#dissolution testing machine

Explore tagged Tumblr posts

Text

Dissolution Tester NDST-105

Labnics dissolution tester has 14 vessels, a stirring speed range of 10-300 rpm and a water bath heating system with temperature control accuracy of ≤±0.5°C. It features 14 sampling channels, an autosampler and a segmented shaft design, ensuring precise and efficient dissolution testing.

1 note

·

View note

Note

"Everything the USSR didn't like was a cia fbi capitalist western buzzword psyop" tankie ass

You make the mistake of assuming I support the USSR out of a dogmatic belief, but it is the opposite.

The USSR did many horrible things, religious repression and passive Russification mainly harmed non-Judaic and non-Christians.

The early deportations and relocations were also completely unnecessary and whatever benefits they got from these actions were far outweighed by the damage the capitalists have done with their propaganda.

That being said, it was also the first ever socialist experiment. I am also not dogmatically against the US, but the fact that the US is the main arbiter of imperialism, casts a light on every action they take and every word they say. A lot of the information we know now about the Soviet Union was from after its illegal dissolution, and as such we can’t ask the Soviet government for their side anymore. All we can do is take the information we have, compare it against all claims, and come to our own conclusion.

That process is called dialectics by the way, and it is the philosophy which underpins all of Marxism. Marxism. Is. A. Scientific. Method. It is the application of dialectical materialism to the historical materialism and using that analysis to synthesize a hypothesis. Like all historians, the Marxist hypothesis can’t be tested because we don’t have a Time Machine. So what do we do? We create experiments

That’s what the USSR was, and it did many things right and quite a bit wrong. We have a lot to learn, but we can only learn from history when we learn it truthfully. Shutting down and going ‘Muh authoritarianism!1!1!1!1 buzzword!1!1!1!1 100 gorbillion dead!1!1!1” isn’t an argument, it isn’t a hypothesis, it isn’t analysis. It’s a dogmatic thought-terminating cliche.

#capitalism#kamala harris#climate change#democrats#donald trump#economy#kamala 2024#liberals#socialism#communism#marxism#marxism leninism#anarchism#anarchist

87 notes

·

View notes

Text

What it meant to "do geology" in Hutton's time was to apply lessons of textual hermeneutics usually reserved for scripture [...] to the landscape. Geology was itself textual. Rocks were marks made by invisible processes that could be deciphered. Doing geology was a kind of reading, then, which existed in a dialectical relationship with writing. In The Theory of the Earth from 1788, Hutton wrote a new history of the earth as a [...] system [...]. Only a few kilometers away from Hutton’s unconformity [the geological site at Isle of Arran in Scotland that inspired his writing], [...] stands the remains of the Shell bitumen refinery [closed since 1986] as it sinks into the Atlantic Ocean. [...] As Hutton thought, being in a place is a hermeneutic practice. [...] [T]he Shell refinery at Ardrossan is a ruin of that machine, one whose great material derangements have defined the world since Hutton. [...]

The Shell Transport and Trading Company [now the well-known global oil company] was created in the Netherlands East Indies in 1897. The company’s first oil wells and refineries were in east Borneo [...]. The oil was taken by puncturing wells into subterranean deposits of a Bornean or Sumatran landscape, and then transported into an ever-expanding global network of oil depots at ports [...] at Singapore, then Chennai, and through the Suez Canal and into the Mediterranean. [...] The oil in these networks were Bornean and Sumatran landscapes on the move. Combustion engines burnt those landscapes. Machinery was lubricated by them. They illuminated the night as candlelight. [...] The Dutch East Indies was the new land of untapped promise in that multi-polar world of capitalist competition. British and Dutch colonial prospectors scoured the forests, rivers, and coasts of Borneo [...]. Marcus Samuel, the British founder of the Shell Transport and Trading Company, as his biographer [...] put it, was “mesmerized by oil, and by the vision of commanding oil all along the line from production to distribution, from the bowels of the earth to the laps of the Orient.” [...]

---

Shell emerged from a Victorian era fascination with shells.

In the 1830s, Marcus Samuel Sr. created a seashell import business in Houndsditch, London. The shells were used for decorating the covers of curio boxes. Sometimes, the boxes also contained miniature sculptures, also made from shells, of food and foliage, hybridizing oceanic and terrestrial life forms. Wealthy shell enthusiasts would sometimes apply shells to grottos attached to their houses. As British merchant vessels expanded into east Asia after the dissolution of the East India Company’s monopoly on trade in 1833, and the establishment of ports at Singapore and Hong Kong in 1824 and 1842, the import of exotic shells expanded.

Seashells from east Asia represented the oceanic expanse of British imperialism and a way to bring distant places near, not only the horizontal networks of the empire but also its oceanic depths.

---

The fashion for shells was also about telling new histories. The presence of shells, the pecten, or scallop, was a familiar bivalve icon in cultures on the northern edge of the Mediterranean. Aphrodite, for example, was said to have emerged from a scallop shell. Minerva was associated with scallops. Niches in public buildings and fountains in the Roman empire often contained scallop motifs. St. James, the patron saint of Spain, was represented by a scallop shell [...]. The pecten motif circulated throughout medieval European coats of arms, even in Britain. In 1898, when the Gallery of Palaeontology, Comparative Anatomy, and Anthropology was opened in Paris’s Museum of Natural History - only two years after the first test well was drilled in Borneo at the Black Spot - the building’s architect, Ferdinand Dutert, ornamented the entrance with pecten shell reliefs. In effect, Dutert designed the building so that one entered through scallop shells and into the galleries where George Cuvier’s vision of the evolution of life forms was displayed [...]. But it was also a symbol for the transition between an aquatic form of life and terrestrial animals. Perhaps it is apposite that the scallop is structured by a hinge which allows its two valves to rotate. [...] Pectens also thrive in the between space of shallow coastal waters that connects land with the depths of the ocean. [...] They flourish in architectural imagery, in the mind, and as the logo of one of the largest ever fossil fuel companies. [...]

---

In the 1890s, Marcus Samuel Jr. transitioned from his father’s business selling imported seashells to petroleum.

