#electric central heating boilers

Text

The Benefits of Installing a Electrical Central Heating Boiler: A Comprehensive Guide

In today's modern world, central heating boilers have become an integral part of every household. These efficient heating systems offer a wide range of benefits, providing warmth and comfort throughout the year. Whether you're considering upgrading your existing heating system or installing a new one, this comprehensive guide will highlight the numerous advantages of having a central heating boiler.

#cheap bathroom suites#cheap bathroom suits#complete bathroom suites#column radiators uk#bathroom radiators uk#shower trays uk#electric central heating boilers

1 note

·

View note

Text

Gas Zone Plumbing & Heating | Provide Heating Installation In Stratford

🔥🚿 Gas Zone Plumbing & Heating offers expert’s heating installation in Stratford. Our skilled gas engineers and plumbers provide expert repair services and reliable solutions. As a trusted boiler supplier and heating contractor, we confirm your heating system runs efficiently and effectively. Contact us for exceptional service! 🌟🔧

Business Name : Gas Zone Plumbing & Heating

Address : 1 Canning Rd, London E15 3NW, United Kingdom

Phone : 7300353247

#boiler installers in stratford#boiler repairing services in stratford#commercial gas engineer in stratford#electric central heating in stratford#heating installation in stratford#plumbing services in stratford#gas engineers stratford#boiler service in stratford#boiler repairs in stratford#heating engineers in stratford

0 notes

Text

The Process of Getting to Know the Best Realty Management Company

Being a landlord is a stressful job. After all, you need to cater to the needs of the residents in your apartment complex. In some instances, their demands happen during odd hours like midnight. How would you deal with the situation properly?

The usual issues in managing a real estate business are lack of water supply, plumbing related problems, and electrical faults. First, you need to be prepared if such situations arise in your work place. For example, you need a technician to repair your water system anytime. Or you should have a team on standby when there’s an emergency plumbing issue. Hence, the next step is to work with a reliable company and retain them to assist you when necessary.

In addition, you should make sure that you work with experienced technicians from a building maintenance company. They should possess all the necessary requirements to perform their tasks.

Safe House Services: Giving Emphasis on Providing Letting Agents with Property Maintenance Support

Aside from landlords, letting agents are benefitting from the services offered by Safe House Services. Well, a letting agent is a facilitator through which an agreement is made between a landlord and tenant for the rental of a residential property.

In today’s apartment living arrangements, both letting agents and tenants need the services offered by skilled technicians and plumbers. For instance, a letting agent who rely on the assistance provided by Safe House Services will benefit tenants in one way or another. It’s also one way to keep the property tenanted as much as possible without encountering issues that might affect your real estate business.

In case of property maintenance support, trust Safe House Services to be your dependable property maintenance and repairs service provider. Visit our website at www.safehouseservices.co.uk/ or call us at 0330 1221250 for your property maintenance needs.

Property Refurbishment Is Easier with Safe House Services

If you’re handling a real estate business, refurbishing a property is a common scenario. It includes tasks such as installing new bathrooms, kitchens, or general redecoration. Apart from that, refurbishment tends to increase the overall value and quality of a property.

Since there are tenants who request to refurbish their apartment unit and pay higher rent, you can take this opportunity to augment your income. As such, you need help from us since the in-house team at Safe House services work closely with you to comprehend your requirements and create an effective maintenance plan that meets your budget and schedule.

In addition, we have a wide range of skills and expertise, and the Safehouse team provide a one-stop shop for all your maintenance needs. As a result, you’ll have peace of mind while running your realty business.

Don't neglect your property's maintenance issues. Trust Safe House Services to provide the solutions you need. Visit www.safehouseservices.co.uk or call us at 0330 1221250 today.

Safe House Services

7 Downlands Parade

Upper Brighton Road

Worthing

Sussex

BN149JH

#Building Services#Electrical Services#Boiler Services#central heating services#plumbing services#property maintenance services

0 notes

Text

Electric Central Heating Boiler - Electric Combi Boilers Company

Electric Combi Boiler allows you to have a smooth and hassle-free installation of an electric central heating boiler that enables you to keep the warmth of your residential and commercial property completely intact to deter the London winters in the best possible manner. Reach out to us today to know more.

0 notes

Text

What is Dataflow?

This post is inspired by another post about the Crowd Strike IT disaster and a bunch of people being interested in what I mean by Dataflow. Dataflow is my absolute jam and I'm happy to answer as many questions as you like on it. I even put referential pictures in like I'm writing an article, what fun!

I'll probably split this into multiple parts because it'll be a huge post otherwise but here we go!

A Brief History

Our world is dependent on the flow of data. It exists in almost every aspect of our lives and has done so arguably for hundreds if not thousands of years.

At the end of the day, the flow of data is the flow of knowledge and information. Normally most of us refer to data in the context of computing technology (our phones, PCs, tablets etc) but, if we want to get historical about it, the invention of writing and the invention of the Printing Press were great leaps forward in how we increased the flow of information.

Modern Day IT exists for one reason - To support the flow of data.

Whether it's buying something at a shop, sitting staring at an excel sheet at work, or watching Netflix - All of the technology you interact with is to support the flow of data.

Understanding and managing the flow of data is as important to getting us to where we are right now as when we first learned to control and manage water to provide irrigation for early farming and settlement.

Engineering Rigor

When the majority of us turn on the tap to have a drink or take a shower, we expect water to come out. We trust that the water is clean, and we trust that our homes can receive a steady supply of water.

Most of us trust our central heating (insert boiler joke here) and the plugs/sockets in our homes to provide gas and electricity. The reason we trust all of these flows is because there's been rigorous engineering standards built up over decades and centuries.

For example, Scottish Water will understand every component part that makes up their water pipelines. Those pipes, valves, fitting etc will comply with a national, or in some cases international, standard. These companies have diagrams that clearly map all of this out, mostly because they have to legally but also because it also vital for disaster recovery and other compliance issues.

Modern IT

And this is where modern day IT has problems. I'm not saying that modern day tech is a pile of shit. We all have great phones, our PCs can play good games, but it's one thing to craft well-designed products and another thing entirely to think about they all work together.

Because that is what's happened over the past few decades of IT. Organisations have piled on the latest plug-and-play technology (Software or Hardware) and they've built up complex legacy systems that no one really knows how they all work together. They've lost track of how data flows across their organisation which makes the work of cybersecurity, disaster recovery, compliance and general business transformation teams a nightmare.

Some of these systems are entirely dependent on other systems to operate. But that dependency isn't documented. The vast majority of digital transformation projects fail because they get halfway through and realise they hadn't factored in a system that they thought was nothing but was vital to the organisation running.

And this isn't just for-profit organisations, this is the health services, this is national infrastructure, it's everyone.

There's not yet a single standard that says "This is how organisations should control, manage and govern their flows of data."

Why is that relevant to the companies that were affected by Crowd Strike? Would it have stopped it?

Maybe, maybe not. But considering the global impact, it doesn't look like many organisations were prepared for the possibility of a huge chunk of their IT infrastructure going down.

Understanding dataflows help with the preparation for events like this, so organisations can move to mitigate them, and also the recovery side when they do happen. Organisations need to understand which systems are a priority to get back operational and which can be left.

The problem I'm seeing from a lot of organisations at the moment is that they don't know which systems to recover first, and are losing money and reputation while they fight to get things back online. A lot of them are just winging it.

Conclusion of Part 1

Next time I can totally go into diagramming if any of you are interested in that.

How can any organisation actually map their dataflow and what things need to be considered to do so. It'll come across like common sense, but that's why an actual standard is so desperately needed!

793 notes

·

View notes

Text

New York City steam system

Exploring the Iconic Steam Heating System in New York City

Join us on a fascinating journey through the streets of New York City as we unravel the secrets behind its unique steam heating system.

