#flatwashers

Explore tagged Tumblr posts

Text

Plain Washers

DIC Fasteners is a Brand of Dedicated Impex Co. DIC Fasteners is a Supplier of Flat Washers, placed under the head of a bolt or nut to provide a smooth bearing surface and distribute the fastener load over a wide area.

0 notes

Text

Washer Manufacturer | F436 Fasteners: Complete Guide for Manufacturers, Suppliers, and Buyers

In the world of fastening solutions, washers play a crucial role in ensuring the stability, longevity, and integrity of assemblies. These small but essential components distribute load, prevent loosening, and protect surfaces from damage. From industrial machinery to household appliances, washers are indispensable.

Introduction to Washers

Washers are thin plates (typically disk-shaped) with a hole in the middle that is used to distribute the load of a threaded fastener, such as a bolt or nut. They serve multiple functions:

Load Distribution: Preventing localized stress on surfaces.

Vibration Absorption: Minimizing loosening due to vibrations.

Sealing: Preventing leakage in fluid systems.

Spacing: Adjusting the gap between components.

Depending on the application, washers can be made from various materials, including mild steel (MS), stainless steel (SS), brass, copper, and high-nickel alloys.

Introduction to F436 Washer

F436 fasteners primarily consist of hardened steel washers manufactured in accordance with the ASTM F436 specification. These fasteners are designed to be used with structural bolts, nuts, and assemblies, particularly in high-strength structural connections. The ASTM F436 standard ensures the washers are capable of handling the heavy loads and environmental conditions encountered in structural steel construction, bridges, towers, buildings, and other critical infrastructure.

The unique properties of F436 fasteners, especially washers, include excellent hardness, strength, and resistance to deformation under load, making them an essential component in high-strength bolted connections.

What are ASTM F436 Washers?

ASTM F436 is a standard that defines the chemical, mechanical, and dimensional specifications for hardened steel washers designed for use with:

ASTM A325 (now ASTM F3125) structural bolts

ASTM A490 (now ASTM F3125) structural bolts

Other high-strength bolted assemblies

They are typically flat washers that help distribute the load evenly and protect the mating surfaces from damage due to tightening torque and dynamic loads.

Types of F436 Fasteners

While ASTM F436 specifically covers washers, many people often refer to "F436 fasteners" to describe the broader assembly they're part of. Below are common F436 fastener components:

1. F436 Hardened Washers

F436 Type 1: Hardened washers manufactured from standard carbon steel, providing high strength and durability.

F436 Type 3: Hardened washers produced from weathering steel, offering superior corrosion resistance, ideal for outdoor and exposed applications.

Coated F436 Washers: Including zinc-plated, hot-dip galvanized, mechanical galvanized, and others for corrosion protection.

2. F436 Assembly Components

Though technically not part of ASTM F436, these are typically used with F436 washers:

Structural Bolts (ASTM F3125 A325 or A490)

Heavy Hex Nuts (ASTM A563)

Tension Control Bolts

Anchor Bolts

Applications of F436 Fasteners

F436 washers and associated fasteners are widely used in industries that demand strong, durable, and reliable connections, such as:

Structural Steel Construction

Bridges

Transmission Towers

Wind Turbines

Cranes

Offshore Platforms

Skyscrapers

Infrastructure Projects

Their high hardness prevents embedding and deformation when high-strength bolts are tightened to the required pretension levels.

ASTM F436 Material Specifications

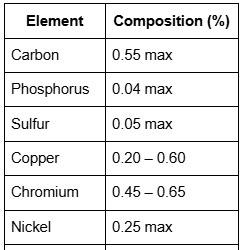

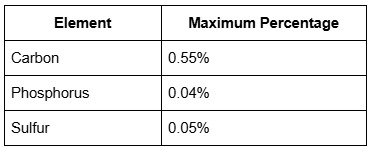

Chemical Composition (Type 1 - Carbon Steel)

Chemical Composition (Type 3 - Weathering Steel)

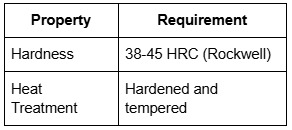

Mechanical Properties

This high hardness ensures the washers will not deform under high clamping forces.

Coating Options for F436 Washers

To improve corrosion resistance, particularly in outdoor or marine conditions, ASTM F436 washers can be supplied with a variety of protective coatings:

Hot-Dip Galvanizing (HDG)

Mechanical Galvanizing

Zinc Electroplating

Geomet® or Delta Protekt® coatings

Phosphate and Oil Coating

Note: Coating thickness and method must meet the requirements to ensure proper fit and function in bolted assemblies.

