#industry 4.0 software development

Explore tagged Tumblr posts

Text

🗜 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 4.0 has become increasingly recognized, and 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐈𝐨𝐓 (𝐈𝐈𝐨𝐓) 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 are driving the #digitaltransformation in the manufacturer's industries. At the same time, the appearance of developed connectivity technology, such as #5G, allows manufacturers to take the edge of technologies such as industrialization, #artificialintelligence, augmented reality, and the Internet of Things (IoT) to build elegant manufacturers.

⚙ Manufacturing, energy, utilities, and various core industry sectors have initiated to embrace the 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐈𝐧𝐭𝐞𝐫𝐧𝐞𝐭 𝐨𝐟 𝐓𝐡𝐢𝐧𝐠𝐬 (𝐈𝐈𝐨𝐓) vision. Being an #industrialiot 4.0 Solution provider, #kpis allows us to decrease the complexity of developing #iotapplications with its 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐈𝐨𝐓 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧 abilities. Our #IIoT sensor networks deliver real-time data and analytics and offer benefits such as: ↪ Automatic machine maintenance and operations ↪ More efficient inventory planning and optimisation ↪ Decreased carbon footprint via operational efficiencies ↪ Risk ease, quicker identification of implementation issues ↪ Enhanced traceability, visibility, and utilisation of field-deployed support and tools ↪ Improve employee security, reducing unsafe conditions resulting in damage or death

🗜 The #Industry40 revolution would not exist if there weren't any connectivity with automation. Leverage our expertise in developing 𝐈𝐈𝐨𝐓 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 to add intelligent capabilities to the manufacturing procedure and connectivity to analogue equipment.

📍 We build 𝐂𝐮𝐬𝐭𝐨𝐦 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐈𝐨𝐓 𝐒𝐨𝐟𝐭𝐰𝐚𝐫𝐞 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 to fulfil your business needs. If you are ready to prepare for the next generation and don't want to be left behind by the industry around you, then #krishnapadamitsolution is willing to help you.

🔊𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬🔊 ➖➖➖➖➖➖➖➖ 🌐 𝐕𝐢𝐬𝐢𝐭: https://www.kpis.in/iot-development 📧 𝐄𝐦𝐚𝐢𝐥: [email protected] 📞 𝐂𝐨𝐧𝐭𝐚𝐜𝐭: +91-6350359218 ➖➖➖➖➖➖➖➖

#internet of things#iot#iiot#industrial iot#industrial internet of things#industry 4.0#aitechology#ai#artificialintelligenceapplication#artificial intelligence#machine learning#bigdata#computer vision#business development#mobile app developer company#mobile application development#app development company#inventory software#software development company#web development company

0 notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Why the Low Voltage Switchgear Market is Booming in 2025?

The low voltage switchgear market is growing rapidly in 2025 due to growth in electricity consumption, development of intelligent devices, and a strong emphasis on sustainability. Energy efficiency, digital transformation, and security are critical for industries and businesses, which leads to a high demand for new, robust, and intelligent switchgear. This article will discuss key drivers of market growth, emerging trends, and their impact on businesses and industries globally.

1. The Growing Demand for Electricity

Over the past few decades, the increasing demand for efficiency in power distribution systems has become ever imminent with the rise of general energy consumption. Rapid urban expansion, industrial development, and the emergence of data centers have been some of the major driving forces boosting the demand for low-voltage switchgear.

Global Electricity Demand on the Rise:

· The IEA projects electricity demand in developing nations will rise at a rate of 4% each year, as consumption steadily climbs.

· Data facilities and cloud computing require relentless power sources, amplifying the need for resilient switching equipment solutions capable of sustaining operations.

· The proliferation of electric vehicle charging points is compelling utilities to renovate distribution networks, ensuring functionality can accommodate increased demand.

Modernization spreads as industries broaden their scope, making electrically-reliable infrastructure an imperative; low voltage switchgear has become integral to conveying energy throughout the grid in a secure and effective manner.

2. Smart & Digital Switchgear: The Industry’s Future

Traditional switchgear technology has evolved rapidly with the integration of intelligent networking capabilities, making electrical distribution safer, more efficient, and easier to monitor remotely. The new digital switchgear incorporates IoT, AI, and cloud-based monitoring solutions to provide real-time insight into energy usage. This allows businesses to proactively optimize performance and reduce costs through more proactive maintenance strategies.

Major Developments in Intelligent Switchgear by 2025:

✅Online Sensor Networks: Constant telemetry from devices throughout the system helps pinpoint potential weaknesses before failures occur.

✅Self-learning Circuitry: AI-powered hardware and software automatically analyze usage patterns to forecast repairs, minimize outages, and heighten uptime.

✅Wireless Remote Management: Mobile apps and web dashboards give administrators off-site control over power flows to streamline usage according to need.

✅Modular Construction: Interchangeable, compact components facilitate scaling and retrofitting within varied infrastructure environments.

The shift toward automated smart grids and Industry 4.0 production is substantially contributing to the booming market for intelligent switchgear solutions. Widespread installation of these next-generation systems will transform electrical distribution networks.

3. Rising Emphasis on Energy Efficiency & Sustainability

Governments and industries worldwide have increasingly pushed for greener, more energy-efficient power solutions in recent years. This has led electrical equipment manufacturers to develop eco-friendly switchgear technologies that considerably minimize energy loss during transmission and help reduce overall carbon footprints.

Sustainable Advancements in Low Voltage Switchgear Design:

Alternative gases to SF6: Traditional switchgear commonly uses SF6 due to its insulating and arc-quenching capabilities, however this gas has an extremely high global warming potential. Many switchgear producers have since designed SF6-free solutions that substitute the highly potent SF6 with other gases that are safer for the environment.

Energy-Efficient Designs: Optimizing circuitry and components has allowed switchgear to conduct electricity with negligible power loss, enabling connected systems to leverage nearly every watt of power. Careful engineering further trims excess material use and redundant parts.

Renewable Energy Integration: Low voltage switchgear has become increasingly vital in smoothly and reliably integrating power from solar arrays and wind farms into existing electrical networks. Without robust switchgear management, it would be difficult for clean energy sources to efficiently feed power onto transmission lines.

With the implementation of more stringent energy performance mandates in countries worldwide, businesses have sound business reasons for upgrading outdated switchgear infrastructure with advanced low loss solutions both to adhere to regulations and lower long-term energy expenditures.

4. Increasing Investments in Infrastructure & Industrialization

Governments and private investors alike are pouring billions into ambitious infrastructure projects around the world, generating skyrocketing demand for reliable low voltage switchgear solutions. From towering commercial skyscrapers to sprawling industrial complexes, and expanding metro networks to bustling international airports — countless utilities depend on robust yet cost-effective switching systems to ensure continuity of operations.

🔹 Key Infrastructure Drivers Stimulating Growth:

🏗️ Smart Cities Uplift Life: Sweeping investments in digital urbanization are revolutionizing everyday living through connected infrastructure that elevates efficiency.

