#foam blowing agents

Text

Expanding Horizons: Insights into the Foam Blowing Agents Market

The selection of the foam blowing agents facilitates a closed-cell structure that reduces heat transfer partly led by the foam blowing agent properties retained within the foam for lifelong use of the foam. The blowing agent can be liquid or gas form dissolved in the foam precursors that also expands after being injected or sprayed, beginning the foaming reaction. The foam blowing agent ,and foam matrix are bonded with the impermeable metal facings ,and are chosen to reduce migration of the blowing foam agent to further increase the thermal conductivity.

In addition, the foam blowing agent with low thermal conductivity enhances foam insulation properties, by facilitating thinner profiles or improved insulation performance. Foam blowing agents are used in a wide variety of buildings, refrigerators, furniture, automobiles, packaging, and, others. A cellular structure formed of liquid plastic resin is created by the blowing agent. Blowing agents also act as an insulating component, when the foam is utilized for insulation.

Foam Applications

Rigid Polyurethane foam is utilized in commercial refrigeration, which includes insulation for metal doors, pipes, and walls in commercial refrigeration equipment, coolers, vending machines, refrigerated transport vehicles, and buoyancy. It is also used in marine floatation foam that facilitates boat manufacturing for structural purposes.

Polystyrene foam is extensively used in extruded sheets for buoyancy, floatation, and packaging purposes. It is also utilized in extruded board stock, and accommodation, including flooring, roofing, walls, and pipes’ insulation.

Foam Blowing Agents

The hydrofluorocarbons are massively utilized as insulation foam blowing agents, owing to their good insulation properties, technical performance, and, low flammability. The low GWP, non-flammable HFOs, and HCFOs are utilized as foam blowing agents, as they facilitate insulation performance that replaces the blowing agents with high-GWPs, such as HFCs, it also can replace several hydrocarbon elements ,and carbon dioxide is blown, majorly depending on enhanced thermal properties.

Foam manufacturing extensively consume

hydrochlorofluorocarbons, as they are widely utilized as blowing agents. The major HCFCs use of the same in rigid polyurethane foam utilized in pipe, appliance insulation, and sandwich panels in extruded polystyrene (XPS) foam and, spray foams. Emerging economies utilize HCFC-containing pre-blended polyols as blowing agent formulations imported from foreign nations.

Therefore, foam blowing agents are highly demanded considering their wide industrial applications for providing insulation.

#Foam Blowing Agents#Market Trends#Insulation#Packaging#Construction#Chemical Compounds#Energy Efficiency#Market Players#Foam Material Innovations#Lightweight Foams#Market Insights

0 notes

Text

Foam Blowing Agents Market to Register a Strong Growth Rate and Huge Profits

The global Foam Blowing Agents Market is estimated to attain a valuation of US$ 2.9 Bn Bn by the end of 2031, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 5.7% during the forecast period, 2022-2031.

The key objective of the TMR report is to offer a complete assessment of the global market including major leading stakeholders of the Foam Blowing Agents industry. The current and historical status of the market together with forecasted market size and trends are demonstrated in the assessment in simple manner. In addition, the report delivers data on the volume, share, revenue, production, and sales in the market.

Request for a Sample of this Research Report (Use Corporate Mail ID for Top Priority) - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=4151

#Foam Blowing Agents Market#Foam Blowing Agents#Foam Blowing Agents Market Size#Foam Blowing Agents Market Share#Foam Blowing Agents Market Growth#Foam Blowing Agents Market Analysis#Foam Blowing Agents Market Trends

0 notes

Text

Asia Pacific foam blowing agents market generated a revenue of $425.95 million in 2021, which is projected to exceed the valuation of $672.68 million by 2030 at a CAGR of 5.4% during the period 2022–2030.

0 notes

Text

How Chemical Blowing Agents Enhance Polymer Performance

The Significance of Polymer Performance -

Polymer performance is at the core of industrial innovation, influencing the functionality and efficiency of countless products. In this context, chemical blowing agents emerge as pivotal contributors, revolutionizing the landscape of polymer manufacturing. These agents, such as the sought-after azodicarbonamide blowing agent, play a crucial role in achieving lightweight, durable, and environmentally conscious polymer products. The strategic incorporation of chemical blowing agents aligns with the quest for superior polymer performance, ensuring products meet the evolving needs of various industries.

