#flexible pcb prototype

Explore tagged Tumblr posts

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

Comprehensive Guide to Flexible PCBs, PCB Prototypes, and Rigid-Flex Circuit Boards

Printed Circuit Boards (PCBs) are at the centre of present day electronic gadgets, powering everything from smart phones to mechanical apparatus. In this direct, we’ll investigate the different sorts of PCBs, counting Flexible PCBs, PCB Prototypes, and rigid-flex circuit Boards, covering their employments, focal points, and applications.

Understanding Flexible PCBs

Flexible PCB, too known as Flex PCBs, are developed from Flexible materials that permit them to twist and overlap without breaking. These PCBs are planned for applications requiring energetic development or space-saving layouts.

Advantages of Flexible PCBs

• Space Proficiency: Their lean and lightweight plan makes them perfect for compact devices.

• Durability in Movement: Flexible PCBs can persevere twisting and bending, making them idealize for wearable technology.

• Heat Resistance: They perform well beneath warm stretch, regularly utilized in car and mechanical settings.

Applications of Flexible PCBs

Flexible PCBs are broadly utilized in shrewd phones, restorative gadgets, and aviation gear, where space and weight imperatives are basic. They are perfect for Flexible gadgets and gadgets requiring visit movement.

What Are PCB Prototypes?

PCB Prototype are preparatory forms of circuit Boards, created to test the format and usefulness of a plan some time recently full generation. Prototypes are basic in the item improvement handle, permitting engineers to confirm plans and make fundamental adjustments.

Benefits of Utilizing PCB Prototypes

• Testing and Approval: Prototypes offer assistance in recognizing plan blemishes early.

• Cost-Efficient: By testing some time recently mass generation, companies can dodge exorbitant errors.

• Faster Time-to-Market: PCB prototyping speeds up the plan approval handle, permitting speedier item launches.

Types of PCB Prototyping Methods

1. Single-Sided Prototyping: Perfect for straightforward circuits and beginning testing.

2. Double-Sided Prototyping: For more complex plans requiring extra connections.

3. Multilayer Prototyping: Reasonable for progressed gadgets with high-density connections.

Introduction to Rigid-Flex Circuit Boards

Rigid Flex Circuit Boards combine the best perspectives of unbending PCBs and Flexible PCBs, coming about in a half breed circuit board with both strong and Flexible areas. This plan permits for improved flexibility, particularly in complex and high-performance applications.

Why Select Rigid-Flex Circuit Boards?

• Design Flexibility: These Boards can be bowed without influencing execution, which is important in complex assemblies.

• Improved Unwavering quality: Rigid-flex Boards diminish the require for connectors and cables, expanding unwavering quality and decreasing potential focuses of failure.

• Space Investment funds: Perfect for gadgets where space is a premium, such as in aviation, military, and restorative devices.

Proto PCB: The Quick Way to Innovation

Proto PCB, or Prototype PCBs, are small-batch circuit Boards utilized to test thoughts rapidly and affordably. They are priceless in early plan stages, giving a fast way to evaluate modern concepts and quicken the advancement process.

Advantages of Utilizing Proto PCBs

• Rapid Testing: Proto PCBs offer speedy input on modern designs.

• Cost Reserve funds: Perfect for new companies and little ventures, where budget imperatives are significant.

• Iterative Plan: Proto PCBs permit for rehashed testing, empowering refinements some time recently last production.

Common Employments of Proto PCBs

Proto PCBs are basic in investigate and advancement, permitting engineers and creators to test modern thoughts, troubleshoot, and refine plans without committing to full production.

Conclusion

Understanding the assortment of PCB types—from Flexible and rigid-flex Boards to prototypes—is fundamental for selecting the right arrangement for your venture. Each PCB sort has one of a kind benefits and applications, whether you're looking to optimize space, increment strength, or conduct careful plan testing.

