#iOT Applications with Data logging

Explore tagged Tumblr posts

Text

iOT Applications with Data logging

#iOT Applications with Data logging#MIS Applications with Data logging#MIS Application with OPC#OPC Interfaced MIS#Cloud Application Solution#iOT Application Development#MIS Application Development#MIS in Industrial Automation#MIS for Power Industry#MIS for Oil and Gas Industry#MIS for Pharma Industry

0 notes

Text

How to Choose the Best Low Voltage Switchgear for Your Project

Low voltage switch gears are significant to an industry, commercial or residential installation in ensuring the safe and effective power distribution. Selecting the right switchgear is key in making sure the system will be reliable, preventing electrical faults, and optimizing energy efficiency. Buying switchgear may appear challenging, given the number of options available in the market. The guide below will assist in grasping the vital aspects to consider in choosing low-voltage switchgear in 2025.

What is Low Voltage Switchgear?

Low voltage (LV) switchgear is an assembly of circuit breakers, disconnects, fuses, relays, and other protective equipment for controlling and protecting electric systems in voltages of up to 1,000V AC. It is commonly used in:

Industrial power distribution systems;

Commercial buildings;

Data centers;

Hospitals;

Renewable energy systems.

Choosing Low Voltage Switchgear: Important Considerations

1. Understand Your Project Requirements

Understanding your project requirements for assessing power distribution should include:

Voltage and current rating. This is for ensuring compatibility of load.

Type of application: For example, both industrial and commercial as well as residential and renewable sources.

The fault current rating: Ensure that it can withstand the maximum possible fault current.

Number of feeders and expansion requirements: Be sure to plan for possible future growth.

2. Safety and Compliance with Standards

As far as safety is concerned, the other critical consideration when selecting switchgear is to ensure that it has met the following:

IEC 61439 or ANSI/NEMA standards-Properly complying with international safety and performance standards.

Arc flash protection-Reduces the risk of being exposed to electrical hazards.

Short-circuit withstand capability-Makes sure switchgear withstands those high fault conditions.

3. Type of Switchgear Configuration

The correct configuration should be selected based on the size and complexity of the project:

Fixed Type Switchgear — Cost-wise, the cheapest and most suitable for small installations.

Withdrawable Type Switchgear — Provides ease of maintenance expected for an industrial facility.

Compartmentalized Switchgear — Offers improved safety and isolation of components.

4. Energy Efficiency and Sustainability

Modern switchgear are also designed to optimize energy usage and reduce losses. Look for: Low power loss components — More efficient. Eco-friendly insulation materials — Leverage the environment. Smart grid compatibility — Include renewables.

5. Smart Features and Digitalization-

Soon after Industry 4.0 and IoT, digital switchgear became a standard. Consider: Remote monitoring and diagnostics-The predictive maintenance help. Automated fault detection-Reduced downtime, and increased safety. Data logging and analytics-Optimizes power usage.

6. Brand Reputation and After-Sales Support

Choosing a reliable brand ensures long-term performance and support. Some of the top low voltage switchgear Suppliers are:

Al Mayar Electric Switchgear Ind LLC is the new milestone in the mastering of Mayar Holding in electrical technology. The company is committed to cater quality electrical and switchgear products in Middle East, Asia, Europe & Africa ensuring high standards and reliability

Enza Electric stands out as the best manufacturer of electrical switchgear in the GCC countries, providing top-notch products that lead the market and offer reliable electrical solutions.

Al Daleel Electrical Switch Gear Trading LLC is one of the leading Supplier and Distributor of Electrical Switchgear Products in GCC.

Civaux Electric proudly stands at the forefront of electrical manufacturing, delivering a diverse range of premium products, including Panel Fans & Filters, Panel Heaters, Cabinet LED Lamps, Regulators, and Indication Lamps & Switches.

Stefan Electric based in Germany, specializes in manufacturing and distributing a wide range of switchgear products such as Current Transformers, Analog and Digital Meters, Relay and Timer Meters, and Door Limit Switches across the UAE, including Dubai, Qatar, Oman, Bahrain, Sharjah, and Saudi Arabia.

Additionally, check for:

Spare parts availability, thereby facilitating easy maintenance and repair.

Local service centers for a quick troubleshooting and support.

Warranty and possible extended service offerings would enhance long-term value.

7. Budget and Cost Considerations

The performance-to-cost trade-off is thus an important consideration. One could consider comparing:

- Initial costs versus future savings: Although more energy-efficient switchgear might entail higher initial costs, the operational expenses are going to be much lesser.

- Customization options: Some brands are more conducive to modular designs to accommodate specific budgets.

- Installation and maintenance costs: Include considerations for servicing and availability of spare parts.

7 notes

·

View notes

Text

Cyberchase: How to Hack the Motherboard

So, when I was writing my episode discussion post on Cyberchase Season 1 Episode 1 "Lost My Marbles", I mentioned that I might make another post about the security breach that allowed The Hacker to infect Motherboard with the virus. What did The Hacker do to set this up? How did the kids accidentally open the breach? And other questions like that. I have a bit of background in software engineering. I will try to keep things as simple as possible.

Much of this is head-canon built on top of what we see in the episode. Of course, the show plays it fast and loose with computer terminology. Don't try to hack things in real life. You will go to prison.

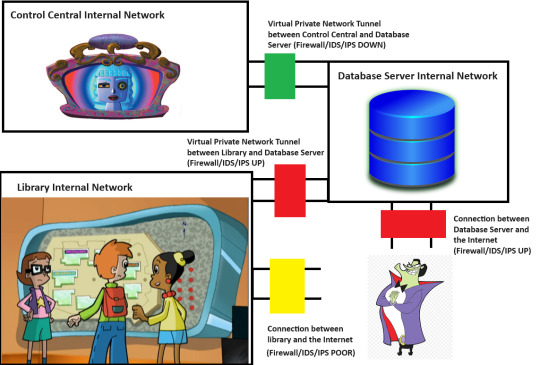

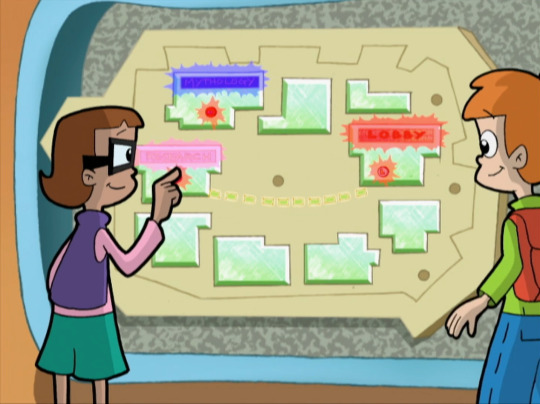

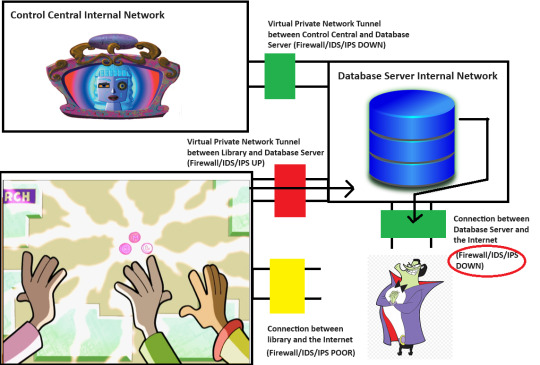

So, here's an MSPaint diagram of a tiny piece of Motherboard's setup. Keep in mind that she is the god of the Internet, and her Internet may even stretch beyond Earth into other galaxies.

So, there are three separate network segments here. We have the library's internal network, which has the big board on it. We have Control Central's internal network, which has Motherboard on it. And then we have a Database Server internal network, which has a Database Server running on it.

The Database Server is something that I invented here. Remember that this whole diagram is head-canon. However, it's not too far-fetched to think that Motherboard must reach across Cyberspace to a separate Database Server, maybe at the Cybrary.

Now, we know that Motherboard is not directly reachable, even with her Firewall down. Otherwise, The Hacker wouldn't have needed a separate security breach to get to her. He would have just pushed the virus once she took down her firewall for maintenance.

However, Motherboard has a Virtual Private Network (VPN) tunnel to the Database Server. If The Hacker can compromise the Database Server and get his virus in there, it might be able to ride the tunnel into Control Central.