🏭 Manufacturing Marvels: Production powerhouses across the globe are scaling new heights, intensifying the necessity for advanced low voltage distribution controls to support increased capacity.

🚆 Transportation Transformations: Rapid progress in rail electrification and proliferation of electric vehicles for land and air are necessitating increasingly resilient switchgear designs.

As global development marches forth, low voltage switchgear has become mission critical in enabling commercial and industrial progress through reliable power distribution. The worldwide infrastructure renaissance is cementing its importance for years to come.

5. Safety & Regulatory Compliance Are Driving Upgrades

Governments and regulatory bodies are increasingly implementing strict compliance standards to safeguard electrical infrastructure and minimize hazards, compelling upgrades across many industries. Potential calamities resulting from power faults or failures necessitate vigilance in maintaining reliable and resilient systems.

New Safety Regulations in 2025:

⚡ Updated IEC & NEC Standards: Stringent low voltage switchgear specifications mandated to bolster protection.

⚡ Arc Fault Protection Technology: Novel solutions critical to curb risks of electrical ignitions and incidents.

⚡ Mandatory Energy Audits: Organizations now required to optimize distribution for both personnel and operational efficiency through audits.

With approaching deadlines to satisfy evolving regulations, operators are proactively replacing outdated switchgear to conform with mounting compliance demands, contributing to an accelerating industry transformation.

6. The Rise of Data Centers & Digital Transformation

The digital sphere fundamentally relies upon data hubs that necessitate constant power and exceedingly reliable electric frameworks. As distributed computing, man-made brainpower, and IoT reception develop exponentially, ventures are putting vigorously in cutting edge low voltage switches to ensure their foundation from energy blackouts which could bring about gigantic budgetary misfortunes.

24/7 control is essential for operations yet breakdowns prompt critical money related setbacks. To guarantee uptime, focal points utilize auxiliary switches for extra dependability and security alongside far off checking abilities through IoT innovations which empower ongoing following and administration from anywhere. With worldwide distributed computing selection quickening at a quickening pace, interest for top notch low voltage switches arriving at new statures to guarantee frameworks stay online consistently.

7. Competitive Market & Technological Advancements

The low voltage switchgear sector has seen remarkable changes and fierce competition between prestigious brands. Manufacturers are pouring resources into innovation to craft smarter, smaller, and affordable switchboard alternatives.

🔹 Notable Advancements by 2025:

⚙️ Solid-state systems promise enhanced performance and lessened upkeep. Long and compound sentences mix with short ones.

⚙️ Remote accessibility through wireless means permits control and tracking from afar.

⚙️ Self-mending grids using AI to immediately spot and amend problems, maintaining dependable power seamlessly. Complex automation alleviates faults autonomously for maximum uptime.

Conclusion: The Future of Low Voltage Switchgear Looks Bright

Low Voltage Switchgear is forecasted to experience market growth in the year 2025 due to the growing electricity consumption in countries, the rising applications of smart technologies, the increased implementation of sustainability practices, the expansive growth in various industries, and safety regulations. As these industries are gradually moving to energy-efficient, AI-powered, and environmentally friendly switchgears, this demand is expected to increase further.

5 notes

·

View notes

Text

Rajasthan’s Innovation-Driven Growth to a Digitally Empowered Workforce: Col Rajyavardhan Rathore

The Vision for a Digitally Empowered Rajasthan

The goal is clear: make Rajasthan a leader in digital innovation and skill development, ensuring that its workforce is ready for a future dominated by technology. This vision includes:

Modern Infrastructure: Establishing IT hubs, smart cities, and innovation centers.

Skilled Workforce: Upskilling youth with digital tools and technologies.

Startup Ecosystem: Creating an environment conducive to entrepreneurship.

Key Pillars of Rajasthan’s Innovation-Driven Growth

1. Smart Cities and Digital Infrastructure

Rajasthan is focusing on creating smart cities with advanced digital infrastructure, including:

Public Wi-Fi Networks: Ensuring seamless internet access for all.

E-Governance: Digitizing public services for transparency and efficiency.

2. Education and Skill Development

Digital Literacy Programs: Training citizens, especially in rural areas, to use technology effectively.

IT Training Institutes: Partnering with tech companies to offer specialized courses in AI, machine learning, and blockchain.

3. Promoting Startups and Innovation

Rajasthan is becoming a hotspot for startups with initiatives like:

Rajasthan Startup Policy: Providing funding, mentorship, and incubation for startups.

Innovation Hubs: Centers to foster collaboration and creativity among young entrepreneurs.

4. Industry 4.0 Adoption

Industries in Rajasthan are adopting cutting-edge technologies to boost productivity, including:

Automation in Manufacturing: Robotics and IoT to streamline processes.

Agri-Tech Solutions: Drones and AI for smarter farming practices.

Government Initiatives Driving Digital Transformation

1. Rajasthan IT/ITES Policy

Offering tax incentives and subsidies to IT companies.

Promoting investments in software development, BPOs, and data analytics.

2. Digital Rajasthan Mission

Connecting every village with high-speed internet.

Training women and marginalized communities to ensure inclusivity.

3. Rajasthan DigiSkill Program

Focused on creating a digitally literate workforce by 2025.

Courses include coding, app development, and digital marketing.

Impact on Rajasthan’s Workforce

Upskilling for the Future

Rajasthan is preparing its youth for the jobs of tomorrow by:

Integrating coding and STEM education into school curriculums.

Offering scholarships and incentives for IT-related higher education.

Job Creation in Emerging Sectors

IT and software development are generating thousands of jobs.

Growth in startups and innovation hubs is fostering entrepreneurship.

Inclusivity in Digital Growth

Focus on training women and rural communities to bridge the digital divide.

Col Rajyavardhan Rathore’s Role in Digital Transformation

Col Rathore has been a vocal advocate for leveraging technology to empower the people of Rajasthan. His contributions include:

Policy Advocacy: Pushing for policies that prioritize innovation and digital literacy.

Youth Engagement: Encouraging young minds to explore careers in IT and entrepreneurship.

Community Outreach: Promoting the benefits of digital transformation in rural areas.

Success Stories of Digital Rajasthan

1. Bhamashah Yojana

One of the first initiatives to leverage digital platforms for direct benefit transfers, empowering women and ensuring financial inclusivity.

2. Rajasthan Sampark

A citizen grievance redressal system that ensures transparency and accountability through digital means.

3. RajNET

A unified network connecting the state’s administrative and public service systems with high-speed internet.

Challenges and Solutions

Challenges

Digital Divide: Ensuring access to technology in remote areas.

Skilled Workforce Shortage: Meeting the demand for advanced IT skills.

Infrastructure Gaps: Lack of high-speed internet in some regions.

Solutions

Targeted Programs: Focused digital literacy drives in rural areas.