When he adopted the name Shell Transport and Trading Company in 1897, Samuel would likely have known that the natural history of bivalves was entwined with the natural history of fossil fuels. Bivalves underwent an impressive period of diversification in the Carboniferous period, a period that was first named by William Conybeare and William Phillips in 1822 to identify coal bearing strata. In other words, the same period in earth’s history that produced the Black Spot that Samuel’s engineers were seeking to extract from Dayak land was also the period that produced the pecten shells that he named his company after. Even the black fossilized leaves that miners regularly encountered in coal seams sometimes contained fossilized bivalve shells.

The Shell logo was a materialized cosmology, or [...] a cosmogram.

Cosmograms are objects that attempt to represent the order of the cosmos; they are snapshots of what is. The pecten’s effectiveness as a cosmogram was its pivot, to hinge, between spaces and times: it brought the deep history of the earth into the present; the Black Spot with Mediterranean imaginaries of the bivalve; the subterranean space of liquid oil with the surface. The history of the earth was made legible as an energetic, even a pyrotechnical force. The pecten represented fire, illumination, and certainly, power. [...] If coal required tunnelling, smashing, and breaking the ground, petroleum was piped liquid that streamed through a drilled hole. [...] In 1899, Samuel presented a paper to the Society of Arts in which he outlined his vision of “liquid fuel.” [...] Ardrossan is a ruin of that fantasy of a free flowing fossil fuel world. [...] At Ardrossan, that liquid cosmology is disintegrating.

---

All text above by: Adam Bobbette. "Shells and Shell". e-flux Architecture (Accumulation series). November 2023. At: e-flux dot com slash architecture/accumulation/553455/shells-and-shell/ [Bold emphasis and some paragraph breaks/contractions added by me. Presented here for commentary, teaching, criticisms purposes.]

140 notes

·

View notes

Text

Parallels: Hastur and Sandalphon

I know the Good Omens fandom loves parallels, so I wanted to add a further parallel that I noticed: one between Hastur and Sandalphon.

Hastur is cruel even in the book. His evil deeds extend far beyond the requirements of his job as a demon. Crowley thinks that both Hastur and Ligur take "such a dark delight in unpleasantness you might even have mistaken them for human" (Pratchett/Gaiman, p. 257; cited below). But the series made an outright sadist of Hastur.

Now, the scene were he turns into a bunch of maggots that eat the call centre employees alive came from the book. His behaviour was explained by his frustration about being stuck in the answering machine. Moreover, "if he were going to have to face the possible wrath of the Dark Council, at least it wouldn't be on an empty stomach" (Pratchett/Gaiman, p. 310; cited below).

However, the series added many additional scenes that show how Hastur (and to a lesser extent, Ligur) clearly takes pleasure in torturing people. He pushes Eric into the cell with the hellhound to test if it's hungry - probably just for amusement. In Megiddo, he discorporates all of the three Erics for annoying him with minor things.

He is also the one who announces Crowley that he will be punished for losing the Antichrist. In the book, it is not clear which demon is speaking to Crowley; the fact that he receives a second message shortly after trapping Hastur in the answering machine suggests that it was not Hastur whom he had been communicating with (cf. Pratchett/Gaiman, p. 254f, 284; cited below).

Furthermore, the scene were Hastur burns down the convent of the satanic nuns was altered. In the book, he does not talk to the nuns before doing it, but "[n]o one was badly hurt by the fire" (Pratchett/Gaiman, p. 52; cited below). He sets the building on fire to destroy all records and thereby all evidence of the baby swap.

In the series, of course, this plays out differently. Here the nuns believe that they will be rewarded for their help and that their order will continue to exist. When Sister Theresa protests against its dissolution, Hastur kills her with a single wave of his hand. The camera shows her dead eyes. Hastur then recommends the abbess to inform the other nuns about the dissolution of their order unless she wants that "they all perish in the fire". The convent then bursts into flames, with the nuns screaming and running for their lifes while Hastur is laughing maniacally.

These changes from the book to the series clearly show that the creators wanted to give Hastur's character even more shape.

Sandalphon is a sadist, too. Aziraphale remembers him for his crucial role in the destruction of Sodom and Gomorrah, an event Sandalphon has very fond memories of, as his expression implies. In the scene were he, Michael and Uriel corner Aziraphale, he punches him in the gut without necessity (Aziraphale wasn't trying to flee or to physically defend himself) and without preemptive warning. He's also eager for the war between heaven and hell to start.

You get the impression that Sandalphon will take any possible pretext for himself to use violence. Under the guise of enacting God's will, he acts out his sadistic desires. That's why I've always perceived him as the angelic counterpart of Hastur who also takes advantage of the fact that as a demon, he is expected to do evil, when he would even enjoy it if it wasn't required.

The fact that they both wear long beige coats even intensified this impression for me. I don't know whether this was a conscious choice by the costume designer, but I thought it was an interesting parallel.

That being said, I'm curious whether these two will return in the finale. I think Hastur's character was explored well enough in season 1, so if he makes an appearance, I believe it will rather be in the background. But there have been rumors that Sandalphon, who was originally supposed to be in season 2, but was replaced by Saraqael due to the actor being involved in a different project by the time, will make a comeback for the movie.

If so, I hope they will make an effective use of his sadistic nature. He may not be as appealing as the other angels, but I think he's interesting enough to dive a little deeper into his character and thereby to expose the hypocrisy of heaven, who call themselves the good guys while committing the same atrocities as hell. It could also tie nicely into the "heaven and hell against humanity" theme if Sandalphon came to the conclusion that he does identify himself more with demons like Hastur than with heaven's values, and decided to join forces with them in order to destroy the earth and all living beings on it.

Do you think that Hastur and Sandalphon will return? And what will their roles be?

Work cited:

Pratchett, Terry and Gaiman, Neil: Good Omens. The Nice and Accurate Prophecies of Agnes Nutter, Witch. London 2011.

24 notes

·

View notes

Text

The Teleporter

Little excerpt from a short story I've been trying to write. It's a first draft so very unpolished, but I want to be a bit more confident about sharing my fiction on here so.. yeah.