0 notes

Text

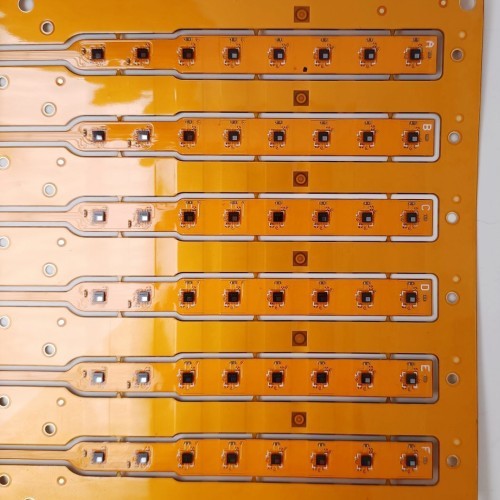

Flex PCB Details Display......

#FPCway#flex PCB#flexible circuit board#rigid-flex PCB#Rigid-flex circuit board#FPC prototype#flex PCB and assembly#rigid-flex PCB manufacturer#flex PCB assembly#flex PCB and SMT#FPC manufacturer#flex circuit prototype#fpcway.com

0 notes

Text

Mistakes You Must Avoid While Hiring PCB Prototype Service Experts

There are some mistakes that you must avoid when hiring professionals who are renowned for PCB Prototype Service. When you avoid the mistakes, you can be confident of the quality standards of the PCB items you order. This short blog provides an outline.

0 notes

Text

A flex PCB prototype is a sample or early version of a flexible printed circuit board. Prototyping is a crucial step in the design and development process, allowing engineers to test and refine their designs before mass production.

0 notes

Text

Festival of Lights… A 'USB Stick' Sparkle Motion WLED driver ✨💡🔌🌟

To wrap up this year, we're doing 8 days (maybe!) of light-filled designs. We started with the Sparkle Motion Mini

which can drive thousands of shimmering RGB LEDs. Next, we were going through some of our NeoPixel samples today and found some "LED Christmas light kit" with star LEDs, its basically these stars

with a little USB plug that has IR, a crummy mic, a tactile switch to cycle modes manually, and a tiny microcontroller that turns the LED selections to different patterns - kinda like this:

The idea is cute - but the implementation could be improved with a lil sparkle motion

! we made a PCB that would fit into the same plastic enclosure but with an ESP32 instead. it's got an IR receiver, ICS-43434 I2S digital microphone

https://www.digikey.com/short/mmv3tthz

gpio 0 button in the 'right' place, 5V 2A fuse, USB-serial converter for uploading/debugging, and two level-shifted outputs. We can probably get the case in quantity or have this be a 'DIY replacement' that folks can use to make their existing setups WLED/xLights friendly.

#festivaloflights#wled#sparklemotion#esp32#neopixels#rgbleds#leddesigns#lightshow#diyleds#holidaylights#electronicsprojects#ledart#usbdriver#techinnovation#custompcb#openhardware#makersmovement#adafruit#holidaydecor#smartlighting#iotdevices#ledengineering#lightdesign#sparklingstars#electronicsmaker#esp32projects#holidaydiy#lightdisplay#lightingideas#techdiy

49 notes

·

View notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

Printed circuit board manufacturing which is our major business, I think you already know, we are a PCB manufacturer. We have 3 branch factories dedicated to Quick Turn PCB Prototypes Manufacturing, Small and Medium-volume Printed Circuit Board, FPC Manufacturing services and PCB assembly services. Our market target is the High Multilayer PCB, High Density PCB, Flexible PCB, Rigid-flex PCB, Heavy copper PCB, Rogers PCB, Ceramic PCB and Special Materials Printed Circuit Boards.

Also, we can help customer sourcing components, wire PCB assembly and provide one-stop service.

Hitech Group is capable of providing full turn-key and partial turn-key PCB assembly services. For full turn-key, we take care of the entire process, including manufacture of Printed Circuit Boards, procurement of components, order tracking, continuous monitoring of quality and final board assembly. Whereas for partial turn-key, the customer can provide the PCBs and certain components, and the remaining parts will be handled by us.

