#gas pipeline mapping software

Explore tagged Tumblr posts

Text

Enhancing Gas Pipeline Management with GIS: Key Benefits and Applications

In the energy and utilities sector, gas pipeline management is complex, requiring precision, safety, and a clear strategy for both existing infrastructure and future expansion. Geographic Information Systems (GIS) have revolutionized pipeline management by providing a spatially accurate, data-rich view of assets. From asset management and leak detection to route planning and demand forecasting, GIS is becoming indispensable for gas companies. This blog delves into the ways GIS transforms gas pipeline management, delivering benefits across safety, efficiency, cost-saving, and planning.

#benefits of using gis for gas pipelines#ensuring gas pipeline safety with gis tools#gas network analysis#gas pipeline asset management#gas pipeline gis mapping services#gas pipeline leak detection using gis#gas pipeline management in gis#gas pipeline mapping software#gas pipeline monitoring tools#gas pipeline risk assessment#gis applications in energy sector#gis for gas pipeline monitoring#gis for infrastructure management#gis in oil and gas industry#gis pipeline maintenance software#gis pipeline monitoring system#gis pipeline route planning#gis software for gas pipeline route optimization#victoryofgoodoverevil#gis solutions for pipeline maintenance and monitoring#gis-based pipeline integrity management#pipeline data management#pipeline geographic information systems#pipeline management solutions#remote sensing for gas pipelines#spatial analysis for gas pipelines#spatial data for gas pipelines

0 notes

Text

What is Dataflow?

This post is inspired by another post about the Crowd Strike IT disaster and a bunch of people being interested in what I mean by Dataflow. Dataflow is my absolute jam and I'm happy to answer as many questions as you like on it. I even put referential pictures in like I'm writing an article, what fun!

I'll probably split this into multiple parts because it'll be a huge post otherwise but here we go!

A Brief History

Our world is dependent on the flow of data. It exists in almost every aspect of our lives and has done so arguably for hundreds if not thousands of years.

At the end of the day, the flow of data is the flow of knowledge and information. Normally most of us refer to data in the context of computing technology (our phones, PCs, tablets etc) but, if we want to get historical about it, the invention of writing and the invention of the Printing Press were great leaps forward in how we increased the flow of information.

Modern Day IT exists for one reason - To support the flow of data.

Whether it's buying something at a shop, sitting staring at an excel sheet at work, or watching Netflix - All of the technology you interact with is to support the flow of data.

Understanding and managing the flow of data is as important to getting us to where we are right now as when we first learned to control and manage water to provide irrigation for early farming and settlement.

Engineering Rigor

When the majority of us turn on the tap to have a drink or take a shower, we expect water to come out. We trust that the water is clean, and we trust that our homes can receive a steady supply of water.

Most of us trust our central heating (insert boiler joke here) and the plugs/sockets in our homes to provide gas and electricity. The reason we trust all of these flows is because there's been rigorous engineering standards built up over decades and centuries.

For example, Scottish Water will understand every component part that makes up their water pipelines. Those pipes, valves, fitting etc will comply with a national, or in some cases international, standard. These companies have diagrams that clearly map all of this out, mostly because they have to legally but also because it also vital for disaster recovery and other compliance issues.

Modern IT

And this is where modern day IT has problems. I'm not saying that modern day tech is a pile of shit. We all have great phones, our PCs can play good games, but it's one thing to craft well-designed products and another thing entirely to think about they all work together.

Because that is what's happened over the past few decades of IT. Organisations have piled on the latest plug-and-play technology (Software or Hardware) and they've built up complex legacy systems that no one really knows how they all work together. They've lost track of how data flows across their organisation which makes the work of cybersecurity, disaster recovery, compliance and general business transformation teams a nightmare.

Some of these systems are entirely dependent on other systems to operate. But that dependency isn't documented. The vast majority of digital transformation projects fail because they get halfway through and realise they hadn't factored in a system that they thought was nothing but was vital to the organisation running.

And this isn't just for-profit organisations, this is the health services, this is national infrastructure, it's everyone.

There's not yet a single standard that says "This is how organisations should control, manage and govern their flows of data."

Why is that relevant to the companies that were affected by Crowd Strike? Would it have stopped it?

Maybe, maybe not. But considering the global impact, it doesn't look like many organisations were prepared for the possibility of a huge chunk of their IT infrastructure going down.

Understanding dataflows help with the preparation for events like this, so organisations can move to mitigate them, and also the recovery side when they do happen. Organisations need to understand which systems are a priority to get back operational and which can be left.

The problem I'm seeing from a lot of organisations at the moment is that they don't know which systems to recover first, and are losing money and reputation while they fight to get things back online. A lot of them are just winging it.

Conclusion of Part 1

Next time I can totally go into diagramming if any of you are interested in that.

How can any organisation actually map their dataflow and what things need to be considered to do so. It'll come across like common sense, but that's why an actual standard is so desperately needed!

789 notes

·

View notes

Text

The universe on display: The powerful instruments that allow us to observe the cosmos

Starting today, the Earth will be passing through a meteor shower. But in astronomy, the human eye is very much a limited tool. But increasingly powerful instruments are allowing us to peer ever deeper into the cosmos and ever further back in time, shedding new light on the origins of the universe.

Today, scientists are able to observe an exoplanet orbiting its star, an individual galaxy and even the entire universe. "The universe is actually mostly empty space," says Jean-Paul Kneib, a professor at EPFL's Laboratory of Astrophysics. "There isn't much that's hidden."

The key is to know what you're looking for, build the right instrument, and look in the right direction. And then to do a little housekeeping.

"Our galaxy sits in the foreground of our field of vision, blocking our view beyond it," explains Kneib. "So if we want to map hydrogen in the early universe, for example, we first have to model this entire foreground then remove it from our images until we obtain a signal a million times smaller than the one emitted by the Milky Way."

Galileo could draw only what he saw with his telescope. But today, astronomers can see the universe in its entirety, right back to its very beginnings. This is largely because of rapid advancements in the instruments they use. And more developments are expected in the years ahead.

The James Webb Space Telescope (JWST), launched in December 2021, aims to observe events that happened 13 billion years ago when the first stars and galaxies were forming. The Square Kilometre Array (SKA) radio telescope—currently under construction and scheduled for completion by the end of the decade—will look back even further to a time when there were no stars and the cosmos contained mainly hydrogen—the element that makes up 92% of all atoms in the universe.

"An easy way to detect this gas is to operate in the radio frequency range, which is exactly what the SKA will do," says Kneib. "The aim is to detect a signal a million times smaller than the foreground signals."

Another project in the pipeline is the Laser Interferometer Space Antenna (LISA), run by the European Space Agency (ESA). Scheduled for launch in 2035, the antenna will observe gravitational waves, shedding light on the growth of black holes and possibly the waves created just after the Big Bang.

Playing digital catch-up

These new instruments wouldn't be so enlightening without advancements in other fields. "As things stand, we don't have the software to process data from the SKA," says Kneib, who's confident that we'll get there eventually thanks to progress in computer and computational science, artificial intelligence (AI) and processing power. AI is invaluable for sorting through vast quantities of data to find an interesting anomaly and for calculating the mass of galaxies, for example.

"Scientists can use the gravitational lensing effect, whereby a large object bends light from a distant source, to calculate the mass of galaxy clusters to within a range of one percent, just as if they were using a scale," explains Kneib. "And we can train AI models to spot distortions in images caused by gravitational lenses. Given that there are probably 200 billion galaxies in the universe, that's a huge help—even if we can measure the mass of only one galaxy in every thousand."

But do the images we see depict what's really out there? A famous image published in 2019 showed a donut-shaped ring of light surrounding a black hole. Would we actually see that ring if we got close to it?