Polymers stand as indispensable players in various industries, forming the backbone of numerous products we interact with daily. The performance of these polymers holds a direct sway over the functionality and efficiency of end-use applications, underscoring the ongoing need for continual improvement and innovation.

Understanding Chemical Blowing Agents -

To enhance polymer performance, manufacturers often turn to chemical blowing agents. These agents are compounds designed to introduce gas and create a cellular structure within the polymer matrix during processing. This controlled expansion leads to several advantageous properties in the final product.

Exploring the Benefits of Chemical Blowing Agents -

Chemical blowing agents offer a range of benefits, including reduced density, improved mechanical properties, enhanced thermal insulation, and sound dampening. In this blog, we'll delve into the fundamental principles behind these agents and how they contribute to elevating polymer performance.

Fundamental Principles of Chemical Blowing Agents -

The Chemistry Behind Chemical Blowing Agents

● Gas Evolution and Expansion Mechanisms:-

Chemical blowing agents release gas upon thermal activation, creating bubbles within the polymer structure. Understanding the chemistry behind this process is crucial for achieving desired performance characteristics.

● Control of Blowing Agent Decomposition:-

Precise control over the blowing agent's decomposition is essential to avoid undesired side effects. Manufacturers must balance decomposition temperature, gas release rate, and other factors to achieve optimal results.

Key Factors Influencing Blowing Agent Selection

● Polymer Type and Processing Conditions:-

Different polymers and processing methods demand specific blowing agents. Compatibility with the base polymer and the processing conditions ensures successful integration and desired performance enhancements.

● Environmental Considerations:-

As sustainability gains prominence, choosing blowing agents with minimal environmental impact becomes crucial. Eco-friendly options contribute to a more responsible and sustainable manufacturing process.

Enhancing Polymer Properties through Chemical Blowing Agents -

Lightweighting and Density Reduction

Enhanced Mechanical Performance:-

By introducing cellular structures, material density is effectively reduced without sacrificing mechanical strength. This results in products that are both lightweight and durable, a particularly advantageous trait in applications within the automotive and aerospace industries.

Improved Fuel Efficiency and Sustainability:-

Reduced weight translates to improved fuel efficiency in transportation, contributing to sustainability goals and aligning with environmental regulations.

Thermal Insulation and Energy Efficiency

Increased Heat Resistance:-

Through the utilization of chemical blowing agents, a polymer's heat resistance is elevated, broadening the spectrum of potential applications in high-temperature environments.

Lower Energy Consumption in Applications:-

Elevated thermal insulation not only curtails energy consumption across diverse applications but also renders products more energy-efficient and cost-effective.

Improved Sound and Vibration Dampening

Noise Reduction Capabilities:-

The cellular structure introduced by blowing agents acts as a sound barrier, contributing to noise reduction in products like automotive components and building materials.

Enhanced Comfort and Safety:-

Reduced vibrations and noise not only enhance comfort but also contribute to safety by minimizing distractions and improving the overall user experience. In conclusion, the strategic use of chemical blowing agents is pivotal in advancing polymer performance across diverse industries. Manufacturers, including the best PVC blowing agent manufacturers in India, continually explore innovative solutions like azodicarbonamide blowing agents to meet evolving demands. As the industry progresses, a focus on sustainable and effective blowing agents will be paramount for achieving optimal polymer performance.

#adcl blowing agent in India#blowing agent manufacturers in india#Best Blowing Agent Supplier in India#blowing agent for artificial leather in india#Best Pvc blowing agent manufacturers in India#best azodicarbonamide blowing agent in india#Foaming agent supplier for Eva in India#Manufacturers list of foaming agent#azodicarbonamide blowing agent#Blowing agent for Roto moulding products in India#Best industrial chemicals manufacturer in India#Thermoplastic elastomer manufacturers in India#Blowing agent for Yoga Mats#Soft Compound Manufacturers in India#Best Filler suppliers for yoga mats in India

0 notes

Text

North America Foam Blowing Agents Market Will Reach USD 451.5 Million By 2030

The size of the North American Foam Blowing Agents Market is USD 305.8 million. In 2023, and over the period from 2024 to 2030 it will increase at a rate of 5.8% per year. In 2030, the goal is to be USD 451.5 million.