4 notes

·

View notes

Text

In developing any Electrical and Electronics System we must first conceptualize and design the circuit and then go to testing and debugging only after these two stages are complete, we go for final fabrication on the PCB. In all these three processes testing and debugging is the most important because here we ascertain that the circuit we developed is working as intended and there is no bugs in the system which might affect the performance of the device. In this stage we fabricate the circuit on the Breadboard or the Perfboard like this with the help of through hole package components to iron out kinks. It is made up of Fiber Glass which is extremely durable and flexible which makes it great to be used in final industry ready product. It has tin coating on holes at one side which allows you to design the PCB on single side only without having to worry about component placement on the board. It is extremely easy to work with and you can easily solder on this board as it has soldering spots and some gap between them to avoid short circuiting but still you need to take care while designing the circuit of these things.

3 notes

·

View notes

Text

Exploring the Top Electronic Lab Equipment Suppliers in Indore

Indore, a rapidly growing hub for education, electronics, and industrial innovation, has become home to several advanced technological ventures. Among its rising sectors, electronic lab equipment suppliers in Indore play a pivotal role in equipping educational institutions, R&D centers, and industrial labs with state-of-the-art instruments. Whether you're setting up a new electronics lab or upgrading your testing infrastructure, the city offers a wide range of high-quality equipment suited for various applications.

Why Indore for Electronic Lab Equipment? Indore is recognized for its educational excellence and industrial dynamism. With leading universities, engineering colleges, and a thriving manufacturing base, the demand for lab equipment is constantly on the rise. This has led to a surge in reliable electronic lab equipment suppliers in Indore, offering everything from basic testing tools to advanced embedded systems trainers. Choosing local suppliers ensures better service, faster delivery, and hands-on technical support. Additionally, many suppliers in Indore offer customized training solutions and product demonstrations, making them ideal partners for institutions and companies alike. Types of Products Offered by Electronic Lab Equipment Suppliers in Indore The range of products offered by electronic lab equipment suppliers in Indore is vast and designed to meet the needs of diverse fields. Here’s a breakdown of the major product categories:

Basic Electronics Lab Equipment Power supplies, function generators, and multimeters

Breadboards and prototyping tools

Oscilloscopes and frequency counters

Embedded Systems & Microcontroller Kits Arduino and ARM-based development boards

8051 and PIC microcontroller kits

Training modules for IoT, robotics, and automation

Communication Systems Analog and digital communication trainers

Fiber optic kits

Satellite communication systems

Electrical Engineering Labs Electrical machines, circuit labs, and power electronics kits

Control system simulators

Power system protection and analysis kits

Renewable Energy & Green Tech Solar PV and wind energy trainers

Smart grid simulation units

Energy auditing and monitoring tools

These offerings demonstrate the depth and versatility of electronic lab equipment suppliers in Indore, catering to both conventional and modern curriculum requirements. Key Advantages of Choosing Indore-Based Suppliers Working with electronic lab equipment suppliers in Indore comes with several benefits: Local Support and Service: Having a local presence allows suppliers to offer quick installation, training, and troubleshooting services.

Cost-Effective Solutions: Indore-based vendors often offer highly competitive pricing without compromising on quality.

Customization Capabilities: Suppliers can tailor lab kits based on the institution’s syllabus or industrial training requirements.

Strong After-Sales Support: Dedicated service teams ensure minimal downtime in case of equipment issues.

These factors make the city’s suppliers ideal for long-term academic and industrial partnerships. Applications in Education and Industry The demand for lab equipment from electronic lab equipment suppliers in Indore spans across sectors. Here’s how different industries and institutions benefit: Colleges & Universities: Equip students with hands-on experience in analog, digital, and embedded systems through robust lab setups.

Research Institutions: Perform advanced experimentation and prototyping with precision electronic instruments.

Technical Training Institutes: Offer practical learning environments with real-world tools and scenarios.

Manufacturing Industries: Use high-end lab tools for PCB testing, automation controls, and sensor integration.

Startups & Innovation Labs: Support R&D through rapid prototyping and testing solutions.

The flexibility and reach of Indore’s suppliers make them valuable contributors to academic growth and technological advancement.

