#factory automation

Explore tagged Tumblr posts

Text

Vidgastech is a leading innovator in Industrial Automation, delivering smart, scalable, and cutting-edge automation solutions to enhance manufacturing efficiency and precision. Our team of experts specializes in PLC programming, SCADA systems, IoT integration, robotics, and turnkey automation projects tailored to your industrial needs.

We help industries reduce downtime, boost productivity, and transition into Industry 4.0 with seamless automation technologies. With a strong commitment to quality, innovation, and customer satisfaction, Vidgastech is your trusted partner for transforming industrial operations.

Services:

PLC & SCADA Development

Industrial IoT (IIoT) Integration

Robotics & Machine Automation

Process Control & Monitoring Systems

Custom Industrial Software Development

Maintenance & Support Services

#Industry Automation#Industrial Automation Company#PLC SCADA Automation#Factory Automation#Smart Manufacturing#IIoT Solutions#Industrial Robotics#Vidgastech Automation#Industry 4.0 Solutions

0 notes

Text

Why Choose a Mitsubishi Servo Drive Supplier in Kuwait Now?

Selecting a Mitsubishi Servo Drive Supplier in Kuwait guarantees access to high-performance motion control for your automation systems. Benefit from genuine Mitsubishi technology, expert support, and fast delivery to keep your operations running smoothly. Whether for robotics or manufacturing, the right supplier ensures reliability and precision. Take your automation to the next level-contact us through our website for tailored servo drive solutions!

0 notes

Text

Smarter Manufacturing with Factory Automation Sensors

Factory automation sensors are key to smarter and faster manufacturing. These sensors monitor temperature, pressure, motion, and more, helping machines work with high accuracy and speed. They reduce human error, improve safety, and boost productivity on the factory floor. With real-time data, manufacturers can quickly detect faults, prevent downtime, and maintain consistent product quality. From assembly lines to packaging units, sensors are making automation more efficient and reliable. Investing in factory automation sensors is a smart move for industries looking to stay competitive and achieve better performance. Upgrade your operations with smart sensing technology today.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#marine automation systems#Factory Automation Sensor#factory automation#sensor

0 notes

Text

Operating earth moving equipment, such as bulldozers, excavators, and loaders, is essential in the construction, mining, and industrial sectors. While these machines are designed for heavy-duty tasks, ensuring the safety of operators, site workers, and bystanders is crucial to prevent accidents. Adhering to safety best practices can minimize risks and create a safer work environment. Below are key safety protocols to follow when operating earth moving equipment.

#seetech parts#Pivot Pins - Cotter Pins#Hinge Pins#Connecting Parts#Automation Components#Configurable components#factory automation#assembly automation

0 notes

Text

How Siemens Controllers Are Revolutionizing Music Production Studios

In the rapidly evolving world of music production, the quest for greater efficiency, precision, and creative control has led to significant advancements in technology. Among the innovations driving these changes are Siemens controllers, which are revolutionizing how music is produced, mixed, and mastered. By integrating Siemens' cutting-edge automation technology into music production studios, professionals are achieving new levels of productivity and sonic quality. Here's how Siemens controllers are making waves in the music industry.

Siemens Controllers: The Backbone of Modern Music Studios

Siemens controllers, including programmable logic controllers (PLCs) and motor controllers, are renowned for their reliability and precision in various industrial applications. However, their impact extends beyond traditional manufacturing environments. In modern music production studios, Siemens controllers are enhancing automation, improving control over studio equipment, and streamlining production processes.

One notable example is the use of Siemens’ SIMATIC PLCs in controlling and automating audio equipment. These advanced controllers manage everything from digital mixing consoles to automated fader adjustments, providing sound engineers and producers with a level of control that was previously unattainable.

Enhancing Efficiency with Siemens Automation Technology

Efficiency is paramount in a music production studio, where time is often as valuable as creativity. Siemens controllers play a crucial role in automating repetitive tasks and optimizing workflows. For instance, automated mixing and mastering processes are facilitated by Siemens controllers, which handle complex signal routing and processing tasks with precision.