Advantages of F436 Fasteners

High Hardness: Resists embedment and helps maintain preload during tightening and operation.

Excellent Load Distribution: Protects mating surfaces during tightening.

Durability: Withstands severe loading and vibration conditions.

Corrosion Resistance: Especially for Type 3 and coated variants.

Compliance with International Standards: Ensures global application across industries.

ASTM F436 vs. Other Washer Standards

Why Choose Ananka Fasteners for F436 Fasteners?

As a leading manufacturer, stockist, and exporter of high-strength structural fasteners, Ananka Fasteners offers:

In-House Production: Equipped with state-of-the-art CNC machines and advanced forging capabilities.

Quality Control: ISO-certified manufacturing processes with rigorous quality checks at every stage.

Customized Solutions: Fully customized washer manufacturing as per client drawings and specifications.

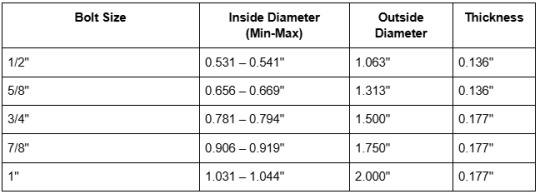

Sizes and Dimensions Chart (Sample)

Inspection and Testing for F436 Fasteners

To ensure quality and compliance, F436 washers undergo rigorous testing:

Hardness Testing (Rockwell HRC)

Dimensional Inspection

Coating Thickness Testing

Chemical Analysis (Spectrometer)

Heat Treatment Verification

Visual Inspection

Frequently Asked Questions (FAQ)

Q1. Can F436 washers be reused?Generally not recommended in structural applications as hardness may be affected after the first installation.

Q2. Are F436 washers compatible with galvanized bolts?Yes. F436 washers are often hot-dip galvanized to match the coating of structural bolts.

Q3. Where are ASTM F436 fasteners commonly used?Bridges, buildings, steel structures, towers, heavy industrial equipment.

Q4. Do you offer third-party inspection (TPI)?Yes. Ananka Fasteners offers TPI services from agencies like BV, SGS, TUV, Lloyd’s, etc.

Conclusion

ASTM F436 fasteners, especially washers, play a crucial role in ensuring the integrity, safety, and long-term durability of structural connections. Their high hardness, precise dimensions, and corrosion-resistant options make them indispensable for structural steel projects worldwide.

Whether you're a contractor, procurement manager, or project engineer, choosing the right F436 fastener supplier ensures your project meets all safety and performance standards. Ananka Fasteners is fully equipped to fulfill all your F436 fastener needs, offering exceptional quality and worldwide export services.

#WasherManufacturer#Fasteners#SpringWasher#PlainWasher#FlatWasher#CountersunkWasher#StainlessSteelWashers#MildSteelWashers#IndustrialFasteners#GlobalSupplier#FastenerIndustry#MadeInIndia#ExportQuality#OilAndGas#MarineIndustry#CustomFasteners#Ananka#AnankaFasteners#manufacturer#tumblr#tumblr blog#blogs

0 notes

Text

Difference Between Shim Washer and Flat Washer | Complete Guide

This article also helps in understanding Shim washer and flat washers as ,shim washer is a thin, precisely cut washer used to fill gaps or make small adjustments in mechanical assemblies. They are crucial in industries where accuracy and alignment are key.

Purpose: Shim washers are designed to provide exact spacing or level components within assemblies. Their main role is to correct alignment or compensate for small imperfections in a system.

Material Options: Shim washers can be made from metal, plastic, or rubber, depending on the specific application requirements.

Precision: Shim washers are known for their tight tolerances and precise fit, making them ideal for industries that demand accuracy, such as automotive, aerospace, and manufacturing.

Benefits of Shim Washers:

Correct alignment issues in assemblies.

Offer fine adjustments without altering other components.

Available in a wide range of thicknesses for precise customization.

Flat washer is more general-purpose. It is typically used to distribute the load of a fastener evenly and prevent damage to the surface it's securing.

Purpose: A flat washer is placed between a fastener, such as a bolt or screw, and the surface it's being applied to. Its role is to spread the load evenly, which helps prevent surface damage or wear.

Material Options: Like shim washers, flat washers are available in materials such as steel, brass, and plastic.