Public-Private Partnerships: Collaborations with tech giants to set up training centers.

Expanding Connectivity: Investments in fiber optics and satellite internet.

The Road Ahead: A Digital Rajasthan

Rajasthan is on the cusp of a digital revolution. With continued focus on innovation, skill development, and inclusive growth, the state is poised to become a beacon of digital excellence in India. Visionaries like Col Rajyavardhan Rathore are ensuring that this transformation benefits every citizen, bridging gaps and unlocking new opportunities.

As Rajasthan strides forward, it not only redefines its identity but also sets an example for other states to emulate.

2 notes

·

View notes

Text

OneAPI Construction Kit For Intel RISC V Processor Interface

With the oneAPI Construction Kit, you may integrate the oneAPI Ecosystem into your Intel RISC V Processor.

Intel RISC-V

Recently, Codeplay, an Intel business, revealed that their oneAPI Construction Kit supports RISC-V. Rapidly expanding, Intel RISC V is an open standard instruction set architecture (ISA) available under royalty-free open-source licenses for processors of all kinds.

Through direct programming in C++ with SYCL, along with a set of libraries aimed at common functions like math, threading, and neural networks, and a hardware abstraction layer that allows programming in one language to target different devices, the oneAPI programming model enables a single codebase to be deployed across multiple computing architectures including CPUs, GPUs, FPGAs, and other accelerators.

In order to promote open source cooperation and the creation of a cohesive, cross-architecture programming paradigm free from proprietary software lock-in, the oneAPI standard is now overseen by the UXL Foundation.

A framework that may be used to expand the oneAPI ecosystem to bespoke AI and HPC architectures is Codeplay’s oneAPI Construction Kit. For both native on-host and cross-compilation, the most recent 4.0 version brings RISC-V native host for the first time.

Because of this capability, programs may be executed on a CPU and benefit from the acceleration that SYCL offers via data parallelism. With the oneAPI Construction Kit, Intel RISC V processor designers can now effortlessly connect SYCL and the oneAPI ecosystem with their hardware, marking a key step toward realizing the goal of a completely open hardware and software stack. It is completely free to use and open-source.

OneAPI Construction Kit

Your processor has access to an open environment with the oneAPI Construction Kit. It is a framework that opens up SYCL and other open standards to hardware platforms, and it can be used to expand the oneAPI ecosystem to include unique AI and HPC architectures.

Give Developers Access to a Dynamic, Open-Ecosystem

With the oneAPI Construction Kit, new and customized accelerators may benefit from the oneAPI ecosystem and an abundance of SYCL libraries. Contributors from many sectors of the industry support and maintain this open environment, so you may build with the knowledge that features and libraries will be preserved. Additionally, it frees up developers’ time to innovate more quickly by reducing the amount of time spent rewriting code and managing disparate codebases.

The oneAPI Construction Kit is useful for anybody who designs hardware. To get you started, the Kit includes a reference implementation for Intel RISC V vector processors, although it is not confined to RISC-V and may be modified for a variety of processors.

Codeplay Enhances the oneAPI Construction Kit with RISC-V Support

The rapidly expanding open standard instruction set architecture (ISA) known as RISC-V is compatible with all sorts of processors, including accelerators and CPUs. Axelera, Codasip, and others make Intel RISC V processors for a variety of applications. RISC-V-powered microprocessors are also being developed by the EU as part of the European Processor Initiative.

At Codeplay, has been long been pioneers in open ecosystems, and as a part of RISC-V International, its’ve worked on the project for a number of years, leading working groups that have helped to shape the standard. Nous realize that building a genuinely open environment starts with open, standards-based hardware. But in order to do that, must also need open hardware, open software, and open source from top to bottom.

This is where oneAPI and SYCL come in, offering an ecosystem of open-source, standards-based software libraries for applications of various kinds, such oneMKL or oneDNN, combined with a well-developed programming architecture. Both SYCL and oneAPI are heterogeneous, which means that you may create code once and use it on any GPU AMD, Intel, NVIDIA, or, as of late, RISC-V without being restricted by the manufacturer.

Intel initially implemented RISC-V native host for both native on-host and cross-compilation with the most recent 4.0 version of the oneAPI Construction Kit. Because of this capability, programs may be executed on a CPU and benefit from the acceleration that SYCL offers via data parallelism. With the oneAPI Construction Kit, Intel RISC V processor designers can now effortlessly connect SYCL and the oneAPI ecosystem with their hardware, marking a major step toward realizing the vision of a completely open hardware and software stack.

Read more on govindhtech.com

#OneAPIConstructionKit#IntelRISCV#SYCL#FPGA#IntelRISCVProcessorInterface#oneAPI#RISCV#oneDNN#oneMKL#RISCVSupport#OpenEcosystem#technology#technews#news#govindhtech

2 notes

·

View notes

Text

SMK Al Fatah adalah lembaga pendidikan kejuruan swasta setara SMA yang berada dibawah pengelolaan Yayasan Ponpes Al Fatah, Banjarnegara. SMK Al Fatah beralamat di jalan Letnan Jenderal S. Parman, Km 3, Parakancanggah, Banjarnegara. SMK Al Fatah menerapkan Kurikulum Pendidikan Nasional dan Kurikulum Pesantren dan memiliki Program Keahlian Teknik Kendaraan Ringan, Rekayasa Perangkat Lunak, dan Perbankan Sekolah Menengah Kejuruan atau yang biasa disebut SMK belakangan mulai menarik perhatian orang tua dan para murid lulusan SMP yang akan melanjutkan sekolah. SMK mulai dipertimbangkan karena prospek lulusannya yang dapat dikatakan lebih baik daripada lulusan SMA. Bagaimana tidak? Dengan dibekali ilmu yang spesifik, lulusan SMK bisa langsung mencari kerja sesuai bidang keahliannya. Jika pun ingin melanjutkan kuliah, kesempatan yang dimiliki lulusan SMK sama dengan lulusan SMA. Banyak sekali pilihan yang dapat dipilih jika bersekolah di SMK. Tidak seperti SMA yang notabene hanya memiliki 2–3 jurusan, keahlian atau jurusan yang bisa dipilih di SMK lebih beragam. Dari sekian banyak jurusan yang ada di SMK, kami telah merangkum 3 jurusan yang menjadi pilihan favorit para calon siswa. Apa saja jurusan keahlian tersebut? Mari simak ulasannya.

Jurusan Perbankan Jurusan yang pertama adalah perbankan. Ya, selain ada di universitas, jurusan ini juga ada di SMK. Oleh karena itu, siswa jurusan ini dapat berkuliah di jurusan yang sama atau jurusan terkait. Dalam jurusan perbankan, siswa akan dibekali dengan mata pelajaran yang berfokus pada hitung-menghitung. Namun jurusan perbankan akan lebih terkonsentrasi pada seluruh kegiatan yang berhubungan dengan bank, seperti perhitungan uang, pembukuan, hingga dokumentasi.Lantas, apa saja prospek kerja jurusan perbankan ini? Lulusan SMK perbankan dapat bekerja di berbagai bidang terkait, seperti menjadi staff accountant, internal auditor, credit analyst, teller (bank), customer service (bank), account officer, funding officer, bahkan menjadi entrepreneur. Prospek yang sangat menjanjikan, bukan?

