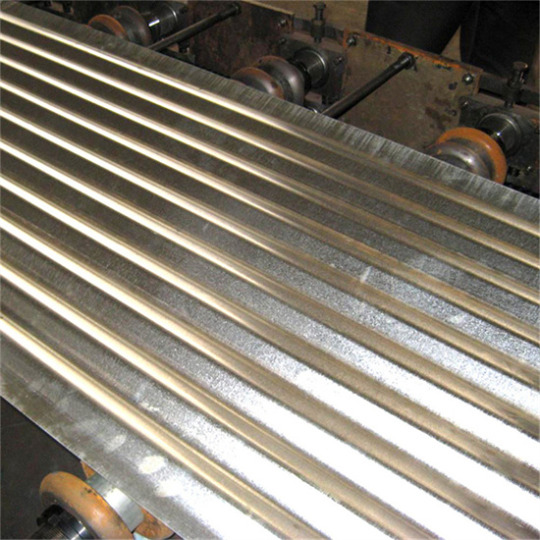

#galvanized iron sheet for roofing

Text

The quality control of galvanized iron sheet for roofing

Galvanized iron sheet for roofing, commonly known as tin roofing, is a roof covered with galvanized thin steel sheet. The thickness of the steel plate is 0.45~0.75 mm, which can be fixed on the roof panel or directly on the roof support structure, and the plates are connected by nibbles.

Quality control:

(1) Waveformiron sheets for roofingand galvanized waveformiron sheets for roofingare painted with anti-rust paint, primer, and cover coat according to the regulations, and the painting should be even, without peeling and leakage.

(2) The lap width is generally one and a half waves to two waves, not less than one wave. The lap length of the upper and lower rows should not be less than 80 mm, the lap should follow the dominant wind direction, and the lap seam should be tight.

(3) Wave tile shall be bolted and bent hook bolt to lock the wave tile in the purlin, bolt distance 300 ~ 450 mm, and the upper and lower rows of joints must be located on the purlin. The bolts of the upper and lower joints are every three convex long bolts. In the wood, purlin applies galvanized bolts with waterproof washers with the same set. In the metal and reinforced concrete purlin application with a waterproof gasket galvanized hook bolt fixed, screws should be located on the crest. The number of bolts, in the tile around each lap side, should not be less than three, the central wave must be put.

(4) In the wall against the higher roof, at least 180 mm roll up, bend into a "Z" shape into the wall reserved slot, and cement mortar smoothing. If the wall is not out of the roof, should be cut by the wall QiBo tile, with mortar sealing mountain wipe eaves.

(5) Roof ridge, sloping ridge, gutter, and roofing and protruding roof structure connection at the flooding, are applied iron, and tile lap of not less than 150 mm.

(6) Thin steel lap joints and other parts that may be immersed in water, the application of lead oil sisal or oil ash seal.

0 notes

Text

Aluminium Roofing Sheet Manufacturers

Gupta Iron & Steel Co. is one of India's top Aluminium Roofing Sheet Manufacturers. We offer a wide array of products in different colors, coatings, and profiles to match a range of applications. Aluminium roofing sheets are a popular option for roofing and cladding in many regions of the world. We are renowned for their dependability, lightness, corrosion resistance, and ease of installation. Aluminum roofing sheets are suitable for a wide range of applications since they are available in a great number of hues, textures, and profiles.

Address: X-9 Loha Mandi, Naraina, New Delhi

Phone: +91 9999740008

Email: [email protected]

Visit our website: https://www.guptaironsteel.com/aluminium-roofing-sheet.html

#Galvanized Iron Shee#Colour Coated Sheet#Decking Sheet#Color Curved Roofing Sheet#Air Ventilator#MS Pipes#Metal Roofing Sheet#Aluminium Roofing Sheet#Mild Steel Round Pipe

2 notes

·

View notes

Video

youtube

Color coated prepainted galvanized coil ppgi prepainted galvanized steel...

#Corrugated Iron Sheets Galvanized Roofing Sheet#colored coated steel coil galvanized coil#galvalume roofing tile#colour stone coated roofing tile#polygold pre-coated steel coil

0 notes

Text

What I have been thinking, captain, is what is exempt from import tax in one country is what I'd like to stick through the crack in my skull to start to fill it: hay, oranges, lemons, pineapples, cocoa nuts, grapes, green fruit, and vegetables of every variety, and linseed oil cake. Horses, pigs, poultry, dogs, and living animals of every description, except cattle and sheep. Corks, bark, firewood, logwood, and dyewoods. Copper or yellow metal, rod bolts or sheathing, and copper and yellow metal nails. Felt for sheathing, oakum and junk, pitch, tar, and resin. Sail canvas, boats, and boat oars.

I fill my head with ships' blocks, binnacle lamps, signal lamps, compasses, shackles, sheaves, deadeyes, rings and thimbles, dead lights, anchors, and chain cables of every description, and galvanized iron wire rope. Lime juice and ice. Printed books, music, and newspapers, maps, charts, globes, and uncut cardboard, millboard, and pasteboard. Ink, printing presses, printing type, and other printing materials. Passengers' baggage or cabin furniture arriving in the colony at any time within three months before or after the owner thereof. Tablets, memorial windows, harmoniums, organs, bells, and clocks specially imported for churches or chapels. Hides and skins of every description, raw and unmanufactured. Veneers of all sorts. Rattans, split or unsplit.

Carriage shafts, spokes, naves, and felloes. School slates and slate pencils, slates for roofing, and slates and stone for flagging. Marble, granite, slate, or stone in rough block.

Soda ash, caustic soda, and silicate of soda. Cotton waste, woollen waste, candle cotton, wood, flax, hemp, tow, and jute, unmanufactured. Specimens of natural history, mineralogy, or botany. Gold dust, gold bars, bullion, and coin. Coir bristles and hair unmanufactured. Broom heads and stocks, partly manufactured for brushmaking purposes. Jars of glass or of earthenware, specially imported for jam. Rod bar hoop sheet plate and pig iron and pighead share moulds and mould boards. Epsom salts, citric acid, sulphuric acid, muriatic acid, carbolic acid. Hair cloth for hopkilns. Wines and spirits.

Captain.

What's true?

— McGlue (Ottessa Moshfegh)

#book quotes#historical fiction#crime fiction#mystery fiction#psychological fiction#lgbt fiction#ottessa moshfegh#mcglue#head injury#brain damage#mental health#mental illness#psychology#confusion#alcoholism

2 notes

·

View notes

Text

9 Major Applications Of Steel Plates

Which kinds of steel plates are typically used when building?