The foam-blowing agents are utilized to designate additives that make cellular structure in the substrate by means of a foaming procedure. Because of the significant size of…

View On WordPress

#North America Foam Blowing Agents Market#North America Foam Blowing Agents Market Demand#North America Foam Blowing Agents Market Outlook#North America Foam Blowing Agents Market Research Report#North America Foam Blowing Agents Market Share#North America Foam Blowing Agents Market Size#North America Foam Blowing Agents Market Trends

0 notes

Note

“i hate how you put yourself in situations like these.”

"I hate how you put yourself in situations like these."

Eight crushed his cheek into the palm of his hand further at the sound of Ain'res' breaking voice, making a point not to turn around as the Chiss tended to his wounds.

"...I couldn't leave you alone." He answered, voice just above a whisper.

The other agent's own expression remained sharp with professionalism-- but Eight could sense the rawness of his emotions without even looking at him. For all his purposeful gentleness, Ain'res' frustrations betrayed him, his fingernails digging so tightly into the kolto-soaked rag that it bubbled with foam beneath his cuticles.

The sting of it against his open skin did little to relieve either of them. Still, dutiful as ever, Ain'res scrubbed at his scars. The repetition was a calming tactic, mere routine in a time of constant threat. It didn't stop tears from blooming at the edges of his crimson eyes.

Saying nothing, Eight reached past his shoulder to interlace his bandaged fingers with his.

Ain'res latched onto him. His forehead came to rest between Eight's shoulderblades, just beneath the shock collar that mirrored his own.

Eight pretended not to hear the sobs muffled into his skin, nor feel the wetness that trailed down his back. He held onto him tighter. Yet his gaze remained fixated on the wall in front of him, refusing to bear witness to his suffering.

This was his fault, after all.

It was his decision to follow him right into Rivix's trap. It had been his choice not to sacrifice Ain'res when he was a step away from landing the finishing blow, and it was now his responsibility to be with him beneath a new master's thumb.

Even if it made them both pawns. Even if he hated him for it.

From now on, he would have to be stronger for both of them.

Eye of the Empire AU

#swtor#oc: orradiz#ain'res#sh: 78#>:^)#sorry i loved the eye of the empire au so much that i got the idea.#tldr: what if they both were there. what if rivix used ain as a shield. eight would do anything for him honestly#ask meme: answered#sorry this took 5 million years i kept getting nervous on how to write aaaaa#i need to do short prompts more often OTL#admin writes

51 notes

·

View notes

Note

Edward: Hey Whiff, what do you make?

Whiff: That depends are you with the military?

Edward: No but what if I was?

Whiff: What do ya want?

Edward: No thanks.

Whiff: Yes tanks I outfit a lot of tanks and armoured personnel carriers and other things.

Edward: This brings me so much pain.

Whiff: Planes? Yeah I do planes you have to make sure those missiles are firing right!

Edward: Whiff! What the the hell!?

Whiff: Icopters yes I also do helicopters.

Edward: Why do you keep talking it's like it's automatic!

Whiff: Grenade launchers yes I made automatic grenade launchers I also made this anti-submarine rocket system, things pretty cool.

Edward: Do you make anything not for the military?

Whiff: Oh yeah blowing agents.

Edward: Spy agencies count and that is a despicable way of getting information out of people.

Whiff: What it's for insulation (blowing agent, liquid and gaseous blowing agents for foam insulation applications such as roof, panel, Apliance and others) what did you think?

Edward: Do you make anything that saves lives?

Whiff: Yeah! Fire alarm systems!

Edward: Oh that's nice.

Whiff: Yeah so if one of my missiles including the nuclear ones I made strikes a building near you our fire alarm system will be the first one to alert ya I gotcha.

LMAOOOOOOOO

Love how we just agreed that Whiff is a crazy scientist dude. Even Edward can't handle him.

