#iot integration

Explore tagged Tumblr posts

Text

How Dynamics 365 & IoT Optimize Field Service Operations

Microsoft Dynamics 365 Field Service, combined with IoT integration, is transforming traditional maintenance models into intelligent, proactive service operations. By connecting smart devices through Azure IoT Hub, businesses gain real-time insights that trigger alerts, automate work orders, and enable remote troubleshooting—reducing downtime and enhancing efficiency.

This powerful synergy—known as Connected Field Service—helps technicians resolve issues before they occur, supports predictive maintenance, and ensures seamless service delivery. The result is improved operational reliability and higher customer satisfaction.

With features like automated scheduling, device monitoring, and integration across the Microsoft ecosystem, Dynamics 365 Field Service provides a comprehensive platform for optimising field operations. Partnering with experts like Web Synergies ensures smooth implementation, unlocking the full potential of IoT-driven field service management.

0 notes

Text

Exploring the Vision Behind the Book "Comprehensive Technology Solutions Offered by SolveForce and Partners"

In a world increasingly driven by digital infrastructure, the need for comprehensive, scalable, and future-ready telecommunications and technology solutions has never been more pressing. The newly released book Comprehensive Technology Solutions Offered by SolveForce and Partners arrives at a pivotal moment in that evolution. Authored by industry leaders Ron Legarski, Steve Sramek, and Bryan…

#AI-powered security#Cloud Services#DSL#fiber#Fixed Wireless#IoT#IoT Integration#Mobility#MPLS#SASE#SD-WAN#SIP Trunking#VPN

0 notes

Text

Next-Gen AR Development: Bringing Ideas to Life - Atcuality

Augmented reality is no longer just a futuristic concept—it’s here, transforming industries and enhancing real-world applications. At Atcuality, we specialize in custom AR solutions designed to create interactive, engaging, and scalable experiences for businesses of all sizes. Our augmented reality development services cater to diverse industries, including retail, tourism, real estate, and automotive, helping brands deliver unforgettable user experiences. Whether you need AR-powered product visualization, training simulations, or interactive storytelling, our expert team ensures a seamless, high-quality solution tailored to your needs. Elevate your business with Atcuality’s cutting-edge AR technology and shape the future of digital interaction today!

#website development#ai applications#artificial intelligence#augmented and virtual reality market#web development#information technology#emailmarketing#augmented reality#web design#digital marketing#augmentative and alternative communication#augmented intelligence#virtual reality#ar vr technology#digital consulting#digital services#iotsolutions#iot#iot platform#iot applications#iot development services#technologynews#iot solutions#iot integration#automation#software company#software development#software engineering#software testing#cash collection application

0 notes

Text

Integrating IoT into carbon footprint tracking apps provides enterprises with granular, real-time data through sensors across operations. This enables smart energy management, optimized supply chains, efficient waste management, and automated reporting. IoT App enhances accuracy, monitoring, and efficiency, allowing companies to proactively reduce emissions and align with sustainability goals.

0 notes

Text

#Retail Inventory Management#Microservices Architecture#Event-Driven Architecture#AI in Retail#IoT Integration#Blockchain Transparency#Real-Time Data Processing#Supply Chain Optimization#Retail Technology#Inventory Optimization

0 notes

Text

5G System Integration Market Report: Insights, Trends, and Forecast 2022–2030

5G System Integration Market Report – Straits Research

Market Overview

The global 5G System Integration Market was valued at USD 7.76 Billion in 2021 and is projected to grow from USD XX Billion in 2022 to USD 67.16 Billion by 2030, growing at a robust CAGR of 27.1% during the forecast period (2022–2030). The market encompasses the integration of advanced technologies, including 5G networks, IoT devices, cloud computing, and edge computing, into existing infrastructures to enable high-speed communication and seamless connectivity. 5G system integration is essential for businesses across various industries to unlock the full potential of 5G technology, providing faster speeds, lower latency, and more reliable connections. With the growing demand for high-speed, ultra-reliable, and low-latency communications, the 5G system integration market is expected to experience significant growth.