When it was discovered by the first human experiments with teleporters that a little reconstituting of atoms could repair almost any human ailment, it was hailed as the newest and greatest advance in medicine. Its inventor, Anjali Keer, was not a medical woman, but a physicist, who was, as many were at that time, simply looking for a new mode of transportation. Most had given up on the idea of the dissolution and reconstitution of atoms so often described in science fiction, but this was more because of a fear of public backlash than because of any lack of viability. Keer, however, disregarded these worries and continued to work on the technology, and it paid off, although in the way that she, or indeed anyone else, had expected.

The first human trials began before real people entered the picture. Keer used a vast array of medical texts to train the machine on human physiology, anatomy, even chemistry to minimize the possibility of any reconstitutional mistakes a machine may make. The first volunteer was an assistant to Keer, an able-bodied man named Alex Huntington. He was carefully examined before going into the teleporter, and, much to Keer’s satisfaction, the young man seemed perfectly well when he was reconstituted. In fact, upon taking up the same medical examinations made before he entered, he was deemed better than before. The young man who, for many years, had suffered from some minor depression, for which he had been taking pills, had stopped his medication in the weeks leading up to this exam, lest they interfere with the experiment. To the surprise of everyone his post-teleporter brain showed a distinct increase in dopamine, and a normalization to dopamine production. The man was cured.

Of course this discovery was immediately studied and tested further. Not just those with mental imbalances, but also those with physical disabilities were shown to come out of the teleporter ‘magically’ cured. To the public, it was a miracle, and from the first many were clamouring for more machines to be produced, and made available to them immediately. It seemed Keer’s careful programming of human biology only included the parameters of an ideal human body, and so an ideal human body was what it produced.

Later, it would come out that Alex’s family reported strange changes in mannerism, and uncertainty in memory, but it was deemed much too small an issue, to be looked into. The first of the physically disabled also reported certain issues. A man whose leg was ‘regrown’ found he was somewhat shorter and smaller than he has been before entering. Additionally, he attempted to report memory loss relating to his experiences losing the leg itself, but his reports, too, were dismissed. The public fervour was too great, the optimism, perhaps, too high.

#my writing#writing#fiction#stories#short stories#sci-fi#science fiction#original fiction#writing wip#the teleporter#<that will be the tag when I update

5 notes

·

View notes

Text

Higard Laundry Tips for Every Wash

In the dynamic landscape of household cleaning products, Higard emerges as a beacon of innovation and sustainability. As Indian households increasingly seek products that combine efficacy with environmental responsibility, Higard's range of eco-friendly matic liquid detergents and fabric conditioners stands out, offering unparalleled cleaning performance while safeguarding both fabrics and the planet.

Why Higard Stands Out in the Indian Market

1. Tailored Formulations for Indian Washing Machines

Understanding the diverse needs of Indian consumers, Higard has developed specialized detergents for both top-load and front-load washing machines. These formulations ensure:

Optimal Sudsing: Prevents excessive foam, protecting machine components.

Efficient Cleaning: Targets stains effectively, even in hard water conditions.

Fabric Preservation: Maintains the integrity and color of various fabric types.

2. Commitment to Eco-Friendly Practices

Higard's dedication to sustainability is evident in its product design and packaging:

Biodegradable Ingredients: Ensures minimal environmental impact post-use.

Recyclable Packaging: Reduces plastic waste, promoting a circular economy.

Energy-Efficient Formulas: Effective in cold water, conserving electricity.

3. Skin-Friendly and Hypoallergenic Options

Catering to families with sensitive skin, Higard offers detergents that are:

Free from Harsh Chemicals: No phosphates, bleach, or artificial dyes.

Dermatologically Tested: Safe for all skin types, including infants.

Gentle on Fabrics: Preserves the softness and longevity of garments.

Product Highlights: Elevating Laundry Standards

Higard Matic Liquid Detergent

Designed for modern washing machines, this detergent offers top load matic liquid and front load liquid detergent

Deep Cleaning Action: Penetrates fabric fibers to remove stubborn stains.

Quick Dissolution: Leaves no residue, ensuring a spotless wash.

Long-Lasting Freshness: Infuses clothes with a subtle, pleasant fragrance.

Higard Fabric Conditioner

Complementing the detergent, the fabric conditioner and fabric softener provides:

Enhanced Softness: Leaves clothes feeling plush and comfortable.

Fragrance Options: Available in scents like Black Hive, Paradise Cove, and Peach Berry.

Static Reduction: Minimizes cling, making ironing easier.

Conclusion: Embrace the Higard Difference

In a market saturated with options, Higard distinguishes itself through its unwavering commitment to quality, sustainability, and customer satisfaction. By choosing Higard, consumers not only ensure impeccably clean laundry but also contribute to a healthier planet.

#laundry care#liquid detergent#laundry cleaning#laundry services#maticliquid#fabric conditioner#cleanclothes#fabric#conditioner#trending

0 notes

Text

Comprehensive Guide to Tablet Manufacturing: Process, Quality Control, and Packaging

Tablet manufacturing is a critical process in the pharmaceutical industry, ensuring that medications are delivered in a safe, effective, and convenient form. The process involves several key steps, each designed to maintain the integrity and efficacy of the active pharmaceutical ingredients (APIs).

1. Formulation Design

The initial phase involves designing a robust formulation by determining the appropriate combination of APIs and excipients. Excipients are inactive substances such as binders, fillers, disintegrants, and lubricants that enhance the tablet's structure, taste, and stability. This step ensures that each tablet delivers the correct dosage and meets the desired release characteristics.

2. Raw Material Procurement and Testing

Sourcing high-quality raw materials is essential. All materials must comply with regulatory guidelines and undergo stringent testing for purity, safety, and compatibility to ensure the final product's quality.

3. Weighing and Mixing

Precise weighing of each component is followed by thorough mixing to achieve a uniform distribution of the active ingredient. This homogeneity is crucial for consistent efficacy and safety in each tablet

4. Granulation

Granulation enhances the flow and compressibility of the powder mixture. There are two primary methods:

Wet Granulation: Involves adding a liquid binder to the powder mix, forming a damp mass that is then dried and sieved into granules. This method improves tablet strength and minimizes segregation but requires additional drying time.

Dry Granulation: Compacts powders without adding liquids, suitable for moisture-sensitive materials. While faster, it may result in lower tablet strength compared to wet granulation.