#ttte#thomas and friends#thomas the tank engine#ttte edward#ttte whiff#ask#ask game#send asks#ask me stuff about the ttte characters#Edward Gets Caught Up In Whiff's War Crimes Ttte AU#EGCUIWWC Ttte AU

11 notes

·

View notes

Text

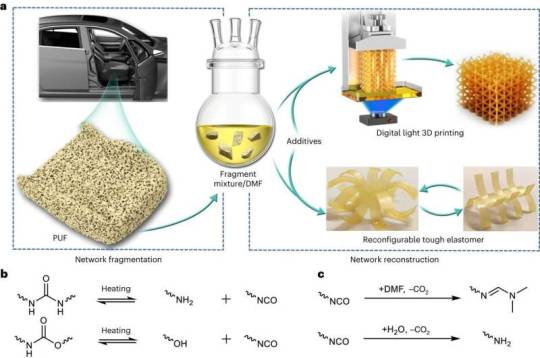

Converting polyurethane foams to 3D printing resins

A team of chemical engineers at Zhejiang University, in China, has developed a way to convert polyurethane foams to 3D printing resins. In their paper published in the journal Nature Chemistry, the group describes their technique and possible ways the resins could be used.

Polyurethane foams (also known as foam rubber) of the types that are found inside of car seats, couches and mattresses are used to make products more comfortable. They are actually a type of plastic that is made to expand by forcing gas bubbles into mixtures using a blowing agent. Such foams are notoriously difficult to recycle because of the curing process that is used to make them.

Current approaches, as the researchers note, tend to be economically unattractive and also lead to the production of subpar byproducts. Because of that, most such products wind up in a landfill. In this new effort, the team in China has developed a novel approach to recycling such materials—one that they claim is both inexpensive and scalable. They describe it as an example of chemical upcycling, where typically discarded materials are converted to high-value products.

Read more.

13 notes

·

View notes

Text

@protectmypeople ://

—☾—

The crowns of ancient maples are wet and black under the scratched mauve hull of sky. A sky ruled by the dark moon. The underbrush holds its breath. The wind howls with wolves, and blows through the open window of a stolen 1994 Dodge Ram Van, where the unconscious threat bound to the scaffold of a deconstructed car seat stirs to gold dice clinking on the rearview mirror.

Tang of rubber and pine, stale wax paper. Piles of books and yellowed, mummified gazettes, husks of flora suspended from a wire stabbed and stretched across the foam ceiling. The emptiness and fullness of a stranger's makeshift living space; the foam board and sleeping bag rolled into the shape of a body and folded into the backseat to make room for his.

The way the stranger hunches, his broad yet hollowed shape, he could be an iron fixture built into his vehicle. Only his scleras seem visible, the hard black shells within them, glinting out from the dark like the slightly upturned blades of bowie knives.

Many minutes pass before his mouth moves, and the stranger's voice is a molasses, a low and gentle timbre that drips between great pauses. Yet his interrogation begins without ceremony.

"What was your car doing parked outside this trail for three nights?"

The threat can't answer gagged. Makes muffled sounds the stranger seemingly deciphers.

"I know." The stranger pauses. "You weren't pursuing me. You have no idea who I am. Agent…"

He jimmies the badge. Brown gloves, stained thumbs—"B-E-L-L-A-M-Y. Special Agent Bellamy Blake. Issued in Washington D.C.."—and drops it onto the crease between Blake's thighs.

"What were you doing, Special Agent Blake? You have no jurisdiction here."

'Here' could mean the van or the dark of the woods. By the furor lurking under his stoic face, the stranger refers to something far beyond the laws of man, let alone New England.

"We're interstates." He lifts his head, parting his lips to lap at some potent, arcane power in the stormy air. A long pause. "Between New Hampshire and Massachusetts. An old college friend of yours lives there. The Ren told me. Hm."

His belief is so strong and permeable, this Ren seems to form in the small, cold pit of the van, dangling its hooked arm from the driver’s side window. With a strange, stilted gulp, the stranger sifts through rubbish. His hide-brown fingers pull a map from its contents, point to a speck of green among a topographical lexicon of tiny hand-drawn symbols.

"Mm." The stranger leans to expunge the balled-up t-shirt and tape from the mouth of the threat. His body musky and warm, his waffle shirt somewhat tacky to the touch, ripe with the earth, as if he'd clambered out of a shallow grave. "You have to answer my question now."