Jurusan Rekayasa Perangkat Lunak (RPL) Jurusan kedua juga sangat diminati oleh calon siswa. Hal ini karena seiring berkembangnya teknologi, keahlian di bidang ini juga semakin dibutuhkan di masyarakat. Sesuai dengan namanya, jurusan RPL mempelajari hal-hal yang berkaitan dengan perangkat lunak, termasuk pembuatan, pemeliharaan, manajemen organisasi pengembangan perangkat lunak, dan manajemen kualitas. Jurusan ini lekat dengan 3 pelajaran yaitu Coding, Desain dan Algoritma yang akan menjadi kunci keberhasilan terhadap rekayasa perangkat lunak tersebut.Jurusan ini memiliki prospek kerja yang banyak, belum lagi kedepannya, saat teknologi semakin berkembang. Diantara pekerjaan yang cocok dengan lulusan RPL adalah Developer IT, Programmer, IT Consultant, System Analyst, Database/Web Engineer, Data Communication Engineer, Intelligent System Developer, dan Software Tester.

Jurusan Teknik Kendaraan Ringan (TKR) Jurusan yang satu ini biasanya paling diminati oleh siswa laki-laki, meskipun tidak menutup kemungkinan ada juga siswa perempuan. Jurusan ini termasuk ke dalam program studi teknik otomotif. Ada beberapa hal yang ditekankan dalam jurusna ini, yaitu perawatan dan perbaikan kendaraan bermotor roda 4 meliputi engine, pemindah tenaga, chassis, kelistrikan bodi, dan kontrol elektronik otomotif. Di era industry 4.0 ini, lulusan TKR sangat banyak diperlukan. Diantara prospek kerja yang paling menjamin untuk lulusan TKR adalah bekerja di Industri, bekerja sebagai teknisi, sebagai operator alat berat, modifikator kendaraan, bahkan juga bisa menjadi entrepreneur dengan cara membuka bengkel sendiri. Ketiga jurusan favorit tersebut ada di SMK Al-Fatah Banjarnegara. Selain merupakan Sekolah Menengah Kejuruan (SMK), kami juga menjalankan pendidikan yang berbasis pesantren, sehingga siswa dapat kompeten sekaligus berakhlakul karimah. Anda dapat mendaftarkan Putra-Putri Anda sebagai Calon Peserta Didik SMK Al-Fatah Banjarnegara (Tahun Ajaran 2021–2022) dengan menghubungi via WhatsApp ke 081225268289 atau klik link berikut: bit.ly/ppdbskafa2021. Untuk informasi lebih lanjut, kunjungi website kami di https://smkalfatah-bna.sch.id/serta ikuti media sosial kami (Instagram: @officialskafabara, Facebook: Smk Al Fatah Banjarnegara) untuk mendapatkan update terbaru

#smk pusat keunggulan#smk al fatah banjarnegara#smk berbasis pondok pesantren#smk hebat#information#rekayasa perangkat lunak#akuntansi dan keuangan lembaga#teknik kendaraan ringan#sekolah.

2 notes

·

View notes

Text

The Evolution of ERP Software: How it is Transforming Engineering and Manufacturing in 2023

In today’s dynamic world of engineering and manufacturing industry, maintaining competitiveness and operational efficiency is of paramount importance. Enterprise Resource Planning (ERP) software has become a fundamental tool for optimising processes, improving efficiency, and facilitating smooth operations in the engineering and manufacturing industries. As we progress into the year 2023, it becomes apparent that enterprise resource planning (ERP) software has experienced a substantial transformation, adapting to the unique requirements of the industry in question. Unlock the full potential of your manufacturing company with ERP software designed and developed by STERP (Shanti Technology). Contact today for a tailored ERP solution for manufacturing company in India that aligns perfectly with your business objectives.

This blog article aims to examine the growth of Enterprise Resource Planning (ERP) software and its significant impact on the fields of engineering and manufacturing.

Historical Perspective: A Brief Overview of ERP Software

The evolution of ERP software since its establishment in the 1960s has been significant, with a notable shift from its initial emphasis on inventory management and order processing. Over the course of several decades, enterprise resource planning (ERP) systems have seen significant growth and development, resulting in the integration of a wide range of corporate functions. These functions include but are not limited to accounting, human resources, procurement, and other related operations. The advancement of technology has led to the evolution of ERP software into a centralised platform that offers real-time data, enhances decision-making processes, and fosters communication across various departments within an organisation.

· Integration of IoT and Industry 4.0:

The combination of the Internet of Things (IoT) and Industry 4.0 technologies represents a notable revolution in ERP software during the year 2023. The Internet of Things (IoT) facilitates the interconnection of various devices and sensors, enabling the collection and sharing of data. This capability offers real-time insights into the industrial process. Enterprise Resource Planning (ERP) systems have the capability to effectively integrate this data, so facilitating manufacturers in making informed decisions based on data analysis and enhancing their operational efficiency.

The principles of Industry 4.0 place significant emphasis on the integration of automation, digitization, and connectivity, which have now been easily included in enterprise resource planning (ERP) software. The integration described enables enterprises to establish a smart industrial setting, increase their control of the supply chain, and optimise operational efficiency.

· Cloud-Based ERP Solutions:

Cloud-based enterprise resource planning (ERP) solutions have significantly transformed the operational landscape of enterprises. This paradigm shift can be attributed to the revolutionary impact of cloud technology on ERP software. In the year 2023, an increasing number of engineering and manufacturing companies are using cloud-based Enterprise Resource Planning (ERP) solutions. The aforementioned solutions possess several benefits, including the ability to scale, adaptability, reduced initial expenses, and convenient availability, rendering them exceedingly appealing to organisations of all sizes. Moreover, the utilisation of cloud-based enterprise resource planning (ERP) systems facilitates the instantaneous exchange of data and promotes collaboration among all parties involved, hence enhancing operational efficiency and cultivating a culture of innovation. Invest in the future of manufacturing. Choose advanced ERP software for engineering companies in India developed by STERP (Shanti Technology) to enhance agility and competitiveness.

· Advanced Analytics and Business Intelligence:

In the current business environment, data holds significant value. Enterprise Resource Planning (ERP) software has evolved to incorporate sophisticated analytics and business intelligence functionalities, enabling the generation of visually appealing data representations and the utilisation of predictive analytics techniques. Manufacturers have the ability to utilise this data in order to anticipate market trends, enhance production schedules, effectively manage inventories, and rapidly make well-informed business decisions. The utilisation of advanced analytics enables engineering and manufacturing enterprises to maintain flexibility and effectively respond to market fluctuations in a timely manner.