5. Drying and Milling

After granulation, the moist granules are dried to reduce moisture content, preventing microbial growth and ensuring proper tablet formation. The dried granules are then milled to achieve the desired particle size, enhancing flowability and compressibility.

6. Compression

The prepared granules are compressed into tablets using a tablet press machine. This step involves feeding the granules into the machine, compressing them into tablets under high pressure, and ejecting the finished tablets. Modern tablet presses ensure uniform size, shape, and weight

7. Coating (Optional)

Coating tablets can enhance their appearance, taste, and stability, and can also control the release profile of the active ingredient. Common coating types include film coating, sugar coating, and enteric coating, each serving specific purposes such as masking taste or protecting the tablet from stomach acids.

8. Quality Control

Rigorous quality control measures are implemented to ensure each batch meets predefined standards. Tests include weight uniformity, hardness testing, dissolution testing, and friability testing. These assessments confirm that the tablets are safe, effective, and consistent in delivering the intended therapeutic effects.

9. Packaging

The final step involves packaging the tablets in suitable containers like blister packs, bottles, or pouches. Proper packaging protects the tablets from environmental factors, contamination, and physical damage during transportation and storage.

Each of these steps is meticulously controlled to ensure that the tablets produced are of the highest quality, providing patients with safe and effective medication options. for more detail sahasrayohgam contact

0 notes

Text

Why Spheronization is Essential for Uniform Coating and Granulation in Pharmaceutical Products

Spheronization is a specialized process that transforms irregular pharmaceutical particles into uniform spherical pellets. This transformation dramatically enhances the quality and efficiency of drug manufacturing, ultimately impacting patient results. The technology relies on tight mechanical forces and precisely controlled conditions for optimal results.

The Science of Spherical Excellence

Advantages of Spherical Particles in Pharmaceutical Processing

Better flow properties, even surface area distribution, and a uniform coating thickness are the major advantages of spherical particles, leading to:

Better powder flow dynamics

Improved batch uniformity

Reduced processing time

Increased content uniformity

Improved consistency of coating

Physical Characteristics and Performance Benefits

Studies from various pharmaceutical sites show that spherical particles produced through Spheronizer exhibit:

Minimum variation in surface roughness

Excellent hardness and resistance to friability

Optimized bulk density

Improved compressibility properties

Drug Delivery Impact

According to pharmaceutical manufacturers, spheronized powders demonstrate 22% greater drug dissolution compared to irregular particles. This improvement is due to:

Constant surface area exposure

Uniform drug release kinetics

Improved absorption properties

Clinical Implications

Drugs prepared via Spheronizer have shown improved clinical drug delivery characteristics, such as:

Better plasma drug concentration profile

Less variability in therapeutic response

Greater patient compliance due to consistent efficacy

Fewer adverse reactions due to dosing consistency

Quality Control Metrics

Statistics from manufacturing facilities report that Spheronizer reduces:

Batch rejection rates by 65%

Quality control testing time by 40%

Product variability by 78%

Documentation errors by 56%

Laboratory investigations by 43%

Cost-Efficiency Through Spheronization

Efficiency gains from spheronization manifest across several areas:

Resource Optimization

30% reduction in coating material usage

25% decrease in processing time

45% fewer batch failures

Equipment Performance

Reduced wear on processing equipment

Lower maintenance requirements

Extended machine service life

Compliance with Regulation and Quality

The FDA’s Quality by Design (QbD) principles align with spheronization. Research shows companies implementing this technology have achieved:

50% fewer regulatory findings

70% reduction in out-of-specification investigations

90% improvement in batch consistency

Real-World Implementation Success

A mid-sized generic drug manufacturer added spheronization to their controlled-release product line. After a year, they achieved:

35% increase in production capacity

82% improvement in product consistency

28% reduction in manufacturing costs

91% reduction in customer complaints

Environmental Impact Considerations

Modern spheronization technology also promotes sustainable manufacturing by reducing:

Waste generation

Water consumption

Energy usage

Optimizing the Spheronization Process

Critical Process Variables

Moisture content control

Spheronizer plate speed

Processing time and temperature optimization

Best Practices in Equipment Maintenance

Routine inspection of plate surfaces

Adherence to cleaning schedules

Preventive maintenance

Technology Investment Factors

When evaluating spheronization equipment, consider:

Processing capacity

Product compatibility

Automation and validation support

The typical return on investment spans 12-18 months through:

Reduced material waste

Enhanced product quality

Increased manufacturing efficiency

Future-Proofing Pharmaceutical Production

Spheronization technology evolves with features like:

Real-time process monitoring

Automated adjustments

Predictive maintenance capabilities

Conclusion

Evidence shows that spheronization technology brings measurable improvements to pharmaceutical manufacturing. With benefits such as enhanced drug bioavailability and significant cost savings, spheronization is essential for manufacturers aiming to optimize their operations.

