#eigembox

Explore tagged Tumblr posts

Text

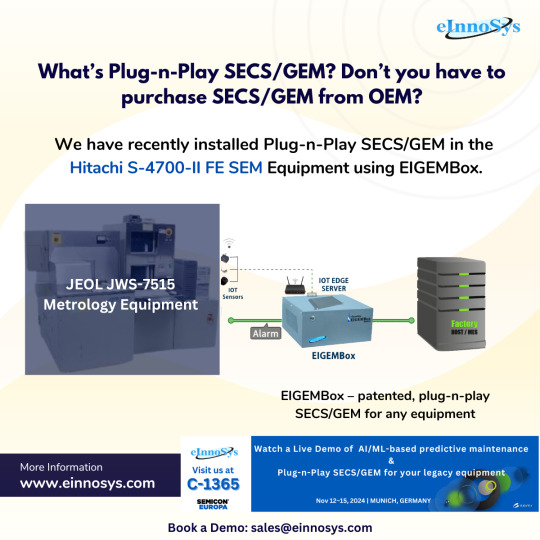

SECS/GEM on JEOL JWS-7515 Metrology Equipment: Enhancing Efficiency with EIGEMBox

In the fast-paced world of semiconductor manufacturing, precision and efficiency are paramount. One key aspect of this process is the metrology equipment used to ensure that every component meets stringent quality standards. The JEOL JWS-7515 is a leading tool in this field, particularly when combined with the EIGEMBox, which facilitates the SECS/GEM protocol. In this blog, we’ll explore the significance of SECS/GEM, the features of the JEOL JWS-7515, and how the EIGEMBox enhances metrology processes.

What is SECS/GEM?

SECS/GEM stands for SEMI Equipment Communication Standard/Generic Equipment Model. It is a widely adopted communication protocol in the semiconductor manufacturing industry that allows for seamless data exchange between manufacturing equipment and host systems. This standard is critical for achieving automation and real-time data acquisition, which helps improve production efficiency and reduce errors.

Why SECS/GEM Matters

Standardization: By providing a uniform communication protocol, SECS/GEM simplifies the integration of various equipment and systems, leading to smoother operations.

Real-time Monitoring: With SECS/GEM, manufacturers can monitor equipment performance in real-time, allowing for quick adjustments and better decision-making.

Data Collection: The protocol facilitates extensive data collection, which is essential for analysis, reporting, and continuous improvement initiatives.

Overview of JEOL JWS-7515

The JEOL JWS-7515 is an advanced metrology tool designed for high-resolution imaging and analysis of semiconductor wafers. Here are some of its standout features:

High-Resolution Imaging

The JWS-7515 utilizes cutting-edge electron beam technology to achieve high-resolution imaging. This capability allows for detailed inspections of wafer surfaces, crucial for identifying defects that could compromise performance.

Versatility

This equipment is versatile enough to handle various materials and applications, making it an invaluable asset in a semiconductor fab. Its ability to analyze different substrates and feature sizes helps manufacturers maintain high standards across diverse product lines.

Automated Functionality

Automation is a key feature of the JWS-7515, which enhances throughput and minimizes human error. The system’s ability to integrate with software tools and other equipment makes it a central hub for metrology operations.

The Role of EIGEMBox

The EIGEMBox is a powerful tool that enhances the capabilities of the JEOL JWS-7515 by facilitating SECS/GEM communication. Here’s how it works:

Seamless Integration

The EIGEMBox acts as a bridge between the JEOL JWS-7515 and the host system, enabling seamless data transfer. This integration is crucial for manufacturers who require real-time insights into their metrology processes.

Enhanced Data Management

With the EIGEMBox, data collected by the JWS-7515 can be efficiently managed and analyzed. The ability to centralize data from multiple sources helps manufacturers streamline operations and improve decision-making.

