#formwork for column

Text

Formwork in construction – Top 5 Formwork types

Formwork in construction – Top 5 Formwork types

Formwork in construction refers to a mould used to shape concrete into structural shapes (beams, columns, slabs, shells) for buildings and other structures. Concrete is one of the most popular building materials due to its exceptional properties and advantages. However, in order to create construction components, concrete must be poured into a specific mould. In order to achieve the desired shape…

View On WordPress

#aluminium formwork#different types of formwork in construction pdf#formwork aluminium#formwork construction#formwork for column#formwork in construction#formwork meaning#formwork of column#formwork types#metal formwork#plastic formwork#plywood formwork#steel formwork#timber formwork#types of formwork in construction#types of formwork materials#types of formwork pdf#types of shuttering in construction#working with forms

0 notes

Text

Exploring The Versatility Of Nova Plastic Formwork: Applications In Different Construction Projects

Formwork is a crucial component in the construction industry, shaping the structure and ensuring the strength and durability of concrete elements. While traditional materials like timber and steel have long been used, plastic formwork is gaining traction for its versatility, reusability, and ease of handling. In this blog, we explore the versatility of Nova Plastic Formwork and its applications in various construction projects, focusing on key areas such as column formwork, slab formwork, beam formwork, and wall formwork.

Understanding Plastic Formwork

Plastic formwork is a modern solution designed to address the limitations of traditional formwork materials. Made from high-quality plastic, it offers numerous advantages, including lightweight handling, durability, and reusability. Nova Plastic Formwork stands out in this category, providing robust and efficient formwork systems suitable for diverse construction needs.

Key Applications of Nova Plastic Formwork

Column Formwork

Columns are critical structural elements that transfer loads from beams and slabs to the foundation. Nova Plastic Column Formwork is designed to provide precise and smooth finishes, ensuring the structural integrity of columns.

Advantages:

Lightweight and easy to assemble.

Reusable multiple times, reducing overall costs.

Provides a smooth surface finish, reducing the need for additional plastering.

Slab Formwork

Slabs form the floors and ceilings in buildings, requiring formwork that can support the weight of wet concrete and construction loads. Nova Plastic Slab Formwork is ideal for creating flat, ribbed, or waffle slabs.

Advantages:

High load-bearing capacity.

Easy to handle and install, speeding up construction time.

Reusability and durability, making it a cost-effective solution.

Beam Formwork

Beams are horizontal structural elements that support loads from slabs and transfer them to columns or walls. Nova Plastic Beam Formwork ensures accurate dimensions and high-quality finishes for beams.

Advantages:

Provides excellent support and stability during concrete pouring.

Can be easily adjusted to different beam sizes.

Durable and reusable, reducing material waste.

Wall Formwork

Walls are essential for enclosing spaces and providing structural support. Nova Plastic Wall Formwork is designed to create strong, smooth, and perfectly aligned walls.

Advantages:

Lightweight and easy to set up, reducing labor costs.

Ensures uniform thickness and smooth surface finishes.

Highly reusable, making it an eco-friendly choice.

Conclusion

Nova Plastic Formwork is revolutionizing the construction industry with its versatility, durability, and ease of use. Whether it’s for residential, commercial, infrastructure, or industrial projects, Nova Formworks provides efficient solutions for column formwork, slab formwork, beam formwork, and wall formwork. By choosing Nova Plastic Formwork, you invest in a sustainable, cost-effective, and high-quality construction method that meets the demands of modern projects. For more information on Nova Plastic Formwork and its applications, visit www.novaformworks.com

#nova plastic formwork#construction formwork#column formwork#slab formwork#wall formwork#beam formwork