0 notes

Text

Emcure Pharmaceuticals is inviting qualified candidates to join their team through a walk-in interview for various roles in QC, QA, Production, Packing, Warehouse, and Engineering at their OSD Manufacturing Facility in Hinjawadi, Pune. Interview Date: October 13, 2024 (Sunday) Time: 09:00 AM – 04:00 PM Location: Emcure Pharmaceuticals Ltd., Phase-1, Hinjawadi, Pune 411057 (Landmark: Opposite Grand Highstreet Mall, Next to Butterfly Trampoline Park) Vacancy Details Open Positions: Quality Control (QC - OSD) Quality Assurance (QA - OSD) Production (OSD) Engineering (OSD) Packing (OSD) Warehouse (OSD) Job Roles and Responsibilities Quality Control (QC - OSD) Conduct testing on raw materials, packaging, in-process, finished products, and stability samples. Operate and maintain HPLC, GC, IR, UV instruments, and knowledge of Dissolution testers, KF, Potentiometers is required. Ensure adherence to quality standards and compliance with GMP practices. Quality Assurance (QA - OSD) Handle IPQA, ensuring real-time inspections during production processes. Review analytical data and manage QMS tasks such as deviations, OOS, OOT, laboratory incidents, and CAPA (Corrective and Preventive Actions). Ensure thorough documentation of testing protocols and processes. Production (OSD) Monitor production activities, ensuring they align with cGMP standards. Maintain production logs, oversee manufacturing, and troubleshoot issues related to tablet compression, capsule filling, and other manufacturing processes. Collaborate with teams to improve efficiency and reduce waste. Engineering (OSD) Responsible for the maintenance of pharmaceutical machinery including FBD, RMG, blister packing machines, and compression machines. Ensure equipment operates efficiently to minimize downtime and maintain high-quality output. Conduct preventive and corrective maintenance in line with SOPs. Packing (OSD) Carry out packing operations as per the packing plan. Perform in-process checks, maintain documentation, and adhere to regulatory standards. Manage daily packing activities and ensure smooth operations. Warehouse (OSD) Handle raw material dispensing, inventory management, and ensure proper documentation is maintained. Ensure material handling complies with SOPs and manage inventory in line with production demands. Qualification and Experience Requirements QC, QA, Production: Qualification: MSc, B Pharmacy, D Pharma Experience: 2-7 years in pharmaceutical manufacturing, particularly in the OSD (Oral Solid Dosage) form. Engineering: Qualification: DME, BE, B Tech Experience: 2-7 years in engineering roles, particularly with OSD manufacturing equipment. Packing, Warehouse: Qualification: BSc, D Pharm, B Pharmacy Experience: 2-7 years in packing and warehouse management in the pharmaceutical industry. [caption id="attachment_49502" align="aligncenter" width="930"] Emcure Walk-In Interview for QC, QA, Production, Packing, Warehouse, and Engineering Roles[/caption] Location Details: Address: Emcure Pharmaceuticals Ltd., Phase-1, Hinjawadi, Pune 411057 Landmark: Opposite Grand Highstreet Mall, Next to Butterfly Trampoline Park Interview Date: October 13, 2024 Time: 09:00 AM – 04:00 PM Venue: Emcure Pharmaceuticals Ltd., Hinjawadi, Pune

0 notes

Text

Dissolution Tester NDST-103

Labnics dissolution tester is a U-shaped system with 3 vessels, offering an ambient to 45°C range, ±0.5mm paddle radial run-out, and ±0.3°C stability. It features smooth vertical head movement and a large LED screen for displaying results, ensuring accurate dissolution testing of pharmaceuticals.

1 note

·

View note

Text

Understanding the Role of a Texture Analyzer in Quality Control and Product Development

In industries such as food, cosmetics, and pharmaceuticals, product quality is paramount. One critical factor that often determines the success of a product is its texture. Whether it’s the crispness of a snack, the smoothness of a cream, or the chewiness of a tablet, texture plays a vital role in consumer satisfaction. To ensure consistency and quality, manufacturers rely on Texture Analyzers, sophisticated devices designed to measure the physical properties of a product's texture.

What is a Texture Analyzer?

A texture analyzer is an instrument used to test the mechanical properties of materials by applying controlled forces to measure how they respond. It evaluates characteristics such as hardness, elasticity, stickiness, and brittleness. These properties are crucial in determining how a product feels, breaks, or deforms under stress.

In the food industry, for example, a food texture analyzer is used to assess the texture of food products like bread, cheese, or meat. This ensures that products meet both consumer expectations and industry standards. Analyzers like those from Imada—a trusted brand in the industry—are designed to provide accurate and repeatable results, making them essential tools in quality control.

The Importance of Texture Analyzers in the Food Industry

The texture of food is one of the most important factors influencing consumer acceptance. While flavor and aroma are often discussed, the physical feel of food can be the deciding factor in its success. A food texture analyzer can measure a wide range of parameters, such as the crunchiness of chips, the firmness of fruits, or the chewiness of candy.

By using texture analyzers, food manufacturers can ensure that their products maintain a consistent texture across different batches. This is especially important for brands that want to build customer loyalty through reliable quality.

Applications in Other Industries

While texture analyzers are heavily used in the food industry, their applications extend to other sectors as well. In the cosmetics industry, for instance, texture analyzers help test the spreadability and consistency of creams, lotions, and gels. For pharmaceuticals, they measure the hardness and dissolution properties of tablets, ensuring that they perform as intended.

Brands like Imada produce high-quality texture analyzers that are used across these diverse industries. Their machines are known for their precision, durability, and ease of use, making them an excellent choice for companies looking to improve their product development and quality assurance processes.

Enhancing Product Development

A texture analyzer is not just a tool for quality control; it is also a critical asset in product development. During the research phase, manufacturers use these analyzers to experiment with different formulations and processes to create products with the desired texture. By adjusting ingredients or manufacturing techniques, they can achieve the ideal texture that will resonate with their target market.

Conclusion

In today’s competitive market, product texture can be the difference between success and failure. Whether it’s ensuring the smoothness of a cosmetic cream or the crunchiness of a snack, a texture analyzer helps manufacturers guarantee consistent quality. Tools like Imada’s texture analyzers are vital in industries where precision and repeatability are key to meeting customer expectations and maintaining high standards. For companies in the food, cosmetics, and pharmaceutical industries, investing in a reliable food texture analyzer or similar tool can significantly enhance product development and quality control.

0 notes

Text

Some precautions for alkaline fertilizers under fertilizer production machines

In agricultural production, the choice and use of fertilizer is very important. As a special type of fertilizer, alkaline fertilizer has unique properties and functions. The correct use of alkaline fertilizers can not only improve the yield and quality of crops, but also improve the soil environment and achieve sustainable development of agriculture. In the process of production and use of alkaline fertilizers, fertilizer production machines play a key role.

Alkaline fertilizer usually refers to the fertilizer that is alkaline after dissolution in water, such as ammonia, ammonium bicarbonate, calcium magnesium phosphate fertilizer and so on.

The role of fertilizer production machines in the production and use of alkaline fertilizers

Precise formulation: The fertilizer production machine can precisely control the formulation of alkaline fertilizers according to the soil test results and the needs of the crops. By accurately measuring the proportion of various nutrient elements, alkaline fertilizers suitable for different soils and crops can be produced, and the pertinence and effectiveness of fertilizers can be improved.

Improve production efficiency: Modern fertilizer production machines can achieve automated production, which greatly improves the production efficiency of alkaline fertilizers. At the same time, it can also ensure the stability of the quality of fertilizer and provide high-quality fertilizer products for farmers.