Flexibility and Scalability

The EIGEMBox is designed to be flexible, accommodating a variety of equipment and systems. As manufacturing needs evolve, the EIGEMBox can be scaled to meet increased demands without significant infrastructure changes.

Benefits of Using SECS/GEM with JEOL JWS-7515 and EIGEMBox

Improved Efficiency

By automating data exchange and analysis, the combination of SECS/GEM, the JEOL JWS-7515, and the EIGEMBox significantly improves operational efficiency. Manufacturers can reduce downtime and optimize workflow, leading to faster production cycles.

Enhanced Quality Control

The ability to conduct real-time monitoring and analysis of wafer conditions ensures that quality control measures are always in place. This capability minimizes the risk of defects reaching the production stage, ultimately enhancing product reliability.

Data-Driven Decision Making

Access to comprehensive, real-time data allows manufacturers to make informed decisions quickly. This responsiveness is critical in a competitive landscape where even minor delays can have significant consequences.

Implementation Considerations

While the benefits of integrating SECS/GEM with the JEOL JWS-7515 and EIGEMBox are clear, several implementation considerations should be taken into account:

Training and Support

To fully leverage the capabilities of these technologies, manufacturers should invest in training for their staff. Understanding how to use the equipment and interpret data is essential for maximizing the benefits.

System Compatibility

Ensuring that the EIGEMBox is compatible with existing systems is crucial for a successful integration. Manufacturers should conduct thorough assessments before implementation to identify any potential challenges.

Ongoing Maintenance

Regular maintenance of both the JWS-7515 and the EIGEMBox is essential to maintain optimal performance. A proactive maintenance schedule can help prevent equipment failures and ensure long-term reliability.

Conclusion: Elevate Your Metrology Operations Today

The integration of SECS/GEM with the JEOL JWS-7515 metrology equipment, enhanced by the EIGEMBox, represents a significant advancement in semiconductor manufacturing. By improving efficiency, enhancing quality control, and enabling data-driven decision-making, this combination positions manufacturers for success in a highly competitive market.

If you're looking to elevate your metrology operations and embrace the future of semiconductor manufacturing, now is the time to act! Contact us today to learn more about how SECS/GEM, JEOL JWS-7515, and EIGEMBox can transform your processes. Don’t miss out on the opportunity to enhance your operational efficiency and product quality!

#secs/gem#fab automation#equipment software#secs/gem software#eigembox#secs/gem protocol#semiconductor#secs gem software#JEOL JWS-7515#Metrology Equipment

1 note

·

View note

Text

SECS/GEM on Canon MPA 600 Super Aligner Through the EIGEMBox

In the dynamic world of semiconductor manufacturing, ensuring that legacy equipment can keep up with modern communication standards is essential for maintaining productivity and efficiency. The Canon MPA 600 Super Aligner, a widely used piece of equipment in semiconductor fabs, often lacks the native SECS/GEM capabilities required for seamless integration into contemporary manufacturing systems. Enter EIGEMBox, a patented, plug-and-play solution that brings SECS/GEM compliance to legacy equipment without the need for extensive hardware or software installations.

In this blog, we will explore the benefits of using EIGEMBox to enable SECS/GEM on the Canon MPA 600 Super Aligner and how this can revolutionize your manufacturing process.

What is SECS/GEM?

SECS/GEM (SEMI Equipment Communications Standard/Generic Equipment Model) is a set of protocols developed by SEMI (Semiconductor Equipment and Materials International) to standardize communication between semiconductor manufacturing equipment and host systems. These protocols are critical for enabling automation, real-time data collection, and equipment control, which are essential for the efficiency and productivity of modern semiconductor fabs.

The Importance of SECS/GEM Compliance SECS/GEM compliance offers several significant benefits for semiconductor manufacturing: Automation: SECS/GEM protocols enable the automation of equipment operations, reducing the need for manual intervention and minimizing the risk of human error. This leads to higher throughput and more consistent production quality.