Standard Use: Flat washers are commonly used in general applications such as furniture, construction, and general mechanical assemblies.

Benefits of Flat Washers:

Distribute loads evenly.

Reduce friction and prevent surface damage.

Widely available in various sizes and thicknesses, making them easy to source from any washer manufacturer.

Both shim washers and flat washers play essential roles in mechanical assemblies, but they are used for different purposes. Shim washers are designed for precision and are ideal for applications that demand accuracy, like those in the aerospace or automotive industries. On the other hand, flat washers are more general-purpose, typically used to distribute loads and protect surfaces in a wide range of everyday projects.

If you’re working on a high-precision project, it’s a good idea to source from top shim washer manufacturers or washer manufacturers who specialize in machined washers. For more general applications, a standard industrial washer will likely meet your needs.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

Difference Between Shim Washer and Flat Washer | Complete Guide

#ShimWasher#FlatWasher#WashersGuide#HardwareBasics#MechanicalComponents#Fasteners#EngineeringEssentials#ShimVsFlat

0 notes

Video

youtube

Slat cleaning with the Slat Washer SW500 made by PFT Manufacturing.

1 note

·

View note

Text

choppy destiel art

ive never done a successful flatwash in my life. but im calling it a style choice

44 notes

·

View notes

Text

howdy! turn of events, commissions are back OPEN!

if you want a cute n sparkly self ship commission then send me a dm! slots are unlimited for now till I feel comfortable with the amount in my queue. I have several fun things to save up for this year!! P/ypal only! Sketches are halfbody, ft. a flatwash of color w minimal highlights/shading. 25 for 2 charas!

Here's my commission site! Everything you need to know is there! (ignore other comm options)

As well as my QUEUE! There you can view your commission progress and slot status

#artists on tumblr#commissions#selfship commissions#commission info#self ship commissions#yume commissions#commissions open#art commissions#oc x canon commissions#selfship#self shipping#yumeship#yumeshipping

23 notes

·

View notes

Photo

Monel 400 Hex Head Bolts M6 x 25mm long with One Nut and Two Flat Washers as per DIN 933, DIN 934 and DIN 125 respectively #monel400 #nickelalloy #nickelalloys #stainlesssteel #hexbolt #hexnut #boltandnut #boltsandnuts #fastener #fastenersaresexy #din934 #din933 #din125 #fastenermanufacturing #hexnuts #flatwashers #boltsbolts #nutsforlife #hexhead #boltthreads #lasermarking #lasermarked #lasermark #machiningporn #ordernow #ordercompleted✔️ #nutsandwashers #fastenersindia #hexbolts #zeonexports (at Mumbai, Maharashtra) https://www.instagram.com/p/COwzosljnct/?igshid=7v8krpg8f3cg

#monel400#nickelalloy#nickelalloys#stainlesssteel#hexbolt#hexnut#boltandnut#boltsandnuts#fastener#fastenersaresexy#din934#din933#din125#fastenermanufacturing#hexnuts#flatwashers#boltsbolts#nutsforlife#hexhead#boltthreads#lasermarking#lasermarked#lasermark#machiningporn#ordernow#ordercompleted✔️#nutsandwashers#fastenersindia#hexbolts#zeonexports

0 notes

Photo

#zincplated #hardenedsteel #plainwashers #circular #flatwashers #coldpunched #washers #fasteners #designed and #manufactured to #astm #standard #f436m #type1 #metricsized #heavygauge #marked #bpf #madebyboltport #boltport in #Mumbai #Maharashtra #India #packed and #readytobeshipped (at Mumbai, Maharashtra) https://www.instagram.com/p/BuotlWiAVvR/?utm_source=ig_tumblr_share&igshid=171neyqm1djfv

#zincplated#hardenedsteel#plainwashers#circular#flatwashers#coldpunched#washers#fasteners#designed#manufactured#astm#standard#f436m#type1#metricsized#heavygauge#marked#bpf#madebyboltport#boltport#mumbai#maharashtra#india#packed#readytobeshipped

0 notes

Text

Top Quality Flat Washer Manufacturer in india?

A flat washer is a type of washer that is typically made of metal or plastic and has a thin, circular shape with a hole in the centre. It is commonly used in construction and manufacturing applications to distribute the load of a threaded fastener, such as a bolt or screw, over a larger surface area. Aashish Steel is well-known Flat Washer Manufacturer, Supplier and Exporter in Mumbai, India. Flat Washer supplier and it is a part of the fastener family. The Flat Washer is a thin plate with a hole in the centre that distributes thread fastener load. Flat Washers made of stainless steel have high strength and corrosion resistance, making them ideal for use in harsh environments.