In this post, we delve into the historical significance and continued usage of steam heating in the bustling metropolis. Discover why steam vents dot the sidewalks, releasing wisps of steam into the air. Find out if steam is still the primary source of warmth for the city's diverse range of buildings.

We take you behind the scenes to uncover the inner workings of the steam system, revealing where and how steam is generated in NYC. Learn about the central steam plants that produce the heat and power the iconic radiators found in countless apartments and offices.

Curious about the efficiency and environmental impact of steam power? We explore its advantages and disadvantages, discussing its sustainability and comparing it to other heating methods like forced air and electricity.

Ever wondered why NYC radiators feel scorching hot or why they sometimes emit mysterious ringing sounds? We've got the answers! Gain insights into the inner workings of NYC apartment radiators and the science behind their heat distribution.

Finally, we address practical concerns, such as the safe distance between curtains and radiators and the potential disadvantages of steam power in New York. Get expert tips and advice on how to maximize comfort and safety in steam-heated environments.

Whether you're a New Yorker interested in your city's rich history or simply fascinated by the engineering marvels that keep the Big Apple warm, this post is a must-read. Join us on this captivating exploration of steam heating in New York City and unlock the mysteries of this iconic system.

Why are there steam vents in New York? Steam vents, also known as steam chimneys or manholes, can be found throughout New York City because they are part of the extensive underground steam distribution system. These vents release excess steam and pressure from the underground steam pipes that provide heating to buildings.

Does New York still use steam heating? Yes, New York City still relies on steam heating to this day. The steam system is one of the oldest and largest district heating systems in the world, providing heat to thousands of buildings throughout the city.

Where is NYC steam generated? NYC's steam is generated at several centralized steam plants. Con Edison, the energy company responsible for the steam system, operates these plants. The major steam plants are located in Manhattan, with others scattered across the other boroughs.

How are NYC buildings heated? Many buildings in New York City are heated using the steam distributed through underground pipes. The steam enters buildings and flows through radiators or heat exchangers to provide heat.

Why are NYC radiators so hot? NYC radiators can feel very hot because they receive high-pressure steam directly from the underground steam pipes. This steam releases its heat into the radiators, making them feel hot to the touch.

How does steam heat work in NYC? Steam heat in NYC operates through a district heating system. Steam is produced at centralized plants and then distributed through a network of underground pipes to individual buildings. The steam enters buildings, heats radiators or heat exchangers, and then condenses back into water, which is returned to the steam plant to be reheated.

Is NYC steam efficient? The NYC steam system is considered relatively efficient because it utilizes waste heat generated by electricity production. The steam plants use this waste heat to produce steam, making it a more efficient process than standalone boilers in individual buildings.

How is steam made in New York? Steam is made in New York by heating water to a high temperature, turning it into steam. The process typically involves burning fuel, such as natural gas or oil, to generate the heat needed to produce steam.

How do NYC apartment radiators work? NYC apartment radiators work by allowing steam to enter them through control valves. As the steam passes through the radiator, it releases its heat, warming up the surrounding air in the apartment.

Is steam heating better than forced air heating in New York City? Both steam heating and forced air heating have their advantages and disadvantages. Steam heating can be more effective in older buildings with existing steam systems, providing consistent heat and requiring less ductwork. Forced air systems, on the other hand, can provide both heating and cooling and are easier to retrofit in newer constructions.

How are buildings heated by steam in New York? Buildings in New York are heated by connecting to the city's steam distribution system. The underground steam pipes deliver the steam to the buildings, and from there, it is used to heat the interior spaces.

Is steam better than electricity in New York? The choice between steam and electricity depends on various factors, including the building's infrastructure, energy efficiency goals, and cost considerations. NYC's steam system is advantageous because it utilizes waste heat, which makes it relatively efficient compared to standalone electric heating systems.

Why are the radiators ringing in New York? Radiators in NYC can sometimes produce a ringing or clanging noise. This noise is often caused by the expansion and contraction of the metal as it heats and cools. It can also be due to air trapped in the system, causing steam to condense rapidly and create noise.

What is the disadvantage of steam power in New York? One disadvantage of the steam system in NYC is that it requires a complex network of underground pipes, which can be costly to maintain and repair. Additionally, steam heating may not be as efficient as other modern heating methods in certain circumstances.

Why is steam so much cheaper in New York? Steam in New York can be relatively cheaper because the city's steam system is fueled by waste heat from electricity generation. This waste heat would otherwise be released into the atmosphere, but instead, it is utilized to produce steam, making it a cost-effective energy source.

Why is steam so much better in New York? Steam is advantageous in New York because of the city's existing infrastructure and the availability of waste heat for steam generation. The extensive steam system provides efficient heating to a large number of buildings.

Is steam power clean in New York? Steam power in New York is considered relatively clean compared to conventional power plants because it utilizes waste heat, reducing the overall environmental impact. However, the burning of natural gas or oil to produce steam still contributes to greenhouse gas emissions.

Is steam power green in NYC? While NYC's steam power is greener compared to traditional fossil fuel power plants, it is not entirely green. The use of natural gas or oil in steam generation results in greenhouse gas emissions. Truly green energy sources are those that rely on renewable energy like solar, wind, or hydro power.

Is steam more efficient than hot water in New York? Steam and hot water heating systems each have their strengths and weaknesses. Steam systems tend to be more efficient in older buildings with existing infrastructure, while hot water systems can be more efficient in newer constructions.

Can curtains touch steam radiators in NYC? It is generally not recommended to let curtains or any other flammable materials touch steam radiators in NYC or anywhere else. Steam radiators can become very hot and could potentially cause a fire if they come into direct contact with combustible materials. It's essential to maintain a safe distance between curtains and radiators to prevent accidents.

#new york#newyork#new york city#new-york#ny#nyc#city#urban#manhattan#usa#United States#buildings#travel#journey#outdoors#street#architecture#visit-new-york.tumblr.com

56 notes

·

View notes

Text

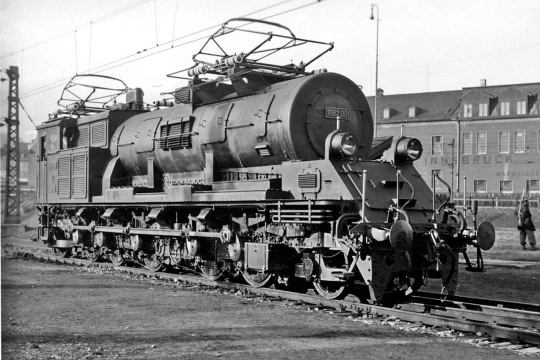

🚂 In need of some cool engines for TTTE OCs? Look no further! 🚃

Here's a list of all sorts of unusual and little known engines to make into your next OCs!

1082 class electric locomotive: Not much is known about this engine, so information is fragmented. This Austrain steam engine was powered by electricity heating up the water in its boiler through electric coils. The hydroelectric system was apparently 50 years ahead of it time and was built in response to the rising prices of imported German Coal during WW2. This engine and ones like it Sweden, were scrapped after the war ended. I'll never understand why. Such a self sufficient engine could have been the key to many break throughs.

2. DRG Class 05: This German streamlined engine was made in response of record breaking streamlined diesel engines made earlier. In 1936, this engine set the world speed record for reaching 124.5 mph, while hauling 217 short tons. However this record was later beaten by Mallard, (Yes, that Mallard. The LNER Gresley one.) on a technicality. Mallard was on a slightly downhill line, and with a heavier train. Interpret that as you will. If you want Gresley family drama, I have a feeling this engine would make a great OC to start it.