The purpose of any Firewall is to apply a set of rules to any network traffic going into or out of a network, device or application. A good Firewall configuration allows on the traffic that is needed and denies everything else. Motherboard's firewall between herself and the Database Server is currently down. The Database Server itself has connection points to the larger Internet without using a VPN tunnel. However, the Database Server's own Firewall for that access point is UP. If The Hacker tried to throw his virus at that access point, it wouldn't work.

However, there is another connection point into the Database Server. This is another VPN tunnel from the library network. Let's say that the board retrieves the data on the locations of different objects on the map and the icons for those objects by reading one of the Databases. Maybe the board also writes data to the Database to log what directions people requested.

The point here is that some traffic from the Board is authorized to pass through the Firewall on that VPN tunnel. Now, is there a way for The Hacker to get the Board to send authorized traffic over the VPN tunnel to tell the Database Server to open a breach in the Firewall for that public access point? Maybe. It is an Internet-of-Things (ioT) device. Alot of people get these devices, and then they either leave passwords set to their defaults or they forget to keep the sofware patches up to date.

There is a public access point to the Board with a poorly-configured firewall. Maybe there's a way for him to get inside. It may be possible for him to dump the virus code into the board, but there's no guarantee that it would be able to go any further, since the Firewall between the Board and the Database Server is working.

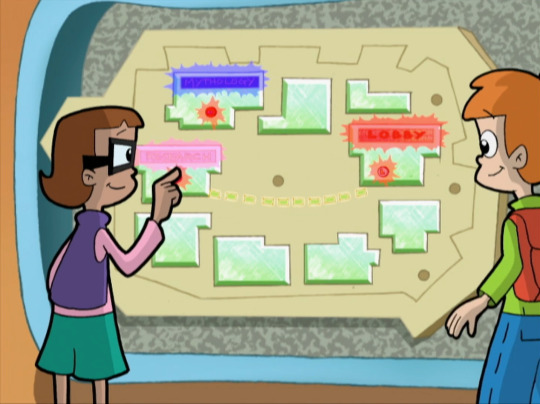

So, let's think about the Board as its own thing.

Suppose that we have two user accounts associated with the board. There is a Principle of Least Privilege that states that a given user account or system process should only be given the minimum amount of permissions required to perform its tasking. That way, if the user account or system process attempts to do something out of line with its permissions, it won't be allowed to perform the operation.

However, if you leave other unnecessary permissions open, and the user account or system process attempts to do something outside of its original intended operations, then the operation may succeed and have unintended consequences.

This also links up with the software development concept of the Minimum Viable Product. You build your software to perform only the exact tasking that it needs it perform. You don't put any additional, undocumented functions in there. Otherwise, those functions could activate and have unexpected consequences.

The board's purpose it to display the different locations. It allows for users to input two points, and it will draw a line between them to assist in navigation. We also established earlier that it reads its information from the Database and writes other information out to the Database.

However, suppose there was some undocumented functionality here. Suppose the developers had a special feature installed in the board that ran a cleanup command against the Database if you pressed three buttons in quick succession. Suppose that the cleanup command in question could be any arbitrary command. Therefore, the developers put the command into a configuration file to be read and executed by the software at runtime.

However, the developers knew that if some kids turned up and started poking the map, they could accidentally kick off the Database Cleanup command. They removed the Database Cleanup command from the configuration file. That way, if someone did poke three buttons in quick succession, the software would check the configuration file, see that there was no command defined, and then do nothing.

The trouble is that they left the part of the software that read the configuration file and ran the arbitrary command in place. So, if the command was somehow added back to that part of the configuration file, then there would be a command for the software to run. Then, if someone else pushed the three buttons, that command would be run. So, yeah, someone could put a command in there to write a bunch of junk into the Database until it filled up and crashed. Again, these are commands being sent to the Database from the Board. The Firewall would let them through just fine.

That's pretty bad, but that only lets them modify the Database, right? It's not like they can just tell the Database to open the Firewall on the server that it is sitting on, right?

Well, what if one of the things that the Database could do, upon request, was to open a command shell on the server and run a command. And what if, that command shell was able to run commands that impacted things on the server beyond the Database itself.

What if we called it "xp_cmdshell" and called the Database Server "Microsoft SQL Server 2000". Windows XP and Microsoft SQL Server 2000 would have been around at the time of "Lost My Marbles" after all. Those were also the key players in the real-world Heartland Payment Systems data breach of 2008, which inspired this post.

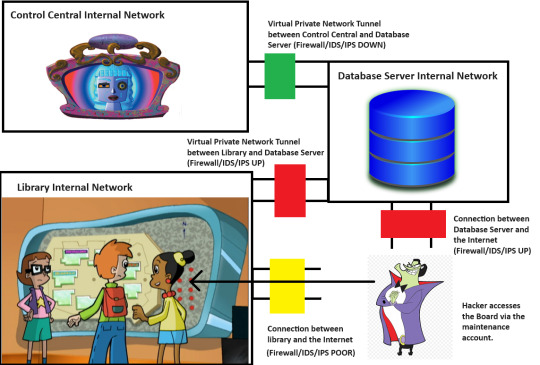

But hey, just because the Database could open a command shell on the Database Server doesn't mean that The Hacker could use it to bust the Database Server's external Firewall, right? He still needs a way to execute "xp_cmdshell". So, he needs an account with the correct permissions to tell the Database to execute "xp_cmdshell", and he needs the Database itself to have high-enough permissions to run a command via "xp_cmdshell" that can bust the Database Server's external firewall and open a path to Motherboard. Thankfully, the Database only run the "xp_cmdshell" for the top-level Database Administrator account.

This is where we get back to the Principle of Least Privilege. The Board should connect to the Database with a fairly low-power account. It only needs to read-from and write-to a few Database tables after all. Likewise, the Database itself should have been started on the Database Server by a fairly low-power account, as it only needs to handle reading and writing its own set of tables.

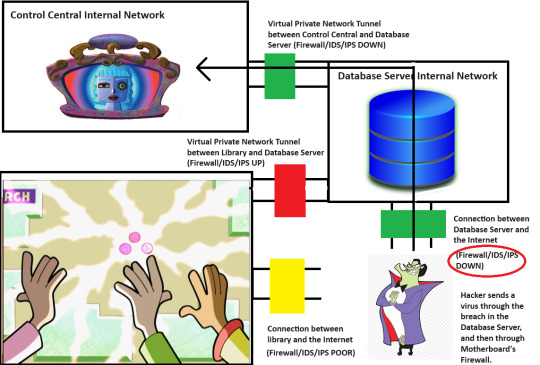

But then some moron decided to hook up the Board to the Database Server on the top-level Database Administrator Account. So, if the Board was configured to send an "xp_cmdshell" command, the Database would run it. Oh, and another moron decided to have the Database Server start the Database with the "root" account for that server. So, if the Board was configured to send in an "xp_cmdshell" command to nuke the external Firewall, then the Database would be able to nuke the external Firewall.

There is a principle called Defense-in-Depth, where you build multiple layers of defense around your critical item. That way, if a layer fails, you may be okay. We're running out of layers.

We only have one or two layers left. We know that the Board doesn't run "xp_cmdshell" for its regular operations today. Sure it has an undocumented debug mode that allows someone to execute any command in its configuration file (including "xp_cmdshell") against the Database. But someone would need to get to that file.

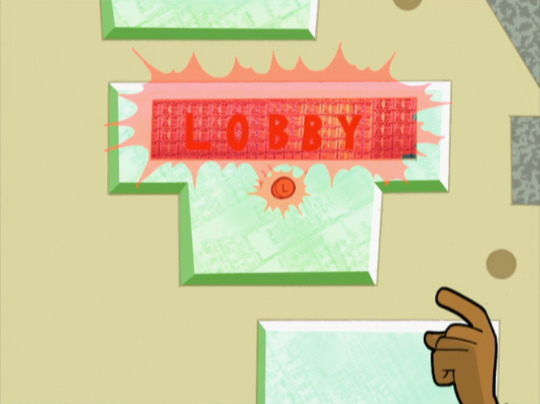

The board's main account doesn't give you a filesystem to play with, as they wouldn't want kids running up, poking things, and deleting the filesystem. No, you only get the interfaces that you get. You can pick two items and see a path between them. Or you can pick three items and see the undocumented debug mode run whatever command is in the configuration file.

But what if there was some sort of maintenance account accessible through the Internet that didn't enable someone to send commands to the Database, but would enable someone to get into the filesystem and mess around with it? And what if that maintenance account was still using a weak or default password because people just don't check that for IoT devices?

