#epe foam box making machine

Text

GREENMAX foam compactor A-C200 makes recycling seafood boxes easy and efficient. The advanced foam recycling machine converts EPS foam waste into reusable material, reducing storage costs and supporting eco-friendly practices. Learn more about how the A-C200 can transform waste management for seafood processors and distributors.、

0 notes

Text

Recycling EPS salmon boxes and ocean buoys is a current project on the Australian island of Tasmania.

The fishery produces a large amount of EPS waste as well. Regardless of the nation, it is one of the primary sources of EPS waste. In Tasmania, Australia, one of GREENMAX's clients works in the fishing industry. During the procedure, it will produce Salmon boxes made of garbage are abundant, and a lot of EPS buoys are required in the water to aid in the spawning process. But since using ocean buoys has been prohibited in this location for some time, not only is this item's terminal use necessary, but it also helps recycle EPS buoys and fish boxes that were previously manufactured.

Following an understanding of the customer's needs and challenges, GREENAMX suggested that the customer recycle using a hot melt machine in conjunction with a water cooling system. Hot melt technique can be used to recycle EPS wastes that have a low water content since the buoys were recovered from the sea and placed on the shore for an extended period of time.

Utilizing an EPS densifier in conjunction with a water cooling system makes recycling EPS more effective.

Out of all the GREENMAX recycling equipment with a compression function, the EPS densifier has the highest compression ratio, up to a maximum of 90:1. It is mostly utilized to increase recycling automation in tandem with the water cooling system. Removing the extruded, semi-melted state is the primary goal of the water cooling system. After being broken up into tiny bits, the EPS foam falls into the sink. The EPS hot melt swiftly cools and is transferred to the collecting device to enable automatic bagging with a push of water flow. Additionally, this optimizes the automation of recycling EPS.

Please get in touch with GREENMAX at any moment if you work in the fishing industry and need to recycle EPS waste. We will walk you through the EPS densifier recycling process in detail.

0 notes

Video

youtube

EPS Foam Fish Box Making Machine, EPS Styrofoam Box Production Line

0 notes

Text

Top 5 Materials Used in Packaging Fitments

When you are designing a box, it’s equally important to look at the inner packaging fitments. These inserts or “things that go inside the box” are just as crucial as the outer box design. While the outer box packaging makes the solid first impression, it’s inner fitments are shouldering the responsibility for delivering the inside good with stability and security. They are ones which create a long lasting impact!

The quality of materials used in the fitments is the key differentiating factor in box quality. Poor choice of fitments can result in damaged products and flimsy boxes. Are you wondering, “What material should I use for the next box I need for my corporate event?”

We’ve got you! We have put together a list of the top five materials for inner packaging fitments. These materials have been rated on four key parameters:

Sustainability

Pricing

Strength

Customization

Let’s begin, shall we?

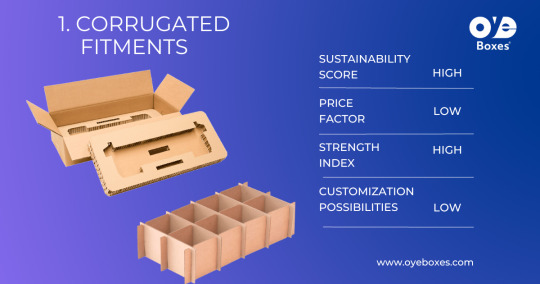

1. Corrugated Fitments:

Corrugated Fitments are the most commonly used materials in manufacturing of fitments and inserts. Depending on the use case, either 3 ply or 5 ply fitment sheets are used. Corrugated fitments are made of recycled materials and score high in terms of sustainability. They are usually 30% less expensive as compared to other materials, however you may have to buy them in larger quantities.

Corrugated fitments, inserts, and dividers provide a lot of sturdiness to the contents and can withstand rough transportation as well. They are ideal for products such as glass jars, machine parts, etc.

They have their limitations with respect to colour availability, however they can be offset printed for larger quantities or digitally printed for shorter quantities.