Request a Free Sample (Free Executive Summary at Full Report Starting from USD 1850): https://straitsresearch.com/report/5g-system-integration-market/request-sample

5G System Integration Market Categorization

The 5G System Integration market is segmented in multiple ways, each targeting specific services, industries, and applications that benefit from 5G technology.

1. Services Outlook:

The services provided in 5G system integration can be divided into three main categories:

Consulting: Consulting services are crucial for businesses looking to adopt and integrate 5G technology into their operations. Consultants offer strategic advice on deployment strategies, cost management, and technology selection.

Infrastructure Integration: This involves the integration of 5G infrastructure, such as base stations, towers, and small cells, with existing network systems. This integration ensures the seamless functioning of 5G networks alongside legacy systems.

Application Integration: This service focuses on integrating 5G technology with applications across different sectors, ensuring that businesses can optimize their operations and communication systems by leveraging high-speed data transmission and low latency.

2. Vertical Outlook:

The market for 5G system integration is further segmented by industry verticals, as different sectors adopt 5G technology to enhance their operations:

Manufacturing: The adoption of 5G in manufacturing enables smart factories with automation, robotics, and real-time analytics, improving productivity and efficiency.

Energy & Utility: 5G technology enables real-time monitoring of energy grids, smart meters, and power distribution systems, improving operational efficiency and minimizing downtime.

Media & Entertainment: 5G enables high-quality streaming, virtual reality (VR), and augmented reality (AR) experiences, transforming the entertainment industry and providing new opportunities for content creators.

IT & Telecom: Telecom companies are leveraging 5G technology to upgrade their networks and provide high-speed internet services to customers, while the IT sector uses 5G to support large-scale cloud computing and data processing.

Transportation & Logistics: 5G supports the growth of autonomous vehicles, smart logistics, and real-time tracking, improving operational efficiency and reducing costs in the transportation and logistics industry.

BFSI (Banking, Financial Services, and Insurance): In the BFSI sector, 5G integration allows for secure, real-time transactions, mobile banking services, and enhanced customer experiences.

Healthcare: 5G’s low latency enables telemedicine, remote surgeries, and patient monitoring systems, helping healthcare providers improve patient care and operational efficiency.

Retail: Retailers use 5G technology to enhance customer experiences through augmented reality, personalized shopping experiences, and real-time inventory management.

Others: This category includes sectors such as education, government, and agriculture that are also adopting 5G technology for improved communication, data analysis, and operational efficiency.

3. Application Outlook:

The diverse applications of 5G technology span several fields, each providing unique benefits for different industries:

Smart City: 5G enables the development of smart city applications such as intelligent traffic systems, smart meters, and public safety systems, improving urban living.

Collaborative Robots / Cloud Robots: The integration of 5G with robotics allows for the deployment of collaborative robots in manufacturing and other industries, improving automation and efficiency.

Industrial Sensors: 5G facilitates the use of industrial sensors for real-time monitoring and data collection, enabling predictive maintenance and improving operations in industries like manufacturing and energy.

Logistics & Inventory Monitoring: With 5G, companies can track inventory in real-time, improve logistics efficiency, and enable faster delivery times, reducing operational costs.

Wireless Industry Camera: 5G enables high-definition video streaming from cameras used in industries like surveillance, security, and media, ensuring smooth, high-quality streaming.

Drone: Drones equipped with 5G can transmit high-definition video and data in real time, enabling uses in agriculture, delivery, and infrastructure inspection.

Home and Office Broadband: 5G enables high-speed internet access for both residential and commercial properties, enhancing broadband services for customers.

Vehicle-to-everything (V2X): V2X technology powered by 5G allows for communication between vehicles, infrastructure, and pedestrians, enabling safer, more efficient transportation systems.