3. B&O #305 Camel: This unique engine was trademarked by the Baltimore and Ohio railroad in the 1900s. It's unusual build allowed to pull trains up steep mountains. This build also came with a terrible flaw. Since the cab was placed directly above the boiler, it became very hot and anyone in it would not only be uncomfortable, but in terrible danger if if the engine ever derailed. And there was very little protection for the crew. In short, it was like an overbred dog. Created purely for one purpose, and not with health or safety in mind. More information can be found at the B&O website.

4. The Rail Pickup Truck??? (GMC Switch Engine): Well, if you need a Fankid that's a cross between a steam engine and a pickup, I've got you covered! Haha! Not much information on these, except that they were used during WW2 and were modified for rail use.

5. Ateliers Moës-Freres Diesel: This little guy is absolutely adorable! He'd definitely make an cute OC! This engine one of many diesels built by the popular Belgian company Ateliers Moës-Freres. They're were know for making exceptional small diesel engines. Even ones that looked like steam engines! Unfortunately, I couldn't any information on what exactly this engine's name is. But if anyone does know, please contact me so I may add it!

6. M-497 (Nicknamed Black Beetle by the press): This futuristic engine was once the fastest engine in North America! It was an experiment, developed by the New York Central Railway. Two J47-19 Jet Engines were attached to a streamlined Budd Rail Diesel Car. The experiment was successful, with the engine reaching a speed of 183.68 mph. Despite the successful run and the valuable data gathered, the project was considered to quote "not considered viable commercially". Black Beetle continued to run after the jet engines were removed, until retirement in 1977 and being scrapped in 1984.

And that's it for now! If you guys like these OC ideas, make sure to let me know, so I can make another one! Also, it's important to note, that I am not an expert on engines. If you see any misinformation here, please let me know, so I can correct it.

Thanks for reading!

#ttte#thomas the tank engine#thomas and friends#ttte mallard#Mallard ttte#real life trains#steam engine#railway#locomotive#steam locomotive

5 notes

·

View notes

Text

okay I got the key to the new house today (key, singular, it feels very anticlimactic and also I mislike that it only has one door because i stress but anyway). there are indeed only three plug sockets in the whole downstairs living area and one of them is for the heater (since it has electric storage heaters or whatever they're called). so NOT GREAT, will be needing many extension leads, although there are at least four (4) sockets in the kitchen and not 3 as i previously thought. but the space for the fridge is exceedingly narrow and if i can't get a fridge that fits there, there are no plug sockets on the side of the room where i would want to put a fridge outside of the kitchen, so, yeah, having some wee hurdles there for sure

also I have absolutely no idea how to make the hot water work in this house since i have never lived somewhere without gas central heating before. there's no ?? boiler ??? how tf

10 notes

·

View notes

Text

As much of the world endures a summer of record-breaking temperatures, Germany is stuck debating a very different kind of heat: the future of the radiator. A controversial law championed by the government would ban almost all new oil and gas heating systems starting next year. Homes and businesses would have to purchase appliances that meet strict environmental standards, such as heat pumps.

The Building Energy Act, known colloquially as just the “heating law,” has opened yet another rift in the tenuous three-party governing coalition led by German Chancellor Olaf Scholz. While Scholz has thrown his support behind the measure, some of his key governing partners stonewalled its initial passage. Meanwhile, the conservative opposition and far right have taken advantage of the discord to boost their poll numbers.

All of this means that a reform rife with scientific jargon and technicalities has now become the latest lighting rod in Germany’s ongoing culture war. Exalted by environmentalists but despised by most other voters, the heating law demonstrates how the political feasibility of serious climate action can become bounded by surges in populist discontent. A reform that experts see as central to achieving Germany’s climate goals could also catapult the far right into power.

“One reason this policy is so controversial is that it’s part of this bigger switch, where climate policy is moving from distant power plants to people’s homes,” said Noah Gordon, the acting co-director of the Sustainability, Climate, and Geopolitics Program at the Carnegie Endowment for International Peace. “It doesn’t make such a difference to your daily life … where the electricity from the wall socket is coming from. But now we’re talking about people going into buildings to improve the insulation and rip out boilers. You get into all these very local politics.”

The law aims to phase out oil and gas heating systems in buildings throughout Germany. It is the brainchild of Vice Chancellor Robert Habeck, a member of the environmentalist Greens who also serves as minister for economics and climate action. If Habeck’s legislation is passed, new heating systems in the country would be required to rely on at least 65 percent green energy sources starting Jan. 1, 2024, and municipalities would have to devise environmentally friendly heating master plans by 2028 at the latest. The law is modeled on existing policies that are commonplace in many Scandinavian countries.

While Germany has dramatically reduced its emissions from the electricity sector over the past decade, it has made little progress in the building sector, which continues to account for about 40 percent of the country’s carbon output, according to the German Energy Agency. The heating law aims to close this gap to keep Berlin on track to achieve climate neutrality by 2045.

But so far, the still-pending reform has done little besides put the far-right Alternative for Germany (AfD) on track for major electoral gains. Since March, the party’s poll numbers have risen steadily, reaching a high of 22 percent on Aug. 31. The AfD has now overtaken each of the three parties that make up Scholz’s motley coalition in national surveys—and holds a steady lead in at least one state that is due to hold elections next year.

Analysts and pollsters see the politicking around the heating law as one of the main drivers of this trend. For Andrea Römmele, the dean of executive education at the Hertie School of Governance in Berlin, the proposed measure is just the latest evidence of the federal government’s dysfunction—proving that Scholz’s coalition “does not support one another.”

Two years ago, when Scholz cobbled together a government with the support of his own Social Democratic Party (SPD), the Greens, and the pro-business Free Democratic Party (FDP)—the first coalition of its kind on a national level—the three groups agreed to the general contours of the heating law. But when Habeck introduced his first draft to the cabinet this spring, it became instant political dynamite.

The Greens lined up enthusiastically behind Habeck. The SPD was split, with Scholz endorsing the proposal while others in his party questioned its potential impact on consumers. And the FDP loudly dissented, calling the proposal too costly and preferring to let the market dictate technological innovation. The Greens and the FDP are fundamentally divided on the state’s role in confronting almost every major issue Germany faces today, and their constant bickering has stymied many of the coalition’s attempts to legislate. Nowhere is this more evident—and existential—than in climate policy.

“If we really want to tackle climate change, the state has to interfere more in what had been private issues because we have to change our behavior,” Römmele said.

But for many voters, a stronger state is not an alluring—or marketable—prospect. “The Greens have a sort of problem in German politics,” Gordon said. “They’re accused of being the party of bans.”

Germany’s right wing has seized upon this talking point to remarkable ends. The AfD has made Habeck public enemy No. 1 and promised to stop the vice chancellor’s “heating hammer.” On the floor of the German parliament, or Bundestag, the party’s co-leader has called to “replace Habeck, not heaters,” falsely implying that Scholz’s government intends to ban existing gas heating systems. Some members of the center-right Christian Democratic Union (CDU) have issued similarly incendiary statements. One CDU politician claimed Habeck wanted to mobilize an “energy Stasi,” a reference to the notorious East German secret police.

Such remarks have been given a platform by right-wing outlets eager to propagate misinformation about Scholz’s left-leaning government. “Some of the tabloid press talked about how Habeck is coming for your gas-powered heater,” Gordon said, even though “[t]hat was never part of the plan.” The Stasi comment was immediately printed in fat, bold letters on the cover of the Bild tabloid, Germany’s most widely circulated newspaper, and the “heating hammer” has now become part of the publication’s standard lexicon.

“The Bild newspaper is very much running a campaign against the Greens,” Römmele said. She accused all outlets belonging to the conglomerate Axel Springer—which in 2021 acquired Politico—of being complicit. The company has a long history of smearing leftist activists and politicians, with sometimes fatal consequences.