So, he's in the Board's filesystem now. That's concerning. And wouldn't you know it, yet another moron left that critical configuration file in a state where the maintenance account can make changes to it. So, of course, he found the empty configuration item for the cleanup command. Remember, this was setup to run any arbitrary command. Of course, he put in an "xp_cmdshell" command that tells the Database to nuke the external firewall on its own server.

While The Hacker was able to put the command in place, the maintenance account doesn't have the power to send commands to the Database on its own. That power is only enabled for the system account tied to the Board's user interface. So, he still has to rely on someone in the real world to push three buttons in quick succession.

Well...shit.

That's not good.

That's not good at all.

Seriously though, don't try this at home.

I suppose we can speculate on the nature of the virus. We know from Season 1 Episode 14 "Cool It" that Motherboard goes through more cryoxide than normal due to the virus. There are actual computer viruses out there that were designed to turn off heat safety warnings on CPUs and then cause them to run hotter. Some CPUs would eventually melt and ruin the computer.

The original infection destroyed the Encryptor Chip, and it is stated that only a replacement Encryptor Chip could cure the virus. The name suggests that it deals with data encryption, but perhaps it is also a virus cleanup tool. Perhaps it worked to weaken the existing virus until it was eventually overwhelmed and destroyed. Perhaps the virus exhausted most of its strength destroying the Encryptor Chip first.

In any case, curing the virus permanently would end the show.

#cyberchase#2000s#cartoon#nostalgia#pbs kids#2000s childhood#not for use in real life#you'll get busted

12 notes

·

View notes

Text

Mastering IoT Communication: Using SMS Gateways Effectively

Unlocking Seamless Connectivity for Your IoT Devices with SMS Gateways

In today's rapidly evolving technological landscape, the Internet of Things (IoT) has become a cornerstone of modern automation and data collection. Effective communication between IoT devices is essential for real-time monitoring, control, and automation. One of the most reliable and cost-effective methods to facilitate this communication is through SMS gateways. This article explores how to leverage SMS gateways for IoT device communication, ensuring low-cost, scalable, and dependable connectivity.

Understanding the role of an SMS gateway in IoT is crucial. An SMS gateway acts as a bridge between your IoT devices and mobile network carriers, enabling devices to send and receive SMS messages seamlessly. This method is particularly advantageous in remote or low-bandwidth environments where traditional internet-based communication might be unreliable or expensive.

Why Choose SMS Gateways for IoT Communication?

Several factors make SMS gateways an attractive choice for IoT communication:

Reliability: SMS messages have high delivery rates, even in areas with poor internet connectivity.

Cost-Effectiveness: SMS is generally cheaper than deploying cellular data plans for each device, especially at scale.

Speed: SMS provides near-instantaneous message delivery, essential for real-time alerts.

Compatibility: Most IoT devices can be integrated with SMS modules, making the setup straightforward.

Setting Up an SMS Gateway for Your IoT Devices

To utilize SMS gateways effectively, follow these essential steps:

Choose a Reliable SMS Gateway Provider: Select a provider that offers robust API support, high delivery rates, and competitive pricing. Many providers offer dedicated APIs designed specifically for IoT applications.

Integrate the Gateway with Your IoT Devices: Use the provider's API to connect your sensors or controllers. Most gateways support standard protocols like HTTP, MQTT, or TCP/IP, simplifying integration.

Configure Alert and Data Transmission Rules: Set rules for when devices should send alerts or status updates. For example, a temperature sensor can send an SMS if the temperature exceeds a predefined threshold.

Implement Security Measures: Ensure data encryption and secure authentication to protect your IoT network from unauthorized access.

Test Your Setup: Conduct thorough testing to verify message delivery, response times, and system reliability.

Best Practices for Using SMS Gateways in IoT

Maximize the benefits of your SMS gateway integration by following these best practices:

Prioritize Critical Alerts: Use SMS for time-sensitive alerts such as security breaches, equipment failures, or environmental hazards.

Optimize Message Content: Keep messages concise and informative to ensure quick understanding and response.

Monitor System Performance: Regularly check message delivery metrics and system logs to identify and resolve issues promptly.

Plan for Redundancy: Implement backup communication channels to ensure continuous operation during network outages.

Scale Gradually: Start with a small number of devices and expand as you refine your system.

Real-World Applications of SMS Gateways in IoT

Many industries benefit from using SMS gateways for IoT communication:

Agriculture: Farmers receive alerts about soil moisture levels or weather conditions to optimize irrigation.

Manufacturing: Equipment sensors alert maintenance teams about potential failures before costly breakdowns occur.

Smart Cities: Public safety systems send alerts about environmental hazards or traffic incidents.

Healthcare: Remote patient monitoring devices send alerts if vital signs cross critical thresholds.

Conclusion

Integrating an SMS gateway into your IoT ecosystem offers a reliable, cost-effective, and scalable solution for device communication. Whether you're managing sensors in remote locations or deploying a large-scale sensor network, SMS provides a dependable channel for real-time alerts and data transmission. To explore effective SMS solutions for your IoT devices, consider visiting sms for iot devices and discover how to enhance your connectivity strategy today.

0 notes

Text

How App Development is Revolutionizing Traditional Industries in 2025

For years, industries like agriculture, manufacturing, and construction relied heavily on manual processes and legacy systems. But in 2025, we’re witnessing a powerful shift—custom app development is driving a wave of digital transformation in even the most traditional sectors.

What was once slow, paper-based, and disconnected is now smart, data-driven, and automated—all thanks to tailored mobile and web applications.

Let’s explore how app development is redefining operations, efficiency, and growth in these core industries.

1. Agriculture: Smarter Fields, Higher Yields

The agriculture industry is embracing technology faster than ever before. Mobile apps are equipping farmers and agribusinesses with tools to boost productivity, monitor crops, and manage resources more effectively.

Key Innovations:

IoT-powered apps help farmers track soil moisture, weather conditions, and pest activity in real-time.

Drone-integrated systems capture crop imagery and analyze health conditions via AI-backed apps.

Marketplace apps connect farmers directly with buyers, reducing dependency on middlemen.

Result: Increased crop yield, reduced waste, and improved income stability for farmers.

2. Manufacturing: From Manual to Predictive

Manufacturing is becoming leaner and smarter. With the rise of Industry 4.0, custom apps are central to integrating machines, people, and data.

Game-Changing Features:

Real-time production monitoring via apps keeps plant managers updated on output, downtime, and maintenance needs.

Inventory and supply chain management apps improve planning and avoid overstock or shortages.

Predictive maintenance tools alert technicians before equipment fails, minimizing costly downtime.

Result: Enhanced productivity, better quality control, and lower operational costs.

3. Construction: Building with Precision and Speed

Traditionally plagued by delays and miscommunication, the construction sector is now using apps to keep projects on time and within budget.

Key Solutions:

Project management apps offer real-time collaboration between on-site workers, architects, and clients.

AR/VR-enabled apps allow stakeholders to visualize plans before construction even begins.

Safety compliance apps ensure that site inspections, hazard reports, and certifications are logged digitally and instantly.

Result: Smoother workflows, better safety compliance, and faster project delivery.

Looking Ahead

In 2025, app development is not just supporting traditional industries—it’s redefining how they operate. What makes the difference is customization. Businesses are no longer relying on off-the-shelf software; they are partnering with app development companies to create tools that speak to their exact needs.

Whether it’s a farmer in the field, a factory supervisor on the line, or a contractor on-site, the right app puts real-time power and insight in their hands.

0 notes

Text

Big Data Technologies: Hadoop, Spark, and Beyond

In this era where every click, transaction, or sensor emits a massive flux of information, the term "Big Data" has gone past being a mere buzzword and has become an inherent challenge and an enormous opportunity. These are datasets so enormous, so complex, and fast-growing that traditional data-processing applications cannot handle them. The huge ocean of information needs special tools; at the forefront of this big revolution being Big Data Technologies- Hadoop, Spark, and beyond.

One has to be familiar with these technologies if they are to make some modern-day sense of the digital world, whether they be an aspiring data professional or a business intent on extracting actionable insights out of their massive data stores.

What is Big Data and Why Do We Need Special Technologies?

Volume: Enormous amounts of data (terabytes, petabytes, exabytes).

Velocity: Data generated and processed at incredibly high speeds (e.g., real-time stock trades, IoT sensor data).

Variety: Data coming in diverse formats (structured, semi-structured, unstructured – text, images, videos, logs).