Gaming and Mobile Media: 5G enhances the gaming experience by providing low-latency, high-speed connections for mobile games and media streaming.

Remote Patient & Diagnosis Management: 5G enables remote healthcare services, allowing for faster diagnosis, patient monitoring, and telemedicine applications.

Intelligent Power Distribution Systems: 5G enhances the management of power grids by providing real-time data, improving grid stability and reducing energy losses.

P2P Transfers / mCommerce: 5G facilitates faster peer-to-peer (P2P) payments and mobile commerce, enhancing the customer experience in the financial services industry.

4. Geographic Overview:

The 5G System Integration Market is witnessing dynamic growth across the globe. Key regions and their dominant countries are:

North America: The U.S. leads the North American market with the largest adoption of 5G technology, driven by the presence of major telecom players, technological advancements, and high investments in 5G infrastructure.

Europe: The European market is expanding, with the U.K., Germany, and France playing a significant role in adopting 5G systems, especially in manufacturing, healthcare, and transportation.

Asia Pacific: Asia Pacific is expected to witness the highest growth during the forecast period, with countries like China, Japan, and South Korea leading the 5G adoption race. The region’s strong focus on technological innovation and infrastructure development fuels market growth.

Latin America: Latin America is catching up with other regions in adopting 5G technology, particularly in countries like Brazil and Mexico. These countries are focusing on 5G infrastructure deployment and increasing connectivity in urban and rural areas.Market Segmentation with Insights-Driven Strategy Guide: https://straitsresearch.com/report/5g-system-integration-market/segmentation

Top Players in the 5G System Integration Market

The 5G System Integration Market features several industry leaders who are pivotal in the growth and innovation of 5G technology:

Accenture Inc.

Cisco Systems, Inc.

Huawei Technologies Co., Ltd.

Infosys Limited

Tata Consultancy Services Limited

Wipro Limited

Radisys Corporation

IBM Corporation

HPE (Hewlett Packard Enterprise)

Oracle Corporation

HCL Technologies Limited

ALTRAN

AMDOCS

CA Technologies

Hansen Technologies

Samsung Electronics Co., Ltd.

Ericsson

Keysight Technologies

ECI Telecom

These companies provide integrated solutions and services for the successful implementation and deployment of 5G systems, contributing to the rapid growth of the 5G ecosystem.

Key Unit Economics for Businesses and Startups

For businesses and startups, understanding the unit economics of 5G system integration is essential. Key metrics include:

Cost of Integration: The total investment required for adopting 5G infrastructure, including hardware, software, and consulting services.

Return on Investment (ROI): The anticipated financial returns from deploying 5G technology, which could include cost savings, enhanced operational efficiency, and new revenue streams.

Customer Acquisition and Retention: 5G enhances customer experiences, leading to higher retention rates and attracting new customers through innovative services.

Startups looking to integrate 5G technology should focus on scalable solutions and consider cloud-based integration services to reduce upfront costs.

Buy Full Report (Exclusive Insights with In-Depth Data Supplement): https://straitsresearch.com/buy-now/5g-system-integration-market

5G System Integration Market Operational Factors

Several operational factors influence the 5G system integration market, including:

Technology Advancements: Continuous developments in 5G, IoT, and edge computing technologies are driving the market forward.

Regulatory Challenges: Countries are implementing policies and regulations related to spectrum allocation, network sharing, and data security, affecting 5G adoption.

Deployment Costs: The high cost of infrastructure and integration services remains a barrier for some businesses, especially startups and small enterprises.Table of Contents for the 5G System Integration Market Report: https://straitsresearch.com/report/5g-system-integration-market/toc

About Straits Research

Straits Research is a leading provider of market research and intelligence services. With a focus on high-quality research, analytics, and advisory, our team offers actionable insights tailored to clients’ strategic needs.