Data Collection and Analysis: SECS/GEM allows for real-time data collection from equipment, which can be analyzed to monitor performance, optimize processes, and predict maintenance needs. This data-driven approach helps in making informed decisions that improve overall efficiency.

Equipment Control: With SECS/GEM, equipment can be controlled remotely by the host system, allowing for better coordination and scheduling of manufacturing tasks. This ensures optimal utilization of resources and reduces downtime.

Interoperability: SECS/GEM provides a standardized communication framework, ensuring that equipment from different vendors can work together seamlessly. This interoperability is crucial for maintaining a cohesive and efficient manufacturing environment.

Challenges with Legacy Equipment

While SECS/GEM offers numerous advantages, many legacy equipment like the Canon MPA 600 Super Aligner lack native SECS/GEM capabilities. Upgrading these machines to meet modern standards can be a complex and costly process, often requiring significant hardware and software modifications. This is where EIGEMBox comes into play.

Introducing EIGEMBox

EIGEMBox is an innovative, patented solution designed to bring SECS/GEM capabilities to legacy equipment without the need for additional hardware or software installations. This plug-and-play device makes it easy to upgrade older machines, ensuring they can communicate effectively with modern control systems and integrate seamlessly into automated manufacturing environments.

Key Features of EIGEMBox

Plug-and-Play Convenience: EIGEMBox is designed for easy installation and operation. Simply connect the device to your legacy equipment, and it starts working immediately, without the need for extensive configuration or setup.

No Hardware or Software Installation Required: Unlike traditional SECS/GEM integration solutions that often require complex hardware and software installations, EIGEMBox eliminates these hassles. This makes it a cost-effective and time-saving solution for upgrading your equipment.

Patented Technology: EIGEMBox utilizes patented technology to ensure reliable and efficient communication between your legacy equipment and modern control systems. This guarantees seamless integration and improved operational efficiency.

Enhanced Data Exchange: With EIGEMBox, your legacy equipment can exchange data in real-time with control systems, enabling better monitoring, analysis, and optimization of manufacturing processes.

Benefits of Using EIGEMBox with Canon MPA 600 Super Aligner

Upgrading the Canon MPA 600 Super Aligner with EIGEMBox offers several significant benefits:

Extended Equipment Life: By enabling SECS/GEM compliance, EIGEMBox extends the operational life of the Canon MPA 600 Super Aligner, allowing you to maximize your investment in this equipment.

Improved Efficiency: Enhanced communication and control capabilities lead to better coordination of manufacturing tasks, increased throughput, and reduced downtime. This results in the overall improved efficiency of your manufacturing process.

Cost Savings: EIGEMBox eliminates the need for costly hardware and software upgrades, providing a more affordable solution for integrating SECS/GEM protocols into your manufacturing processes.

Seamless Integration: EIGEMBox ensures that your Canon MPA 600 Super Aligner can communicate effectively with modern control systems, enabling a smoother and more efficient manufacturing operation.

Case Study: Successful Integration of EIGEMBox with Canon MPA 600 Super Aligner

One of our clients, a leading semiconductor manufacturer, faced challenges in integrating SECS/GEM protocols into their Canon MPA 600 Super Aligner. After implementing EIGEMBox, they experienced a significant improvement in production efficiency. The plug-and-play nature of EIGEMBox allowed for a quick and hassle-free integration process, resulting in a 20% increase in equipment utilization and a 15% reduction in downtime. The client was able to extend the life of their existing equipment while achieving substantial cost savings. How to Get Started with EIGEMBox Ready to revolutionize your semiconductor manufacturing processes with EIGEMBox? Here’s how you can get started:

Contact Us: Reach out to our team for a consultation. We’ll assess your current equipment and provide tailored recommendations for integrating EIGEMBox into your manufacturing environment.

Easy Installation: Once you’ve decided to move forward, our team will guide you through the simple installation process. No need for extensive configuration or setup – just plug it in and start reaping the benefits.

