#how to make money with a cnc machine

Explore tagged Tumblr posts

Text

You won’t believe how easy it is to start a CNC Router Machine business! 🤯 If you’ve been dreaming of passive income and creative work—THIS is your sign. 💸 Hit follow for more business hacks that actually work! #CNCBusiness #SideHustleIdeas #viralbusiness

#business plan for cnc machine#business with a cnc router machine#cnc business#cnc business ideas#cnc machine#cnc machine business ideas#cnc machining business ideas#cnc router#cnc wood machine business#desktop cnc#full time cnc router business#how do i start a cnc business#how to make money with a cnc machine#how to make money with cnc router#make money with cnc router#new business ideas#small business#sucessful cnc business#woodworking#woodworking business

0 notes

Text

Perhaps so the universe has a way to make it up to us for everything else going on, there is currently an explosion in really neat laser-based tools. You can get a laser welder, or a laser CNC machine, or a laser engraver, or... a laser level. I swear I can almost afford that last one. They want like fifteen dollars for it at the Princess Auto. Sheesh. It's like they expect their core customer to be employed now.

Although lasers are probably centuries old, according to a drinking-machine summary of a wikipedia article I glanced at while trying to kill time in line at the parole office, it's only recently that humanity has figured out how to make them more affordable for the common, workaday asshole. What's the secret to this incredible advancement in inexpensive optical technology? Have a factory in China build them.

As a result of all this trans-national becheapening, the local "maker space" has acquired for themselves a thousand-watt laser welder. Any moron off the street can use it to stitch two pieces of metal together in a way that would make professional welders poop with envy. Which is perfect, if you're a moron off the street and your $89 Princess Auto "Li'l Don't Look Directly At The Spark Junior Welder's Kit" doesn't quite have the zoot to put those spring perches on a rusty, oily Ford 8.8 you got out of that big F150 crash on the side of the highway last winter.

Like you would expect, it (the welder, not the axle) cost about as much as a good used car used to cost, before used cars cost $20,000. Still, that's peanuts if you have several hundred members who are willing to pay to use it to make Star Wars pirate memorabilia and combat robots. I, however, am not willing to pay. In fact, I have to be forced to spend money on just about anything. So I decided to see if I could just walk in there, use the laser welder to do my daily welding, and then bounce without opening my wallet.

Friends: it worked great. After a couple minutes of pushing buttons and adjusting various screens that I wouldn't bothered to have read fully even if they weren't written in Chinese, I was able to fart on a pair of narrowed spring perches that were ideal for my Viscount.

Now, you might think it's suspicious that I was able to roll a 175-pound chunk of cast iron through the middle of a warehouse full of nerds without anyone asking me for my ID, but it's all thanks to another fancy new consumer of inexpensive lasers: the smoke alarm on the ceiling. I set that sucker off with a brick to the "test" button, before walking right in the front door while dressed as a firefighter. Sometimes, rock beats laser.

110 notes

·

View notes

Text

Golden Double

—————————————————————————

Don Lorenzo x R.femele.

—————————————————————————

Don Lorenzo next to his girlfriend (you — y/n), a woman who shares her passion for money, but who built her empire with effort and intelligence. The scenario mixes romance, luxury, ambition and the vibrant chemistry between two people who not only understand each other, but also feed each other with ambition and power

—————————————————————————

The Italian sun bathed the ancient stone walls around the Ubers' villa, where Don Lorenzo lived temporarily during the Neo Egoist League. The black gate opened slowly, revealing the aggressive roar of a custom engine: a sculptural motorcycle, with a chrome finish and touches of brushed gold in the exhaust details. Piloting, she came - y/n, the woman most requested by luxury automakers in the world.

She took off her helmet, revealing a smile that shone like diamonds. Don Lorenzo was lying on the lounger, shirtless, showing off his golden teeth and muscles drawn as if sculpted under the sun. He smiled - not only because she had arrived, but because that woman was worth gold in every way.

- "This motorcycle was made for an Arab sultan, but I decided that you were going to try it first." - she said, handing the key to him as if she were giving a gift of thirty thousand euros with the naturalness of someone who offers a coffee.

Lorenzo laughed, jumping out of the chair and walking to her, his eyes vibrating with pure pleasure.

- "You turn me on when you talk about engines and absurd figures, okay." - he said, taking the key, but turning his hand to pull it by the waist. - "Tell me, how much did this beauty cost?"

- "More than 500 thousand euros." - he replied with a wink. - "The customer only closes if it is exotic, noisy and unique. Like you."

Don Lorenzo turned her in his arms with ease and kissed her as if he were sealing a billionaire fusion. They were an unlikely couple: he, eccentric, raised on the streets, moved by the hunger for power. She, refined by work, molding unique pieces with precision, selling to millionaires, tycoons and princes. But they had something essential in common: raw ambition and a mutual admiration for those who make their own value.

After the kiss, Lorenzo accompanied her to the garage that she had improvised in the basement of his house - with CNC machines, holographic screens, disassembled V12 engines and hand-sewn leather panels.

- "You're like... the most expensive artist in the world of engines. That's sexy for c****, okay."* - he commented, running his fingers through a steering wheel sewn in genuine Italian leather.

- "And you're the most expensive defender Snuffy has ever fed." - she replied with a malicious smile. - "If you throw your teeth on the market, the gold price plummets."

Lorenzo laughed loudly, taking a gear as if it were a rare jewel. He admired her. And not only for the money. By the way she fought for every penny, how she didn't accept crumbs and made a point of winning in a world dominated by old and rich men.

- "Do you know what I like most about you?" - he asked, approaching. - "You never expected anyone to give you anything. You built your empire... gear by gear. This is more precious than any bank safe."

She leaned her forehead against his, both covered in grease and sweat.

- "And you, Lorenzo... you devour aces and multiply ciphers. But deep down, you just want someone who looks at you and sees more than gold on your teeth. I see."

They spent the night together in the workshop, drinking cheap champagne while finishing the interior of a car tailor-made for a Hollywood actress. And before the day dawned, y/n was already reviewing budgets, and Lorenzo was stretching for another match with the Ubers.

Two worlds. Two empires. Two beasts with a thirst for greatness. United by the desire to win - and by the certainty that, together, they were more valuable than any fortune.

—————————————————————————

– presentation to Ubers players

The Ubers' morning training ended with sweat and exhaustion. The impeccable grass field of the Italian headquarters reflected the brightness of the sun - but nothing overshadowed more than the serious and velvety snoring that cut the silence in the parking lot.

A convoy of three custom vehicles entered like a luxury storm: a Lamborghini Veneno with prismatic paint, an electric motorcycle with an apparent engine illuminated by blue neon, and a completely reformulated retro Ferrari with mirrored armored glass panels.

The players stopd. Most had never seen those models even in international exhibitions. When the Lamborghini door opened upwards, the world seemed to be in slow motion.

With stiletto heels, leather gloves and Cartier sunglasses, you, y/n, went down with a tablet in one hand and a diamond key in the other. Her hair was stuck in an elegant bun with purposely rebellious strands. The dark leather jumpsuit enhanced her silhouette, with a zipper up to the height of the bust. Your expression? Pure calculated coldness with a slight smile of someone who knows it's worth a lot - and charges for it.

Don Lorenzo left the locker room and saw you first. His golden smile shone brighter than Ferrari's mirrored hood.

- "Aaaah... my queen has arrived, okay."

He went to you and held your waist with familiarity.

- "You are in front of the most expensive woman I know. She creates machines that make CEO cry with envy and poor people faint just by seeing it."