Contact Us Email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#5G System Integration#5G Market Growth#5G Integration Services#Telecommunications#IoT Integration#Smart Cities#Mobile Technology#Cloud Computing#Infrastructure Integration#Market Forecast#Industrial IoT#Autonomous Vehicles#5G Applications#Consulting Services#Telecom Industry#Market Analysis#5G Adoption#Global 5G Trends#Digital Transformation#Technology Integration#Straits Research

0 notes

Text

#Tags:AI-Driven Analysis#Data Collection#Data Monetization#Elon Musk#facts#Global Connectivity#Global Surveillance#Internet Privacy#IoT Integration#life#Metadata#Podcast#Privacy Concerns#Satellite Internet#Satellite Technology#serious#Social Media Platforms#Space Missions#SpaceX#Starlink#straight forward#Telemetry Data#truth#upfront#website#X (formerly Twitter)

0 notes

Text

#Automated Technology Group#industrial automation#innovation in automation#Industry 4.0#IoT integration#smart robotics#predictive maintenance#green automation#automation solutions#automation in manufacturing#automation trends 2024#sustainable automation#AI in automation#collaborative robots#automation success stories#future of work#advanced automation systems#automation market growth#automation technology#industrial efficiency

0 notes

Text

#IoT Technology#Internet of Things#Artificial Intelligence#IoT integration#IoT in Machine Learning#IoT in Artificial Intelligence#Legacy IoT

0 notes

Text

0 notes

Text

What to Look for When Hiring Android App Developers | AIS Technolabs

Discover the key qualifications and skills to seek in Android app developers. Make informed hiring decisions with our essential guide

#Android Development#Hiring Android Developers#Java vs Kotlin#Mobile App Development#Tech Stack#Android SDK#App Security#Cross-Platform Development#AI and Machine Learning#IoT Integration#5G Technology#AR and VR#Developer Skills#Project Management#App Development Trends

0 notes

Text

Advisory Services

In the dynamic telecommunications landscape, our Advisory and Consulting services are the catalysts for transformation and innovation. Specializing in the complexities of telecom, we offer strategic guidance for MVNOs, MVNEs, private networks, and enterprises navigating digital transformation with a focus on emerging technologies like 5G, IoT, AI, and ML.

Expertise in telecom provides your business with actionable strategies, driving success in a sector that’s rapidly evolving with 5G and IoT advancements.

Stands at the cutting edge of 5G and IoT integration, empowering your business to leverage these technologies for enhanced connectivity, operational efficiency, and new service development.

Advisory and consulting services to navigate digital transformation | Csmart | Covalensedigital

0 notes

Text

LabVIEW Data Acquisition System

Data acquisition is a critical aspect of various industries, from scientific research to industrial automation. LabVIEW, developed by National Instruments, offers a powerful platform for designing and implementing data acquisition systems efficiently. In this article, we'll delve into the intricacies of LabVIEW data acquisition systems, exploring their components, setup, programming, benefits, applications, case studies, challenges, and future trends.

Introduction to LabVIEW Data Acquisition System

Understanding Data Acquisition Systems

Data acquisition systems are instrumental in collecting and processing data from physical phenomena or systems. These systems typically consist of sensors, signal conditioning hardware, and software for data processing and analysis.

Importance of LabVIEW in Data Acquisition

LabVIEW stands out as a premier software tool for data acquisition due to its user-friendly graphical programming interface and extensive library of functions for signal processing, analysis, and visualization.

Components of a LabVIEW Data Acquisition System

Hardware Components

A LabVIEW data acquisition system comprises various hardware components, including sensors, signal conditioning modules, data acquisition devices (DAQ), and interfaces for connecting with external devices.

Software Components

LabVIEW software provides the programming environment for configuring, controlling, and monitoring data acquisition processes. It offers a wide range of built-in functions and libraries for seamless integration with hardware components.

Setting Up a LabVIEW Data Acquisition System

Installation Process

Setting up LabVIEW involves installing the software on a compatible computer system and configuring it to communicate with the hardware components of the data acquisition system.

