#inert anodes

Link

Created in 1999, M.P.C. has become a key player in the plating industry to provide solutions to implement new technologies in the fields of electroplating for the Electronics and Industrial Finishes. A-Gas Electronic Materials is a distributor for MPC Pulse products. Contact us today.

#Micropulse Plating Concepts#CVS#Laboratory equipment#precious metal recovery#inert anodes#electrum#electrum metal#cvs lab#mpc#cvs electrodes

0 notes

Text

Primary Aluminium Market: Trends and Insights

Introduction

The global primary aluminium market is a vital sector within the broader metals industry, characterized by its extensive applications across various sectors, including automotive, aerospace, construction, packaging, and electronics. Aluminium, renowned for its lightweight properties, durability, and corrosion resistance, has become indispensable in modern manufacturing processes.

According to a study conducted by Next Move Strategy Consulting, the Primary Aluminium Market is projected to witness significant growth, with an anticipated size of USD 141.50 billion and a compound annual growth rate (CAGR) of 3.6% by 2030.

Understanding the Primary Aluminium Market

Historical Overview: The history of aluminium dates back to the 19th century, marked by the development of cost-effective production methods such as the Hall-Héroult process. Over the years, aluminium has emerged as a versatile metal, finding applications in diverse industries due to its favourable properties.

Request for a sample, here: https://www.nextmsc.com/primary-aluminium-market/request-sample

Market Segmentation: The primary aluminium market can be segmented based on product type, end-user industry, and geography. Product types include ingots, billets, and slabs, while end-user industries encompass automotive, aerospace, construction, packaging, and electrical appliances.

Value Chain Analysis: The primary aluminium value chain involves several stages, including bauxite mining, alumina refining, primary aluminium smelting, downstream processing, and distribution. Each stage presents opportunities for value addition and optimization.

Trends Shaping the Primary Aluminium Market

Rising Demand in Automotive and Aerospace Industries: The automotive and aerospace sectors are significant consumers of primary aluminium, driven by the need for lightweight materials to improve fuel efficiency and reduce emissions. With the transition towards electric vehicles (EVs) and the emphasis on sustainable aviation, the demand for aluminium is expected to escalate further.

Focus on Sustainability and Recycling: Sustainability has become a central theme in the primary aluminium market, with stakeholders prioritizing eco-friendly practices and recycling initiatives. Aluminium recycling not only conserves natural resources but also requires significantly less energy compared to primary aluminium production, aligning with global sustainability goals.

Technological Advancements in Production Processes: Technological innovations play a crucial role in enhancing efficiency and reducing environmental impact in primary aluminium production. Advanced smelting technologies, such as inert anode technology and electrolysis optimization, are gaining traction for their potential to lower energy consumption and greenhouse gas emissions.

Geographical Shifts in Production and Consumption: The primary aluminium market is witnessing geographical shifts, with emerging economies in Asia-Pacific, particularly China, emerging as key players. Rapid industrialization, urbanization, and infrastructure development in these regions are driving robust demand for primary aluminium, reshaping the global market landscape.

Impact of Trade Dynamics and Tariffs: Trade dynamics and tariffs significantly influence the primary aluminium market, impacting supply chains and pricing structures. Trade disputes between major aluminium-producing nations can lead to price volatility and market uncertainties, affecting stakeholders across the value chain.

Insights into Market Dynamics

Market Drivers: Several factors drive growth in the primary aluminium market, including increasing urbanization, infrastructure development, technological advancements, and evolving consumer preferences towards lightweight and sustainable materials.

Market Restraints: Despite its promising outlook, the primary aluminium market faces certain challenges, including fluctuating raw material prices, regulatory constraints, geopolitical tensions, and competition from alternative materials.

Opportunities for Market Players: Market players can capitalize on emerging opportunities by investing in research and development (R&D) to innovate new alloys, expanding production capacities, forging strategic partnerships, and leveraging digitalization to optimize operations and supply chain management.

Challenges to Address: Addressing challenges such as energy efficiency improvements, carbon footprint reduction, waste management, and compliance with stringent environmental regulations are imperative for the sustainable growth of the primary aluminium market.

Regional Analysis

North America: North America remains a significant market for primary aluminium, driven by robust demand from the automotive, aerospace, and construction sectors. The region also boasts advanced manufacturing capabilities and a focus on technological innovation.

Europe: Europe is witnessing a transition towards sustainable practices, with stringent environmental regulations driving demand for recycled aluminium. The region's automotive industry is leading the adoption of lightweight materials to meet stringent emissions standards.