Traditional relational databases and processing tools were not built to handle this scale, speed, or diversity. They would crash, take too long, or simply fail to process such immense volumes. This led to the emergence of distributed computing frameworks designed specifically for Big Data.

Hadoop: The Pioneer of Big Data Processing

Apache Hadoop was an advanced technological tool in its time. It had completely changed the facets of data storage and processing on a large scale. It provides a framework for distributed storage and processing of datasets too large to be processed on a single machine.

· Key Components:

HDFS (Hadoop Distributed File System): It is a distributed file system, where the data is stored across multiple machines and hence are fault-tolerant and highly scalable.

MapReduce: A programming model for processing large data sets with a parallel, distributed algorithm on a cluster. It subdivides a large problem into smaller ones that can be solved independently in parallel.

What made it revolutionary was the fact that Hadoop enabled organizations to store and process data they previously could not, hence democratizing access to massive datasets.

Spark: The Speed Demon of Big Data Analytics

While MapReduce on Hadoop is a formidable force, disk-based processing sucks up time when it comes to iterative algorithms and real-time analytics. And so came Apache Spark: an entire generation ahead in terms of speed and versatility.

· Key Advantages over Hadoop MapReduce:

In-Memory Processing: Spark processes data in memory, which is from 10 to 100 times faster than MapReduce-based operations, primarily in iterative algorithms (Machine Learning is an excellent example here).

Versatility: Several libraries exist on top of Spark's core engine:

Spark SQL: Structured data processing using SQL

Spark Streaming: Real-time data processing.

MLlib: Machine Learning library.

GraphX: Graph processing.

What makes it important, actually: Spark is the tool of choice when it comes to real-time analytics, complex data transformations, and machine learning on Big Data.

And Beyond: Evolving Big Data Technologies

The Big Data ecosystem is growing by each passing day. While Hadoop and Spark are at the heart of the Big Data paradigm, many other technologies help in complementing and extending their capabilities:

NoSQL Databases: (e.g., MongoDB, Cassandra, HBase) – The databases were designed to handle massive volumes of unstructured or semi-structured data with high scale and high flexibility as compared to traditional relational databases.

Stream Processing Frameworks: (e.g., Apache Kafka, Apache Flink) – These are important for processing data as soon as it arrives (real-time), crucial for fraud-detection, IoT Analytics, and real-time dashboards.

Data Warehouses & Data Lakes: Cloud-native solutions (example, Amazon Redshift, Snowflake, Google BigQuery, Azure Synapse Analytics) for scalable, managed environments to store and analyze big volumes of data often with seamless integration to Spark.

Cloud Big Data Services: Major cloud providers running fully managed services of Big Data processing (e.g., AWS EMR, Google Dataproc, Azure HDInsight) reduce much of deployment and management overhead.

Data Governance & Security Tools: As data grows, the need to manage its quality, privacy, and security becomes paramount.

Career Opportunities in Big Data

Mastering Big Data technologies opens doors to highly sought-after roles such as:

Big Data Engineer

Data Architect

Data Scientist (often uses Spark/Hadoop for data preparation)

Business Intelligence Developer

Cloud Data Engineer

Many institutes now offer specialized Big Data courses in Ahmedabad that provide hands-on training in Hadoop, Spark, and related ecosystems, preparing you for these exciting careers.

The journey into Big Data technologies is a deep dive into the engine room of the modern digital economy. By understanding and mastering tools like Hadoop, Spark, and the array of complementary technologies, you're not just learning to code; you're learning to unlock the immense power of information, shaping the future of industries worldwide.

Contact us

Location: Bopal & Iskcon-Ambli in Ahmedabad, Gujarat

Call now on +91 9825618292

Visit Our Website: http://tccicomputercoaching.com/

0 notes

Text

Advantages and Disadvantages of Pressure Switch Compared to Traditional Mechanical Models

Technological Advancements in Pressure Switch Manufacturing

Pressure Switch Factory products often incorporate technologies in pressure sensing, allowing for enhanced functionality and integration with modern systems. Unlike traditional mechanical pressure switches that rely on physical deformation of diaphragms or bellows to trigger electrical contacts, modern factory-produced versions may use electronic sensors and microcontrollers. This results in greater accuracy, faster response times, and a wider range of customization.

Improved Precision and Control

One of the primary advantages of pressure switches from a specialized Pressure Switch Factory is their ability to offer high precision in pressure detection. Digital or electronic models can detect subtle pressure variations and offer tight switching differentials. Mechanical models, though reliable in many industrial applications, typically have broader switching bands and lower sensitivity, which can limit their usefulness in high-precision or automated environments.

Enhanced Integration with Smart Systems

Pressure switches developed by a modern Pressure Switch Factory are often designed to be compatible with PLCs, SCADA systems, and IoT platforms. This level of integration allows real-time monitoring, remote control, and data logging—features not typically available in older mechanical designs. As a result, smart pressure switches are better suited for predictive maintenance and system optimization.

Durability and Environmental Resistance

Many factory-engineered pressure switches are designed for demanding environments, offering high protection ratings such as IP67 or IP68. They often come with enhanced resistance to vibration, corrosion, and extreme temperatures. While traditional mechanical switches may still perform well in harsh conditions, they often require more frequent calibration and are susceptible to mechanical wear over time.

User-Friendly Features and Adjustability

Modern pressure switches from reputable factories usually feature user-friendly interfaces such as digital displays, LED indicators, or keypad settings for quick adjustments. These features make setup and troubleshooting much easier than with mechanical models, which often require manual tools and disassembly for any change in pressure settings.

Higher Initial Cost and Complexity

Despite the benefits, pressure switches from advanced factories generally come at a higher initial cost. Their electronic components, smart features, and digital interfaces contribute to increased pricing. Additionally, installation and setup may require technical expertise, which can be a barrier for small operations or users accustomed to the simplicity of mechanical models.

Power Dependency and Potential for Electronic Failure

Electronic pressure switches from a Pressure Switch Factory typically rely on a constant power source. This makes them unsuitable for applications where power reliability is a concern. In contrast, mechanical pressure switches are self-powered and continue functioning without external energy, which can be a critical advantage in certain safety systems or remote locations.

Maintenance and Service Considerations

Factory-produced smart pressure switches usually require less frequent maintenance due to fewer moving parts, but if they do fail, repairs may be more complex and expensive. Mechanical switches, on the other hand, are easier to service in-house and have a longer history of field-proven reliability. This simplicity can be particularly valuable in low-tech environments or for backup systems.

Conclusion

Pressure switches manufactured by a modern Pressure Switch Factory offer a wide array of benefits, including precision, smart system compatibility, and environmental durability. However, these advantages must be balanced against potential drawbacks such as higher costs, dependency on power, and increased complexity. When choosing between electronic and traditional mechanical pressure switches, the decision should be based on the specific needs of the application, the available infrastructure, and the level of automation desired.

Two modes can be switched. “Manual Mode” automatically starts and stops the electric water pump according to the set pressures, and also displays real-time pressure. Time mode used for filling up the water tower, the time setting will be changed as 0.1H,0.2H …0.9H, 1H, 2H …24H. Water shortage alarm.

0 notes

Text

NFC Tag Chip Market: Growth Potential of the Semiconductor Manufacturing Sector, 2025–2032

MARKET INSIGHTS

The global NFC Tag Chip Market size was valued at US$ 1.23 billion in 2024 and is projected to reach US$ 2.12 billion by 2032, at a CAGR of 8.1% during the forecast period 2025-2032.

NFC Tag Chips are specialized semiconductor devices that enable near-field communication (NFC) technology in contactless systems. These chips store and transmit data wirelessly over short distances (typically 4cm or less) when activated by an NFC reader device. The technology finds applications in payment systems, access control, smart packaging, and IoT device pairing. Key NFC tag types include NFC Forum Type 1-5 tags with varying memory capacities (from 96 bytes to 32KB) and communication speeds.

The market growth is primarily driven by accelerating contactless payment adoption (projected to reach USD 6.25 trillion transaction value by 2028) and the proliferation of IoT devices (expected to exceed 29 billion connected devices by 2030). Recent developments include STMicroelectronics’ launch of the ST25DV-PWM dynamic NFC tag with PWM output in Q1 2024, expanding industrial automation applications. NXP Semiconductors, STMicroelectronics, and Texas Instruments collectively hold over 65% of the global NFC tag chip market share as of 2024, with Chinese manufacturers like Fudan Microelectronics gaining traction in mid-range applications.