In Gordon’s view, the tabloids are playing on “populist agitation” that the heating law is the work of “elite groups in Berlin that don’t know what it’s like to be worrying about how you’re going to pay for gas and petrol at the end of the month.” This sentiment is especially widespread in the states of the former East Germany, which are poorer than their Western counterparts and where the AfD is strong. As with many climate measures, Gordon stresses, the upfront costs of green technology can be expensive—but it pays dividends in the long run.

Scholz’s coalition seems to have registered some of these critiques. The Greens and the FDP fought publicly about the heating law for weeks before reaching a compromise that softened some provisions, “giving consumers and municipalities more time to figure this out,” Gordon said. For example, the latest draft of the law would allow buildings to continue to install fossil fuel heaters if they could feasibly be powered by green hydrogen once it is produced at scale. Consumer subsidies were also increased.

“Even though the current legislation is not as ambitious as what the Greens initially wanted, it’s still a necessary … step on the path toward cutting emissions from buildings,” Gordon added. A new report from a government watchdog warned that significantly reducing emissions from the building sector is dependent on passing the heating law—but even that might not be enough for Germany to achieve its climate goals.

Habeck had aimed to pass the heating law before the Bundestag’s summer break, but a CDU petition to Germany’s constitutional court stalled progress on the measure until the legislature convenes again on Sept. 4. The center-right party lamented the speed with which Habeck sought to move the heating law through parliament—claiming there was not enough time for proper debate—and the court agreed.

Both Gordon and Römmele have little doubt the measure will be approved swiftly once the Bundestag is back in session. Yet the political damage may have already been done. While October state elections in Bavaria and Hesse will probably see center-right incumbents opposed to the heating law prevail, “we will most likely have an extremely strong AfD” in three state elections in the former East Germany next year, Römmele said. “Perhaps the AfD will even manage to be the strongest party.”

The overwhelming majority of Germans remain fed up with Scholz’s coalition: The chancellor’s disapproval rating currently stands at 70 percent, and 64 percent of Germans want a new government, according to a survey published in August by polling institute INSA. The Greens in particular have suffered in recent months, and the party’s support base has shrunk to a five-year low. Habeck, who was once the most popular politician in Germany, is now reviled by many.

Although the opposition and media onslaught against the vice chancellor has been extreme, Habeck is the first to admit he made mistakes in their initial promulgation of the heating law. After Germans endured their first winter without Russian fossil fuels, most were tired of constantly discussing their heaters—a fatigue Habeck says he failed to take seriously. “Between the first months of this year and today, something happened in Germany, and I—or we—didn’t recognize it in time,” he told public broadcaster ARD in June.

Now, on the other end of summer, Gordon thinks the hot weather Germans experienced has the potential to be a boon for the home stretch of Habeck’s heat pump push. Most Germans don’t have air conditioning, but “a good thing about heat pumps is that some of them can be both heating and cooling,” Gordon said.

“Say you’re building a new house in Germany in 2025 and you want to live there for 20 years. It’s pretty likely that in the 2040s you’re going to want air conditioning,” Gordon said. “That could be another reason to get people to be like, ‘hold on, let’s think about the future. It’s not just that the cost of gas is going up and we need to stop burning it for climate reasons. It’s that the temperatures around the world are going up. And I want this technology that could also keep my place cool in August.’”

5 notes

·

View notes

Text

The Ultimate Overview to A/c: Whatever You Required to Know

Comprehending the Basics of A/c Equipments

A/C, which means Home heating, Air Flow, and Cooling, is an important component of any kind of building, whether it's residential or industrial. This acronym encompasses a large range of systems and tools that collaborate to offer comfy indoor conditions. From maintaining us warm in the winter to cooling us down in the summer, heating and cooling systems play a vital role in keeping ideal temperature level, humidity, and air quality.To fully realize the principle of a/c, it is very important to comprehend its elements. Heater usually include furnaces, central heating boilers, or heatpump, which create and distribute warmth throughout the building. Air flow systems make certain a consistent flow of fresh air by exhausting stagnant air as well as introducing outside air. Air conditioning systems, on the various other hand, amazing and also dehumidify the air, making sure a pleasant setting throughout hot summer season. Comprehending the essentials of a/c systems can aid property owners as well as company owner make educated choices when it pertains to setup, upkeep, and also power efficiency.The Relevance of Regular A/c Upkeep Maintaining a heating and cooling system is essential to guarantee its longevity and optimal performance. Routine maintenance not only assists prevent expensive breakdowns however additionally boosts power efficiency, reduces energy costs, and also enhances indoor air top quality. Disregarding upkeep can cause reduced air movement, lowered cooling or home heating capacity, and also also system failure.Some vital upkeep jobs include cleaning or replacing air filters, checking and also cleansing air ducts, lubricating moving components, inspecting cooling agent levels, and also guaranteeing appropriate electric links. It's recommended to set up expert heating and cooling maintenance at the very least when a year, preferably before the begin of each heating or cooling down period. Home owners can additionally take positive actions to maintain their heating and cooling systems, such as on a regular basis cleansing exterior units, securing duct leaks, and also shows thermostats for energy efficiency.In verdict, comprehending the basics of a/c systems as well as focusing on routine upkeep are crucial to making sure

comfortable as well as healthy interior atmospheres. By familiarizing yourself with the parts of a/c systems and carrying out preventive steps, you can extend the life-span of your system, save money on power expenses, as well as delight in optimum efficiency year-round.

Read more here MorehartAC

2 notes

·

View notes

Photo

Day 15: Pennsylvania Railroad GG1

Information from Wikipedia:

The PRR GG1 was a class of electric locomotives built for the Pennsylvania Railroad (PRR), in the northeastern United States. Between 1934 and 1943 General Electric and the PRR's Altoona Works built 139 GG1s.

The GG1 entered service with the PRR in 1935 and later ran on successor railroads Penn Central, Conrail and Amtrak. The last GG1 was retired by New Jersey Transit in 1983. Most have been scrapped, but sixteen are in museums.

The GG1 was 79 feet 6 inches (24.23 m) long and weighed 475,000 pounds (215,000 kg). The frame of the locomotive was in two halves joined with a ball joint, allowing the locomotive to negotiate sharper curves. The body rested on the frame and was clad in welded steel plates. The control cabs were near the center of the locomotive on each side of the main oil-cooled transformer and oil-fired train-heating boiler. This arrangement, first used on the PRR's Modified P5 class, provided for greater crew safety in a collision and provided for bi-directional operation of the locomotive. Using Whyte notation for steam locomotives, each frame is a 4-6-0 locomotive, which in the Pennsylvania Railroad classification system is a "G". The GG1 has two such frames back to back, 4-6-0+0-6-4. The related AAR wheel arrangement classification is 2-C+C-2. This means one frame mounted upon a set of two axles unpowered (the "2") and three axles powered (the "C") hinged with the ball and socket to another frame of the same design (the +). The unpowered "2" axles are at either end of the locomotive. The GG1 was equipped with a Leslie A200 horn.

A pantograph on each end of the locomotive body was used to collect the 11,000 V, 25 Hz alternating current (AC) from the overhead catenary wires. In operation, the leading pantograph was usually kept lowered and the trailing one raised to collect current, since if the rear pantograph failed it would not strike the forward pantograph. A transformer between the two cabs stepped-down the 11,000 V to the voltages needed for the traction motors and other equipment. Twelve 385-horsepower (287 kW) GEA-627-A1 traction motors (AC commutator motors, not AC induction motors) drove the GG1's 57-inch (1,448 mm) diameter driving wheels on six axles using a quill drive. The power required was such that double traction motors were used, with two motors driving each axle. The traction motors were six-pole field, 400 volts, 25 Hz rated each at 385 hp (287 kW). The motors were frame-mounted using quill drives to the sprung driving wheels, providing a flexible suspension system across a relatively-long locomotive frame, which allowed full wheel weight to rest on the rail for good traction regardless of track condition. A series-wound commutator motor's speed is increased by increasing the applied voltage to the motor, thus increasing the current through the motor's armature, which is necessary for increasing its torque and thus increasing motor speed. The engineer's cab had a 21-position controller for applying voltage to the motors. Four unpowered leading/trailing wheels were mounted on each end of the locomotive.