· Enhanced User Experience and Mobility:

The optimisation of user experience and mobility is a crucial element in contemporary enterprise resource planning (ERP) systems. In the year 2023, the primary emphasis of ERP software lies in delivering an intuitive and user-friendly interface, with the aim of facilitating smooth adoption and utilisation throughout all hierarchical levels within the organisation. Furthermore, the use of mobility enables stakeholders to conveniently access essential data and capabilities while on the move, hence enhancing productivity and facilitating informed decision-making. Stay ahead in the competitive manufacturing landscape. Reach out to an expert - STERP (Shanti Technology) - the most reliable Engineering ERP Software Company in India and elevate your business operations.

· Cybersecurity and Compliance:

The increasing prevalence of cyber risks has prompted ERP software developers to prioritise the integration of robust cybersecurity capabilities. In the year 2023, enterprise resource planning (ERP) systems place significant emphasis on the paramount importance of data security, adherence to industry laws, and the implementation of effective authentication procedures. This practice guarantees the preservation of confidential corporate information, hence cultivating a sense of trust and assurance among users.

Final Thoughts:

The evolutionary progression of Enterprise Resource Planning (ERP) software in the year 2023 signifies a significant and transformational change within the realm of engineering and manufacturing. The convergence of the Internet of Things (IoT), Industry 4.0 technologies, cloud-based solutions, sophisticated analytics, improved user experience, and heightened cybersecurity measures enables organisations to effectively streamline operations, boost efficiency, and attain long-term, environmentally conscious expansion. With the increasing use of these technological developments, the engineering and manufacturing sectors are poised to witness unparalleled levels of efficiency and creativity, hence setting a bright trajectory for the industry.

In order to remain competitive in today's ever-changing corporate landscape, it is imperative to be informed and capitalise on the capabilities of enterprise resource planning (ERP) software. Ready to streamline your manufacturing operations? Contact STERP (Shanti Technology) a renowned company offering manufacturing ERP software in India and see how it can simplify processes, boost efficiency, and drive profitability.

#ERP for manufacturing company in India#ERP software for engineering companies in India#Engineering ERP Software Company in India#Manufacturing ERP software in India#ERP India#Business Solutions#ERP software#Manufacturing#Engineering#business#shantitechnology#STERP

9 notes

·

View notes

Text

Top Robotics Labs for Schools | Robotics Classes in Coimbatore

ROBOMATIIC is an Educational, Research & Development start-up. We are providing Robotics education at Schools / Colleges in STREAM EDUCATION and also providing the new product development and industrial solutions in the sector of Industry 4.0.

We aim to produce the next generation innovators and problem solvers for the world through our unique offerings through our Omni channel presence. Our customized robotic training offers many advantages over the standard approach. Every theory portion of the course is followed by hands-on activity using simulation software and multiple versions of OEM robotic equipment so that each student builds confidence in their ability to navigate and work efficiently on whatever application they may encounter.

#education and learning#education and training#education center#education for students#education courses#education technology#education

2 notes

·

View notes

Text

Business Visa for Indian Tech Professionals – USA, Canada, Germany

Introduction

The global demand for Indian tech talent is stronger than ever. Whether it’s a short trip for a product demo, client onboarding, trade fair, or technical collaboration, business visas open doors for Indian tech professionals in top markets like the USA, Canada, and Germany.

This blog explains the visa options, documentation, and how BTW Visa Services simplifies the entire process for Indian techies planning international business visits.

USA – B1 Business Visa

The B1 visa is ideal for Indian tech professionals attending:

Client meetings

Technical consultations

IT system implementations

Conferences (e.g., AWS re:Invent, Google I/O)

Key Requirements:

Valid passport (6+ months)

DS-160 form & appointment confirmation

Invitation letter from US client

Cover letter from Indian employer

Salary slips and bank statements

Strong travel intent proof (return ticket, job continuity)

Processing Time: 7–15 working days

Pro Tip: Dropbox eligibility (interview waiver) speeds things up for repeat travelers.

Canada – Business Visitor Visa (Temporary Resident Visa)

Indian software consultants, engineers, and tech founders often visit Canada for:

Software deployment

Strategic meetings

Trade expos (e.g., Collision Conference)

Partner integration sessions

Required Documents:

IMM 5257 application form

Invitation from Canadian company

Cover letter with tech role description

Employer letter/NOC

Proof of funds (bank statements/ITRs)

Hotel & travel bookings

Processing Time: 10–20 working days

Tip: Include technical agenda and relationship history with the host to strengthen your case.

Germany – Schengen Business Visa

Germany is the hub of Industry 4.0, automotive, and enterprise software, making it a prime spot for Indian tech professionals.

You can travel for:

Technical workshops

Product launches

European IT expos (e.g., CeBIT, IFA Berlin)

Partnership or vendor meetings

Documentation Checklist:

Visa application form

Invitation letter from German partner

Indian employer letter on letterhead

Day-wise itinerary

Travel medical insurance (min. €30,000)

6-month bank statements

Processing Time: 10–15 working days

Tip: Book VFS Premium Lounge for faster appointment access during peak seasons.

Who Is This Guide For?

Software developers

DevOps engineers

CTOs and product managers

Startup founders

Tech consultants

SaaS and ITES professionals

Whether you’re with an IT MNC, startup, or on a contract assignment, a business visa is your entry ticket to global collaboration.

How BTW Visa Services Helps Tech Professionals

At BTW, we specialize in simplifying visa complexities for the tech industry. We assist with:

Customized document checklists

Invitation and cover letter drafting

Interview prep (USA)

Appointment booking for VFS & consulates

Express and priority processing coordination

Visa planning for multi-country travel

Conclusion

With business travel on the rise, tech professionals from India have endless global opportunities. But a single documentation error can stall your plans. Don’t risk rejection��trust the experts at BTW Visa Services to get your business visa approved quickly and accurately.

Go global with confidence. Get in touch today!

#business visa for tech professionals#USA B1 visa India#Canada business visitor visa#Germany Schengen visa IT#Indian techie visa guide#software engineer visa support#BTW visa consultants#international tech travel#business trip visa India

0 notes

Text

Trends and Forecasts in the Second Life Industrial Robot Market

The Second Life Industrial Robot MarketSecond Life Industrial Robot Market is rapidly expanding as businesses increasingly seek cost-effective automation solutions across manufacturing, logistics, and automotive sectors. These pre-owned, refurbished robots offer a budget-friendly alternative to new systems while delivering reliable performance and extended lifecycles. Growing trends include advanced refurbishing services, AI integration, and alignment with Industry 4.0 technologies, enhancing robot adaptability and efficiency. Despite challenges like standardization gaps, compatibility issues, and skilled labor shortages, the market benefits from rising demand driven by cost optimization and sustainability efforts. With ongoing innovations and a focus on circular economy practices, the second-life robot market is poised for significant growth and greater adoption worldwide.