MARKET DYNAMICS

MARKET DRIVERS

Proliferation of Contactless Payments Accelerates NFC Tag Chip Adoption

The shift toward cashless transactions has reached unprecedented levels, with contactless payment volumes growing over 30% annually since 2020. This boom directly benefits NFC tag chip manufacturers, as these components form the backbone of tap-to-pay systems in credit cards, smartphones, and wearables. Major payment networks now report that more than 60% of in-person transactions under $25 utilize NFC technology, demonstrating how deeply embedded this solution has become in daily commerce. Financial institutions increasingly mandate NFC capabilities in newly issued payment cards, creating sustained demand for reliable tag chips across global markets.

IoT Expansion Creates New Use Cases for NFC Technology

As smart devices multiply across consumer and industrial applications, NFC serves as the critical bridge between physical objects and digital networks. The technology’s ability to enable quick pairing, configuration, and data transfer makes it indispensable in smart home setups, where over 300 million new devices were installed in 2023 alone. Industrial IoT applications leverage NFC for maintenance logging and equipment authentication, particularly in manufacturing plants where wireless connectivity must remain secure yet effortless. Unlike competing wireless protocols, NFC tags require no external power source and can be embedded directly into products at minimal cost – advantages that continue driving adoption through diverse verticals.

Retail Digital Transformation Fuels Shelf Label Innovation

Modern retailers increasingly deploy electronic shelf labels (ESLs) to streamline pricing updates and enhance customer engagement – a movement projected to grow the ESL market at 15% CAGR through 2030. NFC-enabled tags allow shoppers to access detailed product information, reviews, and promotions simply by tapping their smartphones, bridging the online-offline experience gap. Store operators benefit from reduced labor costs associated with manual price changes, with some chains reporting 80% fewer pricing errors after adopting these systems. This digital transformation in retail spaces creates sustained demand for reliable, low-cost NFC chips that can withstand high-traffic environments while maintaining security standards.

MARKET RESTRAINTS

Data Security Concerns Limit Sensitive Applications

While NFC technology offers convenience, potential vulnerabilities in data transmission continue raising concerns among enterprise adopters. Recent studies suggest that certain NFC implementations remain susceptible to eavesdropping and data manipulation when used without additional encryption layers. Financial institutions and healthcare providers consequently mandate rigorous certification processes for NFC components, delaying deployment timelines and increasing development costs. These security considerations particularly impact markets handling sensitive personal data, where regulatory scrutiny continues intensifying.

Material Shortages Disrupt Semiconductor Supply Chains

The semiconductor industry’s ongoing capacity constraints disproportionately affect NFC tag production, as these chips typically utilize mature process nodes prioritized for higher-margin components. Lead times for certain NFC controllers extended beyond 40 weeks during recent supply chain disruptions, forcing OEMs to redesign products or seek alternative solutions. While capacity expansions gradually alleviate these pressures, the market remains vulnerable to geopolitical tensions and trade restrictions that could again restrict access to essential raw materials like silicon wafers and packaging substrates.

MARKET OPPORTUNITIES

Healthcare Digitalization Opens New NFC Applications

Hospitals and clinical laboratories increasingly adopt NFC to track equipment, manage patient data, and verify medication authenticity. The global healthcare NFC market is projected to grow at 22% annually as providers seek to reduce errors and improve operational efficiency. Smart blister packs with embedded NFC tags now help patients adhere to medication schedules, while surgical instrument tracking systems prevent costly losses and sterilization lapses. These applications demand specialized tag chips with enhanced durability and sterilization resistance – a niche that commands premium pricing and higher margins for manufacturers.

Autonomous Vehicle Infrastructure Drives Innovation

Smart transportation systems present a $12 billion opportunity for NFC technology as cities deploy intelligent traffic management and electric vehicle charging networks. Roadside units equipped with NFC readers can communicate with vehicles for toll collection, parking access, and maintenance diagnostics without requiring manual intervention. Automakers increasingly embed NFC tags in key components to streamline service history tracking, with some premium models featuring over 50 tags per vehicle. As autonomous fleets expand, these applications will require ruggedized NFC solutions capable of operating reliably in extreme weather conditions.

MARKET CHALLENGES

Standardization Fragmentation Complicates Global Deployment

The NFC ecosystem suffers from competing technical standards and certification requirements across regions, forcing manufacturers to maintain multiple product variants. Payment applications in Europe demand different security protocols than those in Asia-Pacific, while industrial implementations often require custom firmware modifications. This fragmentation increases development costs and time-to-market, particularly for smaller chip vendors lacking resources to navigate complex compliance landscapes. Industry efforts to harmonize standards show progress but remain years away from eliminating these interoperability challenges.

Consumer Awareness Gaps Slow Adoption

Despite NFC’s technical maturity, many potential users remain unaware of capabilities beyond mobile payments. Surveys indicate that less than 40% of smartphone owners regularly use NFC for tasks like transit ticketing or smart home control, representing significant untapped potential. This education gap delays return on investment for infrastructure deployments, as merchants hesitate to install readers without proven consumer engagement. Marketing initiatives from industry consortia aim to address this challenge, but changing user behavior requires sustained education efforts across device manufacturers, service providers, and retailers.

NFC TAG CHIP MARKET TRENDS

IoT Integration and Contactless Payments Fueling NFC Tag Chip Adoption

The rapid expansion of Internet of Things (IoT) applications and contactless payment systems continues to drive demand for NFC tag chips globally. With over 30 billion IoT devices projected to be connected by 2025, NFC technology has become instrumental in enabling secure wireless communication between devices. Retail sectors are witnessing accelerated adoption, with nearly 60% of POS terminals now NFC-enabled globally. Recent advancements in chip miniaturization allow seamless integration into smaller form factors like wearable devices and smart packaging, further expanding application possibilities.

Other Trends

Smartphone Ecosystem Expansion

The proliferation of NFC-enabled smartphones is creating a virtuous cycle for tag chip demand. With over 85% of new smartphone models now featuring built-in NFC readers, consumers increasingly expect tap-to-connect functionality across retail, transportation, and access control scenarios. This has led to innovative applications in product authentication, where brands leverage NFC tags for anti-counterfeiting measures, and in logistics where real-time inventory tracking relies on NFC’s short-range precision.

Supply Chain Modernization and Industry 4.0 Integration

Manufacturing and logistics sectors are embracing NFC technology as part of digital transformation initiatives. The technology’s ability to store and transfer data without line-of-sight requirements makes it ideal for asset tracking and maintenance logging in industrial environments. Recent deployments in warehouse management systems demonstrate 25-30% improvements in inventory accuracy when replacing traditional barcode systems with NFC-based solutions. Additionally, the emergence of dual-frequency tags combining NFC with UHF RFID creates hybrid solutions that deliver both proximity precision and extended read ranges.

COMPETITIVE LANDSCAPE

Key Industry Players

Semiconductor Giants and Emerging Specialists Compete in Evolving NFC Tag Chip Market

The NFC Tag Chip market demonstrates a diverse competitive structure, blending established semiconductor leaders with specialized manufacturers. NXP Semiconductors currently leads the sector, commanding approximately 30% of the global NFC chip market share in 2024. The company’s dominance stems from its early mover advantage in NFC technology and strong partnerships with payment solution providers.

While NXP holds pole position, STMicroelectronics has been aggressively expanding its footprint through technological innovation. The company’s latest ST25TV series, featuring enhanced read/write capabilities and tamper protection, has gained particular traction in payment card applications. Meanwhile, Texas Instruments leverages its analog semiconductor expertise to deliver differentiated solutions for industrial IoT applications.

Chinese manufacturers are emerging as significant challengers in the space. Fudan Microelectronics has captured nearly 15% of Asia’s domestic market through cost-competitive offerings in access control and transportation cards. Meanwhile, Infineon Technologies has strengthened its position in secure authentication applications, particularly in European markets.

The competitive dynamics continue to evolve as companies adopt diverse strategies. Broadcom maintains its focus on high-performance solutions for mobile devices, while smaller players like EM Microelectronic carve niches in specialized applications such as medical device tracking and smart packaging.

List of Key NFC Tag Chip Companies Profiled

NXP Semiconductors (Netherlands)

STMicroelectronics (Switzerland)

Texas Instruments (U.S.)

Infineon Technologies (Germany)

Broadcom Inc. (U.S.)