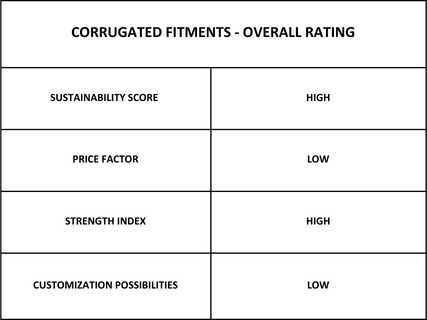

Here’s the rating chart for Corrugated fitments.

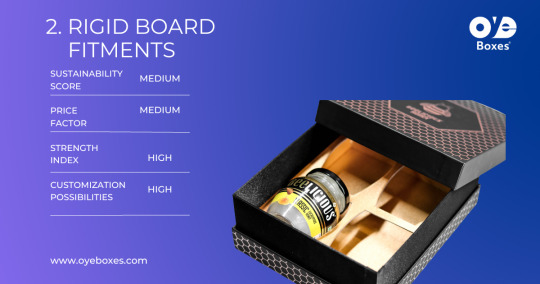

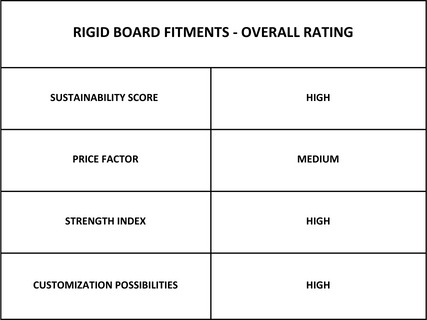

2. Rigid Board Fitments:

Rigid board fitments are an extremely popular choice when manufacturing fitments for packaging. Rigid fitments are frequently used in packaging for cosmetics, FMCG, jewelry, and other luxury items. Many times they are also used in conjunction with XLPE or EPE foam fitments.

Rigid board, commonly known in India as Putha Board, is made of recycled pulp and scores high in the sustainability index.

The price of rigid board fitments is slightly higher that of corrugated sheets. However, the strength and stability they provide is worth the higher price point. If we choose the appropriate thickness of board for making the fitments, then a very superior level of strength and stability can be achieved in the packaging.

The best part about rigid board fitments is that they are completely customizable. Any type of printed or colour sheets can be pasted on top of these rigid fitments.

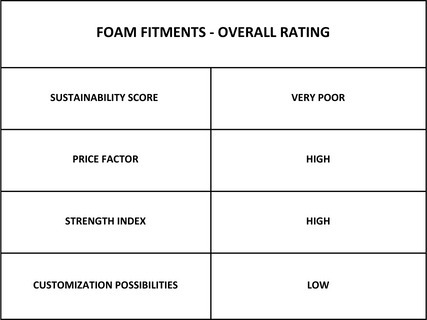

3. Foam Fitments :

Foam based fitments are widely used in packaging of glass, machine tools, and other high-value items. Currently, two of the most commonly available foam fitments are —- XLPE foam or EPE foam.

As expected, they don’t score well on the sustainability scale. They are harmful to the environment since they are non-biodegradable. But, they are the most sturdy and safe fitment option out there.

And, since they are the most sturdy option available in the market, their price is always on the higher side. We would like to highlight that XLPE foam fitments are 40% more expensive than EPE foam fitments.

Lastly, the customisation of these fitments is very expensive. They generally are available in few colour options – white, black, pink and blue. In order to customise them further, they need a layer of paper or paperboard on top of them.

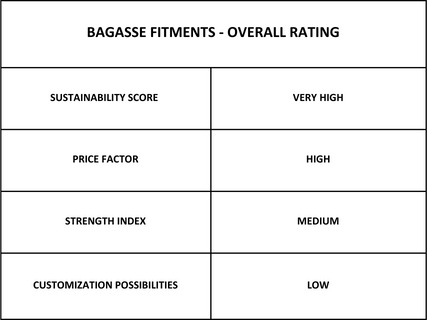

4. Bagasse Fitments

Bagasse is a dry fibrous residue that is generated after extraction of sugar from sugarcane. Nowadays, Bagasse is being used extensively in the making paper moulded fitments and dividers for various packaging applications.

