagnetic field that interacts with a nearby metallic object, causing a change in the sensor’s output. Inductive sensors are commonly used in industrial automation, robotics, and automotive applications.

Capacitive Sensors:

Capacitive sensors use an electric field to detect the presence of an object. They work by generating an electrostatic field between two plates, and when an object enters the field, it causes a change in the capacitance between the plates. Capacitive sensors are used in a wide range of applications, including touchscreens, liquid level sensing, and industrial automation.

Ultrasonic Sensors:

Ultrasonic sensors work by emitting high-frequency sound waves that bounce off objects and return to the sensor, allowing it to calculate the distance to the object. They’re commonly used in robotics and automation, as well as in the automotive industry for parking sensors and collision avoidance systems.

Photoelectric Sensors:

Photoelectric sensors use a beam of light to detect the presence of an object. They work by emitting a beam of light and measuring the amount of light that is reflected back to the sensor. Photoelectric sensors are commonly used in packaging, labeling, and material handling applications.

Magnetic Sensors:

Magnetic sensors use a magnetic field to detect the presence of an object. They work by measuring changes in the magnetic field caused by the presence of a metallic object. Magnetic sensors are commonly used in industrial automation, robotics, and automotive applications.

Conclusion

Proximity sensors are an essential part of many electronics and industrial applications, and there are different types of Proximity sensors available to suit different needs. Whether you’re looking to detect metallic objects, liquid levels, or the presence of an object in general, there’s a proximity sensor that can get the job done. So, get close to proximity sensors and explore their various applications in the world of electronics!

0 notes

Text

Proximity Sensors 101: Their Definition, Types and Utilization- Indus Automation

What Is A Proximity Sensor?

So our first question is “What is a proximity sensor?”. A proximity sensor is a type of sensor that is used to detect the presence of an object. Proximity sensors use various technology and then send signals in a direction to detect the presence/absence of an object in that particular direction. If there is a change in the field or in the return signal, then the instrument determines that there is an object present in that direction. The proximity sensors are very reliable and enjoy a longer lifetime. The object whose presence is detected is called the ‘Target’ of the proximity sensor.

Starting from industrial applications to mobile phones, proximity sensors have created their special fandom in many sectors. Depending on the material type of the targets, the distance between target and sensor, and many other parameters, there are different proximity sensors used for different applications. In this blog, we are going to dive deeper into the different types of proximity sensors. So, continue reading the blog as more interesting stuff is yet to come.

We at Indus automation are building next-generation and technologically advanced automation instruments. Check out and Buy Pepperl Fuchs Proximity sensor offered in the best quality from our website.

What Are the Different Types of the Proximity Sensors?

On the basis of the technology and the types of the sensors used, the proximity sensor can be divided into 4 types, viz.

Inductive sensor

Capacitive sensor

Photoelectric sensor

Ultrasonic sensor

1.

Inductive Sensor

These are based on the principle of Inductance. These possess four substantial parts namely a ferrite core with coils, an oscillator, a Schmitt trigger, and an output amplifier. This type of sensor produces an electromagnetic field to detect the presence of the target.

It can detect the ferrous material with the help of the Eddy current induced on the material surface because of the magnetic field produced by the inductive sensor.

These possess a target detection range from a fraction of millimeters to 60 mm on average.

They are mostly found Some of the common places where these sensors are used include metal detectors, carwashes, traffic lights, and automated industrial processes. Visit our website and Buy Pepperl Fuchs Proximity sensor with premium quality, better reliability and longer working life.

2.

Capacitive Sensor

These are based on the principle of capacitors and capacitance. These sensors produce an electrostatic field to detect the target.

These sensors can detect both the metallic and non-metallic targets which are present in different forms like solid, liquid, powder, and granular.

As these involve charging of plates, hence slower in operation. These possess a target detection range from a few millimeters to 1 inch (25mm) or so.

Due to their non-ferrous detection, these are suitable for use in applications like sight glass monitoring, tank liquid level detection, and also for hopper powder level detection. Alongside this, these are used for many metallic detections as well.

3.