0 notes

Text

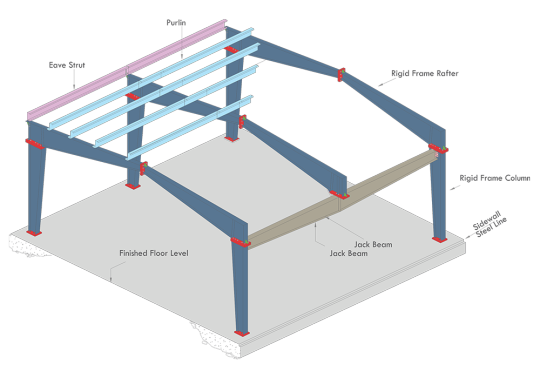

Smith Structure| Jack Beam Elevating Structural Support

Smith Structure introduces jack beams structural component used in construction for temporary or permanent support of floors, roofs, or load-bearing elements

#Jack Beam#Isometric Jack Beam at Sidewall#Isometric Jack Beam at Interior Column Location#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Understanding the Different Types of Concrete Formwork

Formworks remain integral to the construction requirements. However, formworks can be of several types and each one has its separate set of evens and odds. Based on the materials used for manufacturing the forms, the formworks can be of the following types.

Timber Formwork

Timber is probably the earliest of the materials that people used for making formwork structures. For ages, construction sites have used timber formworks for erecting magnificent structures. However, this one comes with two bold limitations.

To begin with, concrete formwork construction with timber involves the felling of the trees. Additionally, in the case of harsh climatic conditions, timber does not show much resilience.

Aluminium Formwork

Aluminum formworks were the second most widely used varieties after timber forms. Compared to timber, aluminum shows more resilience to external climatic factors and offers more strength. This is why many constriction sites once depended on metal formworks like the aluminum ones for longer-running projects.

Steel Formwork

Steel formworks are comparatively a better choice than timber formworks. Steel is durable, strong, and can withstand extreme weather conditions longer than timber or aluminum. Metals tend to get rusted over time when remaining exposed in the open air. Steel is a rust-resistant material and thus is a better choice for construction sites.

Plastic Formwork

Modern concrete formwork companies prefer using plastic for manufacturing a wide range of formwork. Plastic is an eco-friendly alternative for manufacturing formworks as these do not require the felling of the trees. Additionally, plastic structures are lightweight, easy to move, feature flexible setups, and are reusable.

Concrete formworks also vary in terms of their usage. The following is the list of formwork alternatives based on usage.

Concrete Drain Box

Precast concrete drain boxes are a widely used alternative these days. Many construction projects use these ready-to-use drain boxes to make the sewerage system flawless and durable. The best part is that you will find these boxes available in the market in different sizes and shapes. You can also place an order for tailor-made drain boxes as well.

Concrete Beam Formwork

These are a special variety of formworks used for constructing floors and beams. The purpose of concrete formwork construction remains to ascertain more strength and structural stability to the construction. Concrete beam formworks render buildings, bridges, and more structures a perfect finish.

Concrete Box Culvert

Culverts help keep the sewerage system and direction of water flow maintained. For constructing underground culverts or on-road culverts, a special variety of formwork finds extensive application.

Concrete Column Formwork

As the name suggests, column formworks are perfect for constructing smooth surfaced columns of precise dimensions.

Concrete Wall Formwork

Wall formworks are ideal for erecting smooth walls without any surface unevenness and pores. Plastic formworks are an excellent choice for all these construction works.

NovaFormWorks is one of the most trusted concrete formwork companies that deal with manufacturing and supply of premium-grade formworks. Go through the exhaustive collection of plastic formworks for multiple requirements of different construction sites. You will find the products pocket-friendly and quality-wise superior at the same time.

#concrete formwork construction#concrete formwork companies#novaformworks#nova formworks#wall formwork#formwork#column formwork

0 notes

Text

Forms always save a lot of time and money when deployed for constructing concrete structures. For drain box construction as well, the superior-grade forms can be a valuable choice. Since installing these forms does not require hiring skilled labours, the projects save a lot of money from its daily wage payment section.