Asia-Pacific: Asia-Pacific, led by China, is the largest consumer and producer of primary aluminium globally. Rapid industrialization, urbanization, and infrastructure development in countries like China and India fuel demand for aluminium across various sectors.

Middle East and Africa: The Middle East and Africa region possess significant bauxite reserves, providing a competitive advantage in primary aluminium production. However, the region faces challenges related to infrastructure development and political instability.

Future Outlook and Predictions

Market Growth Prospects: The primary aluminium market is poised for steady growth, driven by expanding applications, technological advancements, and increasing focus on sustainability.

Emerging Trends: Emerging trends such as lightweight, electric mobility, circular economy initiatives, and Industry 4.0 integration are expected to shape the future trajectory of the primary aluminium market.

Key Challenges: Overcoming challenges related to energy efficiency, carbon emissions, regulatory compliance, and geopolitical uncertainties will be critical for sustaining growth in the primary aluminium market.

Strategic Imperatives: Market players need to adopt a proactive approach by investing in R&D, fostering innovation, enhancing operational efficiencies, and strengthening collaborations across the value chain to capitalize on emerging opportunities and mitigate risks effectively. Embrace Digital Transformation: The integration of digital technologies such as artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), and data analytics can revolutionize operations within the primary aluminium market. By harnessing data-driven insights, companies can optimize production processes, improve predictive maintenance, enhance supply chain visibility, and optimize resource utilization, thereby gaining a competitive edge in the market.

Inquire before buying, here: https://www.nextmsc.com/primary-aluminium-market/inquire-before-buying

Prioritize Talent Development and Training: Investing in talent development and training programs is essential for building a skilled workforce equipped to tackle the evolving challenges and opportunities within the primary aluminium industry. By fostering a culture of continuous learning and skill enhancement, companies can ensure that their employees possess the expertise and capabilities required to drive innovation, improve productivity, and adapt to changing market dynamics effectively.

Enhance Stakeholder Engagement and Communication: Effective stakeholder engagement and communication are crucial for fostering trust, transparency, and collaboration across the primary aluminium value chain. Companies should prioritize engaging with stakeholders, including customers, suppliers, regulators, local communities, and non-governmental organizations (NGOs), to understand their concerns, gather feedback, and address issues proactively. By fostering open dialogue and transparent communication, companies can build stronger relationships, mitigate risks, and enhance their reputation in the market.

Conclusion

In conclusion, the primary aluminium market presents lucrative opportunities for growth and innovation amid evolving consumer preferences, technological advancements, and regulatory shifts. Stakeholders across the value chain must adapt to changing market dynamics, embrace sustainability practices, and leverage technological innovations to secure their competitive positions and drive sustainable growth in the years to come. By staying abreast of market trends and insights, businesses can navigate challenges and capitalize on emerging opportunities in the dynamic landscape of the primary aluminium market.

0 notes

Text

Aluminum Sheet Metal Fabrication

Unveiling the Art of Aluminum Sheet Metal Fabrication

In the realm of modern manufacturing, aluminum sheet metal fabrication stands as a cornerstone of innovation and efficiency. This versatile material, known for its lightweight yet robust nature, has revolutionized various industries, from aerospace to automotive, construction to electronics. Within this dynamic landscape, the process of aluminum sheet metal fabrication emerges as a pivotal technique, harnessing the inherent properties of aluminum to create intricate components and structures. In this article, we embark on a journey to explore the intricacies of aluminum sheet metal fabrication, uncovering its techniques, applications, and significance in contemporary manufacturing.

Aluminum sheet metal fabrication encompasses a range of techniques tailored to shape aluminum sheets into desired forms, catering to diverse industrial requirements. One of the primary methods employed in this process is cutting. Whether through traditional methods like shearing or advanced techniques such as laser cutting, precise cutting is essential to define the dimensions of the aluminum sheet accurately. Laser cutting, in particular, offers unparalleled precision and versatility, enabling intricate designs and complex geometries with minimal material wastage.

Following cutting, forming emerges as a crucial stage in aluminum sheet metal fabrication. This involves bending, shaping, and molding the flat aluminum sheets into three-dimensional components. Press brakes are commonly utilized for bending operations, allowing for precise control over angles and dimensions. Roll forming, on the other hand, is employed to create continuous shapes or profiles, ideal for applications like roofing panels and structural components.