Market Segmentation:

1. By End Use:

Industrial

Waste Recycling

Others

2. By Type of Refurbishment:

New Controller Technology

Others

3. By Region:

North America

Europe

Asia-Pacific

Rest of the World

Key Market Players

ABB

FANUC

IRS Robotics

Key Demand Drivers

Inexpensive Automation for Small and Medium Businesses: Because second-life robots drastically lower startup costs, automation is now affordable for manufacturers on a budget as well as small and mid-sized businesses (SMEs). This affordability is especially alluring in budget-conscious competitive industries and growing markets.

Goals for the Circular Economy and Sustainability: Businesses are adopting sustainable practices as a result of increased environmental awareness and more stringent e-waste rules. In line with circular economy concepts, refurbished robots prolong the useful life of current gear while lowering the load on landfills and conserving vital resources.

Improvements in Technology: Refurbished robots are becoming more versatile thanks to improved controller systems, AI integration, and machine learning applications. These improvements make older models more useful in high-precision settings and smart factories by enabling them to function on par with machines of the latest generation.

Market Challenges

Absence of Standardized Procedures for Renovation: Variations in robot safety, dependability, and quality caused by inconsistent refurbishing procedures among vendors may worry end users and restrict further adoption.

Integration Difficulties: Connecting legacy systems to automation platforms, Industry 4.0 frameworks, or contemporary software environments may necessitate extensive adaptation. Potential customers may be turned off by these integration fees, which can cancel out any initial savings.

Lack of Skilled Workers: Industrial robot maintenance and repair require specialized technical knowledge. The consistency of refurbished equipment quality and the scalability of services can be affected by a shortage of qualified personnel.

Get your hands on this Sample Report to stay up-to-date on the latest developments in the Second Life Industrial Robot Market.

Gain deep information on Robotics and Automation Market. Click Here!

Future Outlook

Through 2030, the market for used industrial robots is anticipated to develop significantly due to the combined demands of sustainability and economic efficiency. The performance of reconditioned robots will continue to improve with the development of AI-enabled control systems and modular modifications, making them more and more feasible for high-end industrial applications. With the help of favorable government policies, growing SME automation, and fast industrialization, the Asia-Pacific area is expected to grow at the fastest rate. Because of its well-established robotics infrastructure and advanced refurbishing skills, North America is expected to continue to hold its dominant position.

Conclusion

With its perfect blend of cost, sustainability, and performance, the second life industrial robot market is becoming a vital part of the worldwide automation scene. Refurbished robots are turning out to be a valuable asset for contemporary industry as the need for intelligent, environmentally friendly, and scalable automation solutions increases. Even if there are still issues with standardization and integration today, industry cooperation, technical advancement, and training programs should help to lessen them over time. The market for second-life robots is positioned for long-term growth and change because to strong regional demand and growing environmental concern.

#Second Life Industrial Robot Market#Second Life Industrial Robot Industry#Second Life Industrial Robot Report#robotics#automation

0 notes

Text

The Mechatronic Design Engineer: Powering Automation with CODESYS

Mechatronic design engineering is a multidisciplinary field that blends mechanical engineering, electronics, control systems, and software development to create intelligent, automated systems. Mechatronic design engineers are at the forefront of innovation, designing solutions for industries like robotics, automotive, aerospace, and manufacturing. CODESYS, an IEC 61131-3-compliant development platform, is a critical tool for these engineers, enabling them to program and integrate control systems for complex mechatronic applications. This article explores the role of a mechatronic design engineer, how CODESYS supports their work, key responsibilities, required skills, and real-world applications, highlighting the impact of this profession on modern automation.

The Essence of Mechatronic Design Engineering

Mechatronic design engineering focuses on creating systems that integrate mechanical components, electronic circuits, sensors, actuators, and software to achieve precise, reliable performance. These systems, such as robotic arms, autonomous vehicles, or CNC machines, require seamless coordination between hardware and software. Mechatronic design engineers ensure that these components work together to meet performance, safety, and efficiency goals, making them essential in industries embracing Industry 4.0 and smart automation.

CODESYS is a cornerstone for mechatronic design engineers, offering a versatile, hardware-independent platform for programming embedded control systems. Its compliance with IEC 61131-3, support for multiple programming languages, and robust tools for simulation and debugging make it ideal for developing sophisticated mechatronic systems.

Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers undertake a variety of tasks to bring complex systems to life:

System Design and Integration: Designing integrated systems that combine mechanical structures, electronics, and control software to meet specific functional requirements.

Control System Programming: Developing control algorithms to manage sensors, actuators, and motion systems, ensuring precise operation.

Simulation and Testing: Using simulation tools to validate system performance before deployment, minimizing errors and risks.

Prototyping and Commissioning: Building prototypes, integrating components, and deploying systems in real-world environments.

Optimization and Troubleshooting: Analyzing system performance, debugging issues, and optimizing designs for efficiency and reliability.

Collaboration: Working with mechanical, electrical, and software teams to ensure cohesive system development.

How CODESYS Empowers Mechatronic Design Engineers

CODESYS provides a comprehensive environment tailored to the needs of mechatronic design engineers:

IEC 61131-3 Programming Languages: CODESYS supports Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). These languages enable engineers to develop control logic for diverse applications, from simple discrete controls to advanced motion systems.

Hardware Flexibility: Compatible with PLCs and embedded controllers from vendors like Beckhoff, WAGO, and Siemens, CODESYS allows engineers to choose hardware that suits project budgets and requirements.

Motion Control Libraries: CODESYS offers libraries for motion control, supporting tasks like servo motor control, trajectory planning, and multi-axis coordination, critical for mechatronic systems like robotics.

Simulation and Debugging Tools: The built-in simulation mode enables testing without physical hardware, while debugging features like breakpoints and real-time monitoring help identify and resolve issues quickly.

HMI Development: CODESYS provides tools to create Human-Machine Interfaces (HMIs) for operator interaction, including graphical displays and web-based visualizations.

Communication Protocols: Support for EtherCAT, CANopen, Modbus, and OPC UA ensures seamless integration with sensors, actuators, and other devices in mechatronic systems.

Safety Standards: For safety-critical applications, CODESYS supports IEC 61508 (SIL 2/3), enabling engineers to design systems for industries like automotive and aerospace.

Example: Robotic Arm Control Program

Below is a sample Structured Text (ST) program for controlling a robotic arm’s position in a mechatronic system:

RoboticArmControl.st

plain

Show inline

This program implements a proportional control loop to adjust a robotic arm’s joint angle, ensuring precise positioning in a mechatronic application.

Essential Skills for Mechatronic Design Engineers

To succeed, mechatronic design engineers need a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, and control systems programming, including CODESYS and IEC 61131-3 languages.

Control Theory: Understanding of control algorithms, such as PID control, for precise system management.