0 notes

Text

#AluminumColumnFormwork#AluminumFormwork FormworkSystem#Aluminum Column Formwork#Scaffolding and Formwork

0 notes

Video

Best Column Formwork

One type of concrete formwork is column formwork. This is a steel, aluminium, wood, plastic, or other material mould into which wet concrete is poured in order to achieve the desired shape and size for a structure. If you're seeking for column formwork, you've come to the right place. Nav Nirman is a major supplier and manufacturer of innovative formwork systems.

0 notes

Text

20230225. 【🎭】 // Chiaroscuro: Denys Lasdun’s National Theatre.

Beloved Southbank icon and Lasdun’s magnum opus. This is his finest work. The NT is the most magnificent summation of his favourite tropes and motifs, all synthesised into one great building of austerity and gracefulness — quintessential qualities of the architect imbued into the fabric of his architecture to immense success. A noble building conceived by a noble human being.

Throughout his illustrious career, one of Lasdun’s most enduring architectural loves was Hawksmoor. That influence is most discernible in the NT; at the height of his design capabilities, Lasdun responded to that shadowy genius of the English Baroque with his own profound sensibilities. I have no doubt that if Hawksmoor had lived 300 years later, the respect would have been mutual. Here is an intellectual dialogue across three centuries between one inventive man and another.

Inside the NT, space unfolds and expands endlessly. The bulky concrete columns rise like towering trees of deep woods — perhaps a distant trace of the Gothic — while the strata terraces become labyrinthine levels joined by stairways punctured by expository interstices. One feels infinitesimally small amidst the monolithic world of rough grey concrete, made brilliantly exciting by the beautiful natural finish left by timber formwork.

The spatial complexity renders the public realm another stage, on which unfolds the minutiae drama of human life. There is no better place for people watching, or else spending a peaceful afternoon, immersed in the oxymoronic solitude amongst others made possible by the building.

As night falls, the theatrics of architecture multiply tenfold; discordant shadows elongate and swell across the landscape in sensational gestures. The impressive geometries are also transformed as lights flicker on between the structural lattices. Concrete is a spectacular backdrop for dancing lights, manmade or natural.

But look now, theatregoer, the curtains are falling — time to leave the entrancing realm of elegant Brutalism and retire to the rhythm of society. Tomorrow life carries on as it always has.

☞ studygram

#studyblr#studyblr community#archiblr#architecture studyblr#architecture student#dark academia#dark academia aesthetic#architecture#places#brutalism#brutalist architecture#modern architecture#national theatre#denys lasdun#london#writing#venetianwindow#heyzainab#studyvan#astudentslifebuoy#learnelle#nihaohoney#myhoneststudyblr#heysantiago#heypeachblossom#problematicprocrastinator

23 notes

·

View notes

Text

3D Printed Freeform Formwork

youtube

The performance of 3D printed formwork and its geometric complexity varies, depending on the type of plastic used for 3D printing the formwork and the printing technology. The three columns showcase the degree of geometric freedom achievable in concrete formwork when printing with different materials—namely PLA, PVA, and PETG—and using different 3D printing techniques—robotic fused granulate fabrication (FGF) and fused filament fabrication (FFF) cartesian machines.

PLA (Polylactic Acid) is a common plastic material in the 3D printing industry, being both biodegradable and produced from renewable, organic starches. PVA (Polyvinyl Acetate) is a water-soluble synthetic polymer often used for support material on complex 3D prints due to its ease of removal when in direct contact with water. This research uses PVA to directly 3D print the formwork parts. Due to its high sensitivity to moisture, PVA requires airtight storage. Because of the material’s sensitivity, PVA can clog the nozzle of a 3d printer. PETG (Polyethylene Terephthalate Glycol) is a thermoplastic copolyester with high chemical resistance, durability, and ductility. It is also fully recyclable.