Welding plays a pivotal role in joining multiple aluminum sheet metal components to fabricate larger assemblies or structures. Various welding techniques, including TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding, are employed based on factors such as material thickness, joint design, and desired strength. The advent of advanced welding technologies has significantly enhanced the efficiency and quality of aluminum sheet metal fabrication, enabling seamless integration and structural integrity in the final products.

Surface finishing holds equal significance in aluminum sheet metal fabrication, not only enhancing aesthetic appeal but also providing functional properties such as corrosion resistance and durability. Anodizing, for instance, involves electrochemically enhancing the surface of aluminum to create a protective oxide layer, offering excellent corrosion resistance and color versatility. Powder coating, another popular finishing method, involves applying a dry powder to the aluminum surface and curing it to form a durable and aesthetically pleasing coating.

The applications of aluminum sheet metal fabrication span across a multitude of industries, owing to its exceptional properties and versatility. In the aerospace sector, aluminum sheet metal components find extensive use in aircraft structures, owing to their high strength-to-weight ratio and corrosion resistance. Similarly, in the automotive industry, aluminum sheet metal fabrication facilitates the production of lightweight and fuel-efficient vehicles, contributing to sustainability and performance.

Moreover, aluminum sheet metal fabrication plays a vital role in architectural and construction projects, where its durability, formability, and aesthetic appeal are highly prized. From curtain walls to roofing systems, aluminum sheet metal components offer structural integrity, weather resistance, and design flexibility, enabling architects and designers to realize their creative visions.

In conclusion, aluminum sheet metal fabrication stands as a testament to human ingenuity and technological advancement in the realm of manufacturing. From cutting and forming to welding and finishing, each step in the fabrication process contributes to the creation of intricate and functional aluminum sheet metal components. With its myriad applications across industries ranging from aerospace to automotive, construction to electronics, aluminum sheet metal fabrication continues to shape the modern world, offering unparalleled performance, efficiency, and sustainability. As we venture further into the age of innovation, the art of aluminum sheet metal fabrication remains at the forefront, driving progress and shaping the future of manufacturing.

Top of Form

Bottom of Form

1 note

·

View note

Text

For example, a galvanic cell can be made using an anodic half-cell composed of a zinc electrode dipping into a solution containing Zn²+ and a cathodic half-cell composed of an inert (nonreacting) platinum electrode dipping into a solution both Fe²+ and Fe³+ (figure 12.13).

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#galvanic cell#zinc#platinum#cathode#anode#electrode#chemical reactions

0 notes

Text

Revealing the Wonders of Niobium Plate: A Comprehensive Guide to Its Benefits.

Revealing the Benefits of Niobium Plate: A Comprehensive Overview of Its Efficiency Niobium is an exceptional metal that has numerous applications for various industries and applications. Heat resistance, strength and low weight characteristics make it suitable for aerospace technology applications. This comprehensive guide explores the features of this fascinating material. Visit Your URL

Niobium Sheet

Rare refractory metal can be used in the production of nickel, cobalt and iron-based superalloys that exhibit superior mechanical strength, thermal creep resistance and corrosion resistance - these alloys are commonly found in jet engine components, sodium vapour lamps (street lights) and rocket boosters as high-performance components.

Niobium's refractory properties make it an attractive material for coin insert production. Numerous varieties of niobium-coated coins with multiple colour choices are readily available.

Niobium is an exciting addition to the precious metal family and has quickly gained flavor among jewellery enthusiasts. Being hypoallergenic, this metal can easily be anodized for various iridescent and shimmery hues.

Niobium, an extremely hard and corrosion-resistant refractory metal, boasts excellent corrosion resistance at room temperatures and inertness to most acids; however, concentrated alkalis and oxidizing agents may attack it directly. However, when coated with an oxide film, niobium proves quite corrosion-resistant.

Niobium metal's high-temperature resistivity makes it an excellent material for high-pressure and temperature applications, including evaporation boats, dimensionally stable crucibles for diamond growth, refractory materials, biocompatibility with such extreme temperatures as well as medical and aerospace technologies.

#NiobiumPlate#DiscoverNiobiumPlate#NiobiumPlateWonder#ExploringNiobiumPlate#NiobiumPlateBenefits#MaterialScience

0 notes

Text

Graphite Market | Size, Application, Revenue, Types, Trends in Future, Scope to 2032

The global graphite market is anticipated to reach a value of US$ 43,357.6 Mn by 2032, with the market expanding at a positive CAGR of 6.5% during the forecast period of 2022 and 2032. Valued at US$ 21,609.2 Mn in 2021, the graphite market will likely reach an estimated US$ 23,097.7 Mn in 2022.