Photoelectric Sensor

Photoelectric sensors are based on rapidly advancing photoelectric technology. The main basic components present in these sensors are an emitter light source, a photodiode or phototransistor receiver, and supporting electronics designed to amplify the receiver signal.

The photoelectric sensors can be used to detect most the materials like metal, plastic, and wood.

Due to the advanced use of photoelectric technology, these can sense the target present up to a distance of 60 meters or so.

These sensors are found in huge demand and application in the industrial manufacturing sectors.

4.

Ultrasonic Sensor

The Ultrasonic sensors deploy sound waves to detect the presence of a target.

It detects several kinds of materials like plastic, glass, wood, and metal.

The target detection distance ranges from 1 cm up to 11 meters.

These are mainly used in the automated production process. As these are not affected by the color and transparency of the target, that’s why they are used for applications like the detection of clear glass or plastic.

What Do We Offer?

We at Indus automation are providing the best-in-class automation equipment from the well-recognized and quality equipment manufacturers like Pepperl + Fuchs, Autonics, Envitec, and Honeywell. Get the best quality actuators from the large assortment present on our website. Check out and Buy Pepperl Fuchs Proximity sensor at the best price from our website, with the trust of the world-famous Pepperl Fuchs brand and the reliability of Indus automation which is one of the best automation instrument distributors in India.

Conclusion

To buy Buy Pepperl Fuchs Proximity sensor or for any queries, you can contact us at 022 4970 1186 or mail us at [email protected] / [email protected]. We will be really glad to help you out. If you have any doubts related to the proximity sensor and its types, then drop a comment below and we will get back to you at the earliest.

0 notes

Text

THE SENSORS USED IN AN IPHONE

Retrieved from: https://www.azosensors.com/article.aspx?ArticleID=66

Proximity Sensor

The main purpose of a proximity sensor is to measure how close the sensor device is to a particular target. In relation to the iPhone®, this proximity sensor helps the iPhone® device screen switch off as soon as the user moves the device closer to the ear. This sensor-driven control prevents the accidental activation of a touch button whilst the user talks on the phone and saves power.

There are two types of proximity sensors in use: capacitive and inductive sensors. Most modern-day phones are designed with an integrated capacitive proximity sensor. The following video is a great introduction to capacitive touch sensing.

This sensor produces a varying capacitance that interacts with the oscillator circuit. In the event of a change in capacitance as a result of being touched by a finger (external source), the oscillator frequency also changes. This change in capacitance is measured via a frequency measurement component. The basic functional principle is based on a number of variables that change the capacitance. Distance and area are the most important parameters that impact the change in capacitance – the greater the area, the greater the capacitance. A larger distance between the sensor device and the target results in a fall in capacitance.

Motion Sensor/Accelerometer

Motion sensors allow the iPhone® device to switch from a landscape to a portrait display as a result of the user manipulating the direction of the device. A basic functional principle to a motion sensor involves the transformation of the detection of motion into an electrical current. Detection of motion is achieved by measuring the optical change in the target field of view.

The majority of motion detectors are engineered to accurately access data on optical change up to 15–25 meters in length. There are four main types of motion sensors in the iPhone®: passive infrared sensors, ultrasonic, microwave, and tomographic detectors.

Ambient Light Sensor

A typical ambient light sensor detects the intensity of light surrounding the iPhone® and processes this information to help adapt the phone light accordingly. Adjustment to the brightness of the iPhone® screen is a conventional method to help conserve as much battery life as possible. Ambient light sensors work by blocking or filtering the infrared and ultraviolet wavelengths.

Phone devices that are engineered with an ambient light sensor will have these sensors embedded underneath the protective layer of the cover glass. Using photodiodes (light sensors typically used in mobile phones), these sensors detect ambient light intensity and respond to this sensory input by generating a proportional output voltage.

This output voltage travels to the LED driver mode and thus manipulates the LED output current and light intensity to the phone. The following video animates how the LED system works.

The LED structure is silicon-based and has a negative and positive element, which when bridged together create a positive-negative junction and this junction generates energy in the form of light.