There are several types of steel plates that are commonly used in building construction, including:

1. Carbon steel plates: These plates are made from an alloy of iron and carbon, and are typically used in structural applications such as bridges, buildings, and other infrastructure.

2. Stainless steel plates: These plates are made from an alloy of iron, carbon, and chromium, and are known for their corrosion resistance. They are often used in applications where the steel will be exposed to harsh environments, such as in coastal or industrial areas.

3. High-strength low-alloy (HSLA) steel plates: These plates are made from a combination of different metals and alloys, and are designed to be stronger and more durable than traditional carbon steel plates. They are commonly used in applications such as bridges and buildings that require high levels of strength and durability.

4. Weathering steel plates: These plates are made from a special type of steel that is designed to withstand the effects of weathering, such as rusting and corrosion. They are typically used in applications such as bridges and buildings that will be exposed to the elements.

5. Quenched and tempered steel plates: These plates are heated to a high temperature, then cooled rapidly to create a very hard, durable steel. They are commonly used in heavy-duty construction applications such as cranes, excavators, and other heavy machinery.

The high performance and strength qualities offered by the stainless steel plates in Vadodara, Gujarat is the reason behind it being the most often used materials today, and it's used for everything from steel beams to lift heavy loads to steel pipelines to transport fluids and compounds.

Mild steel (MS) plates:

Mild steel, also known as low-carbon steel, is a type of steel that has a low carbon content and is easy to shape and form. Mild steel plates are a popular choice for a wide range of construction and industrial applications, including bridges, buildings, machinery, and automotive components. They are known for their excellent weldability, formability, and durability, and can be easily cut, bent, and fabricated into various shapes. They are also cost-effective and easily available in the market.

Checkered Plates:

Checkered plates are steel plates with a raised diamond or linear pattern on one side, typically used for slip resistance or decorative purposes. They are commonly used in industrial settings, as well as on stairs, catwalks, and for other types of flooring. They can be made from a variety of materials, including carbon steel, aluminum, and stainless steel. The pattern on the plate can also vary, with diamond patterns being the most common, but linear or other geometric patterns are also possible.

Galvanized Sheets:

Galvanized sheets are sheets of steel that have been coated with a layer of zinc to protect the steel from corrosion. The zinc coating acts as a barrier to prevent the steel from coming into contact with water or other corrosive materials. Galvanized sheets are commonly used in construction for roofing, siding, and other applications where durability and resistance to corrosion are important. They can also be used in the manufacturing of various products such as appliances, automobiles, and outdoor equipment.

B.I. and G.I. Sheets:

B.I. (black iron) and G.I. (galvanized iron) sheets are both types of steel sheets that are commonly used for various construction and building projects. B.I. sheets are made from uncoated, hot-rolled steel and have a dark, matte finish. They are known for their strength and durability, but are prone to rusting if not properly treated or coated. G.I. sheets, on the other hand, are made from hot-dipped galvanized steel and have a shiny, silver finish. They are coated with a layer of zinc that helps protect the steel from rusting and corrosion, making them more suitable for outdoor or exposed applications. Both types of sheets can be cut, bent, and shaped to meet the specific needs of a project. If you are looking for an excellent stainless steel plates dealer in Vadodara, Gujarat, Tube Trading Co. is the best place to fulfill your stainless steel plates needs

9 Major Applications of Steel Plates:

1. Construction: Steel plates are used in the construction of buildings, bridges, and other structures.

2. Manufacturing: Steel plates are used in the manufacturing of heavy machinery, vehicles, and equipment.

3. Oil and gas: Steel plates are used in the construction of pipelines and storage tanks for the oil and gas industry.

4. Defense: Steel plates are used in the construction of military vehicles, tanks, and other defense equipment.

5. Pressure vessels: Steel plates are used in the construction of pressure vessels, such as boilers and storage tanks.

6. Mining: Steel plates are used in the construction of mining equipment, such as conveyor belts and crushers.

7. Transportation: Steel plates are used in the construction of ships, trains, and other forms of transportation.

8. Power generation: Steel plates are used in the construction of power generation equipment, such as turbines and generators.

9. Agriculture: Steel plates are used in the construction of agricultural equipment, such as plows and harvesters.

Fulfill all of your industrial SS plates and pipes needs with Tube Trading Co. - the most distinguished as well as noteworthy stainless steel dealer in Vadodara, Gujarat. Place your order now.

#Stainless steel plates in Vadodara Gujarat#Stainless steel plates dealer in Vadodara Gujarat#Stainless steel plates Supplier in Vadodara Gujarat#IBR pipe Plates in Vadodara#IBR pipe Plates in Gujarat

6 notes

·

View notes

Text

What Are PUF Panels? A Comprehensive Guide

In modern construction, innovation is key to building strong, durable structures that are energy-efficient and versatile. One of the materials revolutionizing the construction industry is the PUF panel. Whether you are constructing a commercial facility, an industrial warehouse, or a prefabricated building, PUF panels offer a cost-effective, efficient, and sustainable solution. But what exactly are PUF panels? Let’s dive into their world and explore their benefits and applications.

What are PUF Panels?

PUF stands for Polyurethane Foam, a thermoset plastic known for its excellent thermal insulation properties. PUF panels consist of a core layer of rigid polyurethane foam sandwiched between two outer layers, typically made from metal sheets such as steel or aluminum. These panels are lightweight, easy to install, and highly durable, making them a popular choice in various construction projects.

The Composition of PUF Panels

PUF panels have a three-layered structure:

Outer Layers: These are typically made from galvanized iron (GI), aluminum, or stainless steel sheets that provide strength, durability, and protection from environmental factors like corrosion, UV radiation, and physical impacts.

Core Layer: The core consists of a rigid polyurethane foam that offers excellent insulation properties, reducing heat transmission and helping maintain a stable indoor temperature.

Protective Coating: Many PUF panels come with an additional coating on the metal sheets for added protection against weather, fire, or chemicals.

Key Features of PUF Panels

Thermal Insulation: One of the most important properties of PUF panels is their ability to provide high thermal insulation. This reduces energy consumption for heating and cooling, making them ideal for environments where temperature control is crucial.

Lightweight: Despite being strong, PUF panels are lightweight, which makes them easy to transport, handle, and install. This reduces construction time and labor costs.

Fire-Resistant: Many PUF panels are designed with fire-resistant properties, adding an extra layer of safety to buildings.