You might be aware of bagasse plates and other recyclable cutlery that are widely used today. Bagasse fitments or inserts are slowly starting to trend in the packaging industry as well.

Bagasse is probably the most eco-friendly material amongst the entire list of fitments mentioned here. It is 100% recyclable. However, the costs associated with making a bagasse mould and then manufacturing these fitments is on the higher end when compared to other paper-based or plastic fitments.

Customization of colours in bagasse fitments is extremely difficult and require extremely large quantities to justify the expense. From a durability standpoint, bagasse fitments are sturdy enough to withstand pressure, however not as strong when compared to foam or rigid board fitments.

5. Paper Fitments :

Paper or paperboard fitments are the most pocket friendly fitment option (Probably 25% cheaper than rigid board). These are easy to source and manufacture. Paper fitments are generally made of recycled paper. But, it’s important to remember that they do not provide as much stability as other material options.

The parameter where paper fitments beats the competition is customization. All sorts of customizations are possible with paper fitments, including offset printing, digital printing, foiling, and embossing. So if you are looking for something really unique and tailored to your brand, then paper fitments might be your best bet.

#rigidboxpackaging#rigidboxpackagingfitments#packagingfitments#boxpackaging#CorrugatedFitments#RigidBoardFitments#FoamFitments#BagasseFitments#PaperFitments#luxuryboxpackaging

0 notes

Video

Veinas EPE Foam Box-Making / Framing Machine, Heating Plate, Laminating/Lamination Machine,Laminator

Founded in 2013 in beautiful coastal city-Guangdong Huasu Intelligent Equipment Technology Co., Ltd., previously Zhuhai Huasu Automation Machinery Equipment Co.,Ltd. (VEINAS) is the hi-tech enterprise devoting into the R&D and production of EPE deep-processing automation equipment and plastic machinery. Covering an area of nearly 28000 square meters, Huasu owns independent R&D team, three main workshops and perfect sales and after-sales service system.(contact Jessie: +86 13417787468)

#epe foam box making machine#epe foam hotplate#epe foam framing machine#epe foam laminating machine#epe foam lamination#epe laminator#veinas machinery#huasu automation#expanded polyethylene foam machine

1 note

·

View note

Text

The aid of a polystyrene compactor is essential to increasing the rate of polystyrene recycling.

How well-versed are you in recycling polystyrene? In actuality, recycling polystyrene is not an easy process. There are numerous techniques to recycle polystyrene and complex industries associated with it. The idea that polystyrene can and should be recycled has, thankfully, gained acceptance. The general public is aware of its popularity. According to the Alliance for Foam Packaging Recycling, the polystyrene sector claims a recycling rate of roughly 12%, although this figure includes leftovers from the production of expanded polystyrene, which are right away repurposed.

What exactly is instant recycling? As an illustration, there will be a lot of clean polystyrene scraps created throughout the production and cutting of polystyrene. Usually, these wastes can be directly reused without any further processing, for example, by creating polystyrene packaging for peanuts. These polystyrene materials are employed in a variety of applications, such as furniture packing, EPS fish boxes, etc., and subsequently recycled. This process is known as immediate recycling, despite what we would say. This demonstrates the need for us to keep an eye on polystyrene recycling.

Despite the fact that recycling polystyrene is more difficult than creating new materials, we should focus on resource recycling and sustainable development. In recent years, polystyrene recycling has become easy and affordable with the aid of polystyrene compactors. By lowering the amount of expanded polystyrene, the GREENMAX polystyrene compactor makes polystyrene recycling practical. As much as we can, we want to recycle polystyrene without incurring unnecessary fees. The true development of polystyrene recycling can only be accomplished in this manner.

The polystyrene compactor reduces trash volume to 1/50 of the initial volume. The polystyrene recycling machine from Intco comes in a variety of designs. The device using the cold pressing process is seen above. We also have hydraulic and hot melt technology. Assisted equipment, please inquire!