You took off your glasses slowly, looking at the other players with naturalness of those who know they have the power in their hand.

- "I brought Lorenzo's order. But Bugatti's details will depend on how much he will pay for overtime. I have a busy schedule to Dubai, Miami and Kyoto."

——————————

Players' Reactions:

Barou, who was usually not impressed by anything, furrowed his eyebrows and approached the personalized motorcycle with visible engine.

- "Is this painting... is it real liquid gold?"

You answered with simplicity, typing on the tablet:

- "Mixture of white gold particles with armored resin. The hood reacts to the heat of the sun and changes its hue. It was ordered by a brand from Dubai... but Lorenzo wanted it first, and paid more."

Barou smiled from the corner, something rare.

- "This woman understands the game."

⸻

Snuffy approached with his hands in his pocket, curious, but calm. He observed the interaction between you two and said:

- "So you're the designer who makes Lorenzo's toys look like works of art... he talks a lot about you."

You tilted your head, smiling.

- "I like to create unique pieces. And he... pays very well."

Don Lorenzo laughed out loud:

- "Do you see? It's not just beauty and brain. She has a business vision, okay!"

⸻

Niko whispered with Aiku:

- "Man... she seems as focused as he is."

Aiku laughed:

- "Is it? They're the most dangerous couple I've ever seen. Her ego is not smaller than his."

——————

You were invited by Snuffy to give a lecture on innovation and entrepreneurial mentality. Some players went to his workshop, located in an ultra-modern shed on the outskirts of Milan. There, they saw their world: holograms of engines in development, parts being tested by mechanical arms, and a concept car that floated a few centimeters from the ground.

Aryu, gaping, said:

- "This woman lives in a fashion science fiction movie."

Niko, short, recorded everything with his cell phone.

And you, at the center of everything, explained while fiddling with the hologram of a supermotor cooling system:

- "Here I create dreams... but I charge for every second. Because my time, as well as my engine, never stops."

Don Lorenzo arrived from behind, hugging you from behind, whispering in your ear:

- "I'm thinking of giving you a ring... studded with the parts of the first car you customized for me. Gold, steel and DNA. How about it?"

You smiled, with your eyes fixed on the engine graphics:

- "Only if the value is compatible with my love. And with my work."

He kissed your shoulder.

- "Always, okay."

—————————————————————————

#anime fanfic#fanfic#anime screenshot#anime series#one piece#blue lock x reader#blue lock#don lorenzo x reader#don lorenzo#blue lock drabbles#blue lock masterlist#blue lock x reader fluff#bllk#bllk x reader#bllk x you

14 notes

·

View notes

Text

How Plastic Fabrication Can Benefit Your Business

Plastic fabrication is a process that turns raw plastic materials into useful products for various industries. Whether it’s for prototyping, custom designs, or creating complex components, plastic fabrication offers a wide range of benefits to businesses of all sizes. This article will explore how this versatile method can help elevate your business operations.

Streamlined Production and Customization

One of the most significant advantages of plastic fabrication is its ability to streamline production. With advanced technologies such as CNC machining, laser cutting, and 3D printing, businesses can manufacture precise and complex plastic parts with minimal effort. This reduces the need for additional labor or lengthy production timelines.

Customization is also a key benefit of plastic fabrication. Unlike traditional mass production methods, plastic fabrication allows companies to create customized products that meet their specific needs. Whether you’re creating unique prototypes or designing parts for specific machinery, the ability to customize products ensures your business stands out in a competitive market.

For instance, industries like automotive, aerospace, and healthcare often rely on tailored plastic components to fit specific equipment requirements. By working with a reliable plastic fabrication company, you can ensure that your custom needs are met with high precision and quality.

Cost-Effective Manufacturing

Another benefit of plastic fabrication is its cost-effectiveness, especially for small to medium-sized businesses. Traditional manufacturing methods, such as metal fabrication, can be expensive due to the high costs of raw materials and production processes. In contrast, plastic materials tend to be more affordable and versatile, making it a great choice for businesses looking to save money while still producing high-quality products.

Additionally, plastic fabrication offers long-term savings due to the durability and longevity of the materials used. Many plastic materials are resistant to corrosion, weathering, and wear, ensuring that your products will last longer, reducing the need for frequent replacements.

Versatility Across Industries

Plastic fabrication is incredibly versatile and can be used across numerous industries. Whether you’re in the medical, electronics, packaging, or construction industries, plastic parts and components are essential to your business operations.

For example, in the medical field, plastic fabrication is used to create sterile surgical instruments, medical devices, and protective barriers. In electronics, plastic enclosures are often used to protect sensitive equipment from environmental damage. In packaging, plastic containers and wraps are designed to securely hold products for transportation and sale.

This adaptability makes plastic fabrication an invaluable tool for various businesses. No matter the sector, the ability to produce customized and durable plastic components will always offer a significant competitive edge.

Finding the Right Plastic Fabrication Partner

Finding the right plastic fabrication company is crucial to ensuring that your products meet high standards of quality and precision. Partnering with an experienced and reliable fabricator can make the difference between a successful project and costly errors. To locate the right professional for your needs, it’s essential to consider their experience, reputation, and ability to work with your desired materials.

If you’re looking for a plastic fabrication company near me, you’ll likely find many local professionals who can meet your requirements. Make sure to check reviews and ask for samples of previous work to ensure they can deliver the quality and service you expect. A trusted local fabricator can help you avoid the logistical challenges of long-distance shipping and offer faster turnaround times for your projects.

Plastic fabrication offers numerous benefits for businesses, including cost savings, customization, versatility, and efficiency. By partnering with a professional plastic fabrication company, you can enhance your product development process and ensure your business stays competitive in the marketplace. Whether you’re looking for precision parts, durable products, or customized designs, plastic fabrication is a smart choice for any growing business.

2 notes

·

View notes

Text

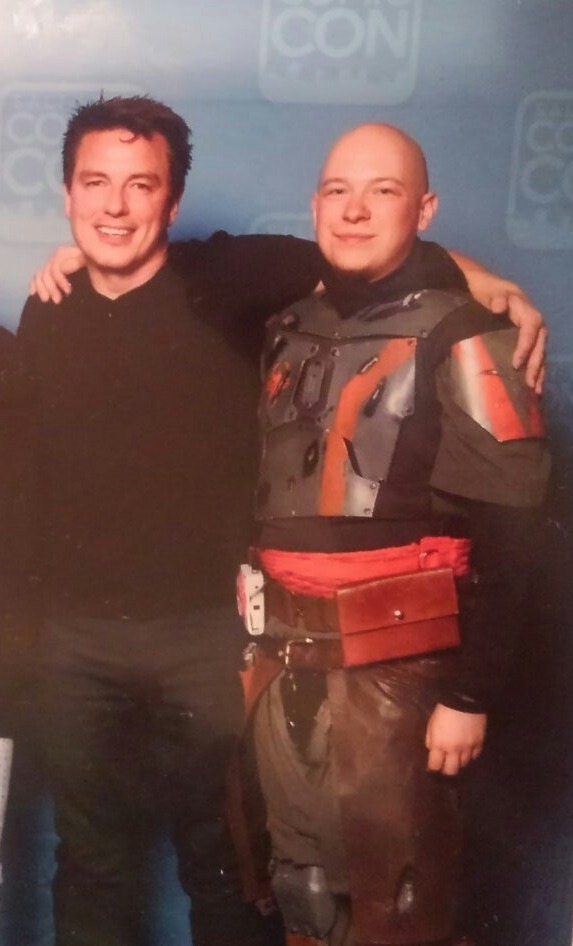

Throwback to the beginnings of my costuming journey. Though this armor has since been retired, mainly due to my unfortunate physical growth, I think back on these times fondly. I like to think the time and care I put into my first build shows, but I may be a touch biased.