Ongoing Support: Our commitment to your success doesn’t end with installation. We offer comprehensive support to ensure that your EIGEMBox operates seamlessly and delivers the desired improvements in efficiency and productivity.

Contact Us Today! Don’t let outdated equipment hold back your semiconductor manufacturing operations. With EIGEMBox, you can achieve modern communication and control capabilities without the need for costly hardware or software installations. Contact us today to learn more about how EIGEMBox can transform your Canon MPA 600 Super Aligner and drive your manufacturing processes forward.

#SECS/GEM integration#Canon MPA 600 Super Aligner#EIGEMBox#semiconductor manufacturing#legacy equipment upgrade#plug-and-play SECS/GEM#SECS/GEM compliance#semiconductor automation#factory automation#SECS/GEM protocol#SECS/GEM communication#equipment control systems#real-time data collection#manufacturing process optimization#cost-effective SECS/GEM solution#improve production efficiency#legacy equipment SECS/GEM#EIGEMBox installation#semiconductor industry standards#SECS/GEM host simulation#reduce equipment downtime

0 notes

Text

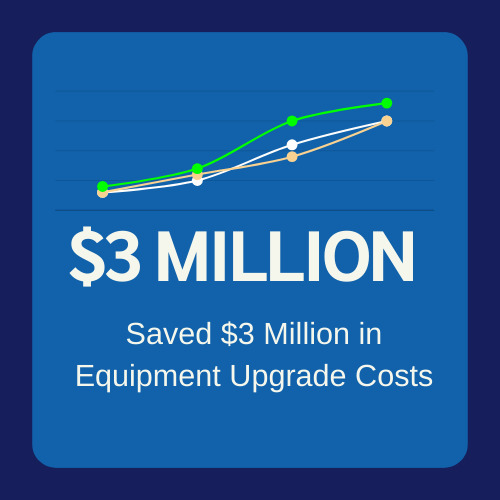

In the fast-paced world of semiconductor manufacturing, staying ahead of technology while managing costs is a constant challenge. Einnosys, a company dedicated to innovative industrial solutions, introduced EIGEMbox—a simple yet powerful device that can transform existing semiconductor equipment by adding modern automation capabilities. This case study explores how EIGEMbox helped semiconductor fabs save a massive $3 million in equipment upgrade costs and enhance their operational efficiency.

#EIGEMBox#SECS/GEM#secs gem software#gem300#secs/gem software#fab automation#predictive maintenance for pumps

0 notes

Link

EIGEMBoxは、ハードウェアやソフトウェアをインストールせずに、既存の機器にSECS / GEM機能を追加する独自の製品です。

工場に古いレガシー機器があり、工場の自動化にSECS / GEM機能が必要な場合、EIGEMBoxは完璧なソリューションとそのプラグアンドプレイです。

EIGEMBoxから機器に1本または2本のケーブルを接続し、工場のホスト、FDC、MES、または別の自動化システムをEIGEMBoxのHSMSまたはSECS-Iポートに接続し、EIGEMBoxレシピを使用してシステムを構成するだけです。編集者、それだけです!これで、機器からデータ、アラーム、およびイベントを収集できるだけでなく、PP-SELECT、START、ABORT、STOPなどのリモートコマンドを送信することもできます。

1 note

·

View note

Link

工业4.0代表了制造技术的第四次革命。它将物理操作与数字技术相结合,例如机器学习,工业物联网(IIoT)和大数据,以创建用于制造和供应链管理的更好连接的生态系统,从本质上创建了网络物理系统。通过创建互连的系统,它可以使各个部门,合作伙伴,供应商,产品和客户之间更好地协作和访问。

0 notes

Link

EIGEMBox is a unique product that adds SECS/GEM capability to your existing equipment without any hardware or software installation!