EM Microelectronic (Switzerland)

Nuvoton Technology (Taiwan)

Fudan Microelectronics (China)

Giantec Semiconductor (China)

Kiloway (China)

Feiju Microelectronics (China)

NFC Tag Chip Market

Segment Analysis:

By Type

Passive NFC Tag Chips Dominate the Market Due to Cost-Effectiveness and Wide-Scale Adoption in Retail and Logistics

The market is segmented based on type into:

Passive NFC Tag Chips

Subtypes: Read-only, Read/Write, and others

Active NFC Tag Chips

Subtypes: Battery-assisted passive (BAP), Fully active, and others

By Application

Mobile Devices Segment Leads Due to Proliferation of Smartphones with NFC Capabilities

The market is segmented based on application into:

Cards (Payment & Access Control)

Shelf Labels (Retail & Inventory Management)

Consumer Electronics

Mobile Devices

Others (Healthcare, Automotive, etc.)

By Memory Capacity

48 Bytes to 168 Bytes Segment Holds Significant Market Share for Basic NFC Applications

The market is segmented based on memory capacity into:

Up to 48 Bytes

48 Bytes to 168 Bytes

168 Bytes to 512 Bytes

Above 512 Bytes

By Frequency

13.56 MHz Segment Dominates Due to Standardization in Most NFC Applications

The market is segmented based on frequency into:

13.56 MHz (Standard NFC)

Other Frequencies (Specialized Applications)

Regional Analysis: NFC Tag Chip Market

North America North America remains a mature yet high-growth market for NFC tag chips, driven by widespread adoption in contactless payments, smart retail, and Industrial IoT applications. The U.S. accounts for over 75% of regional demand due to strong penetration of digital payment systems like Apple Pay and Google Wallet. Canada follows closely, with increasing NFC integration in transit cards and access control systems. While technological maturity creates saturation risks, emerging applications in healthcare (patient tracking) and automotive (smart keys) present new opportunities. Stringent data security regulations also push manufacturers towards developing advanced encryption capabilities in tags.

Europe Europe represents a high-compliance NFC market, shaped by GDPR data protection laws and standardized payment protocols under the EU’s Payment Services Directive (PSD2). Germany and the U.K. lead in retail adoption, using NFC for smart shelf labels and cashier-less stores. Southern European markets show slower uptake due to legacy POS infrastructure. However, EU-wide initiatives like the Digital Identity Wallet program are accelerating demand for secure NFC tags in government IDs and passports. Nordic countries demonstrate particularly strong growth – Finland’s transit sector alone deployed over 10 million NFC-enabled travel cards in 2023.

Asia-Pacific The Asia-Pacific region dominates global NFC tag chip volumes, accounting for nearly 60% of worldwide consumption in 2024. China’s massive manufacturing ecosystem produces affordable tags for global brands while domestic adoption surges through mobile payment platforms like Alipay. India represents the fastest-growing market, with NFC integration in metro transit systems and Aadhaar-enabled payment systems. Japan and South Korea show advanced adoption in consumer electronics and automotive applications. While price sensitivity favors basic passive tags, increasing smart city projects across ASEAN nations drive demand for more sophisticated active NFC solutions.

South America South America presents a mixed picture for NFC tag adoption. Brazil leads with contactless payment initiatives from major banks and NFC-enabled public transit in São Paulo, while Argentina’s economic instability hampers technology investments. The region shows particular promise in livestock tracking and agriculture applications, where NFC tags replace traditional RFID for farm management. Challenges include inconsistent telecommunications infrastructure in rural areas and limited consumer awareness about NFC capabilities beyond payment systems. However, growing e-commerce penetration suggests strong future potential for logistics tracking applications.

Middle East & Africa The MEA region exhibits polarized NFC adoption between tech-forward Gulf states and developing African markets. UAE and Saudi Arabia deploy NFC extensively in government smart IDs, luxury retail, and tourism applications. Israel emerges as an innovation hub for secure NFC applications in defense and healthcare. Sub-Saharan Africa shows nascent growth through mobile money systems like M-Pesa, though infrastructure limitations delay widespread rollout. Long-term prospects remain strong as African fintech startups increasingly incorporate NFC technology and Gulf nations accelerate smart city initiatives ahead of events like Expo 2030 in Saudi Arabia.

Report Scope

This market research report provides a comprehensive analysis of the Global and regional NFC Tag Chip markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The Global NFC Tag Chip market was valued at USD 280 million in 2024 and is projected to reach USD 420 million by 2032, growing at a CAGR of 5.2% during the forecast period.

Segmentation Analysis: Detailed breakdown by product type (Passive vs Active), application (Card, Shelf Label, Consumer Electronics, Mobile Devices), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific currently dominates with 48% market share in 2024.

Competitive Landscape: Profiles of leading players including NXP, STMicroelectronics, Texas Instruments, Infineon, and Broadcom, covering their product portfolios and strategic initiatives.

Technology Trends & Innovation: Assessment of emerging NFC technologies, integration with IoT devices, security enhancements, and evolving industry standards like NFC Forum specifications.

Market Drivers & Restraints: Evaluation of factors including contactless payment adoption, smart packaging demand, supply chain constraints, and chip shortages.

Stakeholder Analysis: Strategic insights for semiconductor manufacturers, OEMs, system integrators, and investors regarding market opportunities.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/global-video-sync-separator-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes_17.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-investments.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/coaxial-panels-market-challenges.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/oled-and-led-automotive-light-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gas-cell-market-demand-for-ai-chips-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-demodulator-ic-market-packaging.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/nano-micro-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/single-mode-laser-diode-market-growth.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/silicon-rings-and-silicon-electrodes.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/battery-management-system-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/scanning-slit-beam-profiler-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/atomic-oscillator-market-electronics.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/plastic-encapsulated-thermistor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ceramic-bonding-tool-market-policy.html

0 notes

Text

What is a PARTICLE COUNTER Understanding Its Working, Types, and Applications

Industries such as pharmaceuticals, cleanrooms, HVAC systems, healthcare, and environmental monitoring heavily rely on airborne particle counters and liquid particle counters to ensure quality control and regulatory compliance. This blog will explore how a particle counter works, the different types of particle counters, and their key applications in different industries.

What is a Particle Counter?

A particle counter is a device used to measure the size and number of particles in air, liquid, or surfaces. These instruments help monitor indoor air quality (IAQ), detect contaminants in pharmaceutical manufacturing, and ensure compliance with ISO standards for cleanroom classifications

Particle counters are crucial in industries where even microscopic contamination can cause product defects, health hazards, or regulatory issues.

Applications of Particle Counters

1. Cleanroom Monitoring

Pharmaceutical and semiconductor industries rely on ISO-certified particle counters to maintain contamination-free environments.

2. Indoor Air Quality (IAQ) Monitoring

HVAC systems, hospitals, and offices use particle counters to detect pollutants like dust, pollen, bacteria, and mold spores.

3. Environmental Monitoring

Air quality monitoring systems help detect pollution sources in industrial zones, urban areas, and construction sites.

4. Pharmaceutical & Food Safety

Liquid particle counters ensure that injections, vaccines, and beverage production meet stringent purity standards.

5. Aerospace & Semiconductor Manufacturing

Highly sensitive particle counters help maintain ultra-clean environments essential for chip fabrication and satellite manufacturing.

Choosing the Right Particle Counter

When selecting a particle counter, consider factors like:

Size range detection – Ensure it meets your required particle size measurement.

Flow rate and sensitivity – Important for real-time air quality monitoring.

Compliance with ISO and GMP standards – Necessary for regulated industries.

Data logging and connectivity – Integration with IoT and remote monitoring capabilities

#AirParticleCounter#CleanroomMonitoring#AirQuality#HVACTesting#LaserParticleCounter#ISO14644#IndoorAirQuality#EnvironmentalMonitoring#ParticulateMatter#DustMonitoring#AirPurity#MedicalCleanroom#AirSamplingTech#PharmaCompliance#ContaminationControl

0 notes

Text

Torque Sensors: Precision Force Monitoring Powered by Star EMBSYS Technology

Torque sensors are essential tools in the measurement and control of rotational force in mechanical systems. From automotive testing and industrial automation to aerospace and robotics, torque sensors enable engineers to monitor performance, ensure safety, and improve efficiency. Star EMBSYS, a leader in embedded system innovation, offers advanced torque sensor solutions that combine mechanical precision with intelligent electronics for high-performance applications.

A torque sensor, also known as a torque transducer, measures the torque—or rotational force—applied to a shaft or axis. It can be used in both static (non-rotating) and dynamic (rotating) applications, making it highly versatile. Depending on the requirement, torque sensors can be based on strain gauge, magnetoelastic, or optical technologies. The electrical signal generated is proportional to the torque applied, which is then processed for display, control, or data logging.