Acknowledgement for 3D Printing Concrete Formwork Project Project Instructor: Assistant Professor Dr. Mania Aghaei Meibodi

Contributing Students: Ryan Craney, Han-Yuan Chang, Monik Gada, Feras Nour, Christopher Voltl, Jessica Lin, Chia-Ching Yen, Carl Uwe Eppinger, Aaron Weaver

#architecture school#architecture student#3d printing#3d printer#concrete 3d printing#computational design#additive manufacturing#taubman college#architecture research

9 notes

·

View notes

Text

Construction Technology

Buildings are constructed by SJ Contracts using modern technologies. Technology has made great progress in the building sector. In our construction company, the following new technologies are frequently used:

1.Building Information Modelling (BIM): BIM is a digital representation of a building's physical and functional characteristics. It allows architects, engineers, and contractors to collaborate effectively by creating a 3D model of the building. BIM facilitates better visualization, clash detection, and coordination among different disciplines, resulting in improved project efficiency and reduced errors.

2.Prefabrication and Modular Construction: Prefabrication involves constructing building components off-site in a controlled environment, while modular construction employs pre-built modules that are manufactured and assembled off-site. Both methods offer advantages such as faster construction time, reduced material waste, enhanced quality control, and improved site safety. Prefabrication and modular construction enable streamlined workflows and increased efficiency.

3.Virtual Reality (VR) and Augmented Reality (AR): VR and AR technologies enhance visualization and design review processes. VR creates immersive virtual environments, allowing stakeholders to experience the building design before construction begins. AR overlays digital information on physical spaces, aiding in tasks like on-site measurements, material placement, and clash detection. Both technologies improve communication, decision-making, and design coordination.

4.Formwork: Formwork is the temporary structure used to support the construction of concrete elements, such as walls, columns, and slabs, until they gain sufficient strength. SJ Contracts may employ modern formwork systems, such as modular or adjustable systems, to optimize efficiency and reduce labor time in concrete construction. These systems offer flexibility, ease of use, and reusability, leading to faster construction cycles.

By utilizing these technologies, SJ Contracts can achieve higher levels of efficiency, accuracy, and productivity in their construction projects. The adoption of BIM improves collaboration and reduces rework, while prefabrication, modular construction, and modern formwork techniques contribute to faster and more controlled construction processes. VR and AR technologies enhance design visualization and coordination, leading to improved project outcomes.

#SJcontracts #construction #constructioncompany #builders #buildingconstruction #enineering #constructionequipment

2 notes

·

View notes

Text

How to improve the construction efficiency of plastic plywood

Plastic plywood wholesale products are generally made of plywood with large surface coverage. The inner and outer epoxy resin film is smooth and waterproof, and has a certain degree of air permeability.

Its construction does not require a complex external support system. The joints are used for sub-ports, the outside is reinforced with steel strips, and the vertical position of the steel pipe is lapped horizontally and vertically to make the vertical effect better. The beam and column can be constructed in one piece, and the wooden circular formwork can be cut arbitrarily, so that the column and the top beam can be built at the same time, and concrete is poured at the same time, which greatly improves the construction efficiency. It is very convenient and quick to install the template and remove the mold. Due to the light weight of the plastic plywood, it can be cut arbitrarily, and two people can operate it independently.

The plastic plywood is easy to operate, and the concrete cylinder produced is not only smooth and well-shaped, with excellent visual and hand feeling, it can be used many times, and it is easy to store.

2 notes

·

View notes

Text

Frequent Problems to Avoid When Adding L-Shaped Anchor Products

L-shaped anchor products, a crucial aspect in structure and design, offer foundational support for structures and machinery. Their own design presents balance and strength, creating them vital in several programs, from developing structure to commercial installations. This short article delves in to the specifics of L-shaped anchor screws, their applications, benefits, and installation techniques. l shaped anchor bolts

What're L-Shaped Point Screws?

L-shaped anchor bolts are characterized by their 90-degree extend, which types an "L" shape. This fold creates a secure hold in concrete, avoiding the bolt from being drawn out easily. They're generally created from high-strength metal and may be galvanized to withstand corrosion.