By integrating Siemens’ automation technology, studios can reduce the time spent on manual adjustments and focus more on the creative aspects of music production. Automated systems controlled by Siemens controllers ensure that equipment settings are consistent and repeatable, which is essential for achieving high-quality results across multiple sessions and projects.

Precision Control with Siemens Motor and Motion Controllers

In a music studio, precise control over equipment is essential for achieving the desired sound quality. Siemens motor controllers and motion control systems provide unparalleled accuracy in adjusting audio equipment. Whether it’s controlling the movement of a motorized microphone stand or fine-tuning the position of speakers and monitors, Siemens controllers ensure that every adjustment is executed with pinpoint accuracy.

The ability to program and control these adjustments via Siemens’ programmable logic controllers allows sound engineers to create intricate setups and configurations that can be replicated with ease. This level of control enhances the overall quality of recordings and ensures that the production process is smooth and efficient.

Streamlining Production with Advanced Automation and Process Automation

Process automation is transforming music production studios by automating complex workflows and enhancing overall efficiency. Siemens controllers are at the heart of this transformation, offering solutions that streamline various aspects of the production process.

For example, Siemens controllers can automate the setup and calibration of audio equipment, reducing the time needed for manual adjustments. This automation extends to the management of recording sessions, where Siemens controllers handle tasks such as track switching, level adjustments, and signal routing with minimal human intervention.

Additionally, the integration of Siemens controllers into digital audio workstations (DAWs) allows for seamless control of software and hardware components. This integration ensures that all elements of the production process work in harmony, resulting in a more cohesive and efficient workflow.

The Impact of Siemens Controllers on Creative Processes

Beyond improving efficiency and precision, Siemens controllers also have a significant impact on the creative processes within music production studios. By automating routine tasks, these controllers free up time for producers and engineers to focus on creative experimentation and innovation.

The ability to program complex automation sequences and recall them with ease enables sound engineers to explore new creative possibilities. For instance, automated dynamic changes in a mix or the creation of intricate effects can be accomplished effortlessly using Siemens controllers, allowing for greater experimentation and artistic expression.

Implementing Siemens Controllers in Your Music Studio

Integrating Siemens controllers into a music production studio involves several key steps. First, assess your studio’s current setup and identify areas where automation and control improvements can be made. Siemens offers a range of controllers and automation solutions, including the SIMATIC PLCs and motor controllers, that can be customized to meet your specific needs.

Once the appropriate Siemens controllers are selected, the next step is to implement them into your studio’s infrastructure. This process may include configuring the controllers, integrating them with existing equipment, and training staff to utilize the new technology effectively.

Ongoing maintenance and support are essential to ensure that Siemens controllers continue to perform optimally. Siemens provides comprehensive support services, including technical assistance and software updates, to help you maximize the benefits of their controllers and maintain peak performance.

Conclusion

Siemens controllers are revolutionizing music production studios by enhancing efficiency, precision, and creativity. With their advanced automation technology, including programmable logic controllers (PLCs) and motor controllers, Siemens is setting new standards for control and automation in the music industry. By integrating Siemens controllers into your music production setup, you can streamline workflows, improve the quality of your productions, and unlock new creative possibilities. As the music industry continues to evolve, Siemens controllers will remain at the forefront of innovation, driving the future of music production.

#siemens#siemens controller#siemens controllers#industrial automation#programmable logic controllers#motor controllers#motion control#factory automation#automation technology#process automation#simatic#controllers#automation#controller#production#automated

0 notes

Text

SECS/GEM on Canon MPA 600 Super Aligner Through the EIGEMBox

In the dynamic world of semiconductor manufacturing, ensuring that legacy equipment can keep up with modern communication standards is essential for maintaining productivity and efficiency. The Canon MPA 600 Super Aligner, a widely used piece of equipment in semiconductor fabs, often lacks the native SECS/GEM capabilities required for seamless integration into contemporary manufacturing systems. Enter EIGEMBox, a patented, plug-and-play solution that brings SECS/GEM compliance to legacy equipment without the need for extensive hardware or software installations.

In this blog, we will explore the benefits of using EIGEMBox to enable SECS/GEM on the Canon MPA 600 Super Aligner and how this can revolutionize your manufacturing process.