Star EMBSYS leverages its deep expertise in embedded systems to develop smart torque sensor solutions that provide real-time, high-resolution measurements. Their sensors are integrated with embedded microcontrollers for advanced signal conditioning, filtering, and digital communication. This results in more stable, noise-free data and allows for seamless integration into modern control systems.

What sets Star EMBSYS apart is their ability to offer custom torque sensor systems tailored to specific industrial needs. Whether for a precision laboratory setup or a rugged field environment, Star EMBSYS provides sensors that include temperature compensation, overload protection, and customizable output ranges. The embedded software also supports features like zero-torque calibration, peak-hold modes, and fault diagnostics.

For industries working with rotating machinery—such as electric motors, pumps, or wind turbines—Star EMBSYS torque sensors offer both static and rotary variants. These sensors can output analog signals (0–5V, 4–20mA) or digital data via UART, CAN, or SPI, providing flexibility for integration with PLCs, DAQs, or cloud-connected IoT platforms.

Moreover, Star EMBSYS includes support for wireless telemetry in demanding applications, allowing real-time torque data transmission without slip rings or complex wiring—ideal for mobile machinery or test benches.

In summary, torque sensors play a vital role in the monitoring and control of mechanical systems. With its focus on smart design, embedded innovation, and application-specific customization, Star EMBSYS delivers high-performance torque sensor solutions that empower engineers and manufacturers to measure with confidence, accuracy, and efficiency.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

Biomedical Refrigerator Market Insights: Technological Advancements and Regional Trends Reshaping Global Demand

1. Technological Advancements Driving Market Evolution 🚀

1.1 Smart Refrigeration: IoT & Remote Monitoring

Modern Biomedical Refrigerator Market increasingly feature IoT-based sensors, real‑time alerts, digital consoles, cloud connectivity, and remote management tools. These innovations ensure continuous temperature tracking, timely alerts for deviations, and automated data logging—vital for complying with GMP/GSP and reducing sample spoilage .

1.2 Focus on Energy Efficiency and Sustainability

There’s a clear shift toward greener labs: manufacturers are incorporating eco‑friendly refrigerants, advanced insulation, dual‑compressor systems, and frequency‑converting compressors that reduce power consumption and carbon footprint . Projects like Haier’s TwinCool ULT freezers and Helmer’s ENERGY STAR®‑certified units highlight industry momentum .

1.3 Precision Cooling for Advanced Therapies

Next‑generation therapies—cell and gene treatments—demand ultra‑low (–80 °C to –196 °C) and cryogenic storage. Market adoption of shock freezers, specialized plasma freezers, and ULT units is driven by increased global approvals (e.g., 36 US gene therapies by March 2024) and rising deal volumes (~ USD 3.5 billion in 2023 investments) .

2. Segmentation & Application-Specific Insights

2.1 Product Types

Ultra‑Low Temperature (ULT) Freezers dominate with ~35 % share, essential for cryogenics and molecular biology .

Plasma Freezers are the fastest‑growing segment (~29 %) due to expanded plasma-based therapies and diagnostics .

Laboratory/Pharmacy/Medical Refrigerators lead in unit numbers (~40 %), primarily used by hospitals, pharmacies, and clinics .

2.2 End‑User Demand

Hospitals hold ~45 % volume share, relying on cold storage for medicine, blood, vaccines, and reagents .

Pharmacies account for ~28‑29 %, particularly for specialty drugs and immunotherapies .

Diagnostic Labs & Research Facilities are the fastest‑growing, driven by AI labs, genomics, diagnostics — demand is increasing for precision refrigeration and data logging .

3. Regional Trends & Market Shifts

3.1 North America: Established Market Leader

Constituting ~40 – 45 % of global revenue, North America—especially the U.S.—leads due to advanced healthcare infrastructure, high R&D investment, and strict regulatory oversight (FDA, CDC) . Key factors: high incidence of chronic disease, growing number of blood transfusions (~16 M components/year), and surge in cell/gene clinical trials .

3.2 Europe: Steady Growth with High Compliance

Europe accounts for ~30 % of the market and shows steady growth with Germany leading at ~7 % CAGR. The region’s emphasis on regulation (CE marking, EU directives) and biotech hubs (UK, France, Germany) supports demand .

3.3 Asia‑Pacific: Rapid Expansion

APAC is growing fastest (7–7.8 %+ CAGR) driven by:

Infrastructure growth in China, India, Japan

Government vaccine programs (India provides 65–70 % of WHO needs)

Increasing blood banking and diagnostic services .

Countries like India, China, and Australia rank among fastest growing individual markets .

3.4 Latin America & MEA: Emerging but Promising

Together accounting for ~10 % of market share, these regions show growing demand due to rising healthcare investments, immunization drives, blood banks, and telemedicine expansion .

4. Market Size & Forecast

Current Market Size: Estimates vary from USD 2.64 billion (2023 FMI) to USD 4.33 billion–USD 4.4 billion across other reports .

Growth Forecast: Expected CAGR from 5.4 % to 7.0 % through 2030–2034, reaching USD 6–7.2 billion .

Type‑Segment Outlook:

Blood bank and plasma freezers: 8.1 % CAGR, projected USD 2.6 billion by 2030 .

Laboratory fridges/freezers: ~6–6.3 % CAGR .

5. Competitive Landscape & Strategic Moves

5.1 Prominent Manufacturers

Top global players include Thermo Fisher Scientific, Haier Biomedical, Panasonic Healthcare, Eppendorf, Helmer Scientific, B Medical Systems, Arctiko, Follett, and PHC Holdings .

5.2 Strategic Initiatives

Energy‑Star Certification for Helmer’s ULT freezers (Feb 2024) .

Eco models: Haier’s TwinCool ULT (Oct 2023) and Thermo Fisher’s locally‑made TSV series in India for cost‑sensitive labs .

M&A & Expansions: Haier acquired Labtech UK (2016); B Medical opened India plant in Gujarat (2022) .

New Product Lines: Arctiko’s Flexaline series (Aug 2023); Haier’s HYC‑461GD/FD pharmacy fridge (Sep 2024) .

6. Challenges & Market Barriers

High Capital Costs: Advanced ULT & IoT units range from USD 2,000–15,000+, deterring smaller facilities .

Operating & Compliance Costs: Energy usage and maintenance calibrations add ongoing expenses. IoT adds security and regulatory complexity.

Regulatory Requirements: Manufacturers must meet diverse standards (FDA, CE, ENERGY STAR, GxP), increasing time-to-market and costs .

7. Future Outlook: Trends to Watch

Precision Medicine Growth: Personalized therapies will drive demand for advanced cryogenic & ULT storage systems.

IoT & AI Integration: Edge-AI for predictive maintenance, blockchain for data integrity, and cloud analytics are emerging priorities.

Sustainable Innovation: Alternative refrigerants (e.g., HFOs), magnetic and caloric cooling R&D may redefine future refrigeration tech .

Market Expansion: APAC, LATAM, and MEA offer high growth potential as healthcare infrastructure spreads.

Distributed Storage: Telemedicine, home healthcare, and point-of-care diagnostics will need compact, smart cold units.

✅ Conclusion

Technological advancements—IoT, smart dashboards, energy-efficient cooling—are synergizing with regional healthcare expansion, especially in North America and APAC, to elevate biomedical refrigerators from functional equipment to critical infrastructure. With market value poised to reach USD 6–7 billion by 2030 and ~6–7 % CAGR, success lies in blending innovation with affordability, sustainability, and compliance.

0 notes

Text

Information Cloud Data Integration: Unifying Data for Smarter Business Decisions

Why Information Cloud Data Integration Matters

Today’s businesses run on data—but that data is often scattered across systems, platforms, and cloud environments. Without integration, information remains siloed, reducing the value organizations can extract from their digital assets.

Information Cloud Data Integration bridges this gap by enabling seamless data flow across cloud-based applications, databases, and on-premise environments. With the right integration strategy, enterprises can unlock real-time insights, improve collaboration, and accelerate data-driven decision-making.

What is Information Cloud Data Integration?

Information Cloud Data Integration refers to the process of combining data from various cloud-based and hybrid sources into a centralized, cohesive system for analysis, reporting, or operational use. This includes integration tools and platforms that allow:

Real-time data synchronization

Batch and ETL (Extract, Transform, Load) processing

API-driven connections

AI-powered data mapping

It is especially critical in multi-cloud and hybrid infrastructures where consistent, reliable data access is key to operational success.