In the 1930s, railroad passenger cars were heated with steam from the locomotive. The GG1 had an oil-fired steam generator to feed its train's "steam line."

Beginning in the late 1910s, the PRR received the FF1, but decided that it was too slow for passenger trains; it was relegated to heavy freight service. In the mid-1920s, it received the L5 electric, which had a third-rail power supply at the time. When the Pennsylvania built the O1 and the P5, it chose the P5 over the O1 for its ability and power on the rails. After a grade-crossing accident with the P5, the cab was moved to the center and was designated P5a. PRR still searched for the ultimate electric, since the P5 did not track well at high speeds and was wondering if the P5a could be improved even further. Soon enough, the Pennsylvania was in luck and found two contacts as early as 1932. The mechanical design of the GG1 was based largely on the EP3, which the PRR had borrowed from the New York, New Haven & Hartford Railroad to compare it to the P5a. In 1933, the PRR decided to replace its P5a locomotives; it asked General Electric and Westinghouse to design prototype locomotives with a lighter axle load and more power than the P5a, a top speed of at least 100 miles per hour (160 km/h), a streamlined body design, and a single (central) control cab.

Both companies delivered their prototypes to PRR in August 1934. Westinghouse's R1 was essentially "little more than an elongated and more powerful version of the P5a" with an AAR wheel arrangement of 2-D-2. General Electric delivered its GG1. Both locomotives were tested for ten weeks in regular service between New York and Philadelphia and on a test track in Claymont, Delaware. PRR chose the GG1 because the R1's rigid wheelbase prevented it from negotiating sharp curves and some railroad switches. On November 10, 1934, the railroad ordered 57 locomotives: 14 assembled by General Electric in Erie, 18 by the PRR's own Altoona Works, and 20 more in Altoona with electrical components from Westinghouse in East Pittsburgh and chassis from the Baldwin Locomotive Works in Eddystone. An additional 81 locomotives were built at Altoona between 1937 and 1943.

On January 28 1935, to mark the completion of electrification of the line from Washington, D.C., to New York City, PRR ran a special train hauled by Pennsylvania Railroad 4800 before it opened the line for revenue service on February 10. It made a round-trip from D.C. to Philadelphia; it completed the return leg in a record 1 hour and 50 minutes.

In 1945, a Pennsylvania GG1 hauled the funeral train of President Franklin D. Roosevelt from Washington Union Station to New York Pennsylvania Station.

In the mid-1950s, with declining demand for passenger train service, GG1s 4801–4857 were re-geared for a maximum speed of 90 miles per hour (140 km/h) and placed in freight service. They initially retained their train-heating steam generator, and were recalled to passenger service for holiday-season mail trains and 'Passenger Extras' such as those run for the annual Army–Navy football game in Philadelphia.

Timetable speed limit for the GG1 was 75-80 mph until October 1967, when some were allowed 100 mph for a couple of years. When Metroliner cars were being overhauled in the late 1970s, GG1s were again allowed 100 mph for a short time when hauling Amfleet cars on trains scheduled to run 226.6 miles from New York to Washington in 3 hours and 20 to 25 minutes.

On June 8, 1968, two Penn Central GG1s hauled Robert F. Kennedy's funeral train from New York Penn Station to Washington, D.C.

The first designer for the GG1 project was industrial designer Donald Roscoe Dohner, who produced initial scale-styling models, although the completed prototype looked somewhat different. At some point, PRR hired famed industrial designer Raymond Loewy to "enhance the GG1's aesthetics." The final design is retrospectively 'Art Deco' as we know it today.

Although it was thought until 2009 that Loewy was solely responsible for the GG1's styling, Dohner is now understood to have contributed as well. (Dohner's GG1 designs influenced the modified P5as, which debuted before the GG1 — not, as was thought, the other way around.) Loewy did claim that he recommended the use of a smooth, welded body instead of the riveted one used in the prototype. Loewy also added five gold pinstripes and a Brunswick green paint scheme.

In 1952, the paint scheme was changed to Tuscan red; three years later, the pinstripes were simplified to a single stripe and large red keystones were added.

On September 6 1943, the Congressional Limited crashed at Frankford Junction, in the Kensington neighborhood of Philadelphia, Pennsylvania, in the United States. The train was pulled by GG1 4930. The accident was caused by a journal box fire (a hot box) on the front of the seventh of the train's 16 cars. The journal box seized and an axle snapped, catching the underside of the truck and catapulting the car upwards. It struck a signal gantry, which peeled off its roof along the line of windows "like a can of sardines". Car #8 wrapped itself around the gantry upright in a figure U. The next six cars were scattered at odd angles over the tracks, and the last two cars remained undamaged. In total, 79 passengers died, all from cars #7 and #8, and 117 were injured, some seriously.

On January 15 1953, train 173, the overnight Federal from Boston, was approaching Washington behind GG1 4876. The train passed a signal 2.1 miles (3.4 km) north of Union Station between 60 and 70 miles per hour (97 and 113 km/h), and the engineer decreased the throttle and started applying the brakes. When the engineer realized that the train was not slowing down, and applying the emergency brake had no effect, he sounded the engine's horn. A signalman, hearing the horn and noting the speed of the 4876, phoned ahead to the station master's office. 4876 negotiated several switches at speeds well over the safe limits and entered the station at around 35 to 40 miles per hour (56 to 64 km/h). The train demolished the bumping post, continued through the station master's office and into the concourse, where it fell through the floor into the station's basement. Thanks to the evacuation of the concourse, no one died, either in the station or aboard the train. A temporary floor was erected over the engine, and the hole it created, for the inauguration of President Dwight D. Eisenhower. 4876 was eventually dismantled, removed from the basement and reassembled with a new frame and superstructure in Altoona. The reconstructed 4876 survives at the B&O Railroad Museum in Baltimore.

The accident was determined to have been caused by a closed "angle cock", a valve on the front and rear of all locomotives and rail cars used in the train's airbrake system, on the rear of the third car in the train. The handle of the angle cock had been improperly placed and had contacted the bottom of the car. Once it was closed, the air brake pipe on all the cars behind the closed valve remained at full pressure, keeping the brakes released on those cars while the brakes on the locomotive and first three cars were applied in emergency. The only major electro-mechanical breakdown of the GG1 was caused by a February 1958 blizzard that swept across the northeastern United States and put nearly half of the GG1s out of commission. Exceptionally fine snow, caused by the extreme low temperatures, passed through the traction motors' air filters and into the electrical components. When the snow melted, it short-circuited the components. On about 40 units, the air intakes were later moved to a position under the pantographs.

In 1968, the PRR, with its 119 surviving GG1s, merged with the New York Central Railroad to form Penn Central. Penn Central went bankrupt in 1970 and its freight operations were later assumed by government-controlled Conrail, which used 68 GG1s in freight service until the end of electric freight traction in 1980.

After its creation in 1971, Amtrak purchased 30 GG1s for $50,000 each and leased another 21, of which 11 were for use on New York and Long Branch commuter trains. Amtrak initially renumbered the purchased GG1s as Nos. 900 to 929; later the railroad added a prefixed "4". This replicated some of the numbers of the leased units, which were renumbered 4930 to 4939, except 4935, which kept its old PRR/PC number.

Amtrak unsuccessfully attempted to replace the GG1s in 1975 with the General Electric E60. An E60 derailed during testing at 102-mile-per-hour (164 km/h), forcing an investigation (the E60 used the same trucks as the P30CH diesel then in service with Amtrak) that delayed acceptance. The hoped-for 120 miles per hour (193 km/h) service speed was never achieved (timetable limit was 90 mph, then 80, then 90).