The completion of this armor lead to a great many things in my life. Some of the most fun I've ever had, some of the best friends I've ever made, and some of the coolest opportunities I never thought I'd have.

In 2016 I was invited to attend a convention in Salt Lake where I met the man himself, big boss Boba Fett, Jeremy Bulloch. While it was a brief (but incredibly cool) opportunity, he wasn't the only hero I got to meet that weekend. While attending a panel for Mark Hamill, I also got a high five from Jason David Frank (RIP). Another man I've loved and respected for as long as I can possibly remember.

While manning the Star Wars Costuming Clubs booth that same year, along with a new friend, we were blown away by a random surprise visit by Michael Rooker. Though I regret missing this opportunity to get a picture, the conversation we had without a massive group of people interrupting him, is all the memory of the event I need. What a genuinely cool guy.

Over the years my armor evolved and grew with me, but continued to open doors I never thought possible. Growing up in the middle of nowhere, no real money to my name, and no opportunities to truly geek out with the people left in my hometown, I never thought that Comic Cons and costume groups would be part of my life. I had followed what the 501st Legion was doing since I was a kid, and was truly blown away when I saw them on tv marching in the Rose Bowl Parade in 2007. Still, I never thought anything like that would exist in Montana. At that point, the Mandalorian Mercs were just starting, so I hadn't even heard of them yet.

By the time I started college, I was made aware of the existence of the MMCC. Sitting in my dorm dreaming that I'd have the money, time, space, skills, etc, to start a build of my own some day. Then one day in 2015, I saw this helmet for sale from Headshot Props, and I knew it was time. I had to make this purchase. I checked my accounts, moved some stuff around, skipped getting groceries for a few weeks, and 2 months later, there it was in all of its glory. Sitting at my doorstep when I got off work, I don't think I had ever been that excited. I took it inside, ripped open the box, knocked off just enough of the sharp edges to put it on without cutting myself, and low and behold... it didn't fit.

Motivation: demolished. Faith: gone.

I was, frustrated, to say the least. I'm the type of person to take setbacks like this extremely personally because of how often it seems like it happens to me. I set it on the shelf and looked at it for a few days. I knew there was nothing I could do about a return because the dimensions were posted, and I measured my head. It should have fit. I didn't take into account the cheeks of the helmet being a tighter spot, and my bigass fivehead just wasn't gonna do it without breaking the helmet. I had to do something though. I sanded the hell out of the inside of the cheeks to the point that you could see light through them, and I could get the helmet on, though it wasn't a pleasant experience. I then took my heat gun, thinking there's no way this will work, heated the resin just enough to push the cheeks out that little bit extra, and I'll be damned. It was just enough. The helmet was still tight, but it fit, and it was back to game on.

The course of the next few months brought on a ton of changes. I was lucky enough to be working at a sign shop at the time I began this journey, and that shop had a seemingly endless supply of foamed PVC board and a flatbed CNC machine. I was able to trace out my armor design and just have it cut right there! Barely even had to trim and sand anything! It was amazing! I started learning skills I never even knew I wanted. Using a heat gun to form shapes, learning to paint, kit bashing parts to make in-universe looking props, it just never seemed to end! Halfway through my build, I moved, but I didn't let that move ruin my motivation. In that tote was a pile of loose parts and a helmet. Within a month of moving into my new place, it was wearable. Rough, but wearable. Around Halloween that year, I had met up with some local guys that were also building armor, and we handed out candy at the Zoo! It was amazing, and I had so much fun. Met some of my future best friends that day.

Over the years of doing local events, I've been humbled on a few occasions. Mostly from people who joined the group later on that have told me their journey started when they saw me at one event or the other. That's such an incredible feeling and honestly makes all the time, effort, money, stress, blood, and love I've put into this build worth it.

If you've stuck with this post this far, I applaud you. You can probably tell I'm not much of a writer and I'm all over the place with no real conclusion to any of it. I'm really just reminiscing. This weekend I will be parting out this original kit, or at least most of it, in order to help new costumers, new friends, get a foothold in their build, and hopefully motivate them to continue.

If you've ever wanted to build a costume, regardless of what fandom it's for, don't let anyone tell you not to do it. Buy it, build it; piece by piece or all it once, it doesn't matter. Just do it. Solid chance you'll never regret it.

9 notes

·

View notes

Text

... I'd like to push back a little bit on the vision of how society would look if we didn't have injection molded plastics. I agree that it would be more rectangular than it is now, and maybe more sharp. But

In the 1910s, we were pushing the limits of what technology at the time would let us do with casting iron. All of my beautifully curved sewing machines? Cast iron.

We really advanced the ability to stamp thin sheets of metal into compound curves in the '30s and '40s. Look at the difference in car design between a car from 1920 and from 1940 (as much as this is the Ford hating website, Ford is a great example of this). Modern cars are also made of stamped metal and those are not rectangle having machines (with one remarkably bad exception).

We invented bakelite and similar moldable plastics in the '40s.

Household appliances of the '50s were defined in all their swoopy curves by stamped metal and bakelite.

We invented CNC machining at the same time as we invented computers and immediately went to work perfecting it. We now have robots at every scale and cost point to create all sorts of things out of all sorts of materials. A four axis CNC milling machine can make parts that can't be stamped or cast.

The thing that separates these processes from injection molding is that they're slow. They're so fucking slow. Stamped metal is pretty fast, but it still can be pretty slow.

So my guess at what society would look like without injection molding is slower and heavier and with less production excess. More objects would have applied details instead of integral decoration - imagine the amount of money that could be made selling swappable trim packs when the trim is held on with little tabs that go through the shell of the appliance.

But humans love curves. We invented special tools to make making spoons easier. We put curves on the decorative trim in our homes, we go crazy over an arched doorway, we bend wood (which hates that shit!) to make hoops from which to make tools and toys from.

I think a lot about manufacturing processes because they’re the most impressive things humanity has ever done and injection moulding wacks me out the most. I was looking at the toy keyboard I bought a while back and it got me thinking about how much of what we consider to be the look of The Modern Era is down to injection moulding.

I hold that injection moulding is one of the pillars of modern society and technology. Can you imagine a world where you couldn’t use injection moulding. It’d look completely foreign. Like looking into an alien world. When you consider it you have to conclude that injection moulding has shaped our culture as much as the development of the camera or the invention of the piano or the creation of glassblowing. If archaeologists had to name our culture in the style of the Corded Ware culture or the Funnel Beaker culture, we’d be the Injection Moulded Plastic culture.

Injection moulding is how we get, oh, almost every plastic thing you’ve ever seen. The keys on your keyboard are injection moulded. Your phone case is injection moulded. Unless you’ve got a fancy milled metal laptop like a macbook then your laptop’s chassis is mostly injection moulded plastic. Your lightswitches are injection moulded. Plastic water bottles are injection moulded. Injection moulding is how we can produce extremely similar objects at breakneck pace for almost no money.

Now it’s important to rememeber that injection moulding isn’t cheap, or, well, injection moulding is only cheap for mass production. Every single unique piece of plastic needs a mould, and each mould will cost somewhere around thousands to tens of thousands of dollars EACH, depending on how tight the tolerances are and how complex the geometry is. Look at how many unique plastic pieces there are on that keyboard. Each one represents an investment of like $7000 into making this toy that gets sold for about $20, so there’s no way this would get made unless the company had plans to sell literally hundreds of thousands of these things.