Core Components of a Cloud Data Integration Strategy

Unlike traditional integration methods, cloud data integration must account for agility, scalability, and security. Key components include:

1. Data Connectors and APIs

Allowing integration between SaaS apps (e.g., Salesforce, SAP, ServiceNow) and cloud storage (e.g., AWS S3, Google Cloud Storage).

2. Data Transformation and Cleansing Tools

Ensuring consistency and accuracy across formats and sources.

3. Secure Transfer Protocols

Encrypting data in transit and at rest, ensuring compliance with regulations like GDPR or HIPAA.

4. Automation and Orchestration Engines

Automating workflows, scheduling updates, and triggering data-based actions.

Real-World Use Cases

Supply Chain Visibility

Manufacturers integrate supplier, logistics, and inventory data into a central analytics dashboard for improved forecasting and reduced delays.

Marketing & Sales Alignment

B2B enterprises synchronize CRM, email automation, and customer data platforms to create unified customer profiles and enhance targeting.

Healthcare Data Exchange

Hospitals use cloud integration to combine EMRs, lab systems, and patient engagement platforms for a 360° view of patient history.

Financial Reporting

Banks merge data from loan management, customer transactions, and compliance systems for real-time financial analysis and risk management.

Benefits of Information Cloud Data Integration

✔ Centralized and accurate business intelligence ✔ Real-time data access across departments ✔ Reduced manual data handling and errors ✔ Better customer and employee experiences ✔ Scalable architecture for future growth

Common Challenges and Solutions

Challenge

How to Overcome

Data silos in legacy systems

Use hybrid integration platforms that support both cloud and on-premise

Inconsistent data formats

Apply automated data cleansing and transformation rules

Security and compliance risks

Implement access control, encryption, and audit logs

Trends Shaping Cloud Data Integration in 2025

AI-Driven Integration: Automating data mapping and anomaly detection.

iPaaS Growth: Integration Platform as a Service is becoming the standard for enterprise-grade integration.

Self-Service Tools: Empowering business users to build data flows without IT dependency.

Edge-to-Cloud Data Pipelines: Enabling insights from IoT and remote devices in real time.

How Enterprises Can Maximize Cloud Data Integration

Unifying cloud ecosystems requires a well-planned data integration strategy—one that balances performance, security, and scalability. Success begins with selecting the right tools, building flexible architectures, and ensuring seamless data flow between systems like Salesforce, Azure, SAP, and various APIs.

A strategic approach to integration empowers organizations to automate operations, eliminate data silos, and gain real-time insights that drive innovation and faster decision-making.

Conclusion

Information Cloud Data Integration is vital for organizations aiming to stay competitive in a data-driven world. As your integration needs grow, aligning with the right expertise ensures long-term success. At Prophecy Technologies, we specialize in delivering customized cloud integration solutions that are secure, scalable, and aligned with your business goals—empowering you to turn information into action.

#CloudDataIntegration#DataUnification#RealTimeInsights#DataDrivenDecisions#DigitalTransformation#ProphecyTechs

0 notes

Text

Time Temperature Indicator Labels Market Future Trends Driven by Food Safety and Cold Chain Expansion

The time temperature indicator (TTI) labels market is witnessing transformative growth, fueled by heightened awareness around food safety, pharmaceutical integrity, and cold chain reliability. These smart labeling solutions, designed to monitor and visually communicate exposure to temperature over time, are gaining traction as critical components in ensuring product quality and safety from production to consumption.

With the global movement toward more traceable and accountable supply chains, TTIs are evolving from basic indicators to sophisticated tools integrated with digital platforms. As a result, the market is on the cusp of numerous exciting trends that will redefine its scope, utility, and technological sophistication over the coming years.

Rising Adoption Across Cold Chain Applications

Cold chain logistics—especially for food, beverages, and pharmaceuticals—has emerged as a major driver of TTI label demand. Ensuring that temperature-sensitive products maintain optimal storage conditions from production facilities to end consumers is vital for health, compliance, and brand reputation. TTIs are increasingly being employed across frozen foods, dairy, seafood, vaccines, biologics, and other perishable items to maintain quality assurance throughout the chain.

The future will likely see an increased preference for TTIs with broader temperature sensitivity ranges, multi-threshold indicators, and clear, irreversible visual cues. Businesses are also showing interest in bulk implementation to cover secondary and tertiary packaging layers.

Integration With Smart Packaging Technologies

One of the most prominent future trends is the integration of TTIs with broader smart packaging solutions. As the Internet of Things (IoT) continues to penetrate logistics and retail, TTIs are being embedded with digital sensors and QR codes for real-time data capture and sharing.

Smart TTIs that can communicate directly with mobile apps or centralized monitoring systems are beginning to replace passive indicators. These labels not only show visual color changes but also log data that can be analyzed for inventory management, quality control, and predictive analytics. This integration offers transparency, faster decision-making, and greater control over supply chain variables.

Demand From E-Commerce and Direct-to-Consumer Models

With the rise of online food delivery and direct-to-consumer pharmaceutical services, TTIs are becoming more essential in smaller packaging formats. Consumers are now more aware of freshness indicators and often demand proof of proper handling during transit.

TTI labels are expected to play a bigger role in boosting consumer trust in online food platforms, meal kits, and prescription deliveries. Companies that include these indicators on packaging enhance perceived value and demonstrate their commitment to safety and transparency, creating competitive differentiation in the market.

Innovation in Label Materials and Printing Techniques

As sustainability becomes a growing concern, future TTI development will also focus on eco-friendly materials, non-toxic indicator inks, and recyclable adhesives. Biodegradable substrates and compostable labels are in demand, especially among companies pursuing green certification and reducing packaging waste.

Innovative printing technologies like inkjet and roll-to-roll digital printing are being explored to reduce costs and enhance the scalability of TTI labels. This evolution in production methods also enables greater customization, allowing companies to design TTI labels suited for specific use-cases and branding needs.

Expansion Into Emerging Markets

As cold chain infrastructure improves in emerging economies such as India, Brazil, and Southeast Asia, the demand for TTIs is expected to surge. Governments and regulatory agencies are tightening food and pharma handling laws, encouraging local businesses to adopt TTIs for compliance and export-readiness.

The future will likely see wider adoption across local meat markets, dairy cooperatives, vaccine storage facilities, and agricultural exporters in these regions. Local manufacturing of TTIs in these markets will also help reduce costs and increase penetration.

Regulatory Influence and Compliance Standards

Global food and drug regulatory bodies such as the FDA, EFSA, and WHO are increasingly encouraging or mandating the use of time temperature monitoring tools. TTIs are being viewed as crucial evidence in compliance audits, recalls, and quality assurance practices.

In the coming years, expect TTIs to become standard in packaging across high-risk products. As new legislation emerges focusing on traceability and consumer protection, more companies will proactively integrate TTIs into their packaging processes to stay ahead of regulatory requirements.

Personalized and Customizable Indicator Solutions

As industries diversify, the need for customizable TTI labels will increase. Companies are requesting indicators tuned to specific time-temperature thresholds that reflect the perishability and stability of individual products. For example, the temperature tolerance of a fresh salad kit differs significantly from a vial of insulin.

Label providers that offer personalization options, on-demand printing, and integration with digital platforms will gain a significant edge in the evolving market. This shift towards tailored solutions will define the next wave of innovation in the TTI space.

Enhanced Focus on Consumer Awareness

Consumer education about freshness and safety indicators is expected to grow, further influencing demand for TTIs in retail packaging. Packaging that visibly shows freshness status builds brand trust and enhances product appeal. As shoppers become more informed, TTI-labeled products will increasingly become a deciding factor at the point of sale.

Brands that actively promote their use of TTIs in marketing campaigns are likely to strengthen their value proposition, especially in health-conscious and premium product segments.

Conclusion

The future of the time temperature indicator labels market lies in its adaptability, integration with digital ecosystems, and alignment with global safety standards. As cold chains grow more complex and consumers demand greater transparency, TTIs will evolve into intelligent tools offering insights beyond simple temperature tracking. Players in this space who innovate in technology, sustainability, and user experience are poised to lead the next phase of growth in this essential and rapidly expanding market.

#TimeTemperatureIndicatorsMarket#SmartPackaging#ColdChainLogistics#FoodSafetySolutions#PharmaPackaging

0 notes

Text

52013l4 in Modern Tech: Use Cases and Applications