A replacement was finally found after Amtrak imported and tested two lightweight European locomotives: X995, an Rc4a built by ASEA of Sweden, and X996, a French design. The railroad picked the ASEA design, initially nicknamed the "Swedish swifty" or the "Mighty Mouse" and later often referred to as the "Swedish Meatball". Electro-Motive Diesel, then a part of General Motors, was licensed to build a derivative called the AEM-7. As AEM-7s arrived, Amtrak finally ended GG1 service on April 26, 1980.

The last GG1s in use were some of the 13 assigned to New Jersey Transit (#4872–4884) for its North Jersey Coast Line between New York and South Amboy (the former New York and Long Branch) that ran until October 29, 1983, thus retiring the locomotive after 49 years of service.

Fifteen production locomotives and the prototype were preserved in museums. None are operational; their main transformers were removed because of the PCBs in the insulating oil.

PRR/PC/CR 4800 — Railroad Museum of Pennsylvania, Strasburg, Pennsylvania (nicknamed "Old Rivets" due to it being the only GG1 to have been built with a riveted body)

PRR/PC/CR 4859 — Transportation Center, Harrisburg, Pennsylvania (designated Pennsylvania State electric locomotive in 1987)

PRR/PC/CR/NJT 4876 — B&O Railroad Museum, Baltimore, Maryland (Reconstructed with new frame and superstructure as well as reusable components from the original 4876 following the 1953 Washington Union Station wreck)

PRR/PC/CR/NJT 4877 — United Railroad Historical Society of New Jersey, Boonton, New Jersey (nicknamed "Big Red")

PRR/PC/CR/NJT 4879 — United Railroad Historical Society of New Jersey, Boonton, New Jersey

PRR/PC/CR/NJT 4882 — National New York Central Railroad Museum, Elkhart, Indiana (currently painted in Penn Central colors)

PRR/Amtrak 4890 — National Railroad Museum, Green Bay, Wisconsin

PRR 4903/Amtrak (4)906 — Museum of the American Railroad, Frisco, Texas (hauled Robert F. Kennedy's funeral train with GG1 4901 from New York to Washington on June 8, 1968).

PRR 4909/Amtrak 4932 — Leatherstocking Railway Museum, Cooperstown Junction, New York

PRR 4913/Amtrak (4)913 — Railroaders Memorial Museum, Altoona, Pennsylvania

PRR 4917/Amtrak 4934 — Leatherstocking Railway Museum, Cooperstown Junction, New York

PRR 4918/Amtrak (4)916 — National Museum of Transportation, St Louis, Missouri

PRR 4919/Amtrak (4)917 — Virginia Museum of Transportation, Roanoke, Virginia

PRR 4927/Amtrak 4939 — Illinois Railway Museum, Union, Illinois

PRR 4933/Amtrak (4)926 — Central New York Chapter of the National Railroad Historical Society, Syracuse, New York. It has been cosmetically restored and is on display at the NYS Fairgrounds Historic Train Exhibit.

PRR 4935 / Amtrak 4935 — Railroad Museum of Pennsylvania, Strasburg, Pennsylvania (nicknamed "Blackjack")

During the mid-1930s, many railroads streamlined locomotives and passenger cars to convey a fashionable sense of speed. While the Union Pacific had the M-10000 and the Chicago, Burlington & Quincy Railroad the Zephyr, the PRR had the GG1. The GG1 has "shown up over the years in more advertisements and movie clips than any other locomotive." It was also featured in art calendars provided by PRR, which were used to "promote its reputation in the public eye."

PRR-painted GG1s appear in the films Broadway Limited in 1941, The Clock in 1945, Blast of Silence in 1961, the 1962 version of The Manchurian Candidate, and Avalon in 1990. Two GG1s appear in the 1973 film The Seven-Ups—a black Penn Central locomotive and a silver, red and blue Amtrak locomotive. A Penn Central GG1 also appears in another 1973 film The Last Detail. PRR GG1 4821 appears briefly in the 1952 film The Greatest Show on Earth, hauling the Ringling Bros. Barnum & Bailey Circus into Philadelphia's Greenwich Yard, as the movie's director Cecil B. DeMille narrates the scene of its arrival. Near the end of the 1951 film Bright Victory, GG1 #4849 is shown pulling into the station.

A GG1 and the Congressional were featured on a postage stamp as part of the United States Postal Service's All Aboard! 20th Century American Trains set in 1999.

The PC games Railroad Tycoon II, Railroad Tycoon 3, Sid Meier's Railroads!, Train Fever, Transport Fever and Transport Fever 2 allow players to purchase and operate GG1 locomotive engines on their train routes. The GG1 is also available with the default Trainz Simulator Games in recent years, and is available as add-ons for Railworks, Train Simulator by Dovetail Games and Microsoft Train Simulator.

Model GG1s have been produced in G, O, S, HO, N and Z scales by Rivarossi, Bachmann, Tyco, Lionel, MTH, USA Trains, Kato, Astor, Fine Art Models, Marklin and other manufacturers.

models and route by: Protrainz, Auran, and Download Station

#PRR#Pennsylvania Railroad#Pennsy#PRR GG1#Pennsylvania Railroad GG1#GG1#Electric Locomotive#Trains#Trainz Simulator#Advent Calendar#Christmas#Christmas 2022 🎄🎅🎁

5 notes

·

View notes

Text

Gas Zone Plumbing & Heating | Heating Engineers in Stratford

Welcome to GasZone Plumbing and Heating, your trusted expert Heating Engineers in Stratford! With over 15 years of experience, we are Gas Safe Certified and proud to be approved installers for BAXI, Vaillant, and Mains. Our services include comprehensive plumbing services, heating installation, and boiler repairs in Stratford. We specialize in boiler installation, servicing, and repairs, general plumbing work, heating issues, system conversions, and radiator replacement. We also offer landlord gas safety inspections, gas appliance installation, gas leak inspections, and emergency call-outs. Serving both private tenants and landlords across London, we also handle contracted work for estate agents. Contact us today for a FREE inspection and quote!

Business Name : Gas Zone Plumbing & Heating

Address : 1 Canning Rd, London E15 3NW, United Kingdom

Phone : 07300353247

GMB Url :

click here 👆🏻 for more information

#Boiler repairs in Stratford#Boiler service in Stratford#Plumbing services in Stratford#heating engineers in Stratford#boiler installers in Stratford#heating installation in Stratford#electric central heating in stratford#Gas engineers Stratford#Boiler repairing services in Stratford#commercial gas engineer in Stratford

0 notes

Text

Broadway, New York City

Steam Heating in the Concrete Jungle: A Comprehensive Analysis of New York City's Historic and Sustainable Heating Infrastructure

Introduction

1.1 Historical Overview of Steam Heating

Steam heating has a storied history in New York City, dating back to the mid-1800s. Before steam heating, buildings relied on individual coal-burning stoves or fireplaces for warmth, resulting in uneven heating and numerous health hazards. The advent of steam heating, pioneered by engineer Stephen Gold in the 1850s, marked a significant advancement in heating technology. It offered a centralized heating solution, where steam generated in large plants could be distributed efficiently through a network of underground pipes to individual buildings, providing consistent and reliable heat throughout the city.

1.2 Advantages and Disadvantages of Steam Heating

The adoption of steam heating brought several advantages to New York City. It allowed for the elimination of individual heating units in each building, reducing maintenance costs and fire risks. Steam heating systems operate quietly, without the noise associated with forced-air systems, contributing to a more peaceful urban environment. Additionally, steam heating radiators became architectural features, adding a distinctive charm to buildings' interiors.