(This mould can spit out one chair every 30 seconds and it probably cost twenty thousand dollars to make)

Once you learn to see injection moulding you can’t unsee it. It’s like learning about kerning, or musical intervals, or disability compliant designs, or the pantone colours, or about how many insulator disks are needed on different voltage power lines. You start to see it everywhere, you realise that everything in your life relies upon our ability to jam plastic through a heated screw and into a mould reliably, hundreds of times per day, all day, every day.

Unless you’re wandering alone in the wilderness (and even then, maybe: check your clothing), look around and see if there’s something injection moulded near you. I can tell you the answer, there definitely is. It’s inescapable.

What would a world without injection moulded parts look like? It’d be weird. Everything we think of as cheap and easy to make is suddenly expensive. Complex curves and slopes like you’d find on a one dollar potato peeler now require hours of work to form. Every budget consumer item would be like those cheap sheet metal PC cases that have drawn blood from everyone who build a PC in them. Everything now has the aesthetics of a Sun 3/280 system:

Heck, even this sheet steel cube has a dozen injection moulded parts visible.

All the chunky plastic housing of the 90′s and 2000′s, all the sleek curves of the 2010′s, all the cheap plastic knick-knacks, the plastic toy horses, the snugly-fitting appliance chassis, the stacking plastic chairs. All these things now cost ten times as much and have to be formed from heavy steel, or milled out of chunks of cast plastic, or replaced with formed sheet metal.

Our culture, artistic sensibilities, and sense of value has been irrevocably shaped by our ability to squeeze liquid plastic into a metal die.

7K notes

·

View notes

Text

Affordable CNC Milling India , Best Manufacturers & Suppliers

Need affordable CNC machining in India? Choose from leading CNC Milling Suppliers that offer quality work at competitive prices. Call us now.

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed software to control machinery. It allows for precise cutting, drilling, and shaping of materials like metal, plastic, and wood. Imagine a robotic sculptor working with extreme accuracy—that’s CNC machining.

Why Choose CNC Machining in India?

India offers top-tier CNC machining services with a unique edge:

Lower operational costs

Highly skilled engineers

Advanced equipment

Faster project turnaround

That’s why global brands are outsourcing their CNC needs to Indian suppliers—it saves money without sacrificing quality.

Suppliers: Bridging Industries and InnovationEqually important to the CNC Milling Manufacturers chain are CNC Milling Suppliers, who connect industries with the right equipment and services. They offer a range of products, from compact desktop milling units to high-end industrial machines. These suppliers act as consultants, helping clients choose the most appropriate technology based on application, budget, and output requirements.

Modern suppliers provide value added services like installation, training, preventive maintenance, and troubleshooting. Their role is indispensable in sectors that demand minimal downtime and continuous productivity. They also facilitate customization, offering different table sizes, control units, and compatibility with CAD/CAM software systems.

Key Benefits of CNC Machining

High Precision: Ensures accuracy to within microns.

Consistency: Identical results even in large batches.

Efficiency: Faster production with less waste.

Complex Designs: Capable of producing intricate shapes and structures.

Whether you need a single prototype or thousands of units, CNC machining is up to the task.

Applications :

CNC machining is used everywhere, including:

Automotive: Engine parts, gear systems

Aerospace: Aircraft components

Medical Devices: Surgical tools, implants

Consumer Electronics: Device casings, connectors

Defense: Precision hardware

Indian CNC manufacturers cater to all these sectors and more.

How Indian CNC Suppliers Ensure Quality

Top suppliers in India use:

ISO-certified processes

CMM inspection tools

Real-time monitoring

Highly trained operators

They don’t just meet global standards—they exceed them.

Top CNC Machining Manufacturers in India

Some of the most reputable names include:

Deccanew

Ace Micromatic Group

Jyoti CNC Automation

LMW (Lakshmi Machine Works)

Micromatic Grinding Technologies

These companies have global reach, export capabilities, and strong quality control systems.

Factors That Affect CNC Machining Costs

CNC machining is affordable in India, but prices vary based on:

Material type

Part complexity

Volume (single or batch production)

Surface finishing

Machine run time

India’s lower labor and energy costs make even complex jobs more budget-friendly.

CNC Milling India Is Gaining Momentum

India offers a blend of affordability, engineering talent, and high-precision outputs. Many global and local manufacturers are tapping into CNC services in India for prototype development, mass production, and custom fabrication. By investing in CNC milling, industries are reducing human error, minimizing waste, and significantly improving operational efficiency. CNC machines are digitally programmed, allowing for consistent results with excellent repeatability.

How to Select the Right CNC Supplier

Here’s what to look for:

Experience in your industry

Custom capabilities

Certifications like ISO, AS9100

Prompt delivery records

After-sales support

It’s not just about cost—it’s about reliable performance.

Materials Commonly Used in CNC Machining

Indian CNC machining shops work with:

Metals: Aluminum, steel, brass, titanium

Plastics: Nylon, ABS, PEEK, acrylic

Composites: Carbon fiber, fiberglass

Make sure the supplier has experience with your specific material needs

Deccanew is one of India’s emerging leaders in CNC Milling India. They offer:

Custom CNC solutions

Fast delivery

Affordable pricing

Reliable customer service

From design to delivery, Deccanew combines technical precision with business-friendly pricing.

Trends in Indian CNC Machining Industry

Modern Indian CNC firms are embracing:

AI and machine learning

Smart factories (Industry 4.0)

Eco-friendly machining

Digital twins and cloud-based design

These trends ensure sustainability, efficiency, and innovation for future manufacturing.

Visit: https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.phpContact: +91 9657039991

0 notes

Text

Why Top Automakers Trust Forged Components Over Cast Ones

Walk into the heart of any major car manufacturing plant, and you’ll see something that hasn’t changed much over the decades — the trust placed in forged automotive components. These parts, shaped under extreme pressure, are the unsung heroes behind the speed, strength, and reliability of modern vehicles. While casting may seem easier or cheaper on the surface, leading automakers don’t take shortcuts when it comes to performance and safety. So why exactly do top automotive brands stay loyal to forging?

Let’s take a closer look.

It's All About Strength — No Compromises

The roads may look smooth, but what cars go through daily is anything but gentle. Potholes, sudden braking, sharp turns, heavy loads — every bit puts stress on a vehicle’s parts. Forged components handle these pressures far better than their cast counterparts.

Why? Because forging doesn’t just shape metal — it transforms it. When metal is forged, its grain structure is aligned along the shape of the part, giving it enhanced toughness and fatigue resistance. Cast parts, on the other hand, are cooled from a liquid state, which can lead to internal weaknesses like air pockets or cracks.

In simple words, forged parts are like solid muscle. Cast parts? They can sometimes be more like brittle bones.

Safety: The Non-Negotiable

Automakers carry an enormous responsibility. Every car they put on the road must protect the people inside it — and those around it. That’s why critical components like suspension arms, steering knuckles, crankshafts, and connecting rods are almost always forged.

Forging offers a level of reliability and consistency that casting struggles to match. There’s just no room for error in parts that bear the weight of your vehicle at 100 km/h. A cracked casting can lead to a catastrophic failure. But a well-forged component can take punishment and keep going.

It's not just about avoiding failure. It's about building cars people can trust with their lives.

Performance That Speaks for Itself

Have you ever wondered what separates a good car from a great one? One answer lies deep in the mechanics — and forged components are often at the center of it.