#protectmypeople#m. au | murder!kylo: the dice killer#closed starter#thread tbd#queue de la k#edited: for quality assurance

9 notes

·

View notes

Text

A Snowy heart: Awake

Warning: torture

Everything was calm until Mango was pulled out of his cell forcefully. Something say that someone was pissed and now using him as a stress ball.

Tied to the similar bloody table once again, his restraints bit into his flesh. Something was different. He was not put to a numbing agent. He was very much awake.

Watching ever move the man was making. Grabbing the scalpel and going close near the middle of his neck bone.

Slowly digging deep into the skin, cutting into the flesh and dragging it down.

Mango struggled against his restraints. His body feels like it's burning, it hurts badly. Wanting to get away from the thing that is hurting him.

Mango much preferred when he was put to sleep instead so then he won't feel anything besides when he woke up.

Soon the worse part came, the opening slice opens more, the Man using clamps to spread the injury open, revealing his ribs and organs.

Mango screamed...or the best he can screams as some sort of leather shut his vocals out. All came out was muffled screaming.

One by one, he felt all his organs slowly be pulled out. Mango wants to vomit, he felt acid in his throat as his eyes rolled on the back of his head.

Tears foaming out of his eyes non stop and soon enough darkness falls.

His heart beat slowly stops

Soon enough, it all stops together.

Waking up again, he's in his cell bed. Looking down, he saw bandages. Next to him was some painkillers and water.

Mango sighs and took them. His physical pain numbed but what he have to see did not.

It replayed in his mind.

The laughter.

Whispers entered into his mind.

He had one hand covering half of his face and the other over his chest.

Yet something is different.

He doesn't hear it.

He

doesn't

hear

it

his own

heart beat.

----

The forest now cold as ever, Mango continues to walk and walk. The wind blows heavily and nothing to be seen besides trees tall as mazes.

Mango stopped and started to dig, where is it?

WHeRE Is IT?

Do you know?

#A Snowy Heart AU#avm king orange#alan becker#animation vs minecraft#animator vs animation#avm#ava#ava mt#avm mango

28 notes

·

View notes

Text

Cyclopentane Market Size, Share, Trends & Forecast

According to a new report by Univdatos Market Insights, the Global Cyclopentane Market is expected to reach USD 695.35 million in 2032, growing at a CAGR of 6.91%. The market is experiencing significant growth driven by increasing insulation, refrigeration, and electrical demand, coupled with stringent environmental regulations promoting eco-friendly blowing agents.

Market Dynamics

The cyclopentane market continues to grow due to several factors. Firstly, the global push for energy efficiency, particularly in household appliances, has led to increased demand for cyclopentane as a blowing agent in polyurethane foam insulation. For instance, in May 2024, Whirlpool Corporation reported a 12% increase in sales of its energy-efficient refrigerator line using cyclopentane-based insulation.

Moreover, the phase-out of hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) under the Montreal Protocol and subsequent amendments has accelerated the adoption of cyclopentane as an environmentally friendly alternative. In February 2024, the European Union implemented stricter regulations on fluorinated greenhouse gases, further boosting cyclopentane demand in the region.

The construction industry's recovery post-COVID-19 pandemic has also contributed to increased cyclopentane usage in insulation materials. For instance, in 2024, according to the report published by the United States Census Bureau, the construction spending during May 2024 was estimated at a seasonally adjusted annual rate of USD 2,139.8 billion, 0.1 percent (±1.0 percent) below the revised April estimate of USD 2,142.1 billion. The May figure is 6.4 percent (±1.6 percent) above the May 2023 estimate of USD 2,011.8 billion. During the first five months of this year, construction spending amounted to USD 836.3 billion, 8.8 percent (±1.2 percent) above the USD 768.6 billion for the same period in 2023.

Additionally, technological advancements in cyclopentane production have improved efficiency and reduced costs. In August 2023, BASF SE announced a new catalytic process for cyclopentane production, which reduced energy consumption by 30% and decreased carbon emissions by 25% compared to conventional methods.