Software Development: Experience with embedded systems programming and real-time operating systems (RTOS).

Problem-Solving: Analytical skills to troubleshoot and optimize complex systems.

Teamwork: Collaboration with cross-functional teams to integrate hardware and software components.

Adaptability: Staying updated with emerging technologies like IoT, AI, and cybersecurity.

Benefits of Using CODESYS

Streamlined Development: The integrated IDE and simulation tools reduce development time and errors.

Cost Efficiency: Hardware independence and code reusability lower project costs.

Scalability: CODESYS supports projects from small prototypes to large-scale industrial systems.

Flexibility: Multiple programming languages and protocols cater to diverse project needs.

Community Support: A global user base and resources like the CODESYS Store provide access to libraries and tutorials.

Applications in Industry

Mechatronic design engineers leverage CODESYS in various sectors:

Robotics: Developing control systems for industrial and collaborative robots.

Automotive: Designing ECUs for engine management, braking, and autonomous driving.

Manufacturing: Automating production lines, CNC machines, and material handling systems.

Aerospace: Controlling actuators and sensors in aircraft and spacecraft.

Medical Devices: Creating precise control systems for surgical robots and diagnostics.

Challenges in Mechatronic Design Engineering

Interdisciplinary Complexity: Integrating mechanical, electrical, and software components requires broad expertise.

Learning Curve: Mastering CODESYS and IEC 61131-3 languages can be time-intensive for beginners.

Resource Constraints: Embedded systems often have limited processing power, necessitating optimized code.

Safety Requirements: Meeting standards like IEC 61508 for safety-critical applications adds complexity.

Getting Started with CODESYS

To begin as a mechatronic design engineer using CODESYS:

Install CODESYS: Download the free IDE from the official website.

Learn Programming: Study IEC 61131-3 languages through tutorials and documentation.

Select Hardware: Choose a compatible PLC or embedded controller.

Develop and Simulate: Write control logic, test in simulation mode, and debug.

Deploy: Compile and deploy code to the target hardware.

Future Trends

As industries embrace digital transformation, mechatronic design engineers will increasingly use CODESYS for IoT-enabled systems, cloud-based monitoring, and AI-driven control. Support for protocols like OPC UA and MQTT positions CODESYS for smart manufacturing, while advancements in cybersecurity ensure its relevance in safety-critical applications.

Conclusion

Mechatronic design engineers by Servotechinc are key to creating the intelligent systems that drive modern automation, from robotics to autonomous vehicles. CODESYS empowers these professionals with a flexible, IEC 61131-3-compliant platform for programming, testing, and deploying control systems. Its robust features, hardware independence, and support for motion control and communication protocols make it indispensable for mechatronic applications. As technology advances, CODESYS and mechatronic design engineers will continue to shape the future of automation, delivering innovative, efficient, and reliable solutions.

0 notes

Text

Automation and Integration Needs Power Robust Growth in System Integrator Market

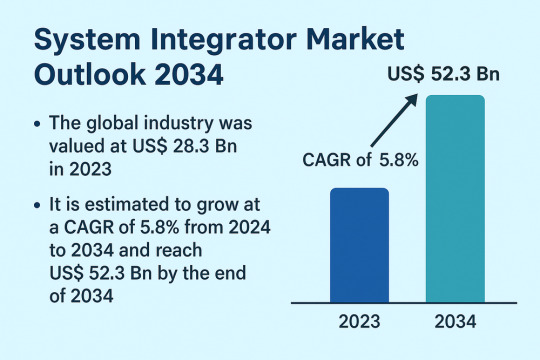

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Unlocking Manufacturing Excellence: How Simcenter Femap Streamlines Your Production Process

In today's highly competitive manufacturing landscape, efficiency, innovation, and cost-effectiveness are paramount. Companies are constantly seeking ways to optimize their processes, reduce time-to-market, and deliver superior products. This is where advanced simulation software like Simcenter Femap comes to the rescue! Simcenter Femap, a leading pre- and post-processor for finite element analysis (FEA), empowers engineers to virtually test and refine designs, predict performance, and identify potential issues long before physical prototyping begins. This translates directly into a streamlined manufacturing process, leading to significant gains across the board.

What Simcenter Femap?

Simcenter Femap is not just a software; it's a comprehensive pre- and post-processor for finite element analysis (FEA) that empowers engineers to virtually model, analyze, and optimize product designs before ever building a physical prototype.

Using Femap’s digital simulation capabilities you can:

Predict and improve product performance and reliability

Reduce time-consuming and costly physical prototyping and testing

Evaluate different designs and materials

Optimize your designs and reduce material usage

Simcenter Femap Software Comes to the Rescue!

In essence, Simcenter Femap transforms the manufacturing process from a reactive, problem-solving approach to a proactive, predictive one. It empowers engineers to make informed decisions earlier, leading to superior product designs and a more efficient, cost-effective manufacturing pipeline. Whether it's structural integrity, thermal performance, or dynamic response, Femap provides the tools to simulate the real world accurately, ensuring your products are ready for success.

Why Choose DDSPLM?

When it comes to implementing and maximizing the benefits of Simcenter Femap, choosing the right partner is crucial. DDSPLM Private Limited stands out as a reliable and experienced Siemens Expert Partner, offering a distinct advantage:

Proven Expertise

Industry-Specific Solutions

Comprehensive Support and Training

Focus on Digitalization and Industry 4.0

Strong Customer Endorsements

Conclusion

Simcenter Femap software is an indispensable tool for modern manufacturing, enabling businesses to innovate faster, reduce costs, and deliver higher-quality products. Its advanced simulation capabilities allow for virtual prototyping, comprehensive analysis, and design optimization, fundamentally streamlining the entire product development lifecycle.

By partnering with an experienced and dedicated expert like DDSPLM, you not only gain access to this powerful software but also benefit from their in-depth knowledge, tailored solutions, and unwavering support. Embrace the power of Simcenter Femap with DDSPLM, and take a significant leap towards manufacturing excellence and sustained success in today's dynamic global market.

0 notes

Text

How App Development is Revolutionizing Traditional Industries in 2025

For years, industries like agriculture, manufacturing, and construction relied heavily on manual processes and legacy systems. But in 2025, we’re witnessing a powerful shift—custom app development is driving a wave of digital transformation in even the most traditional sectors.

What was once slow, paper-based, and disconnected is now smart, data-driven, and automated—all thanks to tailored mobile and web applications.

Let’s explore how app development is redefining operations, efficiency, and growth in these core industries.

1. Agriculture: Smarter Fields, Higher Yields

The agriculture industry is embracing technology faster than ever before. Mobile apps are equipping farmers and agribusinesses with tools to boost productivity, monitor crops, and manage resources more effectively.

Key Innovations:

IoT-powered apps help farmers track soil moisture, weather conditions, and pest activity in real-time.

Drone-integrated systems capture crop imagery and analyze health conditions via AI-backed apps.

