#dyes Product Testing Laboratory

Text

Lab Equipment for Color Dye Testing | RK Industries | Baroda

Explore the range of laboratory equipment offered by RK Industries in Baroda, designed for precision and reliability in industrial applications.

#development of dyes product laboratory#dyes Product Testing Laboratory#dyes Product quality Testing Laboratory#Best quality dyes product in India

0 notes

Text

Jan Bartek - AncientPages.com - New scientific research has revealed a piece of tartan found in a peat bog in Glen Affric around forty years ago can be dated to circa 1500-1600 AD, making it the oldest known surviving specimen of true tartan in Scotland.

The Scottish Tartans Authority commissioned Dye Analysis and Radiocarbon testing on the woolen textile to prove its age.

Scotland's Oldest Tartan On Display For The First Time!

Glen Affric tartan - Scotland's oldest-known true tartan discovered by The Scottish Tartans Authority to go on display for the first time at V&A Dundee's Tartan exhibition.

Credit: Alan Richardson Pix-AR

The first investigation was dye analysis carried out by analytical scientists from National Museums Scotland. Using high-resolution digital microscopy, four colors were visually identified for dye analysis: green, brown, and possibly red and yellow.

The dye analysis confirmed the use of indigo/woad in the green but was inconclusive for the other colors, probably due to the dyestuff degradation state. However, no artificial or semi-synthetic dyestuffs were involved in making the tartan, which pointed to a date of pre-1750s.

Further clarification on the age of the tartan involved radiocarbon testing at the SUERC Radiocarbon Laboratory in East Kilbride. The process involved washing out all the peat staining, which would have otherwise contaminated the carbon content of the textile.

The Radiocarbon testing results identified a broad date range between 1500 and 1655 AD, with the period between 1500 and 1600 AD the most probable. This makes it the oldest-known piece of true tartan found in Scotland – the Falkirk ‘tartan,’ dating from the early third century AD, is actually a simpler check pattern woven using undyed yarns.

The Glen Affric tartan, which measures around 55cm by 43cm, is now on display for the first time at V&A Dundee’s Tartan exhibition.

by TaboolaSponsored Links

The piece will be the oldest exhibit among more than 300 objects. The exhibition examines tartan’s universal and enduring appeal through iconic and everyday examples of fashion, architecture, graphic and product design, photography, furniture, glass and ceramics, film, performance, and art.

“The testing process has taken nearly six months, but the effort was well worth it, and we are thrilled with the results!

In Scotland, surviving examples of old textiles are rare as the soil is not conducive to their survival. As the piece was buried in peat, meaning it had no exposure to air and was therefore preserved.

The tartan has several colors with multiple stripes of different sizes, and so it corresponds to what people would think of as a true tartan.

“Although we can theorize about the Glen Affric tartan, it’s important that we don’t construct history around it. Although Clan Chisholm controlled that area, we cannot attribute the tartan to them as we don’t know who owned it.

“The potential presence of red, a color that Gaels considered a status symbol, is interesting because of the more rustic nature of the cloth. This piece is not something you would associate with a king or someone of high status; it is more likely to be an outdoor working garment," Peter MacDonald, Head of Research and Collections at The Scottish Tartans Authorit said.

Scotland's Oldest Tartan On Display For The First Time!

New scientific research has revealed a piece of tartan found in a peat bog in Glen Affric, Scotland around forty years ago can be dated to circa 1500-1600 AD, making it the oldest known surviving specimen of true tartan in Scotland. Credit: Credit: Alan Richardson Pix-AR

“The Glen Affric tartan is clearly a piece of national and historical significance. It is likely to date to the reign of James V, Mary Queen of Scots, or James VI/I. “There is no other known surviving piece of tartan from this period of this age. It's a remarkable discovery and deserves national attention and preservation. “It also deserves to be seen and we’re delighted that it is to be included in the Tartan exhibition at V&A Dundee,” John McLeish, Chair of The Scottish Tartans Authority, said.

“We knew The Scottish Tartans Authority had a tremendous archive of material and we initially approached them to ask if they knew of any examples of 'proto-tartans' that could be loaned to the exhibition.

I'm delighted the exhibition has encouraged further exploration into this plaid portion and very thankful for The Scottish Tartans Authority's backing and support in uncovering such a historic find.

To be able to exhibit the Glen Affric tartan is immensely important in understanding the textile traditions from which modern tartan derives, and I'm sure visitors will appreciate seeing this on public display for the very first time," James Wylie, curator at V&A Dundee said.

Tartan at V&A Dundee opens on Saturday, 1 April, until 14 January 2024.

Written by Jan Bartek - AncientPages.com Staff Writer

Source: Facebook

Source: AncientPages.com

239 notes

·

View notes

Text

Garg Chemical Industry is a one of the eminent name in the chemical industry, known for its exceptional quality and diverse range of chemical products. With decades of experience and expertise, Garg Chemical Industry has established itself as one of the leading chemical manufacturers in Delhi, catering to a wide array of industries.

Wide Range of Chemical Products: Garg Chemical Industry offers an extensive range of chemical products that find applications across various sectors. The company specialises in the manufacturing of industrial chemicals, laboratory chemicals, pharmaceutical chemicals, and specialty chemicals. Whether it's acids, solvents, dyes, pigments, or any other chemical, Garg Chemical Industry ensures that every product is manufactured with precision and adheres to the highest quality standards.

Quality Assurance: At Garg Chemical Industry, quality is given utmost priority. The company follows stringent quality control measures at every stage of the manufacturing process to ensure that the final products meet or exceed customer expectations. The raw materials used are carefully sourced from trusted suppliers, and rigorous quality tests are conducted to ensure their purity and effectiveness. Garg Chemical Industry has earned various certifications and accolades for its commitment to quality and continuous improvement.

Industry Expertise: With its extensive industry experience, Garg Chemical Industry has developed in-depth knowledge and expertise in understanding the unique requirements of different sectors. The company's team of experts works closely with customers to provide tailored solutions and develop customized chemical formulations that meet specific industry needs. From manufacturing to packaging and timely delivery, Garg Chemical Industry ensures a seamless experience for its customers.

Commitment to Sustainability: Garg Chemical Industry is not only focused on delivering quality products but also committed to sustainable manufacturing practices. The company strives to minimize its environmental impact by implementing eco-friendly processes and adhering to all relevant environmental regulations. Garg Chemical Industry actively invests in research and development to develop greener alternatives and promote the efficient use of resources.Customer Satisfaction:Customer satisfaction is at the core of Garg Chemical Industry's business philosophy. The company believes in building long-term relationships with its clients by delivering superior products and exceptional service. The dedicated customer support team at Garg Chemical Industry is always ready to assist customers with their queries and provide technical assistance whenever needed.

Conclusion: As one of the leading chemical suppliers in Delhi , Garg Chemical Industry has earned a reputation for its commitment to quality, extensive product range, and customer satisfaction. With a strong focus on sustainability, industry expertise, and continuous innovation, the company is well-positioned to meet the evolving needs of various sectors. As Garg Chemical Industry expands its footprint and embraces new technologies, it continues to be a trusted partner for businesses seeking reliable and high-quality chemical products. Chemical Industries in Delhi

Contact:- +91 9953507979

Address:- 2950/220, Vishram Nagar, Tri Nagar, DELHI 110035

Thanks for Scrolling…

#chemical industries in delhi#chemical company in delhi#chemical manufacturers in delhi#chemical company in India#best chemical company in India#top chemical company in india

2 notes

·

View notes

Text

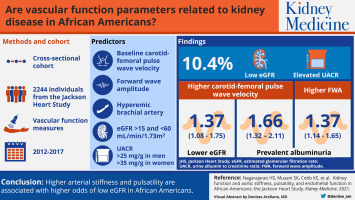

Understanding African American and non-African American eGFR laboratory results

Understanding why eGFR laboratory reports include African American and non-African American results

Glomerular filtration rate (GFR) is the best way to measure how well your kidneys are working, but this test is complicated and cannot be easily done in a doctor’s office. To get around this, laboratories use mathematical equations to estimate the glomerular filtration rate instead of measuring it. This is why laboratories report estimated GFR or eGFR.