"It wasn't an optical photo," says Kneib. "It was a purely digital rendering. In order to accurately observe the millimeter-wavelength signals emitted by the black hole, scientists had to combine multiple ground-based telescopes to create one roughly the size of the globe. The image was then reconstructed via interferometry [a measurement method using wave interference].

"But the image nevertheless represents a real signal, linked to the amount of matter in the dust cloud surrounding the black hole. In simple terms, the dark part is the black hole and the lighter part is the matter orbiting it."

Seeing in four dimensions

"Calculations are only part of the equation in astronomy—you need to be able to visualize things, which also helps you check that your calculations are correct," says Kneib, who is capable of reading the majestic image of the Lagoon Nebula, situated 4,000 light-years away, like a book.

"That image was produced using optical observations at different wavelengths to depict the various gases. Of course, there was a bit of artistry involved in enhancing the colors. But the image also has a great deal of significance for physicists. The colors indicate the presence of different gases: red for hydrogen, blue for oxygen and green for nitrogen. The compact, black areas contain large quantities of dust. These are typically the regions where stars form."

Visualization is especially important when observing objects in more than two dimensions. "By studying the cosmos in three dimensions, we're able to measure the distance between celestial objects," says Kneib.

In early April, scientists working on the Dark Energy Spectroscopic Instrument (DESI) project—including astrophysicists from EPFL—announced they had created the largest ever 3D map of the universe's galaxies and quasars.

But that's not all: researchers are also studying the universe in the fourth dimension—time—and, in doing so, opening up incredible possibilities for observing bright yet fleeting phenomena. "For example, we don't really understand the origin of fast radio bursts, which are incredibly bright blasts of electromagnetic radiation that last only a few seconds at most, and sometimes just a fraction of a millisecond," says Kneib.

Will we ever find life on an exoplanet? Kneib replies, "With infrared interferometry, there's a very real prospect that we could take a photo of a planet orbiting around another star. The image would likely be blurry, but we'd be able to observe and characterize features such as clouds and structural variations on the planet's surface. That's definitely a possibility, maybe 20 or 30 years from now."

When it comes to some fundamental questions, however, we're unlikely to find the answers through imaging alone. Why is the universe expanding at an accelerating rate? Is it because of dark energy? Why is 80% of matter invisible? Are we completely wrong about gravity? Future generations of astrophysicists will keep their eyes trained on the skies or glued to their screens as they try to unravel the deepest mysteries of our universe.

IMAGE: The Lagoon Nebula. Credit: NASA, ESA, STSCI

4 notes

·

View notes

Text

Using AR Wearables for Better Safety on Job Sites

Introduction

Imagine walking onto a construction site and instantly receiving real-time hazard alerts, step-by-step equipment instructions, and immediate access to safety protocols – all projected directly onto your field of vision. This is the promise of AR wearables for job site safety. By integrating Augmented Reality (AR) technology into wearable devices, we’re creating safer, more efficient, and more informed work environments.

In this blog, we will explore how AR wearables are revolutionizing safety practices, offering a new level of protection and awareness for workers in demanding industries.

What are AR Wearables?

AR wearables are wearable devices, such as smart glasses or helmets, equipped with Augmented Reality technology. These devices overlay digital information onto the user’s real-world view, providing contextual data, instructions, and alerts in real-time. In the context of job sites, this means workers can access critical safety information hands-free, improving response times and reducing the risk of accidents.

How AR Wearables are Transforming Job Site Safety

Real-Time Hazard Detection

AR wearables can use sensors and cameras to identify potential hazards and alert workers instantly:

Object recognition identifies unsafe conditions, like blocked pathways or faulty equipment.

Proximity alerts warn of nearby machinery or dangerous areas.

Environmental monitoring detects gas leaks, temperature extremes, or other environmental risks.

Hands-Free Access to Information

AR wearables allow workers to access crucial information without interrupting their tasks:

Step-by-step instructions for equipment operation and maintenance are projected directly in view.

Digital schematics and blueprints are overlaid on the physical environment for accurate navigation and task execution.

Instant access to safety protocols and emergency procedures is available at all times.

Improved Communication and Collaboration

AR wearables facilitate better communication and collaboration among team members:

Remote experts can provide real-time guidance and support through AR-enabled video conferencing.

Workers can instantly share visual information and report hazards.

Team leaders can monitor site conditions and provide immediate feedback.

Enhanced Training and Skill Development

AR wearables offer interactive and immersive training experiences:

Simulated scenarios allow workers to practice safety procedures in a safe and controlled environment.

Real-time feedback and guidance help workers improve their skills and knowledge.

On-the-job training becomes more effective with AR-guided instructions and demonstrations.

Reduced Accidents and Injuries

By providing real-time information, improving communication, and enhancing training, AR wearables contribute to:

Fewer workplace accidents and injuries.

Increased worker awareness and preparedness.

Safer and more productive work environments.

Industries Embracing AR Wearables for Safety

Construction

Real-time hazard alerts, equipment guidance, and remote expert support.

Manufacturing

Step-by-step assembly instructions, quality control checks, and safety protocol reminders.

Oil and Gas

Leak detection, pipeline inspection, and remote maintenance assistance.

Mining

Hazard mapping, equipment monitoring, and emergency response coordination.

Challenges in Implementing AR Wearables

Cost

Initial investment in AR wearable devices and software can be significant.

Connectivity

Reliable internet connectivity is crucial for real-time data transmission and remote support.

User Adoption

Workers may require training and support to use AR wearables effectively.

Ergonomics

Comfort and usability are essential to ensure workers can wear devices for extended periods.

The Future of AR Wearables in Safety

As AR technology continues to advance, we can expect to see:

More sophisticated hazard detection capabilities.

Integration with IoT devices for real-time data collection and analysis.

Enhanced AI-powered assistance for personalized safety recommendations.

Conclusion

AR wearables are revolutionizing job site safety by providing workers with real-time information, improving communication, and enhancing training. By embracing this technology with the help of Modnexus, industries can create safer, more productive, and more efficient work environments.

0 notes

Text

Saudi Arabia's Drone Revolution: What’s Coming Between 2025–2031

The future is flying—literally.

If you haven’t been paying attention to Saudi Arabia’s skies lately, now’s the time. The country is embracing drone technology at full throttle. From construction megaprojects to smart farming, drones are shaping industries in bold new ways.

And the forecast? 📊 Massive growth between 2025 and 2031.

✨ Why Drones Matter More Than Ever

Here’s why UAVs (unmanned aerial vehicles) are no longer just for hobbyists in Saudi Arabia:

🔹 Construction Projects Like NEOM Huge developments need constant visual tracking. Drones are perfect for aerial progress shots, mapping, and even 3D modeling.

🔹 Oil & Gas Goes Safer Flare stack inspections? Pipeline surveys? Now handled by drones—faster and safer than manual checks.

🔹 Smart Logistics in Smart Cities Drone delivery? It’s not sci-fi anymore. Saudi Arabia’s urban projects are testing it for real-world applications.

🔹 Tech-Driven Farming Thermal imaging, crop monitoring, and water tracking—drones are making desert farming smarter and more efficient.

📍 The Market Forecast: 2025 to 2031

Based on research from Studio52, we’re expecting:

✔️ Year-on-year growth in drone deployment ✔️ Demand explosion for aerial media, inspections & data capture ✔️ Increased investment in drone software & AI integration

✈️ Flight Plans Backed by Law

The GACA (General Authority of Civil Aviation) in Saudi Arabia isn’t holding tech back. Their licensing and regulation systems make commercial drone use easier than ever.

🎥 Not Just Pretty Footage—Powerful Tools

Drones help businesses:

Monitor real estate & site development

Promote with stunning aerial content

Cut inspection time and boost safety

Make data-driven decisions from above

📌 Bottom Line: Saudi Arabia is not just catching up with the drone revolution—it’s leading it.

💡 Want to capture the skies for your next project?

Studio52 offers drone filming services in Saudi Arabia for industrial, corporate, and cinematic needs. Let’s fly higher—together.

#drone filming services in saudi arabia#drone filming#saudi arabia drone filming in saudi arabia#drone photography

0 notes

Text

High-Precision Mapping |Our Drone & Aerial Surveying Services

In today’s fast-paced and technology-driven world, traditional surveying methods are rapidly being replaced by advanced drone and aerial surveying solutions. Whether it’s construction planning, land development, mining operations, or agricultural monitoring, drone technology is revolutionizing the way we map, measure, and manage large-scale projects.

If you're looking for top drone and aerial surveying services in India, you're in the right place. Our expert drone service providers deliver accurate, efficient, and cost-effective mapping solutions tailored to meet the diverse needs of industries across the country.

Why Choose Drone Surveying & Mapping Services?

Drone-based surveying is not just a trend—it’s a powerful tool that offers several advantages over conventional methods:

High-Accuracy Results: Capture detailed images and data with centimeter-level accuracy using GPS-enabled drones and RTK technology.

Faster Data Collection: Complete surveys that once took weeks in just hours with aerial drones.

Reduced Manpower & Cost: Cut down on labor costs and time with automated drone flights.

Safety & Accessibility: Survey remote, hazardous, or hard-to-reach areas without risking lives.

Versatile Applications: Suitable for multiple industries—construction, mining, agriculture, oil and gas, urban planning, and more.

Our Drone Surveying Services Include:

Topographic & Contour Mapping We create precise topographic maps and contour lines for land development, construction, and urban planning projects.

Orthomosaic Mapping Generate georeferenced high-resolution maps stitched from drone-captured images, ideal for planning and analysis.

Digital Elevation Models (DEM) & Digital Surface Models (DSM) Get elevation data critical for hydrological modeling, flood risk analysis, and infrastructure design.

3D Modeling & Photogrammetry Create realistic 3D models of terrain, structures, and infrastructure with detailed visual representations.

Land Surveying & Volume Estimations Accurate volume calculations for stockpiles, cut/fill operations, and earthwork planning in mining and construction.

Asset Inspection & Monitoring Perform aerial inspections for power lines, pipelines, solar farms, wind turbines, and industrial assets without shutdowns.

Industries We Serve

We provide drone surveying and mapping services for:

Construction and Real Estate

Agriculture and Forestry

Mining and Quarrying

Oil and Gas

Infrastructure Development

Environmental Monitoring

Urban Planning and GIS Projects

Pan-India Coverage with Professional Support

Our drone service network spans across Delhi, Mumbai, Bangalore, Hyderabad, Chennai, Pune, Ahmedabad, and other major cities, ensuring timely project delivery and complete regulatory compliance with DGCA (Directorate General of Civil Aviation) guidelines.

Our licensed drone pilots and GIS specialists are trained professionals equipped with state-of-the-art drones and software to deliver exceptional results. From pre-project planning to post-processing and analysis, we offer end-to-end drone solutions that are reliable, scalable, and designed for success.

Contact Us Today Ready to take your surveying and mapping projects to new heights? Contact us now for a free consultation and discover how drone technology can optimize your operations and decision-making process.

0 notes

Text

The Role of Fixed-Wing Drones in Modern Aerial Intelligence

In today’s fast-evolving landscape of unmanned aerial technology, fixed-wing drones are proving to be a game-changer across industries. At the forefront of this innovation is Aebocode Technologies, a company dedicated to harnessing the power of drone technology to deliver smarter, more efficient aerial solutions. From large-scale surveying to precision agriculture, fixed-wing drones are paving the way for more comprehensive and cost-effective aerial data collection.

What Are Fixed-Wing Drones?

Unlike their multi-rotor counterparts, fixed-wing drones are designed with a rigid wing structure that mimics traditional airplanes. This configuration enables them to glide through the air using aerodynamic lift, resulting in greater endurance and coverage compared to rotary drones. With the ability to fly for extended periods (often exceeding one hour) and cover vast distances, fixed-wing UAVs are ideal for missions that require long-range aerial intelligence and high-efficiency mapping.

Why Fixed-Wing Drones Matter in 2025

As industries become more data-driven, the demand for high-resolution, geospatially accurate data is growing exponentially. Fixed-wing drones meet this demand by offering:

Extended Flight Time: Capable of staying airborne for 60–180 minutes.

Large Area Coverage: Perfect for mapping hundreds of hectares in a single flight.

Fuel and Power Efficiency: Uses less energy compared to multi-rotors.

Higher Speed and Altitude: Allows fast deployment over difficult terrain.

Key Applications of Fixed-Wing UAVs

1. Land Surveying and Topographic Mapping

Fixed-wing drones, equipped with LiDAR or high-resolution RGB cameras, can quickly scan vast terrains and generate precise topographic maps. This is particularly useful for civil engineering, construction planning, and land development. At Aebocode Technologies, our drone solutions provide centimeter-level accuracy, ensuring that project decisions are based on reliable geospatial data.

2. Precision Agriculture

With the ability to fly over large crop fields efficiently, fixed-wing drones help farmers monitor crop health, detect irrigation issues, and assess yields. Our integrated NDVI and multispectral imaging systems allow for early detection of stress conditions, empowering smart, data-driven decisions in farming.

3. Infrastructure Inspection

Whether it’s pipelines, railways, or power lines, fixed-wing drones offer long-range surveillance with real-time telemetry. Unlike helicopters or ground patrols, drones can safely and affordably inspect remote areas with minimal human risk and environmental disruption.

4. Disaster Response and Environmental Monitoring

In emergency situations, quick aerial assessment is critical. Fixed-wing drones can fly over disaster-hit areas, map flood zones, or track wildfires in real time. Their long endurance allows for continuous data collection, enabling emergency teams to act with precision.

How Aebocode Technologies Leads the Way

At Aebocode Technologies, we don’t just build drones—we build end-to-end aerial data solutions. Our fixed-wing platforms are engineered for durability, precision, and performance, and our software ecosystem ensures seamless data integration from sky to screen.

Key features of our drone systems include:

Autonomous Flight Modes – Simple mission planning with GPS waypoints.

AI-Powered Data Processing – Transform raw data into actionable insights.

Modular Payload Options – Customize with LiDAR, multispectral, thermal, or RGB sensors.

Cloud Integration – Real-time data sync and analytics via our secure platform.

We cater to a wide range of sectors including agriculture, mining, infrastructure, oil and gas, and environmental science. Our mission is to make aerial data more accessible, accurate, and impactful.

The Fixed-Wing vs. Multi-Rotor Debate

While multi-rotor drones are better suited for vertical take-offs, tight navigation, and smaller job sites, fixed-wing UAVs excel in scale, efficiency, and speed. For industries requiring large-scale data collection—especially in rural or remote regions—fixed-wing systems are the preferred choice.

FeatureFixed-WingMulti-Rotor

Flight Time 1–3 hours 20–40 minutes

Coverage Area Up to 5000+ hectares/day Limited

Payload Capacity Moderate to high Moderate

VTOL (Vertical Take-Off and Landing) Optional Built-in

Ideal Use Case Surveying, agriculture, inspection Inspection, filming, surveillance

Aebocode offers hybrid VTOL fixed-wing drones, combining the best of both worlds—easy take-off with the long-range capability of a winged aircraft.

Regulatory Compliance and Safety

Drone operations, especially fixed-wing, often fall under strict aviation regulations. Aebocode ensures that every flight adheres to local DGCA (India) or international aviation guidelines, with trained pilots and mission planning that emphasizes safety, privacy, and compliance.

Choosing the Right Fixed-Wing Drone for Your Needs

Before investing in a fixed-wing drone solution, consider:

Flight Duration Requirements

Terrain Type and Accessibility

Sensor Needs (LiDAR, RGB, Thermal, etc.)

Budget and ROI Goals

Aebocode Technologies offers consultation services to help businesses select the right drone based on mission profile and operational needs.

The Future of Fixed-Wing Drones

With advancements in AI, edge computing, and battery technology, fixed-wing drones are becoming more autonomous, intelligent, and capable. They are no longer just flying machines—they are platforms for data intelligence and smart decision-making.

As 5G and IoT expand connectivity, expect fixed-wing UAVs to be part of integrated smart infrastructure in agriculture, urban planning, and disaster response systems. The integration of swarm technology and BVLOS (Beyond Visual Line of Sight) capabilities will further revolutionize the way aerial data is collected and applied.

Conclusion

Fixed-wing drones represent the next frontier in aerial surveying, inspection, and environmental monitoring. With their superior range, efficiency, and adaptability, they offer unmatched value for industries looking to scale operations with data-first strategies.

At Aebocode Technologies, we are committed to delivering the best in fixed-wing drone solutions—built for performance, tailored for your mission, and backed by expert support. Explore the future of unmanned aerial intelligence with us.

0 notes

Text

How to Conduct an Accurate Route Survey: Step-by-Step Process

In any infrastructure project - these are roads, pipelines, power lines, or telecommunications networks - accuracy is important in planning. A route survey is the foundation that ensures that the proposed path is possible, efficient and safe. In this initial stage, errors can lead to later delays, cost overrun and design changes. This is the reason why it is necessary to detect the root survey properly for the success of the project.

In this blog, we will break the step-by-step process to conduct an accurate passage survey using a combination of traditional and modern techniques.

What Is a Route Survey?

A route survey is the process of collecting and analyzing geographical data with a proposed corridor for the development of infrastructure. The goal is to define the most suitable path for construction, while the terrain, while accounting for environmental conditions and man -made obstacles.

Examples of where route surveys are used:

Road and highway plan

Railway construction

Pipeline alignment (oil, gas, water)

Strength and telecom line layout

This type of survey usually includes horizontal and vertical alignment, topography, cross-section and sometimes property limitations.

Tools and Technologies in Route Surveying

Modern survey has come a long way from manual measurement. Today, professional equipment and technology rely on:

Total Stations: For measuring distances and angles precisely.

GNSS/GPS Receivers: To obtain accurate geographic coordinates.

Drones (UAVs): Useful for aerial views and 3D terrain modeling.

LIDAR Sensors: For high-resolution elevation and terrain data.

Software Tools: AutoCAD Civil 3D, GIS software, and point cloud tools are used for processing data and creating visual layouts.

These tools help reduce human error and speed up the surveying process while improving precision.

Step-by-Step Process to Conduct a Route Survey

Step 1: Define Scope and Objectives

The first step is understanding the scope of the project-which requires the formation of the area, the size and the end-user requirements.

Consider the following:

Type of infrastructure (road, rail, pipeline)

Start and end locations

Regulatory guidelines

Expected deliverables (maps, digital models, reports)

Being clear objectives will be streamlined by the entire survey process and unnecessary data collection will be avoided.

Step 2: Desktop Study

Before going to the area, study a desktop to review the existing data and maps.

Gather:

Topographic and cadastral maps

Satellite images

GIS layers (forests, rivers, elevation)

Land-use data

This step helps shortlists potential routes and estimate potential challenges, such as preserved land or vertical areas.

Step 3: Field Reconnaissance

Field reconnaissance is an early site trip, also known as "walkover survey". This is a chance to inspect the physical conditions of the route on the ground.

Checklist for field recon:

Note man-made and natural obstacles

Observe slope gradients and soil types

Identify entry points and access roads

Speak with locals or landowners if necessary

This step verifies the beliefs made during the desktop study and prepare the team for full data collection.

Step 4: Establish Control Points

To maintain accuracy throughout the project, you have to install the survey control point. All these are reference points used for measurement and mapping.

Process:

Use GNSS equipment or total stations to fix primary control points

Set secondary points at regular intervals

Record elevation and coordinate data

Mark them physically on the ground using stakes, flags, or paint

These control points ensure that your measurements are aligned with real world coordinates. ,

Step 5: Route Alignment Survey

This route is the main activity in the survey process. This involves collecting detailed topographic and height data along the proposed corridor.

Typical activities include:

Running a centerline through the proposed route

Measuring horizontal and vertical distances

Capturing cross-sections at set intervals (e.g., every 25 meters)

Noting landmarks, vegetation, water bodies, and buildings

Use a combination of total stations, GPS Survey receivers and leveling instruments to collect this data.

Step 6: Use of Drones (Optional but Recommended)

Drone routes are bringing revolution in surveys, especially in hard-to-wheel or large-scale projects.

Benefits of drone surveys:

Fast and efficient data collection

High-resolution aerial imagery

3D terrain modeling using photogrammetry

Safe access to difficult or hazardous terrain

When paired with ground control points, drone can offer centimeter-level accuracy.

Step 7: Data Processing and Mapping

Once the data is collected, it should be processed using special software.

Tools commonly used:

AutoCAD Civil 3D: For creating alignment layouts, profiles, and cross-sections

QGIS or ArcGIS: For spatial analysis and mapping

ReCap or Pix4D: For processing drone imagery

You will convert raw data into usable outputs such as topographic maps, root alignment, profiles and area models.

Step 8: Evaluate Route Alternatives

If many route options are available, compare them based on several factors:

Cost implications

Construction feasibility

Environmental impact

Social and legal constraints

GIS equipment can help score each route and highlight the most practical path. Often, the best route is not the smallest, but the least resistance and cost.

Step 9: Mark Final Alignment

After selecting the optimal passage, the site has time to mark the physically final alignment.

Process:

Place stakes or flags to mark the centerline and key features (e.g., bridge locations)

Paint markers on pavements or trees where applicable

Use GPS to re-verify alignment locations

Inform construction teams of alignment coordinates

The final marking ensures that the passage is clearly defined to designers and contractors.

Step 10: Reporting and Documentation

The final stage is to compile a comprehensive report describing the entire survey process and its findings.

The report should include:

Overview of methods used

Maps and drawings

Control point data

Elevation profiles and cross-sections

Environmental and legal notes

Drone images (if used)

This documentation is essential for engineering team, customers and government regulators.

Challenges in Route Surveying

Even the best survey plan can withstand real -world obstacles. Common challenges include:

Difficult terrain: Hills, rivers, and forests can slow down data collection.

Weather conditions: Rain and fog affect GPS signals and visibility.

Land ownership issues: Trespassing laws or disputes can restrict access.

Data errors: Inconsistent or inaccurate measurements can derail the design process.

To overcome these, always have backup plans, use strong equipment, and double-checked data for stability.

Why Accuracy Matters in Route Surveys

There are long -term benefits of an accurate route survey that affect the entire project life cycle:

Better design decisions: With reliable data, engineers can optimize construction techniques.

Lower construction costs: Fewer surprises during construction mean fewer budget overruns.

Regulatory approvals: Accurate maps and reports help secure permits faster.

Environmental safety: Well-planned routes reduce impact on ecosystems and communities.

1 note

·

View note

Text

Dimensional Control Survey Services

Dimensional Control Survey Services: Precision That Powers Modern Industry

In the complex world of engineering, construction, and manufacturing, precision isn’t just a preference—it’s a necessity. Whether aligning massive offshore platforms, verifying the position of structural steel in skyscrapers, or assembling high-tolerance equipment in aerospace, accuracy can mean the difference between success and costly rework. This is where Dimensional Control Survey Services play a crucial role.

These services are designed to ensure that every component of a project—no matter how large or intricate—is positioned and constructed exactly as intended. With the help of advanced technology and proven measurement methodologies, dimensional control survey services provide the confidence industries need to move forward with precision.

What Are Dimensional Control Survey Services?

Dimensional control survey services refer to the application of highly accurate measurement techniques to verify and align physical components according to design specifications. Unlike general land surveying, which might focus on mapping property lines or topography, dimensional control specializes in the precise spatial positioning of structures, systems, and equipment.

These services are used in settings where tolerances are tight and accuracy is critical. They ensure that fabricated parts, structural assemblies, and installed systems fit together perfectly, preventing errors that can delay projects, compromise safety, or increase costs.

Industries That Depend on Dimensional Control

A wide range of industries rely on dimensional control survey services, including:

Oil and Gas In offshore and onshore environments, dimensional control is essential for platform installation, module alignment, and pipeline routing. These projects require millimeter-level accuracy to ensure safety and structural integrity under harsh conditions.

Construction and Infrastructure Large-scale building projects often involve prefabricated components and complex geometries. Dimensional control helps ensure everything fits correctly during assembly—especially in high-rise buildings, bridges, stadiums, and industrial plants.

Aerospace and Defense In industries where performance and safety standards are non-negotiable, dimensional control supports quality assurance during manufacturing, assembly, and inspection processes.

Shipbuilding and Maritime From hull construction to engine alignment, dimensional control enables the accurate fitting of components and systems on vessels of all sizes.

Renewable Energy Wind turbines and solar arrays require exact positioning to optimize performance. Dimensional control survey services ensure proper alignment, especially in offshore installations.

Heavy Equipment Manufacturing Complex assemblies such as turbines, pressure vessels, and large machinery parts need to meet precise tolerances. Survey services help verify alignment during manufacturing and installation.

How Dimensional Control Works

Dimensional control survey services follow a systematic process that includes planning, measurement, analysis, and reporting:

Planning and Setup Surveyors begin by establishing reference points or control grids based on design drawings and engineering requirements. These control points form the basis for all measurements.

Data Acquisition Using advanced equipment like total stations, 3D laser scanners, photogrammetry tools, and laser trackers, surveyors capture exact spatial data about structures or components. These instruments offer sub-millimeter precision.

Data Processing and Analysis Collected data is processed through specialized software to compare actual measurements with design specifications. Deviations, if any, are identified and quantified.

Reporting and Recommendations A detailed report is generated, often with 3D models or visual overlays, showing the current condition of the structure or system relative to the intended design. If corrections are needed, the survey team provides adjustment instructions.

Key Technologies Used in Dimensional Control Surveying

Total Stations Combining electronic distance measurement and angle measurement, total stations are used to collect precise point data in 2D or 3D space.

Laser Scanners 3D laser scanners capture millions of data points quickly, creating high-resolution point clouds that represent the measured environment in detail.

Laser Trackers These portable instruments are often used in industrial environments for measuring large components with extreme accuracy.

Photogrammetry Using high-resolution photographs to reconstruct accurate 3D models, this method is valuable for both documentation and measurement.

CAD Integration Modern survey services integrate directly with Computer-Aided Design (CAD) software, enabling a seamless comparison between as-built and as-designed models.

Benefits of Dimensional Control Survey Services

Accuracy and Precision Dimensional control ensures that construction and assembly are performed to exact specifications, minimizing rework and error.

Time and Cost Savings Identifying potential misalignments or discrepancies early in the process reduces costly delays and material waste.

Improved Safety By ensuring proper alignment and structural integrity, these services reduce the risk of failure during or after construction.

Quality Assurance Dimensional control adds an extra layer of verification that helps maintain the high standards required in industries like aerospace and energy.

Digital Documentation Survey results are stored in digital formats, enabling future reference, maintenance planning, and compliance documentation.

Challenges in Dimensional Control Surveying

Although dimensional control survey services offer undeniable benefits, they also come with challenges:

Complex Environments Crowded job sites, poor lighting, and weather conditions can impact the ease and accuracy of measurement.

Technical Expertise Operating advanced surveying instruments and interpreting the data correctly requires specialized training and experience.

Integration with Other Systems Ensuring smooth communication between field data and design software is critical for accurate comparisons and adjustments.

Cost of Equipment High-end laser scanners and trackers are expensive, and maintaining them to ensure accuracy requires ongoing investment.

The Future of Dimensional Control Surveying

As technology advances, dimensional control survey services are poised to become even more precise, efficient, and integrated. Future trends include:

Automation and Robotics Robotic systems will increasingly take on repetitive or hazardous measurement tasks, improving safety and consistency.

Real-Time Monitoring Using sensors and IoT technology, engineers will be able to track structural changes in real time, enabling predictive maintenance and early intervention.

Artificial Intelligence AI algorithms will help process survey data faster, identify errors automatically, and suggest optimal correction strategies.

Virtual and Augmented Reality VR and AR tools will allow engineers and clients to visualize survey data interactively, enhancing collaboration and decision-making.

Conclusion

Dimensional control survey services are the unsung heroes of precision-driven industries. They ensure that what’s built in the field matches what’s designed on paper—down to the last millimeter. From massive offshore platforms to finely tuned manufacturing assemblies, these services reduce errors, enhance safety, and uphold the highest standards of quality and efficiency.

As industries continue to evolve and embrace digital transformation, the demand for dimensional control will only grow. Investing in these services is more than a measure of precision—it’s a commitment to excellence, sustainability, and the future of modern engineering.

1 note

·

View note

Text

Hydrographic Survey

Hydrographic Survey: Mapping the World Beneath the Waves

When we think of maps, our minds often go to mountains, roads, or cityscapes. But just as the land above water is charted and studied, the vast and complex terrain beneath oceans, rivers, and lakes also demands careful measurement. That’s the role of a Hydrographic Survey—a specialized field dedicated to exploring, mapping, and understanding underwater environments. These surveys are vital for navigation, engineering, resource management, environmental protection, and scientific discovery.

A Hydrographic Survey doesn’t just capture depth; it reveals the character, structure, and dynamic processes of the aquatic world. As industries expand offshore and climate change intensifies the need for coastal resilience, the importance of accurate underwater data has never been greater.

What Is a Hydrographic Survey?

A Hydrographic Survey is the process of measuring and describing the physical features of oceans, seas, coastal areas, rivers, lakes, and the seabed. The primary focus is on bathymetry—measuring the depth of water and determining the topography of the underwater surface. However, it can also involve current profiling, tide and wave monitoring, sediment sampling, and shoreline analysis.

Using advanced equipment such as single-beam and multi-beam echo sounders, side-scan sonar, LiDAR, GPS, and autonomous vehicles, hydrographers gather precise data that inform critical decisions in construction, navigation, and environmental conservation.

The Evolution of Hydrographic Surveying

Historically, hydrographic surveys involved manual methods like lead line soundings, which were slow, labor-intensive, and prone to error. Today, however, the field has been revolutionized by technology. Multi-beam sonar systems can map vast seafloor areas in high resolution, while airborne LiDAR bathymetry allows for rapid coastal assessments. Unmanned Surface Vessels (USVs) and Autonomous Underwater Vehicles (AUVs) further increase coverage and safety.

Modern Hydrographic Surveys rely heavily on software for data processing, visualization, and integration into Geographic Information Systems (GIS). The ability to analyze and present detailed underwater models is essential for engineering, navigation, and policy-making.

Why Are Hydrographic Surveys Important?

Hydrographic Surveys serve multiple industries and public needs. Here are some of the most significant applications:

Safe Navigation Perhaps the most critical application of hydrographic surveys is supporting maritime safety. Accurate charts help ships avoid underwater hazards, navigate shallow waters, and approach ports and harbors with confidence. National and international hydrographic offices use survey data to produce official nautical charts and publications.

Marine Construction and Infrastructure Any construction project near or on water—such as bridges, tunnels, piers, or offshore wind farms—requires detailed hydrographic data. Engineers need precise depth measurements, seabed conditions, and current data to design safe and effective structures. Surveys are often performed before, during, and after construction to ensure alignment and structural integrity.

Dredging Operations Maintaining navigable waterways often involves dredging, where sediment is removed from the bottom of rivers, ports, or canals. Hydrographic Surveys guide dredging efforts by identifying sediment buildup and verifying post-dredging results. This helps avoid over-dredging or under-dredging, optimizing both costs and environmental impact.

Environmental Monitoring Understanding aquatic environments is essential for protecting ecosystems. Surveys can reveal erosion patterns, sediment transport, water quality indicators, and habitat changes. They are essential tools in managing marine protected areas, planning coastal resilience strategies, and evaluating environmental impact.

Subsea Cable and Pipeline Routing Telecommunication cables, gas pipelines, and power connectors laid underwater depend on hydrographic data for safe and efficient routing. Surveys identify suitable paths, assess potential obstacles, and monitor the condition of these critical infrastructures over time.

Disaster Response and Risk Management In the wake of natural disasters like tsunamis or hurricanes, hydrographic surveys help assess damage to underwater infrastructure, ports, and shorelines. They also aid in search and rescue efforts by identifying debris or submerged hazards.

Scientific Research and Exploration Oceanographers, marine biologists, and geologists rely on hydrographic surveys to understand seabed features, plate tectonics, coral reefs, and underwater volcanoes. These surveys contribute to our knowledge of the planet and uncover new opportunities for sustainable development.

Core Technologies in Hydrographic Surveys

To meet the growing demands for precision, speed, and safety, hydrographic surveyors utilize a suite of sophisticated tools:

Echo Sounders: These send sound pulses to the seabed and measure the time it takes for the echo to return. Multi-beam echo sounders provide wide swath coverage, creating detailed 3D maps.

Side-Scan Sonar: Produces high-resolution images of the seabed by emitting sound waves at an angle. It is especially useful for detecting objects like shipwrecks or pipelines.

GNSS and RTK GPS: Provide centimeter-level positioning accuracy for survey vessels and equipment.

LiDAR (Light Detection and Ranging): Especially useful in shallow or coastal areas, airborne LiDAR systems can map both land and water surfaces simultaneously.

Unmanned Vessels: Remote-controlled or autonomous survey vessels can operate in hazardous or shallow areas without risking human safety.

Challenges of Hydrographic Surveys

Conducting a Hydrographic Survey is not without obstacles. Environmental conditions such as rough seas, strong currents, and limited visibility can interfere with measurements. Equipment calibration, data processing, and georeferencing require expertise and careful attention to detail. Additionally, collecting data in politically sensitive or remote regions poses logistical and regulatory challenges.

Data management is another major consideration. The volume of information collected during a single survey can be enormous. Converting raw data into usable formats for charts, 3D models, or GIS applications takes time, processing power, and trained personnel.

Emerging Trends in Hydrographic Surveying

As the world continues to digitize and automate, Hydrographic Surveys are evolving in step. Key trends shaping the future of the industry include:

Integration with BIM and Digital Twins: Survey data is increasingly being used in Building Information Modeling (BIM) systems to create real-time, interactive representations of marine and coastal infrastructure.

Artificial Intelligence and Automation: Machine learning algorithms can now process and interpret large datasets faster and more accurately than ever, accelerating decision-making.

Cloud-Based Collaboration: Teams across continents can now work on the same survey projects using cloud-based platforms that allow for real-time data sharing and analysis.

Sustainability and Climate Resilience: Hydrographic data is crucial in modeling sea-level rise, storm surge, and erosion. This makes it a cornerstone of climate adaptation strategies for coastal cities and vulnerable communities.

Conclusion

A Hydrographic Survey is far more than a series of measurements—it is a gateway to understanding the underwater world and enabling human progress in harmony with natural forces. From ensuring the safety of maritime navigation to laying the groundwork for renewable energy, the applications are both vast and vital.

As technology continues to advance and the demand for coastal development increases, Hydrographic Surveys will play a central role in shaping the future of marine infrastructure, environmental protection, and ocean science. Whether you're steering a vessel, designing an underwater pipeline, or planning a resilient coastline, the accuracy and insight provided by hydrographic surveying are indispensable.

1 note

·

View note

Text

Hydrographic Survey DimCon

Hydrographic Survey DimCon: Understanding Its Role in Modern Marine and Infrastructure Development

In today’s rapidly evolving world of marine exploration, offshore construction, and coastal infrastructure, accurate data about underwater terrain and water depth is critical. This is where a Hydrographic Survey DimCon becomes essential. The term refers to a hydrographic survey process tailored by dimensional control (DimCon) standards, which ensure that every measurement aligns precisely with engineering and construction specifications. Whether for ports, oil platforms, underwater pipelines, or scientific research, the Hydrographic Survey DimCon methodology supports safe, efficient, and cost-effective project execution.

Understanding this concept requires diving into the fundamentals of hydrographic surveying, dimensional control, and how the integration of the two transforms operations beneath and around bodies of water.

The Fundamentals of Hydrographic Surveying

At its core, hydrographic surveying is the science of measuring and describing features that affect maritime navigation, marine construction, dredging, offshore drilling, and related activities. It includes measuring water depth (bathymetry), locating underwater obstacles, charting the seafloor, and gathering data on tides, currents, and sediment.

The tools used in hydrographic surveys have become increasingly advanced, with technologies such as single-beam and multi-beam echo sounders, side-scan sonar, LiDAR (Light Detection and Ranging), GNSS (Global Navigation Satellite System), and autonomous surface vehicles (ASVs). Each tool contributes to building an accurate map of the underwater world, which is vital for safety, environmental protection, and engineering precision.

What Is Dimensional Control (DimCon)?

Dimensional control is a precise measurement process used across many industries, especially in construction, manufacturing, and oil and gas. It ensures that every component of a project aligns with design specifications, minimizing error margins and maximizing structural integrity.

DimCon methodology revolves around the accurate positioning of assets and structures, whether on land or underwater. By using control points, reference grids, and advanced measurement equipment like laser scanners, total stations, and 3D modeling software, dimensional control verifies that everything fits as planned. It reduces rework, ensures compliance with engineering standards, and saves both time and money.

The Intersection of Hydrographic Surveying and Dimensional Control

When hydrographic surveying is executed with dimensional control standards, it becomes Hydrographic Survey DimCon. This integration is particularly critical in marine construction projects where underwater structures must match up perfectly with those above the surface.

For example, when installing offshore wind turbines, underwater foundations must be positioned with centimeter-level precision. A Hydrographic Survey DimCon ensures that the seabed is mapped correctly, anchoring points are positioned within tight tolerances, and the infrastructure is aligned as per design. This level of accuracy is vital not only for structural integrity but also for regulatory compliance and long-term maintenance.

Similarly, in dredging operations, combining hydrographic data with DimCon principles ensures that excavation follows exact plans, avoiding over-dredging or under-dredging, both of which can have serious financial and environmental consequences.

Applications of Hydrographic Survey DimCon

The applications of Hydrographic Survey DimCon span across industries and geographies. Here are some of the most common use cases:

Port and Harbor Development: Before expanding a port or building new berths, developers need accurate bathymetric data. A Hydrographic Survey DimCon ensures docks, piers, and mooring facilities align precisely with ships and cargo infrastructure, enabling safe navigation and efficient operations.

Oil and Gas Projects: Underwater pipelines, platforms, and risers must be placed accurately to avoid stress and ensure operational safety. A DimCon-based hydrographic survey supports engineering teams in achieving flawless alignment and depth accuracy.

Subsea Cables and Telecommunications: Laying underwater cables for telecommunications or power requires exact mapping of the seabed to avoid natural hazards and optimize cable routes. Hydrographic Survey DimCon plays a crucial role in both planning and post-lay verification.

Environmental Monitoring: Projects that aim to study or preserve aquatic ecosystems need precise data on topography, sediment transport, and water movement. Combining hydrographic surveys with dimensional control enhances the reliability of environmental models and impact assessments.

Bridge and Tunnel Construction: Infrastructure that crosses water bodies, such as bridges or immersed tube tunnels, depends on accurate underwater surveys for alignment. Hydrographic Survey DimCon helps prevent costly misalignments during construction.

Dredging and Reclamation: Coastal development often involves dredging and land reclamation. A DimCon approach ensures the dredged areas match volume and depth requirements while minimizing ecological disturbance.

Key Benefits of Hydrographic Survey DimCon

There are multiple reasons why engineering firms and marine developers are increasingly adopting Hydrographic Survey DimCon:

Precision: High-resolution mapping and tight dimensional tolerance lead to better construction outcomes and lower error rates.

Efficiency: Accurate data reduces rework, delays, and unexpected field adjustments.

Safety: Knowing the exact underwater terrain reduces the risk of accidents or equipment damage.

Regulatory Compliance: Many jurisdictions now mandate high-accuracy surveys for marine and offshore construction. DimCon compliance ensures smooth approval processes.

Cost Savings: Accurate execution minimizes project overruns, litigation risk, and post-construction corrections.

Integration: Data from Hydrographic Survey DimCon can be seamlessly integrated into Building Information Modeling (BIM) systems and other digital engineering workflows.

Challenges in Implementing Hydrographic Survey DimCon

Despite its advantages, implementing Hydrographic Survey DimCon isn’t without challenges. It requires:

Specialized Equipment: High-end sonar, GNSS receivers, and dimensional measurement tools are expensive and require calibration.

Trained Personnel: Engineers and surveyors must be skilled in both hydrography and dimensional control techniques.

Data Management: The volume of data collected can be immense, requiring sophisticated processing software and workflows.

Environmental Conditions: Weather, currents, tides, and underwater visibility can affect measurement accuracy.

These challenges, however, are often outweighed by the long-term gains in efficiency, safety, and quality assurance.

Future of Hydrographic Survey DimCon

As global infrastructure moves toward smarter, more sustainable designs, the demand for accurate, integrated data will continue to rise. The future of Hydrographic Survey DimCon is likely to be shaped by:

Automation: Autonomous vehicles (underwater and surface) equipped with high-precision sensors will expand the speed and scale of data collection.

AI and Machine Learning: Smart algorithms will help interpret vast hydrographic data sets in real-time, providing actionable insights faster.

Digital Twins: Hydrographic DimCon data will feed into digital replicas of marine assets and environments, allowing for predictive maintenance and advanced simulation.

Sustainability Compliance: As environmental regulations tighten, detailed underwater data will be essential for minimizing impact and proving compliance.

Conclusion

Hydrographic Survey DimCon stands at the intersection of marine science and precision engineering. It brings together the power of hydrographic data with the accuracy of dimensional control to meet the complex demands of today’s underwater construction and exploration projects. Whether for oil rigs, ports, or environmental research, this approach enables professionals to make better decisions, reduce risk, and build with confidence.

As industries push further into offshore territories and seek smarter, more sustainable infrastructure solutions, the value of Hydrographic Survey DimCon will only grow. It’s not just about measuring water depth—it’s about mastering the unseen world beneath the surface with the precision that modern development demands.

1 note

·

View note

Text

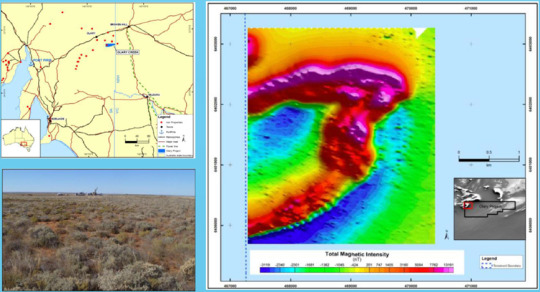

Proton Magnetometer | High-Sensitivity Geomagnetic Survey Device

Abstract

The GEO-M Proton Magnetometer represents a breakthrough in ground-based magnetometer technology, engineered for geophysical exploration professionals. As the fastest proton precession magnetometer currently available, this lightweight field instrument delivers 0.05nT sensitivity for detecting subtle magnetic anomalies across 20,000-120,000nT dynamic range. This professional magnetometer integrates military-grade durability with cutting-edge measurement capabilities. Its OCXO-stabilized system ensures ±0.1nT absolute accuracy, making it ideal for mineral prospecting, archaeological surveys, and tectonic studies.

Why Choose GEO-M Magnetometer?

Ultra-Precise Measurement

0.01nT resolution with temperature-compensated OCXO oscillator

Multi-Scenario Adaptability

3 operational modes (Mobile/Walking/Base) for diverse field conditions

Smart Synchronization

30μs GNSS time sync across GPS/BeiDou/GLONASS systems

Military-Grade Protection

IP67-rated aluminum housing withstands -40℃~55℃ extremes

Advanced Features of Proton Magnetometer

Real-Time Data Visualization

Magnetic field curves display with gradient measurement capability

Efficient Workflow Design

Continuous walking-mode acquisition (3-60s sampling)

Dual Data Transfer

USB/R232 interfaces with 32MB internal storage

Professional Software Integration

Generate contour maps and 3D magnetic profiles

Key Applications of GEO-M Magnetometer

Mineral Exploration

Iron/copper/zinc ore detection with 5000nT/m gradient tolerance

Energy Sector

Oil & gas reservoir mapping through structural analysis

Environmental Monitoring

Earthquake/volcanic precursor observation networks

Engineering Survey

Pipeline detection & underground infrastructure mapping

Archaeological Research

Non-invasive relic localization technology

Field Implementation Scenarios

Iron Ore Prospecting

In Mongolia’s Gobi region, GEO-M units achieved 150 survey points/day with 0.08nT repeatability, identifying 3 potential deposits through magnetic anomaly mapping.

Archaeological Discovery

Brazilian teams utilized walking-mode acquisition to map 12th-century settlement patterns, detecting buried artifacts at 2.3m depth through magnetic contrast analysis.

Specifications

SpecificationsSensitivity : 0.05nT Dynamic range :20,000-120,000nT Absolute accuracy :± 0.1nTResolution : 0.01nT Sample :3~ 60s @Mobile Mode; 3~3600s @Base Mode. Gradient Tolerance: >5000nT/mRemote Control : optional remote control via RS-232 interface Input/Output : RS-232 via 10 pin weatherproof connector with USB adaptorInternal Memory :32MB(209715 readings in Manual Mode, 699050 readings in Base Mode)Dimension & weight:Console: 220mm(L)×70mm(H)×175mm(W);1.57kg Sensors: 140mm(L)×70mm(D); 1kg Operating Temperature:– 40°C to + 55°CStandard ConfigurationGPM-10 Console 1xHarness / Charger1xSensor with Cable 1xAluminum rod 50cm 4xStandard GPS 1xRS-232 Cable with USB adapter 1xInstruction Manual 1xShipping Case 1x

Case study

**Challenge:** Accurately map complex banded iron formations through 50m+ overburden.

**Solution:** GEO-M’s 0.05nT sensitivity enabled detection of:

12 distinct mineralized zones

3 previously unknown fault lines

**Result:** 22% faster survey cycle vs traditional proton magnetometers.

0 notes

Text

How is Drone Technology Shaping Surveying and Mapping in the UAE? Explore the Benefits

Technology continues to revolutionize conventional Emirates industries with extraordinary speed throughout the rapidly changing environment of the United Arab Emirates. Drone surveying and mapping represents a transformative monitoring system which changes our methods of visual and quantitative analysis of the real world environment. Drones along with their advanced sensing capabilities offer insights to Dubai's skyline and Abu Dhabi's infrastructure expansion and the vast arid terrains between them which was previously inaccessible or financially unreachable.

The Rise of Aerial Precision in the Emirates

The UAE's progressive development plan requires both specific and efficient and inventive approaches. surveying through traditional methods struggles to handle complex terain conditions and large construction works and continuous area monitoring requirements in the UAE. Drone Surveying & Mapping UAE services serve as the ideal solution because they provide accurate data acquisition functions that deliver fast operations and affordable solutions.

Applications Transforming Industries

Construction and Infrastructure Development

The architectural wonders of the nation receive vital lifecycle support from drone technologies used in construction projects. The mapping process through the air ensures the timely completion of projects and budget goals, together with quality maintenance.

Urban Planning and Smart City Initiatives

Detailed topographical information combined with 3D modeling functionality provided by drone surveys is the key form of support for UAE smart city implementation. The collected information helps city planners create data-based strategies regarding future city expansion and required infrastructure systems and environmental stewardship.

Oil and Gas Exploration

The energy industry adopts drone technology to provide safer remote site inspection services and drilling site mapping and remote pipeline surveillance through rugged terrain. The decrease of employee hazards at work sites becomes a major operational improvement point through drones.

Environmental Monitoring and Conservation

The utilization of drones enables ecological researchers to study ecological habitats while protecting sensitive natural environments since they offer exclusive data access.

Technological Capabilities

Three core features of contemporary drone surveying capabilities offer multiple sensing technologies and information processing features:

The use of LiDAR technology allows surveyors to create thorough three-dimensional point cloud data arrays.

Multispectral and thermal imaging for advanced analysis

Photogrammetry software generating centimeter-accurate ortho mosaic maps

Real-time data transmission for immediate decision-making

Regulatory Framework and Future Outlook

The UAE government has constructed evolving rules which achieve a harmony between advancements in technology while addressing safety and privacy matters. A licensed drone operator needs to follow stringent rules which become especially important while flying around airspace adjacent to airports as well as government buildings and residential districts. As technology progresses more laws are generated while new practical applications become available.

The future of Drone Surveying & Mapping UAE looks exceptionally bright. The implementation of artificial intelligence for both automated flight pattern operation and data evaluation processes will provide constantly developing capacities. Professionals in mapping and surveying will exclusively depend on drones as their essential inspection tool because of ongoing improvements in flight duration capabilities, sensor refinement and data analysis programming.

The Selection of an Ideal Drone Surveying Organization is Vital for Success

Organizations must carefully choose their service provider when they want to utilize these beneficial technologies. Key considerations include:

Technical expertise and equipment quality

Your selection of a service provider should include operators who hold expertise within your industry niche.

The selection process should focus on how providers handle data processing functions as well as their delivery format capabilities.

Proper licensing and regulatory compliance

Privacy and data security protocols

The United Arab Emirates shows excellence in technological leadership which serves as the perfect setting to advance drone surveying and mapping applications further. Supersmart flying data-gathering systems are becoming both more powerful and widely accessible while changing our ways of comprehending and developing physical aspects of our world. Drone technology serves as a modern essential asset in the Emirates' path toward impressive development activities as it supports both architectural advancements and natural terrain protection initiatives.

Accurate Survey offers expert drone surveying and mapping services in UAE. If you would like to explore more you can visit the page.

0 notes

Text

Control Surveys in Southwest Georgia: Ensuring Accurate Land Development

When it comes to land surveying, precision is everything. Whether you're developing property, constructing infrastructure, or mapping land boundaries, accurate measurements are crucial. This is where control surveys play a vital role. For residents and businesses in Southwest Georgia, understanding the importance of control surveys can streamline projects and ensure long-term success. At NASH SURVEYING & DESIGN, we specialize in delivering high-quality control surveys to support your development goals.

What is a Control Survey?

A control survey is a type of land survey that establishes precise reference points for future mapping and construction activities. These reference points form a network of horizontal and vertical control points that guide engineers, architects, and construction teams throughout the project.

In Southwest Georgia, where land conditions can vary between flat plains and uneven terrains, control surveys ensure that measurements remain consistent and reliable. This method prevents costly mistakes and minimizes errors in large-scale developments.

Why Are Control Surveys Important?

Control surveys provide a foundation for accurate mapping and design. They are critical for:

1. Construction Projects: From roads and bridges to commercial developments, control surveys ensure that structures are aligned correctly and meet design specifications.

2. Land Subdivision: Accurate boundary lines are crucial for property division, avoiding disputes and legal issues.

3. Infrastructure Development: Control surveys support the installation of utilities such as water lines, gas pipelines, and power grids.

4. Mapping and GIS Data Collection: Control points create reliable reference systems for geographic mapping, ensuring data accuracy for planners and developers.

5. Floodplain Management: Accurate elevation data from control surveys helps determine flood risk zones and guide proper drainage system planning.

Key Components of a Control Survey

Control surveys involve several essential steps to ensure precision:

1. Establishing Reference Points: Surveyors place stable, durable markers in key locations to act as permanent reference points.

2. Using Advanced Equipment: High-precision GPS devices, total stations, and laser scanners are employed to gather accurate data.

3. Data Analysis: Collected data is analyzed using specialized software to confirm accuracy and create detailed mapping frameworks.

4. Verification Process: Cross-checking measurements ensures all control points align with existing geographical data.

Benefits of Choosing NASH SURVEYING & DESIGN

Choosing an experienced team like NASH SURVEYING & DESIGN ensures your project in Southwest Georgia receives accurate and dependable results. Our experts specialize in:

Customized Solutions: We tailor our control surveys to match the unique needs of your property and project.

State-of-the-Art Equipment: We utilize advanced GPS technology, total stations, and digital mapping software to deliver precise data.

Local Expertise: With extensive knowledge of Southwest Georgia's landscape, we account for environmental factors and regional conditions to ensure accurate results.

Compliance Assurance: We adhere to state and national surveying standards, ensuring your project meets all legal and regulatory requirements.

Applications of Control Surveys in Southwest Georgia

In Southwest Georgia, control surveys are particularly valuable in the following sectors:

Agricultural Land Management: Accurate measurements support irrigation planning, boundary marking, and land division for farms and plantations.

Urban Development: Growing cities like Albany, Thomasville, and Bainbridge rely on precise mapping to expand infrastructure efficiently.

Transportation Projects: From highway expansions to new road networks, control surveys are vital for aligning routes and structures.

Environmental Preservation: Surveys aid in mapping conservation areas, ensuring ecosystems are protected during development.

Final Thoughts

For any land development project in Southwest Georgia, investing in a professional control survey is essential to ensure accuracy, efficiency, and compliance. At NASH SURVEYING & DESIGN, we are committed to delivering reliable results with precision and expertise. Our team understands the local landscape, ensuring your project starts with a strong foundation.

0 notes

Text

The Role of Natural Gas LDAR Programs

Natural gas LDAR (Leak Detection and Repair) programs are essential for minimizing methane emissions and ensuring environmental compliance. These initiatives utilize advanced technologies to detect, measure, and repair leaks in natural gas systems. By identifying leaks early, industries can prevent significant losses, reduce greenhouse gas emissions, and adhere to strict regulatory standards.

Implementing a natural gas LDAR program requires collaboration between skilled professionals and innovative technology. The process often involves routine inspections, real-time monitoring, and precise repairs to maintain system integrity. Companies that prioritize these programs benefit not only from enhanced safety but also from improved operational efficiency and reduced environmental impact.

Advanced Gas Leak Detection Devices

Gas leak detection devices are critical tools in the battle against gas leaks. These devices leverage sophisticated sensors and cutting-edge technology to identify leaks in pipelines, storage facilities, and other infrastructure. Their precision and reliability enable industries to detect even the smallest leaks, reducing potential hazards and financial losses.

The versatility of gas leak detection devices allows them to be used across various industries, including oil and gas, manufacturing, and utilities. By integrating these devices into regular maintenance routines, organizations can enhance safety, prevent costly repairs, and contribute to a cleaner environment.

Using Gas Leak Survey Equipment for Comprehensive Monitoring