Moisture Sensor

The design and engineering process for the iPhone® range is continuously changing to help create the most intuitive device possible for its user. Moisture sensors have also become an important sensor component for this range of cell phones. This type of sensor works by alerting the user when the phone has contact with water.

Moisture sensors are commonly used to take soil moisture measurements. One method to help prevent a malfunction with the iPhone® following its immersion into the water may be to envelop the moisture sensor in a conductive glue to behave as an insulating layer. The idea here is for the device to detect the speed at which the conductive glue is eroded by water molecules.

Recent developments

With the development of newer generations of the iPhone®, a host of other sensors have been introduced.

Gyroscope

A three-axis gyroscope was introduced starting with the iPhone® 4 models. Along with the accelerometer, this gives the phone a six-axis operation, making it more responsive for applications that require the phone to detect how it is held and moved. The gyroscope in the iPhone® is a tiny microelectromechanical (MEMS) device that captures orientation with great accuracy.

Location Sensor/GPS

A GPS system inside the phone determines the location of the phone using satellites. It connects to different satellites, and the satellite data can also be combined with other phone data, such as signal strength, to provide the location with much greater accuracy.

Barometer

A barometer senses air pressure and may be used for weather sensing or to determine altitude.

Compass

iPhone® models now come with a built-in compass that can help show in which direction one is going. Although it does not work in a standalone mode, it works in tandem with location sensors, GPS, and other apps, to help determine the phone’s location.

Fingerprint Sensor

iPhone® models starting with the iPhone 5s have a fingerprint sensor that can be used to unlock the phone and apps. It is embedded in the Home button and allows one to use a fingerprint to unlock the device rather than or in addition to using a passcode.

Face ID

Some latest models of the iPhone® come with a facial recognition sensor, replacing the fingerprint sensor or the passcode for unlocking the phone. The sensor works by projecting more than 30 000 dots on a face, which helps build a 3D map of the face. An infrared camera converts these dots into an image, which is compared to the data stored on the phone to unlock the device.

0 notes

Text

What are protection Modules? Why protection modules are required?

Protection modules are components used in the circuit or in the control panel to avoid the interference of noise.

Electrical apparatus used; may be enclosed (e.g., motors) or placed in the open (e.g., transmission lines). All such equipments’ undergo aberrations in their lifetime due to various reasons. It becomes necessary to avoid these abnormal operating circumstances for the safety and longevity of the equipment.

What is Noise?

Noise is an unwanted signal that combines with the original signal and this could be in a temporary or either in a permanent form. Noise gets generated in the electrical and electronic systems while transmitting signals.

The level of noise in any signal depends on the length of the cable, the proximity of the strongest signal in nearby cable and the other wires around the signal cable.

For sensor and communication signals; especially noise is an enemy and it could tremendously degrade the quality of the signals.

It is difficult to eliminate noise from the surrounding but Connectwell has solutions that eliminates its effect from affecting your control system. This solution is known as protection modules.

Given below are scenarios that causes noise and solutions on how we can avoid it.

What Causes Noise?

There are two causes of noise, one being natural phenomena and the other is due to electrical and electromechanical instruments.

What are the Natural sources of Noise?

· Lightning

· Static electricity

· Thermal shot

· Solar radiation

· Hurricanes

The above mentioned are some of the natural phenomena that affect the electrical signal tremendously. Although this cannot be avoided; however we can prevent our equipment from damage.

Solutions to avoid interference through natural sources?

There are various solutions available in the market such as Surge Protectors, Earth-leakage circuit breakers, phase failure devices, metal oxide varistor, diode modules, RC circuits or fuse modules are used in the panels to protect your control panel from damage.

What are the sources of noise other than Natural Phenomena?

Other than the natural phenomena mentioned above there are other factors which causes the noise. I have listed a few of them below.

1. Electromagnetic interference.

This is a major source of noise; if two cables are running parallel to each other, then the electromagnetic interference of one cable causes an effect on the other cable and noise gets induced in this second cable, this noise would change the potential of the signal which causes misbehaving of the devices running on that signal.

How to avoid electromagnetic interference-

To avoid this noise, the signal carrying cables should be twisted in pairs. This would eventually nullify the electromagnetic effect.