Forged parts are typically stronger and lighter. That means better acceleration, improved fuel efficiency, and smoother handling. When every gram and every fraction of a second counts — especially in performance cars or commercial vehicles — automakers turn to forging.

Think of it like this: athletes wear performance gear because it’s engineered to push limits. Forged components are the performance gear of the automotive world.

Long-Term Durability = Lower Costs

Some people look at forging and think, “But it’s more expensive than casting.” That’s true — at first. But here’s the thing: forged parts tend to outlast cast parts by years. They handle stress better, require fewer replacements, and reduce the risk of failure.

In the long run, forged parts save money. For automakers, that means fewer warranty claims. For drivers, it means fewer trips to the mechanic.

It’s a win-win — and in an industry where reputation matters, durability is a currency.

Why Not Just Use Both?

This is a question many newcomers to the industry ask. And yes — there are places where casting makes sense. Interior parts, non-load bearing brackets, decorative elements — in these cases, casting is just fine.

But when it comes to power, motion, and structure? Forging wins. Every. Single. Time.

Automakers have learned this lesson the hard way over the years. Failures in cast components have led to recalls, lawsuits, and damaged trust. That’s why today’s top brands don’t gamble with the parts that matter most.

Also Read: The Future of Metal Fabrication: How CNC Machined Parts Are Shaping Modern Engineering

The Final Word

Choosing forged components isn’t about being flashy or expensive. It’s about responsibility, performance, and trust. The kind of trust automakers build with every mile their vehicles travel — and every life they protect.

When a part has to work, when safety is not optional, when performance is everything — forging is the answer.

As the Ministry of Road Transport and Highways (MoRTH), Government of India, continues to tighten safety and quality standards for vehicles, the choice between casting and forging isn’t just technical anymore — it’s a question of accountability. And top automakers are making that choice loud and clear.

Forged, not cast. Every time.

0 notes

Text

How to Budget for Used Woodworking Machinery at Auction?

Purchasing used woodworking machinery at auction can be a smart way to save money while acquiring quality equipment. However, without proper budgeting, buyers can easily overspend or underestimate the true cost of ownership. Planning your budget carefully ensures you make informed, cost-effective decisions and avoid surprises after the auction ends.

Determine Your Equipment Needs and Priorities

Before calculating costs, start by identifying the specific types of machinery your woodworking operation requires. Consider both immediate needs and potential future upgrades. Whether you’re looking for a table saw, CNC router, planer, or edge bander, knowing your essential tools will help you avoid impulsive bidding on items that don’t align with your workflow.

Create a priority list of must-have machines and nice-to-have additions. This will allow you to allocate your budget based on business-critical purchases while maintaining flexibility for unexpected deals.

Research Market Prices and Set Limits

To build a realistic budget, research the average selling price for the models you’re interested in. Visit manufacturer websites for new prices and compare listings on auction platforms, used machinery dealers, and classifieds. Understanding typical market value gives you a clear benchmark for determining your maximum bid and evaluating if an auction price truly represents a bargain.

Once you know the fair market value, set a strict bidding limit for each item. Factor in depreciation, condition, age, and brand reputation. Be sure to stick to your limit even in the heat of a competitive auction—overpaying eliminates the financial advantage of buying used.

Account for Buyer’s Premiums and Taxes

Most auctions charge a buyer’s premium, which is an additional fee—typically between 10% to 20%—added to the final bid price. This amount can significantly raise your total cost. Local sales tax may also apply depending on the auction location and your business registration.

When setting your budget, always include these fees so you’re not caught off guard after winning the bid. Auction platforms usually list buyer’s premiums and applicable taxes in the terms and conditions, so review them carefully before participating.

Include Shipping, Rigging, and Setup Costs

Woodworking machines are often large and heavy, requiring special transport arrangements. Budget for freight shipping or local pickup with a suitable vehicle. If a third-party rigging service is needed to disassemble, load, or install the machine, get estimates in advance.

In some cases, you may also need to prepare your workshop with additional wiring, flooring, or ventilation. These setup costs should be included in your total budget so you have a clear picture of the full investment required.

Plan for Repairs and Upgrades

Used machines may need replacement parts, repairs, or maintenance before they’re ready for use. Set aside a portion of your budget for things like new blades, belts, lubricants, or minor repairs. If the machine is older, you may want to upgrade safety features or retrofit it with digital controls.

Conclusion

Budgeting for used woodworking machinery at auction goes far beyond the winning bid. By researching market prices, planning for hidden costs, and sticking to spending limits, you can make confident purchasing decisions that strengthen your workshop without financial strain. A well-planned budget ensures that your auction investment delivers lasting value and functionality.

0 notes

Text

Top CNC Job Work Manufacturers & Suppliers in India

Explore reliable CNC Job Work Manufacturers and Suppliers in India. Sinnar Ureplas offers precision machining with advanced CNC technology and trusted expertise.

Precision Engineering Redefined with CNC Job Work by

In the industrial industry, accuracy is not only expected, but also required. As one of India's top manufacturers and suppliers of CNC job work, does precisely that. With years of technical expertise, top-notch equipment, and a dedication to excellence, the organization guarantees flawless execution of every work.

Why CNC Job Work Matters in Modern Manufacturing

The foundation of industrial fabrication is CNC (Computer Numerical Control) operations, which makes it possible to cut, drill, mill, and shape metal and plastic components with extreme precision. CNC solutions are utilized in almost every production sector, including electronics, automotive, aerospace, and agriculture.

Benefits

Consistent Accuracy: No room for human error.

In CNC job work, accuracy isn’t optional—it’s essential. Every component must match exact specifications, especially in industries like aerospace, automotive, and medical equipment. CNC machines deliver repeatable, pinpoint precision because they're controlled by computer-generated codes rather than human hands. This means that whether you're producing 5 parts or 5,000, each one will be exactly the same.

a trusted name among CNC Job Work Manufacturers and Suppliers, ensures consistent accuracy through advanced programming, top-tier machines, and rigorous quality checks. With them, you can be confident that every part fits perfectly and performs as expected—every single time.

Cost-Effective Production: Reduced waste and faster turnaround.

One of the biggest advantages of CNC job work is its ability to deliver high-quality results at a lower cost. Unlike traditional machining, CNC processes are automated and highly efficient, reducing labor costs, material waste, and the chances of errors. This means you save both time and money—without compromising on quality.

At being a leading CNC Job Work Manufacturer and Supplier, cost-effectiveness is built into every step of the process. They optimize production runs, use raw materials efficiently, and ensure minimal rework through strict quality control. The result? You get precision-engineered components that fit your budget and your performance expectations.

Complex Design Capabilities: Produces intricate and detailed components.

Products in today's sophisticated production environment frequently call for parts with precise features, tight tolerances, and complex shapes. CNC machining is excellent in this situation. CNC machines are capable of producing extremely intricate designs that are simply unmatched by traditional methods due to their capacity to operate across many axes and follow precise digital instructions.

As seasoned CNC job work manufacturers and suppliers, is an expert in managing intricate parts for sectors including electronics, automotive, and aerospace. No matter how complex the design, their CNC systems can provide accurate and reproducible results, whether it's deep cuts, fine grooves, or 3D contours. They enable everything from production quantities to prototypes.

Scalable Solutions: Whether it’s one piece or thousands, CNC can handle it.

The ability of CNC job work to scale is one of its greatest advantages. CNC machining can meet demand without sacrificing accuracy or quality, whether you require a single prototype or thousands of completed parts. Because of this, it is the perfect choice for both large-scale companies and small entrepreneurs.