0 notes

Text

In daily life,how to Recycle EPS in

EPS is the abbreviation of "Expanded Polystyrene" in English. The Chinese name is expanded polystyrene, commonly known as "foam" or "foam". It is a white foamed plastic. After taking the mold into a block, the volume is 50 times the original, which contains 95-98% air and 2-5% pure polystyrene. Small particle foam can be used to make plastic cups and small containers, medium particle foam can be used to make packaging bags, and large particle foam is used in bulk packaging materials. The main characteristics of this substance are: insulation, light weight and water resistance.

First, collect waste EPS foam

Second, transport the waste foam to the GREENMAX EPS recycling machine.

Then the EPS foam blocks are shredded, compressed into blocks, smashed, and then melted and extruded into a plastic extruder for granulation.

The last thing that comes out is the regenerated PS particles

These plastic particles can be used to produce drying racks and CD boxes, etc.

0 notes

Text

China CNC cnc eps foam cutting machine For Sale

cnc eps foam cutting machine adopt integrated casting machine body by well heat treated, which makes machine more stable, rigid, endurable. Adopting Imported high-precision ball screw and Taiwan HIWIN linear square rails, which ensure the machining precision. Especially with a wider travel distance, which is designed for large scale production and suitable for EPS, casting wood mold, engineering plastics and other non-metal material mold.

IGOLDENCNC cnc eps foam cutting machine with many optional configuration and service available. According to your requirement, different configurations of foam carving machine will be offered. For example, the Z axis can be heighten, and the whole working size also can be customized. To learn more about our EPS/Foam CNC Router,

This cnc eps foam cutting machine with the function of linear automatic tool changer, it makes the whole processing more time-saving and more efficient. And it is ideal for high-volume users.

📷

Features of cnc eps foam cutting machine:

— The aluminum frame connected by specialized fastenings creates stable performance and precise cutting.

— Equipped with stepping motor, suited to cut the specially designed figures with the requirement of adjustable speeds. The cutting precision can be 0.3-0.5mm.

— Equipped with 3KW transformer and adjustable power the output ranges from 0 to 70V under electrical control.

— 20 pcs of cutting wires can be set at one time, which increase the production capability.

— The function of cutting stroke protection: when the machine the regulated cutting stroke, the

machine will stop running automatically.

— With 17” Screen and branded computer, the machine records and reflects the design & cutting.

All software for drawings and cutting are available in English version.

— It is easy to understand and operate. The cutting software has powerful functions, such as

automatic memory system while power shut-off, reverse and rotating cutting. Mirror symmetry

cutting, automatic clearance compensation system. Which answers accurate and convenient

cutting.

— The rotation platform is optional, achieving 5 axis cutting.

Attention for cnc eps foam cutting machine:

1.EPS block should be dried before cutting to increase efficiency and avoid damage of hot wires;

2.Check cutting machine before operation to ensure reliability of ground connection, correct running direction of main cutter, air blower and limit switch;

3.Strictly prevent foam beads and cutting fragments entering into the electric system to avoid conflagration because this equipment is a strong electric current working system;

4.Maintenance and attention points of variable-speed gear box.

5.Replace lubricating oil in gear box every half a year.

6.Keep enough lubrication oil in oil tank and check it regularly;

7.Pay attention to running condition of whole equipment during its working, Stop to check when there is any unusual situation.

8.Notice: Do not whack the gear box.

9.Fire Extinguisher must be prepared at working site and operator should monitor the machine during operation;

10.Operators is allowed to operate after training.

Advantage of cnc eps foam cutting machine:

1. Accurate – orientation system , the cutting error is less than 1mm, cutting speed to 100mm/s.

2. Unique numerical control program system with patent.

The program can make the machine run without computer, reach one computer control many machines at the same time. (But for common foam CNC cutting, one computer can only control one cutting machine.)

3. Even if the computer failure, the machine can run out of computer.

4. Use Industrial Energy-saving stabilized voltage power source, save energy 80%, the cutting is more uniform and stable.