Two commonly used estimating equations for eGFR are the CKD MDRD (Modification of Diet in Renal Disease) and the CKD EPI (Chronic Kidney Disease Epidemiology Collaboration) equations. Using these math equations, eGFR is calculated from the amount of creatinine in the blood.

Creatinine is a waste product that comes from the normal wear and tear on your body’s muscles and also from the foods you eat. Everyone has creatinine in their bloodstream. However, creatinine levels can differ between people. This reason for this difference may not only be related to kidney disease – it may be affected by several other factors, such as age, sex, and body weight.

Race was originally included in eGFR calculations because clinical trials demonstrated that people who self-identify as Black/African American can have, on average, higher levels of creatinine in their blood. It was thought the reason why was due to differences in muscle mass, diet, and the way the kidneys eliminate creatinine. Since a patient’s race is not always used when laboratory tests are ordered, laboratories used different eGFR calculations for African American and non-African American and included both numbers in their lab results.

The use of race in calculating eGFR has been a subject of debate. Race is not a biological concept, but a social construct. Using race as a factor for calculating eGFR does not account for the diversity within communities of color. Also, people who self-identify as multiracial might not want to be put in a single racial bucket.

What is the NKF doing to address concerns about using race in measuring eGFR?

In 2020, the National Kidney Foundation (NKF) and the American Society of Nephrology (ASN) formed a joint task force to review the use of race in eGFR calculations. On September 23, 2021, the Task Force announced a new race-free calculation for estimating eGFR. The National Kidney Foundation is working with the nation’s laboratories to get this new calculation into use as quickly as possible. The NKF is also creating materials to show how this new equation may impact patient care.

How is eGFR used?

Estimated GFR is one of the key tests for diagnosing kidney disease. The earlier kidney disease is detected, the better the chance of managing it or keeping your condition from getting worse. Your eGFR informs healthcare professionals about your kidney function and helps them to recommend the best treatments for you. For instance, eGFR results are used in the following ways:

Confirming that kidney function is normal for a potential living kidney donor

Making sure the right dose of medicine is used

Enrollment in clinical trials that use kidney function as an inclusion or exclusion criterion

Making sure the right type of imaging tests and dyes are used

When to refer someone to a nephrologist or kidney doctor

If and when to plan for dialysis

When to start an evaluation for a kidney transplant

Although the NKF alone cannot solve all inequalities, the NKF is working to help identify, confront and reverse them. NKF advocates for making affordable healthcare more available and making sure that communities of color are not left behind. NKF’s CARES helpline is available to all people with kidney disease. NKF’s educational offerings include the impact of kidney disease on diverse communities, and the reasons why communities of color have been disproportionately affected by COVID-19. NKF is committed to continuing its work to address inequalities in kidney health.

#gfr#african american#kemetic dreams#african#africans#lab test#laboratory#health#clincial#clinical laboratory test market

7 notes

·

View notes

Text

Knitted Fabric Testing in NABL Accredited Laboratories

Introduction:

Knitted fabrics have become integral components of our daily lives, finding applications in a wide range of industries, including fashion, sports, and home textiles. To ensure the quality, performance, and compliance of these fabrics, rigorous testing procedures are conducted in NABL accredited laboratories. This blog explores the significance of knitted fabric testing in NABL accredited laboratories and highlights the key tests and standards employed to evaluate various properties and characteristics of knitted fabrics.

The Importance of Knitted Fabric Testing:

Understanding knitted fabrics: Provide an overview of knitted fabrics, including their construction, characteristics, and applications. Explain how testing plays a crucial role in determining the quality, durability, and performance of these fabrics.

Ensuring compliance and safety: Discuss the importance of knitted fabric testing in ensuring compliance with industry standards, regulations, and safety requirements. Highlight how NABL accredited laboratories adhere to stringent guidelines and protocols to maintain the highest levels of quality and reliability in their testing processes.

Key Tests for Knitted Fabrics:

Physical and dimensional properties: Explore the tests conducted to evaluate physical properties such as fabric weight, thickness, density, and dimensional stability. Explain how these tests provide insights into the fabric's structure, handle, and performance characteristics.

Mechanical properties: Discuss the tests performed to assess the fabric's strength, elongation, tear resistance, and bursting strength. Highlight the significance of these tests in determining the fabric's durability and ability to withstand various stresses and strains.

Colorfastness and dyeing properties: Explain the tests carried out to evaluate colorfastness to various factors such as washing, rubbing, light, and perspiration. Discuss the importance of assessing dyeing properties, including color uniformity and colorfastness, to ensure consistent and long-lasting colors in knitted fabrics.

Standards and Certifications for Knitted Fabric Testing:

Overview of relevant standards: Introduce internationally recognized standards for knitted fabric testing, such as ISO, ASTM, AATCC, and EN standards. Explain how these standards provide guidelines and specifications for conducting tests related to different fabric properties.

NABL accreditation: Highlight the significance of NABL (National Accreditation Board for Testing and Calibration Laboratories) accreditation for knitted fabric testing laboratories. Discuss how NABL accreditation ensures adherence to international standards, competence in testing methodologies, and accurate and reliable test results.

Innovations and Challenges in Knitted Fabric Testing:

Advancements in testing techniques: Explore innovative testing techniques and technologies that have enhanced the efficiency, accuracy, and speed of knitted fabric testing. Discuss the benefits of automated testing systems, digital imaging, and computerized data analysis in improving testing processes.

Addressing emerging challenges: Shed light on the evolving challenges faced in knitted fabric testing, such as the testing of eco-friendly and sustainable materials or the characterization of advanced functional textiles. Highlight how NABL accredited laboratories adapt to these challenges by updating their testing capabilities and incorporating new methodologies.

Conclusion:

Knitted fabric testing conducted in NABL accredited laboratories ensures the quality, performance, and compliance of these versatile fabrics. By subjecting knitted fabrics to a battery of tests encompassing physical, mechanical, and colorfastness properties, NABL accredited laboratories contribute to the production of reliable, safe, and high-quality knitted fabrics for diverse industries. Through their commitment to excellence, adherence to standards, and continuous innovation, these laboratories play a vital role in promoting consumer confidence and driving the advancement of knitted fabric technologies.

2 notes

·

View notes

Text

Hazardous Chemicals in SHEIN Products Break EU Regulations.

Greenpeace has conducted research on the Chinese fashion company SHEIN that identifies high levels of hazardous chemicals which break European Union regulations by up to 100% or more. Some 47 products were randomly tested and 7 (15%) were found to have contained hazardous chemicals that break EU regulatory limits. 5 were found to break the EU limits by 100% or more.

The products are purchased online from Germany, Austria, Spain Italy, and Switzerland. They were also purchased from a pop-up store in Munich, Germany. All the products tested included children's clothes and shoes. All the garments were sent to an independent laboratory BUI for chemical analysis.

SHEIN is at the forefront of ultra-fast fashion which has environmentalists up in arms. There are many reasons too, including the short life span of their products, ultra-low pay to Chinese workers, and now clear breaches of EU health regulations. Established fashion designers like Prado have also been vocal about intellectual property theft.

BUIs findings included very high levels of phthalates in shoes and formaldehyde in a baby girl’s dress indicate at the very least SHEIN is not regulating its product production.

Munich Pop-Up store. Photo by Maria irl. Greenpeace.

SHEIN targets TikTok users.

Rebecca Morter, founder of the sustainable e-commerce site Lone Design Club recently said in an interview with Glossy,

“The worry with what Shein is doing — especially with their target audience of Gen-Zers* — is that it is making them think that it’s OK to pay next to nothing for an item of clothing, when the only way to have reached that price would mean exploiting people along the supply chain, from the makers to the designers,”

* Gen-Z (people born between the mid-to-late 1990s and 2012).