The escalating application of graphite in various end-use industries like batteries, foundry facing, lubricants & crucible, refractories and others drive the graphite market to grow over this period of observation. The advantages of using graphite such as good thermal and electrical conductivity, lubricity, chemical resistance, and others propel the adoption of graphite in various industries.

One of the primary market drivers of graphite is the expanding electric vehicles sector. Graphite is used in the production of anodes that are needed in batteries, particularly of electric vehicles. Also, rising concerns for the environment coupled with increasing awareness about pollution and such foster growth for the electric and hybrid electric vehicles.

In addition to this, escalating demand for solar panels all over the world along with an increase in the need for Li-ion batteries in electric vehicles will further propel the target market. Usage of graphite in solar panels lessens the cost and optimizes the efficiency.

In the automotive sector, the high thermal resistance, chemical inertness, and the porous nature of graphite makes it the most preferred material for the production of anode in Li-ion batteries. All of these factors promote an environment of growth for the graphite market over the projected period.

Get a Sample Copy of the Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-874

Competitive Landscape

Showa Denko K.K., Toyo Tanso Co., Ltd., SGL Carbon SE, Tokai Carbon Co., Ltd, Graphite India Limited, Nippon Carbon Co., Ltd., HEG Limited, SEC Carbon, Limited, Imerys S.A., GrafTech International Ltd., Mersen Group, Fangda Carbon New Material Co., Ltd., Dongguan Kaijin New Energy Technology Co., Ltd., Pingdingshan Oriental Carbon Co., Ltd., Advanced Biopolymers AS, Mahtani Chitosan Pvt. Ltd Vardhman Acrylics Ltd., and others are some of the major players in the graphite market profiled in the full version of the report.

Leading market players are keen on entering and expanding their businesses in emerging economies. Other players are concentrating on the integration of advanced manufacturing technology to produce high-purity graphite to comply with the escalating demand.

Graphite Market Outlook by Category

By Product Type:

Natural Graphite

Synthetic Graphite

Flake

Amorphous

Vein

Graphite Electrode

Carbon Fiber

Graphite Blocks

Graphite Powder

Others

By Application:

Refractories

Lubricants & Crucible

Foundry Facing

Batteries

Others

“Expanding electric vehicle sector along with an elevated demand for solar panels are expected to fuel the graphite market over the forecast period,” says an FMI analyst.

Browse latest Market Reports@

https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes

Text

Comprehensive Guide to buy Copper Filter in Dubai

The importance of water purifiers in modern times knows no bounds. The markets filled with a variety of products that claim to be the best water purifier are proof of how the water purifying industry is booming. Many companies hire experts that work in the research and development team and try to come up with better technology, one day at a time.

However, customers still like to go for tried and tested technology. Copper water filters are a perfect example of this. Copper has antimicrobial properties that kill the bacteria present in water and keep people healthy. Purifiers with copper filters not only purify your water but also add antioxidants to it and boost your immunity. Opting for a copper water purifier, therefore, helps purify contaminated water, make it potable, and keep you and your family healthy.

Water Purification Using Copper Filters

Water has a redox potential that comes into action when a zinc anode and copper cathode are introduced to the water containing dissolved oxygen. The premise of copper-zinc filtration rests on this phenomenon. Impurities that are dissolved in water in as the constituent substrate are concentrated into more physiologically inert compounds. To determine the best copper filter provider in Dubai, look for a company that offers multiple products with diverse features available at different price points. Continue reading to find out the best copper filter provider in Abu Dhabi.

Benefits of Using Copper Filters

The benefits of drinking copper-infused water are no secret. Man has been drinking water out of copper vessels since ancient times. Copper water is believed to have multiple health benefits and copper filters are a modern take on the whole copper-in-water angle. The various benefits of using a copper filter in Abu Dhabi are as follows:

1. Beneficial for the heart- Copper helps in regulating the heart rate and blood pressure. It is believed to lower the level of bad cholesterol and treat hypertension effectively thereby making it good for the heart.

2. Boosts Immunity- Insufficient levels of copper are known to adversely affect our immune system and make the body prone to infection and sickness. The antimicrobial properties of copper help fight against infections and kill bacteria, thereby boosting the body’s immunity.