With current and voltage digital display, isolation with indoor electric, avoid the risk of electric shock.

5. Use timing belt and ball screw as guide rail, it makes the cutting more precise.

BAR CODE SCANNING

convenient workflow enhancement to save time and cut down on human errors

save you current job (drawings and configuration parameters) to a pdf file with a unique custom barcode

print out the pdf and scan the barcode to easily re-open all drawings and configuration settings associated with it

built-in barcode manager with unlimited number of sets/pdfs

simple plug'n'play solution with iXshaper support built-in requiring no special drivers

requires an additional free USB port on your PC (apart from the one used to connect the machine to)

INDEPENDENT AXIS CONTROL

📷

0 notes

Text

What is EPS Shape Moulding Machine and How does it work

EPS Machine system adopts multiple heating method, adopts solid and shifting balance valve system, control instrument and control valve parts to complete the cycle, thus making the machine more steam saving. The unstable factors of product quality caused by unstable steam source are solved and the quality is greatly improved. Steam and cooling water valves are imported components, safe operation, stable performance, foam molding machine can operate 2-3 machines.

The working principle of foam molding machine is similar to the principle of syringe, it is by virtue of the thrust of screw, the plastic has been plasticized into the molten state of injection into the mold cavity, after curing and shaping the product process.Injection molding is a cyclic process, one cycle mainly includes: quantitative feeding – melt plasticizing – pressure injection – mold cooling – mold opening and taking. After the product is taken out, the mold is closed again for the next cycle.

EPS Shape Molding Machine can change different Mould to produce different foam products, EPS Mould can be customized, the most common foam vegetable boxes, foam fish boxes, seedling trays, ICF Blocks and So on.

We have recently begun to manufacture a series of machinery and equipment for EPS Mould facilities that require high multi-fold expansion capabilities.

EPS Raw Material Project is the first pre-expanding machine to produce EPS beads with a density of 16-20g/l and a capacity of 1,500-2,000kg/h. The main purpose of this multi-expansion design is to have a secondary expansion capacity of 120/150m3/h.

The heating coil type fluidized bed dryer is made of stainless steel. In addition, the steam surface of the all stainless steel steam container is a wedge-shaped line. The machine is fully automatic. PLC with touch screen and Mitsubishi trademark as an automatic control partner is optional. It is equipped with a vibration sensor and an automatic density control unit.

We manufacture various types of block and shape forming EPS processing machinery and equipment, such as vertical block forming machines, automatic cutting lines, and forming machines.

Expandable polystyrene (EPS) and other industrial Styrofoam are 98% air which makes them very bulky in comparison to their weight. Because of the high volume, products made with these materials fill dumpsters quickly, leading to much higher waste disposal costs.

Foam Compactors reduce the volume of EPS, and in turn, fewer fees are incurred in the process. Also, a benefit, compacted foam products and industrial Styrofoam can be shipped economically to a recycling center. Compacting foam plastics can save thousands in unnecessary waste disposal costs!

EPS Recycling Machine can benefit a wide variety of markets. Here are some examples of businesses that can benefit from it.

Manufacturers

Furniture Stores

Appliance Stores

Food/Seafood Companies

Property Management Agencies

Retailers

Schools/School Districts

Stadiums and Parks

Expandable Plastic Recycling Programs

TODAY, THE DEMAND FOR EPS RECYCLING IS GROWING EVEN STRONGER

Waste reduction is a priority for many companies and communities as the impact of consumer waste has become much more evident. Recycling initiatives have been rolled out across many industries. Now, you can find recycling programs for paper, aluminum, plastic bottles, EPS and industrial Styrofoam waste.

RECYCLED EPS MATERIALS ARE RICH IN VALUE

Companies value recycled materials because they can be used to make a wide range of products. Recycled EPS is used to make items like picture frames, plastic lumber and packaging. Companies are now paying substantial amounts of money for recycled polystyrene as it is valued more than some metals, glass, paper and other recyclables.

0 notes

Text

Banning foam is not the only solution!