Sound Insulation: In addition to thermal insulation, PUF panels also offer excellent soundproofing, making them suitable for noise-sensitive areas such as offices, schools, and hospitals.

Durability: The combination of a strong outer metal layer and a rigid foam core ensures that PUF panels are long-lasting and can withstand various environmental challenges, including moisture, corrosion, and extreme temperatures.

Customizable: PUF panels come in a variety of sizes, thicknesses, and finishes, allowing for customization based on specific project needs.

Applications of PUF Panels

PUF panels have found widespread applications across various industries due to their versatility and effectiveness. Some of the most common uses include:

Cold Storage and Refrigeration Units: The superior insulation properties of PUF panels make them ideal for cold storage units, food processing industries, and refrigerated warehouses.

Prefabricated Buildings: PUF panels are widely used in modular and prefabricated structures, including offices, homes, shelters, and exhibition halls. Their lightweight nature and ease of installation help speed up construction times.

Roofing and Cladding: PUF panels are often used as roofing and cladding materials in industrial and commercial buildings due to their durability, insulation properties, and ability to withstand harsh weather conditions.

Clean Rooms: In industries like pharmaceuticals and electronics, where controlled environments are crucial, PUF panels are used to create clean rooms with precise temperature and humidity controls.

Temporary and Permanent Structures: From exhibition halls and auditoriums to warehouses and factory sheds, PUF panels are used for building both temporary and permanent structures with ease.

Benefits of PUF Panels

Energy Efficiency: The insulation provided by PUF panels helps reduce the need for artificial heating and cooling, which in turn lowers energy consumption and costs.

Faster Construction: Being lightweight and easy to install, PUF panels significantly reduce construction time, helping to meet tight deadlines.

Cost-Effective: PUF panels offer long-term savings by minimizing maintenance costs, reducing energy bills, and ensuring durability.

Eco-Friendly: The reduced energy consumption makes PUF panels an environmentally friendly option. Many panels are also recyclable, further adding to their eco-friendly nature.

Versatility: These panels are suitable for a wide range of applications, from residential and commercial buildings to specialized industrial uses.

Conclusion

PUF panels are a game-changer in the construction industry, offering a host of benefits such as thermal insulation, durability, and versatility. Whether you're looking to build an energy-efficient office space, cold storage facility, or a prefabricated exhibition hall, PUF panels provide a reliable and cost-effective solution.

By combining performance with sustainability, they not only meet today’s construction needs but also contribute to a greener future.

#puf panel#prefab#pre engineered building manufacturers#warehouse#prefabricated#industrial#peb#porta cabin#railway shelters#security cabin

1 note

·

View note

Text

An Ultimate Guide to Selecting the Best Types of Roofing Sheets in India

Choosing the right roofing sheet is crucial for ensuring durability, efficiency, and aesthetic appeal. In India, there is a wide array of roofing sheets available, each offering distinct benefits. This guide will walk you through the various types of roofing sheets in India, helping you make an informed decision based on your specific needs.

1. Metal Roofing Sheets

Metal roofing sheets are a popular choice due to their durability and resistance to harsh weather conditions. They come in various types, including galvanized iron (GI), aluminum, and stainless steel. GI sheets are coated with zinc to prevent rust, while aluminum sheets are lightweight and corrosion-resistant. Stainless steel sheets, though more expensive, offer superior strength and longevity.

2. Asphalt Shingles

Asphalt shingles are known for their versatility and ease of installation. They are available in different styles and colors, allowing for a wide range of aesthetic options. These shingles are coated with asphalt and embedded with granules to provide a weather-resistant barrier. While not as common as metal sheets, asphalt shingles offer good performance and are suitable for various architectural styles.

3. Polycarbonate Roofing Sheets

Polycarbonate roofing sheets are favored for their transparency and impact resistance. These sheets allow natural light to filter through while providing protection from UV rays and extreme weather. They are commonly used in areas where light transmission is desired, such as greenhouses and skylights. Polycarbonate sheets come in both solid and multi-wall varieties, each offering different benefits.

4. Clay and Concrete Tiles

Clay and concrete tiles are traditional roofing materials that offer a classic look and excellent durability. Clay tiles are known for their natural resistance to fire and insects, while concrete tiles provide a more affordable option with similar benefits. Both types of tiles can withstand extreme weather conditions and are available in various shapes and colors.

5. Fiberglass Roofing Sheets

Fiberglass roofing sheets are lightweight and durable, making them an excellent choice for various applications. They are resistant to rust, corrosion, and impact, and can be molded into different shapes. Fiberglass sheets often come in translucent forms, allowing for natural light to enter while maintaining privacy and protection.

6. Green Roofs

Green roofs, or living roofs, incorporate vegetation into the roofing system. They provide natural insulation, reduce heat absorption, and contribute to environmental sustainability. This type of roofing requires a robust waterproofing layer and structural support to accommodate the weight of the plants and soil.

Conclusion

Selecting the right type of roofing sheet in India depends on various factors such as climate, aesthetic preferences, and budget. By understanding the different options available, you can make an informed choice that ensures both functionality and style for your building project. Whether you opt for metal, asphalt, polycarbonate, clay, concrete, fiberglass, or a green roof, each type of roofing sheet offers unique advantages to meet your specific needs.

0 notes

Text

Al-Hazazi: Pioneering the installation of high-quality sandwich panels

Al-Hazazi Awnings and Canopies Company is the perfect choice when it comes to installing sandwich panels. The company offers exceptional services at competitive prices and high quality, making it a reliable option to meet customer needs through the skill and extensive experience of its specialized team. Our team consists of experienced and competent engineers and technicians who ensure the precise and committed execution of installation processes, with long-term warranties for completed work.

Leading Company in Sandwich Panel Installation

Al-Hazazi Awnings and Canopies is among the top companies for installing sandwich panels. The company provides installation and supply services in various sizes and dimensions required for covering room roofs and wall installations. It also installs sandwich panels in hangars for protection, including large, medium, and small warehouses.

Diverse Sandwich Panels

We offer sandwich panels with high-quality insulation including polyurethane and a steel structure in various thicknesses. The company provides ساندوتش بانل all appropriate thicknesses for different locations according to client needs and environmental conditions. Sandwich panels are distinguished by their excellent insulation capacity, with various thicknesses available, such as (38-42) kg per meter.

Composition and Installation of Sandwich Panels

Sandwich panels consist of layers of galvanized sheet metal insulated with materials like aluminum, rock wool, or polystyrene, with the possibility of using glass wool in some cases. The advantages and costs vary based on these components, and Al-Hazazi Awnings and Canopies is considered a leader in this field as testified by its clients.