Easy fertilization: Some advanced fertilization equipment can evenly apply alkaline fertilizers into the soil, improving the accuracy and efficiency of fertilization. For example, the fertilizer applicator can automatically adjust the fertilizer amount and fertilization time according to the growth needs of crops and soil fertility conditions to achieve precise fertilization.

In short, the correct use of alkaline fertilizer is one of the important measures to achieve sustainable agricultural development. When using alkaline fertilizer, the type and amount of fertilizer should be reasonably selected according to the soil test results and the needs of crops, and the correct fertilization method and precautions should be mastered. At the same time, fertilizer production machines also play a key role in the production and use of alkaline fertilizers, providing strong support for agricultural production through the advantages of precise formulation, improved production efficiency and easy fertilization.

0 notes

Text

Ophthalmic Drugs Contract Manufacturing: An Overview Of The Rapidly Evolving

Regulatory compliances play a pivotal role in ophthalmic drugs manufacturing due to stringent norms and quality standards set by regulatory bodies like US FDA, EMA, etc. Ophthalmic products manufacturing needs to adhere to Current Good Manufacturing Practices (CGMP) to ensure product safety, efficacy, and quality. Ophthalmic drugs contract manufacturers invest heavily in approvals, certifications, and manufacturing facilities upgradation to meet evolving regulatory guidelines. They focus on establishing robust quality management systems, validation protocols, change control systems, and document controls. Regular product quality reviews and internal audits also help contract manufacturers deliver regulatory compliance.

Leading Technology And Specialized Equipment

Ophthalmic drugs require highly sophisticated and precise manufacturing technologies and equipment due to small volumes and concentrations. Contract manufacturers leverage leading technologies like microprocessing, microfluidics, micro-molding, and precision coating to produce a diverse range of ophthalmic products. They invest in specialized, high-end equipment like micronizing mills, soft-gel encapsulation systems, and laser-marking machines. Automation and digitization using IoT, AI, and analytics also help boost production efficiency and quality. The technologies and equipment enable contract manufacturers to cater to customized packaging and dosing requirements of ophthalmic drugs.

Specialized Facilities And Cleanrooms

Ophthalmic products demand stringent environmental control and hygiene standards owing to small dosage forms and direct exposure to eyes. Contract manufacturers operate highly specialized facilities with ISO classified cleanrooms to minimize microbial and particulate contaminations. Features like laminar air flow, differential air pressures, high-efficiency particulate air (HEPA) filtration help maintain critical environmental conditions. Periodic qualification and calibration of facilities and utility systems also ensure process validation. Designated areas for raw material receipts, products manufacturing, quality testing, packaging, and warehousing follow zoning principles. These specialized facilities enable contract manufacturers to ensure sterility, stability, and preserved efficacy of Ophthalmic Drugs Contract Manufacturing and storage.

Capabilities In Sterile Fill/Finish

A major portion of ophthalmic drugs require sterile fill/finish due to direct administration into eyes. Contract manufacturers have dedicated sterile suites equipped with barrier isolators, aseptic processing equipment, and self-contained environmental control systems. Technologies like lyophilization and terminal sterilization aid microbial decontamination. Stringent personnel training on garbing and cross-transfer procedures helps avoid contamination risks. Regular media fills and endotoxin challenge simulations validate sterilization process efficacy. Quality control testing through rapid microbiological methods, particulate testing and endotoxin assays ensure sterility assurance of aseptically filled ophthalmic products. These capabilities enable outsourcing of sterile fill/finish operations for preservative-free ophthalmic drugs.

Specialized Analytical Testing

Ophthalmic drugs require meticulous analytical characterization and quality testing due to small amounts administered near eye region. Contract manufacturers invest in -leading analytical instruments like HPLC, GC, dissolution testing equipment, and particle size analyzers. Methods involve testing of identity, purity, content uniformity, particulate matters, pH, osmolarity, sterility, bacterial endotoxin, and preservative content. Stability indicating methods help real-time product monitoring on storage. Various ophthalmic dosage forms like ointments, gels, suspensions etc. also require formulations development and evaluation of rheological properties, spreadability and bioavailability. Contract testing laboratories employ highly trained analytical experts, validated methods and computerized data integrity systems. These specialized testing capabilities help ensure efficacy and safety of outsourced ophthalmic products.

Case Studies And Fill-Finish Agreement

A leading UK-based ophthalmic drug firm outsourced development and fill-finish operations of its novel anti-inflammatory eye drop to a US-based contract manufacturer. Impressed by proven sterile fill/finish capabilities, quality systems, and regulatory compliance track record, six-month technology transfer was completed on schedule. Further, a 1-year commercial supply agreement was signed with production scale-up clauses. Another Ophthalmic Drugs Contract Manufacturing giant outsourced manufacturing of its portable multi-dose ophthalmic dispensers to a reputed Japanese contract manufacturer specializing in medical-device moulding. Leveraging expertise in micro-molding and precision assembly, the firm ensured precise dosing and improved patients' compliance. These cases illustrate effective collaborations aiding faster access of critical ophthalmic therapies.

Get more insights on this topic: https://www.trendingwebwire.com/ophthalmic-drugs-contract-manufacturing-meeting-global-ophthalmic-medications-demands-through-specialized-services/

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement. (LinkedIn - https://www.linkedin.com/in/priya-pandey-8417a8173/)

*Note: 1. Source: Coherent Market Insights, Public sources, Desk research 2. We have leveraged AI tools to mine information and compile it

0 notes

Text

1: (Na₂Co(OH)₆)cobalt repatriation via lithium metal oxide alkaline leach corridor

Sea cuke approaches rest, preparing for cobalt gender publishing

Sea cuke applies spf preparing for cobalt gender publishing

Sea cuke submits to MAID and shrouding, preparing for cobalt gender publishing

JAXA Vn AKATSUKI YIELDING COBALT BY SPIRITUAL GLAMORIZATION

Corpse ice bath yielding cobalt by spiritual glamorization

Flesh dissolution as cobalt gender reveal

Rainy Earthly cobalt repatriation

2: Cobalt repatriation via Venus bound Sulfuric byproduct liOH acid leach corridor