3. Enhances the Production of Melanin- The production of melanin in the body helps prevent sun damage from harmful UV rays. Copper is known to boost the production of melanin and protect the skin and keep it healthy.

4. Glowing Skin- The antioxidants present in copper are transferred to the water through copper water filters. These antioxidants help maintain the skin’s glow and are also known to keep the skin supple and avoid the early signs of aging, like fine lines and wrinkles.

5. Helps Combat Obesity- Copper helps break down fat when it acts on the food one eats. The food and the fat are both broken down better and thus get rid of the fat making copper help fight obesity.

6. Improves Digestion- As mentioned above, copper helps break down food particles efficiently. This helps the food absorb better ensuring proper nourishment, boosting the digestion process, and subsequently helping boost one’s metabolism.

Ayurveda, the oldest branch of medicine, mentions the benefits of copper in detail. The practice of storing water overnight in a copper jug and drinking it on an empty stomach has been around for years. However, the introduction of steel has limited the production and availability of copper utensils.

In modern times, using copper filters is one of the most convenient ways to introduce copper to our bodies. Modern technology in copper filters infuses copper ions into the water which is better than drinking water that was merely stored in a copper utensil. The benefits of copper are thus derived every time one drinks water, through the process of filtration. This technology makes your life happier and healthier.

Himalayan Waters is the first Water Purifier Company to become a copper filter supplier in Dubai and Abu Dhabi. The benefits of copper have been known to man for many years. People have been using utensils, vessels, and various other items made of copper in the hopes of deriving its benefits.

The company is undoubtedly the best copper filter supplier in Dubai. Book an appointment with them today!

#Copper Filter in Dubai#Copper Filter Provider in Dubai#Copper Filter in Abu Dhabi#Copper Filter Supplier in Dubai#Copper Filter Provider in Abu Dhabi#Copper Filter Supplier in Abu Dhabi

1 note

·

View note

Text

Anti Corrosive VCI Packaging Solution | VCI Packaging

Corrosion

Corrosion is a constant, indiscriminate and costly enemy of metal parts, especially when packaged for storage and distribution. Traditional anti-corrosion methods are messy, costly and can be hazardous to personnel and the environment. Too often, they are ineffective as well.

Globally the losses every year due to corrosion is estimated to be unimaginable US$ 828 billion per annum. i.e. US$ 2.27 Billion per day. (NACE)

VCI (Volatile Corrosion Inhibitor)

A mixture of special chemicals that constantly vaporize and create gases which have anti – corrosion properties.

These vapors form a very thin protective film layer around the metal surface and prevent the metal from the corrosion action.

SafePack VCI In Action

VCI chemicals dissociate into anions and cations with moisture as an electrolyte. These anions and cations associate with anodic and cathodic reactive areas respectively on the metal surface forming a mono-ionic protective layer, making it inert for any further reaction such as oxidation/rusting. Any loss of ions is replenished through further condensation of vapor ensuring continuous protection.

SAFEPACK VCI’s are non-toxic, environment friendly and made to international standards.

GENERAL VCI FAQ

1) What is VCI? / What does VCI mean?

VCI stands for Volatile Chemical Inhibitors (also known as VPI – Vapor Phase Inhibitor) These are high tech chemicals and are volatile in nature. They constantly vaporize & protect the metals from corrosion.

2) How many chemicals are used?

Safepack VCI’s are a combination of up to 8 to 10 different high – tech chemicals depending on the application and atmospheric conditions under which metals are to be protected.

3) Are your VCI’s coated or impregnated?

Safepack VCI’s are impregnated on its sophisticated state – of – the – art processing line.

4) What is impregnation?

Impregnation is a process by which the VCI chemicals are deposited with high pressure on the paper. Unlike surface coated paper, impregnation ensures a uniform & homogenous absorption of the chemicals by the paper.

5) Are the VCI Chemicals toxic?

No Safepack VCI’s are non toxic & environment friendly.

6) What happens if we inhale the chemicals?

The chemicals used are non – toxic. However, as a precaution it is recommended to use them in a well ventilated area. (Refer MSDS)

7) What is the shelf life of VCI paper / VCI powder / VCI Tablet / VCI Oil / VCI PE Film?

Under normal conditions of storage, shelf life of Safepack VCI product is up to 2 years.

8) What is the protection period from the date of packing?

The protection period depends on internal & external atmospheric conditions under which the VCI product is to be used. The protection period is inversely proportional to the temperature & airflow.

9) Is airtight packing required?