Applications of L-Shaped Point Products

L-shaped anchor products are versatile and found in a variety of settings, including:

Construction: These products are typically embedded in cement foundations to protected architectural steel columns, light poles, and different heavy-duty applications.

Industrial Machinery: They point heavy equipment to concrete surfaces, ensuring balance all through operation.

Power Installations: L-shaped bolts are used to secure power posts, signposts, and guardrails.

Breeze Mills and Systems: They offer the required support to tolerate large winds and environmental stresses.

Benefits of L-Shaped Point Bolts

L-shaped point products offer many benefits:

High Energy: Produced from durable materials, these bolts may tolerate substantial masses and stresses.

Security: The L-shaped style ensures a secure hold in cement, stopping displacement.

Flexibility: Suitable for a wide variety of purposes, from mild poles to major machinery.

Deterioration Resistance: When galvanized, these screws withstand deterioration, extending their lifespan even yet in hard environments.

Choosing the Right L-Shaped Point Bolts

Choosing the correct L-shaped anchor bolts is dependent upon several facets:

Substance: Choose products made from high-strength steel for large loads. Galvanized screws are perfect for outside or corrosive environments.

Measurement and Length: Assure the bolt length and diameter match the strain demands and the range of the concrete.

Fill Demands: Look at the tensile and shear masses the screws will have to withstand.

Installment Guide for L-Shaped Anchor Bolts

Proper installation is critical for the efficiency and protection of L-shaped anchor bolts. Here will be the steps to ensure a protected installation:

Preparing: Establish the exact keeping the bolts in the concrete formwork based on structural plans.

Placing the Products: Place the products in the formwork before putting the concrete. Use templates or jigs to steadfastly keep up accurate spacing and alignment.

Pouring Concrete: Carefully pour the cement round the products, ensuring they remain in place and do not shift.

Recovering: Allow the concrete to cure fully before using any loads. This process usually takes many days to months, depending on the cement combine and environmental conditions.

Inspection: Following recovering, examine the screws to ensure they're solidly secured and clear of defects.

Frequent Mistakes to Prevent

Avoiding these common problems may guarantee the usefulness and security of L-shaped point products:

Incorrect Position: Misaligned bolts can bargain structural integrity. Always use themes for precise placement.

Limited Cement Coverage: Guarantee bolts are stuck strong enough to provide ample support.

Applying Unsuitable Components: Use high-strength, corrosion-resistant components right for the precise application.

Preservation and Inspection

Normal maintenance and inspection may increase the lifetime of L-shaped anchor screws:

Schedule Inspections: Always check for signals of rust, use, or loosening.

Securing: Sporadically tighten bolts to keep protected connections.

Alternative: Replace any damaged or corroded bolts rapidly in order to avoid architectural failures.

Conclusion

L-shaped anchor bolts are a basic portion in ensuring the security and protection of varied structures and machinery. Understanding their applications, benefits, and proper installation techniques can considerably improve the longevity and performance of your projects. By selecting the proper materials and staying with most readily useful techniques, you are able to maximize the effectiveness of L-shaped point screws in your structure and industrial applications.

0 notes

Text

Nova Formworks Ongoing Monolithic Structure

Constructing the future with resilience and accuracy. Nova's dedication to innovation and superior construction practices is demonstrated by our continuing monolithic structure project.

0 notes

Text

Revolutionizing Construction: The Role of Concrete Pumping Services

In the realm of modern construction, efficiency is key. As skyscrapers rise higher, bridges span farther, and infrastructure projects become increasingly ambitious, the need for innovative solutions becomes ever more apparent. Among these solutions, one unsung hero stands tall: concrete pumping services.

Concrete pumping services have quietly revolutionized the construction industry, offering a versatile and efficient method for delivering concrete to even the most challenging locations. From high-rise buildings to remote construction sites, these services have become indispensable for contractors worldwide.