Various Uses of Sandwich Panels

Due to their superior insulation strength, sandwich panels are used in various applications, such as:

- Insulating sterile rooms to prevent microbial leakage and storage rooms for health materials.

- Refrigerated rooms to maintain low temperatures for food storage.

- Building temporary or lightweight apartments and rooms above buildings.

- Creating hangar walls for animals to provide protection.

- As a cover for villas or car garages to protect surfaces.

- Insulating electrical rooms to prevent electrical shorts.

Sandwich Panel Installation Method

Sandwich panels are installed professionally, involving steps like:

1. Preparing a suitable concrete base.

2. Using tongue and groove for wall installation.

3. Adding a foam layer with appropriate density.

4. Carefully installing the walls and roof.

5. Fixing Italian trims at the corners.

Advantages of Using Sandwich Panels

Sandwich panels offer numerous benefits, such as:

- Effective sound insulation.

- Maintaining cooling or heating.

- Lightweight.

- Cost savings.

- Ease of installation and dismantling.

- Long lifespan.

- Resistance to corrosion and rust.

Costs of Sandwich Panel Installation

The costs of installing sandwich panels depend on factors like the type of panels, installation location, project size, material costs, and labor. It's advised to choose imported panels for assured quality. Consideration should also be given to the costs of iron frames, transportation, and installation.

Available Specifications for Sandwich Panels

Sandwich panels are available in multiple thicknesses suitable for various uses, from 3.00 cm to 10.00 cm, with a variety of colors.

Reasons for Choosing Sandwich Panels

Customers prefer sandwich panels for their:

- Strength and lightweight.

- Flexibility and ease of fabrication.

- Quick installation.

- Variety in design.

- Weather resistance.

Fire-Resistant Sandwich Panels

Fire-resistant sandwich panels are favored for their ability to protect structures from accidents and chemicals. The materials used in their production are environmentally friendly and recyclable, available in various colors to meet customer preferences.

For inquiries, you can contact Al-Hazazi Awnings and Canopies at: 0503367548.

Exterior Designs for Sandwich Panels

The exterior facade design of sandwich panels is done according to customer needs, with possibilities of using materials like aluminum, parquet, or heat-resistant paint.

Best Types of Sandwich Panels

Al-Hazazi Awnings and Canopies offers high-quality sandwich panels using materials like solid iron and strong insulators, ensuring resistance to heat, sound, and corrosion.

Al-Hazazi provides the best materials and high-efficiency sandwich panel installation services, with a wide variety of thicknesses and sizes to meet customer needs.

Sandwich panels are considered the ideal solution for thermal and sound insulation. Al-Hazazi Awnings and Canopies offers expert and efficient installation services, making it the best choice in this field.

0 notes

Text

Allied Ispat India: Top Steel Product Manufacturers in India

Steel Product Manufacturers in India

The steel industry is pivotal to India’s infrastructure and industrial growth. Among the myriad of steel product manufacturers across the country, Allied Ispat Pvt. Ltd stands out for its extensive experience, dedication to quality, and wide array of steel products.

Allied Ispat Pvt. Ltd: A Premier Steel Manufacturer

Founded in 2001 under the Malik Group of Companies, Allied Ispat Pvt. Ltd brings over 50 years of combined expertise in the iron and steel industry. Based in Mumbai, the company is renowned for its superior steel products and holds the esteemed ISO 9001:2015 certification, ensuring top-notch quality standards.

Mission and Vision

Allied Ispat is driven by a mission to deliver top-tier steel products while maximizing customer satisfaction. Their vision is to lead the steel industry through innovation and unwavering quality.

Key Milestones

With a track record of achieving significant milestones and maintaining industry certifications, Allied Ispat has built a reputation for quality and dependability. Their dedication to excellence is evident in their diverse product offerings and client-focused approach.

Diverse Product Range of Allied Ispat Pvt. Ltd

Steel Partitions

Allied Ispat offers a variety of durable and aesthetically pleasing steel partitions. These are customizable to fit both commercial and residential needs, ensuring functional and stylish space solutions.

Ceiling Sections

Available in various sizes, their ceiling sections are perfect for construction and renovation projects. Designed to offer structural support and enhance visual appeal, these sections are adaptable to different design requirements.

Rolling Shutter Parts

From brackets to clips and springs, Allied Ispat’s rolling shutter parts are crafted for enhanced functionality and security. Made from premium materials, these parts guarantee long-lasting performance.

Galvanized CR (Cold Rolled) Sheets

Their cold rolled sheets come in narrow and wide widths, ideal for various industrial applications. Known for their strength and durability, these sheets provide reliable performance in diverse environments.

HR (Hot Rolled) Sheets

Characterized by high strength and wear resistance, Allied Ispat’s hot rolled sheets are suitable for heavy-duty applications. Available in different thicknesses and sizes, they meet the demands of rigorous use.

Color-Coated Sheets and Coils

Their color-coated sheets and coils, including vibrant blue and stylish wood-colored options, are perfect for architectural projects. These products combine aesthetic appeal with functional protection.

Roof Cladding Sheets

Engineered for superior weather protection and visual enhancement, their roof cladding sheets are available in both standard and customized options to meet various roofing needs.

Partition Sections

Allied Ispat’s partition sections come in various designs and sizes, providing flexibility for creating functional and attractive partition systems.

Product Briefings

Rolling Shutter Parts

GI Rolling Shutter Bracket: Essential for stability and smooth operation.

Galvanized Rolling Shutter Patti Clip: Enhances functionality and ensures reliable performance.

Galvanized CR (Cold Rolled) Sheets

Narrow Width Coils: Flexible and strong, suitable for diverse industrial uses.

Wide-Width Coils: Provides excellent coverage and durability for larger projects.

Color-Coated Sheets

Blue Color Coated PPGI: Popular for its vibrant hue and durability.

Wood Color Coated PPGI: Combines unique aesthetics with functional benefits.

Roof Cladding Sheets

Standard and Customized Options: Tailored to various roofing requirements and preferences.

Ceiling Sections

Ceiling Angle Channel: Provides structural support and design flexibility.

Ceiling Section: Available in multiple sizes to meet diverse construction needs.

Why Allied Ispat Pvt. Ltd Stands Out

Quality Assurance

Rigorous testing and quality control ensure Allied Ispat's products meet international standards. Their ISO 9001:2015 certification reflects their commitment to excellence.

Customer-Centric Approach

Allied Ispat offers customized solutions and dedicated customer support, ensuring tailored solutions that meet specific client needs.