Sector Specific Growth

Refrigeration and Air Conditioning: The refrigeration and air conditioning sector remains the largest consumer of cyclopentane, driven by stringent energy efficiency standards and the shift towards eco-friendly refrigerants. For instance, in June 2024, according to Daikin, the company is focused on increasing its localization level, leveraging the PLI scheme for the air conditioning sector. The company plans to enhance local manufacturing of PCB circuits to achieve this goal. The company expects to manufacture 2 million units in India this fiscal year and has plans to scout for more export opportunities by making India a manufacturing hub. The company has sold seven lakh residential air conditioners (RAC) units in the first three months of the year, helped by a blistering summer this season, and expects over 50 percent growth. Therefore, this will increase the demand for cyclopentane-based insulation materials in the coming years.

Construction and Insulation: The construction and insulation segment has been a significant driver of cyclopentane demand, particularly in developing economies. The growing emphasis on green building practices has further boosted cyclopentane adoption. In January 2024, the Indian Green Building Council reported a 20% increase in green building certifications, with many projects utilizing cyclopentane-based insulation materials.

Electrical and Electronics: The electrical and electronics industry is emerging as a promising growth area for cyclopentane, particularly in producing circuit breakers and switchgear. In February 2024, Huntsman Building Solutions (HBS), the global leader in high-performance, energy-efficient, and resilient building envelope solutions, announced the launch of its all-new Icynene Series spray polyurethane foam insulation product line. The collection of spray foam systems offers the highest performance available in the industry today and includes key product certifications.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=63784

Sustainability Drives Innovation in Cyclopentane Production and Application

The market is witnessing rapid technological developments and significant efforts from industry leaders in researching sustainable production methods. In October 2023, a consortium of European chemical companies unveiled a breakthrough in bio-based cyclopentane production, utilizing renewable feedstocks derived from agricultural waste. This innovation is expected to reduce the carbon footprint of cyclopentane production by up to 70% compared to conventional methods. The trend towards circular economic practices is also influencing the cyclopentane market. In September 2023, a major European appliance manufacturer launched a pilot program for recovering and purifying cyclopentane from end-of-life refrigerators, aiming to reduce virgin material consumption and minimize waste.

Conclusion:

With increasing environmental concerns, stringent regulations, and the growing demand for energy-efficient products, the cyclopentane market is poised for substantial growth in the coming years. The industry's focus on sustainable production methods, innovative applications, and circular economy practices is expected to drive further expansion and geographic diversification of the market.

As the global economy continues to prioritize sustainability and energy efficiency, cyclopentane is likely to remain a critical component in various industries, particularly in insulation, refrigeration, and electrical applications. The future of the industry will largely depend on its ability to adapt to evolving regulatory landscapes, consumer preferences, and technological advancements in green chemistry and manufacturing processes.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

0 notes

Text

Cyclopentane Prices | Pricing | Trend | News | Database | Chart | Forecast

Cyclopentane prices is a key component in the production of foam insulation and other industrial applications, making it a significant chemical in the market. The pricing of cyclopentane is influenced by various factors, including raw material costs, demand and supply dynamics, global economic conditions, and environmental regulations. Over the years, cyclopentane prices have shown a degree of volatility due to these factors. Raw materials such as naphtha and crude oil play a crucial role in determining cyclopentane prices, as they are primary inputs in its production process. Fluctuations in the prices of these raw materials can directly impact the cost of producing cyclopentane, leading to variations in its market price.

Demand for cyclopentane is closely tied to the insulation foam industry, particularly in the production of polyurethane foam. As industries such as construction, refrigeration, and automotive grow, the demand for polyurethane foam increases, thereby boosting the demand for cyclopentane. However, the global economic conditions also play a crucial role in this context. During periods of economic growth, construction activities tend to rise, leading to increased demand for insulation materials, including cyclopentane. Conversely, during economic downturns, construction and other industrial activities may slow down, reducing the demand for cyclopentane and putting downward pressure on prices.

Get Real Time Prices for Cyclopentane: https://www.chemanalyst.com/Pricing-data/cyclopentane-1512

Supply dynamics are another critical factor influencing cyclopentane prices. The production capacity of cyclopentane is concentrated in specific regions, and any disruptions in these areas can lead to supply shortages, driving up prices. Natural disasters, geopolitical tensions, or unexpected shutdowns in key manufacturing facilities can create supply bottlenecks. Additionally, transportation and logistics challenges can further complicate the supply chain, affecting the availability of cyclopentane in various regions and leading to regional price variations.