Can you imagine a world without foam? There are many general categories of foam, such as EPS XPS EPE EPP. The application is also extremely wide. If there is no foam like EPS, we may no longer be able to enjoy fresh salmon. The EPS fish box has the function of heat preservation, insurance and anti-collision during the transportation of fish. At the same time, it prevents the overflow of fish blood and water and maintains hygiene. If there is no XPS, we will not be able to enjoy the warmth of the house. It is well known that the thermal insulation device in the wall is made of XPS thermal insulation board and cement. The two kinds of foam, EPP and EPE belong to the two types with strong toughness and hardness. Without the foam, our lives will be very inconvenient, so why are there so many people calling for the ban on the use of foam? This is because foam has become a major source of pollution due to poor handling.

In order to continue to use this material and at the same time protect the environment, GREENMAX manufactures many kinds of Styrofoam recycling equipments for foam recycling. Two of the most popular are foam densifier and foam compactor. The foam densifier generates heat during the working process, which can heat the foam into a gel and then extrude it. This machine is almost suitable for processing all kinds of foam, especially the EPE EPP with high elasticity and high hardness. The compression ratio is 90:1. The foam compactor is used for recycling foam. No heat is generated in the process of using the screw to compress the foam, which is more suitable for processing foam such as EPS XPS. The compression ratio is 50:1.

GREENMAX is committed to helping you close the recycling loop. We purchase compressed polystyrene to make environmentally friendly frame strips to help you completely solve waste foam.

0 notes

Text

cnc rotary table 4th axis cnc router 4th axis rotary table for cnc

What is a rotary axis cnc router?

Most CNC routers have at least three axes which determine the direction in which the tools and workpieces can move during the manufacturing process. A rotary axis cnc router is simply a machine that has an additional rotational axis to provide more efficient and versatile machining.

📷

Features of rotary axis cnc router for Drilling Engraving Foam/EPS Mould:

Multifunctional (with flat table and big rotary device):

1. Engrave flat materials.

2. Engrave column materials, rotary cnc foam cutting, rotary mould making.

3. Engrave and cut soft materials: foam, MDF, EPS, PVC, wood, acrylic, etc.

4. Engrave and cut hard materials: stone, marble, granite.

5. With low table, the Z axis working space up to 1000mm, could stand heavy materials.

6. 4 axis system could engrave complex sculptures, 3D carving.

7. Auto tool changer spindle, save time when change cutters.

9. Italy HSD 9KW Air cooling spindle, auto tool change, powerful and long cutters can be hold.

10. Japan Yaskawa high Power Servo motors and drivers.

rotary axis cnc router Transcript:

• Manually move the bit of the knife so that it is close to the live center on the tailstock.

• Push the tailstock gently to the router bit.

• Move the tip of the knife very slowly to bring it close to the central spike, and stop when the end touches the spike

• Use the combination key ON/OFF + C- to clear the coordinates of the Z-axis. Then use the combination key ON/OFF + C+ to clear the coordinates of the X-axis.

• Press Z+ to raise the tool.

• Push the tailstock toward the workpiece; tighten the bolts to keep the tailstock in place.

• Use the rotation wheel to make the spikes hold the workpiece, and then lock the thimble.

• Press the C+ key to turn the square wood to level on the rotary table.

• Manually move the tool to a suitable position.

• Use the key combination ON/OFF + C+ to clear the coordinates of the Y-axis.

• Now, we have completed the setting of the workpiece origin. The coordinates of the four motion axes X/Y/Z/A on the controller are all zero.

• Press the RUN key to enter the file list; then move the cursor to the desired file and press the OK key. The working parameter setting dialog box appears.

• Set appropriate processing parameters(press DELETE key to set the value)

• After setting the parameters, press the OK button, the system checks the code, and then

rotary axis cnc router applications:

Woodworking industry: door, furniture, loudspeaker boxes, musical instruments, etc.

Advertising industry: 3D billboards, signage, medals, badges, traffic signs, letter punches, logos, etc.

Model industry: various 3D models, landscape models, exhibition models, architecture models, car models, etc.