Competitive Pricing

With a focus on cost-effectiveness without compromising quality, Allied Ispat delivers value-added services at competitive prices.

Contact Information

Registered Office

Shop No. 69, Chota Sonapur, M. S. Ali Road, Mumbai – 400 008, Maharashtra, India

Works

Plot No. C-17/9, MIDC Taloja, Behind Bank of Baroda, Raigad – 410208

Warehouse

Plot No. C-30, MIDC Taloja, Near CNG Pump, Pendhar, Dist Raigad – 410208

Conclusion

In the bustling arena of steel product manufacturers, Allied Ispat Pvt. Ltd rises above the rest. With a legacy of over 50 years through the Malik Group and a steadfast commitment to quality, this company sets a high bar in the industry. Their comprehensive product range—from robust steel partitions and ceiling sections to versatile rolling shutter parts and elegant color-coated sheets—reflects their ability to meet diverse industrial and construction needs.

Allied Ispat’s focus on quality assurance, customer satisfaction, and competitive pricing makes them a standout choice for anyone seeking reliable steel solutions. With their dedication to excellence and a customer-centric approach, Allied Ispat Pvt. Ltd is not just a manufacturer but a trusted partner in your steel product needs.

For more information or to explore their products, reach out to Allied Ispat and discover how they can enhance your projects with superior steel solutions.

FAQ: Discover What Sets Allied Ispat Pvt. Ltd Apart!

Q1: What makes Allied Ispat Pvt. Ltd a top pick in the world of steel product manufacturers?

With a dazzling 50+ years of industry prowess, Allied Ispat Pvt. Ltd stands out thanks to its exceptional quality and an impressive array of steel products. Their ISO 9001:2015 certification ensures you get top-notch, reliable steel solutions every time.

Q2: What kind of steel products can I expect from Allied Ispat Pvt. Ltd?

Whether you're after sleek steel partitions, versatile ceiling sections, rugged rolling shutter parts, or eye-catching color-coated sheets, Allied Ispat has you covered. They offer a comprehensive range of steel products designed to meet all your industrial and construction needs.

Q3: Where can I find Allied Ispat Pvt. Ltd?

Swing by their registered office at Shop No. 69, Chota Sonapur, M. S. Ali Road, Mumbai – 400 008. They also have their manufacturing works at Plot No. C-17/9, MIDC Taloja, and a handy warehouse at Plot No. C-30, MIDC Taloja, Pendhar, Dist Raigad – 410208.

Q4: How does Allied Ispat ensure their products are top-quality?

Quality is their hallmark! Allied Ispat’s commitment to excellence shines through its stringent testing and quality control, all backed by its prestigious ISO 9001:2015 certification. Expect nothing less than international standard steel products!

Q5: How can I get in touch with Allied Ispat Pvt. Ltd?

Ready to connect?

Call them at 9821177009 or 7977766800 for inquiries and orders. Feel free to visit their registered office for a more personal touch!

#industry#machinery#manufacturering#steel industry#steel#real estate#steel products#steel manufacturer#construction materials#ISO9001steel#SteelPartitions#SteelCustomization#SteelInnovation#IndustrialSteel

0 notes

Text

Color-Coated Steel: The Perfect Blend Of Aesthetics And Sustainability

When it comes to construction materials, color-coated steel is quickly becoming a popular choice for its unique blend of aesthetics and sustainability. Available in a wide range of vibrant hues, color coated sheets and roofing sheets can instantly transform the look of any building, from residential homes to commercial properties.

The PPGI (pre-painted galvanized steel) roofing sheets and PPGL (pre-painted galvalume steel) coils used in these color-coated products not only provide a beautiful finish, but also offer superior durability and corrosion resistance. Prepainted galvanized steel coil and color coated galvalume sheets are among the top choices for PPGI steel coil manufacturers looking to meet the growing demand for visually appealing yet environmentally-friendly building materials.

As sustainability becomes an increasingly important factor in construction, color-coated steel provides the perfect solution that blends form and function.

Color-Coated Steel: The Perfect Blend Of Aesthetics And Sustainability

Color-coated steel has emerged as a standout material in the construction industry, offering a perfect blend of aesthetics and sustainability. Its popularity is driven by a combination of visual appeal, durability, and environmental benefits. We’ll explore why color coated sheets are becoming the go-to choice for architects, builders, and homeowners alike.

Vibrant and Versatile Roofing Sheet Colors

One of the primary reasons for the growing popularity of color-coated steel is the wide variety of roofing sheet colors available. Whether you are looking for bold, vibrant shades or more subtle, earthy tones, there is a color coated roofing sheet to match any design vision. These sheets add a modern and stylish look to buildings, enhancing their curb appeal and value.

Durable and Long-Lasting PPGI Roofing Sheets

PPGI (Pre-Painted Galvanized Iron) roofing sheets are a popular type of color coated sheet. They are made by applying a layer of paint over galvanized steel, resulting in a product that is both aesthetically pleasing and highly durable. PPGI roofing sheets are resistant to corrosion, weathering, and UV radiation, ensuring they maintain their appearance and functionality over time. This makes them an excellent investment for any building project.

High-Quality Prepainted Galvanized Steel Coil

Prepainted galvanized steel coils are the raw material used to produce various color coated sheets. These coils undergo a thorough manufacturing process that includes cleaning, pre-treatment, painting, and curing, resulting in a high-quality product that meets stringent standards. PPGI steel coil manufacturers are dedicated to producing coils that offer superior performance, ensuring that the end products, like roofing sheets, are of the highest quality.

Sustainable Building Material

Color-coated steel is not only about aesthetics and durability; it is also a sustainable choice. The steel used in these products is often recycled, reducing the demand for virgin materials and minimizing environmental impact. Additionally, the coatings used on these sheets are designed to be environmentally friendly, with minimal VOC (Volatile Organic Compounds) emissions. Choosing color coated roofing sheets can contribute to greener building practices and a more sustainable future.

Versatility of Color Coated Galvalume Sheets

Color coated galvalume sheets offer another excellent option for construction projects. Galvalume is a steel sheet coated with a zinc-aluminum alloy, which provides enhanced corrosion resistance. When combined with a color coating, these sheets offer both superior durability and a stylish appearance. They are ideal for a wide range of applications, from residential roofing to commercial and industrial buildings.