What is SECS/GEM?

SECS/GEM (SEMI Equipment Communications Standard/Generic Equipment Model) is a set of protocols developed by SEMI (Semiconductor Equipment and Materials International) to standardize communication between semiconductor manufacturing equipment and host systems. These protocols are critical for enabling automation, real-time data collection, and equipment control, which are essential for the efficiency and productivity of modern semiconductor fabs.

The Importance of SECS/GEM Compliance SECS/GEM compliance offers several significant benefits for semiconductor manufacturing: Automation: SECS/GEM protocols enable the automation of equipment operations, reducing the need for manual intervention and minimizing the risk of human error. This leads to higher throughput and more consistent production quality.

Data Collection and Analysis: SECS/GEM allows for real-time data collection from equipment, which can be analyzed to monitor performance, optimize processes, and predict maintenance needs. This data-driven approach helps in making informed decisions that improve overall efficiency.

Equipment Control: With SECS/GEM, equipment can be controlled remotely by the host system, allowing for better coordination and scheduling of manufacturing tasks. This ensures optimal utilization of resources and reduces downtime.

Interoperability: SECS/GEM provides a standardized communication framework, ensuring that equipment from different vendors can work together seamlessly. This interoperability is crucial for maintaining a cohesive and efficient manufacturing environment.

Challenges with Legacy Equipment

While SECS/GEM offers numerous advantages, many legacy equipment like the Canon MPA 600 Super Aligner lack native SECS/GEM capabilities. Upgrading these machines to meet modern standards can be a complex and costly process, often requiring significant hardware and software modifications. This is where EIGEMBox comes into play.

Introducing EIGEMBox

EIGEMBox is an innovative, patented solution designed to bring SECS/GEM capabilities to legacy equipment without the need for additional hardware or software installations. This plug-and-play device makes it easy to upgrade older machines, ensuring they can communicate effectively with modern control systems and integrate seamlessly into automated manufacturing environments.

Key Features of EIGEMBox

Plug-and-Play Convenience: EIGEMBox is designed for easy installation and operation. Simply connect the device to your legacy equipment, and it starts working immediately, without the need for extensive configuration or setup.

No Hardware or Software Installation Required: Unlike traditional SECS/GEM integration solutions that often require complex hardware and software installations, EIGEMBox eliminates these hassles. This makes it a cost-effective and time-saving solution for upgrading your equipment.

Patented Technology: EIGEMBox utilizes patented technology to ensure reliable and efficient communication between your legacy equipment and modern control systems. This guarantees seamless integration and improved operational efficiency.

Enhanced Data Exchange: With EIGEMBox, your legacy equipment can exchange data in real-time with control systems, enabling better monitoring, analysis, and optimization of manufacturing processes.

Benefits of Using EIGEMBox with Canon MPA 600 Super Aligner

Upgrading the Canon MPA 600 Super Aligner with EIGEMBox offers several significant benefits:

Extended Equipment Life: By enabling SECS/GEM compliance, EIGEMBox extends the operational life of the Canon MPA 600 Super Aligner, allowing you to maximize your investment in this equipment.

Improved Efficiency: Enhanced communication and control capabilities lead to better coordination of manufacturing tasks, increased throughput, and reduced downtime. This results in the overall improved efficiency of your manufacturing process.

Cost Savings: EIGEMBox eliminates the need for costly hardware and software upgrades, providing a more affordable solution for integrating SECS/GEM protocols into your manufacturing processes.

Seamless Integration: EIGEMBox ensures that your Canon MPA 600 Super Aligner can communicate effectively with modern control systems, enabling a smoother and more efficient manufacturing operation.

Case Study: Successful Integration of EIGEMBox with Canon MPA 600 Super Aligner

One of our clients, a leading semiconductor manufacturer, faced challenges in integrating SECS/GEM protocols into their Canon MPA 600 Super Aligner. After implementing EIGEMBox, they experienced a significant improvement in production efficiency. The plug-and-play nature of EIGEMBox allowed for a quick and hassle-free integration process, resulting in a 20% increase in equipment utilization and a 15% reduction in downtime. The client was able to extend the life of their existing equipment while achieving substantial cost savings. How to Get Started with EIGEMBox Ready to revolutionize your semiconductor manufacturing processes with EIGEMBox? Here’s how you can get started:

Contact Us: Reach out to our team for a consultation. We’ll assess your current equipment and provide tailored recommendations for integrating EIGEMBox into your manufacturing environment.