Taking these aspects into account ensures that your lab setup is efficient, scalable, and future-ready. Future Trends in Lab Equipment With the rise of Industry 4.0 and smart technologies, electronic lab equipment suppliers in Indore are also evolving. Expect to see integration of: IoT-enabled lab kits

Cloud-based learning platforms

AI-assisted training modules

Virtual simulation labs

These advancements are helping bridge the gap between theoretical knowledge and real-world skills, making technical education more interactive and industry-aligned. Conclusion As education and industry continue to evolve, the need for practical, hands-on learning tools becomes more crucial. Electronic lab equipment suppliers in Indore have stepped up to meet this demand by offering a diverse, high-quality range of lab products tailored for electronics, communication, automation, and renewable energy. By choosing a local supplier in Indore, institutions and businesses gain not only access to top-notch instruments but also technical guidance, training support, and affordable solutions. Whether you're building a new lab or upgrading an existing one, the right supplier in Indore can help you drive innovation, enhance skill development, and stay ahead in today’s competitive landscape.

0 notes

Text

circuit board wire

Circuit board wire is essential for connecting electronic components on a PCB. These wires transmit electrical signals and power between components, ensuring proper functionality. Available in various gauges and insulation types, they are used in both prototyping and final products. Circuit board wire must be durable, flexible, and capable of handling specific voltages and currents, making it a key element in building and repairing electronic circuits.

circuit board wire

0 notes

Text

Leading PCB Manufacturers in Canada: Quality and Innovation

Discover the top PCB manufacturers in Canada that specialize in providing high-quality printed circuit boards for various industries, including aerospace, automotive, medical, and consumer electronics. These companies offer a range of services, from prototype development to mass production, ensuring precision engineering and compliance with international standards. With state-of-the-art technology and skilled professionals, Canadian PCB manufacturers are committed to delivering innovative solutions, fast turnaround times, and exceptional customer service. Partner with these trusted manufacturers to meet your electronic design and manufacturing needs.

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Exploring Flexible PCB, PCB Prototype, and Proto PCB : A Glimpse into Electronics Innovation

The hardware industry has created quickly, and printed circuit boards (PCBs) have too advanced altogether. Current frontrunners in this improvement incorporate adaptable PCBs, PCB models, and proto PCBs, which give engineers with the capacity to plan and provide complex circuits for high-tech electronic gadgets. In this article, we investigate the significance of adaptable PCBs, different PCB models, and proto PCBs, and centre on their affect on equipment fabricating.

What is a Flexible PCB?

A Flexible PCB or flex PCB is a sort of circuit board planned to twist and distort without harm. Not at all like inflexible PCBs, which are made from difficult materials, adaptable PCBs are made from adaptable materials such as polyimide, permitting them to adjust to a assortment of shapes and spaces. This adaptability permits for more flexible applications in hardware, particularly in gadgets with complex shapes or restricted space.

Advantages of Flexible PCBs

1.Space-Saving Design: Flex PCBs are bendable and foldable by nature thus making it ideal for compact electronic gadgets where space is limited in size.

2. Durability: These PCBs can withstand vibrations and mechanical push way better than conventional unbending boards, which is why they are utilized in car and aviation industries.

3. Lightweight: Flex PCBs are lighter than inflexible boards, which is pivotal in applications where weight lessening is critical, such as wearable gadgets and restorative implants.

4. Enhanced Unwavering quality: The capacity of Flexible PCBs to withstand rehashed bowing makes them more solid in energetic applications.

What is a PCB Prototype?

A PCB Prototype is an early test of a circuit board made amid the plan stage to test its usefulness some time recently full-scale generation. PCB prototyping permits engineers to distinguish and settle any plan blemishes some time recently mass fabricating, guaranteeing the last item performs as expected.

Importance of PCB Prototyping

1. Error Location: Prototyping makes a difference recognize potential issues in the plan, such as inaccurate component arrangement or destitute flag integrity.

2. Cost-Effective: Catching plan blemishes early in the prepare makes a difference dodge exorbitant botches amid mass production.

3. Faster Time to Advertise: PCB models permit for quick testing and alterations, speeding up the improvement handle and bringing items to advertise faster.

4. Customization: Prototyping gives engineers the opportunity to explore with diverse plans and arrangements, optimizing the PCB for particular applications.