However, steam heating also presented challenges. One of the primary concerns was heat loss during steam transportation through the extensive underground pipe network. Proper insulation became crucial to mitigate energy waste and ensure efficient heat distribution. Additionally, as the steam system aged, it became susceptible to leaks, and repairing the aging infrastructure posed logistical and financial hurdles.

1.3 Comparison with Other Heating Systems

Compared to forced air and electric heating systems, steam heating offered unique benefits. Forced air systems, prevalent in modern construction, tend to create drafts and circulate dust, potentially exacerbating respiratory issues. Steam heating's ability to deliver consistent warmth without air movement was preferred in many buildings. Electric heating, while convenient and clean, often proved less efficient and costlier, especially for larger buildings served by the steam system.

How Steam Heating Works in New York

2.1 Steam Generation in Centralized Plants

The heart of the New York City steam heating system lies in its centralized plants. These large facilities, situated strategically throughout the city, house powerful boilers that generate steam from various energy sources, including natural gas, oil, and coal. In recent years, efforts have been made to transition towards cleaner fuels and renewable energy options, aligning with the city's sustainability goals.

2.2 Distribution of Steam in Underground Pipes

Once steam is produced, it is conveyed through an extensive network of underground pipes, known as steam mains. These mains crisscross the city, providing steam to thousands of buildings. The pipes are insulated to minimize heat loss, maximizing the efficiency of the distribution process.

2.3 Steam Radiators and Heat Exchange

Upon reaching individual buildings, the steam is directed to steam radiators or heat exchangers, depending on the building's size and heating requirements. Steam radiators are common in residential buildings, where the steam enters the unit and releases its latent heat as it condenses back into water, effectively warming the surrounding air. Heat exchangers are prevalent in commercial and industrial settings, where the steam's heat is transferred to the building's air or water distribution systems.

2.4 Steam Traps and Venting

Steam traps are essential components of the steam heating system. They are designed to remove condensate, the water formed when steam cools down, from the system. Proper venting is equally crucial, as it releases air and non-condensable gases from the pipes, preventing air locks and ensuring efficient steam flow. Specialized venting devices, such as air vents and steam traps, are installed throughout the system to maintain its optimal performance.

New York City Steam Heating System

3.1 Overview of NYC Steam System

The New York City steam heating system stands as one of the largest and oldest in the world. The responsibility for its operation and maintenance lies with private utility companies, which have historically managed the network's intricate web of steam mains, radiators, and heat exchangers.

3.2 Steam Plants in New York City

New York City's steam plants are strategically located to serve the varying heating demands of different neighborhoods. These plants are equipped with modern boilers and state-of-the-art emission control technologies to reduce environmental impacts. Efforts to further improve air quality and sustainability are continuously underway.

3.3 Steam Distribution Network

The steam distribution network encompasses over 100 miles of steam mains, which interconnect and branch to supply steam to individual buildings. The network's design considers factors such as pressure requirements, building density, and historical demand patterns to ensure an efficient and consistent supply of heat throughout the city.

3.4 Maintenance and Upgrades of NYC Steam System

Maintaining such an extensive steam heating system requires regular inspections and maintenance. The aging infrastructure presents challenges, making ongoing upgrades essential to ensure the system's longevity and continued efficiency. Modernization efforts include replacing older pipes with more robust materials, improving insulation, and upgrading boiler technologies to enhance energy efficiency.

Heating Buildings with Steam

4.1 Steam Heating in Residential Buildings

Steam heating systems are a common sight in older residential buildings across New York City. The iconic steam radiators, often found beneath large windows, have become cherished architectural elements. Residents appreciate the steady and cozy heat these systems provide during the harsh winter months.

4.2 Steam Heating in Commercial and Industrial Buildings

Commercial and industrial buildings extensively utilize steam heating due to its ability to meet the substantial heating demands of such structures. Heat exchangers play a crucial role in these settings, where steam heat can be efficiently transferred to large air or water distribution systems, catering to diverse heating requirements.

4.3 Steam Heat vs. Forced Air: Considerations and Comparisons

In the perennial debate between steam heating and forced air systems, each has its merits. While steam heating boasts even heat distribution, quiet operation, and a lack of airborne dust circulation, forced-air systems can also provide air conditioning and ventilation, adding flexibility to building comfort. The choice between these heating methods depends on the specific needs and priorities of each building owner or occupant.

Efficiency and Sustainability of New York City Steam Heating

5.1 Assessing the Efficiency of Steam Systems

Efficiency is a critical aspect of the steam heating system, as it directly affects operating costs and environmental impacts. Regular assessments of individual steam systems and the overall distribution network are conducted to identify opportunities for improvement. Efforts are focused on reducing heat loss, optimizing boiler performance, and upgrading insulation to maximize energy efficiency.

5.2 Environmental Considerations and Emissions

Given the environmental challenges of fossil fuel-based energy sources, New York City is actively exploring ways to reduce emissions associated with steam heating. Increased reliance on cleaner fuels, as well as integration with renewable energy sources, is being pursued to lower the system's carbon footprint and align with the city's commitment to sustainability.

5.3 Energy-Saving Measures and Upgrades

To further enhance the efficiency and sustainability of the steam heating system, energy-saving measures and technological upgrades are continually implemented. These may include installing advanced control systems for better operational management, adopting waste heat recovery techniques, and exploring the integration of renewable energy into steam generation.

Operation and Maintenance of New York City Steam Heating Systems

6.1 Proper Operation and Control of Steam Systems

Operating steam heating systems requires skilled personnel who are well-versed in the complexities of steam distribution and radiator control. Proper monitoring and adjustments to steam pressure and temperature are essential to maintain efficient heat distribution and prevent energy wastage.

6.2 Common Issues and Troubleshooting

Despite rigorous maintenance practices, steam heating systems can encounter occasional issues, such as leaks in underground pipes, uneven heating in specific areas, or water hammer (the loud noise resulting from sudden condensate contact with steam). Timely detection and troubleshooting are vital to minimize disruptions and ensure a comfortable indoor environment.

6.3 Safety Considerations and Maintenance Practices

The safe operation of steam heating systems is paramount, considering the high temperatures and pressures involved. Regular safety inspections and adherence to strict maintenance protocols are essential to prevent accidents, protect occupants and workers, and maintain the integrity of the entire steam heating infrastructure.

Future Trends and Alternatives to New York City Steam Heating

7.1 Innovations in Steam Heating Technology

As technology continues to advance, innovations in steam heating are expected to improve the efficiency and sustainability of the system. These may include advancements in boiler design, better insulation materials, and smart technologies that optimize steam generation and distribution, ultimately enhancing overall system performance.

7.2 District Energy Systems and Combined Heat and Power

District energy systems, also known as district heating or cooling, involve the sharing of heat and cooling resources among neighboring buildings. Such systems can enhance the efficiency of energy use and reduce overall emissions by utilizing waste heat from one building to serve the needs of another. Similarly, Combined Heat and Power (CHP) systems integrate power generation with steam generation, maximizing the utilization of energy resources and reducing greenhouse gas emissions.

7.3 Exploration of Alternative Heating Methods

In pursuit of greater sustainability, New York City is exploring alternative heating methods that can complement or replace steam heating where feasible. Geothermal heating, solar thermal systems, and heat pumps are among the technologies under consideration. These systems harness renewable energy sources to provide heating, potentially reducing reliance on fossil fuels and contributing to a cleaner urban environment.

Conclusion

The New York City steam heating system has left an indelible mark on the city's history, revolutionizing how buildings are heated and providing comfort to millions of residents and workers. The network's robust infrastructure, combined with ongoing efforts to improve efficiency and sustainability, reflects the city's commitment to maintaining a reliable, efficient, and environmentally responsible heating system. As the future unfolds, advancements in technology and the exploration of alternative heating methods will further shape the destiny of steam heating in New York City, ensuring its relevance and resilience for generations to come.