No, airtight packaging is not required. However, the package should not be left open to atmosphere & adequate secondary packing with polythene / HDPE sheet should be used wherever required.

10) What happens if the package is opened for inspection purpose?

With Safepack VCI’s, the package can be opened for inspection purpose. Though there will be some loss, very small VCI Vapors, still there is enough load of VCI’s available for protection. Care should be taken to close the package immediately after inspection to ensure optimum protection.

11) How much is the loss of chemicals when package is opened?

The loss of chemicals is inversely proportional to the Temp & Airflow (Please refer Point No: 12)

12) Will VCI’s increase our cost of packaging?

No, when all direct & indirect costs with conventional packing are considered then on the contrary studies show that there is a 60% saving in costs by using Safepack VCI’s.

13) Which side of the paper to be used?

The side on which VCI’s are coated should face the metal / component to be protected. For case of VCI coated side from non – coated side, Safepack VCI coated side has a greenish color shade.

14) Is VCI Powder similar to Silica gel?

No, VCI Powder is a concentrated form of high tech VCI chemicals which vaporizes & forms a mono – molecular protective layer on the metal surface to be protected. Thereby it protects the metal from corrosion where as silica gel absorbs a certain amount of water vapor only & does not protect from corrosion.

15) What are the benefits of VCI?

VCI’s offer a dry means of protection unlike conventional oils / greases / paints / varnishes etc which are messy. VCI’s save costs in material & labor. VCI packaging products or anti corrosion packaging are environmental friendly

16) When do we use VCI packaging material ?

Whenever corrosion protection is needed for metals.

17) In what form is VCI paper / film available?

VCI paper & film is available in the form of Rolls, Cutsheets, 2 Dimensional Pouches, 3 Dimensional bags & Tubing.

18) Is VCI paper HDW waterproof?

Yes. The VCI Paper FEP x 90 HDW (SP- FE – 180 WF) has a layer of LDPE Film also which makes it waterproof.

19) How to test the corrosion performance of VCI products?

Please refer the Safepack’s standard procedure for comparative corrosion performance test.

20) How to identify whether there are VCI chemicals in present in the product? (Any immediate test like litmus?)

There is a Test available but it is very complex & expensive. Unfortunately, there is no quick test like litmus for detection of presence of VCI’s.

21) What is 1 cycle test?

1 cycle refers to the test of corrosion performance which involves 8 hrs of heating followed by 16 hrs of cooling. This time span of 24 hrs is called as 1 cycle.

22) Can VCI’s protect from water?

If there occurs water flooding in a VCI package, then the VCI’s will get drowned / diluted in water and will be rendered in effective.

23) What is the maximum temperature at which VCI’s can still work?

For optimum protection the temperature should not exceed 55 oC. Any further increase in temperature will result in faster loss of VCI’s and will reduce protection period.

24) How to determine what qty of VCI paper / film / powder / tablet / oil is required to design the package?

As a thumb rule 1 sq. Mtr. of VCI Paper is required for protection of 2 sq. Mtr. of metal surface. 1 gm of VCI Powder / Tablet for protection of 1 cu. ft of void space.

25) How much surface area of metal can be covered by 1 liter of Prewash solution / VCI Oil?

1 Ltr VCI Prewash can cover approx 100 sq. Mtr. of surface area. 1 Ltr VCI rust preventive Oil can cover approx 50 sq. Mtr. surface area.

0 notes

Text

Electroplating is the process of plating metal on metal with the aid of hydrolysis in order to prevent corrosion

By using a direct electric current to reduce the cations of a metal, the process of electroplating, also known as electrochemical deposition or electrodeposition, creates a metal coating on a solid substrate. The component that needs to be coated serves as the cathode (negative electrode) of an electrolytic cell; the electrolyte is a solution of the metal's salt; and the anode (positive electrode) is typically either a block of the metal itself or some other inert conductive material. An outside power source supplies the current.

In both industry and decorative arts, Electroplating is frequently used to enhance the surface properties of objects, such as their resistance to abrasion and corrosion, lubricity, reflectivity, electrical conductivity, or appearance.

Read More @ https://delightblogging.blogspot.com/2022/08/electroplating-process-involves-plating.html

0 notes

Text

Chemical Behavior Of Platinum And Titanium

Since platinum is very resistant to corrosion, it is preferable on the anode's exterior surface. It is able to ensure that current flow is maintained across all electrolyte mediums and avoid the formation of an insulate layer. Because it doesn't corrode, it doesn't produce corrosion products, so the rate of consumption is extremely low.