Easy Installation: Once you’ve decided to move forward, our team will guide you through the simple installation process. No need for extensive configuration or setup – just plug it in and start reaping the benefits.

Ongoing Support: Our commitment to your success doesn’t end with installation. We offer comprehensive support to ensure that your EIGEMBox operates seamlessly and delivers the desired improvements in efficiency and productivity.

Contact Us Today! Don’t let outdated equipment hold back your semiconductor manufacturing operations. With EIGEMBox, you can achieve modern communication and control capabilities without the need for costly hardware or software installations. Contact us today to learn more about how EIGEMBox can transform your Canon MPA 600 Super Aligner and drive your manufacturing processes forward.

#SECS/GEM integration#Canon MPA 600 Super Aligner#EIGEMBox#semiconductor manufacturing#legacy equipment upgrade#plug-and-play SECS/GEM#SECS/GEM compliance#semiconductor automation#factory automation#SECS/GEM protocol#SECS/GEM communication#equipment control systems#real-time data collection#manufacturing process optimization#cost-effective SECS/GEM solution#improve production efficiency#legacy equipment SECS/GEM#EIGEMBox installation#semiconductor industry standards#SECS/GEM host simulation#reduce equipment downtime

0 notes

Text

How consumer Electronics are driving Industrial Electronics?

Consumer Electronics are driving Industrial Electronics #Electronics #factoryautomation #industrialelectronics #electronicgadgets #GenerativeAI

Can consumer and Industrial Electronics be interconnected? Is it possible for consumer electronics to drive the Industrial Electronics market? When the term consumer electronics pops up, the images that pop out are smartphones, smart speakers, wireless earbuds, head speakers, and other electronic gadgets. When we talk about Industrial electronics, it’s factory automation, power grids, and…

0 notes

Text

Optimizing Operations: Industrial IoT (IIoT) Strategies

Introduction

In today's rapidly evolving industrial landscape, optimizing operations is crucial for maintaining competitiveness and driving growth. Industrial Internet of Things (IIoT) strategies play a pivotal role in achieving operational excellence by leveraging data-driven insights and automation. This article explores key strategies for optimizing operations through the implementation of IIoT solutions.

Outline

Understanding Industrial IoT (IIoT)

Strategies for IIoT Implementation

Use Cases Across Industries

Benefits and Challenges

Future Trends

Conclusion

FAQS

Background

The Industrial Internet of Things (IIoT) refers to the integration of sensors, devices, and software in industrial environments to enable real-time data collection, analysis, and decision-making. IIoT empowers organizations to streamline processes, enhance efficiency, and drive innovation across various sectors.

Strategies for IIoT Implementation

Successful IIoT implementation requires careful planning and execution. Key strategies include defining clear objectives, selecting appropriate technology solutions, ensuring data security and privacy, fostering collaboration between stakeholders, and investing in workforce training and development.

Use Cases Across Industries

IIoT finds applications in diverse industries, including manufacturing, energy, healthcare, transportation, and agriculture. Use cases range from predictive maintenance and asset tracking to remote monitoring and supply chain optimization, demonstrating the versatility and impact of IIoT solutions.

Benefits and Challenges

The adoption of IIoT offers numerous benefits, such as improved operational efficiency, reduced downtime, enhanced safety, and cost savings. However, challenges such as cybersecurity risks, data interoperability issues, and integration complexities need to be addressed to maximize the potential of IIoT.

Future Trends

The future of IIoT is characterized by advancements in edge computing, artificial intelligence, digital twins, and 5G connectivity. These trends enable organizations to unlock new opportunities for innovation, agility, and resilience in an increasingly interconnected and data-driven world.

Conclusion

IIoT strategies play a critical role in optimizing operations, enabling organizations to stay competitive and responsive to market demands. By harnessing the power of IIoT, businesses can unlock new levels of efficiency, productivity, and profitability in their operations.