Marketplace apps connect farmers directly with buyers, reducing dependency on middlemen.

Result: Increased crop yield, reduced waste, and improved income stability for farmers.

2. Manufacturing: From Manual to Predictive

Manufacturing is becoming leaner and smarter. With the rise of Industry 4.0, custom apps are central to integrating machines, people, and data.

Game-Changing Features:

Real-time production monitoring via apps keeps plant managers updated on output, downtime, and maintenance needs.

Inventory and supply chain management apps improve planning and avoid overstock or shortages.

Predictive maintenance tools alert technicians before equipment fails, minimizing costly downtime.

Result: Enhanced productivity, better quality control, and lower operational costs.

3. Construction: Building with Precision and Speed

Traditionally plagued by delays and miscommunication, the construction sector is now using apps to keep projects on time and within budget.

Key Solutions:

Project management apps offer real-time collaboration between on-site workers, architects, and clients.

AR/VR-enabled apps allow stakeholders to visualize plans before construction even begins.

Safety compliance apps ensure that site inspections, hazard reports, and certifications are logged digitally and instantly.

Result: Smoother workflows, better safety compliance, and faster project delivery.

Looking Ahead

In 2025, app development is not just supporting traditional industries—it’s redefining how they operate. What makes the difference is customization. Businesses are no longer relying on off-the-shelf software; they are partnering with app development companies to create tools that speak to their exact needs.

Whether it’s a farmer in the field, a factory supervisor on the line, or a contractor on-site, the right app puts real-time power and insight in their hands.

0 notes

Text

Integrating Real-Time Control Systems for Manufacturing with Embedded Edge Intelligence

The industrial manufacturing landscape is undergoing a profound transformation. Increasing demands for efficiency, customization, and agility are prompting manufacturers to rethink how they manage operations and control systems. Central to this evolution is the integration of real-time control systems with embedded edge intelligence. These integrations represent more than just a technological upgrade; they symbolize a shift toward smarter, faster, and more adaptive manufacturing environments.

Real-time control systems have been the backbone of manufacturing automation for decades. They ensure machines operate within defined parameters, maintain synchronization across processes, and prevent errors that could lead to downtime or defective products. Traditionally, these systems relied on centralized architectures and predetermined logic. However, with the rise of edge computing, manufacturers are now able to decentralize decision-making and enable more nuanced, context-aware responses directly at the site of data generation.

This article explores the symbiosis of real-time control and embedded edge computing in manufacturing. It examines how these technologies work together, the benefits and challenges of implementation, and the future prospects of this integrated approach. As the manufacturing sector embraces Industry 4.0, the fusion of edge intelligence with control systems is poised to redefine operational excellence.

Understanding Real-Time Control Systems in Manufacturing

Real-time control systems are essential for maintaining the integrity and efficiency of industrial operations. These systems continuously monitor and adjust manufacturing processes to ensure optimal performance. They are designed to respond to inputs and changes within milliseconds, making them indispensable in environments where timing is critical, such as robotic assembly lines or chemical mixing.

Typically, real-time control systems involve a combination of sensors, actuators, and controllers. Sensors gather data on variables like temperature, pressure, or position. Controllers process this data and make decisions based on pre-set algorithms, which then drive actuators to perform necessary adjustments. This closed-loop control ensures that any deviation from the desired outcome is immediately corrected.

The reliability of these systems is paramount. Any delay or failure in processing can result in costly downtime or product defects. For this reason, traditional real-time control architectures have been centralized and rigid, favoring stability over flexibility. However, as manufacturing processes become more complex and variable, the limitations of such centralized systems become apparent.

Manufacturers are now looking to enhance these systems with local, intelligent processing capabilities. By bringing computational power closer to the machinery, they can enable real-time analytics, adaptive control strategies, and quicker response times. This is where embedded edge intelligence becomes a game-changer.

The Rise of Embedded Edge Intelligence

Embedded edge intelligence refers to the capability of computing devices to process data locally, at or near the source of data generation, without relying on centralized cloud systems. In the context of manufacturing, this means that machines and control systems can independently analyze sensor inputs and execute actions based on real-time insights.

The adoption of embedded edge intelligence is fueled by several technological advancements. Miniaturization of hardware, improvements in processor performance, and reductions in power consumption have made it possible to embed significant computing capabilities within small devices. These devices can be integrated into machinery, control panels, or even individual sensors.

Moreover, the development of edge-focused software platforms allows for sophisticated analytics, machine learning, and condition monitoring to be performed on-site. These capabilities enable predictive maintenance, anomaly detection, and adaptive control strategies that go beyond traditional static logic.

By decentralizing computation, manufacturers reduce latency and increase system resilience. If a centralized server goes offline, edge-enabled systems can continue to operate autonomously. This is particularly valuable in remote or high-risk environments where continuous connectivity cannot be guaranteed.

Embedded edge intelligence not only enhances performance but also supports scalability and modularity. New machines or sensors can be added to the system without overhauling the entire architecture. This flexibility is critical as manufacturers seek to respond quickly to changing market demands and production requirements.

Benefits of Integrating Edge Intelligence with Real-Time Control

The integration of embedded edge intelligence into real-time control systems offers a host of benefits that are transforming manufacturing operations. One of the most significant advantages is enhanced responsiveness. Traditional systems often depend on cloud-based analytics, which introduces latency due to data transmission and processing delays. Edge computing eliminates this bottleneck by processing data locally, enabling near-instantaneous reactions to changes in the production environment.

Another key benefit is improved reliability and resilience. By distributing processing capabilities across edge devices, manufacturers reduce their dependence on central servers. This decentralized approach minimizes the risk of system-wide failures and ensures that individual machines can continue functioning even if network disruptions occur.

Operational efficiency also sees a marked improvement. Edge-enabled systems can optimize processes in real time based on current conditions rather than pre-programmed rules. For instance, a packaging line equipped with edge intelligence can adjust its speed or pressure dynamically to accommodate variations in material thickness or temperature.

Moreover, this integration supports advanced analytics and machine learning. Embedded edge devices can continuously learn from operational data, identifying patterns and making predictive adjustments. This leads to proactive maintenance, reduced downtime, and extended equipment life.

Finally, integrating edge intelligence into real-time control systems facilitates greater flexibility and scalability. Manufacturers can easily reconfigure or upgrade individual components without disrupting the entire system. This adaptability is crucial in modern manufacturing, where agility and responsiveness are key competitive differentiators.

Technical Components and Architectures

Implementing embedded edge intelligence in real-time control systems involves a blend of hardware and software components that work together to deliver localized processing and decision-making. The architecture typically comprises edge devices, sensors, actuators, communication interfaces, and integration middleware.

Edge devices are at the core of this setup. These may include microcontrollers, embedded systems, or industrial PCs equipped with sufficient processing power to handle data analytics and control algorithms. The choice of device depends on the complexity of the application and the computational requirements.