If your factory has old, legacy equipment for which you need SECS/GEM capability for factory automation, EIGEMBox is the perfect solution and its plug-n-play.

All you need to do is just connect one or two cables from the EIGEMBox to your equipment and connect your factory host, FDC, MES, or another automation system to the HSMS or SECS-I port of the EIGEMBox, configure the system through EIGEMBox Recipe Editor and that’s it! Now you are not only able to collect data, alarms, and events from the equipment but also able to send remote commands such as PP-SELECT, START, ABORT, STOP, etc.

0 notes

Link

The legacy equipment can be from any manufacturer or model, could be running any Operating System, or can be a process, inspection, or metrology equipment, it wouldn’t matter! The best part is this product doesn’t require any hardware or software to be installed on your existing legacy equipment, so you can be assured that EIGEMBox-2000 can not affect the reliability or performance of your legacy equipment. Communication is enabled through HSMS or SECS-I port.

0 notes

Link

EIGEMBox-2000 is a unique product that enables SECS/GEM, Modbus, or OPC capability on your existing equipment, and it does it without requiring any software or hardware installation on the equipment. All you need is to connect the display cable from your equipment’s PC to EIGEMBox. If you want to control the equipment for recipe selection/download or remote start and stop or setting any set-points, you need to connect EIGEMBox to the equipment PC through keyboard and mouse ports (USB or PS/2) as well. That’s it!

0 notes

Link

EIGEMBox 하드웨어 또는 소프트웨어 설치 없이 기존 장비에 SECS/GEM 기능을 추가하는 고유한 제품입니다!

1 note

·

View note

Link

EIGEMBox-2000 is a unique product that enables SECS/GEM, Modbus, or OPC capability on your existing equipment, and it does it without requiring any software or hardware installation on the equipment. All you need is to connect the cable from your equipment’s PC to EIGEMBox. If you want to control the equipment for recipe selection/download or remote start and stop or setting any set-points, you need to connect EIGEMBox to the equipment PC through keyboard and mouse ports (USB or PS/2) as well. That’s it!

#Legacy Equipment#SECS GEM#old semiconductor equipment#semiconductor equipment#used semiconductor equipment#EIGEMBox-2000#Industry 4.0#GEM300#Fabs/Assemblies#OEMs#eigemequipment#smart equipment#SECS GEM For Legacy Equipment

0 notes

Link

EIGEMBox-2000 solves these problems!! And it does without requiring any software or hardware installation on your equipment!

#EIGEMBox-200#SECS/GEM#SECS/GEM capability#EIGEMBox#OPC capability#Equipment Software#Industry 4.0 & Smart Factory#Factory Automation

0 notes

Link

SmartXBox is a unique product that enables automation through Modbus, OPC, MQTT, or JSON capability on your existing equipment, and it does it without requiring any software or hardware installation on the equipment. All you need is to connect the display cable(VGA, DVI, or HDMI) from your equipment’s PC to SmarXBox. If you want to control the equipment for recipe selection/download or remote start and stop or setting any set-points, you need to connect EIGEMBox to the equipment PC through keyboard and mouse ports (USB or PS/2) as well. That’s it!

#Old equipment automation#Old machine automation#Old factory automation#Data extract from old equipment#Data extract from old machine#Automation of legacy equipment#Automation of legacy machine#Old machine IoT capable#Old equipment IoT capable#Industry 4.0 on legacy equipment#Industry 4.0 on legacy machine#Industry 4.0 on old equipment

0 notes

Link

EIGEMBox-2000 is a unique hardware product equipped with required software which enables SECS/GEM capability on an equipment that currently doesn’t have one.

youtube

SECS GEM For (OLD) LEGACY Equipment

#SECS GEM For (OLD) LEGACY Equipment#EIGEMBox-2000#secs gem for legacy equipment#Automation for legacy equipment#SECS/GEM for Legacy Machines#legacy equipment#legacy equipment software

0 notes