Environmental regulations also significantly impact the cyclopentane market. As a blowing agent in foam production, cyclopentane is favored for its lower environmental impact compared to other hydrocarbons like CFCs and HCFCs, which are known for their ozone-depleting properties. However, stringent environmental regulations aimed at reducing carbon emissions and promoting sustainability can affect the production processes and costs associated with cyclopentane. Compliance with these regulations may require manufacturers to invest in cleaner technologies or alternative processes, which could increase production costs and, subsequently, the market price of cyclopentane.

The cyclopentane market is also influenced by the availability of substitutes and advancements in technology. As the industry evolves, alternative blowing agents and insulation materials may emerge, potentially reducing the reliance on cyclopentane. If such alternatives become more cost-effective or efficient, they could erode the demand for cyclopentane, putting downward pressure on prices. On the other hand, technological advancements that improve the production efficiency of cyclopentane or enhance its properties could boost its demand, potentially leading to higher prices.

Global trade policies and tariffs also play a role in shaping cyclopentane prices. Import and export regulations can influence the flow of cyclopentane between countries, affecting its availability in certain regions. Trade tensions between major economies can lead to the imposition of tariffs or other trade barriers, impacting the cost of importing or exporting cyclopentane. Such policies can create disparities in cyclopentane prices across different markets, depending on the local supply-demand balance and the costs associated with cross-border trade.

In recent years, the cyclopentane market has been impacted by the broader trends in the chemical industry, including the push towards sustainability and the adoption of circular economy principles. Companies are increasingly looking for ways to minimize waste and reduce the environmental impact of their products, which has led to innovations in production processes and the use of more sustainable materials. This trend has the potential to influence cyclopentane prices, particularly if new, more sustainable alternatives are developed or if production processes are modified to align with these goals.

Looking ahead, the cyclopentane market is likely to be shaped by a combination of these factors. The ongoing shift towards more sustainable and environmentally friendly practices, coupled with advancements in technology, will likely influence the demand for cyclopentane and its substitutes. Additionally, the evolving global economic landscape, including changes in trade policies and regulations, will continue to impact the supply and pricing of cyclopentane. As such, stakeholders in the cyclopentane market will need to stay informed about these trends and developments to navigate the challenges and opportunities that lie ahead.

Get Real Time Prices for Cyclopentane: https://www.chemanalyst.com/Pricing-data/cyclopentane-1512

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Cyclopentane#Cyclopentane Price#Cyclopentane Prices#Cyclopentane Pricing#Cyclopentane News#Cyclopentane Price Monitor#Cyclopentane Database

0 notes

Text

What is Trending in the World of Foam Blowing Agents?

Foam blowing agents, can works wonderfully well in decreasing the surface tension of the liquid and produce a lot of uniform and stable foam by mixing with pressurized air. Elements of a foaming agent comprise surfactants, foam stabilizers etc. The molecules of surfactants comprise two parts, hydrophobic cluster and hydrophilic cluster, which accrue at the interface amid liquid and gas in the…

View On WordPress

#Foam Blowing Agents Market#Foam Blowing Agents Market Growth#Foam Blowing Agents Market Outlook#Foam Blowing Agents Market Share#Foam Blowing Agents Market Size#Foam Blowing Agents Market Trends

0 notes

Text

0 notes

Photo

Eco-friendly foam can insulate buildings without warming the globe

Rigid foam boards used to insulate buildings can prevent energy loss, making homes more efficient at keeping warm or cool. The advantages in energy efficiency, however, are undercut by environmental concerns over polystyrene products. Blowing agents used in foam production, such as hydrocarbons and hydrofluoroolefins, end up in the atmosphere and contribute to global warming.

Scientists at Oak Ridge National Laboratory developed a competitive, eco-friendly alternative made without harmful blowing agents. The nontoxic thermoplastic foam is made using hollow glass spheres and expandable polymer microspheres.

"The combination of these two sources allows us to tailor formulations to maintain the material's thermal performance across a limited range of densities" said ORNL's Meghan Lamm. "We are also working with thermoset materials, which offer high-temperature stability, for improved flame resistance."

Read more.

15 notes

·

View notes