Sculpture: human sculptures, character sculptures, fauna and flora sculptures, etc.

Film industry: movie props, activity props, etc.

Other industries: cutting and curving the 3D surface and outline of gift wrapping, tabletops, sports equipment, wood products, etc.

0 notes

Text

EPE Foam Punching Machine

Features of EPE Foam Punching Machine

1.EPE foam cutting machine is special design for buyer to cut EPE foam sheet / Air bubble film more efficiently.

2.This punching machine is special design for cutting EPE foam sheet and in-line hole punching on same machine.

3.For small dia. of hole, like 8 mm hole. We can punch the holes and remove the holes fully automatically. For the numerous of waste, MING JILEE design the vacuum system to collect all the waste. It is very easy to collect the waste by collecting 1 bag.

4.Machine is equipped auto conveyor to get very good stacking result on the finished product. The operator can take the stack sheet to next process for tying or put in the carton box.

5.We offer the optional punch equipment for the cold pin stacking. If the buyer need to cut long sheet and request to get good stacking for the long sheet, then they can choose this additional solution.

1. The EPE Foam punching machine is used to full cut or half cut various non-metallic sheet materials with forming knives.It is suitable for the industries such as plastic, EPE packing, rubber, printing, etc.

2.Foam punching machine adopts PLC control system. It is easy to operate, fast and accurate. Besides, it can store multiple datas according to the shape of the die needed for the work. When changing the die, there is no need to re-set it.

3. Foam punching machine main machine adopts double oil cylinder, double crank connecting rod balance, four-post precision guide mechanism, the cutting depth of each position is exactly the same.

4. When the pressure plate is pressed down, it will automatically slow down when the distance between the pressure plate and the cutter is only 10mm, the cutter is turned to flexible cutting so that there is no dimensional error between the upper layer and the lower layer.

5. The central oil supply automatic lubrication system improves the service life and accuracy of the machine.

6. It can be equipped with a unilateral or bilateral automatic feeding system to improve the production efficiency of the whole machine.

7.It can be equipped with micro-moving device for cutting board to make the cutting board consume evenly and save cost.

8. It can be equipped with pneumatic clamping device for knife mold, which is convenient and fast for changing the knife mold.

9. It is equipped with a knife holder to fix the knife mold, it is easy to disassemble and replace.

10. The cutting area has safety grating protection device (CE standard) to ensure safe operation.

11. The EPE Foam punching machine adopts high-pressure electrostatic spraying instead of manual painting so the surface is better. Besides, it adopts secondary processing to avoid deformation.

12. It adopts electrical appliances made in Janpan and Taiwan and imported hydraulic system which saves electricity, has low noise, simple operation and has higher work efficiency.

13. Foam punching machine Optional parts:

A. Unilateral and bilateral automatic feeding system

B. Micro-movement device of cutting board;

C. Pneumatic clamping device for knife mold.

0 notes

Text

How does an EPS densifier work while processing waste EPS foam?

The popular EPS recycling machine on the market are commonly two types, one is EPS compactor, the cold compress machine is safe and pollution-free, and the other is EPS densifier, which is efficient and easy to operate. Both of the two types of machines aim at foam volume reduction and making loose foam into dense ingots, among which EPS foam densifier is more popular. So, how does the EPS densifier work?

Crush loose EPS foam into pieces

The first step for EPS foam volume reduction is crushing. EPS densifier is usually equipped with a crusher, you need to put the loose EPS foam boxes into the crusher hopper, the equipment will crush the loose and bulky foam into small pieces, which is more convenient for the next step.

Melt foam scraps with heat

The crushed foam scraps will fall into the screw heating chamber. When the EPS gradually accumulates, the motor will quickly heat up to melt the foam. The feeding speed during the melting process needs to be controlled at a stable frequency, too fast or too slow will cause the material to block the equipment.