2. Back E.M.F.

In components which include an induction coil, Back EMF is generated. The induction coil stores some part of the energy and in the absence of the main source it discharges itself. The discharge is typically of low period and high current, which acts as sure for the other component in the systems, typically a panel. E.g Relays, transformers, and contactors produce Back EMF. This Back EMF eventually damages the other components.

How to avoid Back EMF?

Back EMF cannot be avoided, but it can either be utilised as energy or, it can be grounded. Railways employ the circuit in a way that while breaking the motors; the back EMF generated to provide back to the electric line. This involves complex and costly components and circuit design. For smaller application relays and transformers-a simple protection diode can be used.

3. Direct Electric contact-

This type of noise is generated due to common ground for the two different signals. In this case, the voltage variation in one signal causes variation in another, this is known as direct electric contact or Galvanic Noise.

How to prevent Direct Electric Contact type Noise?

Use separate signal cables for the return path cables. This would eliminate galvanic noise.

4. Electrostatic noise-

Following are some of the common reasons that cause electrostatic noise.

1. Two cables running parallel to each other generate an electrostatic capacitance. This generates the electrostatic noise. The electrostatic capacitance gets generated between the two signal cables and causes an additional voltage level in the signal.

2. The potential difference between two conductors is a source of noise.

3. A non-operating fluorescent bulb is a source of generation of noise due to fluctuation.

4. Open conductors also generate noise.

How to avoid Electrostatic noise-

By using the shielded cables the electrostatic capacitance eliminates the electrostatic noise.

5. Radio Frequency interference-

Tele-communication network uses radio frequency signals for communication. Around the globe, the telecommunication network has evolved tremendously. Gadgets like television, telephone, mobiles, radios/FM uses radiofrequency for communication and hence causes a glitch to the signal carrying cables. Although the radio signal effect on the signal cable is low as compared to other types due to the low signal levels when affected, it degrades the signal.

How to avoid radio frequency interference-

Generally, radio frequency signals are fixed and hence the filter can be designed in such a way that the particular frequency signal can be avoided. A complex filter circuit is required for avoiding the radio frequency signals.

What Connectwell Offers?

Connectwell offers various types of protection modules such that surge protectors, SPDs, fuse modules, diode modules and RC filters which will protect your instruments from noise and interference

Surge suppression Terminal block

These are specially designed terminals with surge suppression unit and are generally used for protection from surges due to natural as well non-natural phenomena.

Terminal with MOV.

MOV stands for Metal oxide varistor. It acts as short circuit in case of surge at the input so that the extra voltage can be grounded and the output component can be saved from damage.

Terminal Block with Protection diode

Diodes are generally used for polarity protection as it blocks reverse current. This is generally used with inductive load which saves the equipment from back EMF.

RC protection terminal block

RC filter finds the application in various segments. To avoid radio frequency interference these modules are used. Noise generated through the electromagnetic interference can be nullified by using RC filters.

Terminal block with fuse.

There are multiple instances where the instrument damages due to the overcurrent. Using fuse module can save your instrument from damage.

0 notes

Text

Proximity Sensors Market 2020 Major Growth Player to 2027

The market study on the global market for Proximity Sensors examines current and historical values and provides projections based on accumulated database. The report examines both key regional and domestic markets to provide a conclusive analysis about the developments in the Proximity Sensors market over the forecast period.

Get Free Research Summary of the Report@ https://www.researchkraft.com/request-sample/1061862

The Global Proximity Sensors market report provides a systematic picture of the sector by way of study, synthesis, and summary of info originated from different sources. The experts have provided the various sides of the sector with a particular goal on identifying the major manipulators of the sector. The Global Proximity Sensors market report correspondingly comprises a detailed market & vendor landscape aside from a SWOT analysis of the major players.