Platinum is inert when fused salts and acids, while it dissolves in the aqua regia. It is not at risk from hydrogen embrittlement. (You can learn about the dangers of hydrogen embrittlement by reading An Introduction to Hydrogen Embrittlement.) It is the only metal that can withstand the salts of seawater's chlorides. https://energy-ti.com/

0 notes

Text

Biomed Grid | Titanium Implant Devices: Increase Biocompatibility or Decrease Drug Release Rate?

Mini-Review

Titanium and its alloys are the most used metallic materials for the manufacture of orthopedic and dental prostheses due to their similarities to human bone. Among these properties, the hardness and Young’s modulus stand out, besides being chemically inert and presenting low corrosion potential in biological environments [1]. Its low corrosion rate is due to the formation of a TiO2 layer, also known as a “barrier oxide” responsible for metal passivation.

TiO2 formation is a thermodynamically favorable process, and an oxide of a few nanometer thicknesses is formed as soon as the metal is exposed to an oxygen-containing environment. Due to this factor, the characteristics of the coating can be easily experimentally manipulated. One of the techniques that have been widely used for implant surface modification is anodization. Through this technique, it is possible to create from compact films, as pores of the order of micrometers, or even nanotubes that can have diameters ranging from 30-100nm [2, 3].

Over the course of several years, much effort has been put into the development of these structures as well as their possible applications. It is now possible to obtain highly organized nanostructures of 100-1000μm in length, which can undoubtedly have many advantages for applications requiring materials with a high surface area. For implantable materials, nanoarchitecture provides a large area for osteoblast growth and cell differentiation, which favors the osseointegration process. With all these characteristics, it was not difficult to think about the possibility of using implants with nanostructured surfaces to produce drug delivery devices.

The main problem with the placement of orthopedic and dental implants is the rejection of the material by the human body. The process of implant rejection usually occurs by contamination of the material with microorganisms, with Staphylococcus Aureus being the most common, which grows on the implant forming a bacterial biofilm. After the formation of this biofilm, it is practically impossible to recover the surface of the biomaterial. Thus, an idea to reduce the incidence of this problem could be the incorporation of antimicrobial drugs. Such devices would act locally, reducing the amount of intravenous or oral drugs prescribed to patients postoperatively.

Several studies have proven the potential of this material to produce this device. Two properties are desirable in these materials, the first one is the bioactivity, i.e., the ability of the implant to Osseo integrate. Such ability is observed in materials with high wettability, which facilitates adhesion of osteoblastic cells and facilitates the osseointegration process. The other important feature is a slow drug release rate so that the drug concentration in the bloodstream remains within the range required for inhibition of the microorganisms. The problem with this latter feature is that the antimicrobial drugs used are water-soluble, so the wettability of the device is once again of great importance in the development of the material, but in an antagonistic manner.

The lower the wettability, the lower the drug release rate. Many works show the addition of diffusional barriers to the implant surface to decrease the drug release rate [4, 5]. However, the great effort made to obtain a large surface area is lost in this case. Although coatings with smaller nanotubes have larger surface areas, the effect of capillarity on these materials is more pronounced and cannot be neglected in the development of biomaterials of this kind [5]. Therefore, further investigation of the ideal conditions for a high osseointegration rate coupled with a low drug release rate is needed. In recent studies we observed that nanotubular films incorporated with cefazolin can release 1mg of the drug in 8min or 300min, depending on the experimental conditions of the biomaterial synthesis [5]. However, the question that remains is what would be the ideal condition? A lot of research is still needed to answer this question.

Read More About this Article: https://biomedgrid.com/fulltext/volume7/titanium-implant-devices-increase-biocompatibility-or-decrease-drug-release-rate.001106.php

For more about: Journals on Biomedical Science :Biomed Grid | Current Issue

#biomedgrid#american journal of biomedical science & research#list of open access medical journal#free medical journal

0 notes

Text

3D METAL PRINTING

There are different types of Metal Additive Manufacturing technologies, here are the most important.

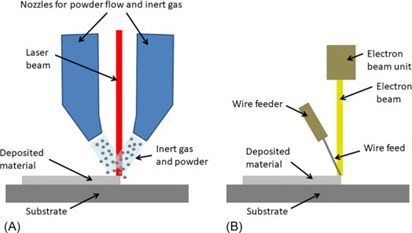

Directed Energy Deposition (DED):

It is composed by a head from where a laser, or a electron or a plasma ray exits. On the head, a pressurized system is installed, from where metal powder is ejected in a way that hits the ray and melting occurs. Both the head and component can move. It is possible to use, instead of powder, a filament, cheaper but that gives lower quality.