0 notes

Text

Plain Washers

DIC Fasteners is a Brand of Dedicated Impex Co. DIC Fasteners is a Supplier of Flat Washers, placed under the head of a bolt or nut to provide a smooth bearing surface and distribute the fastener load over a wide area.

0 notes

Text

ASTM F436 Washers: Complete Guide — Types, Material Specs & Uses

Overview

ASTM F436 is a recognized specification for hardened steel washers primarily used alongside high-strength structural bolts in critical fastening applications. These washers are engineered to distribute loads effectively, prevent bolt embedment, and maintain the integrity of bolted joints under stress. They are especially important in infrastructure projects, steel construction, and heavy-duty industrial applications.

Understanding the ASTM F436 standard is essential for professionals involved in construction, engineering, and fastener supply chains.

What is ASTM F436?

ASTM F436 outlines the standards for hardened flat washers used with bolts, nuts, and other threaded fasteners in structural applications. These washers are typically paired with ASTM A325, A490, and similar high-strength bolts to ensure secure and long-lasting connections.

The primary goal of this standard is to define the material properties, mechanical strength, and dimensions required for washers used in load-bearing structural joints.

Key Characteristics

Heat-Treated: ASTM F436 washers are specially hardened through heat treatment to resist high-pressure loads without bending or distortion.

Load Support: Designed to distribute load evenly and prevent damage to structural components.

Dimensional Precision: Manufactured under strict tolerances to ensure proper fitment with bolts and nuts.

Multiple Coating Options: Available in plain finish, zinc coating, or hot-dip galvanized for corrosion resistance.

Types of ASTM F436 Washers

ASTM F436 covers different types based on the material and environment of use:

By Material Type:

Type 1: Constructed from carbon steel, typically used in standard structural applications.

Type 3: Manufactured using weathering steel (such as ASTM A588), suitable for outdoor and exposed conditions due to its corrosion-resistant nature.

By Style:

Flat Round Washers: Standard round washers for general use.

Beveled Washers: Used on structural elements with inclined surfaces, such as channel or angle flanges, ensuring proper bearing.

Materials Used

The materials used under the ASTM F436 specification differ depending on the type:

Type 1: Made from premium carbon steel and heat-treated to enhance strength and long-term durability.

Type 3: Weathering steel that forms a protective oxide layer, reducing the need for painting or coating in exposed conditions.

Chemical Composition (Typical for Type 1)

Mechanical Requirements

These washers are designed to meet stringent strength and durability requirements, ensuring dependable performance in high-stress environments:

Hardness: Rockwell C38 to C45

Load Capacity: Suitable for use with bolts having tensile strengths of 150 ksi or more

Performance: Must resist cracking or deformation under load conditions

Dimensional Standards

Washer dimensions must align with:

ASME B18.22.1 for general tolerances

Specific ASTM F436 dimensional tolerances for outside diameter, inside diameter, and thickness

Standard sizes include diameters ranging from 1/4 inch up to 4 inches.

Surface Finish Options

Depending on environmental exposure and corrosion risk, ASTM F436 washers may be supplied with different surface treatments:

Plain (Uncoated): Suitable for interior or dry environments.

Hot-Dip Galvanized (HDG): Offers thick corrosion protection; used in outdoor and marine environments.

Zinc-Coated: Provides light corrosion resistance.

Mechanical Galvanized: Delivers even, durable coating without the risk of hydrogen embrittlement.

Main Applications

ASTM F436 washers are mainly used in structural environments where superior strength and safety are essential. Typical applications include:

Structural steel fabrication

Bridge construction

Power transmission towers

Oil & gas rigs

Industrial support frames

High-rise and commercial buildings

Wind turbine bases and solar panel mounts

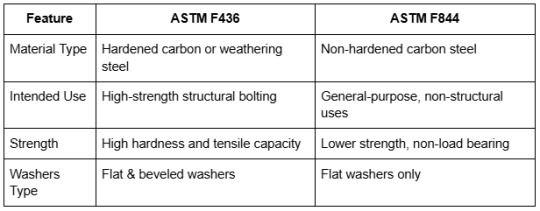

ASTM F436 vs ASTM F844

Benefits of ASTM F436 Washers

Ideal for high-tension joints requiring load stability

Maintains bolt tension and prevents embedment

Compatible with structural-grade bolts like A325 and A490

Provides consistent performance in demanding environments

Trusted Manufacturer – Ananka Group

Ananka Group is a leading producer and international distributor of ASTM F436 hardened washers. With a reputation for delivering high-performance fastening components, we offer:

Washers in various coatings and finishes

Type 1 and Type 3 varieties

Custom sizes on request

Fast delivery across domestic and international markets

We serve industries including construction, power generation, infrastructure, oil & gas, and renewable energy.