Global Proximity Sensors Market Fragmentation as follows:

Fragmentation by Type Analysis

Inductive Proximity Sensors

Capacitive Proximity Sensors

Magnetic Proximity Sensors

Photoelectric & Ultrasonic Proximity Sensors

Optical Proximity Sensors

Fragmentation by Application Analysis

Aerospace & Defense

Automotive

Industrial Manufacturing

Consumer Electronics & Building Automation

Others

Fragmentation by Company Analysis

Omron Corporation, Pepperl + Fuchs, Broadcom, STMicroelectronics, Honeywell, Sick, Avago Technologies, Schneider Electric, Red Lion, Panasonic Corporation, Balluff GmbH, IFM Electronic, Rockwell Automation, Eaton, Shanghai Lanbao Sensing Technology, Comus Group

Global Proximity Sensors Market Regional analysis includes::

North America

Europe

China

Japan

Southeast Asia

India

Get this report at an attractive cost @ https://www.researchkraft.com/check-discount/1061862

The Global interest for Proximity Sensors Market is gauge to report solid improvement driven by utilization in major developing markets. Area astute government strategy, advertise condition, serious scene, present patterns in the market, mechanical development, up and coming advances and the specialized advancement in related industry are immensely significant elements affecting the development of the market. Since more development open doors are relied upon to come up between 2020 to 2027 contrasted with a couple of years prior, it implies the fast pace of progress and is protected to state that the Proximity Sensors market improvement status and future pattern is required to be promising over the world.

Make an Enquiry about this report @https://www.researchkraft.com/send-an-enquiry/1061862

About Us:

Customization of this Report: The report is customized to satisfy the customer's requirements. Please join to all our sales, who'll make sure you acquire a report which works for your needs.

Contact Us:

Email: [email protected]

0 notes

Text

Capacitive Proximity Sensors Market: Comprehensive Analysis and Future Estimations 2026

With emerging industrial developments and advancement in technologies, many industries are adopting upgraded technologies. A non-contact sensing technology that detects solids, liquids, metals and nonmetals is termed as capacitive sensing. The capacitive proximity sensors do not have any physical contact with materials and they work on the principle of capacitor. Capacitive proximity sensors are used on a large basis during the production process to detect various materials such as plastics and granular materials such as powders. Unlike the inductive sensors which use magnetic field for sensing, capacitive proximity makes use of electrostatic force to sense the target object. Oscillator, plate, threshold detector and output circuit are the primary components of a capacitive proximity sensor.

Material handling is one of the growing applications in automation, manufacturing and other extended industries. Capacitive proximity sensors are highly essential to manage material handling activities efficiently during the production processes. Detection of non-ferrous materials from the end product or during the production process is necessary and capacitive proximity sensors help in performing these functions as they are highly functional in detection of non-ferrous materials such as liquids, wood, glass and plastic.

Request Brochure https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=20093

Capacitive proximity sensors can see through many objects to detect the materials such as package and boxes amongst many others. This feature of capacitive proximity sensors give them an added advantage over the traditional sensing technologies driving the demand for capacitive proximity sensor market. It is a high result yielding and cost effective method of material handling and management for organizations. Complexities in using optical detection methods has also increased the demand for capacitive proximity sensors as capacitive proximity sensors come with added advantages. Capacitive proximity sensors are usually of low cost and high speed, also, they consume less power compared to photoelectric sensors and ultrasonic sensors.

Such features make capacitive proximity sensors cost effective and increases their popularity among the customers. Increase in manufacturing facilities and the growth of production plants is one of the major driver of the capacitive proximity sensors market. The ability to simplify and decrease the time consumption in production functions, while enhancing dependability, accurateness and involvement of low task force are the additional market drivers. One of the limitations to capacitive proximity sensor market could be their sensitivity towards environmental changes such as humidity and temperature, which may affect the sensing strength of capacitive proximity sensors. With growing awareness of capacitive proximity sensors, various end use industries are adopting capacitive proximity sensors to enhance the procedures and processes.

Get ToC Of Report https://www.transparencymarketresearch.com/sample/sample.php?flag=T&rep_id=20093

Rectangular capacitive sensor and cylindrical capacitive sensor are two types of capacitive proximity sensors according to the shape. Manufacturing, transportation, automotive, energy and defense are a few end use verticals of capacitive proximity sensors. Parallel plate and parallel fingers are some of the basic topologies used in the capacitive proximity sensors. Sensor topologies depend on different parameters such as distance between the sensor and target, dielectric constant of the target and the desired sensitivity.