Proto PCB: An Fundamental Instrument in Development

A Proto PCB alludes to a model PCB particularly outlined for testing and advancement purposes. It serves as the physical representation of a plan concept, permitting engineers to approve the usefulness of their circuits in real-world conditions.

Benefits of Proto PCBs

• Quick Approval: Proto PCBs offer a quick way to approve plan concepts and test execution, guaranteeing the circuit works as planning some time recently full-scale production.

• Iterative Plan: By making numerous Proto PCBs, engineers can refine their plans, making essential alterations to move forward execution or decrease fabricating costs.

• Hands-On Testing: Engineers can test and investigate Proto PCBs in genuine situations, giving profitable experiences into potential issues that may not be unmistakable in reenactments or computerized models.

How Prototyping and Flexible PCBs Work Together

In numerous cases, Flexible PCBs are created and tried through a arrangement of models. By making Flexible PCB models, engineers can try with bowing and collapsing in real-world applications. This permits for way better optimization of plans in businesses such as wearables, therapeutic gadgets, and shopper hardware, where adaptability and space-saving arrangements are key.

Conclusion

Flexible PCBs, PCB models, and Proto PCBs speak to vital steps in the advancement of gadgets plan and fabricating. Flexible PCBs permit for imaginative and compact plans, whereas prototyping guarantees that these plans are tried and refined some time recently mass generation. Together, these advances are forming the future of electronic gadgets, giving the establishment for high-performance, solid, and space-efficient items.

0 notes

Text

Flex PCB Details Display......

#FPCway#flex PCB#flexible circuit board#rigid-flex PCB#Rigid-flex circuit board#FPC prototype#flex PCB and assembly#rigid-flex PCB manufacturer#flex PCB assembly#flex PCB and SMT#FPC manufacturer#flex circuit prototype#fpcway.com

0 notes

Text

Keep Your Budget Under Control by Hiring a Top-Notch PCB Assembly Service Provider

If you want to maintain a firm grip on the budget while investing in hiring PCB manufacturing and fabrication services, then you must go for a top company in the industry. The production process of a renowned PCB company is cost-effective. The manufacturing steps are optimized, suiting the specific business needs you have.

#Printed Circuit Board Manufacturer#prototype pcb manufacturing#rigid flex printed circuit boards#flexible printed circuit manufacturers

0 notes

Text

Unraveling the World of Flex Circuit Prototypes: Choosing the Right FPC Manufacturer

Introduction

Flex Printed Circuit Boards (Flex PCBs), often referred to as Flex Circuits, have become indispensable in today's electronics industry. These bendable and versatile circuit boards are a crucial component in various applications, from medical devices and aerospace systems to consumer electronics. When it comes to designing and producing Flex PCB prototypes, choosing the right FPC manufacturer is paramount. In this blog post, we will explore the world of Flex Circuit Prototypes and discuss the key considerations when selecting an FPC manufacturer.

Understanding Flex Circuit Prototypes

Flex Circuit Prototypes are specialized printed circuit boards designed to be flexible, allowing them to conform to intricate shapes or fit into compact spaces. These boards are typically made from flexible substrates like polyimide (PI) or polyester (PET) and can have single or multiple layers, depending on the complexity of the circuit. Flex circuits can be found in products ranging from smartphones and wearable devices to automotive control systems.

Why Choose Flex Circuit Prototypes?

Space Efficiency: Flex PCBs are ideal for applications with space constraints, as they can be folded or bent to fit into tight spaces, reducing the overall size of the device.

Reliability: Flex circuits offer excellent reliability due to their reduced number of interconnects, which minimizes the risk of connection failures and short circuits.

Weight Reduction: Flex circuits are lightweight, making them a preferred choice in applications where weight reduction is critical, such as aerospace and automotive industries.

Durability: These circuits are more robust and can withstand vibrations and shock, making them suitable for applications that experience harsh environments.

Click here for more information: https://www.tumblr.com/fpcway/731599943480000512/exploring-fpc-assembly-flex-pcb-material-and

#Flex PCB#Flex Circuit Prototype#FPC Manufacturer#Flex PCB Material#FPC Prototype#Flexible Printed Circuit

0 notes