SheIn Women's Casual V Neck Sleeveless Ribbed Knit Cami Crop Top. Photo by Shop8447. Flickr.

The Supply Chain.

SHEIN's business model relies on products being produced and delivered almost instantly. The fast fashion style forces suppliers to deliver at breakneck speed which in turn makes things very hard for regulators.

Earlier this month SHEIN announced the opening of a 170,000 sq ft. Warehouse and Office in Greater Toronto Area. The company is set to keep expanding and if regulators don't start looking into this soon there could be really bad ramifications.

Dye Factory in Shaoxing, China. Photo by Lu Guang. Greenpeace.

Greenpeace's point of view.

Viola Wohlgemuth, Greenpeace Overconsumption & toxics Campaigner in Germany said,

“Greenpeace is calling for the EU to enforce its laws on hazardous chemicals – which are a basic requirement for achieving a circular textiles economy and the end of fast fashion, as set out in the EU’s own Textiles Strategy.”

“But the EU’s proposals also need to take on the inhuman system of exploitation and destruction by ultra fast fashion that should have no place in any industry in the 21st century, by holding companies fully responsible for environmental and social exploitation in their supply chains and the impacts from fashion waste. This also needs to be urgently addressed through a global treaty, similar to the recently agreed UNEA plastics treaty that is currently being discussed, to finally tackle the giant fashion footprint.”

In conclusion.

SHEIN's business model needs investigating by the authorities soon rather than later. If their business model is putting people at risk of exposure to dangerous levels of toxins then the public has a right to know. Parents should do some research and make sure their kids are not put at risk because of new fashion trends.

Sources: THX News, LinkedIn, SHEIN, Glossy, Euro News & Greenpeace.

Read the full article

3 notes

·

View notes

Text

How Yarn Testing Laboratories Ensure the Safety of Textile Products?

In the textile industry, ensuring the safety of textile products is crucial for protecting consumers and maintaining product integrity. Yarn testing laboratories play a pivotal role in this process by evaluating yarns for various safety attributes and compliance with regulations. This blog delves into how yarn testing laboratories ensure the safety of textile products, highlighting key testing procedures, safety standards, and the impact on overall textile quality.

The Importance of Safety in Textile Products

Safety in textile products encompasses several factors, including:

Chemical Safety: Ensuring that textiles do not contain harmful chemicals.

Physical Safety: Verifying that textiles are durable and do not pose physical risks.

Environmental Safety: Confirming that production processes and materials are environmentally friendly.

By addressing these aspects, yarn testing laboratory help manufacturers produce textiles that are safe for consumers and compliant with industry standards.

Key Areas of Safety Assessed by Yarn Testing Laboratories

1. Chemical Safety

One of the primary concerns in textile safety is the presence of harmful chemicals. Yarn testing laboratories assess yarns for:

Chemical Residues: Testing for residual chemicals used during yarn production, such as dyes, finishing agents, and preservatives.

Toxic Substances: Screening for harmful substances like heavy metals, formaldehyde, and azo dyes, which can be hazardous to health.

Compliance with Regulations: Ensuring that yarns meet safety standards set by organizations like OEKO-TEX® and GOTS.

Key Insight: Testing for chemical safety ensures that yarns do not contain harmful substances that could negatively impact consumer health.

2. Physical Safety

The physical safety of textiles is essential for preventing injuries and ensuring durability. Yarn testing laboratories evaluate:

Strength and Durability: Assessing the tensile strength and abrasion resistance of yarns to ensure they can withstand regular use and stress.

Elasticity: Testing yarns for their ability to stretch and recover without losing shape, which affects the longevity of the textile.

Pilling Resistance: Evaluating the yarn's resistance to pilling, which can lead to fabric degradation and potential hazards.

Key Insight: Physical testing ensures that yarns used in textiles are robust and reliable, reducing the risk of accidents and extending product life.

3. Compliance with Industry Standards

Yarn testing laboratories ensure that yarns comply with various industry standards and regulations. These include:

ISO Standards: International standards that provide guidelines for textile testing, including safety requirements.

ASTM Standards: Standards that cover various aspects of textile testing, including yarn properties and safety.

OEKO-TEX® and GOTS Certifications: Certifications that verify compliance with safety and environmental standards.

Key Insight: Compliance with industry standards guarantees that yarns meet established safety criteria, providing assurance to manufacturers and consumers.

4. Environmental Safety

Environmental safety is a growing concern in textile production. Yarn testing laboratories contribute to environmental safety by:

Testing for Eco-Friendly Materials: Verifying that yarns are made from sustainable or recycled fibers and do not contribute to environmental harm.

Assessing Production Practices: Evaluating the impact of production processes on the environment and ensuring adherence to eco-friendly practices.

Key Insight: Ensuring environmental safety supports sustainable textile production and minimizes the ecological impact of yarn manufacturing.

5. Health and Comfort

The comfort and health implications of textile products are directly influenced by yarn quality. Yarn testing laboratories assess:

Breathability: Testing yarns for their ability to allow air circulation, which affects comfort and prevents overheating.

Allergen Testing: Screening for allergens and irritants that could cause skin reactions or allergies.

Skin Contact Safety: Ensuring that yarns are safe for prolonged skin contact and do not cause irritation.

Key Insight: Health and comfort testing ensures that textiles are suitable for daily use and do not cause adverse reactions.

The Role of Yarn Testing Laboratories in Ensuring Safety

1. Advanced Testing Techniques

Yarn testing laboratories employ advanced testing techniques to ensure the safety of yarns. This includes:

Chromatography: For detecting chemical residues and contaminants.

Spectroscopy: To analyze the composition of yarns and identify harmful substances.

Mechanical Testing: To assess the physical properties of yarns and their performance under various conditions.

Key Insight: Utilizing advanced testing techniques enhances the accuracy of safety assessments and ensures reliable results.

2. Strict Quality Control

Quality control is a critical component of yarn testing. Laboratories implement strict quality control measures, such as:

Regular Equipment Calibration: Ensuring that testing equipment is accurately calibrated and maintained.

Standard Operating Procedures (SOPs): Following detailed procedures for each test to ensure consistency and reliability.

Proficiency Testing: Participating in inter-laboratory comparisons to validate testing accuracy.

Key Insight: Rigorous quality control ensures that testing processes are reliable and produce accurate safety assessments.

3. Detailed Reporting and Documentation

Yarn testing laboratories provide detailed reports and documentation, including:

Test Results: Comprehensive data on yarn properties and safety assessments.

Compliance Certificates: Documentation verifying adherence to industry standards and regulations.

Recommendations: Suggestions for improving yarn safety and addressing any identified issues.

Key Insight: Detailed reporting supports transparency and provides valuable information for manufacturers and regulators.

4. Supporting Certification Processes

Yarn testing laboratories assist with certification processes by:

Conducting Required Tests: Performing tests necessary for certification programs like OEKO-TEX® and GOTS.

Issuing Certificates: Providing certificates that confirm compliance with safety and environmental standards.

Facilitating Audits: Supporting manufacturers during certification audits and inspections.

Key Insight: Assisting with certification processes helps manufacturers demonstrate compliance and gain market recognition.

Conclusion

Yarn testing laboratories are essential for ensuring the safety of textile products. By evaluating chemical safety, physical safety, compliance with industry standards, environmental safety, and health and comfort factors, these labs play a crucial role in delivering textiles that are safe for consumers and compliant with regulations.

Investing in reliable yarn testing ensures that textile products meet safety requirements, enhance consumer protection, and support sustainable production practices. As the textile industry evolves, yarn testing laboratories will continue to be instrumental in maintaining high safety standards and driving innovation. For manufacturers committed to producing safe and high-quality textiles, partnering with a reputable yarn testing lab is a key step towards achieving excellence and consumer satisfaction.