Some of the vendors engaged in capacitive proximity sensors market are Pepperl+Fuchs GmbH, Rockwell Automation Inc., Honeywell International Inc., Omron Corporation, General Electric (GE), Eaton Corporation Plc., Panasonic Corporation, Siemens AG, Balluff Inc., Broadcom Limited, Altechcorp, Gravitech and Standex Electronics GmbH.

0 notes

Text

Types Of Proximity Sensors Used In Industrial Automation

Want to understand the difference between inductive and capacitive proxes? Want to learn how photoelectric sensors operate? Read up on the different types of proximity sensors used in manufacturing! #automation #sensors #manufacturing #PLC #robotics

When you write logic in a PLC that initiates motion, you want to be certain that the motion you are expecting actually occurs. This is where sensors come into play. Sensors provide indication to the PLC, robot, or other controller that some physical event has taken place. As examples, sensors may detect that a part is present, that a part is notpresent, that an actuator is in a certain position,…

View On WordPress

#capacitive sensors#hall effect sensors#inductive sensors#industrial automation#magnetic sensors#photoelectric sensors#photoeyes#prox sensors#prox switch#proxes#proximity sensors#proximity switches#sensor applications#sensor basics#ultrasonic sensors

0 notes

Text

Capacitive Proximity Sensors Market: Repository of Analysis and Information for Every Facet of the Market

With emerging industrial developments and advancement in technologies, many industries are adopting upgraded technologies. A non-contact sensing technology that detects solids, liquids, metals and nonmetals is termed as capacitive sensing. The capacitive proximity sensors do not have any physical contact with materials and they work on the principle of capacitor. Capacitive proximity sensors are used on a large basis during the production process to detect various materials such as plastics and granular materials such as powders. Unlike the inductive sensors which use magnetic field for sensing, capacitive proximity makes use of electrostatic force to sense the target object. Oscillator, plate, threshold detector and output circuit are the primary components of a capacitive proximity sensor.

Material handling is one of the growing applications in automation, manufacturing and other extended industries. Capacitive proximity sensors are highly essential to manage material handling activities efficiently during the production processes. Detection of non-ferrous materials from the end product or during the production process is necessary and capacitive proximity sensors help in performing these functions as they are highly functional in detection of non-ferrous materials such as liquids, wood, glass and plastic.

Capacitive proximity sensors can see through many objects to detect the materials such as package and boxes amongst many others. This feature of capacitive proximity sensors give them an added advantage over the traditional sensing technologies driving the demand for capacitive proximity sensor market. It is a high result yielding and cost effective method of material handling and management for organizations. Complexities in using optical detection methods has also increased the demand for capacitive proximity sensors as capacitive proximity sensors come with added advantages. Capacitive proximity sensors are usually of low cost and high speed, also, they consume less power compared to photoelectric sensors and ultrasonic sensors.

Request Brochure https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=20093

Such features make capacitive proximity sensors cost effective and increases their popularity among the customers. Increase in manufacturing facilities and the growth of production plants is one of the major driver of the capacitive proximity sensors market. The ability to simplify and decrease the time consumption in production functions, while enhancing dependability, accurateness and involvement of low task force are the additional market drivers. One of the limitations to capacitive proximity sensor market could be their sensitivity towards environmental changes such as humidity and temperature, which may affect the sensing strength of capacitive proximity sensors. With growing awareness of capacitive proximity sensors, various end use industries are adopting capacitive proximity sensors to enhance the procedures and processes.

Rectangular capacitive sensor and cylindrical capacitive sensor are two types of capacitive proximity sensors according to the shape. Manufacturing, transportation, automotive, energy and defense are a few end use verticals of capacitive proximity sensors. Parallel plate and parallel fingers are some of the basic topologies used in the capacitive proximity sensors. Sensor topologies depend on different parameters such as distance between the sensor and target, dielectric constant of the target and the desired sensitivity.