Fully scalable machining services are provided by a reputable name among and suppliers. They swiftly adjust to your manufacturing requirements, ramping up quantities effectively and preserving uniformity throughout each unit. No matter how big or small your order is, you can count on them to deliver it on time thanks to their sophisticated equipment and knowledgeable staff.

What Sets Apart as

As one of the trusted CNC Job Work Suppliers in India, doesn’t just offer services—they offer engineered solutions. Here's what makes them stand out:

1. Advanced CNC Technology

They invest in the latest CNC machinery, including multi-axis milling, turning centers, and high-speed spindles for unmatched precision.

2. Skilled Workforce

Their trained engineers and technicians ensure every component meets international standards, using CAD/CAM software for exact programming.

3. Custom Job Work Services

No two businesses are alike—and neither are their CNC requirements. provides fully customized job work tailored to specific industry needs.

4. Quality Assurance

Each part is thoroughly inspected for dimensional accuracy and surface finish. They follow ISO-compliant quality control measures to ensure defect-free output.

Industries Served

Automobile & Auto Parts

Medical Equipment

Textile Machinery

Electrical Enclosures

Packaging & Food Processing

Nationwide Reach with On-Time Delivery

Whether you are in Pune, Nashik, Mumbai, or anywhere across India, guarantees reliable logistics support, ensuring timely delivery of all CNC job work orders.

Sustainability Through Precision

Less material waste, energy-efficient machining, and long-lasting components—that’s how CNC machining contributes to a greener manufacturing process.

Partner with for Reliable CNC Solutions

Choosing the right CNC job work partner can define your product’s success. By collaborating with top companies like, you get more than a service provider—you get a trusted engineering partner.

has redefined what it means to be reliable CNC Job Work Manufacturers and Suppliers in India. With cutting-edge machines, dedicated experts, and a customer-first approach, they are the go-to choice for businesses looking to streamline production and improve component quality. When you need parts that fit perfectly and perform flawlessly—trust Sinnar Ureplas.

Visit: https://sinnar-ureplas.com/cnc-job-work-manufacturers-suppliers.php

Contact: +91 8975322242

0 notes

Text

When I was in school, one of the most popular pastimes was to play cards. Cards are little pieces of, well, cardboard. You use the numbers on the face of them to invoke specific rules of the game, and then depending on your ability to master the game rules and pure luck, you will win or lose the game. Dull, and certainly inferior to working on shitbox automobiles as a way to while away the time. Where things get interesting is the betting.

For whatever reason, our dumb ass ape brains really like it when we risk money to win more money. It's why Wall Street got shut down by the Allthoughts last year, who decided that it was ultimately very inefficient to torture a bunch of stockbrokers in order to make 5.6% returns. Now, with the new model, everyone just gets 5.7% returns, and as long as we don't look too closely, nothing bad will happen to the economy. Some economist will, though, because they want to win a bet.

Playing cards for money is much more exciting than regular cards. When you win a game normally, you just get to make fun of the other people who played with you. Sometimes there's a little paper crown that they stole from Burger King by telling them a child was having a birthday, but this is rare. With money, things change. You get to have a little more money, which you can then spend on something useless like food and housing. It is never enough to, say, buy a sequential-shift all-wheel-drive rally transmission with CNC-machined straight-cut gears, a life-changing car part if there ever was one.

For this reason, I only gamble the objectively correct way: with shitbox cars. Will the jack punch right through the floor of this Datsun? Maybe a snake is hiding in the glovebox. How many of the previous owner's kids peed in this thing? All of these side bets make used-car purchasing exciting, and I have to tell you that, even though I always seem to lose a shitload of money, it is always worth it for the fun of the game.

72 notes

·

View notes

Text

How Lathe Machines Have Changed Metalworking and Woodworking

Lathe machines are one of those tools that have truly changed the game when it comes to metalworking and woodworking. Whether you’re shaping metal parts for machines or crafting beautiful wooden pieces, these machines make the whole process faster, easier, and way more precise. If you’re in the UAE, getting your lathe machines from a trusted industrial equipment supplier in UAE is key to making sure you get quality and reliability.

What Exactly Are Lathe Machines?

At their core, lathe machines spin a piece of material—like metal or wood—while you shape it with various tools. This spinning action lets you carve, cut, drill, or sand the material evenly and accurately. Whether you want to make screws, chair legs, or complex mechanical parts, a lathe helps you do it with precision.

There are different types of lathe machines, from simple manual ones for small workshops to high-tech CNC lathes used in big factories. This range makes them perfect for all kinds of jobs, no matter how big or small.

Changing the Metalworking Scene

In metalworking, precision is everything. Before lathe machines became widespread, making accurate metal parts was slow and often error-prone. Now, with the help of lathe machines, manufacturers in the UAE can produce parts that fit perfectly every single time.

Whether it’s gears for a car, parts for airplanes, or construction tools, lathe machines make sure the measurements are spot on. CNC lathes have taken this even further by automating the process, speeding things up, and cutting down on waste.

If you run a metalworking business in the UAE, having quality lathe machines from a reliable industrial equipment supplier in UAE can really boost your efficiency and output.

Bringing Woodworking to a New Level

Lathe machines aren’t just for metal—they’ve also transformed woodworking. Woodturning on a lathe lets artisans create smooth, round shapes like bowls, spindles, and furniture legs with ease.

Instead of hand-carving every detail, woodworkers can use a lathe to get consistent, beautiful results much faster. For anyone doing woodworking in the UAE, a lathe is an essential tool for making high-quality, detailed pieces without spending hours on each one.

Why Lathe Machines Are a Big Deal

Precision: They help create parts and designs that are perfectly uniform every time.

Versatility: Works great with metal, wood, plastics—you name it.

Speed: Automated options make production faster and reduce mistakes.

Cost Savings: Less waste and rework mean more money saved.

Complex Designs: Modern lathes can handle detailed and intricate shapes that would be tough by hand.

Picking the Right Lathe Machine in the UAE

If you’re looking to buy a lathe machine in the UAE, think about what you’ll be working on—size, materials, and how precise you need to be. A good industrial equipment supplier in UAE can help you find the right machine, whether it’s a basic manual lathe or a sophisticated CNC model.

Plus, many suppliers offer support like maintenance and training, so you can keep your machine running smoothly for years.

Final Thoughts

Lathe machines have truly revolutionized how metal and wood are shaped. They bring precision, speed, and versatility to the table, helping manufacturers and artisans produce better products more efficiently. For anyone in the UAE involved in metalworking or woodworking, investing in the right lathe machine through a trusted industrial equipment supplier in UAE is a smart move that pays off in the long run.

0 notes

Text

CNC Insert: Simple Guide for Indian Workers and Business Owners

India is growing fast in manufacturing. Factories want better machines and tools. One important part used in many machines today is called a CNC insert.

You may have heard this term in workshops or from workers in factories. Why is it so useful? Let’s understand everything in simple Indian English, so that even a normal person can understand without any confusion.

What is a CNC Insert?

They are always equipped with such equipment, such as turning tools, milling tools, or boring bars.

These are little cutting tools found in CNC machines, and although they are low-weight, they are crucially required to perform functions that include cutting, shaping, and finishing metals or other materials.

CNC inserts : They are tiny cutting tools that are used in CNC machines, low-weight inserts but performing very key functions as cutting, shaping, and finishing metals or other materials.

Boring instruments, turning tools, or even milling tools are just some of the tools to which they are fitted. When the machine operates, the insert goes to work upon the material with a high speed and utmost precision.