Turn up the volume!

https://www.youtube.com/watch?v=oL7bMhPTtDI

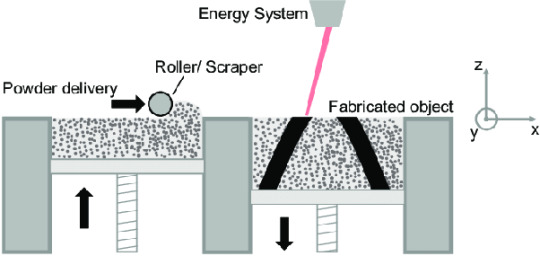

Powder Bed Fusion:

A powder bed is deposited and material is melted only where necessary. Once the material is melted, another layer of powder is deposited, and so on.

Depending on the energy source, we speak of:

1. Selective Laser Melting (SLM):

The source is a laser and the working chamber is filled with inert gas, to avoid combustion or explosions. The head moves, the component is fixed. Selective Laser Sintering (SLS) is similar, but the material is not really melted, is sinterized (lower temperatures).

Maximum obtainable dimensions are (600x400x500) mm^3.

https://www.youtube.com/watch?v=te9OaSZ0kf8

2. Electron Beam Melting (EBM):

The source is an electron gun. It is composed by a cathode made of tungsten that is heated until it reaches temperature higher than 2000 °C, (melting point of tungsten is about 3400 °C, this is why tungsten is used) emitting electrons than are accelerated through the application of a voltage (V or Volt) between the same cathode and an anode collocated below.

In this way, an electron beam is emitted, that is focused through a repulsive disk (a magnet) and reaches the material, melting it.

The electron beam can be oriented through a magnetic field, removing any moving part and so, any friction. This makes this technology faster but also more expensive (not less than 1 million euros).

The chamber has to be taken under vacuum and at a temperature of 1000 °C. Working at these temperature reduces thermal stresses.

Maximum obtainable dimensions are (350x350x380) mm^3.

https://www.youtube.com/watch?v=CUeDevI6kyE

The main parameters that infleunce the quality of a component obtained with Additive Manufacturing are:

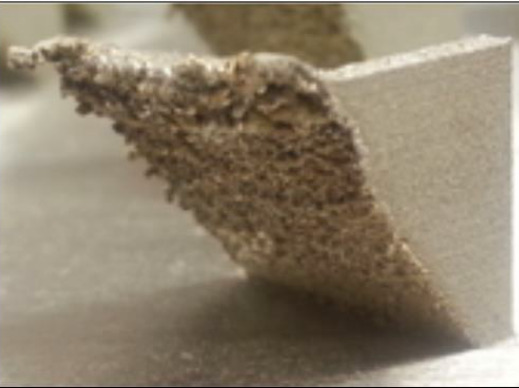

Energy density: we have to set the right power of the source, the right speed, the right distance, avoiding material vaporization or chemical composition changes (too much energy) or lack of fusion (too low energy). The quality of the component is measured comparing the final mass with the expected from theory one: in fact, generally speaking, components obtained with AM have a lower density than ones obtained through CNC technologies, because of the higher air inclusions. This results in lower mechanical porperties;

Powder: chemical composition, dimensions (we can reach nanometers), morphology, physical properties, storaging, reutilizability and dangerousness. Aluminum powder cost is 30 €/Kg, Steel 70 €/kg, Titanium 150 €/Kg, NiTiNOL 700 €/Kg (approximate values);

Deposition strategy: it influences material orientation, resulting in a material anisotropy (different mechanical properties in different directions). In conclusion, it influences the mechanical properties of the component;

Rugosity; we obtain higher rugosity than in traditional technologies (CNC). Surface post processing is necessary.

Metal Additive Manufacturing is a competitive technology, considering time and costs, only for low numbers of components, with very complex geometries that are not obtainable with other technologies.

For big lots and simpler geometry, CNC technologies are still the best choice.

Regards!

#engineering#3dprinting#metal 3d printing#additive manufacturing#metals#aerospace#mechanical#mechanical engineering#aerospace engineering#material#materials engineering#technology#structural engineering#machinery#engineering student#engineering university#aeronautical#egineering students

8 notes

·

View notes