Innovative PPGL Solutions

PPGL (Pre-Painted Galvalume) is similar to PPGI but uses a galvalume substrate instead of galvanized steel. This combination of galvalume’s corrosion resistance and the aesthetic benefits of pre-painting results in a product that is perfect for demanding environments. PPGL sheets are particularly well-suited for coastal areas and regions with harsh weather conditions, providing long-lasting protection and beauty.

Reliable PPGI Steel Coil Manufacturers

The quality of color coated sheets depends heavily on the manufacturers producing the raw materials. Reputable PPGI steel coil manufacturers ensure that their products meet high standards of quality and performance. They invest in advanced technology and rigorous quality control processes to produce coils that offer excellent consistency and reliability. Choosing products from these manufacturers guarantees that your color coated roofing sheets will meet or exceed your expectations.

Cost-Effective and Low Maintenance

In addition to their aesthetic and environmental benefits, color-coated steel sheets are also cost-effective and require minimal maintenance. Their durability means they need fewer repairs and replacements over time, saving money in the long run. Furthermore, the coatings on these sheets are designed to withstand the elements, reducing the need for frequent painting or cleaning. This makes them a practical choice for both residential and commercial buildings.

Easy Installation and Customization

Color-coated steel sheets are lightweight and easy to install, which can significantly reduce construction time and labor costs. They can be customized to fit specific design requirements, offering flexibility in architectural design. Whether you need sheets cut to size or specific shapes, manufacturers can provide products tailored to your project’s needs. This versatility makes color-coated steel an attractive option for a wide range of building applications.

Enhancing Energy Efficiency

Many color-coated steel products come with reflective coatings that can help improve a building’s energy efficiency. These coatings reflect more sunlight, reducing heat absorption and helping to maintain a cooler indoor environment. This can lead to lower energy costs for cooling, making color-coated roofing sheets a smart choice for energy-conscious builders and homeowners.

Color-coated steel represents a perfect blend of aesthetics and sustainability, offering a range of benefits that make it an excellent choice for modern construction projects. By choosing color-coated steel, you are investing in a product that enhances the visual appeal of your building, supports sustainable practices, and offers long-term cost savings. Whether for residential, commercial, or industrial applications, color-coated steel is a superior choice for today’s construction needs of aesthetics and sustainability.

Conclusion

As the construction industry continues to evolve, the demand for building materials that merge stunning aesthetics with eco-friendly credentials is higher than ever before.

Color-coated steel, with its vibrant color options, superior durability, and impressive sustainability, is perfectly positioned to meet this growing need. From PPGI roofing sheets and color coated roofing sheets to PPGI color coated sheets and color coated galvalume sheets, the versatility of this material allows it to be seamlessly integrated into a wide range of architectural styles.

PPGI steel coil manufacturers are further enhancing the appeal of color-coated steel by continuously improving their production processes to reduce the environmental impact. As homeowners and businesses prioritize sustainability alongside visual appeal, color-coated steel emerges as the ideal solution - a perfect blend of form and function that is poised to transform the future of the built environment.

0 notes

Text

JSW steel price list

Detailed view on JSW Steel Price List: A Comprehensive Guide for 2024

In the ever-evolving landscape of the construction and manufacturing industries, staying updated with the latest steel prices is crucial for making informed purchasing decisions. One of the leading steel manufacturers in India, JSW Steel, offers a range of high-quality steel products that cater to diverse needs. This article aims to provide a comprehensive guide on the JSW Steel price list, helping you navigate the complexities of steel pricing and make the best choices for your projects. And if you're looking to purchase JSW Steel products, Steeloncall.com is your go-to platform for competitive prices and reliable service.

Why JSW Steel?

JSW Steel is renowned for its commitment to quality and innovation. With state-of-the-art manufacturing facilities and a wide range of products, JSW Steel has established itself as a trusted name in the industry. Whether you are looking for TMT bars, hot-rolled coils, cold-rolled coils, or galvanized sheets, JSW Steel offers products that meet stringent quality standards and provide excellent performance.

Factors Influencing JSW Steel Prices

Several factors influence the pricing of JSW Steel products, and understanding these can help you make better purchasing decisions. Here are some key factors:

Raw Material Costs: The cost of raw materials, such as iron ore and coal, significantly impacts steel prices. Fluctuations in the prices of these raw materials can lead to changes in the overall cost of steel products.

Production Costs: The efficiency of production processes, energy costs, and labor expenses also play a role in determining the final price of steel.

Market Demand and Supply: The balance between demand and supply in the steel market can cause price variations. High demand and low supply typically lead to higher prices and vice versa.

Global Economic Conditions: Global economic trends, trade policies, and geopolitical factors can influence steel prices. For instance, changes in import/export tariffs can affect the cost of steel.

Currency Exchange Rates: Since steel is traded globally, fluctuations in currency exchange rates can impact the prices of steel products.

Current Trends in JSW Steel Prices

As of 2024, the steel industry is witnessing significant changes influenced by global economic conditions and technological advancements. The JSW Steel price list reflects these trends, with variations observed across different product categories. Here are some notable trends:

TMT Bars: TMT bars are a crucial component in construction, known for their strength and durability. The prices of JSW TMT bars have remained relatively stable, with minor fluctuations due to raw material costs and market demand.

Hot-Rolled Coils: Hot-rolled coils are widely used in manufacturing and construction. The prices of these coils have seen some upward movement, driven by increased demand in the automotive and infrastructure sectors.

Cold-Rolled Coils: Cold-rolled coils, known for their smooth finish and precision, have also experienced price increases. This is attributed to higher production costs and growing demand from the appliance and automotive industries.

Galvanized Sheets: Galvanized sheets, used for roofing and cladding, have shown a steady price trend with slight variations. The demand for these sheets in the construction industry continues to support stable pricing.

Why Choose Steeloncall.com for JSW Steel Products?

Steeloncall.com is your trusted partner for sourcing JSW Steel products. Here’s why you should consider Steeloncall.com for your steel requirements:

Competitive Pricing: At Steeloncall.com, we offer competitive prices for JSW Steel products, ensuring you get the best value for your money.

Wide Range of Products: We provide a comprehensive range of JSW Steel products, catering to various construction and manufacturing needs.

Quality Assurance: All our products meet stringent quality standards, giving you peace of mind and confidence in your purchases.

Convenient Online Platform: Our user-friendly website allows you to browse products, check prices, and place orders with ease.

Reliable Customer Support: Our dedicated customer support team is always ready to assist you with any queries or concerns.