FAQs

Q: How can IIoT improve asset management in manufacturing? A: IIoT enables real-time monitoring of equipment health, predictive maintenance, and asset tracking, leading to optimized asset utilization and reduced downtime in manufacturing facilities.

Q: What are the cybersecurity considerations for IIoT implementation? A: Cybersecurity measures such as encryption, authentication, access control, and continuous monitoring are essential for safeguarding IIoT systems and data from potential cyber threats and breaches.

Q: How does IIoT contribute to sustainability in the energy sector? A: IIoT enables energy efficiency optimization, renewable energy integration, smart grid management, and environmental monitoring, contributing to sustainability goals and reducing carbon footprint in the energy sector.

0 notes

Text

Factory Automation Market - Forecast(2025 - 2032)

Factory Automation Market is projected to reach $233.5 billion by 2027, growing at a 3.3% CAGR between 2022-2027. Factory Automation is a technology, which involves the usage of automated equipment or machines in various industries to reduce or eliminate human efforts and increase the efficiency of work in a short period of time.

𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐒𝐚𝐦𝐩𝐥𝐞@

In Factory Automation, the manufacturing and industrial sector is growing rapidly and has led to the advancement of technology such as distributed production by factories and services, the implementation of autonomous plants and the increasing use of remote operations to automate certain operations.

0 notes

Text

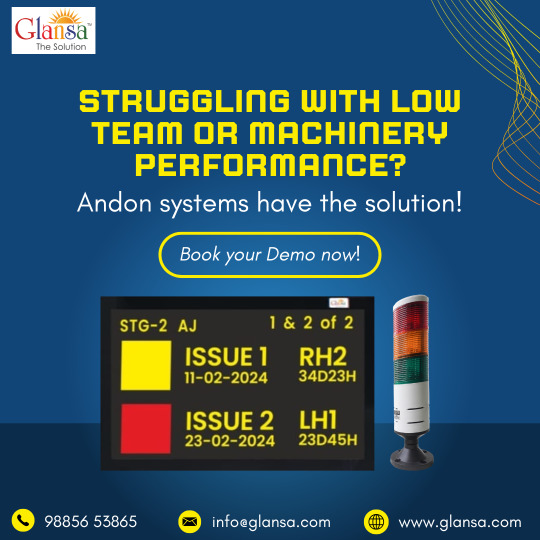

Andon System for Real-Time Manufacturing Alerts – Glansa Solutions

Glansa’s Andon System improves manufacturing efficiency with real-time alerts, visual signals, and performance tracking. Discover how our solution reduces downtime and boosts productivity.

#Andon System#Manufacturing Alerts#Lean Manufacturing#Digital Andon#Shop Floor Monitoring#Production Efficiency#Glansa Solutions#Real-Time Alerts#Factory Automation

0 notes

Note

Thoughts on Factorio and other automation games of the sort?

AUTOMATION IS FUN

BABA LOVE AUTOMATION

#baba is you#post is queue#ask is answer#factorio#dude i LOVE factory/automation games#shapes 2.... been looking at modulus too...#i know if i had satisfactory or factorio id never be a person again.#got that brand of autism

267 notes

·

View notes

Text

Factory automation sensors play a crucial role in increasing production speed, efficiency, and accuracy. These smart sensors monitor temperature, pressure, motion, and position, helping manufacturers reduce errors and downtime. By providing real-time data, they improve decision-making, ensuring smooth operations and minimal waste. Automation sensors also enhance safety by detecting malfunctions before they cause major failures. With improved consistency and quality control, factories can meet higher demands without compromising precision. Investing in automation sensors leads to lower costs, higher output, and a competitive edge in manufacturing. Discover how these sensors can revolutionize your production line for faster, smarter operations.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#marine automation systems#Factory Automation Sensor#factory automation#sensor

0 notes

Text

Hamsters in the Crocs Shoe Factory Maze ep. 1 🐹

30 notes

·

View notes

Text

A new title screen for Fakutori! Does it make you want to grab a hard hat and start BUILDING??

54 notes

·

View notes