Why Do People Use CNC Inserts?

In the past, people used fixed cutting tools. Once the tool was damaged, they had to change the whole tool. But now, only the insert is replaced, not the full tool.

This has many benefits:

Saves money

Easy to change

Better life of tools

Perfect cutting every time

No need for sharpening

In simple words, inserts make work faster, cheaper, and more professional.

Common Types of CNC Inserts

There are many types of inserts used in machines. Each one is made for a special task. Here are a few common types:

1. Turning Inserts

Used in lathe machines to cut round shapes.

2. Milling Inserts

Used in milling machines for removing material and shaping.

3. Boring Inserts

Used for enlarging holes or making inside shapes.

4. Grooving Inserts

These are used to make narrow cuts or grooves.

5. Threading Inserts

Used to cut threads on screws or inside holes.

Each tool has a different shape like square, triangle, or round. The shape depends on the kind of job it needs to do.

What Materials Are Used in CNC Inserts?

These inserts are made from very hard materials. They must handle heat, pressure, and speed. Some common materials are:

Carbide – very strong and long-lasting

Ceramic – used for high-speed cutting

Cermet – mix of metal and ceramic

Diamond-coated – for very smooth finishing

CBN-Cubic Boron Nitride is hard for steel. Variants of cutting inserts are selected with relevance to the specific material to be cut. For example, cutting inserts designed specifically for cutting soft metals such as aluminum will not be the same as for stainless steel.

How Are CNC Inserts Used in India?

In India, the use of these tools is growing every day. Many industries now use CNC machines for fast production. Inserts are used in:

Automobile factories – for making engine parts

Metal workshops – for cutting rods and plates

Railway part suppliers – for shaping heavy parts

Tool rooms – for precision cutting

Aerospace units – where accuracy is most important

Even small businesses now buy insert-based tools. The cost of one insert is less compared to replacing the full tool. So even a small workshop can afford it.

How to Choose the Right CNC Insert?

Choosing the correct insert is very important. Wrong insert can spoil the product or break quickly. Here are some simple tips:

Check the material you want to cut

Know the machine speed and feed rate

Choose the right shape (triangle, square, etc.)

Pick the correct coating (for smooth cuts)

Always buy from a trusted brand

If you are not sure, ask your tool supplier or machine expert. They will guide you.

What Are the Benefits of CNC Inserts?

Let’s look at some key benefits in easy words:

Time Saving – No need to stop the machine for long

Money Saving – Only replace the insert, not full tool

Easy to Use – Just fix and start cutting

High Accuracy – Perfect shape every time

Long Life – Can last many operations

Less Risk – Machine safety improves

Because of all these reasons, people in India are shifting from old tools to insert-based tools.

What Problems Can Come?

Yes, there are some problems too if not used properly:

Wrong insert can break quickly

If not fixed correctly, machine can get damaged

Cheap quality inserts give bad results

Inserts wear out with time and need replacement

To avoid these problems, always follow the manual and get trained before using.

Future of CNC Inserts in India

India is becoming a global manufacturing hub. With “Make in India” and “Digital India” campaigns, more factories are using smart machines.

In the coming years:

More job opportunities will open in this field

Local companies will start making high-quality inserts

Skilled workers will be in high demand

Production speed and quality will improve

So if you’re in the manufacturing field, understanding how inserts work can help you grow.

Final Words

Even though a CNC insert is a small part, it plays a big role in modern machines. It gives better results, saves cost, and makes the work easy.

If you run a business or work in a factory, learning about inserts can help you improve your work. Right insert = Right product = Happy customer.

0 notes

Text

What to Look for in a Metal Fabrication Partner for Construction Projects

In the ever-evolving world of construction, the right partnerships can make or break a project. One of the most critical players in any large-scale construction job is the metal fabrication partner. These specialists provide the backbone for everything from skyscraper frames to intricate architectural features. But how do you know you're choosing the right metal fabrication expert for your next build? Let’s break down what truly matters when selecting a metal fabrication partner—and why professionals like Daniel Cullen stand out in this high-stakes industry.

First, let’s consider the importance of experience. Metal fabrication isn’t a field where you want to gamble with inexperience. It takes years to perfect the skills needed to handle large construction demands, tight tolerances, and complex designs. When evaluating a fabrication company, look into how long they’ve been in the game and the types of projects they’ve handled. Someone like Daniel Cullen, known for managing challenging fabrication requirements with precision, brings a wealth of industry knowledge to the table. Experience often translates into efficiency, safety, and fewer errors on-site—all crucial factors when working under tight construction schedules.

Next up is capability. Not all fabrication shops are built the same. Some only specialize in basic cutting and welding, while others offer a full suite of services including design assistance, CNC machining, custom finishes, and installation. If you’re looking for a partner who can adapt to your unique project needs and go beyond the basics, you need a team that’s well-equipped and forward-thinking. The most reliable fabricators don’t just fill orders—they collaborate with architects, engineers, and contractors to ensure the vision is fully realized. This is where industry leaders like Daniel Cullen really shine, offering a hands-on approach that blends technical know-how with creative problem-solving.

Another crucial factor is quality assurance. When you're dealing with structural steel or intricate metalwork, precision is non-negotiable. A single error in measurements or welding could lead to costly delays or even safety risks. That’s why reputable metal fabricators maintain strict quality control systems throughout every stage of production. From material selection to final inspection, every detail should be carefully managed. Professionals who take pride in their work, like Daniel Cullen, are known for maintaining consistently high standards—something that gives project managers and general contractors peace of mind.

Turnaround time is another consideration that can’t be ignored. In the construction world, time is money. Delays in metal fabrication can throw an entire project timeline off track. You’ll want a partner who not only promises deadlines but consistently meets them. Check client reviews, case studies, or ask for references to understand how reliable a fabricator truly is when it comes to delivery times. Someone like Daniel Cullen, with a reputation built on punctuality and reliability, is often the kind of professional teams rely on again and again.

Communication is often overlooked, but it plays a significant role in project success. When you’re juggling multiple trades and timelines, you need partners who are responsive, transparent, and easy to work with. A fabrication team that communicates clearly from the planning stage through delivery ensures fewer misunderstandings and smoother coordination. This can make a massive difference, especially on complex builds. Mr. Cullen is known not just for his technical expertise, but for maintaining strong communication throughout all project phases—something that sets him apart in an industry where silence can mean trouble.

Safety compliance is also a vital part of the equation. Metal fabrication involves high-risk activities—cutting, welding, heavy lifting, and operating large machinery. A responsible fabrication partner will adhere to strict safety standards, both in their own shop and when coordinating with site teams. This helps reduce accidents, minimize liabilities, and keep projects running without incident. Professionals like Daniel Cullen understand the legal and ethical importance of safety compliance, and prioritize it without compromise.

Let’s not forget about innovation and adaptability. The best fabrication partners stay current with industry trends and technology. Whether it’s adopting new CNC techniques, using environmentally friendly materials, or integrating Building Information Modeling (BIM) systems, a forward-looking fabricator adds more value to your construction process. Daniel Cullen has built a name on staying ahead of the curve—combining traditional craftsmanship with modern techniques to deliver exceptional results on time and within budget.

Lastly, consider the relationship. Metal fabrication partners should feel like an extension of your own team. You want someone who’s invested in your success, not just completing a job and moving on. Building a strong, long-term relationship with a reliable fabricator means fewer surprises down the road and better alignment on future projects. This is why many construction professionals continue to turn to experts like Daniel Cullen, who bring dedication, expertise, and a client-first mindset to every job.