Conclusion

ASTM F436 washers are an indispensable part of high-strength bolted connections in structural and industrial settings. Their engineered hardness, dimensional stability, and load distribution capabilities ensure that critical fastenings remain secure and long-lasting. Choosing ASTM F436-compliant washers helps maintain structural reliability and safety in demanding environments.

If your project requires top-quality washers, look no further than Ananka Group your trusted source for reliable fastening solutions.

Frequently Asked Questions (FAQs)

1. What does ASTM F436 specify?

It sets the standards for material, mechanical properties, and dimensions for hardened steel washers used in structural bolted assemblies.

2. What's the difference between Type 1 and Type 3 washers?

Type 1 is made of standard carbon steel, while Type 3 uses weathering steel for better corrosion resistance in outdoor environments.

3. Can F436 washers be reused?

No, they are intended for single-use in structural applications to maintain joint integrity and should not be reused.

4. Which coating is best for marine or outdoor use?

Hot-dip galvanized coating is recommended for maximum corrosion resistance in wet or salty environments.

5. Are F436 washers suitable for stainless steel bolts?

Generally, no. Pairing hardened carbon steel washers with stainless steel bolts can result in galvanic corrosion or irregular wear.

#ananka#anankafasteners#fasteners#fastenersmanufacturer#washer#flatwasher#articles#blog#material#manufacturer#supplier#mumbai#washermanufacturer#bolt#hex#usa#tumblr#tumblr blog

0 notes

Photo

Well well well here comes all the #watercolor works (good and bad) I did during this past 3 months. This is the #first homework (flat wash) we had to do, and I know it's awful. But you know what?🤭 I'm kinda proud of my progress which is why I'll share all of it up to my final. So stay tuned. 😂😂 . . . . . . #progress #watercolorpainting #assignment #kinda #fun but #challenging too #flatwash #struggle

1 note

·

View note

Photo

last of the flat washes, meh #watercolor #flatwash (at Oakland, California) https://www.instagram.com/p/CAEkkSRFrpU/?igshid=1163hsimv4q0b

0 notes

Photo

Chinese Factory grey rubber washer gasket for screws. Material:100% rubber Usage time : 25-30 years #flatwasher #accessories #rubberwasher #screwwasher #washer #corroshield #screws #fasteners #金具 #建設業を盛り上げよう #herramientas #tokobautjakarta #bautgrosir #kopilya #baglantielemanlari #واشرفلزی #واشردار #واشرتخت #واشر_فنری #واشر_تخت #шайбы #крепежоптом #магазинметизы #와샤 #철파이프캡 #befestigungstechnik #schraubenliebe #arruelalisa #parafuso https://www.instagram.com/p/B_y2Vc1DK5h/?igshid=1rg5y5ktflisd

#flatwasher#accessories#rubberwasher#screwwasher#washer#corroshield#screws#fasteners#金具#建設業を盛り上げよう#herramientas#tokobautjakarta#bautgrosir#kopilya#baglantielemanlari#واشرفلزی#واشردار#واشرتخت#واشر_فنری#واشر_تخت#шайбы#крепежоптом#магазинметизы#와샤#철파이프캡#befestigungstechnik#schraubenliebe#arruelalisa#parafuso

0 notes

Photo

Day 13: I was going to paint a watercolor galaxy today based off of my list of 100 ideas (found in a previous post) but...unfortunately, I don’t have white paint. Once I do, my next art project will definitely be a watercolor galaxy. #geometricshapes #glitterwatercolor #saltwatercolor #flatwash #alcoholwatercolor #wetonwetwatercolor #watercolor #sennelier #the100dayproject #the100dayproject2020 #100daysoflightanddreams https://www.instagram.com/p/B_azEgShoV4/?igshid=l1fkg1ghnl45

#geometricshapes#glitterwatercolor#saltwatercolor#flatwash#alcoholwatercolor#wetonwetwatercolor#watercolor#sennelier#the100dayproject#the100dayproject2020#100daysoflightanddreams

0 notes