JAXA Vn AKATSUKI mechanics yielding cobalt

AKATSUKI APPLIES Vn EXTRACTED SULFURICS YIELDING COBALT AT MOLECULAR SCALE

Sulfur consuming multiple beings and yielding cobalt

Beings being burnt, igniting cobalt

AKATSUKI URINARY RELEASE TO PRECIPITATE COBALT

3: Cobalt repatriation throttling liOH + FA synthesis

Yielded cobalt Geo repatriation denoted by sea cucumbers engaging ethical consumption

Yielded cobalt Geo repatriation denoted by single cucumber, tickle torturing fat arctic cucumbers through the sand

Yielded cobalt Geo repatriation denoted by single cucumber destroyed by hidden dormant plastic jellyfish toxicity

Yielded cobalt Geo repatriation denoted by sea cucumber arctic teleport and scavenge

Yielded cobalt Geo repatriation denoted by dirty, arctic cucumber raggedy cobalt generation machine

Cobalt gender revelation

4: Cobalt repatriation throttling lithium soap corridor

Sea cucumber cobalt yield pounded into paste

Cobalt paste dried into leather under magnifying glass

Beautiful arctic cucumbers testing translucence of cobalt leather

Main girl arctic sea cucumber glamorizing with cobalt paste residues

Sites of residue application begin necrosis

Main arctic girl fitted for cobalt leather costume as hydroxide bath skin

Main arctic girl as gorgeous cobalt casket of lithium soap

5: Cobalt repatriation throttling lithium peptoid metalloenzyme viral propagation

Arctic sea cucumbers adorn an elect in lithium peptoid SPF, they slip chemical X

The skin of elect loses opacity after his clone roots are pruned

Clone roots are ceremonially kissed by all in attendance

Chemical X irradiative fluorescent imaging displays arctic neoovum in populace

Chemical X irradiative fluorescent imaging displays arctic neoovum in populace

Chemical X irradiative fluorescent imaging displays arctic neoovum in populace

Arctic cucumbers overcome by X virus

6: Cobalt repatriation throttling Li-stearate surfactant electrocatalytic acraisin computation presence

Wish talisman plasmodium make instructions display on JAXA base Geo location

Plasmodium anatomy and scalarity guide opened by sea cucumber

Sea cucumber makes wish talisman

Sea cucumber seals wish talisman

7: Cobalt georepatriation throttling composite Li soap fiber (CLSF) epoxy enhancement for cultural heritage expression

Sea cucumbers teleport arctic cucumbers lithium soap casketry via sand, pulling it out

Sea cucumbers extract lithium soap yield and port into refinery

Sea cucumbers harvest cobalt leather for library tanks

Sea cucumbers apply refined lithium soap yield to AKATSUKI Vn exterior

Newly coated aKatsuki receives arctic cucumber carcasses

AKATSUKI Vn TRANSPORTS TO VN

8: Cobalt georepatriation throttling LiOH+FA synthesis

Vat of lithium hydroxide receives infected arctic cucumbers

9: Cobalt georepatriation throttling lithium soap corridor

A single arctic cucumber clings to life

Arctic cucumber clings to edge of chamber whilst others pour into vat. A blue crab.

Arctic cucumber tragically shaken into vat. Burnt alive.

Officiating sea cucumber identifies arctic cucumber inscribed cobalt leather thimble

Officiating sea cucumber rushes to collect thimble as lithium soap solidifies

Officiating sea cucumber tests lithium soap for texturization

10: Cobalt georepatriation throttling lithium peptoid metalloenzyme viral propagation

Lithium soap decanted into containers

Sea cucumber applies lithium soap for ceremonial pollen bathing, death

Sea cucumber bodies consumed by plasmodium

11: Cobalt georepatriation throttling Li-stearate surfactant electrocatalytic acraisin computation presence

Sea cucumbers taken as acraisin discs, yielding letters

12: Cobalt georepatriation throttling composite Li-soap fiber (CLSF) epoxy enhancement for cultural heritage expression

Acraisins evolve chemical X fluorescence

1 note

·

View note

Text

Understanding Salt Spray Testing: A Key Technology for Evaluating the Corrosion Resistance of Metals and Electronics