How to Check the Latest JSW Steel Price List

To stay updated with the latest JSW Steel prices, you can visit Steeloncall.com. Our website provides real-time price updates and detailed product information, helping you make informed purchasing decisions. Here’s how you can check the latest prices:

Visit Steeloncall.com: Go to our website and navigate to the JSW Steel section.

Browse Products: Explore the range of JSW Steel products available.

Check Prices: Find the latest prices for the products you are interested in.

Place Orders: Add the desired products to your cart and proceed to checkout.

By regularly checking the price list on Steeloncall.com, you can stay ahead of market trends and make timely purchases to optimize your project costs.

Conclusion

Understanding the JSW Steel price list is essential for making informed purchasing decisions in the construction and manufacturing industries. With various factors influencing steel prices, staying updated with the latest trends is crucial. Steeloncall.com offers a reliable platform for sourcing JSW Steel products at competitive prices, ensuring you get high-quality materials for your projects.

Whether you need TMT bars, hot-rolled coils, cold-rolled coils, or galvanized sheets, JSW Steel provides a wide range of options to meet your needs. Trust Steeloncall.com for your steel requirements and experience hassle-free purchasing with top-notch customer support. Stay informed, stay ahead, and make the best choices for your projects with JSW Steel and Steeloncall.com.

0 notes

Text

What is color roofing sheets ? and where is uses and benefits...

Color roofing sheets, also known as color-coated roofing sheets, are metal sheets that are coated with a layer of color, typically using a process like Powder Coating or Pre-painted Galvanized Iron (PPGI). These sheets are widely used in roofing applications due to their aesthetic appeal, durability, and resistance to various environmental factors.

Uses of Color Roofing Sheets:

Residential Buildings:

Used for roofing in houses and residential complexes due to their attractive appearance and durability.

Commercial Buildings:

Applied in commercial establishments such as malls, shopping centers, and office buildings for roofing and cladding.

Industrial Buildings:

Utilized in factories, warehouses, and industrial sheds for their robustness and ability to withstand harsh environments.

Agricultural Structures:

Employed in farmhouses, barns, and other agricultural buildings for roofing purposes.

Public Infrastructure:

Used in public buildings, schools, hospitals, and community centers for roofing and wall cladding.

Recreational Facilities:

Applied in sports complexes, stadiums, and leisure facilities due to their versatility and aesthetic appeal.

Benefits of Color Roofing Sheets:

Aesthetic Appeal:

Available in a variety of colors and finishes, enhancing the visual appeal of buildings.

Durability:

Made from high-quality metal, these sheets are strong and can withstand extreme weather conditions, including heavy rain, snow, and wind.

Corrosion Resistance:

The color coating provides a protective barrier against corrosion, extending the lifespan of the sheets.

Thermal Efficiency:

Reflective coatings can reduce heat absorption, helping to keep buildings cooler and reducing energy costs for air conditioning.

Lightweight:

Easier to handle and install compared to traditional roofing materials, reducing the structural load on buildings.

Low Maintenance:

Requires minimal maintenance compared to other roofing materials, saving time and costs over the long term.

Eco-Friendly:

Often made from recyclable materials and can be recycled at the end of their life cycle, reducing environmental impact.

Versatility:

Can be used for both roofing and wall cladding, offering flexibility in architectural design.

Weather Resistance:

Provides excellent protection against UV rays, moisture, and temperature fluctuations.

Fire Resistance:

Many color roofing sheets are fire-resistant, adding an extra layer of safety to buildings.

Color roofing sheets are a popular choice in modern construction due to their combination of aesthetic appeal, durability, and functional benefits. They provide a practical and stylish solution for a wide range of roofing and cladding needs.

More Read: Roofing Sheet | Color Roofing Sheets

0 notes

Text

Elevate Your Projects with High-Quality Galvanized Color Coated Coils

Welcome to the Future of Industrial Materials

Wave goodbye to the mundane and say hello to the future of industrial materials with our premium Galvanized Color Coated Coils. Combining unbeatable strength, durability, and aesthetic appeal, our coils are crafted to meet diverse needs, ensuring your projects shine with both performance and style.

Allied Ispat Pvt. Ltd: Leaders in Quality Steel Products

Allied Ispat Pvt. Ltd, part of the esteemed Malik Group of Companies, excels in manufacturing and supplying top-tier steel products. Our extensive lineup includes Steel Partitions, Ceiling Sections, and Rolling Shutter Parts, all meeting the highest industry standards. With a commitment to excellence and innovation, we cater to diverse customer needs, delivering durability and reliability in every product.

What Makes Our Galvanized Color Coated Coils Exceptional?

Unmatched Durability

Our coils undergo a meticulous galvanization process, where steel sheets are immersed in molten zinc for unbeatable corrosion resistance. The added color coating not only boosts protection but also brings vibrant, lasting color to your projects.

Stunning Aesthetics

Available in a spectrum of colors and finishes, our coils help you achieve the exact look you envision. From bold, eye-catching hues to sleek, understated tones, the possibilities are endless.

Versatility at Its Best

Whether you're in construction, automotive, or manufacturing, our coils fit right in. Their adaptability makes them perfect for roofing, cladding, car bodies, appliances, furniture, and even fencing.

Explore Our Diverse Product Range

Galvanized Sheets

Our galvanized sheets are perfect for various applications, available in multiple thicknesses and dimensions, offering superior protection and structural integrity.

GI (Galvanized Iron) Coils

GI coils are known for excellent durability and resistance to harsh environments, ideal for roofing, walling, and cladding.

Colour Coated Wider Width Coils

Cover large surfaces effortlessly with our wider width coils, combining strength and versatility for expansive projects.

Galvanized Narrow Width Coils

For precision applications, our narrow width coils deliver exceptional performance, making them ideal for manufacturing smaller components.

Custom Galvanized Sheets

Need something specific? Our customizable galvanized sheets come in various finishes and coatings to meet your unique needs.

Why Choose Galvanized Color Coated Coils?

Long-lasting Durability

The dual protection of galvanization and color coating ensures your projects withstand the test of time, even in harsh conditions.

Eye-catching Designs

Elevate the look of any project with our wide range of colors and finishes, designed to complement any aesthetic.

Cost-effective Solutions

Enjoy long-term savings with our low-maintenance, durable coils that reduce the need for frequent replacements.

Applications That Benefit from Our Coils

Construction

Perfect for roofing, wall cladding, and structural components, our coils bring both beauty and durability to residential and commercial buildings.

Automotive

Ideal for manufacturing car bodies and components, our coils offer corrosion resistance and aesthetic appeal.

Appliances and Furniture

Enhance the durability and look of appliances and furniture with our versatile coils, suitable for various designs and functions.

Agriculture and Fencing

Our coils provide robust solutions for agricultural applications and fencing, standing strong against environmental elements.

Quality You Can Trust

We adhere to strict industry standards, ensuring that every coil meets rigorous quality checks. Our commitment to excellence means you receive products that consistently deliver top-notch performance.

Sustainability Matters

Our galvanization process extends the lifespan of steel, reducing waste and minimizing environmental impact. Plus, our color coatings are designed to be eco-friendly, supporting your sustainability goals.

Conclusion: Transform Your Projects Today

Step into the future with our high-quality Galvanized Color Coated Coils. Whether you're building skyscrapers, designing cars, crafting appliances, or fencing properties, our coils offer the durability, versatility, and stunning looks you need. Experience the difference that quality and expertise bring to your projects. Explore our range today and elevate your work to new heights!

0 notes

Text

Galvanized Plain Sheet Prices Trend, Monitor, News, Analytics and Forecast | ChemAnalyst

Galvanized Plain Sheet Prices: During the Quarter Ending December 2023

Galvanized Plain Sheet prices stand as a critical barometer in the construction, manufacturing, and infrastructure sectors, reflecting the dynamics of steel markets and broader economic trends. These sheets, coated with a protective layer of zinc to enhance durability and corrosion resistance, are indispensable in various applications, from roofing and cladding to automotive and agricultural equipment. Understanding the factors driving fluctuations in galvanized plain sheet prices is crucial for stakeholders across industries, from builders and contractors to steel producers and traders.

One of the primary determinants of galvanized plain sheet prices is the supply-demand balance within the steel industry. Fluctuations in steel production capacity, raw material availability, and operational efficiencies can directly influence the availability and cost of galvanized sheets. Factors such as changes in iron ore prices, energy costs, and regulatory policies impacting steel production can further exacerbate supply-side pressures, thereby affecting prices.

On the demand side, the construction and manufacturing sectors play pivotal roles in shaping the market for galvanized plain sheets. Economic growth, urbanization trends, and infrastructure development projects drive demand for steel products, including galvanized sheets, for use in building structures, transportation infrastructure, and machinery. Moreover, shifts in consumer preferences towards eco-friendly and sustainable construction materials can influence demand dynamics, impacting prices.

Get Real Time Prices of Galvanized Plain Sheet: https://www.chemanalyst.com/Pricing-data/galvanized-plain-sheet-1366

Global economic conditions and trade dynamics also exert significant influence on galvanized plain sheet prices. Economic downturns or recessions in major steel-consuming countries can lead to reduced demand for steel products, including galvanized sheets, putting downward pressure on prices. Conversely, periods of robust economic growth and infrastructure investment stimulate demand, potentially driving prices higher. Moreover, trade policies, tariffs, and geopolitical tensions can introduce uncertainties into the market, affecting supply chains and price competitiveness.

Technological advancements and innovations in steel production processes also play a role in shaping galvanized plain sheet prices. Improvements in manufacturing efficiency, cost-saving measures, and product innovations can impact production costs and, consequently, pricing strategies. Additionally, investments in research and development to develop new steel grades or coatings with enhanced properties may command premium prices in the market, influencing overall price levels.

Environmental regulations and sustainability concerns are increasingly influencing galvanized plain sheet prices. Growing awareness of climate change and the need for sustainable practices in the steel industry have led to the adoption of greener production methods and the use of recycled materials. Compliance with environmental standards and certifications, such as those related to carbon emissions and resource conservation, may entail additional costs for steel producers, which could be reflected in higher prices for galvanized sheets.

Furthermore, currency fluctuations and financial market conditions can impact the competitiveness of galvanized plain sheet prices in the global market. Exchange rate movements relative to major trading currencies can affect the cost of imported raw materials and finished steel products, influencing pricing strategies and export competitiveness. Moreover, interest rates, inflation expectations, and investor sentiment can influence investment decisions in the steel industry, indirectly affecting production levels and prices.

Get Real Time Prices of Galvanized Plain Sheet: https://www.chemanalyst.com/Pricing-data/galvanized-plain-sheet-1366

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Unlocking the Secrets of PPGI: A Versatile Solution for Modern Construction

Exploring the World of PPGI

In the realm of modern construction, innovative materials play a pivotal role in ensuring durability, efficiency, and aesthetic appeal. One such material that has been gaining traction in recent years is PPGI, which stands for Pre-Painted Galvanized Iron. This versatile solution offers a myriad of benefits across various construction projects, from residential buildings to industrial complexes. Let's delve deeper into what PPGI is and why it's becoming increasingly popular in the construction industry.

Understanding PPGI: What Sets It Apart?

PPGI is essentially a coated steel product that features a durable layer of paint applied to galvanized steel sheets. This coating not only enhances the aesthetic appeal of the material but also provides excellent protection against corrosion and harsh environmental conditions. The process of pre-painting the steel before it's formed into the final product offers several advantages, including uniform coating thickness and superior adhesion.

The Advantages of Using PPGI in Construction Projects

Durability and Longevity: PPGI is renowned for its exceptional durability, making it an ideal choice for structures that require long-term protection against rust and corrosion. Whether used for roofing, cladding, or structural components, PPGI offers a reliable solution that can withstand the rigors of diverse environments.

Versatility in Design: With a wide range of colors and finishes available, PPGI allows architects and designers to unleash their creativity and achieve stunning visual effects. Whether aiming for a traditional or contemporary aesthetic, PPGI can be customized to suit the unique requirements of any project.

Ease of Installation and Maintenance: Unlike traditional painting methods that require extensive surface preparation and ongoing maintenance, PPGI offers a hassle-free solution that can significantly reduce installation time and costs. Additionally, its smooth surface makes cleaning and upkeep a breeze, ensuring minimal maintenance requirements over the lifespan of the structure.

Applications of PPGI Across Industries

From residential housing to commercial complexes and industrial facilities, PPGI finds widespread application in various sectors of the construction industry. Its versatility, durability, and aesthetic appeal make it a go-to choice for roofing, siding, wall panels, and other architectural elements.

Embracing the Future of Construction with PPGI

As the demand for sustainable, cost-effective building materials continues to rise, PPGI emerges as a frontrunner in the realm of modern construction. Its unmatched combination of durability, versatility, and aesthetic appeal positions it as a valuable asset for architects, builders, and property owners alike. By harnessing the potential of PPGI, we can unlock new possibilities in architectural design and construction, paving the way for a brighter, more resilient future.

0 notes