Extrude foam ingots out after melting

With the accumulation of foam scraps, the melted foam waste can be continuously and slowly extruded under the push of the screw. The hot melt foam ingots that have just come out may not be shaped well. If the material is continuously fed for a period of time, the melted foam ingots will become smooth and in high quality. You can put a tray at the discharge port to fix the hot melt into dense blocks.

GREENMAX EPS densifiers are used to compact loose foam products into dense blocks for easier transportation or storage before recycling. The traditional baler can be used to compact the foam, but the effect is not so good. A 48-foot truck of bale foam weighs about 16,000 pounds, while a truck of dense foam weighs 40,000 pounds. The efficiency of the EPS densifier is not only more than 2 times, and the compressed material can also be sold, thus creating a great economic benefits.

0 notes

Text

GREENMAX Polystyrene Compactor helps Australian Supermarkets Recycle Waste Polystyrene Packaging

According to The Daily News, the pressure is now mounting on Australia’s supermarkets to drastically reduce the amount of environmentally toxic plastic packaging such as polystyrene on their shelves.

Plastic packaging is often considered as a blessing for supermarkets since it can be deployed to protect food, preserve freshness, and prevent spoilage and waste. For example, lots of fruit and vegetables are packed with polystyrene boxes to protect from being damaged and maintain one temp to keep them fresh before reaching residents’ kitchens. However, these polystyrene boxes are often thrown away within minutes of use, yet they can persist in the environment for 1,000 years.

Can these polystyrene boxes discarded be recycled or reused? The answer is “Yes”, but there is still far to go.

Polystyrene is considered not to be recycled

In many people's minds, polystyrene cannot be recycled, like most disposable plastic waste. If you know the fact that polystyrene is composed of 98% air, and these air can be compressed out, you may have a different opinion. When the air in the waste polystyrene is squeezed out, they will become dense objects that are as hard as rocks and can be used to make new products. Acknowledging that polystyrene waste can be recycled is the first step in the reasonable and effective recycling of polystyrene.

Polystyrene packaging waste is not accepted

Even if it is known that polystyrene waste can be recycled, it is still not accepted in some local recycling centers or roadside recycling points in Australia. Because of its bulky volume and lightweight, polystyrene waste is often refused since large storage space will be occupied and high transportation costs will generate, while it needs to be placed in designated places and undergoes special treatment before it can be recycled.

Professional Polystyrene Recycling Machine is needed

Some local councils or specialized polystyrene recycling facilities in Australia are usually equipped with specialized polystyrene recycling machines. At present, the main working principle of the recycling machine on the market is to exhaust the air in the waste polystyrene through extrusion or hot melt, greatly reducing its volume. For example, the GREENMAX Polystyrene Compactor, manufactured by INTCO Recycling, the leading provider of renewable polystyrene foam (EPS) solutions in Australia, is welcomed by local councils, such as Muswellbrook Shire Council, East Gippsland Shire Council, Albury City Council, etc.

The GREENMAX Polystyrene Compactor Apolo Series can compact polystyrene waste into dense and uniform blocks with a volume reduction ratio of 50:1, greatly reducing the volume and saving storage and transportation costs. Meanwhile, the compressed polystyrene block can be processed into various exquisite wall decoration products with INTCO Recycling’s expertise. This matches for the circular economy and sustainability sense in many countries, as well as improved polystyrene recycling efficiency while reducing costs, saving a lot of forest resources, and protecting nature surroundings.

With the promulgation of Australia's plastic restriction order, more and more supermarkets have joined the activities of reducing and recycling polystyrene packaging, such as the Melbourne Market. If you have a need in effective recycling of polystyrene, Get Your Customized Recycling Solution Now.

0 notes

Video

EPE Foam Box-making Machine,Heating Plate Machine,Framing Machine,Lamina...

Place EPE on both sides of direction to jig, after heating of vertical hot plate, horizontally move via jig from one side of EPE to vertical plate, when vertical hot plate drops, quickly laminate with opposite side, to complete box-making.

#EPE Foam Box-making Machine#hot plate#heating plate#epe framing machine#lamination machine#laminating machine#foam laminator#protective foam equipment#guangdong huasu#zhuhai huasu

0 notes