#broadway#New York City#new york#newyork#New-York#nyc#ny#manhattan#urban#city#usa#buildings#visit-new-york.tumblr.com#New York City Steam

202 notes

·

View notes

Text

The right heating systems make a difference when it comes to keeping your house warm and comfortable. Of late, electric boilers are in trend as they offer excellent efficiency and install easily without causing any harm to the environment. This is a blog about the merits of an electric boiler and why you should select our Electric Boiler Installation Services in London.

0 notes

Text

The Ultimate Guide to Central Heating Installation in Egypt by Flyer Heat

Central heating has become an essential aspect of home comfort, especially in colder regions. In Egypt, where temperatures can drop significantly during winter, installing a central heating system can enhance comfort and energy efficiency. Flyer Heat, a leading name in heating solutions, offers top-tier central Central heating installation in Egypt services tailored to the unique needs of Egyptian homes.

Why Choose Central Heating in Egypt?

Although Egypt is known for its hot summers, the winter months can be quite chilly, particularly in northern regions. Many homes, especially in Cairo and other urban areas, are now considering central heating systems for consistent warmth and comfort. The benefits of central heating go beyond just warmth:

Even Distribution of Heat: Central heating ensures every room in the house receives an even amount of warmth, eliminating cold spots.

Energy Efficiency: Compared to portable heaters, central heating systems are more energy-efficient, helping homeowners save on energy bills in the long run.

Improved Air Quality: Central heating systems often come with filters that improve the air quality by reducing dust and allergens.

Why Flyer Heat is Your Go-To for Central Heating Installation

Flyer Heat stands out as one of Egypt’s premier providers of central heating solutions. Here’s why Flyer Heat is trusted by many Egyptian homeowners:

Expert Installation Services: Flyer Heat ensures a seamless installation process, conducted by highly trained professionals. The company understands the intricacies of installing central heating systems in Egyptian homes, where older infrastructure might present challenges.

Custom Solutions: Every home is different, and Flyer Heat provides custom heating solutions based on the size of the home, the climate, and the preferences of the homeowner. This approach ensures optimal performance and energy savings.

High-Quality Equipment: The company uses only the best quality heating equipment, ensuring durability and longevity. This is crucial in Egypt, where climate conditions can be harsh.

Post-Installation Support: Flyer Heat offers comprehensive after-sales services, including maintenance and repairs. This ensures that your central heating system remains efficient and reliable for years to come.

The Central Heating Installation Process by Flyer Heat

Understanding the installation process can help you make an informed decision. Here's how Flyer Heat handles the process, step by step:

Initial Consultation and Assessment: The process starts with a consultation to assess the home’s heating needs. Flyer Heat's experts visit the site to determine the most efficient system for your space, considering factors like room size, insulation, and budget.

Choosing the Right System: Based on the assessment, Flyer Heat recommends the most suitable central heating system. Whether you prefer gas, electric, or renewable energy sources, they offer a range of options to match your specific requirements.

Installation: Once the system is selected, Flyer Heat's team of professionals handles the installation. The process involves placing the boiler, installing radiators, and setting up the necessary piping and controls. The team ensures minimal disruption during the installation.

Testing and Commissioning: After installation, the system is thoroughly tested to ensure it functions optimally. This includes checking the heat distribution and ensuring that the controls are user-friendly.

After-Sales Support: Flyer Heat's job doesn't end with installation. They offer a comprehensive after-sales package, which includes regular maintenance, system upgrades, and emergency repairs.

Types of Central Heating Systems Flyer Heat Installs

Flyer Heat provides a variety of central heating systems, each suited to different needs and preferences:

Gas Boilers: A popular option in Egypt due to the availability of natural gas. Gas boilers are highly efficient and cost-effective.

Electric Boilers: For homes where natural gas isn’t available, electric boilers are an excellent alternative. They are easy to install and provide consistent heating.

Renewable Energy Heating Systems: Flyer Heat is also at the forefront of sustainable energy solutions, offering heating systems powered by solar energy. This is an eco-friendly option that aligns with Egypt’s growing focus on renewable energy sources.

0 notes

Text

Expert Plumbing and Electrical Services by Thames Tradesmen

When it comes to keeping your home or business running smoothly, finding reliable professionals is essential. At Thames Tradesmen, we are proud to offer a comprehensive range of plumbing, heating, and electrical services to meet the needs of residents and businesses in the Oxford area. With our expert team of Plumbers Oxford, heating contractors, and electricians, we are committed to delivering high-quality services tailored to your unique requirements. Whether you need an emergency plumber, a heating contractor near me, or a skilled electrician near me, Thames Tradesmen has the experience and expertise to handle any task with efficiency and professionalism.

Trusted Plumbing Services in Oxford

At Thames Tradesmen, we take pride in offering professional and reliable plumbing Oxford services to homeowners and businesses throughout the area. Our skilled plumbers Oxford are well-versed in all aspects of plumbing, from simple repairs to complex installations. Whether you’re dealing with a dripping tap, a clogged drain, or a major plumbing issue, we provide timely and efficient solutions to ensure your plumbing system is back in perfect working order.

Our team understands the importance of a fully functional plumbing system, and we are committed to addressing your plumbing concerns promptly and effectively. We use the latest tools and techniques to diagnose and resolve issues, providing long-term solutions that prevent future problems.

24/7 Emergency Plumbers Oxford

Plumbing emergencies don’t wait for a convenient time, and neither do we. Our team of emergency plumbers Oxford is available 24/7 to handle urgent plumbing situations, no matter the time of day or night. From burst pipes and severe leaks to overflowing toilets and water heater failures, we understand that these emergencies require immediate attention. That’s why we are always ready to respond quickly to your call and provide efficient, effective solutions to minimize damage and restore your plumbing system.

Our emergency plumbers are trained to handle all types of urgent plumbing issues with professionalism and care. We arrive promptly, assess the situation, and work to resolve the issue as swiftly as possible, ensuring your property is safe from further harm. Thames Tradesmen’s emergency plumbers Oxford are your trusted partners when disaster strikes, providing peace of mind when you need it most.

Your Local Heating Contractor Near Me

When the temperatures drop, having a reliable heating system is crucial to the comfort of your home or business. At Thames Tradesmen, we are proud to serve as your trusted heating contractor near me, offering a range of services to ensure your heating system is functioning optimally. From installation and maintenance to repairs and replacements, our experienced team has the knowledge and expertise to handle all aspects of your heating needs.

We work with a variety of heating systems, including boilers, radiators, and central heating systems, to provide solutions that meet your specific requirements. Whether you’re looking to upgrade to a more energy-efficient system, need routine maintenance to keep your system in top shape, or require urgent repairs, we are here to help. Our commitment to quality workmanship and customer satisfaction means that you can rely on us for all your heating needs.

Professional Electricians Near Me

In addition to our expert plumbing and heating services, Thames Tradesmen also offers skilled electrical services to homeowners and businesses throughout Oxford. Finding a reliable electrician near me is essential for ensuring the safety and functionality of your electrical systems. Our team of certified electricians provides a wide range of services, from electrical installations and repairs to routine maintenance and emergency services.

Whether you need to upgrade your home’s wiring, install new lighting, or troubleshoot electrical issues, our electricians are equipped to handle it all. We adhere to strict safety standards and regulations, ensuring that all electrical work is completed to the highest industry standards. When you choose Thames Tradesmen, you can trust that our electricians will provide reliable, safe, and efficient services that meet your needs

Contact Thames Tradesmen Today

If you’re looking for reliable plumbers Oxford, a heating contractor near me, or an electrician near me, look no further than Thames Tradesmen. Contact us today to schedule an appointment or to learn more about our services. We’re here to provide the expert solutions you need to keep your home or business running smoothly.

0 notes