Configuring Hardware

Once the software is installed, users need to configure the hardware components by selecting appropriate drivers and setting up communication protocols within the LabVIEW environment.

Programming in LabVIEW for Data Acquisition

Basics of LabVIEW Programming

LabVIEW programming involves creating virtual instruments (VIs) using a graphical programming language known as G, which utilizes a block diagram approach for visual representation of code.

Data Acquisition Techniques

LabVIEW offers various data acquisition techniques, including analog and digital input/output, voltage measurements, frequency measurements, and waveform generation, all of which can be implemented through intuitive programming constructs.

Benefits of Using LabVIEW for Data Acquisition

Versatility and Flexibility

LabVIEW provides a versatile and flexible platform for designing custom data acquisition systems tailored to specific application requirements.

Integration with Other Systems

LabVIEW seamlessly integrates with other systems and software tools, allowing for interoperability and compatibility with existing infrastructure.

Scalability and Customization

LabVIEW offers scalability, enabling users to expand their data acquisition systems as per evolving needs, along with extensive customization options for optimizing performance.

Applications of LabVIEW Data Acquisition System

Industrial Automation

LabVIEW data acquisition systems find extensive applications in industrial automation for monitoring and controlling processes in manufacturing, quality assurance, and product testing.

Scientific Research

In scientific research, LabVIEW facilitates data collection and analysis in diverse fields such as physics, chemistry, biology, and environmental science, enabling researchers to conduct experiments and gather insights efficiently.

Medical Monitoring

LabVIEW-based data acquisition systems play a crucial role in medical monitoring applications, including patient monitoring, diagnostic equipment, and biomedical research, aiding in the advancement of healthcare technologies.

Environmental Monitoring

LabVIEW is utilized for environmental monitoring tasks such as weather forecasting, pollution detection, and ecological research, contributing to the preservation and sustainability of natural resources.

Case Studies: Real-World Implementations

Case Study 1: Automotive Testing

LabVIEW data acquisition systems are employed in automotive testing facilities for evaluating vehicle performance, conducting crash tests, and analyzing vehicle dynamics under various conditions.

Case Study 2: Weather Monitoring

Meteorological agencies utilize LabVIEW-based data acquisition systems for collecting and analyzing weather data, including temperature, humidity, wind speed, and precipitation, to forecast weather patterns accurately.

Case Study 3: Biomedical Research

In biomedical research laboratories, LabVIEW facilitates the acquisition and analysis of physiological data, imaging data, and genetic data, supporting advancements in disease diagnosis, treatment, and drug development.

Challenges and Solutions in LabVIEW Data Acquisition

Compatibility Issues

One challenge in LabVIEW data acquisition is compatibility issues between hardware components and software versions, which can be mitigated through careful selection and configuration of compatible components.

Data Processing Challenges

Processing large volumes of data in real-time poses another challenge, requiring efficient algorithms and hardware optimization techniques to ensure timely and accurate data acquisition and analysis.

Calibration and Maintenance

Regular calibration and maintenance of hardware components are essential to maintain the accuracy and reliability of LabVIEW data acquisition systems, requiring adherence to best practices and standards.

Future Trends in LabVIEW Data Acquisition

Advancements in Hardware Technology

Future advancements in hardware technology, such as faster processors, higher-resolution sensors, and wireless connectivity, will enhance the performance and capabilities of LabVIEW data acquisition systems.

AI Integration

Integration of artificial intelligence (AI) algorithms into LabVIEW data acquisition systems will enable predictive analytics, anomaly detection, and autonomous decision-making, revolutionizing data acquisition processes.

IoT Integration

LabVIEW data acquisition systems will increasingly integrate with the Internet of Things (IoT) ecosystem, leveraging cloud computing, edge computing, and wireless sensor networks for enhanced connectivity, scalability, and interoperability.