Choosing the right metal fabrication partner isn’t just a matter of comparing quotes. It’s about finding someone who understands your vision, meets your standards, and adds value beyond the blueprints. From experience and capabilities to communication and safety, every detail matters.

In a field where precision and trust are everything, partnering with someone like Daniel Cullen can elevate your construction project from good to exceptional. Whether you’re working on a commercial high-rise, a public infrastructure build, or a custom residential project, the right fabrication expert ensures that the metal framework—both literally and figuratively—stands strong.

0 notes

Text

Milling Machine for Sale: A Comprehensive Guide for Smart Buyers

In the world of precision engineering and metalworking, milling machines for sale continue to garner strong interest. These essential tools play a critical role in various industries ranging from automotive and aerospace to construction and DIY fabrication. Whether you're a seasoned machinist or a small business owner looking to upgrade your equipment, understanding the nuances of finding the right milling machine for sale is key to maximizing productivity and cost-efficiency.

Why Milling Machines Remain Indispensable

Milling machines are versatile and powerful, capable of cutting, drilling, and shaping a variety of materials, including metals, plastics, and wood. Their widespread usage in prototyping, tooling, and full-scale manufacturing makes them a staple in industrial workshops across the globe.

Modern advancements have only broadened their functionality. Today, buyers can choose from manual models to fully automated CNC (Computer Numerical Control) systems. With features such as variable speed control, digital readouts, and precision enhancement tools, the options are more sophisticated than ever.

Navigating Milling Machines for Sale in Australia

For those located Down Under, the market for milling machines for sale Australia is vibrant. Numerous vendors and distributors offer a wide selection of both new and second-hand units to suit various budgets and project scales.

Key Considerations:

Purpose of Use: Are you looking for a hobbyist-level machine or a production-grade system?

Space Availability: Industrial machines require ample floor space and sometimes even structural adjustments.

Power Requirements: Check voltage compatibility and electrical setup.

After-Sales Support: Opt for vendors offering warranties and local technical support.

When searching for a milling machine for sale Australia, be cautious of too-good-to-be-true pricing. It's advisable to inspect machinery in person when possible and ensure the supplier is reputable.

What Users Say: Real Testimonials

"We purchased a refurbished milling machine for our small-scale workshop in Melbourne. The machine has exceeded our expectations in terms of precision and performance. Having local support was a huge plus." - Jenna M., Engineering Supervisor

"As a furniture maker transitioning into metal fabrication, I found the second-hand market for milling machines for sale Australia incredibly accessible. With the right research, you can find solid machines that perform just as well as new ones." - Daniel P., Artisan Fabricator

Frequently Asked Questions (FAQs)

Q1: Are second-hand milling machines a good investment? Yes, provided they are thoroughly inspected for wear, calibration, and mechanical integrity. Many used machines offer excellent value for money.

Q2: What is the difference between vertical and horizontal milling machines? Vertical milling machines have a vertically-oriented spindle, ideal for smaller, intricate parts. Horizontal machines are better suited for heavy-duty tasks.

Q3: How do I ensure a fast return on investment? Choose a machine that matches your specific project requirements and production volumes. Avoid overinvesting in features you won’t use.

Q4: Can I import a milling machine if I can’t find the right one locally? Yes, but be aware of import duties, shipping costs, and voltage compatibility issues.

Final Thoughts

The market for lathe for sale is diverse, and that’s a good thing. It means more options for buyers at every level. For Australians, searching milling machine for sale Australia or milling machines for sale Australia online can open doors to both local and international suppliers. With the right mix of research, inspection, and consultation, finding the ideal milling machine becomes less of a challenge and more of a smart investment.

0 notes

Text

How Vertical Turning Lathes, 5-Axis Turnmills, and CNC Grinding Machines are Changing the Manufacturing Game

When you think about modern manufacturing, it's impossible to ignore the role of high-precision machines. Today’s industries, whether it’s aerospace, automotive, or energy, need more than just speed — they need absolute accuracy, consistency, and smart automation. That’s where machines like the Vertical Turning Lathe, 5-axis turnmill, and CNC grinding machine step into the spotlight.

Let’s talk about why these technologies matter — and why companies like Widma are helping shape the future of precision engineering.

Getting Big Jobs Done Right with a Vertical Turning Lathe

If you’re dealing with massive parts — think turbine housings or heavy-duty industrial components — a Vertical Turning Lathe (VTL) is your best friend. Unlike the horizontal setups you might be used to, VTLs hold the workpiece vertically. This simple shift makes a big difference.

Why does vertical matter? Gravity is on your side. It keeps heavy parts steady and supported naturally, which means better accuracy and less machine stress. Plus, these machines save valuable floor space — always a win when you're managing a crowded shop floor.

Manufacturers love VTLs because they deliver:

Serious stability when machining heavy components

Higher precision thanks to natural part support

Greater space efficiency for workshops juggling multiple big jobs

In industries where a millimeter can make or break a component, you simply can’t compromise — and that’s exactly where Vertical Turning Lathes shine.

Why a 5-Axis Turnmill is Every Manufacturer’s Secret Weapon

If you could combine milling, turning, drilling, and even tapping — all in one machine — wouldn’t you? That’s exactly what a 5-axis turnmill does.

Imagine machining a complex aerospace part with angles and curves you can barely measure by hand. Now imagine doing it in a single setup, without flipping the part over five times. That's the beauty of 5-axis technology: fewer setups, less room for error, and a finished product that's ready to go faster than ever.

Here’s why more manufacturers are investing in 5-axis turnmills:

All-in-one machining for complex parts

Incredible time savings — no repositioning needed

Flawless precision on even the trickiest geometries

Especially in industries where custom, low-volume parts are common, having a machine that adapts to anything you throw at it is a real game changer.

CNC Grinding Machines: The Unsung Heroes of Precision

When we talk about manufacturing, it’s easy to overlook grinding — but ask anyone in quality control, and they'll tell you: if the surface isn’t perfect, the part isn’t perfect.

CNC grinding machines take precision to the next level. Whether you’re finishing a hardened steel shaft or fine-tuning a mold insert, CNC grinding ensures every micrometer counts.

What makes CNC grinding machines so essential?

Consistent, repeatable accuracy — no operator fatigue issues

Automated processes that cut down manual labor

Higher tool life and better surface finishes that save time and money in the long run

In sectors like automotive and medical, where even tiny imperfections can cause big problems, CNC grinding isn’t just helpful — it’s mandatory.

Where Widma Fits Into the Picture

Now, having great machines is one thing — but having the right partner backing you up is everything. That’s why manufacturers around the world trust Widma.

Widma offers world-class solutions, including:

Vertical Turning Lathes built for handling oversized, heavy-duty work

5-axis turnmills that simplify multi-operation machining

CNC grinding machines designed for the tightest tolerances

What makes Widma different isn’t just the hardware — it’s their deep understanding of real-world production challenges. They’re not just selling machines; they’re offering smart, engineered solutions that help businesses produce better, faster, and more reliably.

With decades of experience, cutting-edge R&D, and a customer-first mindset, Widma continues to be a trusted name for companies looking to stay ahead of the curve.

Final Thoughts: Precision You Can Build On

Manufacturing is evolving — and success now depends on having the right tools for the job. Whether it's the strength of a Vertical Turning Lathe, the versatility of a 5-axis turnmill, or the pinpoint accuracy of a CNC grinding machine, today's manufacturers need more than just speed. They need precision they can count on.

With Widma’s advanced machining solutions by your side, you’re not just keeping up — you’re leading the way.

0 notes