0 notes

Text

Flow Cytometry is poised to grow from USD 4.25 Billion in 2023 to USD 6.99 Billion by 2031

The flow cytometry market is witnessing a period of remarkable growth and transformation, driven by advancements in technology, increasing research and diagnostic applications, and a rising demand for personalized medicine. As detailed in the latest report by SkyQuest Technology, this sector is poised for significant expansion, with various segments contributing to its dynamism. This article delves into the current trends, future outlook, and market segmentation of flow cytometry, providing a comprehensive overview for stakeholders in the healthcare and life sciences industries.

Flow Cytometry Market Overview

Flow cytometry is a powerful technology used for cell counting, cell sorting, biomarker detection, and protein engineering. Its ability to analyze multiple parameters simultaneously makes it indispensable in clinical diagnostics, immunology, oncology, and drug discovery. According to the SkyQuest report, the global flow cytometry market is expanding due to the increasing prevalence of chronic diseases, growing demand for personalized medicine, and continuous innovations in flow cytometry technology.

Global Flow Cytometry Market size was valued at USD 3.97 Billion in 2022 and is poised to grow from USD 4.25 Billion in 2023 to USD 6.99 Billion by 2031, growing at a CAGR of 7.17% in the forecast period (2024-2031).

The market is characterized by rapid technological advancements, such as the development of high-throughput and multi-parameter flow cytometers, which enhance the efficiency and accuracy of cellular analysis. Additionally, the integration of artificial intelligence and machine learning into flow cytometry systems is revolutionizing data analysis and interpretation.

Market Segmentation

Understanding the flow cytometry market requires a closer look at its segmentation. The market is segmented based on product type, application, end-user, and region. Each segment plays a crucial role in shaping the market dynamics and growth trajectories.

1. By Product Type

- Instruments: This segment includes flow cytometers, which are further categorized into cell analyzers, cell sorters, and others. Innovations in flow cytometer designs, such as those offering enhanced sensitivity and resolution, are driving this segment's growth.

- Reagents and Consumables: Reagents, including antibodies and dyes, are essential for conducting flow cytometry experiments. This segment is also growing due to the increasing demand for specific markers and assays.

- Software: Advanced software solutions for data analysis and interpretation are becoming increasingly important, contributing to the market's expansion.

2. By Application

- Clinical Applications: This includes diagnostics for diseases such as leukemia, lymphoma, and other hematological disorders. The rising incidence of these conditions and the growing need for accurate diagnostic tools are key drivers.

- Research Applications: Flow cytometry is widely used in research settings, including cancer research, immunology, and drug discovery. The demand for high-throughput and multi-parameter analysis in research is fueling this segment.

- Other Applications: This includes environmental and agricultural applications, where flow cytometry is used for microbial analysis and plant research.

3. By End-User

- Hospitals and Diagnostic Laboratories: The demand for flow cytometry in hospitals and diagnostic labs is increasing due to its critical role in patient diagnosis and treatment monitoring.

- Research Institutes: Academic and research institutions are significant users of flow cytometry for various research applications, including fundamental and applied sciences.

- Pharmaceutical and Biotechnology Companies: These companies use flow cytometry for drug development and testing, contributing significantly to the market's growth.

4. By Region

- North America: The region leads the market due to advanced healthcare infrastructure, high adoption rates of new technologies, and substantial research funding.

- Europe: Europe is experiencing steady growth, driven by increasing research activities and collaborations in the healthcare sector.

- Asia-Pacific: This region is emerging as a significant market due to rising healthcare investments, growing research activities, and a large patient population.

- Latin America and Middle East & Africa: These regions are also expected to see growth, though at a slower pace compared to other regions, due to developing healthcare infrastructure and increasing awareness of advanced diagnostic technologies.

Chance to get a free sample: https://www.skyquestt.com/sample-request/flow-cytometry-market

Flow Cytometry Market Top Players Company Profiles

Becton, Dickinson, and Company (US)

Danaher Corporation (US)

Thermo Fisher Scientific, Inc. (US)

Agilent Technologies, Inc. (US)

Sony Group Corporation (Japan)

Bio-Rad Laboratories, Inc. (US)

Miltenyi Biotec GmbH (Germany)

Enzo Biochem, Inc. (US)

Sysmex Corporation (Japan)

bioMérieux S.A. (France)

Cytonome/ ST, LLC (US)

Sartorius AG (Germany)

Cytek Biosciences, Inc. (US)

Union Biometrica, Inc. (US)

Fluxion Biosciences, Inc. (US)

Apogee Flow Systems Ltd. (UK)

Merck KGaA (Germany)

Beckman Coulter, Inc. (US)

Stratedigm, Inc. (US)

Nanocellect Biomedical (US)

Future Outlook

The flow cytometry market is set for substantial growth in the coming years, driven by ongoing technological innovations, increasing research activities, and the rising prevalence of chronic diseases. Companies are focusing on developing more advanced and user-friendly flow cytometry systems, and the integration of AI and machine learning will likely further enhance the capabilities and applications of flow cytometry.

Investments in research and development, along with strategic collaborations and partnerships, will play a crucial role in shaping the future of the flow cytometry market. Additionally, addressing challenges related to high costs and the need for skilled professionals will be key to sustaining growth and expanding market reach.

0 notes

Text

Immunohistochemistry Market Forecast and Analysis Report (2023-2032)

The Global Immunohistochemistry Market is projected to grow from USD 3,102.96 million in 2023 to USD 4,731.81 million by 2032, at a compound annual growth rate (CAGR) of 4.80%.

Immunohistochemistry (IHC) is a powerful technique used in laboratories to detect specific antigens in tissue sections by utilizing the principle of antibodies binding specifically to antigens in biological tissues. This method enables researchers and clinicians to visualize the distribution and localization of specific proteins within cells and tissue samples, providing critical insights into the molecular underpinnings of various diseases, including cancer. IHC is widely employed in diagnostic pathology to identify abnormal cells, such as those found in tumors, by labeling them with chromogens or fluorescent dyes that can be observed under a microscope. The ability to target and highlight specific cellular components makes immunohistochemistry an invaluable tool in both research and clinical settings.

The Immunohistochemistry (IHC) market has shown significant growth, driven by increasing demand for diagnostic testing in oncology, advancements in IHC technology, and a rising prevalence of chronic diseases. Key findings of the study include:

Market Growth: The global IHC market is experiencing robust growth, with a compound annual growth rate (CAGR) expected to remain strong over the forecast period, driven by increasing adoption in cancer diagnostics and the development of novel biomarkers.

Technological Advancements: Continuous advancements in IHC technologies, including the development of automated staining systems and multiplex IHC assays, have enhanced the accuracy and efficiency of diagnostic processes, contributing to market expansion.

Oncology Dominance: The oncology segment remains the largest application area within the IHC market, as the technique plays a crucial role in identifying cancer types, guiding treatment decisions, and monitoring therapeutic responses.

Regional Insights: North America holds the largest market share due to a well-established healthcare infrastructure, high adoption rates of advanced diagnostic techniques, and significant investments in research and development. However, Asia-Pacific is expected to witness the fastest growth, driven by increasing healthcare expenditures, growing awareness, and the rising prevalence of chronic diseases.

Competitive Landscape: The IHC market is highly competitive, with key players focusing on mergers and acquisitions, partnerships, and new product launches to strengthen their market position. Major companies in the market include F. Hoffmann-La Roche Ltd, Danaher Corporation, Agilent Technologies, Inc., Thermo Fisher Scientific, Inc., and Bio-Rad Laboratories, Inc. These companies are heavily investing in R&D to develop innovative products and maintain a competitive edge.

This analysis highlights the growing importance of immunohistochemistry in clinical diagnostics and the ongoing innovations that continue to drive the market forward.

The Immunohistochemistry (IHC) market is witnessing varying growth trends across different regions, driven by factors such as healthcare infrastructure, prevalence of chronic diseases, and adoption of advanced diagnostic technologies. Below are the regional insights for the IHC market:

1. North America

North America dominates the global IHC market, holding the largest market share due to its well-established healthcare infrastructure and high adoption of advanced diagnostic techniques. The United States, in particular, is a significant contributor to the region’s market, driven by the high prevalence of cancer, increasing demand for personalized medicine, and substantial investment in research and development. The presence of leading market players, such as F. Hoffmann-La Roche, Danaher Corporation, and Agilent Technologies, also strengthens the region's market position. Furthermore, favorable reimbursement policies and the growing number of diagnostic laboratories are expected to continue driving market growth in North America.

2. Europe

Europe is the second-largest market for IHC, supported by a robust healthcare system and significant government investments in cancer research. Countries like Germany, the United Kingdom, and France are key markets within the region, owing to their advanced healthcare infrastructure and the presence of major pharmaceutical companies. The growing emphasis on early disease detection and the increasing use of IHC in companion diagnostics are key factors driving market growth in Europe. Additionally, the region's focus on precision medicine and the expansion of automated IHC systems in clinical settings further contribute to its market growth.

3. Asia-Pacific

The Asia-Pacific region is expected to witness the fastest growth in the IHC market during the forecast period. Factors such as the rapidly growing healthcare sector, increasing healthcare expenditure, and rising awareness about early disease diagnosis are fueling the demand for IHC in the region. Countries like China, Japan, and India are the major growth drivers, with China and Japan leading the market due to their advanced medical research facilities and increasing prevalence of chronic diseases such as cancer. The region's growing population and the expansion of healthcare services in rural areas are also contributing to market growth. Additionally, the increasing adoption of Western healthcare practices and the presence of emerging local players are expected to boost the IHC market in Asia-Pacific.

4. Latin America

The IHC market in Latin America is growing steadily, with Brazil and Mexico being the key contributors. The region's market growth is driven by increasing awareness about cancer and other chronic diseases, coupled with improving healthcare infrastructure. Government initiatives to enhance healthcare services and the rising adoption of advanced diagnostic technologies are further propelling the market. However, limited access to cutting-edge technologies and lower healthcare spending in some parts of the region may hinder market growth to some extent.

5. Middle East and Africa

The IHC market in the Middle East and Africa (MEA) is at a nascent stage but is expected to grow significantly over the forecast period. The market is primarily driven by increasing government initiatives to improve healthcare infrastructure and the rising prevalence of chronic diseases. The United Arab Emirates and Saudi Arabia are the key markets within this region, benefiting from substantial investments in healthcare and the adoption of advanced diagnostic techniques. However, the region faces challenges such as limited access to healthcare services in rural areas and the high cost of IHC technologies, which may impact market growth. Despite these challenges, the growing focus on improving healthcare outcomes and the increasing availability of IHC products are expected to drive market growth in MEA.

In summary, while North America and Europe currently dominate the IHC market, the Asia-Pacific region is poised for rapid growth due to its expanding healthcare sector and increasing adoption of advanced diagnostic technologies. Latin America and the Middle East and Africa, though smaller markets, also present significant growth opportunities as healthcare infrastructure continues to improve.

Key Player Analysis

Thermo Fisher Scientific Inc.

Hoffmann-La Roche Ltd.

Merck KGaA

Danaher Corporation

PerkinElmer, Inc.

Bio-Rad Laboratories, Inc.

Cell Signaling Technology, Inc.

Bio SB

Agilent Technologies, Inc.

Abcam plc.

More About Report- https://www.credenceresearch.com/report/immunohistochemistry-market

The Immunohistochemistry (IHC) market is evolving rapidly, driven by technological advancements, increasing demand for personalized medicine, and a rising focus on early disease detection. Here are some key trends shaping the IHC market:

1. Growth in Personalized Medicine

The shift towards personalized medicine is one of the most significant trends in the IHC market. As the understanding of the genetic and molecular basis of diseases improves, IHC is increasingly used to tailor treatment plans to individual patients. This is particularly evident in oncology, where IHC plays a critical role in identifying specific biomarkers that guide targeted therapies. The demand for personalized treatment options is driving the development of new IHC assays and antibodies, enhancing the precision and effectiveness of treatments.

2. Advancements in Automated IHC Systems

Automation is transforming the IHC market, with the development of fully automated staining platforms that offer higher throughput, reproducibility, and accuracy compared to manual methods. These systems are increasingly being adopted in clinical laboratories to streamline workflows, reduce human error, and improve diagnostic efficiency. Automation is also facilitating multiplexing, where multiple biomarkers can be detected simultaneously in a single tissue sample, providing more comprehensive diagnostic information.

3. Expansion of IHC Applications Beyond Oncology

While oncology remains the primary application of IHC, its use is expanding into other areas, including neurology, cardiovascular diseases, and infectious diseases. In neurology, for instance, IHC is used to study the pathology of neurodegenerative diseases like Alzheimer's and Parkinson's. The expansion of IHC applications is broadening the market's scope, creating new opportunities for growth across various medical fields.

4. Integration with Digital Pathology

The integration of IHC with digital pathology is another trend gaining momentum. Digital pathology involves the use of high-resolution scanning of tissue slides, which can then be analyzed and shared digitally. This integration allows for more precise quantification of IHC staining, better data management, and remote consultations. Digital IHC also supports the use of artificial intelligence (AI) in diagnostics, where machine learning algorithms can analyze IHC-stained slides, enhancing diagnostic accuracy and efficiency.

5. Rising Demand for Companion Diagnostics

The growing importance of companion diagnostics, which are tests used to determine the suitability of specific treatments for individual patients, is driving demand for IHC. Companion diagnostics are particularly relevant in oncology, where they help identify patients who are most likely to benefit from targeted therapies. The development of new companion diagnostics using IHC is expected to continue, driven by the increasing focus on precision medicine and the approval of new targeted therapies.

6. Increased Focus on Cost-Effective Solutions

As healthcare systems worldwide face cost pressures, there is an increasing demand for cost-effective diagnostic solutions. IHC companies are responding by developing more affordable antibodies, reagents, and automated systems that maintain high quality while reducing overall costs. This trend is particularly relevant in emerging markets, where cost is a significant barrier to the adoption of advanced diagnostic technologies.

7. Regulatory and Reimbursement Challenges

The IHC market is also navigating a complex regulatory landscape, with stringent guidelines governing the approval and use of IHC assays. Regulatory bodies are increasingly focusing on the validation and standardization of IHC tests to ensure consistent and reliable results. Additionally, securing reimbursement for IHC tests remains a challenge in some regions, impacting market growth. Companies are working to address these challenges by engaging with regulatory authorities and demonstrating the clinical utility and cost-effectiveness of their IHC products.

8. Collaborations and Strategic Partnerships

To stay competitive, companies in the IHC market are increasingly entering into collaborations and strategic partnerships. These partnerships often involve pharmaceutical companies, diagnostic labs, and research institutions, aimed at co-developing new IHC assays, expanding product portfolios, and accelerating the commercialization of innovative diagnostic solutions. Collaborations are also playing a crucial role in the development of companion diagnostics and in expanding the global reach of IHC products.

Segments:

Based on Product:

Antibodies

Primary Antibodies

Secondary Antibodies

Equipment

Slide Staining System

Tissue Microarrays

Tissue Processing Systems

Slide Scanners

Others

Reagents

Histological stains

Blocking Sera and Reagent

Chromogenic Substrates

Fixation Reagents

Stabilizers

Organic Solvents

Proteolytic Enzymes

Diluents

Kits

Based on Application

Diagnostics

Cancer

Infectious Diseases

Cardiovascular Diseases

Autoimmune Diseases

Diabetes Mellitus

Nephrological Diseases

Research

Based on End-use:

Hospitals & Diagnostic Laboratories

Research Institutes

Browse the full report – https://www.credenceresearch.com/report/immunohistochemistry-market

Browse Our Blog: https://www.linkedin.com/pulse/immunohistochemistry-market-analysis-global-industry-l0smc

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Phenylmethanamine Manufacturing Plant Project Report : Setup and Cost

The Phenylmethanamine Manufacturing Plant Project report provides a detailed blueprint for setting up a facility dedicated to producing phenylmethanamine, a versatile compound with applications in pharmaceuticals, agrochemicals, and industrial chemicals. This comprehensive report covers essential aspects such as market analysis, plant design, production processes, and operational strategies, offering valuable insights for investors and entrepreneurs. By outlining the steps required to establish and operate a successful manufacturing plant, the report aims to guide stakeholders through the complexities of the project, ensuring informed decision-making and effective implementation.

Understanding Phenylmethanamine

1. What is Phenylmethanamine?

Phenylmethanamine (C₆H₅CH₂NH₂) is an aromatic amine used in the synthesis of pharmaceuticals and agrochemicals. It serves as an intermediate in the production of various drugs, including antihistamines and antidepressants. In the industrial sector, phenylmethanamine is used in the synthesis of dyes and as a reagent in chemical reactions. Its versatility and importance in chemical manufacturing make it a critical compound in several sectors.

2. Market Demand and Trends

The demand for phenylmethanamine is influenced by its wide range of applications. The pharmaceutical industry, in particular, drives the need for high-purity phenylmethanamine due to its role as a precursor in drug synthesis. The agrochemical sector also contributes to demand as phenylmethanamine is used in the production of pesticides and herbicides.

Key Market Trends:

Growing Pharmaceutical Sector: Increased demand for specialty drugs and pharmaceuticals boosts the need for phenylmethanamine.

Industrial Applications: The compound's use in manufacturing dyes and other industrial chemicals supports steady market demand.

Innovation and Regulation: Advances in chemical synthesis and stricter regulations impact the production and quality standards for phenylmethanamine.

Get a Free Sample Report with Table of Contents @ https://www.expertmarketresearch.com/prefeasibility-reports/phenylmethanamine-manufacturing-plant-project-report

Project Planning and Feasibility

1. Business Plan Development

A well-structured business plan is essential for the successful establishment of a phenylmethanamine manufacturing plant. The plan should include:

Market Analysis: Assess demand, identify potential customers, and analyze market competition.

Operational Plan: Outline plant layout, production processes, and technology requirements.

Financial Projections: Estimate startup costs, operational expenses, and potential revenue.

Regulatory Compliance: Understand industry regulations and obtain necessary permits.

2. Feasibility Study

A feasibility study evaluates the viability of the project by examining:

Raw Material Sourcing: Availability and cost of raw materials required for phenylmethanamine production.

Production Technology: Assessing the technology and equipment needed for manufacturing.

Market Conditions: Analyzing demand, competition, and pricing strategies.

The feasibility study helps determine if the project is financially and technically viable.

Facility Design and Setup

1. Location Selection

Selecting an optimal location for the plant is crucial. Key factors to consider include:

Proximity to Raw Materials: Ensure easy access to benzyl alcohol and other raw materials.

Infrastructure: Access to utilities, transportation, and skilled labor.

Regulatory Environment: Choose locations with favorable regulations and incentives.

2. Plant Layout

A well-designed plant layout enhances operational efficiency and safety. Key areas include:

Raw Material Storage: Facilities for storing benzyl alcohol and other raw materials.

Production Area: The main area where phenylmethanamine is synthesized.

Quality Control Laboratory: For testing the purity and properties of phenylmethanamine.

Packaging and Distribution: Areas for packaging the final product and preparing it for shipment.

3. Equipment and Technology

Investing in appropriate equipment is crucial for efficient production. Key equipment includes:

Reaction Vessels: For carrying out the chemical synthesis of phenylmethanamine.

Separation and Purification Units: For isolating and purifying phenylmethanamine.

Quality Control Instruments: For analyzing the chemical properties and purity of the product.

Production Process

1. Raw Material Preparation

The production of phenylmethanamine begins with the preparation of raw materials, primarily benzyl alcohol and ammonia. Proper handling and storage are essential to maintain material quality.

2. Chemical Synthesis

Phenylmethanamine is produced through the reductive amination of benzyl alcohol. The process involves:

Reaction Setup: Mixing benzyl alcohol with ammonia in the presence of a reducing agent.

Reaction Conditions: Controlling temperature, pressure, and reaction time to ensure optimal yield.

Product Separation: Isolating phenylmethanamine from the reaction mixture and removing by-products.

3. Purification and Drying

The synthesized phenylmethanamine undergoes purification to remove impurities. Techniques such as distillation or recrystallization are used. The purified product is then dried to achieve the desired physical properties.

4. Quality Control

Quality control ensures that the phenylmethanamine meets industry standards. Testing includes:

Chemical Analysis: Verifying the composition and purity of the product.

Physical Properties: Assessing attributes such as melting point and solubility.

5. Packaging and Distribution

The final product is packaged in appropriate containers and prepared for distribution. Efficient packaging helps prevent contamination and ensures safe transportation.

Operational Considerations

1. Workforce Management

A skilled workforce is vital for plant operations. Key roles include chemical engineers, production technicians, quality control analysts, and maintenance staff. Ongoing training ensures that employees stay current with the latest technologies and safety protocols.

2. Regulatory Compliance

Compliance with regulatory standards is crucial for legal operation. This includes adhering to safety regulations, environmental guidelines, and chemical handling practices. Obtaining necessary permits and certifications is required.

3. Environmental and Safety Measures

Implementing measures to minimize environmental impact and ensure workplace safety is essential. This includes:

Waste Management: Proper disposal of chemical waste and by-products.

Emission Control: Monitoring and controlling emissions to comply with environmental regulations.

Safety Protocols: Establishing safety measures and providing adequate training to prevent accidents.

4. Maintenance and Upgrades

Regular maintenance of equipment is necessary to ensure smooth operation and avoid breakdowns. Scheduled inspections and repairs help keep machinery in optimal condition. Staying informed about technological advancements can lead to productivity improvements and cost reductions.

Marketing and Sales Strategy

1. Branding and Positioning

Developing a strong brand identity helps differentiate your phenylmethanamine from competitors. Emphasize quality, reliability, and the unique benefits of your product to attract customers.

2. Distribution Channels

Establish effective distribution channels to reach your target market. This may include partnerships with distributors, direct sales to pharmaceutical companies, and exploring both domestic and international markets.

3. Marketing Tactics

Implement marketing strategies to promote your phenylmethanamine. Utilize industry events, trade shows, and digital marketing to increase visibility. Providing samples or demonstrations can help build relationships and showcase the benefits of your product.

FAQ

What are the main uses of phenylmethanamine?

Phenylmethanamine is used primarily in the pharmaceutical industry as a precursor for drugs, including antihistamines and antidepressants. It is also used in agrochemicals and industrial chemicals.

What factors should be considered when setting up a phenylmethanamine manufacturing plant?

Key factors include selecting a suitable location with access to raw materials, designing an efficient plant layout, investing in the right equipment, and ensuring regulatory compliance. Understanding market demand and developing a strong marketing strategy are also important.

How is the quality of phenylmethanamine ensured?

Quality control involves testing the phenylmethanamine for chemical composition, purity, and physical properties. Rigorous testing ensures that the product meets industry standards and performs as expected.

What are the challenges in operating a phenylmethanamine manufacturing plant?

Challenges include managing production costs, maintaining equipment, ensuring regulatory compliance, and competing with other suppliers. Additionally, fluctuations in raw material prices and market demand can impact profitability.

How can I finance a phenylmethanamine manufacturing plant project?

Funding options include business loans, grants, or investment from venture capitalists. A well-prepared business plan and financial projections are crucial for securing funding and attracting investors.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/

0 notes

Text

How to buy Lead Nitrate for heat stabilizing application?

The process of heating degrades Lead Nitrate. It is a frequently used in pyrotechnics. Both water and dilute nitric acid are soluble, thus making coordination complexes. Its chemical properties make it useful for stabilizing nylon and polyester. Additionally, it can be used as a rodenticide and photo thermographic paper coating. It is supplied through chemical manufacturers to clients where ever they are based.

AVA a chemicals is a well-known as one of the prime Lead Nitrate suppliers in India. For over 40 years the company continues to supply this chemical and several others. We meet the specific needs of customers who order directly or via online channels.

This post offers a simple guideline to understand why lead nitrate is a good heat stabilizer. We can also discuss your requirement for the next project.

Quick facts about Lead Nitrate:

Lead Nitrate does not react with water as it is highly soluble.

It is toxic for humans and should be handled carefully.

It can be a cause for cancer in kidneys and lungs.

Immediate applications

As a regular supplier and Lead Nitrate Manufacturers in India, AVA Chemicals offers it in a powder format. It has a colourless appearance and is very slightly soluble in alcohol.

Customers in different industries use the same for the following applications:

Heat stabilizer in nylon and polyester in the form of a photo thermographic coating.

Making match sticks and special explosives.

Leaching of gold which is done via metallurgical process. Only a tiny amount is required to improve leaching.

Dye and photographic usage.

Engraving process.

It works as a bromide scavenger (for SN1 substitution).

In organic chemistry, it creates isothiocyanates from dithiocarbamates.

In Europe, it first was applied as an initial material to make lead paint pigments. Today, AVA Chemicals continues to make it in the laboratory as Lead Nitrate manufacturers in India. It is an important by product whose commercial production is required globally.

Lab-based thermal decomposition

Heating turns lead Nitrate powder to a yellowish shade. The decomposition temperature begins from the top and then goes below. When hot, it is brown in colour and the yellowness appears when the chemical starts to cool.

Buying process

We have plants that manufacture lead nitrate and other chemicals in large quantities. All our prime sources of material are located close to the plants. We also organise the safe delivery in the powder form.

To buy laboratory grade Lead Nitrate, it is important to approach a certified manufacturer like AVA Chemicals. Other than having decades of experience, the company is ISO: 9001:2015 certified. The company professionals have the required expertise and technical qualifications to conduct lab tests. A large facility is equipped to make bulk quantities of Lead Nitrate. The staff is trained to handle complex chemicals and their distribution to customers.

If you wish to know more about Lead Nitrate as a good heat stabilizer or its other applications in details, do let us know. We have full-fledged team to cater to all kinds of chemical formulations and their requirement in various industries.

#EDTA Disodium Magnesium Manufacturers in India#EDTA Disodium Manganese Suppliers in India#Ammonium Acetate (AR/GR/ACS) Suppliers in India#EDTA Cu Chelated Copper Suppliers in India#EDTA Disodium Magnesium Suppliers in India#Zinc Acetate (EP/LR) Manufacturers in India#Trisodium NTA Powder Suppliers in India#Trisodium NTA Powder Manufacturers in India#Lead Acetate (EP/LR) Manufacturers in India#Lead Acetate (EP/LR) Suppliers in India#Ammonium Formate EP GRADE Suppliers in India#Zinc Acetate (EP/LR) Suppliers in India#Ammonium Formate EP GRADE Manufacturers in India#EDTA Cu Chelated Copper Manufacturers in India#Ammonium Formate LR GRADE Manufacturers in India#Disodium Calcium EDTA Suppliers in India#HEDP 60% Suppliers in India#HEDP 60% Manufacturers in India#Disodium Calcium EDTA Manufacturers in India#Zinc Citrate Suppliers in India#EDTA Calcium Suppliers in India#Zinc Citrate Manufacturers in India#Manganese Acetate Tetrahydrate Suppliers in India#Manganese Acetate Tetrahydrate Manufacturers in India#EDTA Ferric Sodium Suppliers in India#EDTA Ferric Sodium Manufacturers in India#EDTA Calcium Manufacturers in India#EDTA Zinc Manufacturers in India#Zinc Acetate EP Grade Suppliers in India#Zinc Acetate LR Grade Suppliers in India

0 notes

Text

RK Industries | Lab Equipment for Color Dye Testing

RK Industries leverages advanced lab equipment to produce high-quality color dyes, ensuring reliable and precise production that meets industry standards.

#development of dyes product laboratory#dyes Product Testing Laboratory#dyes Product quality Testing Laboratory#Best quality dyes product in India#Vietnam#Brazil

0 notes

Text

While allowing myself a little holiday in Spain, I bumped into an after-sun cream containing urea.

When we hear "urea," the first thought that often comes to mind is agriculture, where urea plays a crucial role as a fertiliser. However, looking at this cream, I thought that the applications of urea extend far beyond the fields.

Automotive Industry:

Urea is a key component in Diesel Exhaust Fluid (DEF), commonly known by the brand name AdBlue. This fluid is essential for reducing harmful emissions in diesel engines, helping to keep our air cleaner.

Pharmaceuticals, Cosmetics, and Personal Care:

Creams are good examples. Its moisturising properties make it a common ingredient in dermatological treatments for conditions such as eczema and psoriasis. It’s also an effective ingredient in lotions, creams, and anti-ageing products.

Chemical Industry:

Urea serves as a raw material in the production of plastics, resins, and adhesives. It's also utilised in the manufacture of urea-formaldehyde, which is a key component in particleboard and other wood products.

Textile Industry:

In the textile industry, urea is used in dyeing and printing processes to enhance colour absorption and fixation on fabrics, ensuring vibrant and long-lasting colours.

Laboratories and Medical Diagnostics:

Urea is utilised in laboratory tests and diagnostic procedures, including the urea breath test, which is used to detect the presence of Helicobacter pylori bacteria in the stomach.

Animal Feed:

Urea is added to animal feed as a non-protein nitrogen source, providing essential nutrients to livestock and promoting better growth and productivity.

And my favourite one - it's in chewing gum! I still remember that commercial of Stimorol with xylitol and urea.

Enjoy your holidays, whoever is having one now!

#urea #fertilisers #fertilizers #chemicals #beauty #pharma #textile #animal #imstory

0 notes

Text

Chemical Manufacturing Companies in Gujarat: A Hub of Innovation and Quality

Gujarat, a state renowned for its industrial prowess, stands as a beacon of excellence in India's chemical manufacturing sector. Among the many esteemed companies in this thriving industry, Purvi Chemicals shines as a leader, offering a diverse range of high-quality chemical products and solutions. Chemical Manufacturing Companies In GujaratThis article delves into the significance of chemical manufacturing companies in Gujarat, with a special focus on Purvi Chemicals and their contributions to the industry.

The Chemical Manufacturing Landscape in Gujarat

Gujarat's chemical industry has been a cornerstone of its economy, contributing significantly to both state and national GDP. The state boasts a strategic advantage due to its well-developed infrastructure, access to raw materials, skilled workforce, and favorable government policies. These factors have collectively propelled Gujarat to become one of the top chemical manufacturing hubs in India.

Key highlights of Gujarat's chemical manufacturing sector include:

Diverse Product Portfolio: Companies in Gujarat produce a wide range of chemical products, including petrochemicals, agrochemicals, dyes, pigments, pharmaceuticals, and specialty chemicals.

Technological Advancements: Embracing cutting-edge technology and innovative processes, chemical manufacturers in Gujarat ensure high standards of quality and efficiency.

Environmental Sustainability: With a growing emphasis on sustainable practices, many companies are adopting eco-friendly manufacturing processes and stringent environmental regulations.

Purvi Chemicals: Leading the Way

Among the prominent chemical manufacturing companies in Gujarat, Purvi Chemicals stands out for its unwavering commitment to quality, innovation, and customer satisfaction. Established with a vision to provide superior chemical solutions, Purvi Chemicals has carved a niche for itself in the industry.

Key Offerings of Purvi Chemicals:

Wide Range of Products: Purvi Chemicals specializes in the production of various chemicals, including industrial chemicals, solvents, and specialty chemicals. Their extensive product line caters to diverse industries such as pharmaceuticals, textiles, agriculture, and more.

Quality Assurance: Adhering to stringent quality control measures, Purvi Chemicals ensures that each product meets international standards. Their state-of-the-art manufacturing facilities are equipped with advanced machinery and testing laboratories.

Customer-Centric Approach: Understanding the unique requirements of their clients, Purvi Chemicals offers customized solutions and reliable technical support. Their dedicated customer service team ensures seamless communication and prompt resolution of queries.

Sustainable Practices: Purvi Chemicals is committed to environmental sustainability. By implementing eco-friendly manufacturing processes and reducing waste, they contribute to a greener and safer environment.

The Future of Chemical Manufacturing in Gujarat

The future of Gujarat's chemical manufacturing industry looks promising, with continued investments in research and development, infrastructure, and sustainable practices. Companies like Purvi Chemicals are at the forefront of this growth, driving innovation and setting benchmarks for excellence.

Key Trends to Watch:

Increased Focus on R&D: With a growing emphasis on innovation, chemical companies are investing heavily in research and development to develop new products and improve existing ones.

Sustainability Initiatives: Environmental sustainability will remain a key focus, with companies adopting green technologies and practices to minimize their ecological footprint.

Global Expansion: Leveraging Gujarat's strategic location and robust infrastructure, many chemical manufacturers are expanding their reach to global markets, enhancing India's position in the global chemical industry.

Conclusion

Gujarat's chemical manufacturing sector continues to thrive, driven by a combination of technological advancements, Chemical Manufacturing Companies In Gujarat skilled workforce, and a conducive business environment. Companies like Purvi Chemicals exemplify the state's commitment to quality, innovation, and sustainability. As the industry evolves, Gujarat is poised to remain a global leader in chemical manufacturing, contributing significantly to India's industrial growth and development.

0 notes

Text

Pharmaceutical Colors: Hridhan Chem’s Commitment to Patient Safety

Pharmaceutical colors play a significant role in making the product more appealing, attractive, and palatable, recognizing the overall dosage forms better. Color additives used in pharmaceuticals provide a great way for businesses to color-code their products in accordance with their corporate identity and make them harder to tamper with. However, there is an increasing concern for the safety, efficacy, and precision of color additives used in the world of pharmaceuticals.

The color of a pharmaceutical product plays an integral role in patient safety in addition to its aesthetic appeal. It stands out for its unwavering commitment to patient safety through rigorous quality assurance in Pharmaceutical colors at Hridhan Chem Pvt Ltd, which manufactures high-quality synthetic dyes and pigments for various industrial applications, including pharmaceuticals.

Well! Here we will walk you through Hridhan Chem’s Commitment to patient safety and quality standards for Pharmaceutical colors and explore how the company adheres to the FDA guidelines for the formulation of color additives, ensuring that they meet all safety requirements and are labeled accurately.

So, let’s dive right in!

Importance of Pharmaceutical Colors for Patient Safety

Colorful medicines show a direct connection of a psychological effect on the patients, helping them to recognize the dosage better and supporting early recovery. The color, size, and shape of a drug greatly influence the patient's mind and reduces the overall risk of counterfeiting. Moreover, pharmaceutical colors help patients quickly identify drugs, and dosages and follow the prescription correctly.

In addition to just improving the visual appearance, pharmaceutical colors play a crucial role in facilitating dosage compliance, identifying products, and increasing recognition, especially for patients with multiple dosage levels. However, the quality and purity of color are what matters a lot when it comes to patient safety and whether it complies with regulatory standards to ensure the well-being of patients.

Hridhan Chem is a leading manufacturer of premium-quality synthetic dyes and pigments supplied to customers worldwide. The company has state-of-the-art infrastructure, advanced machinery, and industry experts specialized in producing a wide range of chemical dyestuff, including pharmaceutical colors, food colors, personal & home care colors, cosmetic colors, inkjet & printing dyes, and coating & plastic dyes with precision and quality.

Rigorous Quality Assurance Standards: Hridhan Chem’s Commitment

It is our main objective at Hridhan Chem to provide pharmaceutical formulations with colors that are safe and effective. Throughout the manufacturing process, we apply meticulous quality assurance measures and rigorous testing procedures to guarantee the safe and effective use of our premium quality pharmaceutical colors. The following are the quality assurance protocols and standards that Hridhan Chem follows to ensure patient safety in the first place:

Pharmaceutical colors we manufacture at Hridhan Chem are specially designed to meet the safety standards and stringent requirements of regulatory authorities across the world. Hridhan Chem strictly adheres to Superior Quality with 100% purity commitment, complying with all relevant safety standards and testing protocols in the first place, whether it is the Food and Drug Administration (FDA) in the USA, FAO/WHO’s Joint Expert Committee on Food Additives (JECFA), the European Medicines Agency (EMA), or other regulatory bodies in China, India, and Japan.

Hridhan Chem's advanced laboratories equipped with sophisticated instruments make sure any pharmaceutical color before it reaches the pharmaceutical industry undergoes rigorous testing and quality standards. The tests are carried out based on various factors, including purity, impurities like heavy metals and forbidden dyes, stability, solubility, and color consistency. In order to maintain the highest level of quality, any deviation from the specified standards is immediately reevaluated.

Pharmaceutical products often have a longer shelf life, and the colors used must remain stable throughout this period. Hridhan Chem conducts extensive stability studies to ensure that its Pharmaceutical colors retain their integrity, color consistency, and safety over an extended period, contributing to the reliability of the pharmaceutical product.

Hridhan Chem’s Formulation Compatibility, Traceability, and Transparency

We understand the importance of traceability and transparency, ensuring accountability and quality control in the world of pharmaceuticals. In order to ensure the integrity of its process, Haridhan Chem provides detailed documentation of each Pharmaceutical color sourced, manufactured, tested, and dispatched via its Integrated Management System. Pharmaceutical colors formulated in our manufacturing plants ensure compatibility with a variety of dosage forms, reducing the possibility of compromising the stability or efficacy of the product.

At Hridhan Chem, the company has a team of chemical experts who know the ins and outs of pharmaceutical formulations and can easily make fine distinctions. Pharmaceutical formulations can be guaranteed the highest quality, allowing the origin of pharmaceutical colors to be traced with precision and quality.

Conclusion

In the bottom line, colors used in pharmaceuticals play an important role in patient safety and well-being; they are more than just additives. We at Hridhan Chem Pvt. Ltd. are committed to providing superior quality Pharmaceutical Colours that prioritize patient safety and adhere to strict quality assurance measures and FDA standards. Hridhan Chem takes pride in being a trusted manufacturer and exporter of high-quality synthetic dyes and pigments. If you choose pharmaceutical colors from Hridhan Chem, you can be confident that the colors used in their formulations are safe, reliable, and compliant with all safety and quality standards.

Moreover, if you need more information on a wide range of synthetic dyes and pigments we produce at our state-of-the-art manufacturing unit, feel free to contact our chemical experts today!

0 notes

Text

Baldwin Technology's TexCoat G4 system ushers in next-gen tech for next gen textile leaders

North Carolina State University’s Wilson College of Textiles has been making inroads challenging the conventional pad finishing process and significantly reducing its environmental footprint in collaboration with Baldwin Technology Inc. Front and center in its finishing lab is Baldwin’s TexCoat G4 digital finishing system.

For nearly 125 years, the Wilson College of Textiles at NC State University has been a hub of innovation and learning, transforming students into experts in the world of textiles. As the textile industry grapples with sustainability challenges, the college has embraced new technologies and innovations to address the issue head-on.

At the forefront of this transformation is the Zeis Textiles Extension for Economic Development, an arm of Wilson College that serves the textile industry’s prototyping and pilot production needs in its five laboratories – spun yarn, knitting, weaving, dyeing, and finishing, and physical testing. Collaborations with various textile companies have allowed the university to foster industry partnerships that bring forth groundbreaking ideas.

The partnership with Baldwin Technology marks a major milestone for the Raleigh, North Carolina-based college’s efforts to contribute to a more sustainable tomorrow.

“When a student comes into the school, one of the major things they ask is ‘What are we doing about sustainability?’” said Andre West, Director of the Zeis Textiles Extension at the Wilson College of Textiles at NC State. “As a university, we need to confront the idea that textiles have not been the most sustainable products out there.”