Get ToC Of Report https://www.transparencymarketresearch.com/sample/sample.php?flag=T&rep_id=20093

Some of the vendors engaged in capacitive proximity sensors market are Pepperl+Fuchs GmbH, Rockwell Automation Inc., Honeywell International Inc., Omron Corporation, General Electric (GE), Eaton Corporation Plc., Panasonic Corporation, Siemens AG, Balluff Inc., Broadcom Limited, Altechcorp, Gravitech and Standex Electronics GmbH.

0 notes

Text

Handset Proximity Sensors Market to Record an Exponential CAGR by 2024

Modern smartphones are packed with a number of sensors that enable them to collect a variety of different kinds of data on who the user is, what the user is doing, and more. Most sensors are added to make smartphones more engaging, convenient, and increasingly useful for the user. Handset proximity sensors are commonly found in touchscreen smartphones and play the primary role of disabling accidental touch events.

Read Report Overview @

https://www.transparencymarketresearch.com/handset-proximity-sensors-market.html

Touch-enabled screens in smartphones often face the issue of touch events such as the cheek or ear coming in contact with the screen while on a call. To solve the issue, manufacturers have started placing proximity sensors close to the phone’s speaker, which detect any activity in the vicinity of the speaker. Typically, the phone assumes the touch events to be accidental and ignores them, avoiding any unwanted inputs or the activation of any other functions on the smartphone in the background.

As smartphones take the world by storm and competition among vendors continues to become increasingly severe, manufacturers are placing increased focus on making their products better than their counterparts’ by introducing innovative features. The addition of proximity sensors is among one such attempts at making smartphones, especially the ones with touch-enables screens, more convenient for use. Over the past some years, proximity sensors have become a norm in most smartphones and the market for these tiny elements has seen a huge surge.

This report on the global handset proximity sensors market gives an expansive account of the present state of the market and a forward-looking perspective about the market’s growth over the period between 2016 and 2024. The report includes a thorough analysis of the impact of major growth drivers, challenges, and trends on the overall development of the market over the said period.

A proximity sensor normally emits a beam of an electromagnetic radiation or an electromagnetic field and calculates the changes in the return signal. A variety of handset proximity sensors are available in the market, including electrical, optical, sonar, and magnetic. The segment of electrical handset proximity sensors includes varieties such as capacitive, photoelectric, and inductive sensors. The segment of optical handset proximity sensors includes varieties such as laser and infrared sensors.

Of these, the class of optical handset proximity sensors, known to be the most cost-effective and non-intrusive proximity sensor varieties in the market presently, is one of the most popular choices of smartphone manufacturers. The market for optical handset proximity sensors, especially infrared sensors, is projected to witness growth at a healthy pace over the forecast period. The market has been examined for the regional markets Asia Pacific, Europe, North America, and for the Rest of the World (RoW).

The global handset proximity sensors market features the presence of many companies and the competition is severe. To overcome the challenge of limitations in product variations, which are also constraining the market’s growth to a certain extent, companies are focusing more on developing sensors with improved sensing capabilities and longer workable life.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=11972

The report gives a thorough overview of the competitive scenario of the global handset proximity sensors market. The report includes detailed business profiles, finance and revenue-related details, market strategies, details pertaining to recent product and technological developments, and other information for some of the most prominent vendors in the market.

0 notes

Photo

Most multi-stream waste recycling systems rely heavily on hand-sorting different types of waste into separate bins. For his senior thesis project, electrical engineering concentrator Samwel Emmanuel, S.B. '17, engineered a small-scale, inexpensive, and easy-to-use waste disposal unit that can identify different materials and sort them into different sections. His device uses five different sensors, a combination of ultrasonic sensor, photoelectric sensor and weight sensor for distinguishing between plastic and glass pieces of waste, an inductive proximity sensor to detect metallic waste, and a capacitive proximity sensor to detect organic waste. Moving forward, he hopes to enhance the robustness of the sorting unit by adding additional sensors and also incorporate smart message system (SMS) capabilities so the device can notify a user by text message when it is full and needs to be emptied.⠀ #Harvard #LifeatSEAS #HarvardSEAS #AmericaRecyclesDay #recycling #sustainability (at Harvard John A. Paulson School of Engineering and Applied Sciences)

0 notes