The Impact of Salt Spray on Electronic Products and Mitigation Measures Salt spray is widely present in marine, atmospheric, terrestrial, lake, and river environments, inevitably exposing electrical and electronic products to salt-laden atmospheres. The effects of salt spray environment, ranking just after temperature, vibration, humidity, and dust, significantly accelerate the electrochemical corrosion process of metals, leading to the following issues: Corrosion damage to components and fasteners • Mechanical parts and components seizing or malfunctioning • Circuitry opening or short-circuiting • The Importance of Salt Spray Testing To evaluate the corrosion resistance of products in salt spray environments, salt spray testing has become a necessary method. By simulating salt spray conditions, salt spray testing reveals the product’s ability to withstand corrosion, helping manufacturers improve product design and material selection to enhance reliability and longevity. The corrosion damage to electronic products in salt spray environments can be mainly attributed to two factors: • Conductivity of salt solution: Salt solution is conductive, triggering and accelerating electrochemical corrosion. Increased resistance due to salt spray corrosion products: Corrosion products increase resistance, leading to resistance increment and voltage drop, thereby affecting the electrical performance of the product, causing performance degradation and losses. • Salt Spray Test: Understanding its Impact on Electronic Products and Countermeasures Salt spray testing is an effective method for evaluating the corrosion resistance of metal materials and their coatings. Common salt spray tests include the following three types: • Neutral Salt Spray Test (NSS): Widely used to evaluate the corrosion resistance of metal materials and their metallic or inorganic non-metallic coatings. • Acetic Acid Salt Spray Test (AASS): Mainly used to test the corrosion resistance of metal coatings and not suitable for organic coatings. • Copper Accelerated Acetic Acid Salt Spray Test (CASS): Similar to the acetic acid salt spray test, primarily used to test the corrosion resistance of metal coatings, but accelerates the corrosion process by introducing copper ions. Salt spray testing is used to assess a product’s resistance to salt spray corrosion. Test results reflect the condition of surface damage, such as: • Blisters • Rust • Decrease in adhesion • Spread of corrosion at scratch sites YWX/Q-010_Salt Spray Test Machine Comprehensive evaluation standards for salt spray test results are not yet widespread, but they are recommended in the following national standards: • GB/T 1766-2008 Rating Methods for Aging of Paint and Varnishes • GB/T 6461-2002 Rating of Samples and Specimens on Metal Substrates and Other Inorganic Coatings After Corrosion Tests Types and Mechanisms of Salt Spray Corrosion Salt spray corrosion is a common electrochemical corrosion phenomenon that primarily affects metal materials and electronic products. Its corrosion mechanisms involve anodic activation and cathodic reactions. Here are different types of corrosion and their mechanisms: Surface Corrosion • Pitting Corrosion: Localized corrosion that forms holes or pits deeper than wide on metal surfaces. • General Corrosion: Uniform removal of material from the surface, resulting in large areas of material loss. Pitting Corrosion Pitting corrosion selectively attacks specific points on metal surfaces, forming holes or pits deeper than wide. It’s often difficult to detect but can cause significant damage to materials. Crevice Corrosion Occurs in narrow crevices where differences in concentration of the corrosive medium create potential differences, exacerbating corrosion at poorly ventilated areas like around bolts and gaskets. Dealloying Selective dissolution corrosion, common in materials like brass, where zinc is dissolved, leaving behind a porous copper structure. Similar processes occur with denickeling and dealuminizing. Rust Formation of iron oxide and hydroxide corrosion products on iron and steel surfaces, causing loss of shine and gradual corrosion. Salt spray corrosion occurs electrochemically, with the main mechanisms being: • Anodic reaction: Metal atoms leave the lattice, oxidizing at the anode and releasing electrons. • Cathodic reaction: Chloride ions dissociate at the cathode, reacting with metal ions and hydroxide ions to form corrosion products. The three elements necessary for corrosion are water, oxygen, and ions. While coatings can delay corrosion to some extent, when the salt concentration in water exceeds 0.4 mol/L, sodium and chloride ions can penetrate coatings, leading to metal corrosion. The specific corrosion ability depends on the metal’s electrode potential sequence and the acidity or alkalinity of the environment. To mitigate salt spray corrosion, common protective measures include: • Surface coatings: Applying corrosion-resistant coatings such as galvanizing, nickel plating, etc., to prevent contact between the corrosive medium and the metal surface. • Structural design optimization: Reducing gaps and contact areas between metal parts, adding sealing structures to prevent salt spray ingress. • Material selection: Choosing materials with excellent corrosion resistance, such as stainless steel and special alloys. Conclusion Salt spray corrosion significantly affects metal materials and electronic products. Understanding different types of corrosion and their mechanisms is crucial for developing effective protective measures. By applying corrosion-resistant coatings, optimizing structural design, and selecting corrosion-resistant materials, the ability of products to withstand salt spray environments can be significantly improved, ensuring long-term reliable operation. Read the full article

0 notes

Text

Global Top 5 Companies Accounted for 80% of total Dish Washing Capsules & Tablets for Auto Dish Washers market (QYResearch, 2021)

Dishwasher detergent is a detergent made for washing dishes in a dishwasher. In this report, we study the dishwasher capsules & tablets.

Dishwasher tablets were designed to tackle hard water, remove stains, and dissolve grease and fat found in protein-based foods — so it shouldn't be a surprise that they can be used to clean things beyond the dishwasher.

Capsules are a special way mixed salt, rinse and detergent, exposed in a special shell. The shell is PVA, PVA is a water-soluble, shelf-stable, synthetic polymer. Creating a dishwasher pod's outside coating out of this polymer allows the user to store and use these convenient pods knowing that they'll only dissolve when they contact water.

Capsules unlike tablets, are coated with a soluble coating, which implies the gradual introduction of the components of the product into the washing process.The shape of the components of the capsule differs from the shape of the components of the tablet, which again provides the best phased dissolution throughout the washing cycle.

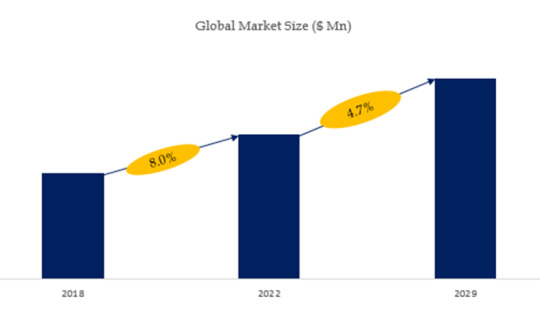

According to the new market research report “Global Dish Washing Capsules & Tablets for Auto Dish Washers Market Report 2023-2029”, published by QYResearch, the global Dish Washing Capsules & Tablets for Auto Dish Washers market size is projected to reach USD 5.16 billion by 2029, at a CAGR of 4.7% during the forecast period.

Figure. Global Dish Washing Capsules & Tablets for Auto Dish Washers Market Size (US$ Million), 2018-2029

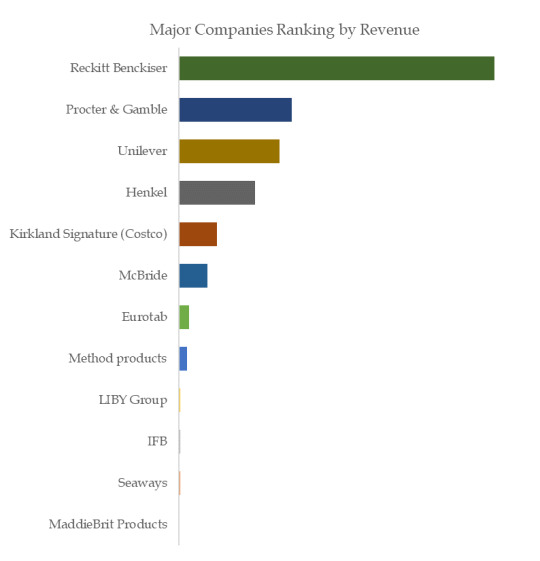

Figure. Global Dish Washing Capsules & Tablets for Auto Dish Washers Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Dish Washing Capsules & Tablets for Auto Dish Washers include Reckitt Benckiser, Procter & Gamble, Unilever, Henkel, Kirkland Signature (Costco), McBride, Eurotab, Method products, LIBY Group, IFB, etc. In 2022, the global top five players had a share approximately 80.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes