#gold nanoparticles

Text

A 1.4-nm gold cluster covalently attached to antibodies improves immunolabeling.

This is the paper that I had to present. It's not a very long paper and it certainly wasn't very difficult to understand. The gist of the paper is that this group was able to create a 1.4 nm gold nanoparticle with a surrounding organic shell that contained a maleimide group. That single maleimide group covalently bonds to a sulfhydryl group that is part of the Cysteine amino acid in the protein. Once the protein has coupled to the gold it can be measured using transmission electron microscopy (TEM) and/or scanning transmission electron microscopy (STEM) to measure the stoichiometry of the interaction. This allows us to determine if the gold to protein ratio is one-to-one, which, for the purposes of my project, is what we want.

···

This development is useful because having a dense gold particle attached to the relatively "non-dense" protein allows us to "see" where the proteins are using cheaper imaging techniques like small angle x-ray scattering and dynamic light scattering. This is useful because with this technique we do not need to dry the solution and we can therefore observe the proteins in their "natural" state and observe its properties without much obstruction.

0 notes

Text

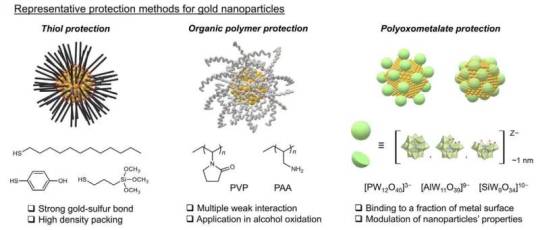

A protective layer applied to gold nanoparticles can boost its resilience

For the first time, researchers including those at the University of Tokyo have discovered a way to improve the durability of gold catalysts by creating a protective layer of metal oxide clusters. The enhanced gold catalysts can withstand a greater range of physical environments than unprotected equivalent materials can.

This advancement could increase the catalysts' range of possible applications, as well as reduce energy consumption and costs in some situations. These catalysts are widely used throughout industrial settings, including chemical synthesis and production of medicines, these industries could benefit from improved gold catalysts.

The research appears in Nature Communications.

Read more.

11 notes

·

View notes

Text

Don’t let the purple hue fool you – this image captured by a scanning electron microscope is actually showing us mesoporous gold nanoparticles.

Photograph: Javeria Bashir/AIBN

2023 Australian Institute For Bioengineering And Nanotechnology Image Contest

#javeria bashir#photographer#australian institute for bioengineering and nanotechnology image contest#micro photography#scanning electron microscope#mesoporous gold nanoparticles#nature

4 notes

·

View notes

Text

it’s because those inks are infused with heavy metals, YLOISE, those are gonna go right into your bloodstream and fuck up the balance of your humours or smth

#two minutes later and i have a tab open with a study called#Biocompatibility of Gold Nanoparticles and Their Endocytotic Fate Inside the Cellular Compartment: A Microscopic Overview#anyway it's magic

24 notes

·

View notes

Text

Gold Nanoparticles Market Focusing On The Basis Of End Use, Region And Forecast 2030: Grand View Research Inc.

San Francisco, 20 June 2023: The Report Gold Nanoparticles Market Size, Share & Trends Analysis Report By End-use (Medical & Dentistry, Electronics, Catalysis), By Region, And Segment Forecasts, 2023 – 2030

The global gold nanoparticles market size is expected to reach USD 15.65 billion by 2030, as per a new report by Grand View Research Inc. It is projected to register a CAGR of 22.3% over the…

View On WordPress

#Gold Nanoparticles Industry#Gold Nanoparticles Market#Gold Nanoparticles Market 2023#Gold Nanoparticles Market 2030#Gold Nanoparticles Market Revenue#Gold Nanoparticles Market Share#Gold Nanoparticles Market Size

0 notes

Text

It's really appealing to be able to control particle shape, because that changes many of the properties. This is the synthesis that almost everyone uses. It’s been used for 20 years, and for that whole period of time, these seeds were simply described as ‘particles.

#nanotechnology#materialsscience#advancedmaterials#nanoparticles#chemistry#engineering#scienceandtechnology

9 notes

·

View notes

Note

I love that I'll see an artist, like yourself, post and I'll go 'Oh, I wonder what this is!' Only to find out that you're going to have a degree in physics. Like, I was not aware that that was a thing that's happening, but congratulations!!

Yeah, I just finished a year-long project on gold nanoparticles. A pain, but it did give me the trivia that in stained glass, the yellow comes from silver and the red comes from gold :D

82 notes

·

View notes

Text

Prussian Blue, a pigment used by Picasso in his Blue Period and for Van Gogh’s “Starry Night,” could become useful for recycling cell phone components and disposing of nuclear waste

Jennifer Ouellette:

Prussian blue is the first modern synthetic pigment. Granted, there was once a pigment known as Egyptian blue used in ancient Egypt for millennia; the Romans called it caeruleum. But after the Roman Empire collapsed, the pigment wasn't used much, and eventually the secret to how it was made was lost. (Scientists have since figured out how to recreate the process.) Before Prussian blue was discovered, painters had to use indigo dye, smalt, or the pricey ultramarine made from lapis lazuli for deep-blue hues.

It's believed that Prussian blue was first synthesized by accident by a Berlin paint maker named Johann Jacob Diesbach around 1706. Diesbach was trying to make a red pigment, which involved mixing potash, ferric sulfate, and dried cochineal. But the potash he used was apparently tainted with blood—one presumes from a cut finger or similar minor injury. The ensuing reaction created a distinctive blue-hued iron ferrocyanide and eventually came to be called Prussian blue (or Berlin blue).

…

The pigment has other uses. It's often used to treat heavy-metal poisoning from thallium or radioactive cesium … Prussian blue helped remove cesium from the soil around the Fukushima power plant after the 2011 tsunami. Prussian blue nanoparticles are used in some cosmetics, and it's used by pathologists as a stain to detect iron in, for example, bone marrow biopsy specimens.

63 notes

·

View notes

Text

Scientists 3D Print Self-Heating Microfluidic Devices - Technology Org

New Post has been published on https://thedigitalinsider.com/scientists-3d-print-self-heating-microfluidic-devices-technology-org/

Scientists 3D Print Self-Heating Microfluidic Devices - Technology Org

The one-step fabrication process rapidly produces miniature chemical reactors that could be used to detect diseases or analyze substances.

MIT researchers have used 3D printing to produce self-heating microfluidic devices, demonstrating a technique which could someday be used to rapidly create cheap, yet accurate, tools to detect a host of diseases.

MIT researchers developed a fabrication process to produce self-heating microfluidic devices in one step using a multi-material 3D printer. Pictured is an example of one of the devices. Illustration by the researchers / MIT

Microfluidics, miniaturized machines that manipulate fluids and facilitate chemical reactions, can be used to detect disease in tiny samples of blood or fluids. At-home test kits for Covid-19, for example, incorporate a simple type of microfluidic.

But many microfluidic applications require chemical reactions that must be performed at specific temperatures.

These more complex microfluidic devices, which are typically manufactured in a clean room, are outfitted with heating elements made from gold or platinum using a complicated and expensive fabrication process that is difficult to scale up.

Instead, the MIT team used multimaterial 3D printing to create self-heating microfluidic devices with built-in heating elements, through a single, inexpensive manufacturing process. They generated devices that can heat fluid to a specific temperature as it flows through microscopic channels inside the tiny machine.

The self-heating microfluidic devices, such as the one shown, can be made rapidly and cheaply in large numbers, and could someday help clinicians in remote parts of the world detect diseases without the need for expensive lab equipment. Credits: Courtesy of the researchers / MIT

Their technique is customizable, so an engineer could create a microfluidic that heats fluid to a certain temperature or given heating profile within a specific area of the device. The low-cost fabrication process requires about $2 of materials to generate a ready-to-use microfluidic.

The process could be especially useful in creating self-heating microfluidics for remote regions of developing countries where clinicians may not have access to the expensive lab equipment required for many diagnostic procedures.

“Clean rooms in particular, where you would usually make these devices, are incredibly expensive to build and to run. But we can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods. This is really a way to democratize this technology,” says Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the fabrication technique.

He is joined on the paper by lead author Jorge Cañada Pérez-Sala, an electrical engineering and computer science graduate student. The research will be presented at the PowerMEMS Conference this month.

An insulator becomes conductive

This new fabrication process utilizes a technique called multimaterial extrusion 3D printing, in which several materials can be squirted through the printer’s many nozzles to build a device layer by layer. The process is monolithic, which means the entire device can be produced in one step on the 3D printer, without the need for any post-assembly.

To create self-heating microfluidics, the researchers used two materials — a biodegradable polymer known as polylactic acid (PLA) that is commonly used in 3D printing, and a modified version of PLA.

The modified PLA has mixed copper nanoparticles into the polymer, which converts this insulating material into an electrical conductor, Velásquez-García explains. When electrical current is fed into a resistor composed of this copper-doped PLA, energy is dissipated as heat.

“It is amazing when you think about it because the PLA material is a dielectric, but when you put in these nanoparticle impurities, it completely changes the physical properties. This is something we don’t fully understand yet, but it happens and it is repeatable,” he says.

Using a multimaterial 3D printer, the researchers fabricate a heating resistor from the copper-doped PLA and then print the microfluidic device, with microscopic channels through which fluid can flow, directly on top in one printing step. Because the components are made from the same base material, they have similar printing temperatures and are compatible.

Heat dissipated from the resistor will warm fluid flowing through the channels in the microfluidic.

In addition to the resistor and microfluidic, they use the printer to add a thin, continuous layer of PLA that is sandwiched between them. It is especially challenging to manufacture this layer because it must be thin enough so heat can transfer from the resistor to the microfluidic, but not so thin that fluid could leak into the resistor.

The resulting machine is about the size of a U.S. quarter and can be produced in a matter of minutes. Channels about 500 micrometers wide and 400 micrometers tall are threaded through the microfluidic to carry fluid and facilitate chemical reactions.

Importantly, the PLA material is translucent, so fluid in the device remains visible. Many processes rely on visualization or the use of light to infer what is happening during chemical reactions, Velásquez-García explains.

Customizable chemical reactors

The researchers used this one-step manufacturing process to generate a prototype that could heat fluid by 4 degrees Celsius as it flowed between the input and the output. This customizable technique could enable them to make devices which would heat fluids in certain patterns or along specific gradients.

“You can use these two materials to create chemical reactors that do exactly what you want. We can set up a particular heating profile while still having all the capabilities of the microfluidic,” he says.

However, one limitation comes from the fact that PLA can only be heated to about 50 degrees Celsius before it starts to degrade. Many chemical reactions, such as those used for polymerase chain reaction (PCR) tests, require temperatures of 90 degrees or higher. And to precisely control the temperature of the device, researchers would need to integrate a third material that enables temperature sensing.

In addition to tackling these limitations in future work, Velásquez-García wants to print magnets directly into the microfluidic device. These magnets could enable chemical reactions that require particles to be sorted or aligned.

At the same time, he and his colleagues are exploring the use of other materials that could reach higher temperatures. They are also studying PLA to better understand why it becomes conductive when certain impurities are added to the polymer.

“If we can understand the mechanism that is related to the electrical conductivity of PLA, that would greatly enhance the capability of these devices, but it is going to be a lot harder to solve than some other engineering problems,” he adds.

“In Japanese culture, it’s often said that beauty lies in simplicity. This sentiment is echoed by the work of Cañada and Velasquez-Garcia. Their proposed monolithically 3D-printed microfluidic systems embody simplicity and beauty, offering a wide array of potential derivations and applications that we foresee in the future,” says Norihisa Miki, a professor of mechanical engineering at Keio University in Tokyo, who was not involved with this work.

“Being able to directly print microfluidic chips with fluidic channels and electrical features at the same time opens up very exiting applications when processing biological samples, such as to amplify biomarkers or to actuate and mix liquids. Also, due to the fact that PLA degrades over time, one can even think of implantable applications where the chips dissolve and resorb over time,” adds Niclas Roxhed, an associate professor at Sweden’s KTH Royal Institute of Technology, who was not involved with this study.

Written by Adam Zewe

Source: Massachusetts Institute of Technology

You can offer your link to a page which is relevant to the topic of this post.

#3d#3D printing#additive manufacturing#amazing#applications#biodegradable#biomarkers#Biotechnology news#blood#chemical#chemical reactions#Chemistry & materials science news#chips#computer#Computer Science#conference#continuous#covid#Developing countries#Developments#devices#Disease#Diseases#energy#Engineer#engineering#equipment#Fabrication#Featured life sciences news#Featured technology news

2 notes

·

View notes

Text

Research team develops anti-icing film that only requires sunlight

A KAIST research team has developed an anti-icing and de-icing film coating technology that can apply the photothermal effect of gold nanoparticles to industrial sites without the need for heating wires, periodic spray or oil coating of anti-freeze substances, and substrate design alterations.

The group led by Professor Hyoungsoo Kim from the Department of Mechanical Engineering (Fluid & Interface Laboratory) and Professor Dong Ki Yoon from the Department of Chemistry (Soft Material Assembly Group) revealed that they have developed an original technique that can uniformly pattern gold nanorod (GNR) particles in quadrants through simple evaporation and have used this to develop an anti-icing and de-icing surface.

The study is titled "Plasmonic Metasurfaces of Cellulose Nanocrystal Matrices with Quadrants of Aligned Gold Nanorods for Photothermal Anti-Icing" and is published in the journal Nature Communications.

Read more.

#Materials Science#Science#Ice#Anti icing#KAIST#Coatings#Nanoparticles#Photothermal#Gold#Metasurfaces#Plasmonics#Cellulose#Biomaterials

17 notes

·

View notes

Text

Fascinating 9 min video of Dr Gold discussing the vax in light of most recent PV video. As a reminder Dr Gold founded American Frontline Doctors to fight the Covid insanity and she went to jail for Jan 6 after being let in and speaking for freedom. The video has to watched intently to really take it in. Highlights:

Pfizer surely knows that in a still unexplained way the vaccine can be shed to the unvaxed.

Japan mandated a Pfizer study on the body’s internal distribution of the lipid nanoparticles in the vax. Study showed they concentrated in the ovaries affecting all forms of womens health and fertility. Japan never released this info the the US.

Both of the above were denied by Pfizer and the establishment.

8 notes

·

View notes

Text

Carbon Nanotubes Could Revolutionize Everything from Batteries and Water Purifiers to Auto Parts and Sporting Goods: Update from Lawrence Livermore National Laboratory

Carbon Nanotubes Could Revolutionize Everything from Batteries and Water Purifiers to Auto Parts and Sporting Goods: Update from Lawrence Livermore National Laboratory

Vertically aligned carbon nanotubes growing from catalytic nanoparticles (gold color) on a silicon wafer on top of a heating stage (red glow). Diffusion of acetylene (black molecules) through the gas phase to the catalytic sites determines the growth rate in a cold-wall showerhead reactor. Credit: Image by Adam Samuel Connell/LLNL

Scientists at the Department of Energy’s Lawrence Livermore…

View On WordPress

#Carbon Nanotubes#Genesis Nanotechnology#Lithium Ion Batteries#LLNL#Nanomaterials#Nanotechnology#Sporting Goods#Water Filtration

6 notes

·

View notes

Text

ATLAS ⋅𖥔⋅ UTP, UTP ⋅𖥔⋅ BIOTECH

trigger warnings: human experimentation, death, grief, car accident mention

They say lineage is a thread that connects generations from the beginning of the world. If so, then you think that yours must be one threaded in gold — the whispers in which they speak your name; half awe, half fear. If lineage is a thread, then you think yours can easily be made a halo upon your head — OR THE NOOSE AROUND YOUR NECK. A coin flips whenever a child enters the world bearing the bloodline of your family. Is it brilliance that runs through their veins — or madness?

Your family has become synonymous with innovation. If Ishikawa Industries bears the crown, then you are the knight at their side, sword constructed of tiny nanoparticles that collect energy from the stars — shining; blinding; everlasting. It was your family that invented Scales; that made the tech affordable and accessible to the lower classes. BUT IT WAS ALSO YOUR FAMILY THAT SENT THE SUN INTO SUPERNOVA, GREEDY FOR THE ENERGY OF A GOD YOU WILLED TO OBEY YOUR MORTAL HAND. That cursed the universe to bear the curse of your failings; of your avarice; of your pursuit of greater things that could be just an excuse for the development of a greater ego.

Perhaps it was guilt that started the unravelling your ancestors' threads of brilliance. Or perhaps it truly was a curse — the shortening to lifelines as the generations go on; as if the universe is asking for repayment of the lives it has lost. You witnessed it yourself as the years have gone on — your grandparents, then your own parents, minds clear and sharp becoming fragmented as they grew older. Until simple physics equations could no longer be recited and your name a string of scrambled syllables upon their lips. So you work, ignoring sleep; ignoring rest. Time is a beast that grows closer and closer. Time has caught the scent of blood in the water. Time will unhinge its jaw and gnaw upon the best part of you — will chew up your mind until it is no longer recognizable.

DYNAMICS

SAGAN ⋅𖥔⋅ THE SILENCE THROUGH WHICH YOU MOVE IS MY VOICE PURSUING YOU

You were a contract engineer for Project Orpheus, coveted solely for the recognition of your family. You thought you would find answers for the curse you can feel settle within the marrow of your bones with every passing day, but instead, you found them. Delirious, afraid. Unable to answer your questions with anything more than a jumble of words that made no sense. You weren't directly involved the experiment that concerned them — and frankly you doubt you would be able to get the clearance to even look into their file, but you can't absolve your blame, either. Didn't you walk by their door, day by day, peering in but never truly allowing yourself to see? Your chest aches whenever you think of your last day there — of the way you walked out without a look back. It's nothing new, but your vision blurs, nonetheless.

HALIMEDE ⋅𖥔⋅ YOU COULD DESCEND LIKE RAIN, DESTROY LIKE FIRE IF YOU CHOSE TO. IF YOU CHOSE TO

Your families have worked together for generations, and in your mind, he is the only rightful heir to S Corp. Though you are not privy to the inner machinations of the heirs, when FENRIR left, you had hoped HALIMEDE would take the crown. But what came next was disappointment. You could only watch as he changed; as intelligence became indulgence, and the one you had sworn loyalty to painted himself as nothing more than a farce. You know better than anyone the wolf that hides beneath; of the new world he could usher in — a better world — if he would simply choose to. Your time is running short, and you'll be damned if you don't get the chance to watch him rise. He's a wolf, hiding in his self-defined cave — and you don't mind creating a little provocation. If only to remind him how it feels to snarl.

SYCORAX ⋅𖥔⋅ OH MY LOVE, CALL ME BY A NAME LINKED TO A VERY OLD, FORGOTTEN TENDERNESS. I WILL REBUILD THE PLOT OF A PURELY INNER TRAGEDY.

For a time, you had been afraid that the one you loved would be forced to watch as your mind withered. You had even considered leaving them — but before you could, they left you. Or rather — THEY WERE TAKEN FROM YOU, last breaths ragged, blood filling their lungs in a crashed hovercar. You know the story behind the accident. You tell yourself over and over that no one regrets it more than SYCORAX; that the loss of a sibling hurts no less than the loss of a lover. Still, when more liquor than blood runs through your veins; when time finally slows and you stand in front of their door, the grief is unable to be held back. For your lover, for your family. For yourself.

OPEN ⋅𖥔⋅ DEVYN GARCIA

3 notes

·

View notes

Note

🌻

When I was in high school I got a full-ride to a summer university thing where I took a microscopy class (basically we looked at REALLY small particles and tried to synthesize tiny particles ourselves. I made a minor discovery in that one method of gold nanoparticle synthesis can be performed by freezing the solution and then thawing it rather than heating it on a hot plate. But that is NOT The Point of this ramble.

The university we were at had a 2 million USD transmission electron microscope (TEM.) Part of how it works is there is a vacuum chamber where the sample is held, and if anything is dropped in it, the microscope has to be shut down for weeks and it cost like, tens or hundreds of thousands of dollars to clean.

Our professor looked all of us square in the face and she said “if you break it, I’ll kill you. If you break it AND you don’t tell me…I’ll kill you slowly.”

Needless to say all of us asked a lab tech to put our samples in LMAO.

8 notes

·

View notes