The Power of Precision

At the heart of concrete pumping services lies precision. Gone are the days of laboriously pouring concrete manually or relying on cumbersome equipment to transport it across sprawling construction sites. With concrete pumping, accuracy and efficiency are paramount.

State-of-the-art pumps, operated by skilled professionals, ensure that concrete is delivered exactly where it's needed, eliminating waste and minimizing the risk of errors. Whether it's filling intricate formwork or reaching inaccessible areas, concrete pumping services excel where traditional methods fall short.

Versatility Redefined

One of the most remarkable aspects of concrete pumping services is their versatility. These systems are adaptable to a wide range of construction projects, from residential developments to large-scale infrastructure endeavors. Whether it's pouring foundations, constructing columns, or paving roads, concrete pumping can handle the task with ease.

Furthermore, advancements in pump technology have expanded the scope of what's possible. Today, contractors can choose from a variety of pump types, including boom pumps, line pumps, and even specialized models designed for specific applications. This flexibility ensures that no project is too complex or too remote to benefit from concrete pumping services.

Efficiency in Action

In an industry where time is money, efficiency is non-negotiable. Concrete pumping services offer a streamlined approach to construction, accelerating project timelines and reducing labor costs. By eliminating the need for manual labor and minimizing downtime, these services help contractors stay on schedule and within budget.

Moreover, the speed and precision of concrete pumping can have a ripple effect throughout the entire construction process. Faster concrete placement means faster curing times, allowing subsequent work to proceed more quickly. This domino effect ultimately translates into substantial time and cost savings for project stakeholders.

In conclusion, the next time you witness the impressive progress of a construction project, take a moment to appreciate the unsung hero behind the scenes: the Concrete pumping services. Its silent efficiency speaks volumes about the transformative power of innovation in construction.

#concrete pumping services#concrete pumping#concrete pumping services in derby#concrete pumping services in uk

0 notes

Text

Sustainability in formworks - How Nova Formworks Contributes towards Sustainability?

Sustainability has become one of the major concerns of modern production processes. Even for the components, parts, and other products used in various sectors, sustainability remains an issue. As far as construction site waste generation is concerned, the use of modern formworks like plastic formworks can make the projects more eco-friendly.

The followings remain the few most popular formwork varieties that had found extensive application in a number of construction projects for decades. However, all these alternatives are not equally sustainable and often result in huge quantities of debris.

Timber Formwork: Timber formwork is probably the oldest and one of the most popular alternatives. However, this one is not suitable for harsh conditions such as areas with heavy rainfall or harsh winters with snowfall.

Also for underwater construction projects, timber remains a poor choice. Additionally, these are not ideal for multiple uses and require indiscriminate felling of trees. In short, timber is far from an ideal sustainable choice for formwork material.

Aluminium & Steel Formwork: Steel column formwork is also a popular choice for several construction projects. However, this metal alloy is also not a perfect option for the most sustainable formwork material. Even though steel looks aesthetically pleasing and exhibits qualities like anti-corrosion and weathering resistance, reusability remains an issue with this one.

Less flexible and customisable, this one is one of the traditional varieties of formworks that need to be more adaptable to the latest requirements of modern projects. Similarly, metal formworks like Aluminium formworks also offer several advantages but are not the best choice as a sustainable formwork.

Why The Plastic Formworks Stand Apart?

Plastic formworks have been the latest additions to the existing pool of formworks. NovaFormWorks is one of the most reliable manufacturers of plastic forms ideal for a wide variety of construction projects. The followings are a few features of these plastic forms that make them one of the most eco-friendly choices at present.

Economically More Viable: Reusability remains one of the primary issues with traditional formworks. On the other hand, plastic formworks can be used by multiple projects without much ado.

To be precise, one plastic form can find application in more than 100 construction projects. Therefore, plastic formworks are undeniably one of the most cost-effective alternatives for construction houses. This alternative makes every construction project more profitable and revenue-generating.