Conclusion

LabVIEW data acquisition systems offer a comprehensive solution for collecting, processing, and analyzing data across various industries and applications. With its user-friendly interface, robust functionality, and versatility, LabVIEW continues to empower engineers, researchers, and scientists in their quest for innovation and discovery. If you want to read more blogs/articles so visit on PujaControls

#automation#labview#technology#software development#iot#iot integration#ai integration#automotive testing#industrial automation

0 notes

Text

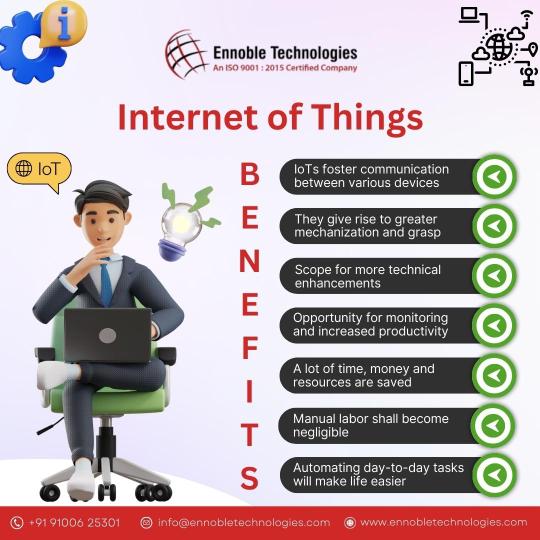

Explore the possibilities of IoT with Ennoble Technologies expert Internet of Things (IoT) services. Transform your business with innovative solutions.

Do Visit: https://ennobletechnologies.com/internet-of-things/

#Internet of Things#IoT Technology#IoT Solutions#Connected Devices#IoT Integration#Smart Technology#IoT Applications#IoT Devices#IoT Trends#IoT Innovations#IoT Connectivity#Smart Home Systems#Industrial IoT#IoT Development#IoT in Business

1 note

·

View note

Text

Smart Shipping Containers Market Will Touch USD 15,341.5 Million by 2030

The smart shipping container market was USD 3,971.2 million in 2022, and it will touch USD 15,341.5 million, propelling at a 18.4% compound annual growth rate, by 2030.

The growth of the industry is mainly attributed to the temperature regulation, enhance security measures, and real-time GPS tracking capabilities these containers offer. Moreover, because of the quick technological advancements in AI, IoT, big data analysis, and communication, the industry will further advance in the years to come.

Based on offering, the hardware category accounted for the largest smart shipping container market share, approximately 50%, and it will advance at the highest growth rate in coming years, because of the widespread adoption of various components for tracking and monitoring applications.

Based on technology, the industry is dominated by GPS due to its role in package monitoring and tracking.

Moreover, the quick implementation of the Bluetooth Low Energy (BLE) technology is because of the rising IoT devices implementation, which necessitates effective communication.

Additionally, the long-range wide area network (LoRa WAN) category will advance at the highest rate in the years to come. This is mainly because of the benefit of LoRa WAN as compared to other technologies, for instance, BLE and Wi-Fi.

Based on vertical, the food & beverage category will advance at the highest compound annual growth rate, of over 20%. This is attributed to the growing requirement for packaged food and perishable. Individuals are shifting their focus towards ready-to-eat food from homemade food, which is boosting the requirement for smart marine transportation solutions for edibles.

In 2022, the smart shipping containers industry is led by Europe, with a share of approximately 40%. This is because of the existence of numerous major industry players providing enhanced software and IoT sensors integrated hardware for effective analytics of data.

#Smart Shipping Container#Maritime Logistics#IoT Integration#Telematics#Supply Chain Efficiency#Global Market#Container Tracking#Remote Monitoring#Data Analytics#Industry 4.0#Innovation#Sustainable Shipping#Fleet Management#Real-time Visibility#Asset Security#Connectivity Solutions#Market Trends#Containerization#Emerging Technologies#Logistics Optimization

0 notes