Environmental Benefits: For manufacturing plastic formworks, the felling of trees or indiscriminate mining of metals is not a prerequisite. Therefore, the entire process does not involve any environmental hazard. This is another reason why most construction projects are now replacing traditional formworks with the latest plastic ones.

Safety Benefits: Unlike Aluminium formworks, plastic formworks are lightweight and easy to relocate. Every part of these humongous structures remains perfectly riveted through clips. Therefore, handling plastic formworks remains an entirely safe task for all.

NovaFormWorks is inarguably one f the leading manufacturers of plastic formworks. Check its exhaustive collection of modular and customisable formworks to pick the best ones for your construction projects to minimise on-site waste generation.

1 note

·

View note

Text

The Benefits of Aluminium Formwork in Construction

The construction industry is constantly evolving, seeking new technologies and materials to improve efficiency, reduce costs, and achieve higher quality standards. In this pursuit, aluminium formwork has emerged as a game-changer. Compared to traditional wood or steel formwork systems, aluminium formwork offers a multitude of advantages that are revolutionizing the way we build.

What is Aluminium Formwork?

Aluminium formwork is a modular system comprised of lightweight, reusable panels manufactured from high-strength aluminium alloys. These panels are designed to be easily assembled and disassembled, creating a mould for pouring concrete. Once the concrete cures, the formwork is removed, leaving behind a smooth, high-quality finish.

Why Choose Aluminium Formwork?

The benefits of aluminium formwork are extensive, making it a compelling choice for a variety of construction projects. Here's a closer look at some of the key advantages:

Faster Construction Speeds: Aluminium formwork's modular design allows for quick and easy assembly, significantly reducing construction timeframes. The lightweight nature of the panels eliminates the need for heavy machinery, further streamlining the process.

Enhanced Cost-Effectiveness: While the initial investment in aluminium formwork might seem higher, the long-term cost savings are substantial. The reusability of the panels eliminates the need for continuous purchases of disposable formwork materials. Additionally, faster construction translates to lower labour costs and reduced project overhead.

Superior Quality Finishes: Aluminium formwork panels are precision-engineered to ensure consistent dimensions and a smooth surface. This translates to high-quality concrete finishes that require minimal post-construction rectification work.

Reduced Labor Requirements: The user-friendly design of aluminium formwork systems makes them suitable for assembly by semi-skilled or skilled labour. This reduces reliance on highly specialized workers, leading to greater flexibility and cost savings.

Environmental Sustainability: Aluminium is a recyclable material, making aluminium formwork an eco-friendly option. Compared to wood formwork, which often ends up in landfills, aluminium panels can be reused for multiple projects, minimizing environmental impact.

Improved Safety: The lightweight nature of aluminium formwork minimises the risk of injuries associated with handling heavy materials. Additionally, the modular design ensures a stable and secure formwork structure, enhancing overall safety on the construction site.

Applications of Aluminium Formwork:

Aluminium formwork's versatility makes it suitable for a wide range of construction projects, including:

Walls (both load-bearing and non-load-bearing)

Columns

Beams

Slabs

Staircases

Elevator shafts

Finding the Right Aluminium Formwork Solution in India:

The Indian construction industry has witnessed a significant rise in the adoption of aluminium formwork. To cater to this growing demand, numerous Aluminium formwork companies in India offer high-quality systems. When selecting a provider, consider factors like the company's reputation, product range (including vertical formwork system and monolithic formwork system options), and after-sales support. A well-established company like Shriconst Aluform, for instance, offers a comprehensive range of Aluminium formwork solutions along with technical expertise and reliable service.

Aluminium formwork represents a significant leap forward in construction technology. By leveraging its numerous benefits, construction companies can achieve faster project completion times, reduce costs, and ensure superior quality finishes. As the industry continues to strive for efficiency and sustainability, aluminium formwork is poised to play an increasingly vital role in shaping the future of construction.

#aluminium formwork manufacturers#aluminium formwork companies#monolithic formwork system#vertical formwork system#Shriconst Aluform

0 notes